Patents

Literature

50results about How to "Solve process difficulties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing 8014-H22 state aluminium alloy air-conditioner foil by cast-rolled blank

ActiveCN101805878AImprove use value and economic benefitsSolve process difficultiesRoll mill control devicesMetal rolling arrangementsCrystalliteHeat sink

The invention provides a method for producing 8014-H22 state aluminium alloy air-conditioner foil by a cast-rolled blank, belonging to the technical field of aluminium alloy plate belt foil processing. The method particularly comprises the steps of: adopting the production way of cast-rolling and cold-rolling, carrying out homogenizing annealing on the cast-rolled blank before cold rolling, and controlling the annealing temperature to be 520-530 DEG C and the annealing time to be 22-25h; after the homogenizing annealing, leading compound to be dispersed, thinning crystalline grains so as to be beneficial to the cold rolling and ensuring the final mechanical property of the product; reasonably distributing the cold rolling channels by the plasticity of metal and the capability of rolling equipment, and carrying out eight-channel cold rolling on the cast-rolled blank with the thickness of 6.4-7.4mm; and carrying out finished product annealing on aluminium foil which is rolled to be 0.17-0.24mm, and controlling annealing temperature to be 360-370 DEG C and the annealing time to be 14-17h. By adopting the method, the mechanical properties of the 8014-H22 state aluminium alloy air-conditioner foil with the thickness of 0.17-0.24mm can be controlled to be: tensile strength sigma b: 120-135MPa; percentage of elongtation delta: 25-30%; and the blank convex valve: more than or equal to 6.5. The method meets the requirement of the mouldability of a large air-conditioner radiating fin.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD +1

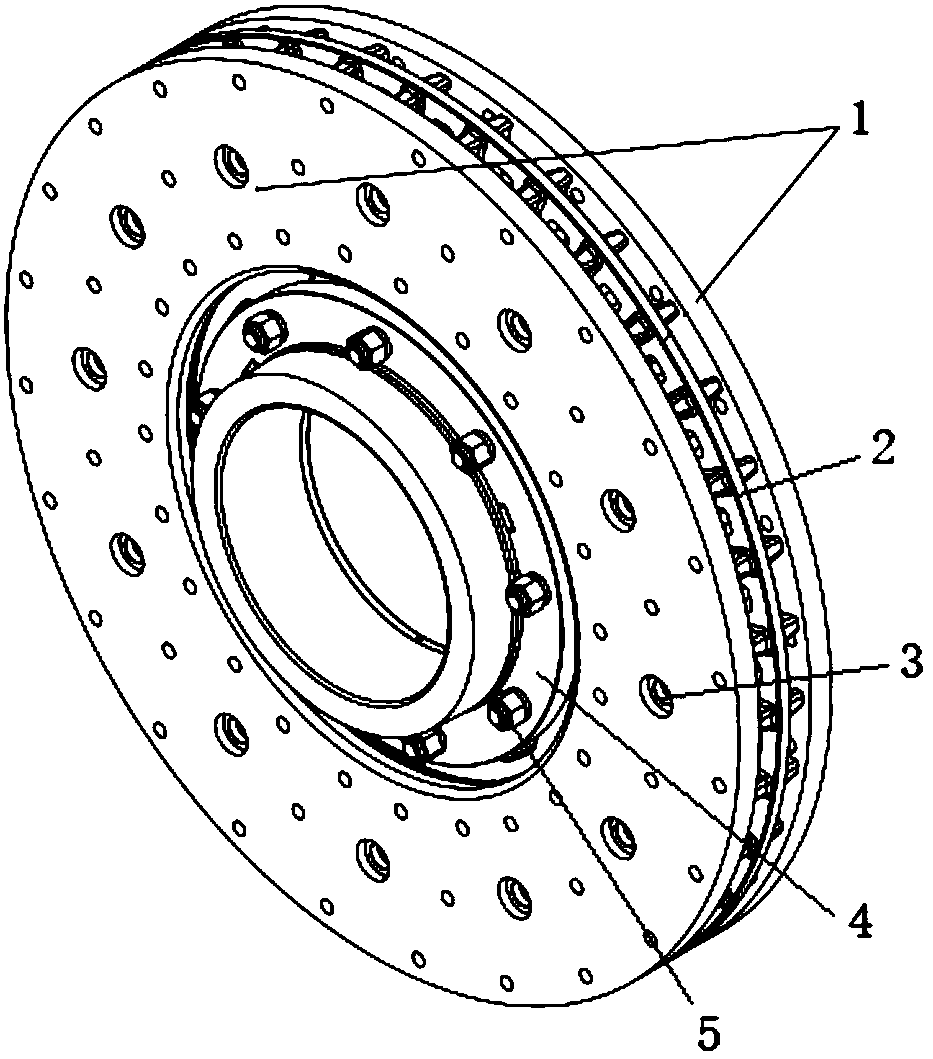

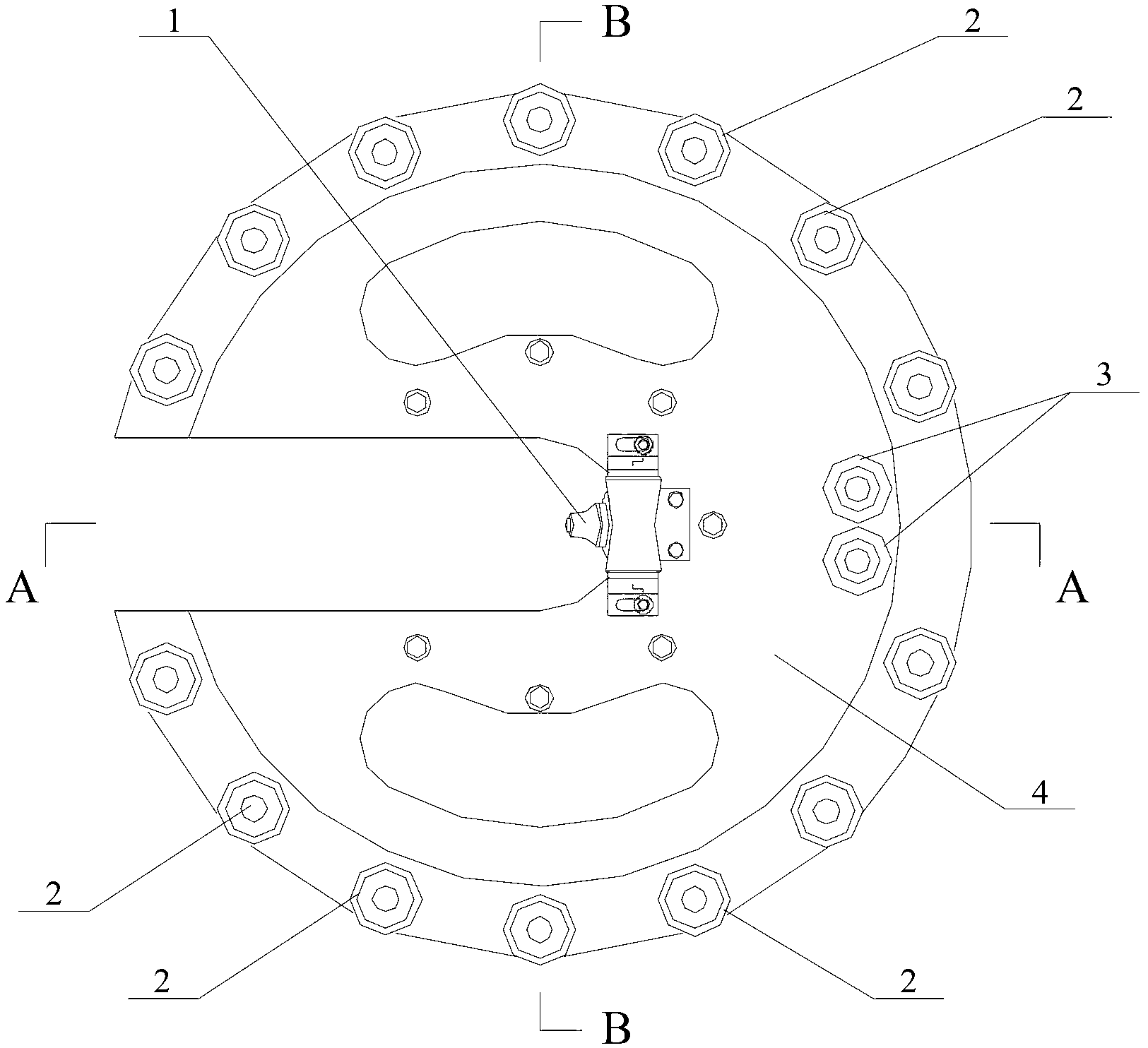

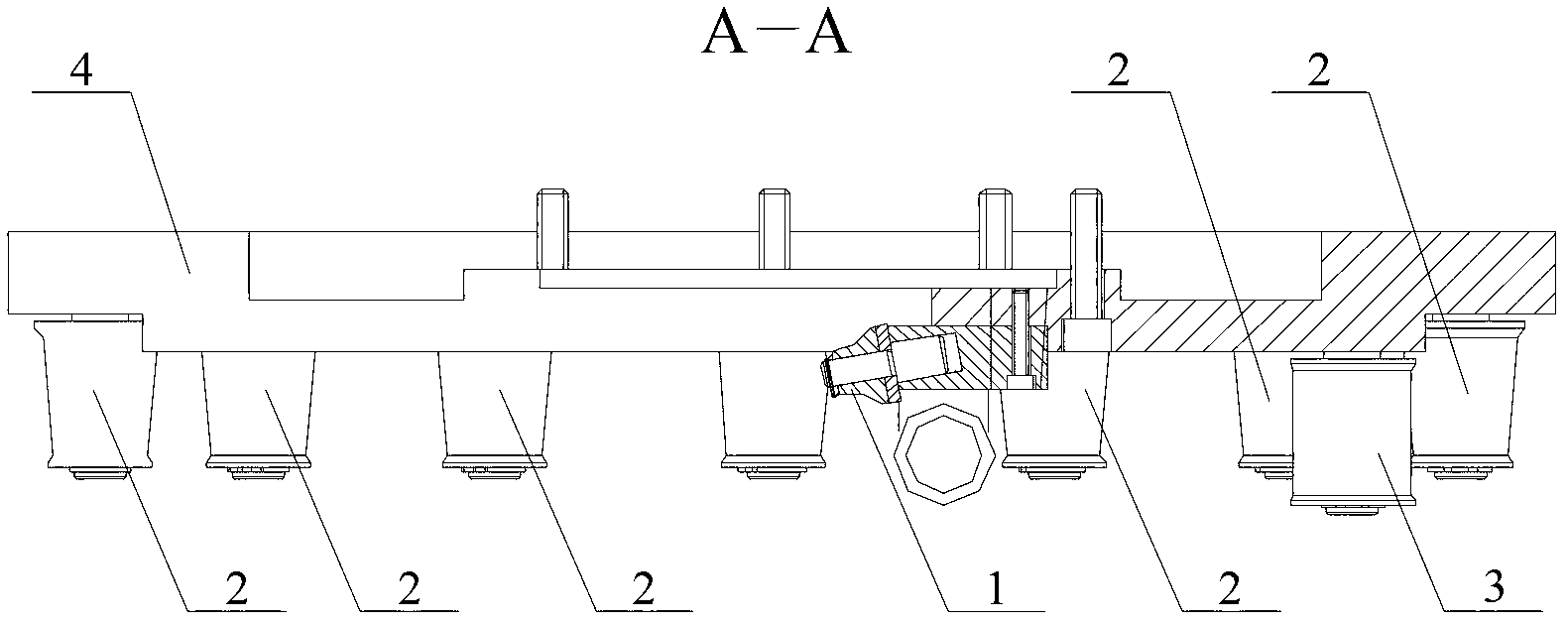

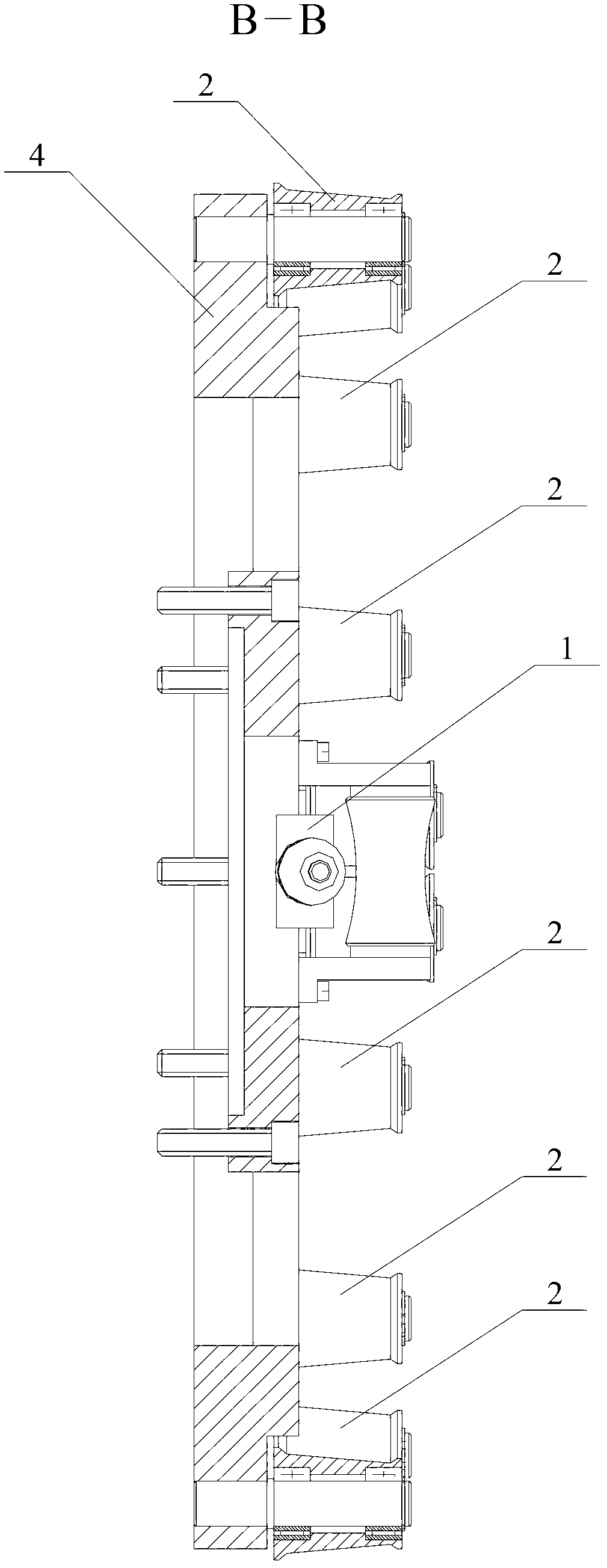

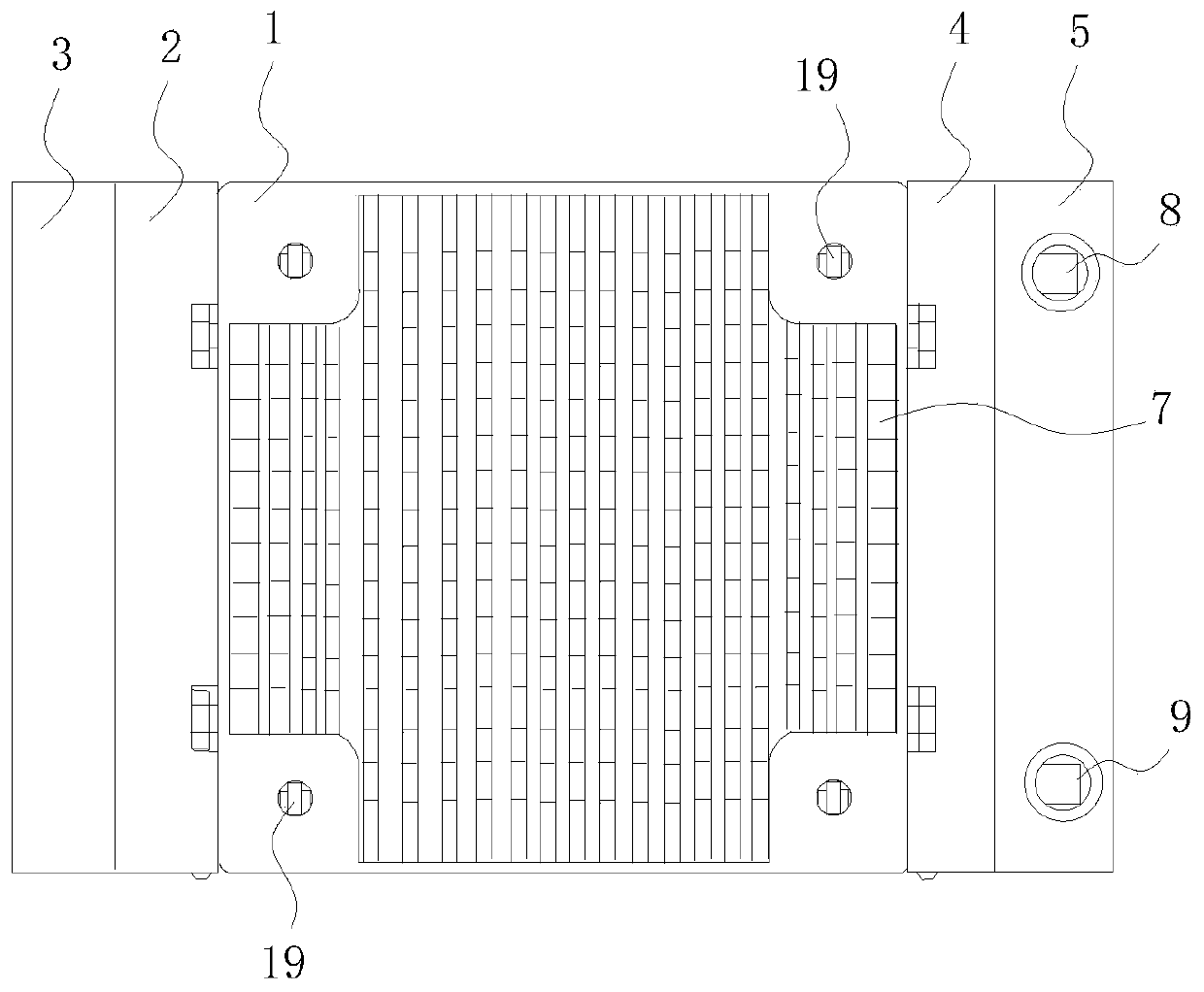

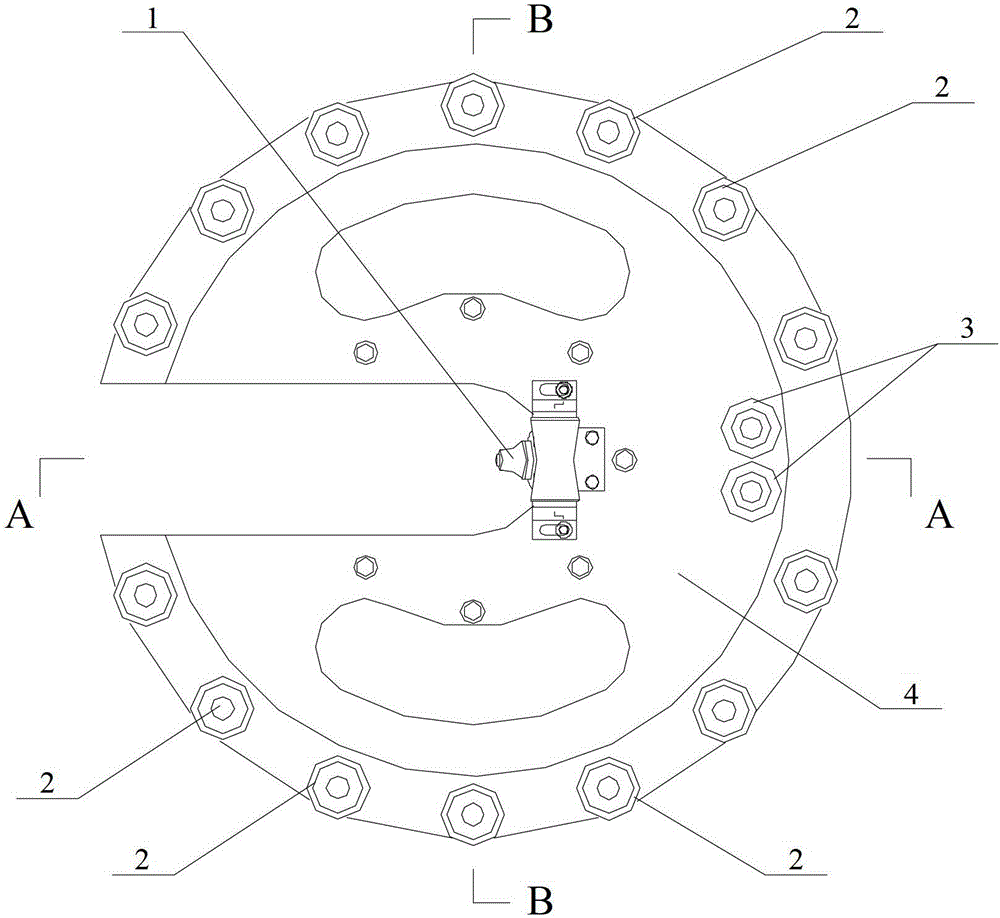

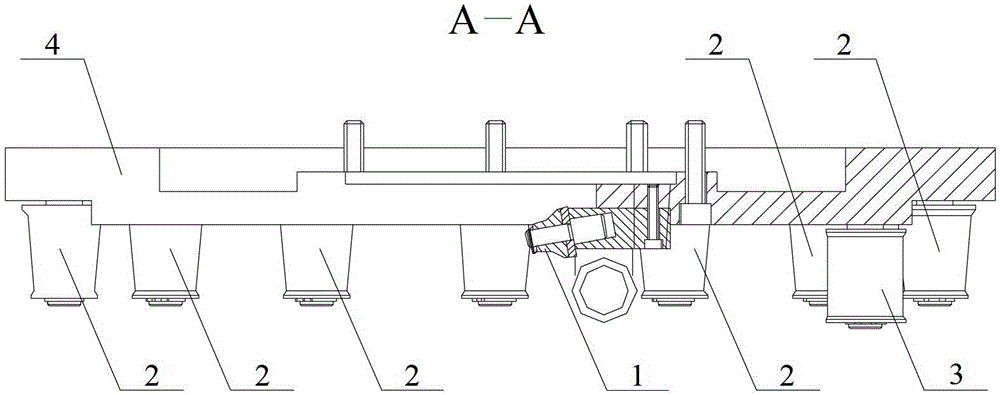

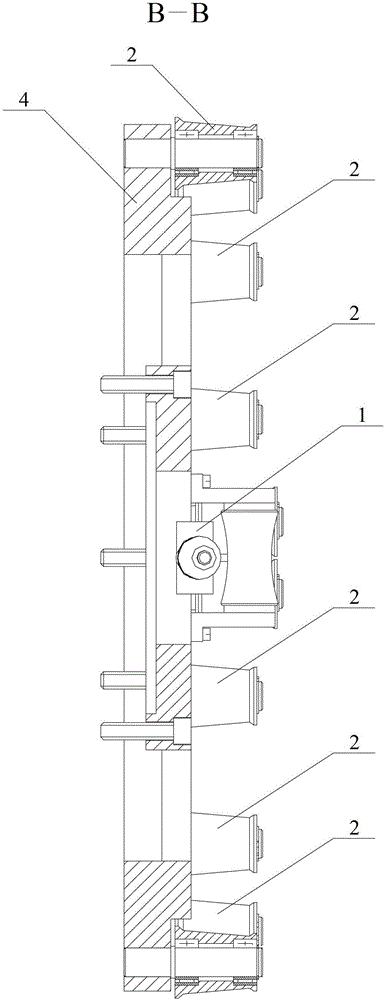

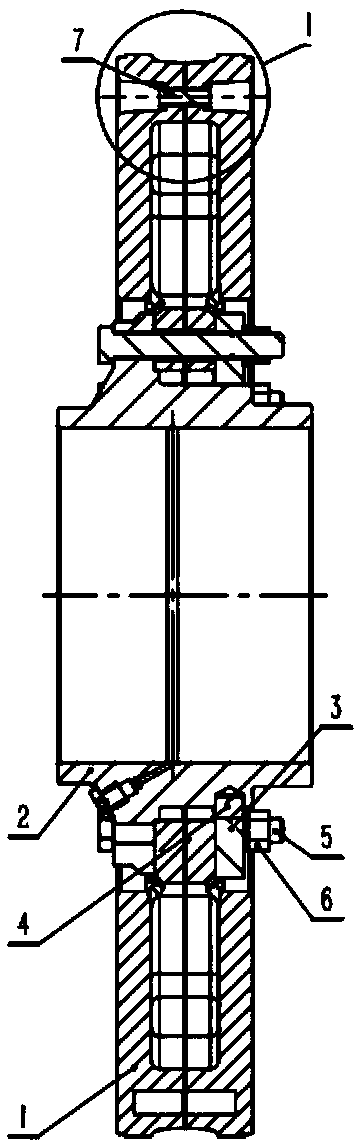

Shaft-mounted brake disc module for high-speed train

PendingCN108317194ASolve processing technology problemsSolve the cooling problemBraking discsTemperature resistanceEnergy consumption

The invention discloses a shaft-mounted brake disc module for a high-speed train. The module comprises brake discs, a support disc and a disc hub; two sets of brake discs are provided, are coaxially laminated on the disc surfaces on the two sides of the support disc, and are clamped and locked with the support disc through first connecting structures; the brake discs are composite material brake discs with smooth disc surfaces on two sides; heat dissipating structures are arranged on the disc surfaces on the two sides of the support disc, and are laminated with the brake discs to form heat dissipating channels; and a connecting flange is arranged on an inner ring of the support disc, and is fixedly sleeved with the disc hub through a second connecting structure. Compared with a traditionaloverall brake disc, the module has the characteristics of simple structure, reliable connection, high-temperature resistance, convenience to maintain, light weight and good braking effect, reduces the energy consumption in operation and braking of the high-speed train, realizes application of a composite friction material to a high-speed train braking system, and greatly saves the high-speed train company operation and maintenance costs.

Owner:HUNAN SHIXIN NEW MATERIALS CO LTD

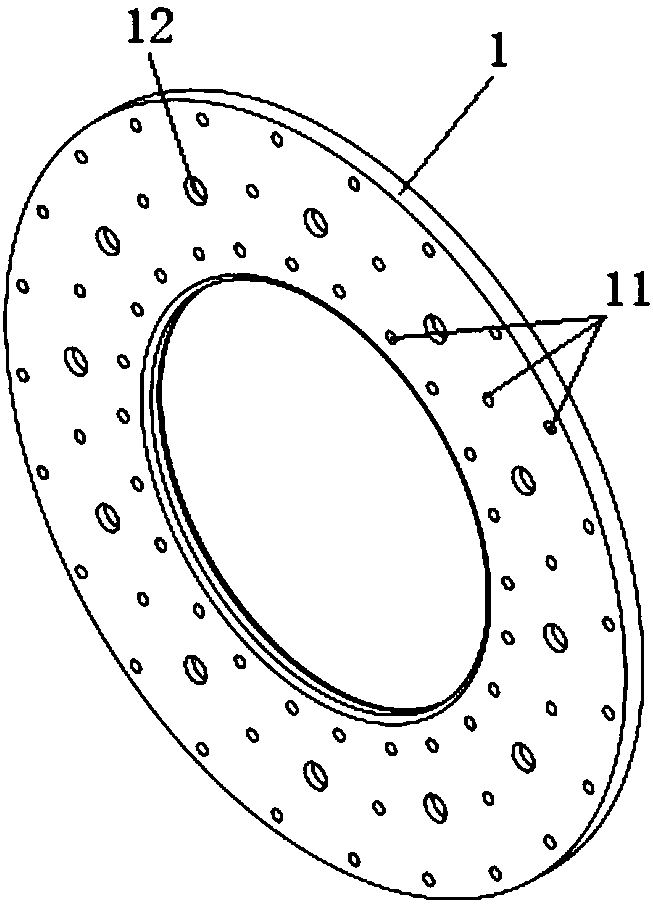

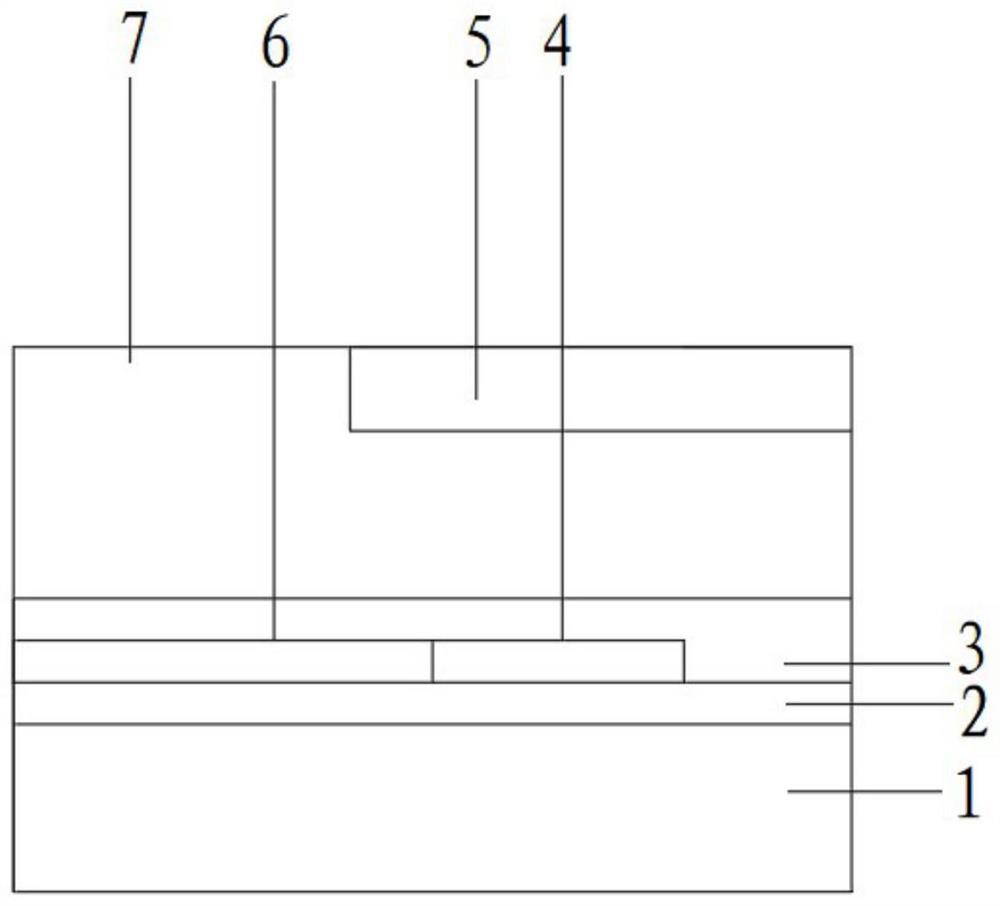

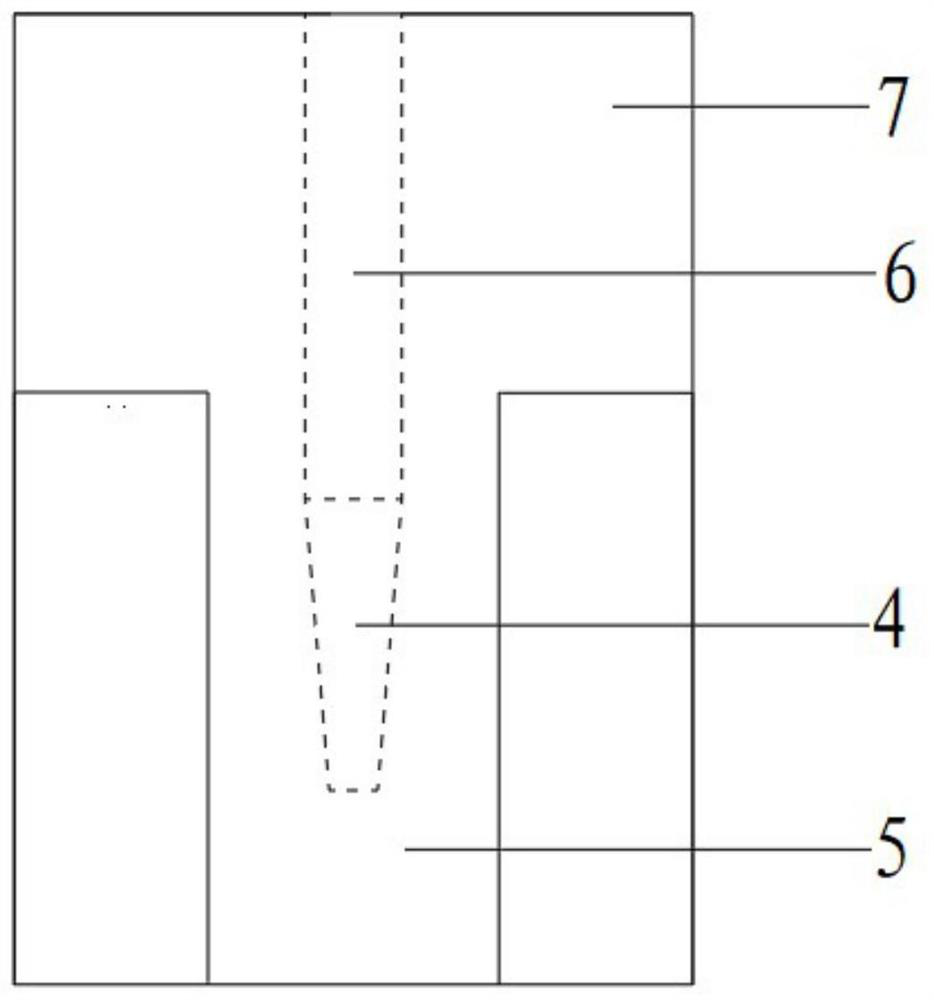

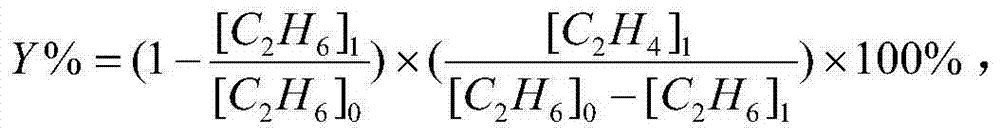

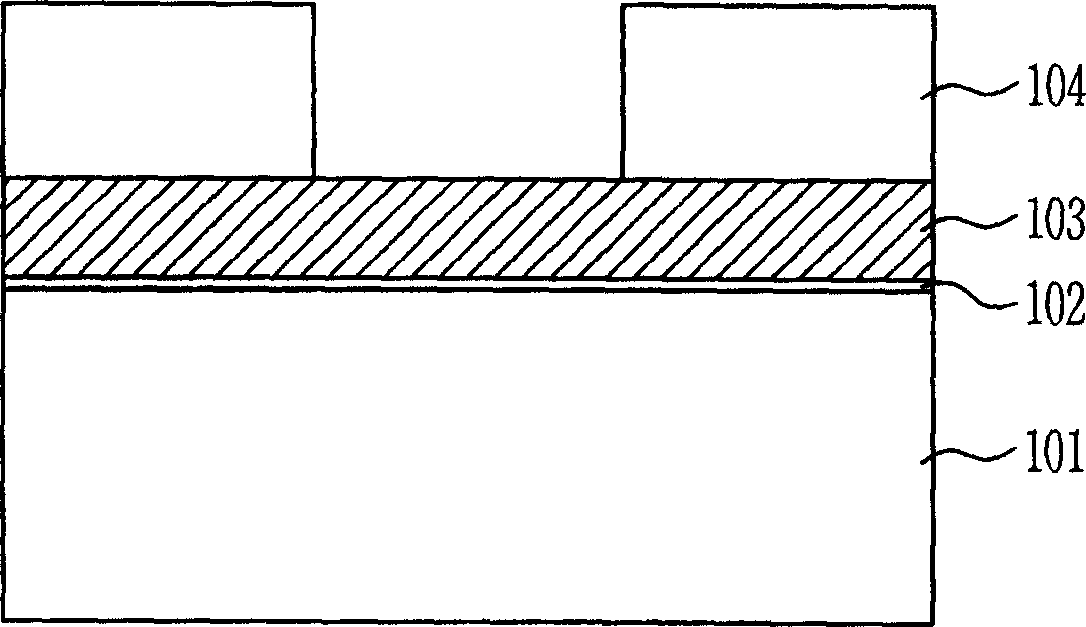

Silicon waveguide end face coupling structure and manufacturing method thereof

ActiveCN111679363ASolve the problem of multi-mode transmissionSolve process difficultiesOptical waveguide light guidePhotonic ChipThin membrane

The invention relates to the technical field of photonic integrated devices, and discloses a silicon waveguide end face coupling structure and a manufacturing method thereof. The structure comprises substrate silicon, an oxide layer, a silicon waveguide and a silicon nitride layer which are sequentially stacked from bottom to top, the end of the silicon nitride layer is of a ridge-shaped structureto form a ridge-shaped silicon nitride waveguide, and the ridge-shaped silicon nitride waveguide is used for being coupled with the end face of a common single-mode optical fiber. The method comprises the following steps of preparing a silicon waveguide by using a thin film silicon layer positioned on an oxide layer on the upper surface of substrate silicon in a silicon-on-insulator substrate, preparing a pointed cone structure of which the width is gradually reduced at one end, coupled with the optical fiber, of the silicon waveguide to form a silicon waveguide pointed cone structure, depositing a silicon nitride layer on the silicon waveguide and the oxide layer, and carrying out shallow etching on the silicon nitride layer to prepare a ridge-shaped structure so as to form the ridge-shaped silicon nitride waveguide. The ridge-shaped silicon nitride waveguide conversion mode field can be matched with a common single-mode optical fiber, and is suitable for low-loss coupling of the silicon waveguide and the common single-mode optical fiber in the silicon photonic chip packaging process.

Owner:TSINGHUA UNIV

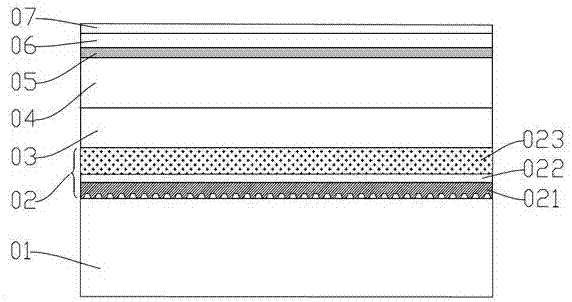

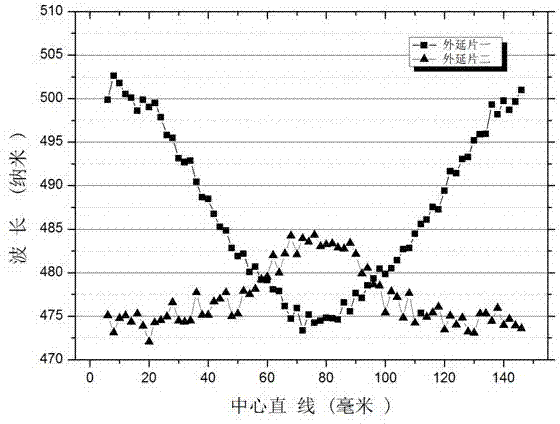

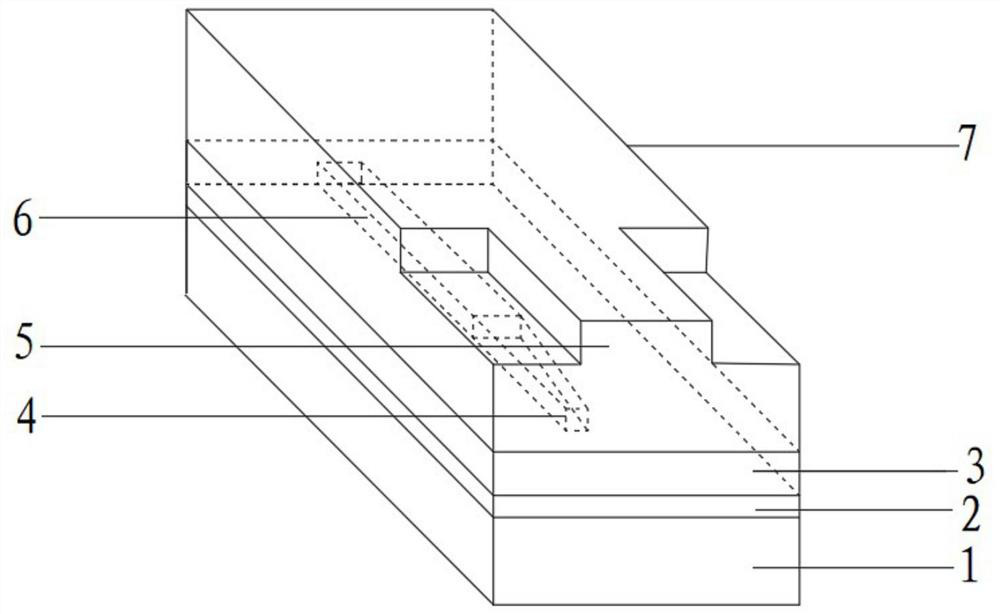

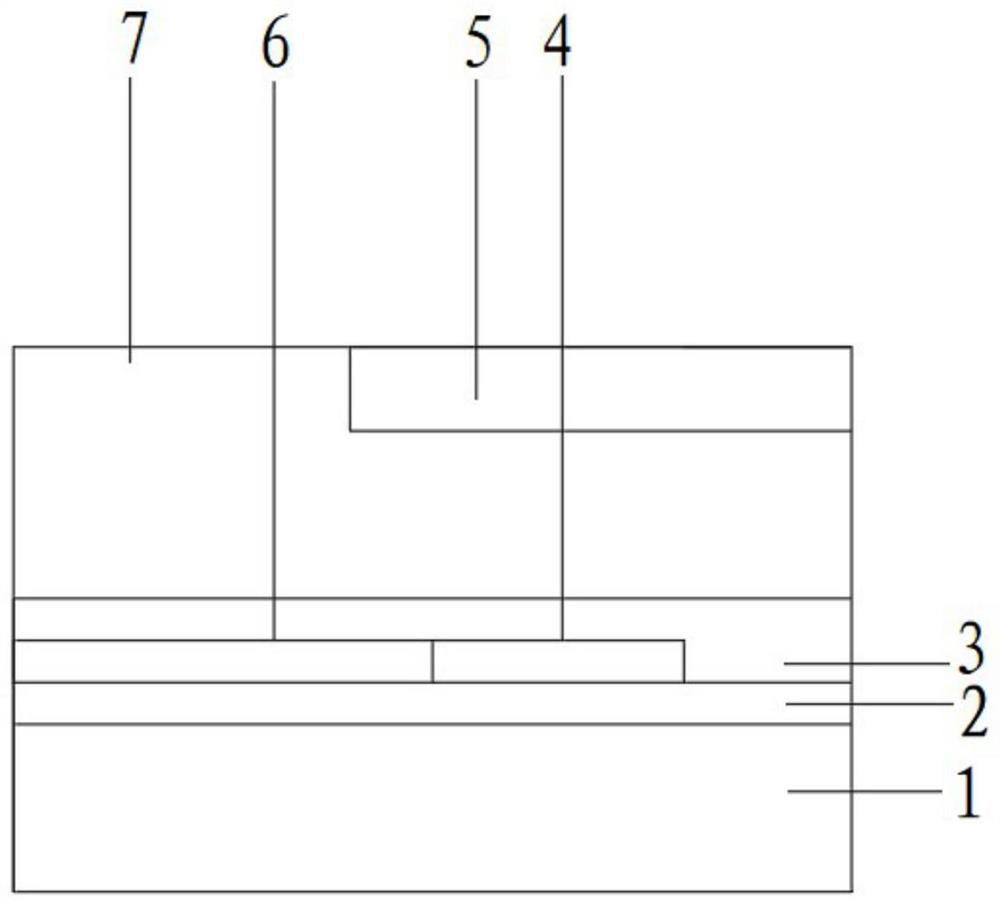

Large-size light emitting diode epitaxial wafer and growing method thereof

InactiveCN107452845AFacilitated releaseImprove crystal qualitySemiconductor devicesEpitaxial materialThermal expansion

The invention discloses a large-size light emitting diode epitaxial wafer and a growing method thereof, and belongs to the technical field of semiconductors. A substrate is provided with a buffer layer, an unintentional doped GaN layer, an N-type doped GaN layer, a multiple quantum well layer, an electronic blocking layer and a P-type doped GaN layer which successfully and epitaxially grows on the substrate, wherein the buffer layer growth includes the successful growth of a first, a second and a third buffer layer on the substrate. According to the invention, three buffer layers are employed to effectively release the stress which is generated due to the differences of coefficients of thermal expansion between the substrate and the GaN, to reduce the stress which is generated due to the differences of lattice constants between the substrate and the GaN, to reduce the probability of tattering and shredding of the substrate when the large-size epitaxial wafer grows at high temperature, provides sound basis for the growth of the unintentional doped GaN layer and active layer structure in a nitride thin film structure layer. The substrate herein can increase the quality of large-size epitaxial material, improve the uniformity of the wavelength of the epitaxial wafer and adjusts the warpage of the epitaxial wafer.

Owner:YANGZHOU ZHONGKE SEMICON LIGHTING

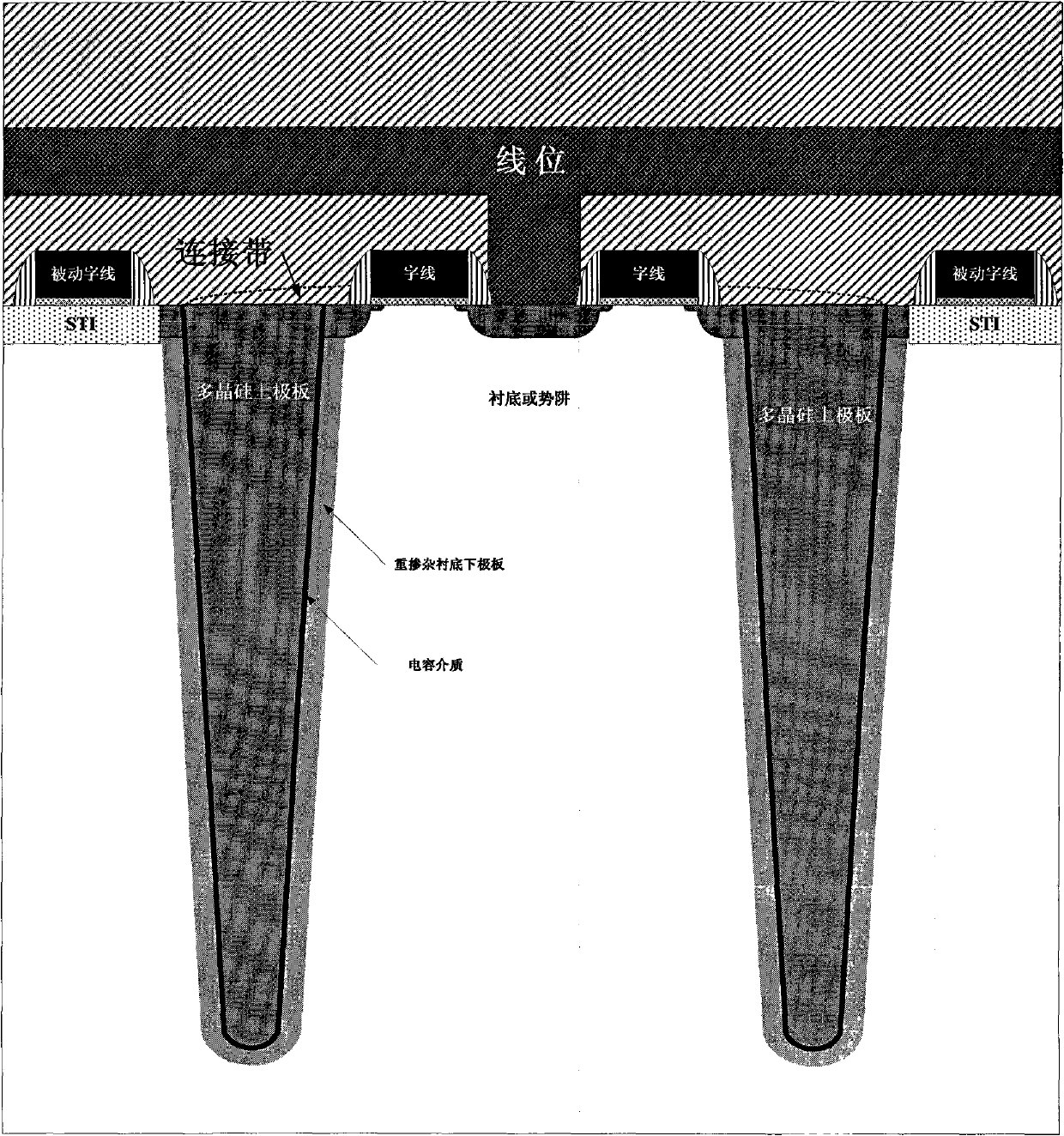

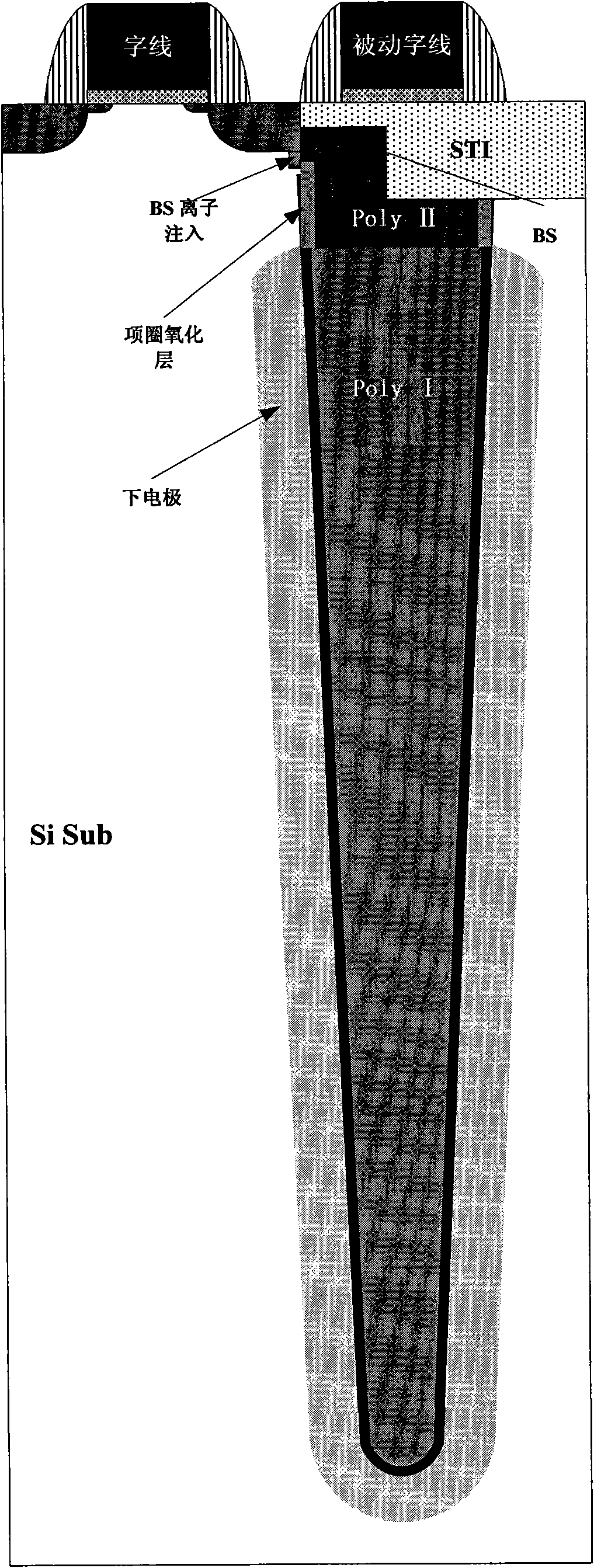

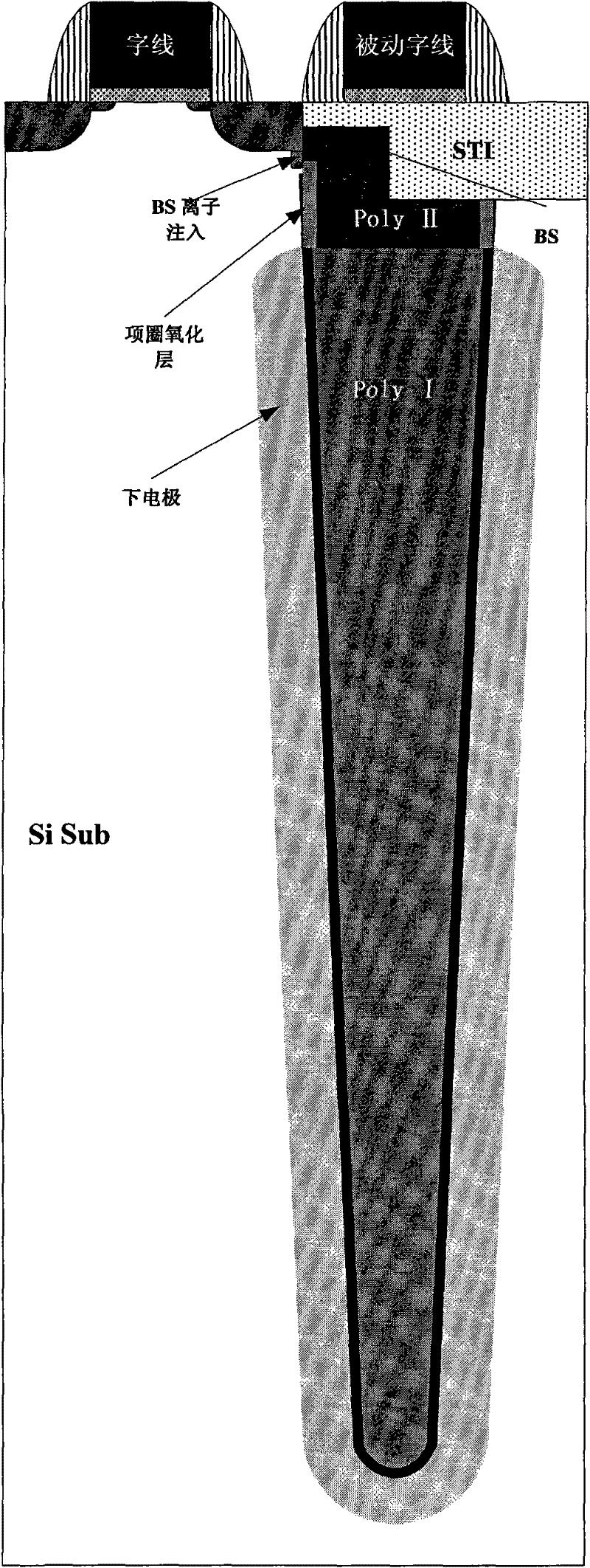

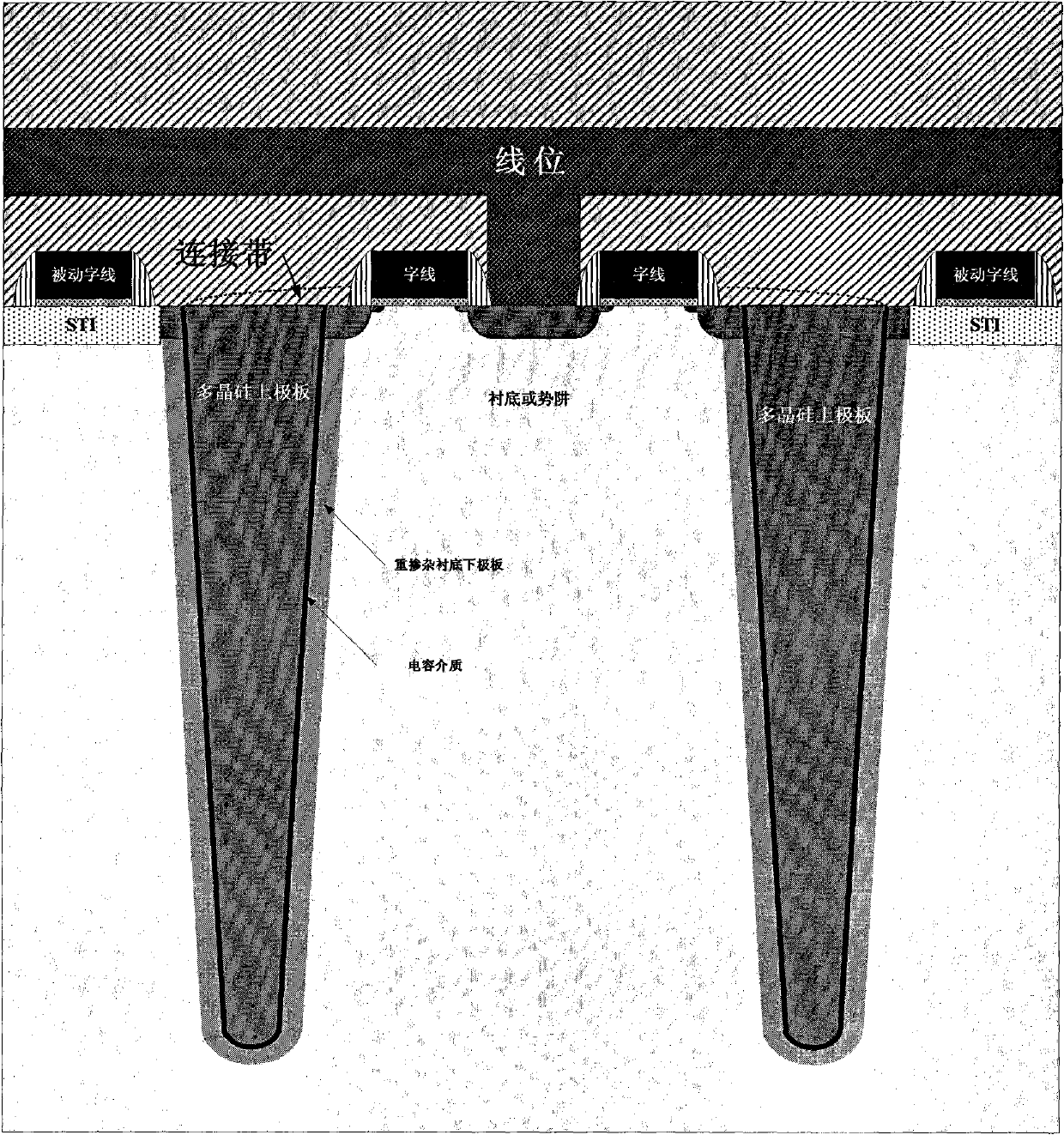

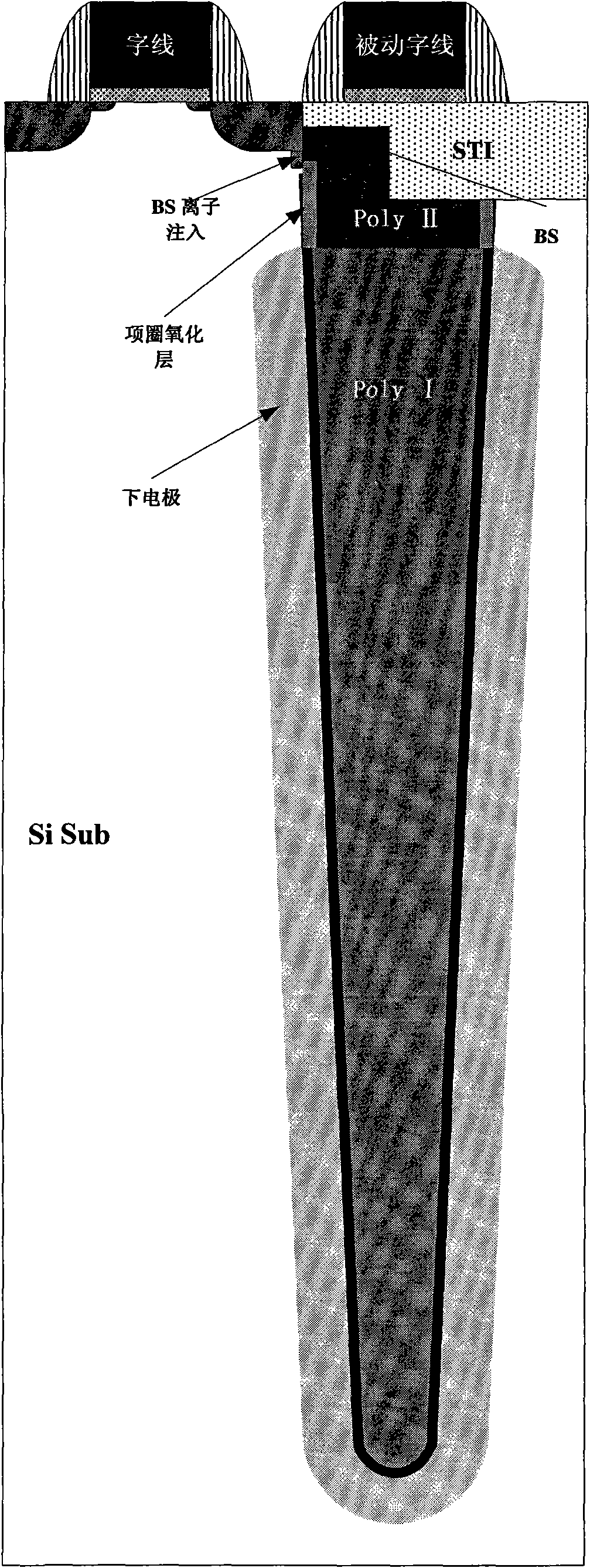

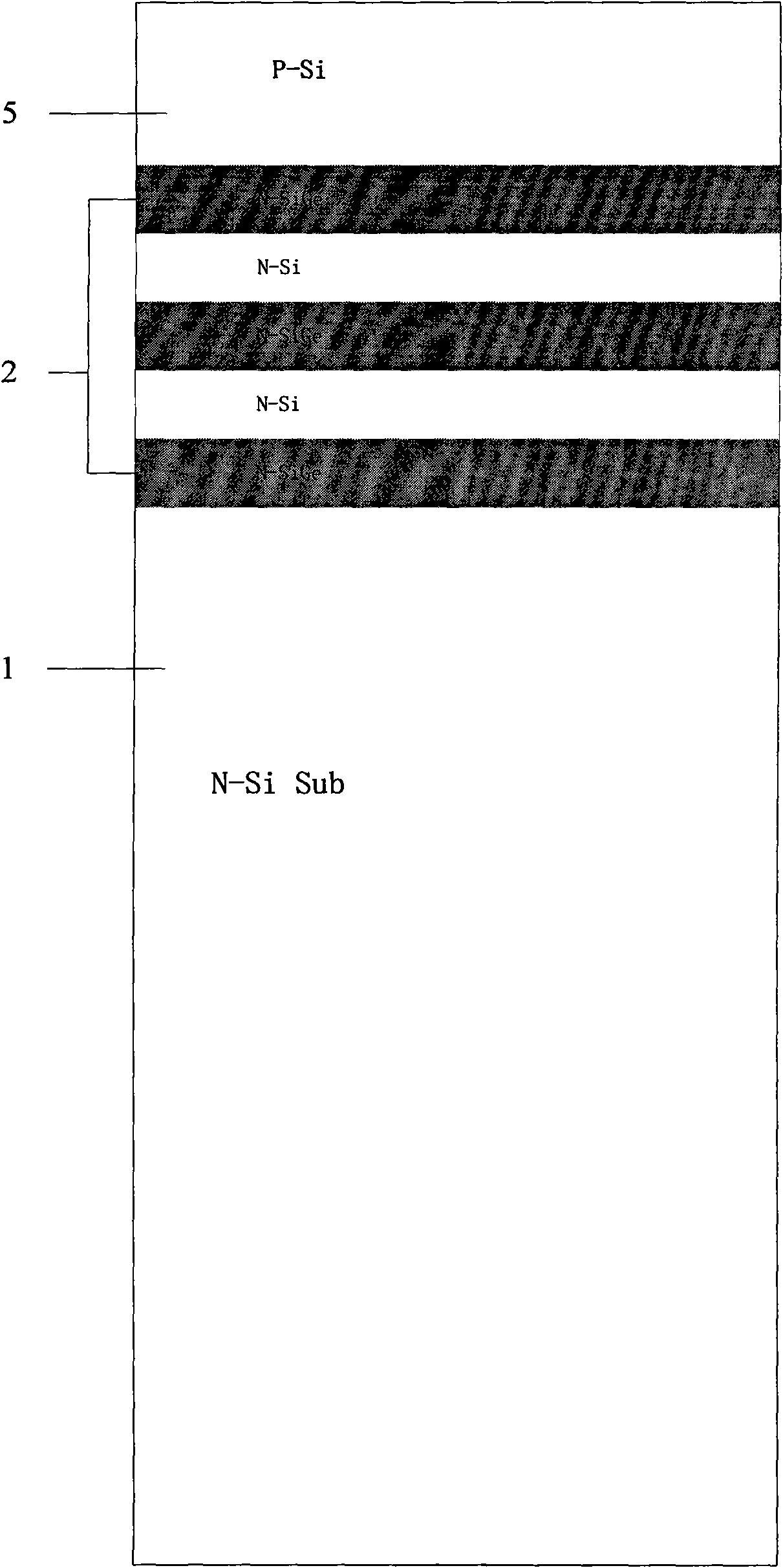

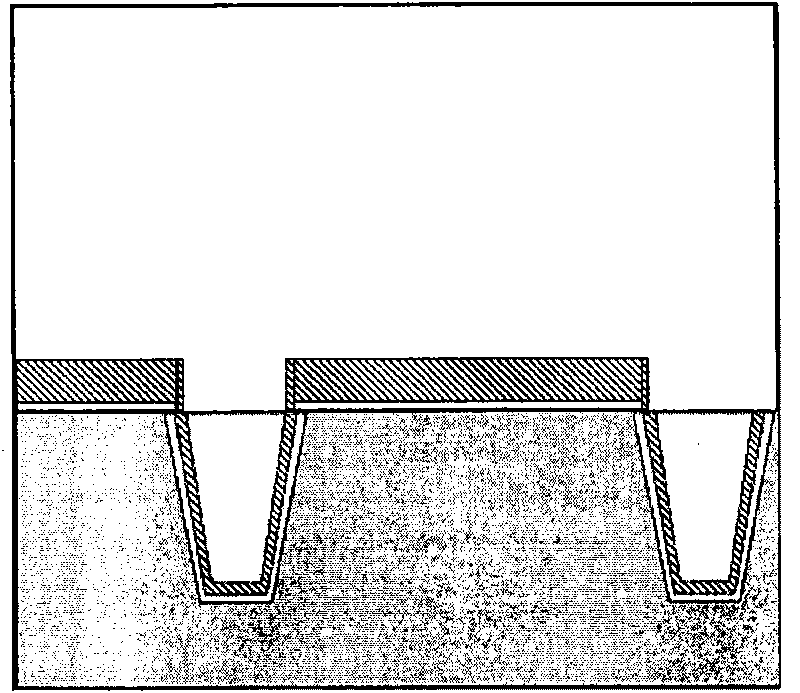

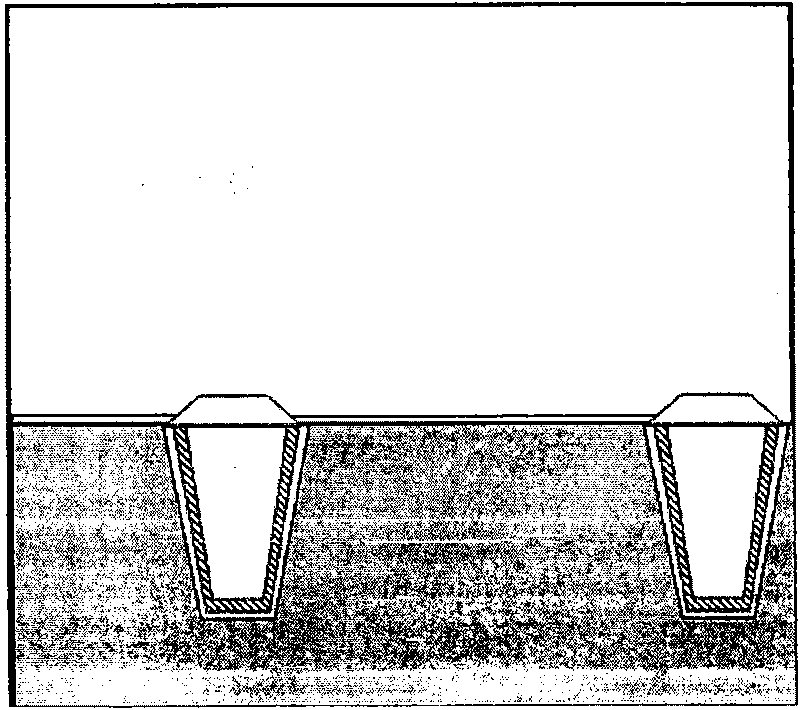

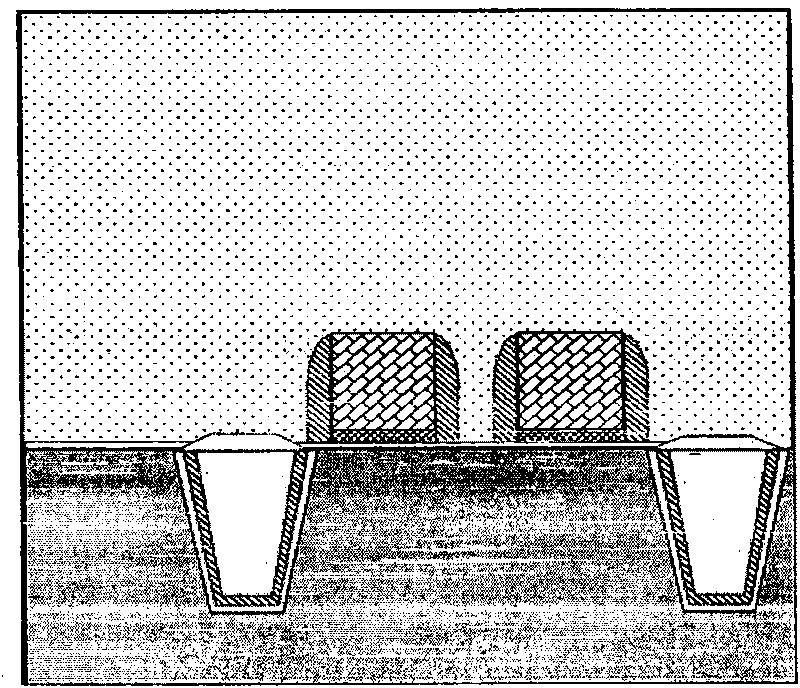

DRAM (Dynamic Random Access Memory) structure with extended groove and making method thereof

InactiveCN101996999ASimple manufacturing processSimple processTransistorSolid-state devicesEtchingEngineering

The invention discloses a DRAM (Dynamic Random Access Memory) structure with an extended groove and a making method thereof. The structure comprises a PMOS (P-channel Metal Oxide Semiconductor) transistor and a groove capacitor which is connected with a source electrode of the PMOS transistor; the groove capacitor comprises a semiconductor substrate, alternatively arrayed P-type SiGe layers and P-type Si layers, a groove, a dielectric layer and a polysilicon layer, wherein the groove is positioned in the alternatively-arrayed P-type SiGe layers and P-type Si layers and inserted into the semiconductor substrate, the profile of the alternatively-arrayed P-type SiGe layers and P-type Si layers is in a shape of comb teeth, and the alternatively-arrayed P-type SiGe layers and P-type Si layers are used as a lower pole plate of the groove capacitor; the dielectric layer is positioned on the surface of the inner wall of the groove; the polysilicon layer is filled in the groove and used as an upper pole plate of the groove capacitor; an N-type Si layer is also prepared on the alternatively-arrayed P-type SiGe layers and P-type Si layers; and the PMOS transistor is made on the N-type Si layer. In the invention, the P-type SiGe layers and the P-type Si layers alternatively grow by adopting a doping and epitaxial technology, and the comb-tooth-shaped lateral wall is made by adopting selective etching, therefore, the structure of the deep groove type capacitor in a DRAM is improved, and the making process is simplified.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

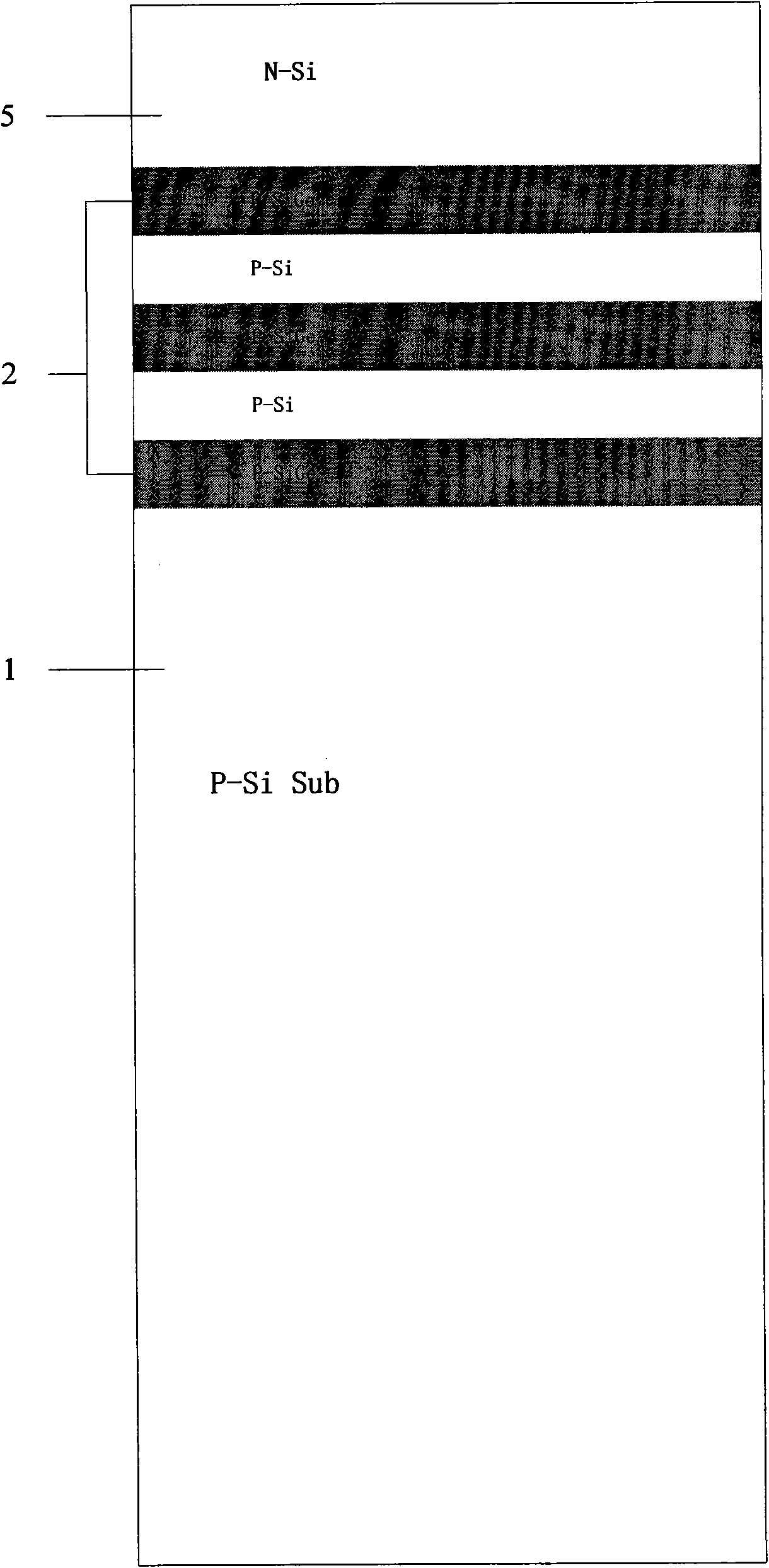

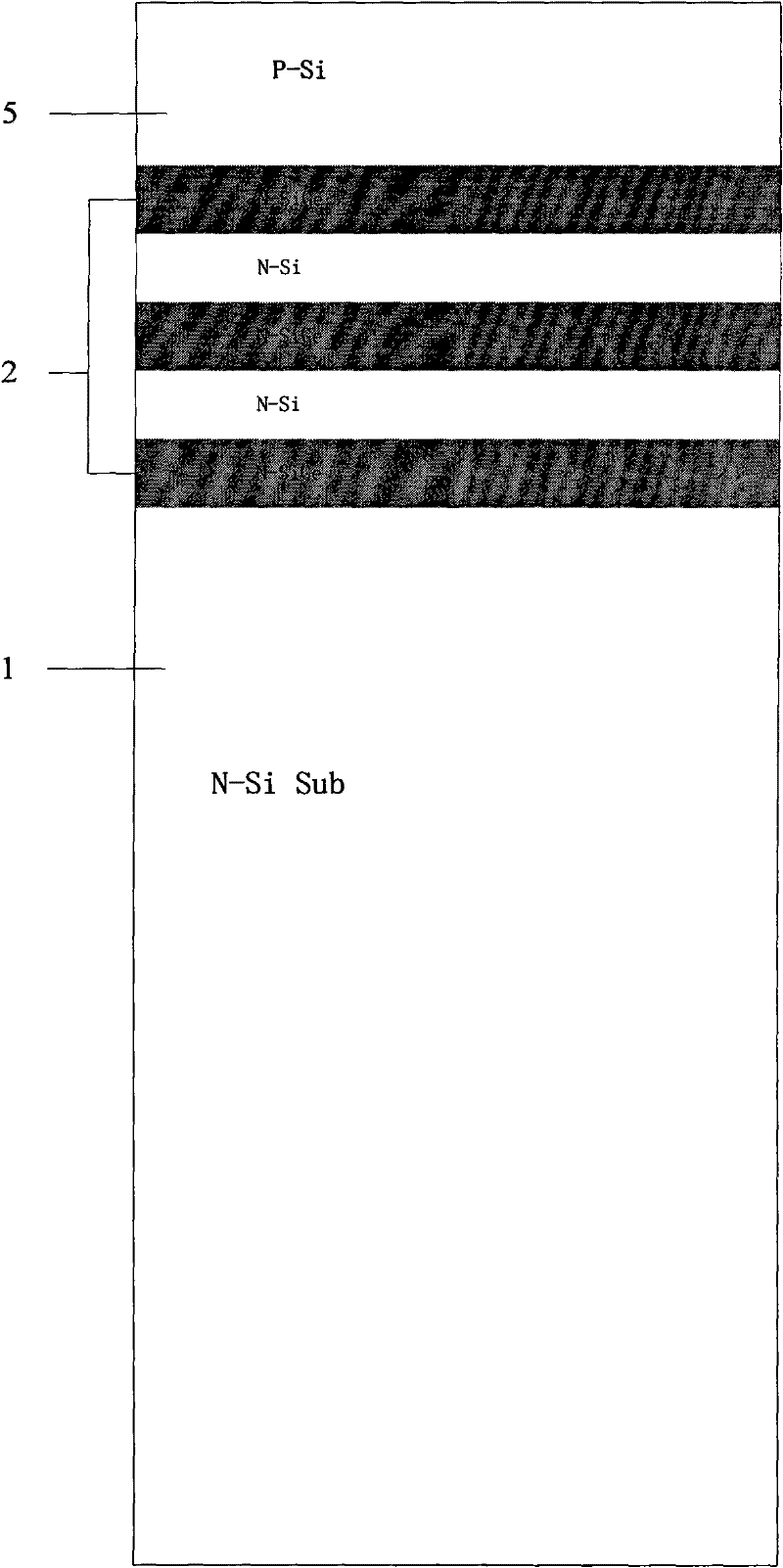

DRAM (Dynamic Random Access Memory) structure with expansion groove and manufacturing method thereof

InactiveCN101997000BSimple manufacturing processSimple processTransistorSemiconductor/solid-state device manufacturingEtchingEngineering

The invention discloses a DRAM (Dynamic Random Access Memory) structure with an expansion groove and a manufacturing method thereof. The structure comprises an NMOS (N-channel Metal Oxide Semiconductor) transistor and a groove capacitor connected with a source electrode thereof, wherein the groove capacitor comprises a semiconductor substrate, an N-type SiGe layer and an N-type Si layer which arealternately arranged, a groove, a dielectric layer and a polysilicon layer, wherein the groove is located in the N-type SiGe layer and the N-type Si layer which are alternately arranged and extends into the semiconductor substrate, and the section of a side wall of the groove is in a comb tooth shape; the N-type SiGe layer and the N-type Si layer which are alternately arranged are utilized as a lower pole plate; the dielectric layer is located at the surface of the inner wall of the groove; the polysilicon layer is filled in the groove and utilized as an upper pole plate of the groove capacitor; a P-type Si layer is also prepared on the N-type SiGe layer and the N-type Si layer which are alternately arranged; and the NMOS transistor is manufactured on the P-type Si layer. Through the method, the N-type SiGe layer and the N-type Si layer are alternately grown by utilizing a doping and epitaxial technique and the side wall in the comb tooth shape is manufactured by utilizing selective etching; and the method improves the structure of a deep groove capacitor in the DRAM and simplifies the manufacturing process.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

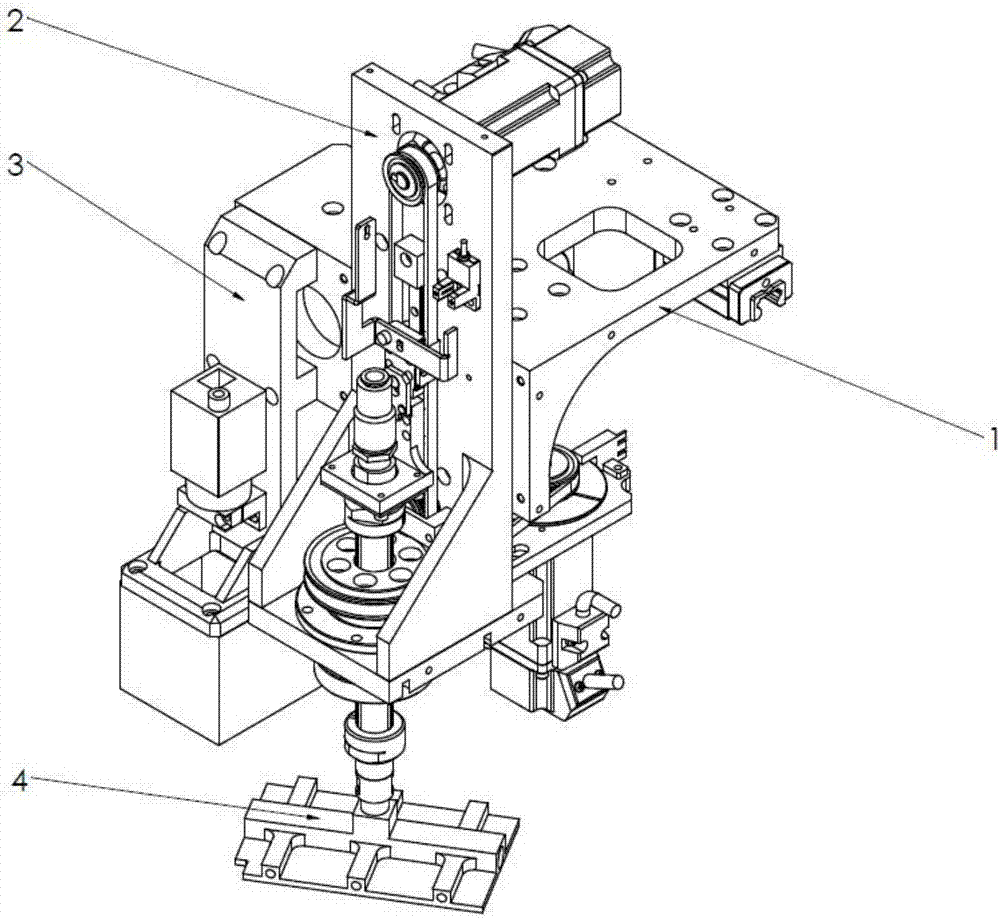

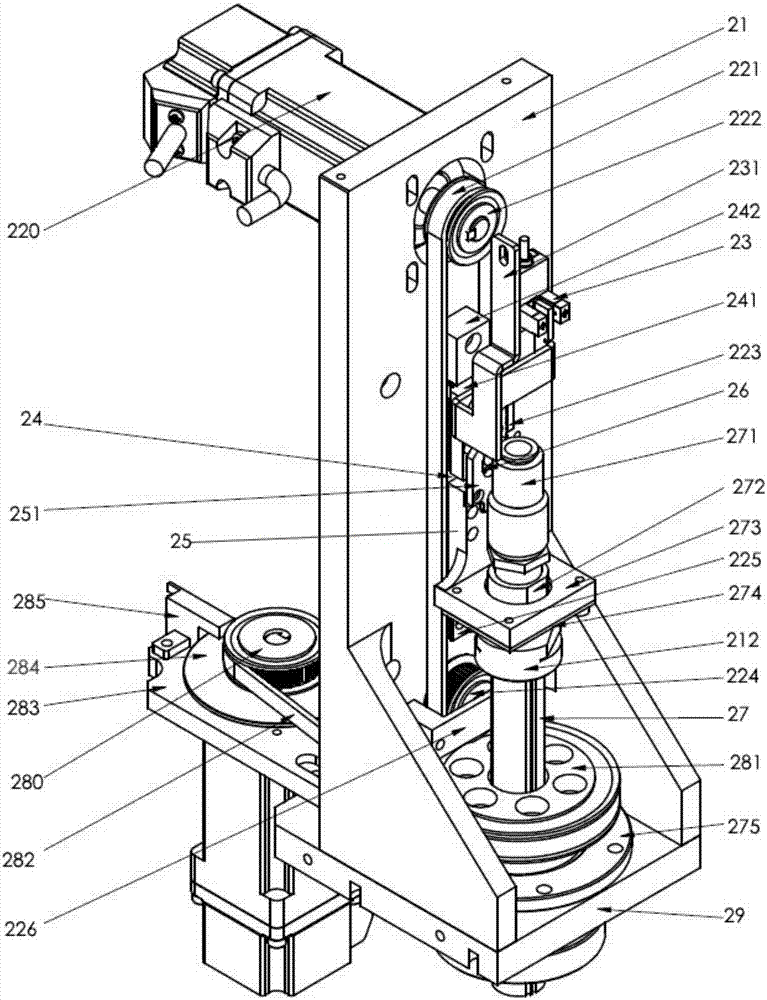

Large-size special-shaped material pasting device and pasting control method

InactiveCN106907381AImprove placement accuracyImprove stabilityPlastic deformation fasteningEngineeringVisual recognition

The invention discloses a large-size special-shaped material pasting device. The pasting device is composed of an installation base assembly, a pasting assembly, a visual recognition assembly and a special-shaped material taking assembly. The pasting assembly comprises a driving assembly, a Z-axis pasting assembly and an R-axis rotating assembly, wherein the driving assembly and the Z-axis pasting assembly are installed on a spline installation base, and the R-axis rotating assembly is arranged on a bottom fixing seat. The Z-axis pasting assembly is fixed through a three point and one line over-positioning type Z-axis spline, and pasting angle errors caused by rotation deviation are reduced by using various Z-axis buffering or pressure control connecting structures based on a single-sliding-rail and double-sliding-block fixing manner. The large-size special-shaped material pasting device has the beneficial effects that by the adoption of the large-size special-shaped material pasting head and a matched pasting control method, the pasting precision and pasting stability of large-size special-shaped materials can be improved, the material throwing rate is reduced, and the product pasting yield is increased; and the technical difficulty that automatic equipment is used for replacing manual work is overcome, manual work is saved, the production cost is reduced, and the production efficiency is improved.

Owner:深圳逻辑自动化科技有限公司

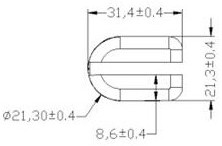

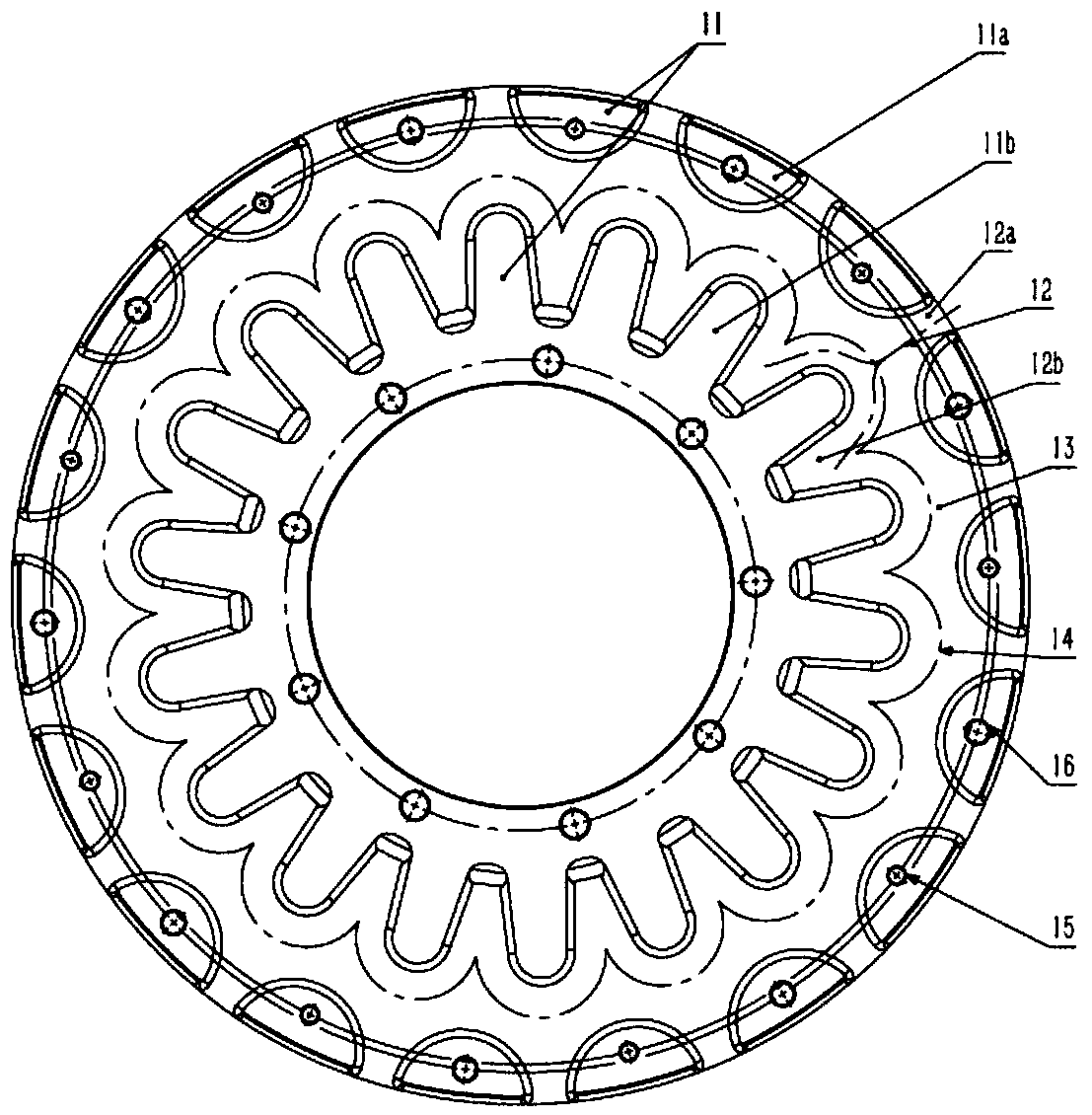

Wire winding disk of aviation tire bead ring winding machine

The invention provides a wire winding disk of an aviation tire bead ring winding machine, belonging to the technical field of bead ring winding disks. The wire winding disk comprises a wire nozzle, winding displacement rolls, two wire guide rolls and a wire winding disk, wherein the wire nozzle is fixed on the center of the wire winding disk, the winding displacement rolls are fixed on the periphery of the wire winding disk, and the two wire guide rolls are fixed on the wire winding disk. The wire winding disk has the beneficial effects that 1, the winding of a large-diameter steel wire can be ensured, the process difficulty of the large-diameter steel wire is overcome; 2, the bending of the large-diameter steel wire is reduced, the plastic deformation of the steel wire is avoided, and thus the guarantee is provided for realizing the high-efficiency winding; and 3, due to the reasonable winding displacement rolls design and the reasonable wire guide roll layout, the process difficulties of few fed wires, multiple supplied wires and large passive pulling tensile force in the process of winding the steel wire are solved, and due to the reasonable design of the wire nozzle, the guide function of spirally winding the steel wire is skillfully realized, and the reverse guide function in the process of winding the steel wire is realized with the positive rotation and the negative rotation of the wire winding disk.

Owner:哈尔滨工大宏图橡塑科技有限公司

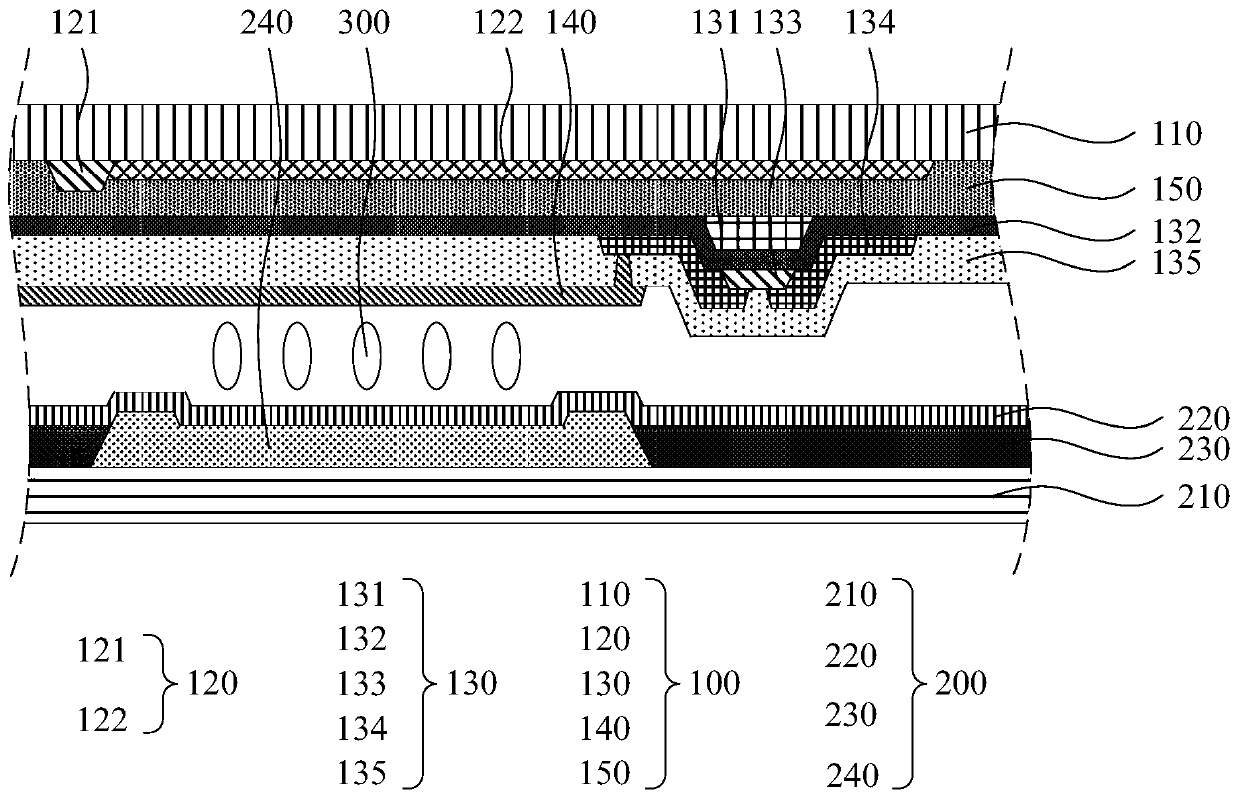

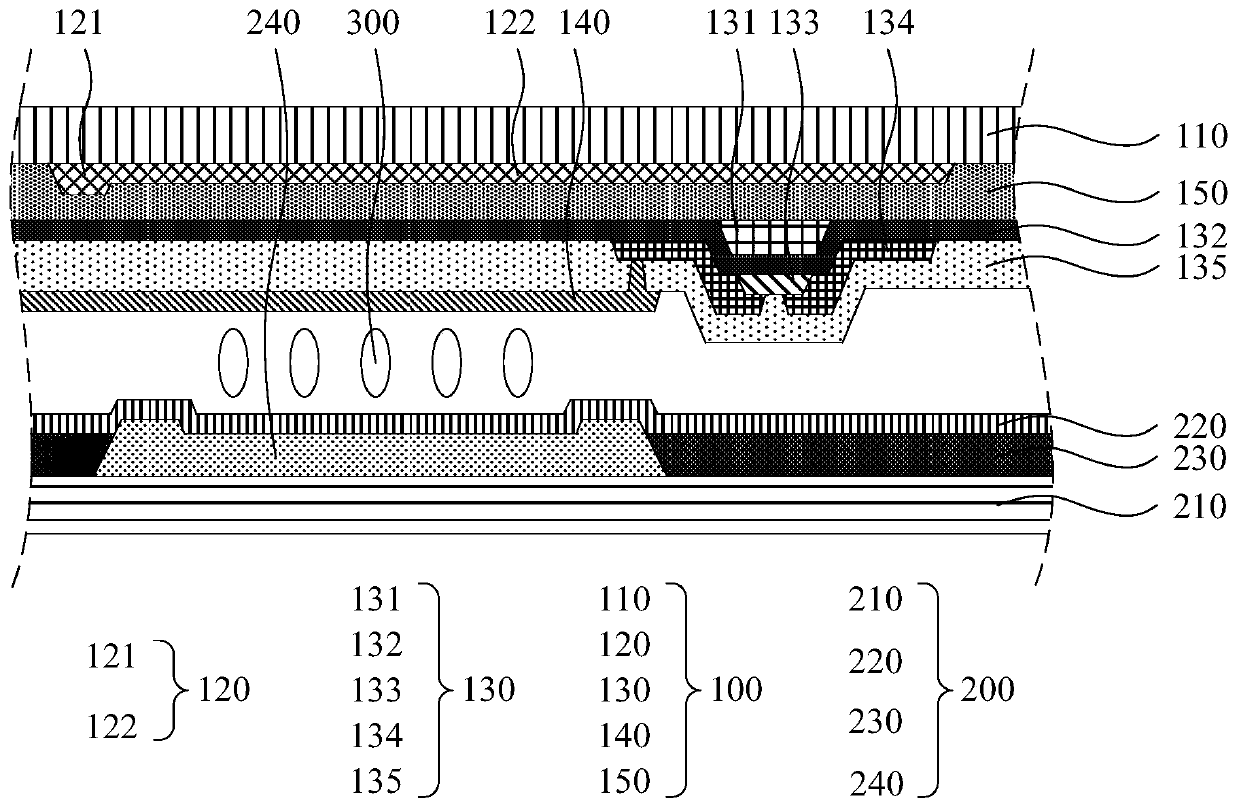

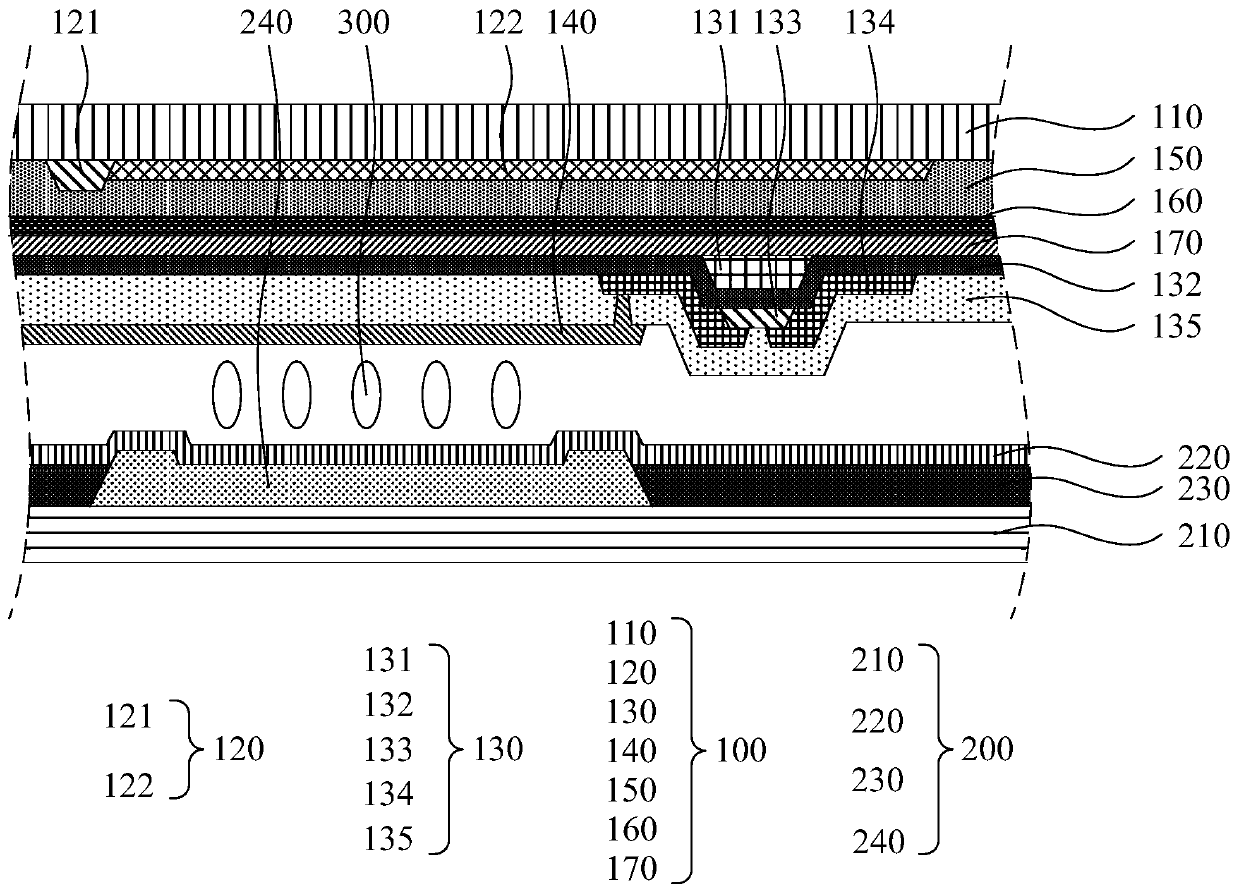

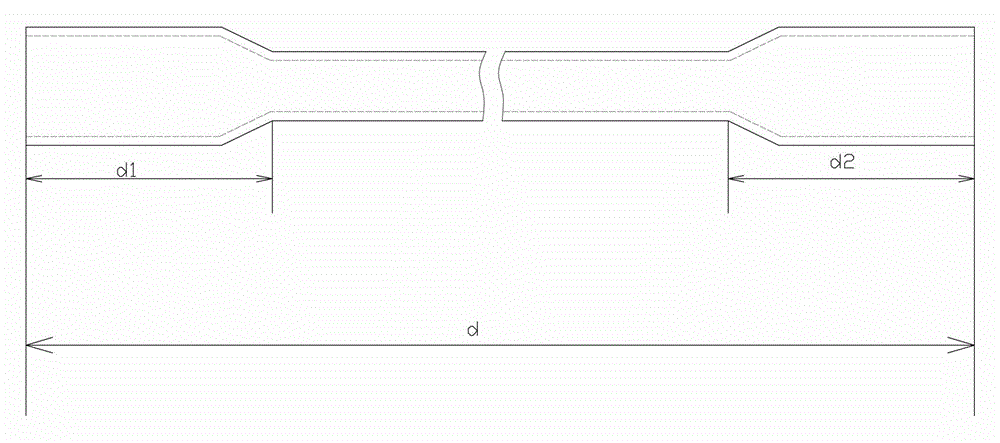

Self-capacitance touch display panel and driving method thereof

InactiveCN111443511ANo border area addedIncreased sensitivityStatic indicating devicesNon-linear opticsCapacitanceProtective glasses

The invention provides a self-capacitance touch display panel and a driving method thereof. The self-capacitance touch display panel comprises a first base plate, a second base plate and a liquid crystal layer, wherein the first base plate comprises a first substrate, a touch electrode layer, a driving circuit layer and a pixel electrode layer, the touch electrode layer is arranged on the side, close to the driving circuit layer, of the first substrate, the driving circuit layer is arranged on the side, away from the first substrate, of the touch electrode layer, and the pixel electrode layeris arranged on the side, away from the first substrate, of the driving circuit layer; the second base plate is arranged opposite to the first base plate and comprises a second substrate and a common electrode layer; and the liquid crystal layer is formed between the first substrate and the second substrate by filling. Integration of a vertical orientation display panel and a self-capacitance touchscheme is realized; compared with an externally-hanging touch display panel, tempered protective glass and a laminating process are omitted, and the cost is saved; compared with a traditional embedded touch display panel, the limitation that the electrodes can only adopt a common electrode reuse mode is broken through; and the sensitivity is higher, and the method is more suitable for large-sizecommercial products.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Forming method of unequal-wall-thickness reducing special-shaped stainless steel pipe

The invention relates to a method for machining a reducing unequal-wall-thickness special-shaped stainless steel pipe by utilizing a cold rolling method, which belongs to the field of the machining and manufacturing of a stainless steel seamless steel pipe. According to the technical scheme, the forming method comprises the following steps: (1) blanking; (2) cleaning the surface; (3) scribing; (4) lubricating the inner wall; (5) primarily cold rolling; (6) lubricating the inner wall; (7) secondarily cold rolling; (8) lubricating the inner wall; (9) thirdly cold rolling; (10) degreasing; (11) carrying out solid-solution treatment; (12) straightening; (13) fixing the size and sawing; and (14) inspecting and packaging. According to the production process, the process difficulties can be solved; moreover, the integrally rolled seamless steel pipe is high in safety, and the use under a severe environmental condition can be satisfied.

Owner:SHANDONG YAO CHENG NEW MATERIALS TECH CO LTD

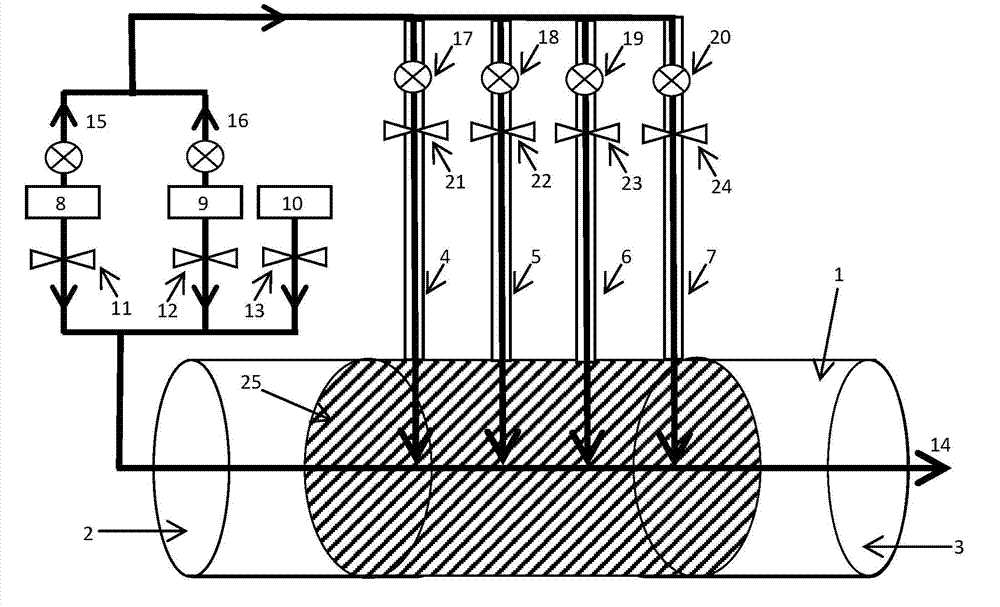

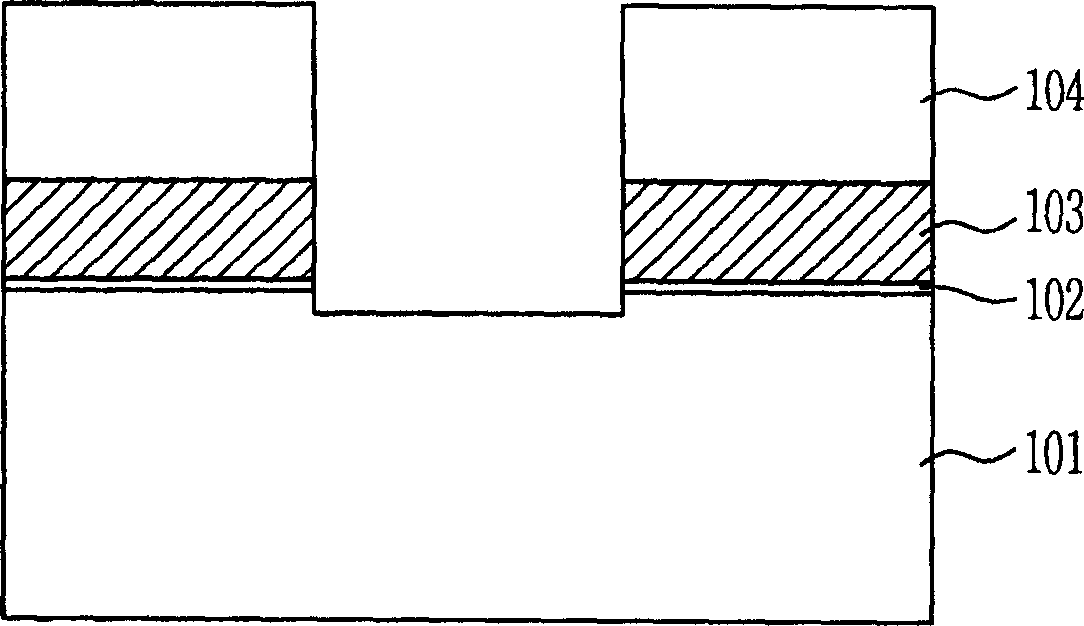

Device and method for preparing ethylene from ethane oxidative dehydrogenation

InactiveCN103933898AIncreased ethylene yieldReduce carbonation rateHydrocarbonsChemical/physical processesPetrochemicalChemistry

The invention belongs to the field of petrochemical production, and particular relates to a device and a method for preparing ethylene from ethane oxidative dehydrogenation. The device for preparing the ethylene from the ethane oxidative dehydrogenation comprises a main reaction tube; the side surface of the main reaction tube is provided with 1-8 branch pipe(s); the main reaction tube is filled with a catalyst, so that a catalyst bed layer can be formed; outlets of all the branch pipes are covered by the side surface of the catalyst bed layer; an oxygen source, an ethane gas source and an inert gas source are combined into one path and flow into a gas inlet hole of the main reaction tube; the oxygen source and the ethane gas source are combined into one path and flow into the plurality of branch pipes after respectively passing through an oxygen branch pipe stop valve and an ethane branch pipe stop valve. The method for preparing the ethylene from the ethane oxidative dehydrogenation comprises the steps of filling the catalyst and controlling technological parameters of the main tube and the branch pipes. According to the device and the method, a plurality of nodes can be provided for adjusting the flow velocity ratio of oxygen to ethane in the catalyst bed layer, so that the yield of the ethylene is obviously increased and reaches up to 18%; furthermore, the carbonization rate of the catalyst is reduced, and the service cycle of the catalyst is prolonged.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

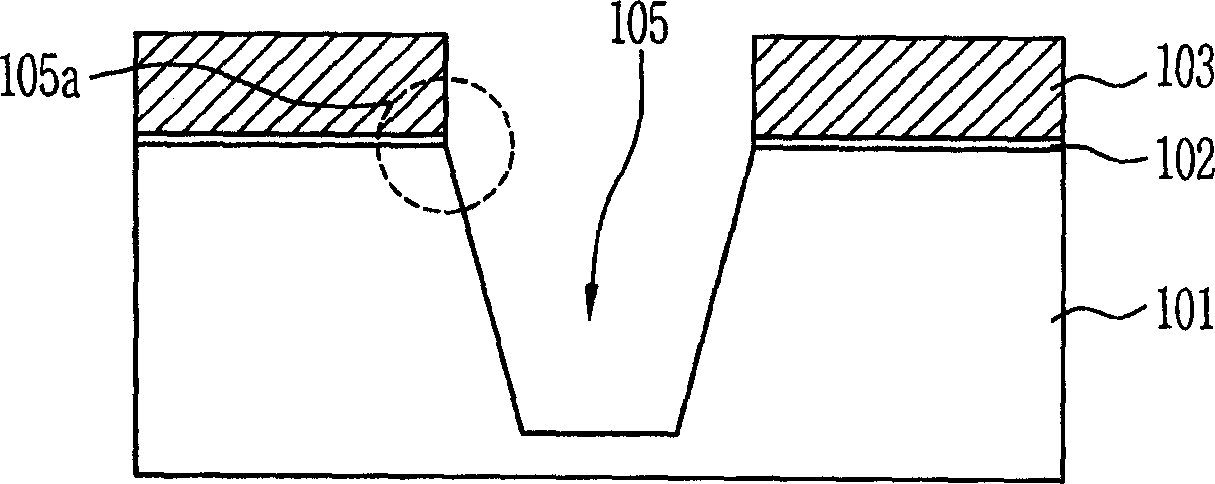

Method of forming isolation membrane in semiconductor device

InactiveCN1499605AExcellent electrical propertiesSolve process difficultiesSemiconductor/solid-state device manufacturingNitrideSemiconductor

Disclosed is a method of forming an isolation film in a semiconductor device. In the process of forming a stack structure of a pad oxide film and a pad nitride film that expose a semiconductor substrate in an isolation region, protrusions of a tail profile are formed at the bottom sidewalls of the pad nitride film and the pad oxide film adjacent to the surface of the substrate, and top corners of a trench are made rounded using the protrusions as an anti-etch film when the substrate is etched, Therefore, it is possible to prevent concentration of an electric field on the top corners of the trench and prohibit generation of the leakage current. Accordingly, reliability of the process and electrical characteristics of the device could be improved.

Owner:SK HYNIX INC

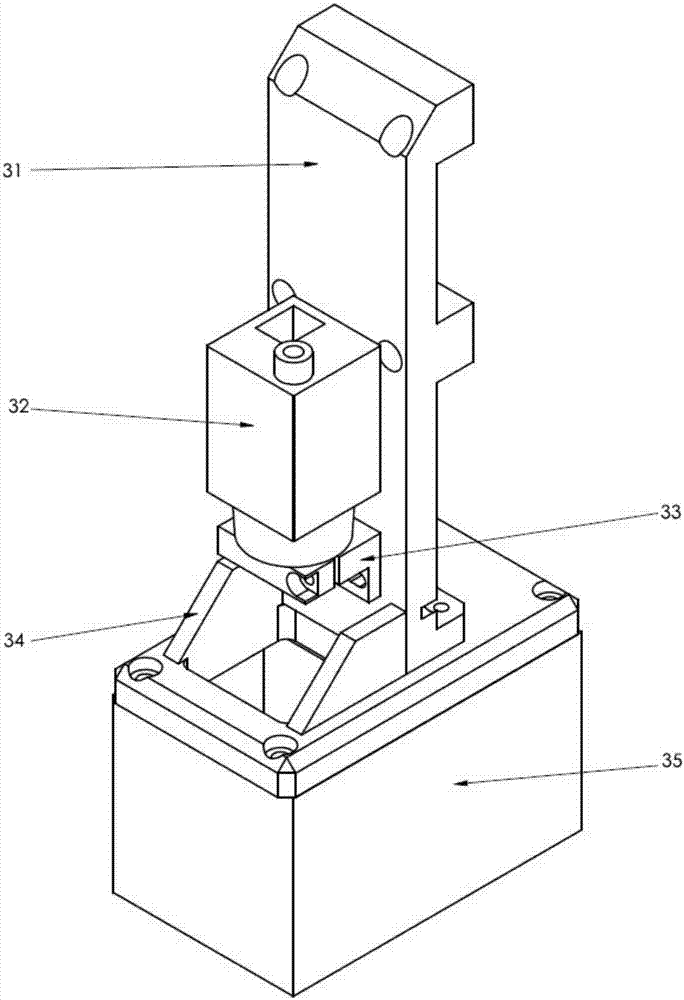

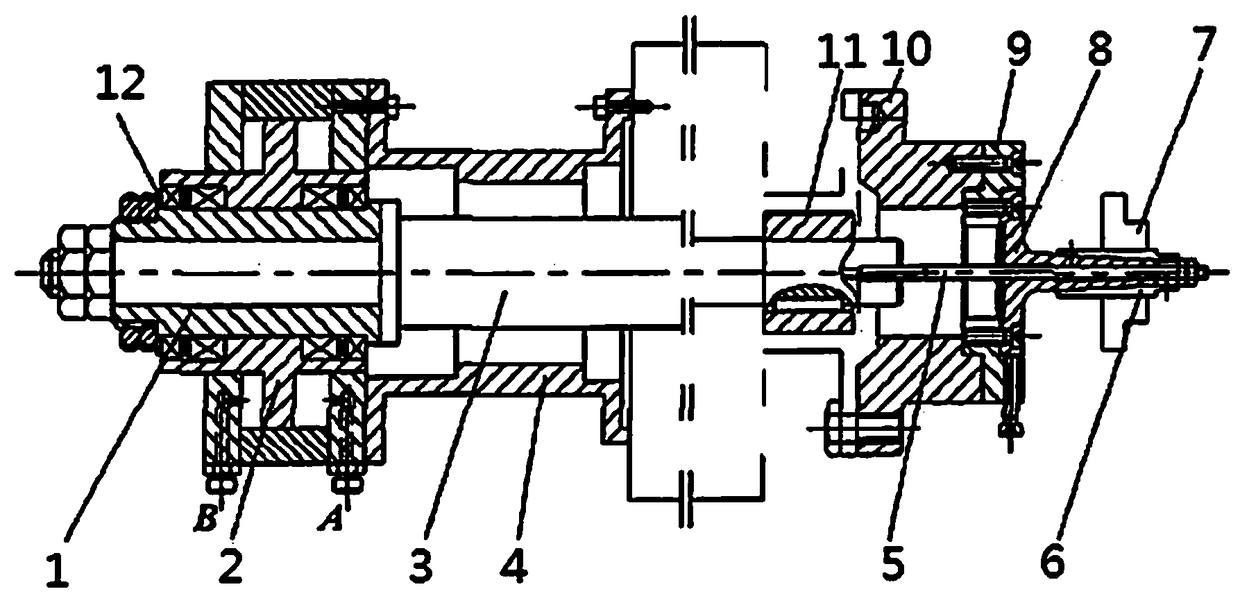

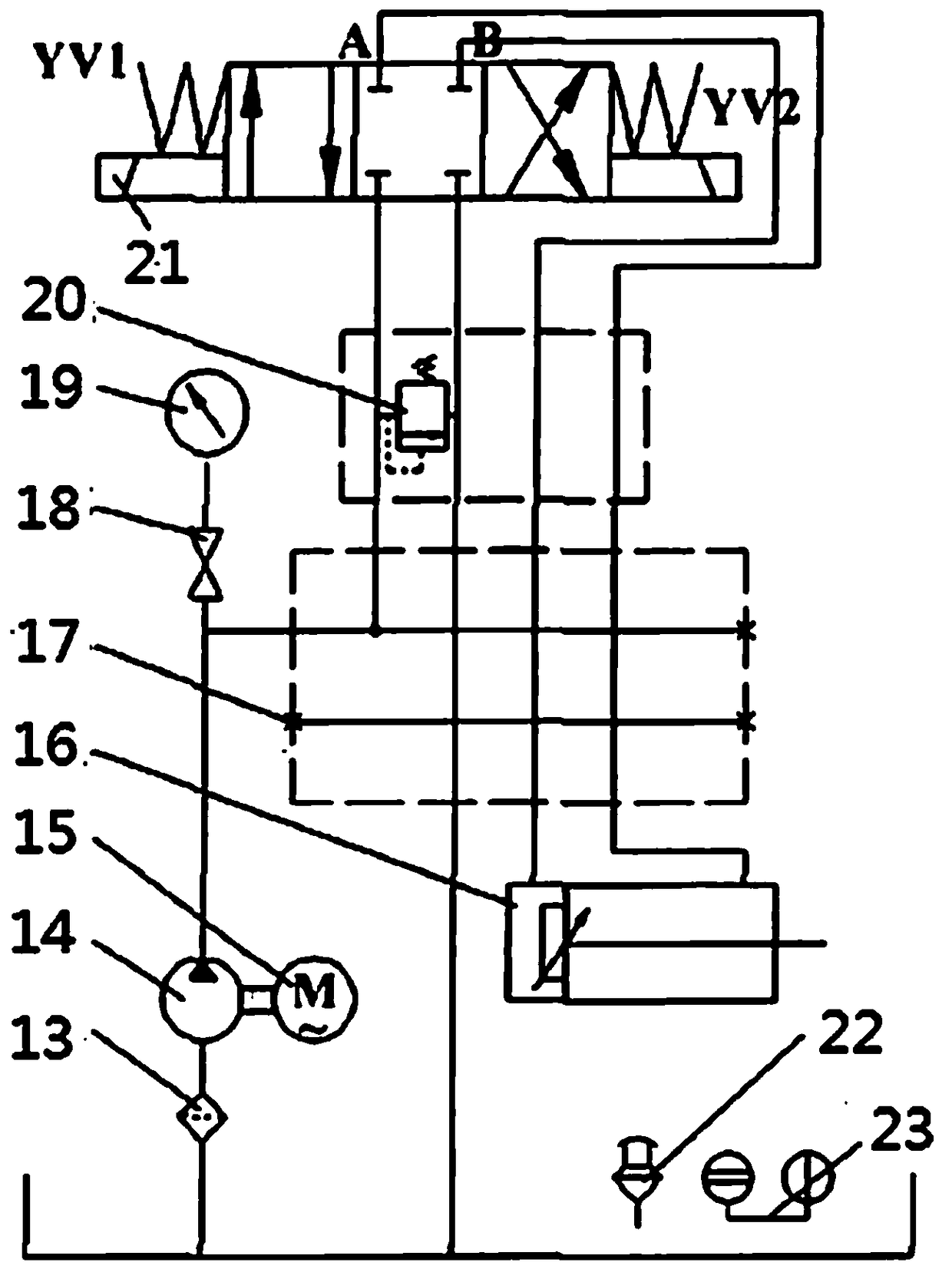

Tooth blank finish turning hydraulic tool system

InactiveCN108081001ASolve process difficultiesMeet the fine car requirementsServomotor componentsWork clamping meansEngineeringFlange

The invention discloses a tooth blank finish turning hydraulic tool system which mainly consists of a bearing sleeve, a rotary oil cylinder, a pull rod, a connecting sleeve, a connecting rod, a finishturning tire sleeve, a tooth blank, a finish turning tire seat, a flange plate, a connecting plate, a locating sleeve, a spacer bush, a corresponding hydraulic system and the like; the front end of the pull rod is connected with the connecting rod; the connecting sleeve is arranged at the tail of a spindle, and after alignment, the special rotary oil cylinder and the pull rod (which penetrates through a spindle hole) are arranged on the connecting sleeve; the connecting plate is arranged at the front end of the spindle of a lathe; finish turning tire sleeves in different sizes can be mountedon the finish turning tire seat as required so as to meet the requirement of machining the tooth blanks in various sizes; the finish turning tire seat is arranged on the flange plate in an alignment manner; and after the connecting plate is aligned, the flange plate is arranged on the connecting plate. The tooth blank finish turning hydraulic tool system is simple in structure, high in working efficiency, simple and convenient in clamping, wide in clamping range, adjustable in tensioning force and high in precision and can meet the finish turning requirements of the tooth blanks better.

Owner:吴丽娜

A kind of chlorinated rubber and production method thereof

InactiveCN102268107ASolve process difficultiesPromote precipitationInformation processingPolymer science

The invention provides a chlorinated rubber and a production method thereof. The chlorinated rubber belongs to C08C19 / 00 in information processing center (IPC) class numbers. The production method comprises the following process steps: after plastifying, heating so as to dissolve a natural rubber to a rubber solution, wherein a used solvent is a mixing solvent of 1,1,2-trichloroethane and trichloromethane, and the mass mixing ratio of 1,1,2-trichloroethane to trichloromethane is (1:6)-(1:8); and after introducing oxygen and dissolving, introducing chlorine for chlorination reaction and preparing the chlorinated rubber finished product. According to the invention, the temperature in the production method of the chlorinated rubber is convenient for control and simultaneously is beneficial to solvent removal, recovery and improvement of capacity; and the main content of the prepared chlorinated rubber can be further increased.

Owner:福建省龙岩龙化化工有限公司

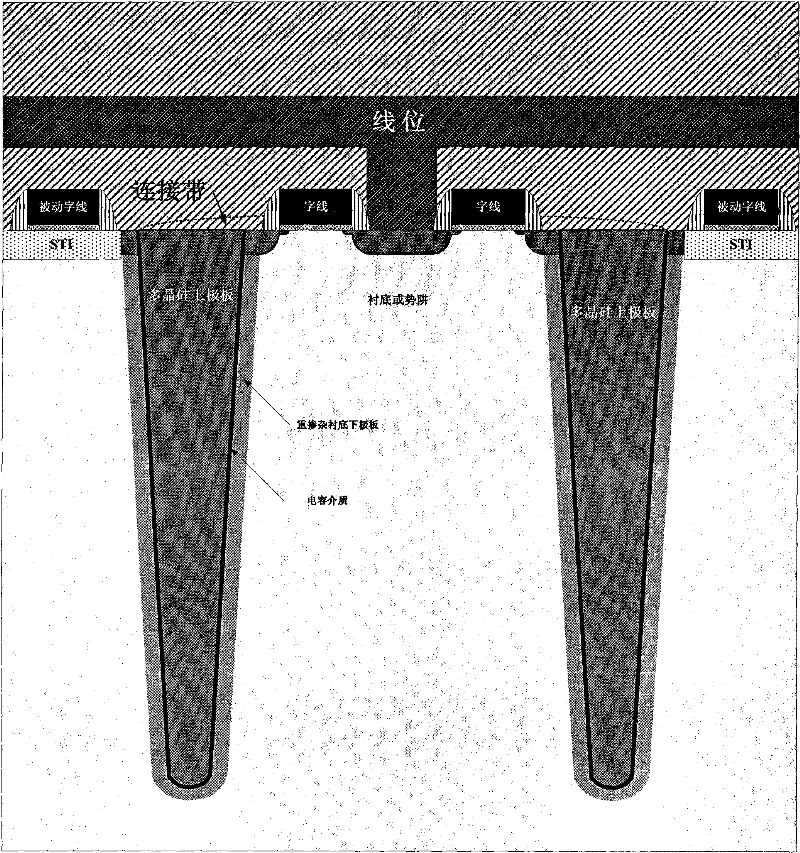

DRAM (Dynamic Random Access Memory) structure with expansion groove and manufacturing method thereof

InactiveCN101997000ASimple manufacturing processSimple processTransistorSemiconductor/solid-state device manufacturingEtchingEngineering

The invention discloses a DRAM (Dynamic Random Access Memory) structure with an expansion groove and a manufacturing method thereof. The structure comprises an NMOS (N-channel Metal Oxide Semiconductor) transistor and a groove capacitor connected with a source electrode thereof, wherein the groove capacitor comprises a semiconductor substrate, an N-type SiGe layer and an N-type Si layer which are alternately arranged, a groove, a dielectric layer and a polysilicon layer, wherein the groove is located in the N-type SiGe layer and the N-type Si layer which are alternately arranged and extends into the semiconductor substrate, and the section of a side wall of the groove is in a comb tooth shape; the N-type SiGe layer and the N-type Si layer which are alternately arranged are utilized as a lower pole plate; the dielectric layer is located at the surface of the inner wall of the groove; the polysilicon layer is filled in the groove and utilized as an upper pole plate of the groove capacitor; a P-type Si layer is also prepared on the N-type SiGe layer and the N-type Si layer which are alternately arranged; and the NMOS transistor is manufactured on the P-type Si layer. Through the method, the N-type SiGe layer and the N-type Si layer are alternately grown by utilizing a doping and epitaxial technique and the side wall in the comb tooth shape is manufactured by utilizing selective etching; and the method improves the structure of a deep groove capacitor in the DRAM and simplifies the manufacturing process.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Method for improving process window of self-aligned cell module in SONOS technology

ActiveCN101740464AImprove the selection ratioSolve process difficultiesSemiconductor/solid-state device manufacturingNon dopedEngineering

The invention discloses a structure for improving a process window of a self-aligned cell module in SONOS technology and a manufacturing method thereof. The structure is characterized in that: the structure comprises film layer structures of a shallow trench isolation module and a self-aligned cell etching (SACE) module; a non-doped oxidation layer is adopted as an interlayer film medium; and phosphate glass is adopted as a field space medium. The method can avoid a series of process difficulties brought by flower pattern introduced when the phosphate glass is used as a PMD interlayer film medium, so that the process window of the whole module is improved greatly.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

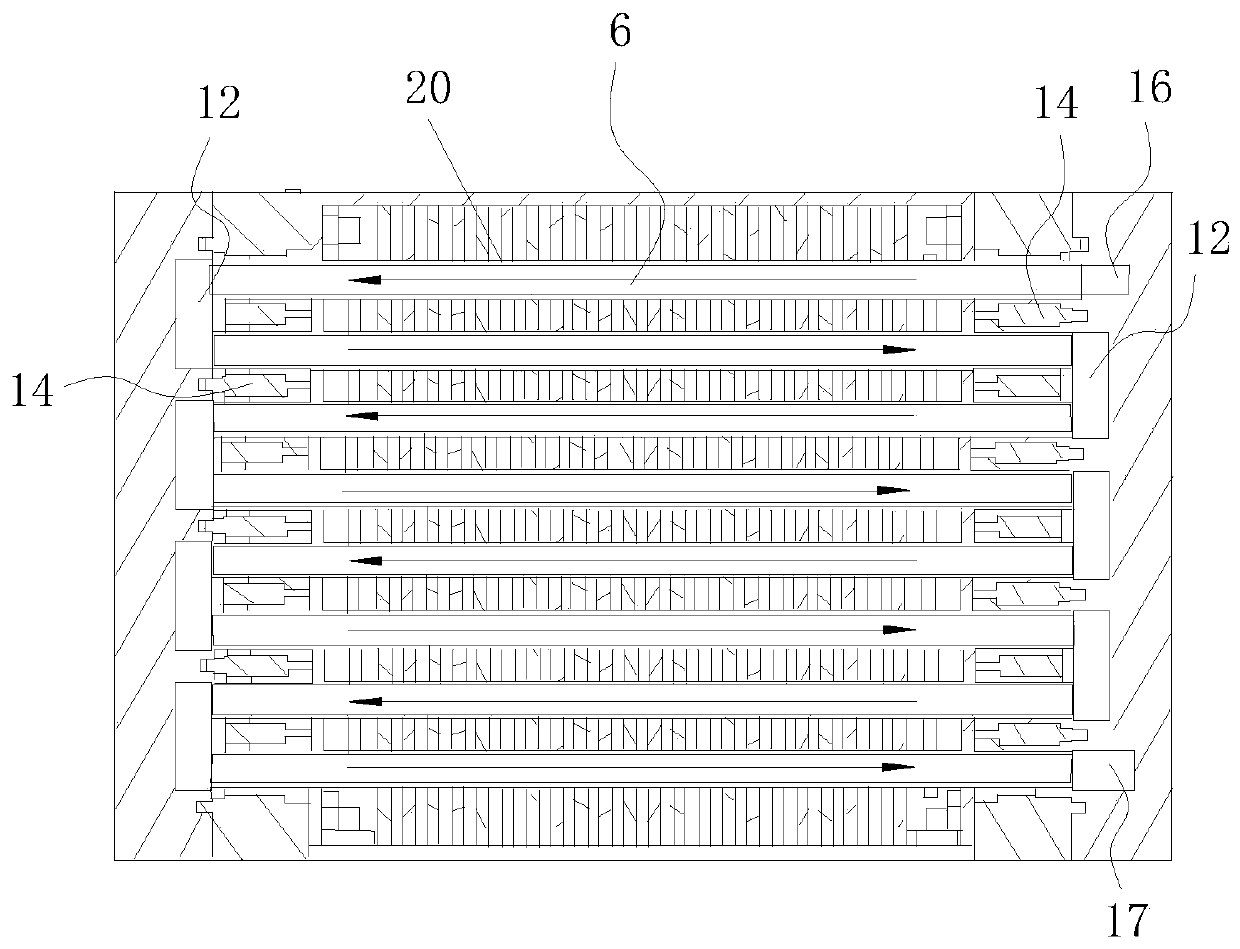

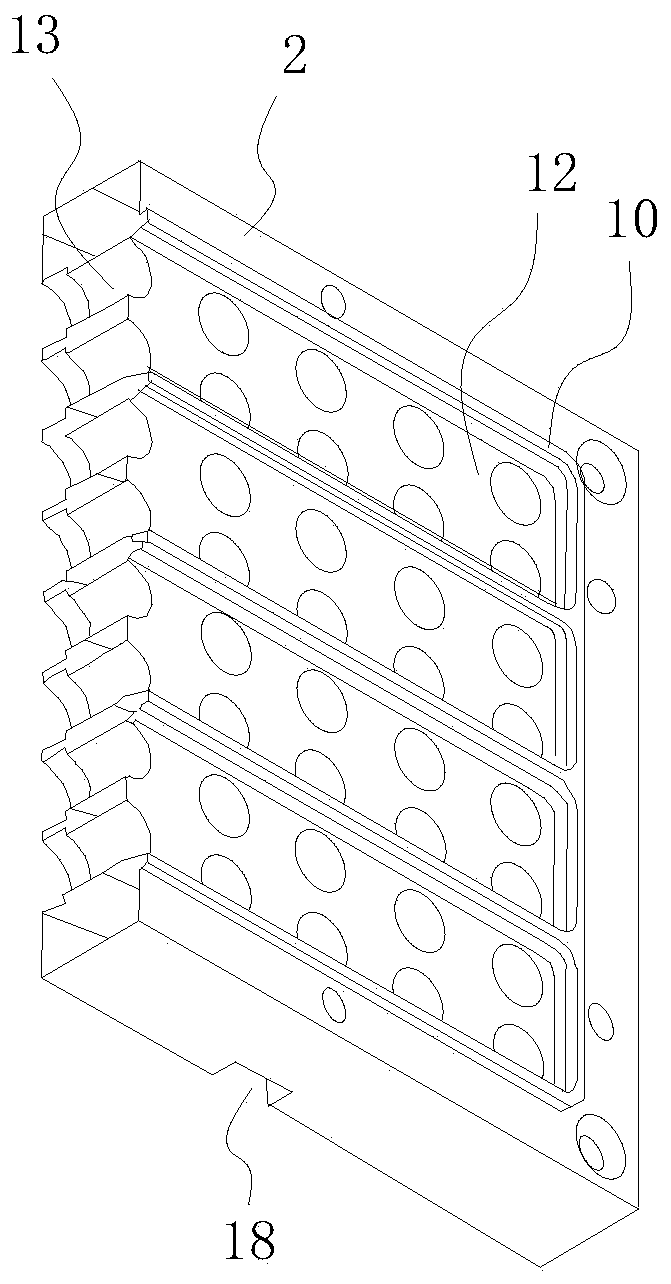

Heat dissipation device for liquid fuel cell system

PendingCN111490266AReduce processing difficultySolve process difficultiesFuel cell heat exchangeThermodynamicsFuel cells

The invention discloses a heat dissipation device for a liquid fuel cell system. The heat dissipation device comprises a fixed frame, a left side end plate arranged in the left side of the fixed framethrough a left side fixed plate, a right side end plate arranged in the right side of the fixed frame through a right side fixed plate, a plurality of pipelines arranged in the fixed frame, a plurality of fins arranged in the fixed frame, and a feeding hole and a discharging hole formed in the right side end plate; the pipelines penetrate through the fins and enable the feeding port and the discharging port to be communicated, the multiple pipelines are arranged into a plurality of layers in the fixed frame, and the left side fixed plate and the right side fixed plate are each provided with agroove rectangular flow channel communicated with the two adjacent layers of pipelines. According to the heat dissipation device for the liquid fuel cell system, through the design of the groove rectangular flow channels in the fixed plates at the two sides, the process difficulty that the joints of every two adjacent layers of pipeline elbows need to be welded is solved, the structure is simple,and the machining difficulty of the heat dissipation device is reduced.

Owner:上海醇加能源科技有限公司

Winding reel of a wire coil winding machine for aviation tires

The invention provides a wire winding disk of an aviation tire bead ring winding machine, belonging to the technical field of bead ring winding disks. The wire winding disk comprises a wire nozzle, winding displacement rolls, two wire guide rolls and a wire winding disk, wherein the wire nozzle is fixed on the center of the wire winding disk, the winding displacement rolls are fixed on the periphery of the wire winding disk, and the two wire guide rolls are fixed on the wire winding disk. The wire winding disk has the beneficial effects that 1, the winding of a large-diameter steel wire can be ensured, the process difficulty of the large-diameter steel wire is overcome; 2, the bending of the large-diameter steel wire is reduced, the plastic deformation of the steel wire is avoided, and thus the guarantee is provided for realizing the high-efficiency winding; and 3, due to the reasonable winding displacement rolls design and the reasonable wire guide roll layout, the process difficulties of few fed wires, multiple supplied wires and large passive pulling tensile force in the process of winding the steel wire are solved, and due to the reasonable design of the wire nozzle, the guide function of spirally winding the steel wire is skillfully realized, and the reverse guide function in the process of winding the steel wire is realized with the positive rotation and the negative rotation of the wire winding disk.

Owner:哈尔滨工大宏图橡塑科技有限公司

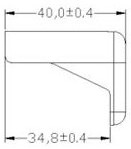

Doubling-acting side-pushing bend-forming Die

PendingCN112170644ASolve process difficultiesNormal automatic returnShaping toolsStripping-off devicesEngineeringStructural engineering

The invention provides a double-acting side-pushing bend-forming die. An upper base plate, an upper clamping plate, a stop plate and a stripping plate are sequentially mounted below an upper die base;a lower die plate and a lower base plate are sequentially mounted above the upper die base; an inner guide column is arranged in the upper clamping plate, the upper clamping plate and the upper baseplate are fixed to the upper die base, the upper die base and the upper clamping plate slide upwards and downwards along the inner guide column, and the inner guide column penetrates through the stripping plate and the lower die plate to realize a guide function; a first punch and a second punch are arranged in the upper clamping plate and penetrate through the stripping plate to enter the lower die plate and drive a forming block and a side-pushing block to move to realize side-pushing formation; and reset springs are arranged in the forming block and the side-pushing block and abut against spring stop blocks, and when the first punch and the second punch move upwards, the forming block and the side-pushing block restore under the effect of the elastic force of the reset springs. The double-acting side-pushing bend-forming die has the beneficial effects of being able to overcome the process difficulty of side-pushing bending and edge covering, realize normal automatic stripping and guarantee continuous production.

Owner:ANHUI XINYUE PRECISION MACHINERY

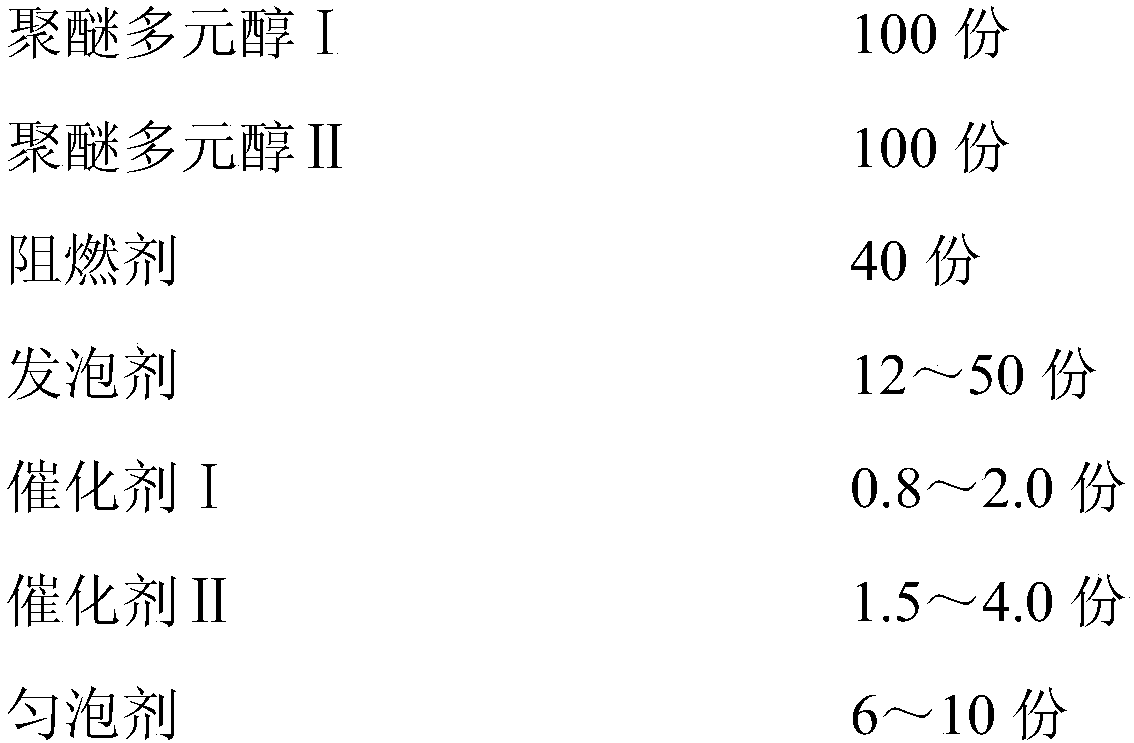

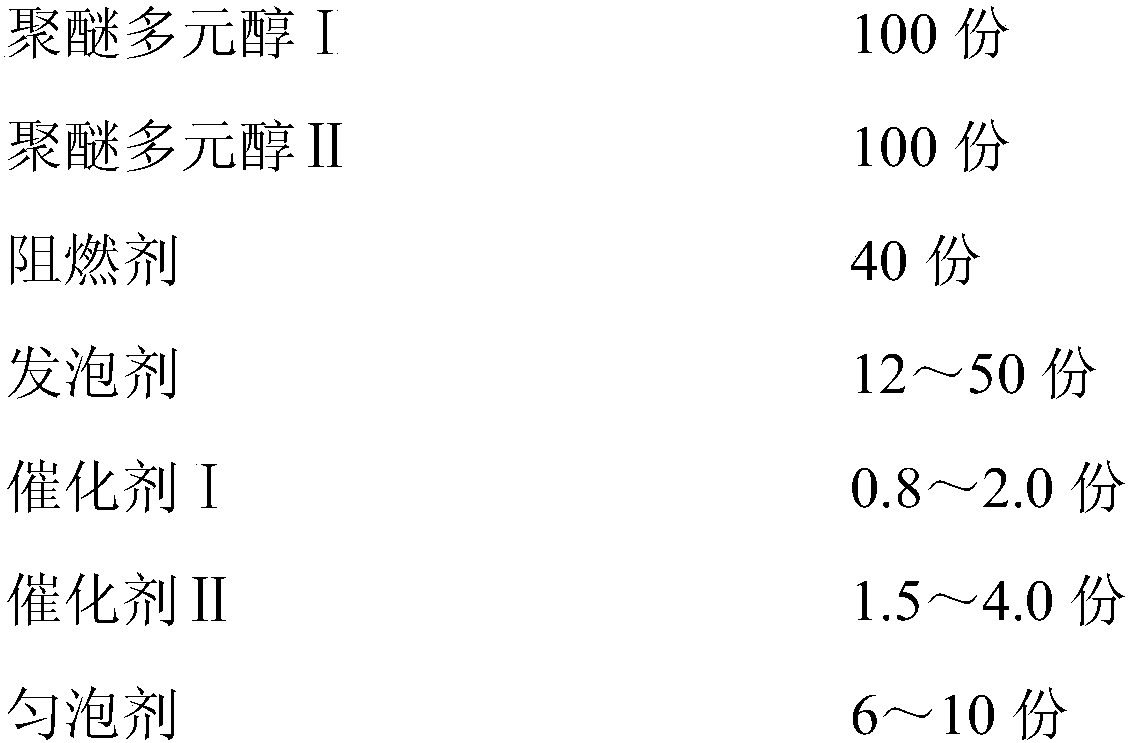

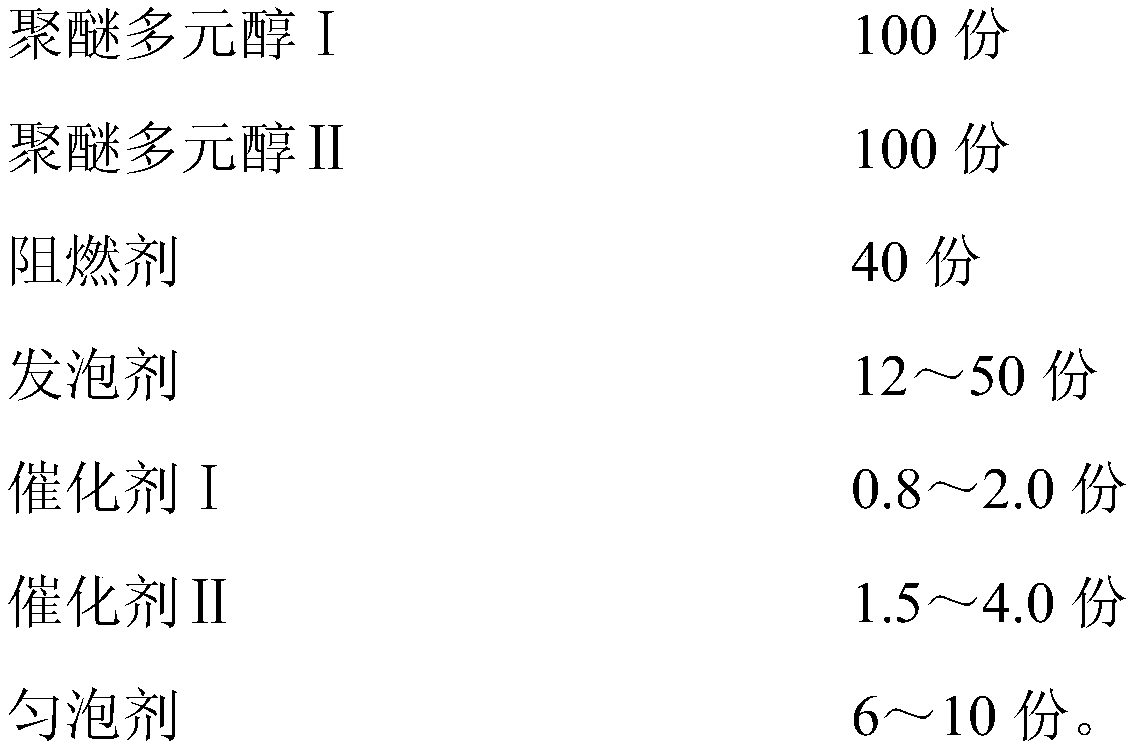

Spray molding high-density polyurethane foam and preparation method thereof

ActiveCN107602813AUniform textureDensity and total thickness can be adjustedPolyphenyl isocyanateThermal insulation

The invention relates to a spray molding high-density polyurethane foam and a preparation method thereof. The preparation method comprises: uniformly mixing polyether polyol, a flame retardant agent,a foaming agent, a catalyst, a foam stabilizing agent and polymethylene polyphenyl isocyanate according to a certain ratio, and carrying out high pressure atomization spray molding through a spray foaming machine, wherein the total thickness of the foam layer can be controlled through layered spraying. According to the present invention, the limitation in the casting molding of the high-density polyurethane foam is broken through, the spray molding of the high-density polyurethane foam is achieved, the technical difficulties that the interior of the foam easily produces foam heartburn, cracking and layering along with the increase of the density of the foam can be overcome, and the convenient and continuous construction of the foam layer on the large-area surface within the short period can be achieved; and the spray molding high-density polyurethane foam has the density of 60-250 kg / m<3>, and has advantages of uniform texture, controlled thickness, excellent thermal insulation property, and excellent mechanical property.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Method for producing 8014-H22 state aluminium alloy air-conditioner foil by cast-rolled blank

ActiveCN101805878BSolve process difficultiesSuccessful control of final mechanical propertiesRoll mill control devicesMetal rolling arrangementsAlcladHeat sink

The invention provides a method for producing 8014-H22 state aluminium alloy air-conditioner foil by a cast-rolled blank, belonging to the technical field of aluminium alloy plate belt foil processing. The method particularly comprises the steps of: adopting the production way of cast-rolling and cold-rolling, carrying out homogenizing annealing on the cast-rolled blank before cold rolling, and controlling the annealing temperature to be 520-530 DEG C and the annealing time to be 22-25h; after the homogenizing annealing, leading compound to be dispersed, thinning crystalline grains so as to be beneficial to the cold rolling and ensuring the final mechanical property of the product; reasonably distributing the cold rolling channels by the plasticity of metal and the capability of rolling equipment, and carrying out eight-channel cold rolling on the cast-rolled blank with the thickness of 6.4-7.4mm; and carrying out finished product annealing on aluminium foil which is rolled to be 0.17-0.24mm, and controlling annealing temperature to be 360-370 DEG C and the annealing time to be 14-17h. By adopting the method, the mechanical properties of the 8014-H22 state aluminium alloy air-conditioner foil with the thickness of 0.17-0.24mm can be controlled to be: tensile strength sigma b: 120-135MPa; percentage of elongtation delta: 25-30%; and the cup drawing valve: more than or equal to6.5. The method meets the requirement of the mouldability of a large air-conditioner radiating fin.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD +1

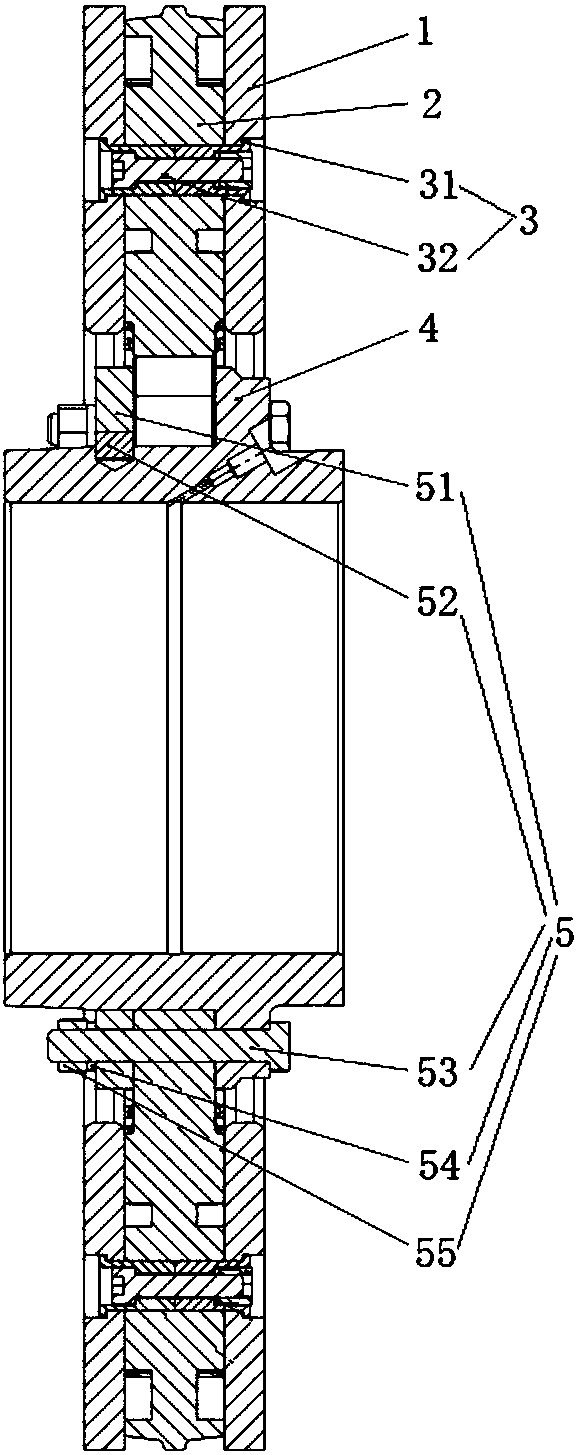

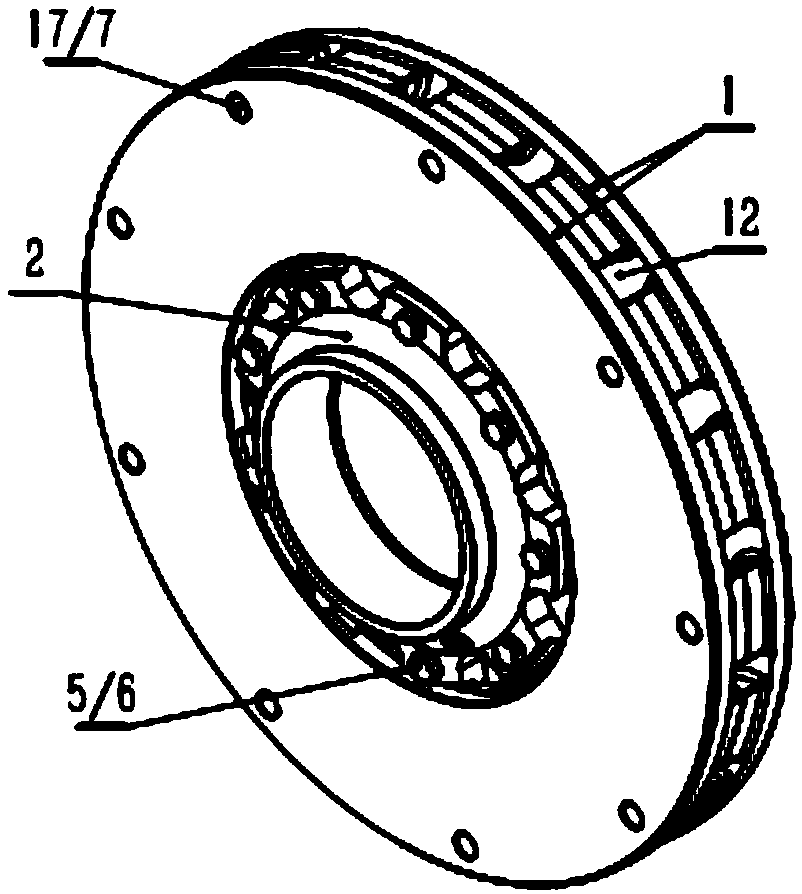

All-carbon ceramic axle-mounted brake disc

ActiveCN109236904AImprove antioxidant capacityImprove convenienceBraking discsFriction liningCeramic compositeUltimate tensile strength

The invention discloses an all-carbon ceramic axle-mounted brake disc. The brake disc includes a disc hub and a plurality of friction discs which are coaxially piled up, wherein the disc hub is sleeved with the friction discs. The friction discs are interlocked and connected through connecting structures into a whole and the friction discs and the disc hub are also interlocked and connected through connecting structures into a whole; the friction discs are made from carbon ceramic composite materials and composed of heat dissipation reinforcement bars with the disc surfaces and the rear surfaces are arranged in the radial direction, the heat dissipation reinforcement bars between the piled-up friction discs make contact in a one-to-one corresponding mode, axial heat dissipation channels are formed in the two sides of the heat dissipation reinforcement bars, and communication grooves communicated with the axial heat dissipation channels on the two sides are formed between the heat dissipation reinforcement bars. The all-carbon ceramic axle-mounted brake disc has the advantages that the structure is simple, the heat dissipation effect is excellent, connection is reliable, maintenanceis convenient, and the weight is low, and reliable braking is ensured while the energy consumption and maintenance cost of a transport tool are reduced.

Owner:HUNAN SHIXIN NEW MATERIALS CO LTD

Preparation method of nano polylactic acid

The invention belongs to the field of nano materials, and particularly relates to a preparation method of nano polylactic acid, which comprises the following steps: step 1, adding polylactic acid into dichloromethane, and carrying out sealed reflux reaction for 10-20 minutes to obtain a polylactic acid dissolved solution; step 2, uniformly spraying the polylactic acid dissolved solution into a constant-temperature reaction kettle, and conducting standing for 20-30 minutes at a constant temperature to obtain a turbid liquid; step 3, purging the reaction kettle with constant-temperature nitrogen, recovering dichloromethane in a two-gradient reduced-pressure cooling mode, wherein the dichloromethane is used for dissolution in the step 1; and step 4, filtering the turbid liquid in the step 2 to obtain solid particles, repeatedly washing the solid particles with distilled water, and drying the solid particles to obtain nano lactic acid particles. According to the invention, the process difficulty of a nano polymer is solved, and the change of polylactic acid in different solvents is utilized to form a rapid spray dispersion effect, so that the effect of polymer nanocrystallization is achieved.

Owner:SUZHOU FIBER EXAMINATION INST +1

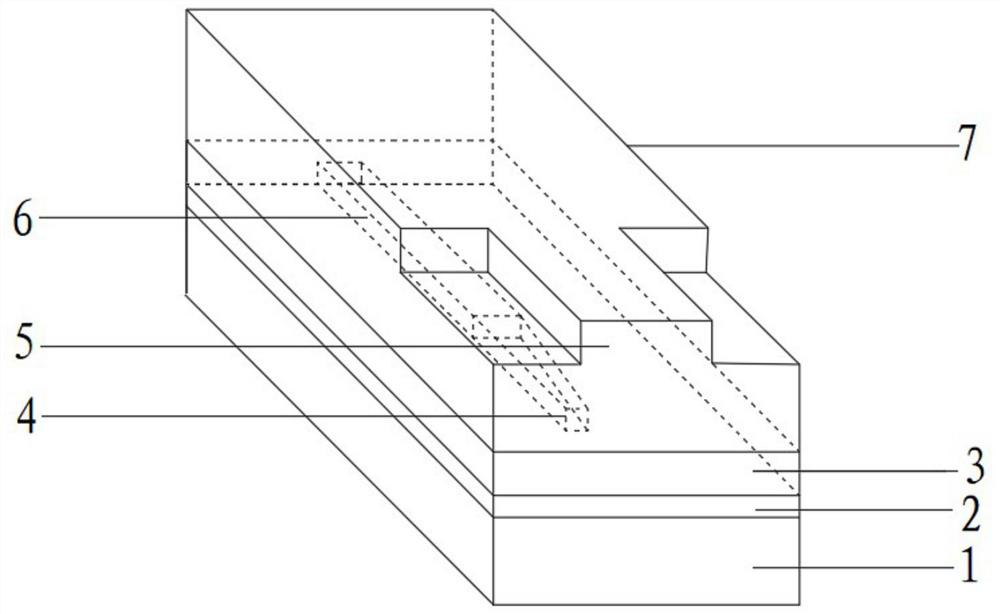

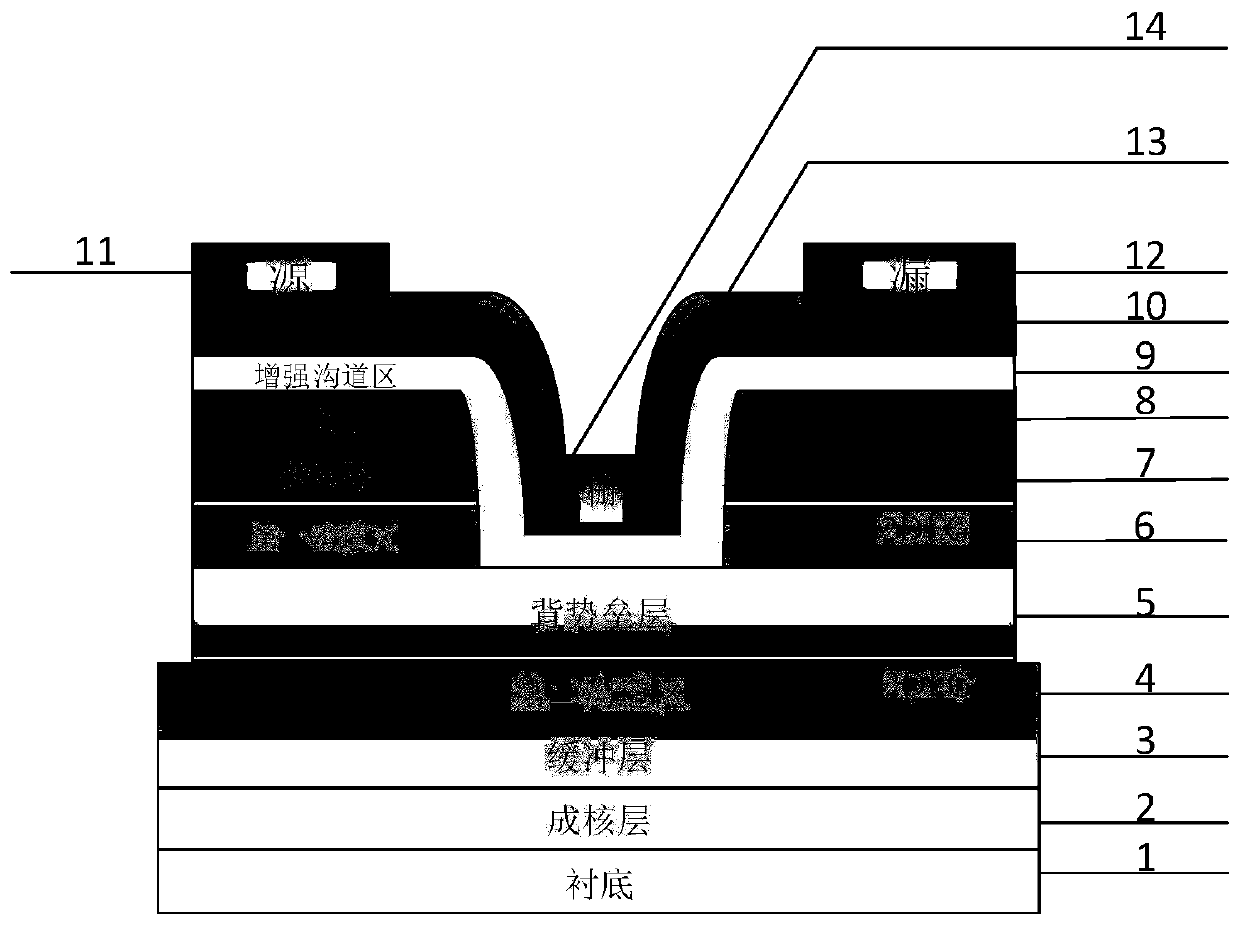

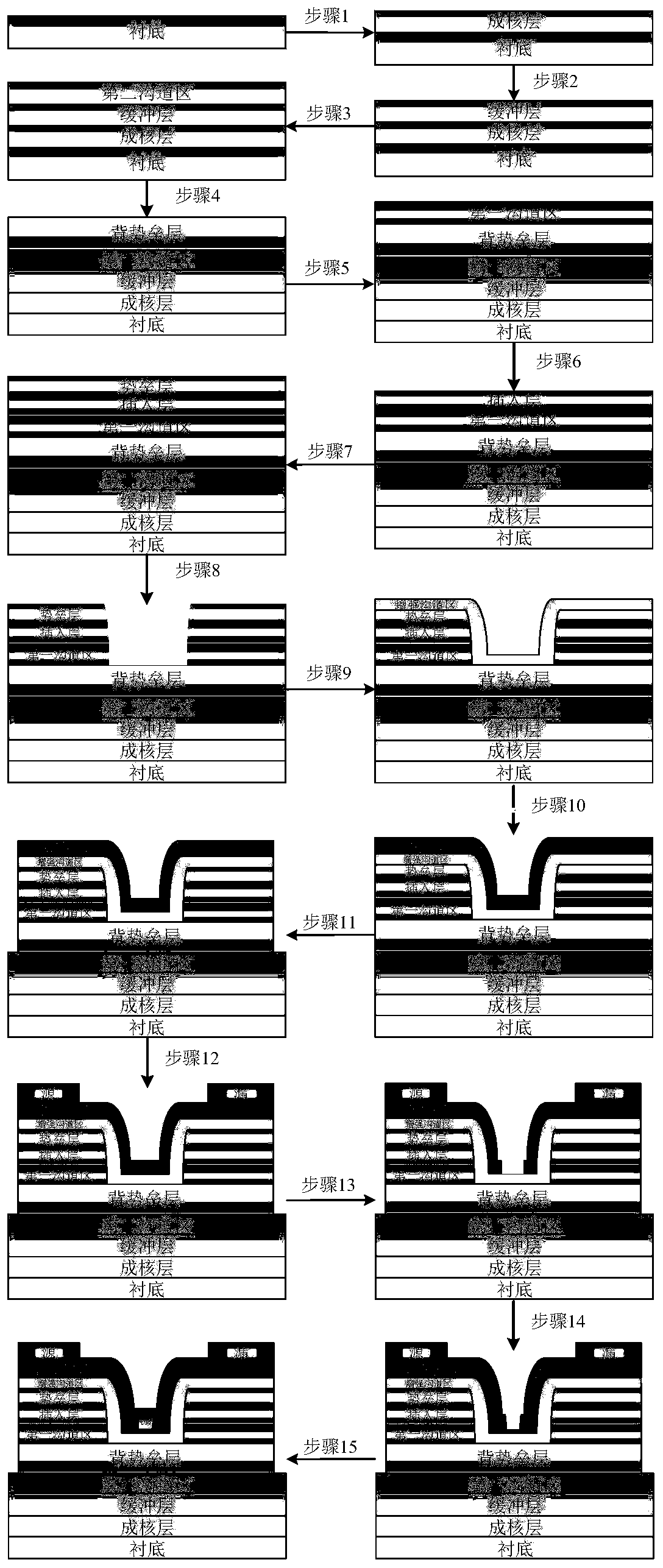

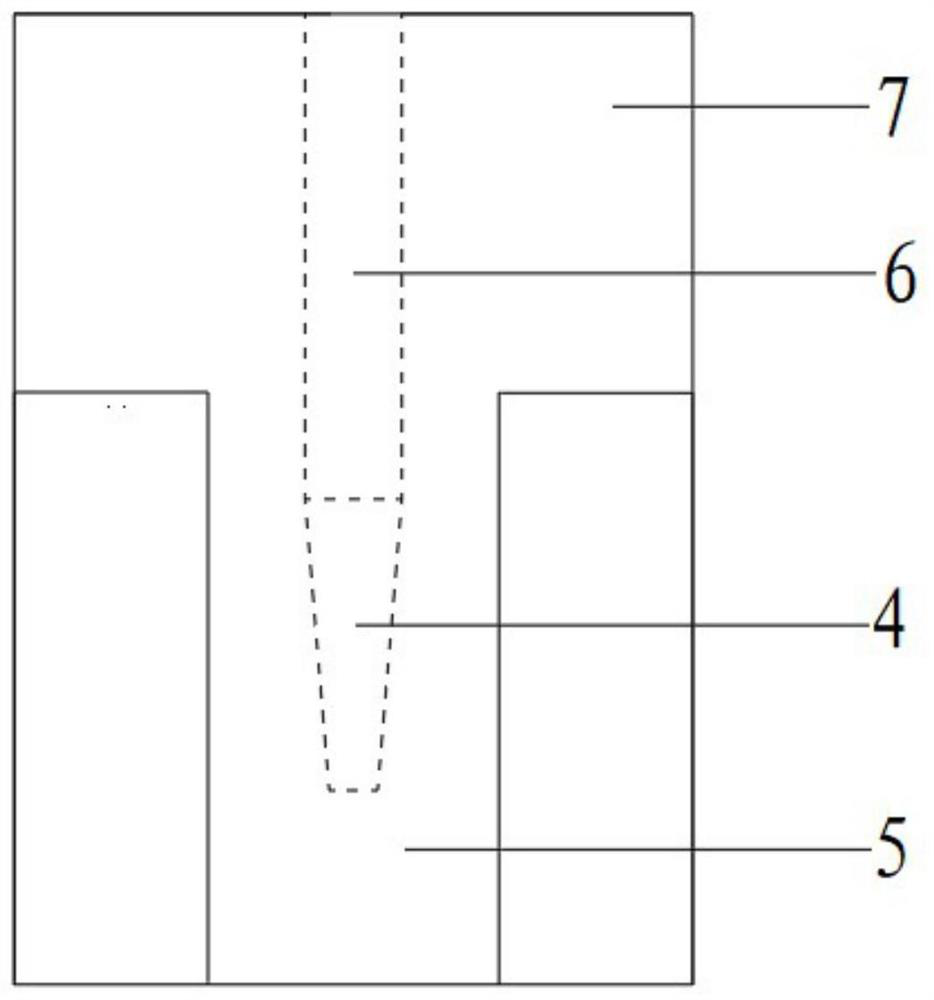

High linearity millimeter-wave device and manufacturing method thereof

ActiveCN106711185BReduce square resistanceReduce contact resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesConductive polymerRadar

The invention discloses a high-linearity millimeter wave device and a making method thereof mainly in order to solve the problem that the existing device is of poor linearity of trans-conductance. The device comprises, from bottom to top, a substrate layer (1), a nucleation layer (2), a buffer layer (3), a second channel region (4), a back barrier layer (5), a first channel region (6), an insertion layer (7), and a barrier layer (8). A groove reaching the back barrier layer is formed in the barrier layer through etching. An enhanced channel region (9) is arranged on the inside wall of the groove and on the barrier layer. A conductive cap layer (10) is arranged on the enhanced channel region. A source electrode (11) and a drain electrode (12) are arranged at the two ends of the conductive cap layer. A grooved gate is engraved on the conductive cap layer in the groove. A passivation layer (13) is arranged on the inside wall of the grooved gate and on the conductive cap layer other than the source electrode and the drain electrode. A T-shaped gate electrode (14) is arranged on the passivation layer in the grooved gate. The trans-conductance peak range is widened, and the linearity of trans-conductance is increased. The high-linearity millimeter wave device can be used in communication, navigation, radar, and base station systems.

Owner:XIDIAN UNIV

Silicon waveguide end face coupling structure and manufacturing method thereof

ActiveCN111679363BSolve the problem of multi-mode transmissionSolve process difficultiesOptical waveguide light guidePhotonic ChipPhysical chemistry

The invention relates to the technical field of photonic integrated devices, and discloses a silicon waveguide end face coupling structure and a manufacturing method thereof. The structure includes substrate silicon, oxide layer, silicon waveguide and silicon nitride layer stacked in sequence from bottom to top. The end of the silicon nitride layer is structured as a ridge structure to form a ridge silicon nitride waveguide. The ridge nitride Silicon waveguides are used for coupling to common single-mode fiber end-faces. The method includes: using a silicon-on-insulator substrate in a silicon-on-insulator substrate to prepare a silicon waveguide with a thin film silicon layer located on the oxide layer on the upper surface of the substrate silicon; preparing a tapered structure with a gradually narrowing width at one end of the silicon waveguide coupled with an optical fiber to form a silicon waveguide. A waveguide cone structure; a silicon nitride layer is deposited on the silicon waveguide and an oxide layer; a ridge structure is prepared by shallow etching the silicon nitride layer to form a ridge-shaped silicon nitride waveguide. The converted mode field of the ridge-shaped silicon nitride waveguide of the invention can be matched with common single-mode optical fiber, and is suitable for low-loss coupling between silicon waveguide and common single-mode optical fiber in the packaging process of silicon photonic chips.

Owner:TSINGHUA UNIV

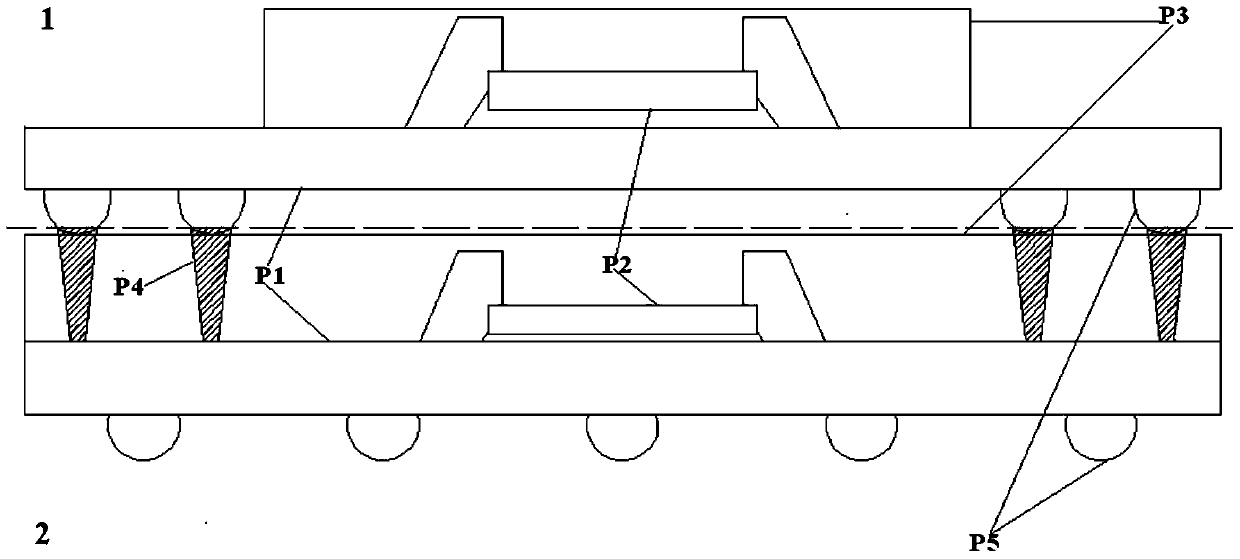

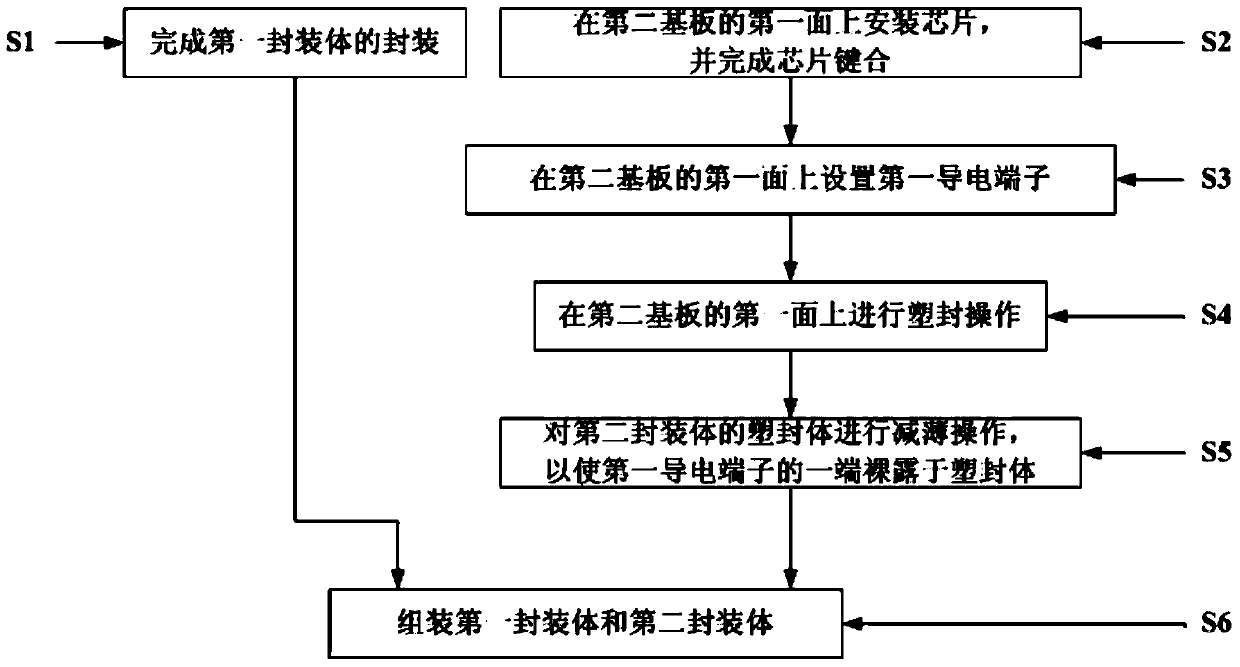

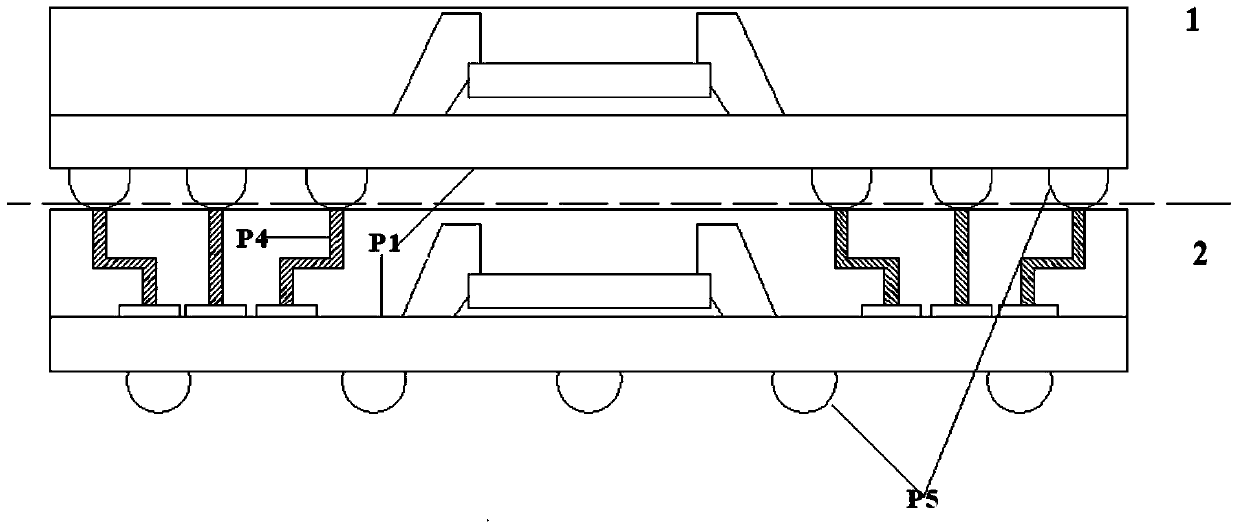

pop packaging structure and its packaging method

ActiveCN103794595BImprove mechanical propertiesSolve process difficultiesSemiconductor/solid-state device detailsSolid-state devicesLaser etchingMachining time

The invention discloses a POP packaging structure and a packaging method thereof. The packaging method includes the following steps that a chip is installed on the first face of a second substrate, and chip bonding is finished; a first electric conduction terminal is arranged on a bonding pad on the first face of the second substrate; plastic package operation is performed on the first face of the second substrate to form a plastic package body, and the chip and the first electric conduction terminal are located in the plastic package body; thinning operation is performed on the plastic package body of a second package body so that one end of the first electric conduction terminal can be exposed out of the plastic package body of the second package body; a first package body and the second package body are assembled. According to the POP packaging structure and the packaging method therefore, the technology difficulties such as laser etching hole filling and plastic package hole filling are avoided in the package process, and therefore the technology processes are simplified and processing time is shortened; special electric conduction terminals are convenient to achieve.

Owner:TSINGHUA UNIV

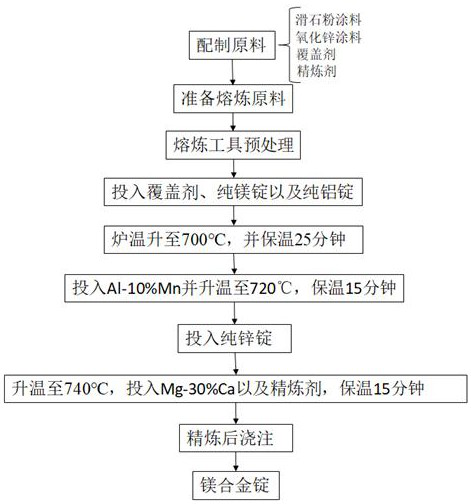

Alkaline-earth heat-resistant magnesium alloy ingot preparation process

The invention discloses a preparation process of an alkaline earth heat-resistant magnesium alloy ingot, which belongs to the technical field of magnesium alloy production technology, and comprises the following steps: firstly preparing a talcum powder coating, a zinc oxide coating, a covering agent and a refining agent, and then adding the covering agent in the process of smelting a magnesium ingot and an aluminum ingot to control the smelting stability; next, introducing Mn element by using Al-10% Mn intermediate alloy, then adding zinc ingots, next, wrapping Mg-30% Ca by using aluminum foil, then adding the wrapped Mg-30% Ca into alloy liquid, and then adding a refining agent so as to control the refining process; and after refining is completed, pouring is conducted in a mold preheated to 200 DEG C, and a magnesium alloy ingot can be obtained after pouring is completed. The technical problems that in the prior art, a magnesium alloy preparation technology is high in cost and difficult are solved.

Owner:惠州云海镁业有限公司

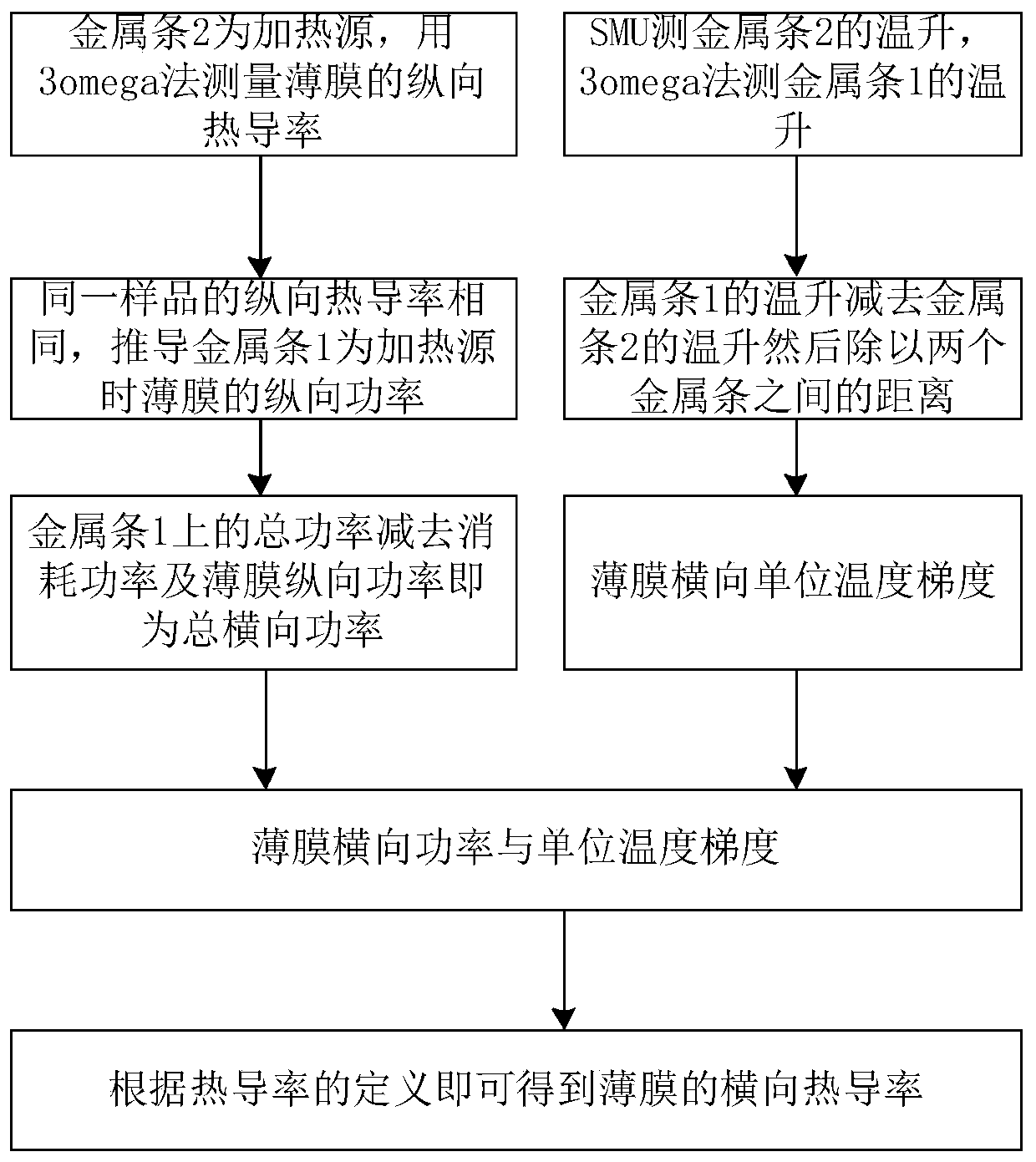

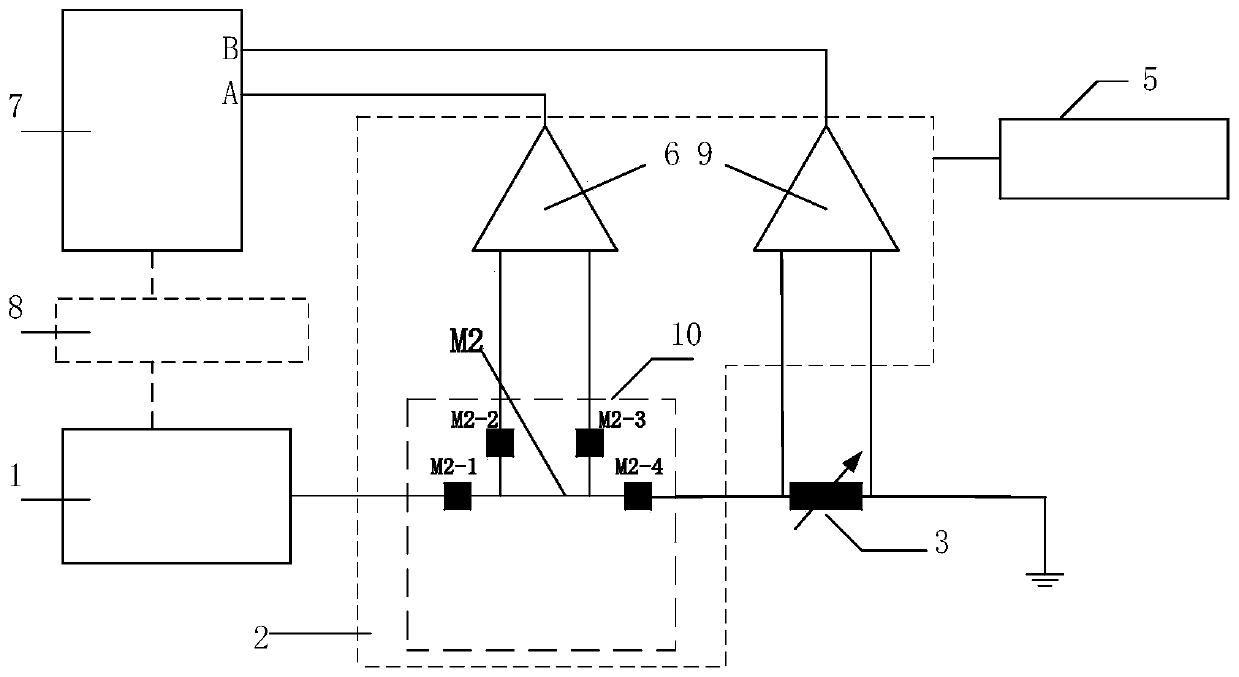

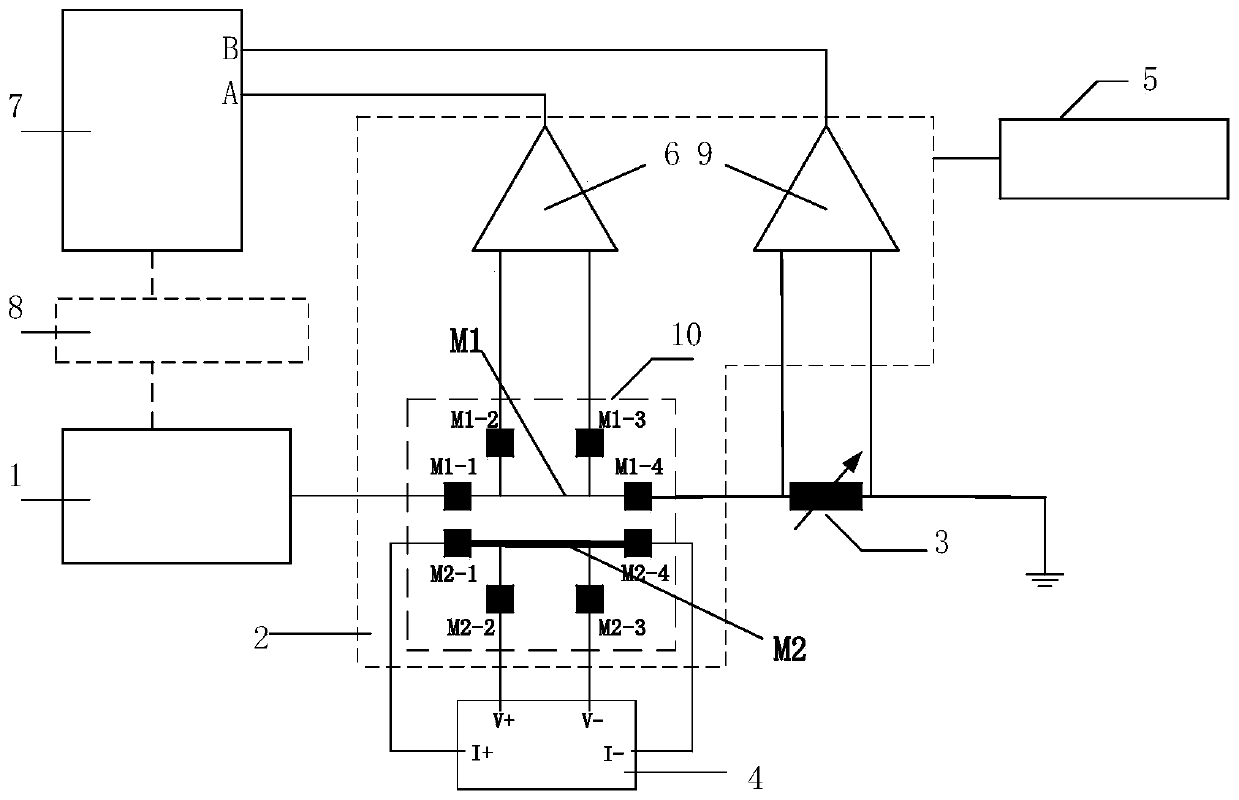

A method and device for measuring the lateral thermal conductivity of a thin film

ActiveCN107966470BSolve the accuracy is not highHigh precisionMaterial thermal conductivityMaterial heat developmentMetal stripsThin membrane

The invention provides a method for measuring the transverse thermal conductivity of a thin film. Firstly, the 3ω method is used to measure the longitudinal thermal conductivity of the thin film to be measured by using the second metal strip deposited on the surface of the thin film to be measured as a heating source; There is a substrate; the longitudinal direction is the direction perpendicular to the film to be tested; then use the 3ω method, using the first metal strip as the heating source, to measure the temperature rise in the longitudinal direction of the film to be tested, and combine the measured longitudinal thermal conductivity to deduce The thermal power in the longitudinal direction of the film to be measured is obtained; the temperature rise of the first metal strip is measured at the same time, and the thermal field generated by the temperature rise of the first metal strip in the transverse direction of the film to be measured leads to the temperature rise of the second metal strip; finally calculated The transverse thermal conductivity of the film to be measured with thickness d. The invention adopts the "substrate / film to be tested / metal strip" sample structure, which effectively avoids the technical difficulties of preparing samples with a suspended structure; the bimetallic strip can accurately measure the lateral temperature difference of the film, and the measurement result has higher accuracy.

Owner:WUHAN SCHWAB INSTR TECH

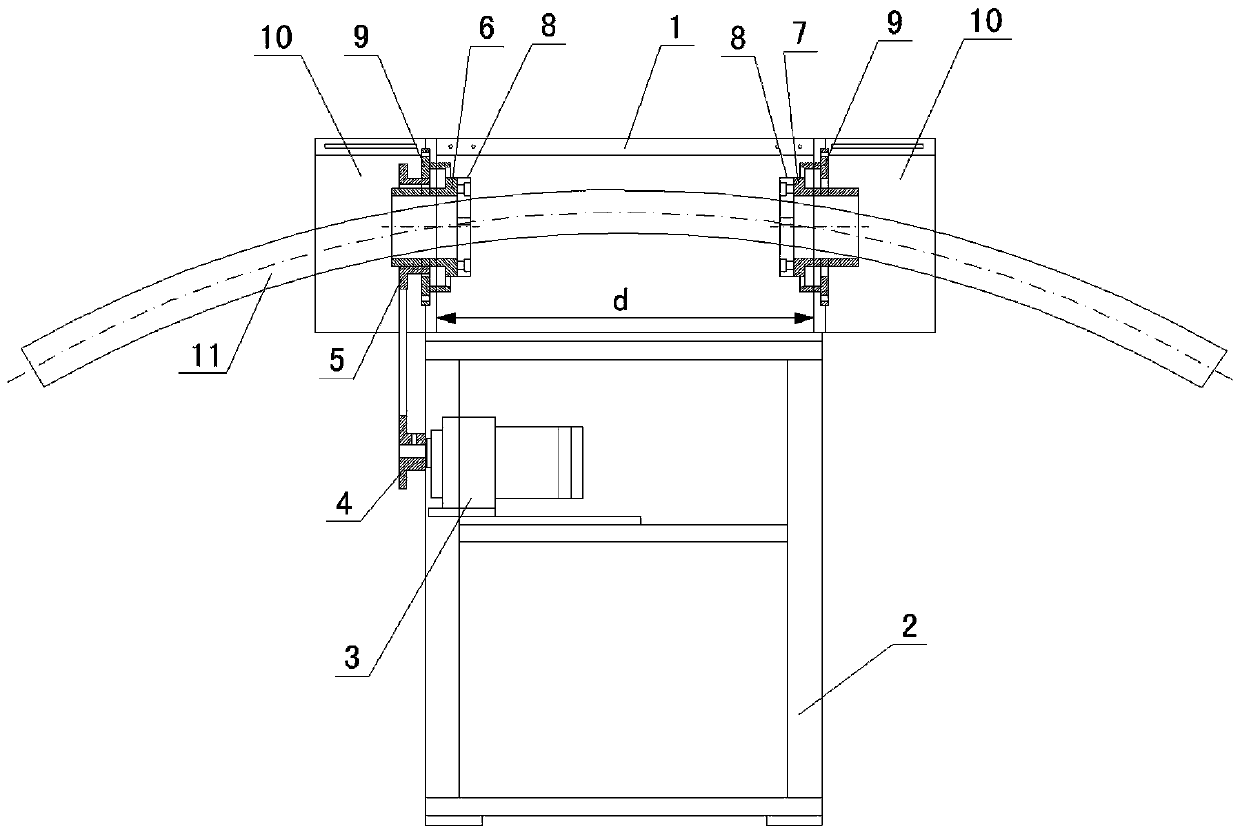

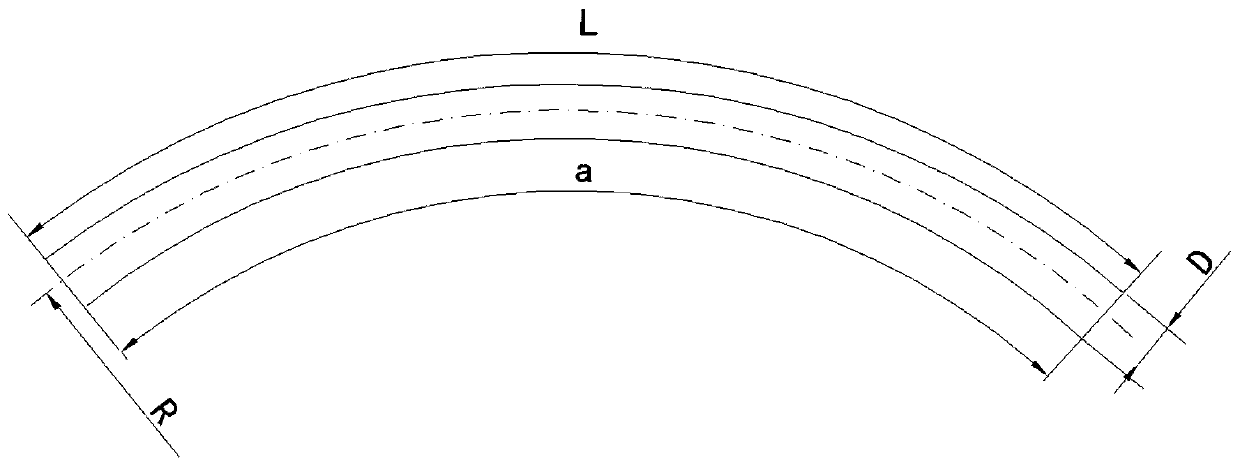

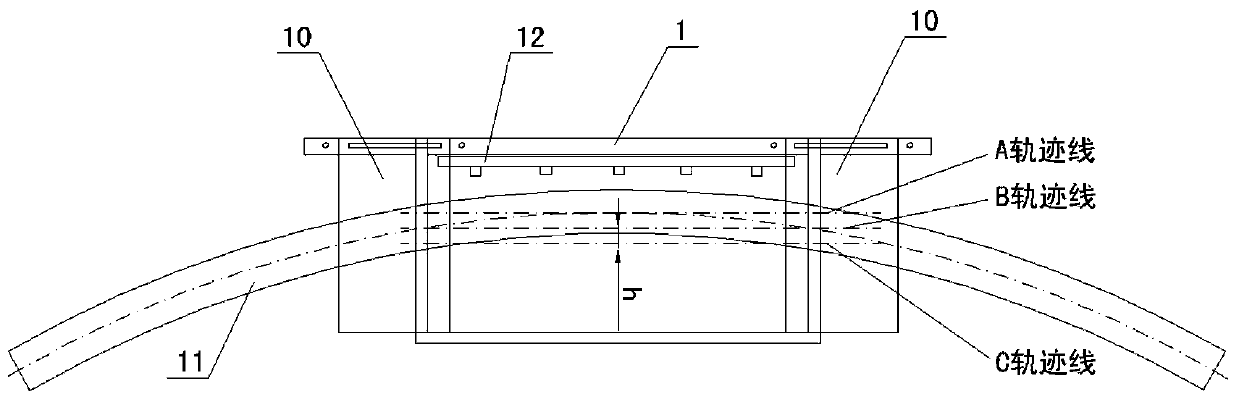

A method for preparing a coating by thermal spraying on large-size bent pipe workpieces

ActiveCN104611665BSolve process difficultiesSolve the rotation problemMolten spray coatingThermal printingPre treatment

A method for thermal spraying preparation of a coating on a large size bending pipe workpiece is as follows: first the bending pipe workpiece surface is pretreated, a specially-designed bending pipe spraying tooling is used for clamping and fixing, the specially-designed bending pipe spraying tooling mainly includes a tooling body, a supporting frame, a motor, a drive chain wheel, a driven chain wheel, a main shaft, a countershaft, a fixing sleeve and a protection plate, the workpiece is fixed on the main shaft and the countershaft through the fixing sleeve and fastening screws, and can be driven, by the drive chain wheel, the driven chain wheel, the main shaft and the countershaft, to rotate, wherein the drive chain wheel, the driven chain wheel, the main shaft and the countershaft are driven by the motor. When in spraying, a spray gun respectively sprays once along A, B and C track lines to form one spray pass, and sprays by repeated multiple passes until needed coating thickness is obtained, and the workpiece is cooled by high-speed air curtain. The method can ensure uniform coating thickness, texture and property of arc length and outer circumference direction of the bending pipe workpiece, can effectively prevent the component deformation, and is especially suitable for thermal spraying preparation of the coating on large size bending pipe workpiece with the curvature radius greater than or equal to 2m, length less than 2m and diameter between 30-140mm.

Owner:GUANGDONG INST OF NEW MATERIALS

Solid reactant for in-situ preparation of chlorine from hydrochloric acid

PendingCN111252737ASolve process difficultiesCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsCopper oxideHydrogen chloride

The invention belongs to a hydrochloric acid process, and particularly relates to a solid reactant for in-situ preparation of chlorine from hydrochloric acid; the reactant is tooth-ball-shaped particles, the particle diameter is 2-3 mm, the specific surface area is 200-300 m<2> / g, and the bulk density is 0.6-0.7 g / cm<2>; provided is a specific preparation method. According to the invention, the process difficulty of preparing chlorine from hydrogen chloride in the prior art is solved, and a copper oxide solid reactant with a large specific surface area is formed by using porcelain clay powderas a carrier and copper salt as a reaction material.

Owner:无锡玖汇科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com