All-carbon ceramic axle-mounted brake disc

A brake disc, carbon ceramic technology, applied in the direction of brake disc, brake type, brake components, etc., can solve the problem of not involving structural design, not suitable for carbon ceramic brake disc, etc., to avoid uneven composition, avoid The effect of breaking the heat dissipation rib and ensuring the structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

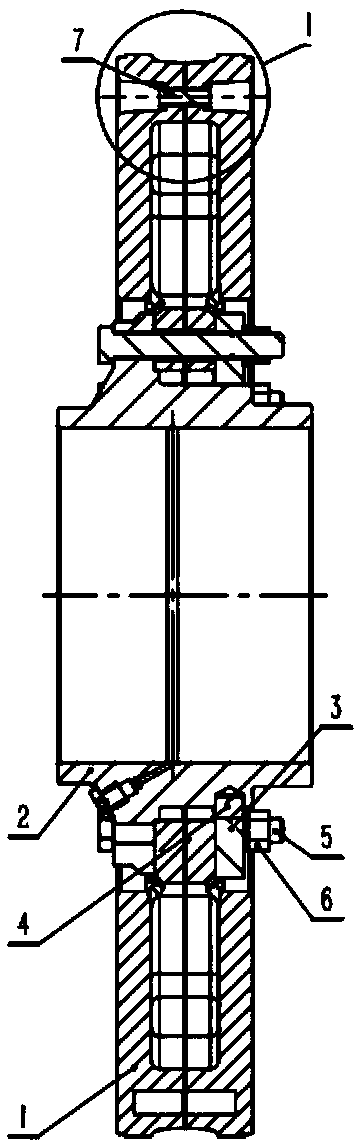

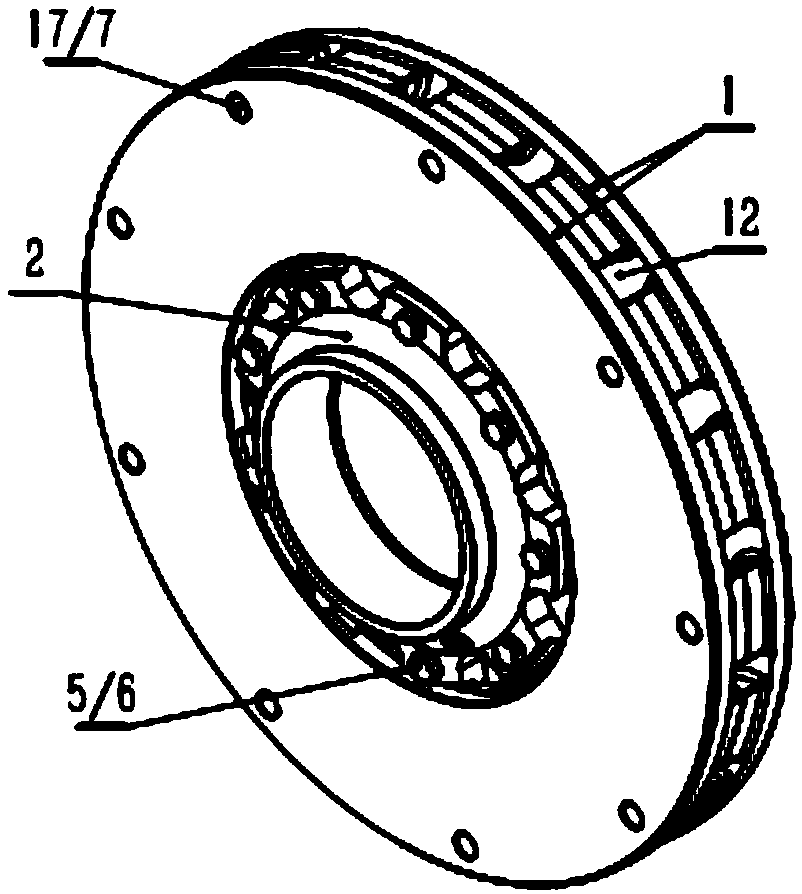

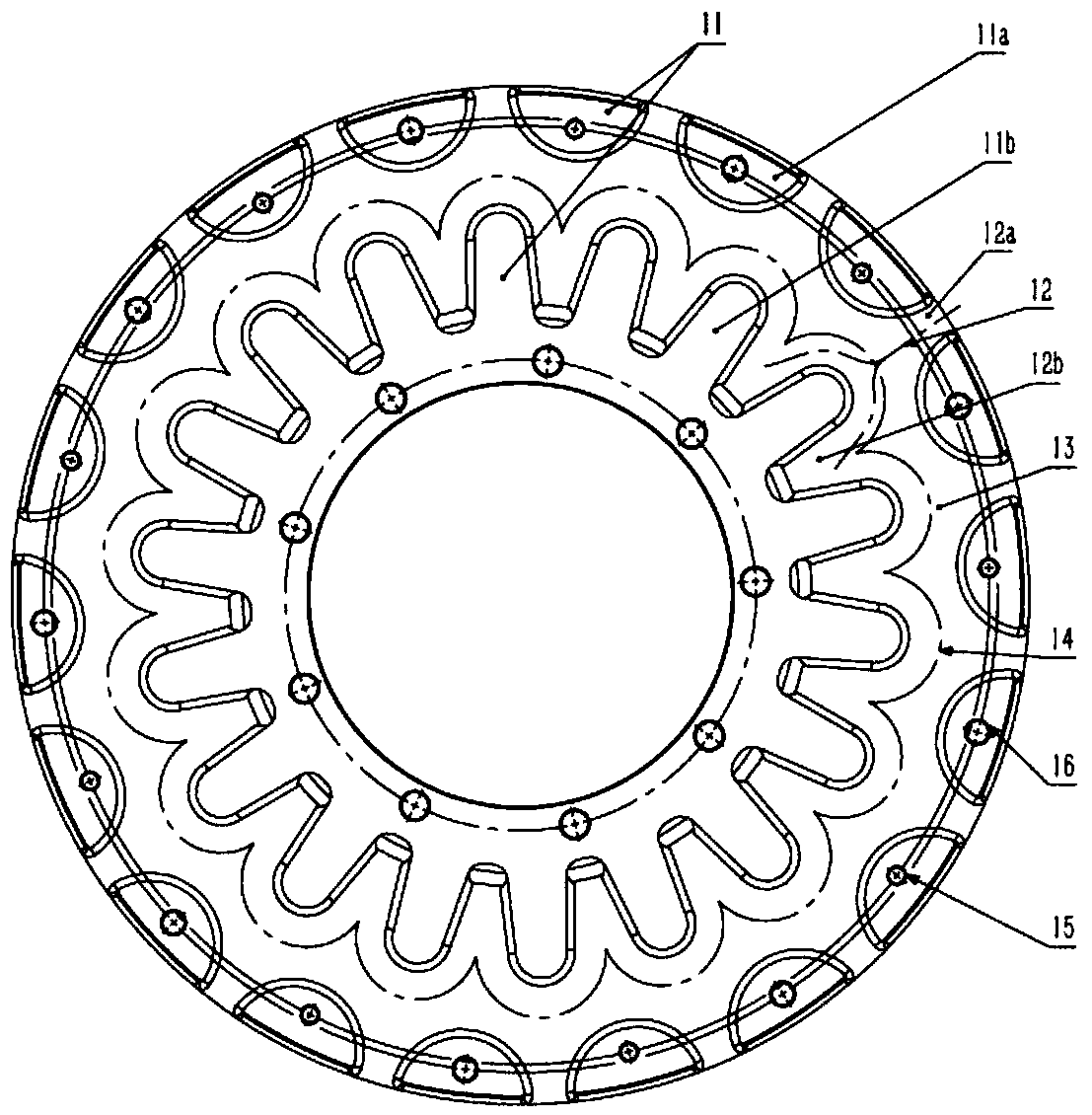

[0042] see figure 1 and figure 2 , the full-carbon ceramic shaft-mounted brake disc in the illustration is the preferred solution of the present invention, and specifically includes a friction disc 1, a disc hub 2, an axial positioning washer 3, a twist pin 4, bolts 5, nuts 6 and rivets 7. Among them, the friction disc 1 is a ring made of carbon-ceramic composite material. Two annular friction discs 1 are coaxially stacked and fixed on the hub 2. The hub 2 is fixedly connected to the axle, and the friction discs 1 are connected by rivets. 7 are connected together and positioned in the circumferential direction, and the flange part of the inner ring of the friction disc 1 and the disc hub 2 are locked and connected by several groups of bolt assemblies composed of axial positioning washers 3 , torque transmission pins 4 , bolts 5 and nuts 6 . This embodiment aims to specifically illustrate the heat dissipation structure of the brake disc and the connection mode with the disc h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com