Patents

Literature

52results about "Plastic deformation fastening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

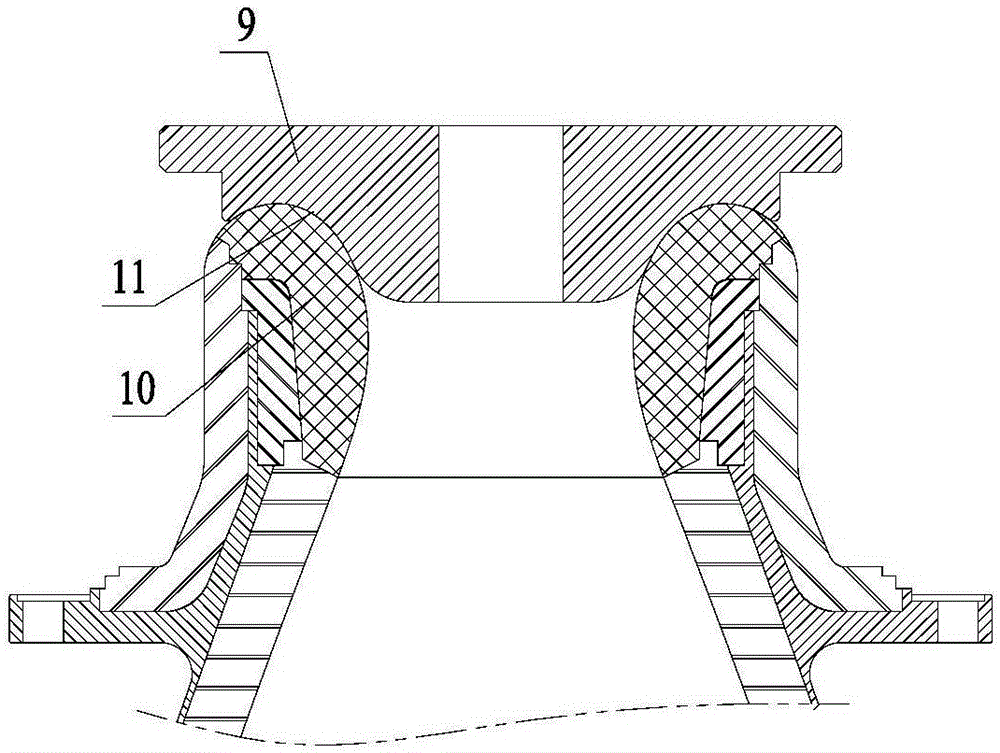

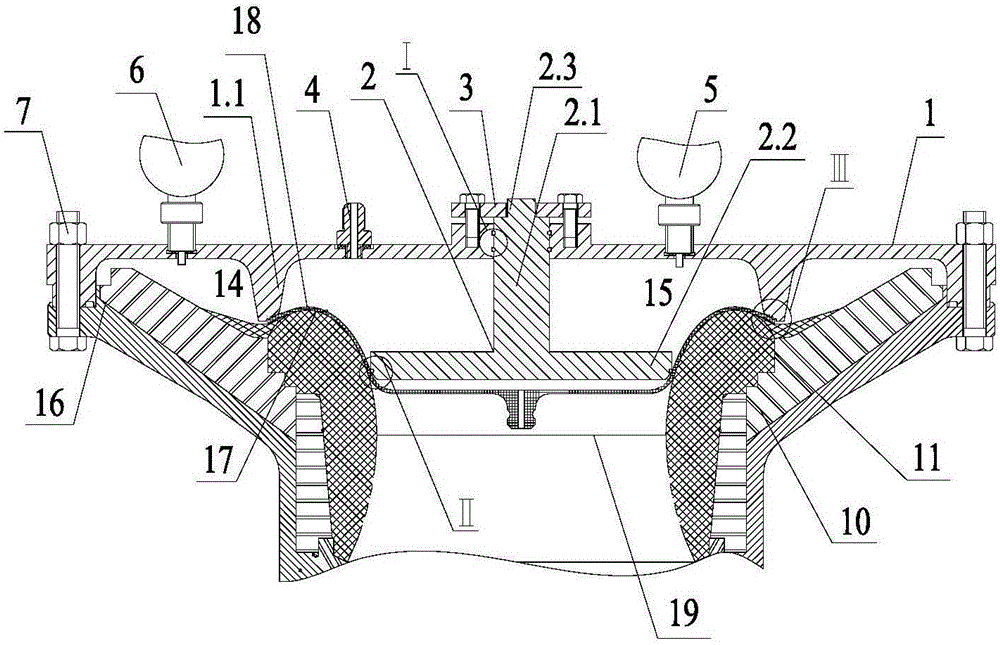

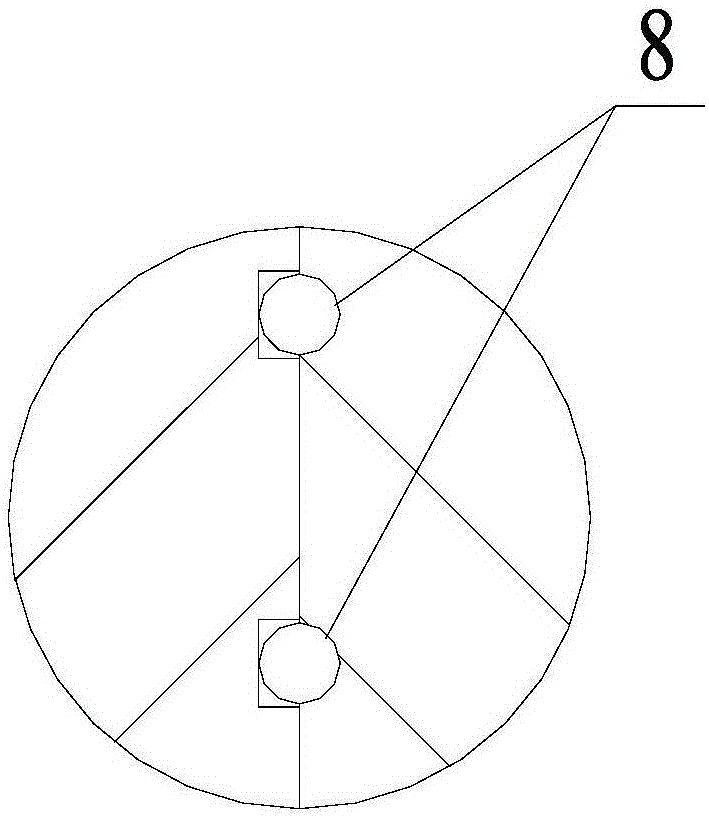

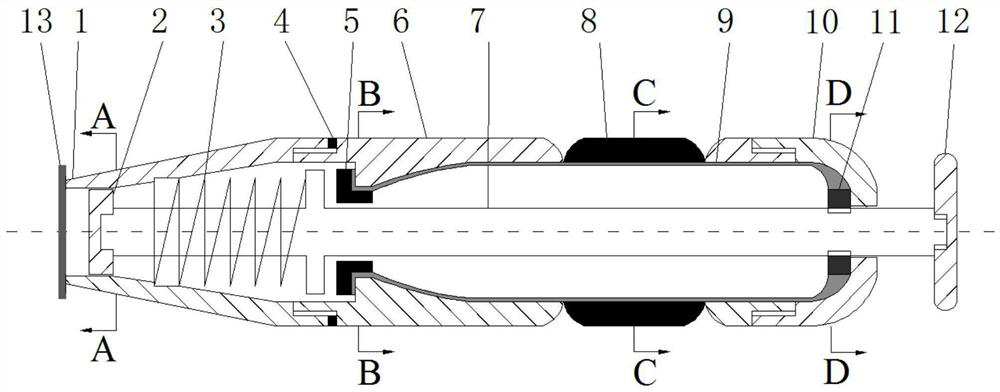

Bonding method for jet pipe and flexible plug cover of solid rocket engine and sealing tool

ActiveCN106287101AImprove bonding qualitySimple methodPlastic deformation fasteningMaterial gluingElectrical junctionAtmospheric pressure

The invention discloses a bonding method for a jet pipe and a flexible plug cover of a solid rocket engine, and a sealing tool. The bonding method includes the steps that after the flexible plug cover and a jet pipe throat lining are bonded in advance, the sealing tool is mounted on the jet pipe, and the flexible plug cover and the sealing tool are matched to form a first sealed space area; and the first sealed space area is pressurized, the external molded surface of the bonding surface between the flexible plug cover and the jet pipe throat lining is pressurized in an air-pressure mode, and finally, pressure-maintaining solidification is carried out. By utilizing the non-directionality of air pressure, air pressure is applied to the flexible plug cover and acts on the external molded surface of the bonding surface, all points on the bonding surface are subjected to normal-direction stressing, surface-contact uniform stressing of the bonding surface is achieved, and therefore the bonding quality is improved; and in addition, the method is simple, operation is convenient, the period is short, the cost is low, and the bonding method is especially suitable for bonding of the jet pipe and the flexible plug cover of the large-diameter solid rocket engine.

Owner:湖北三江航天江北机械工程有限公司

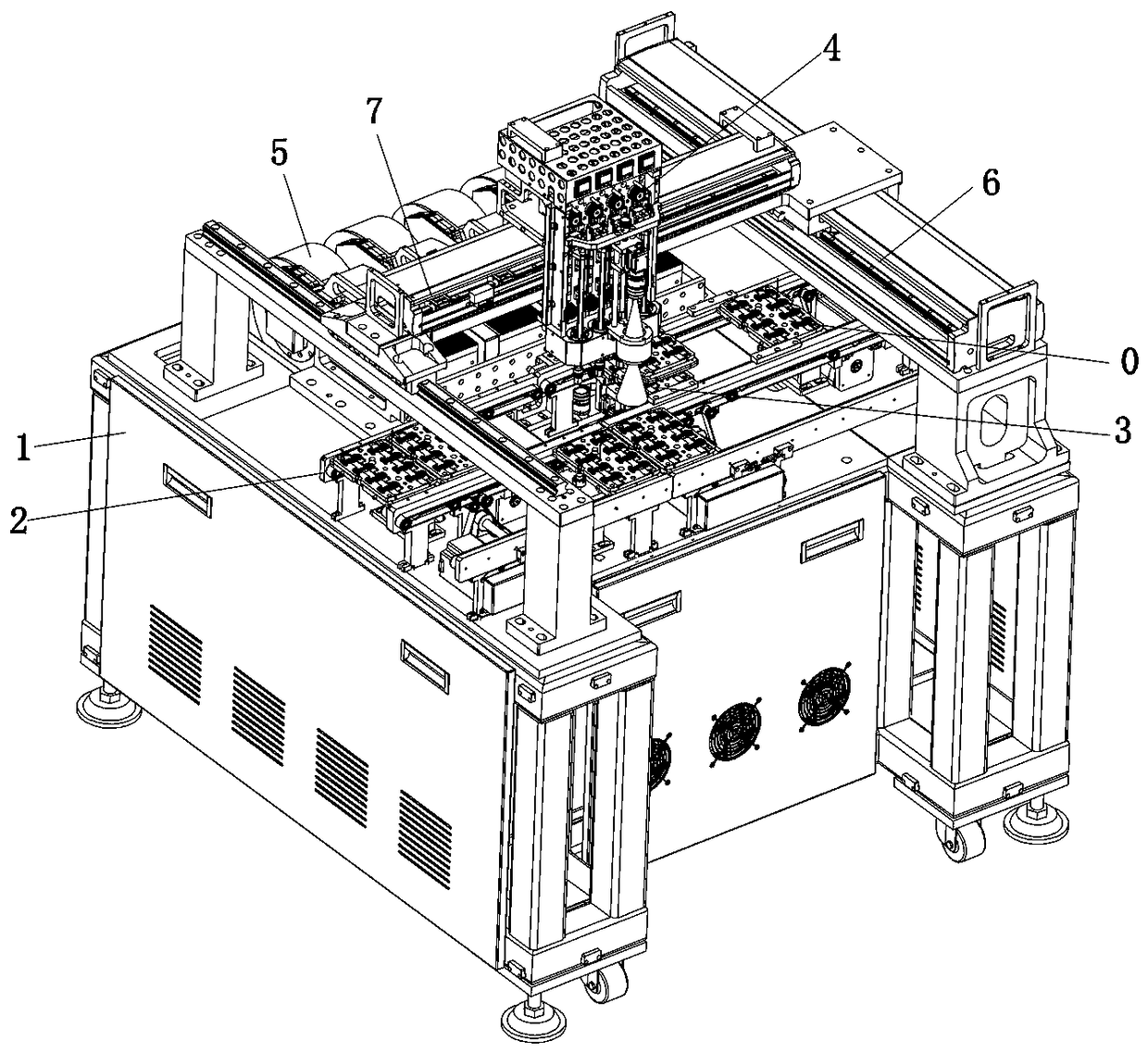

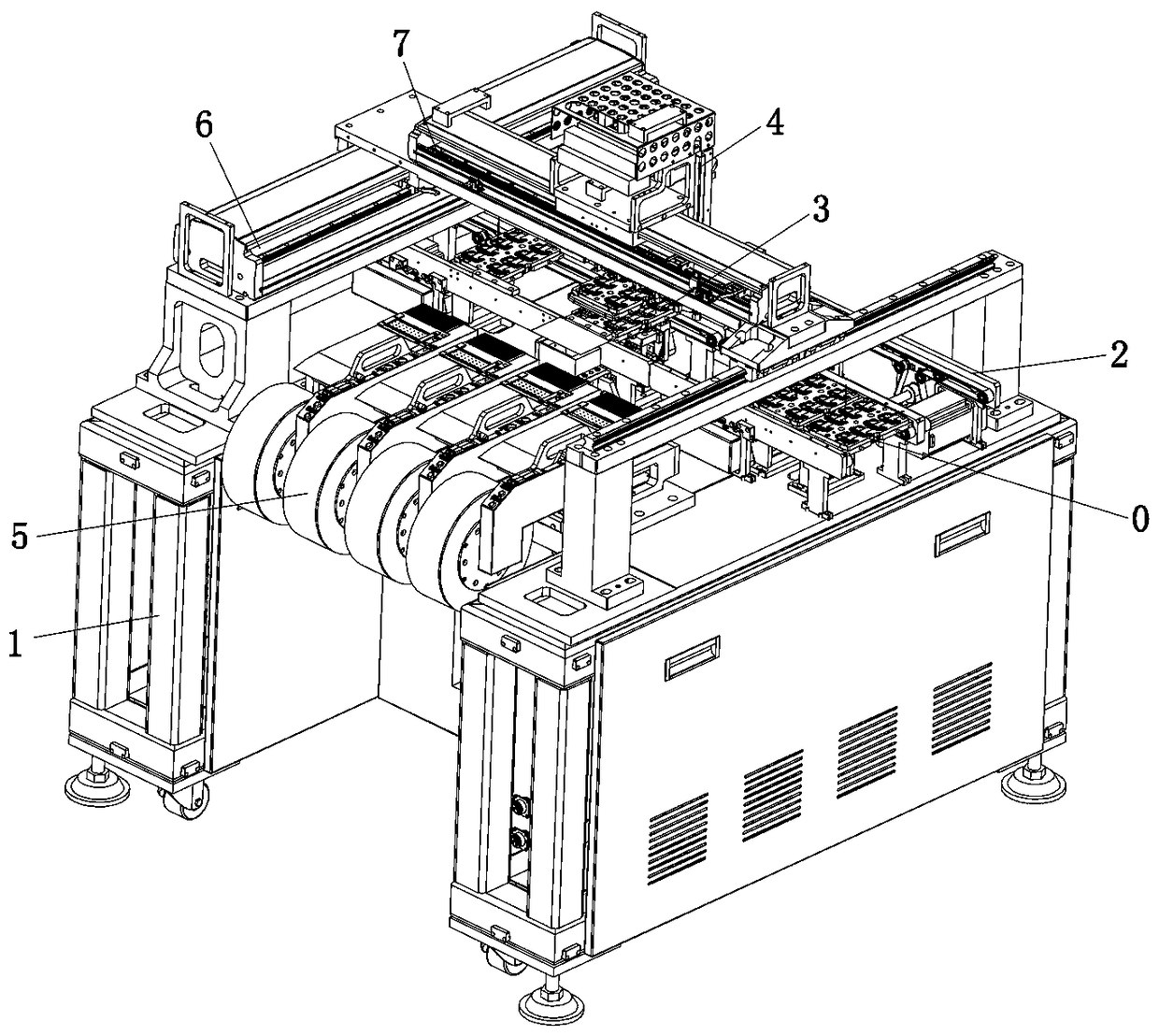

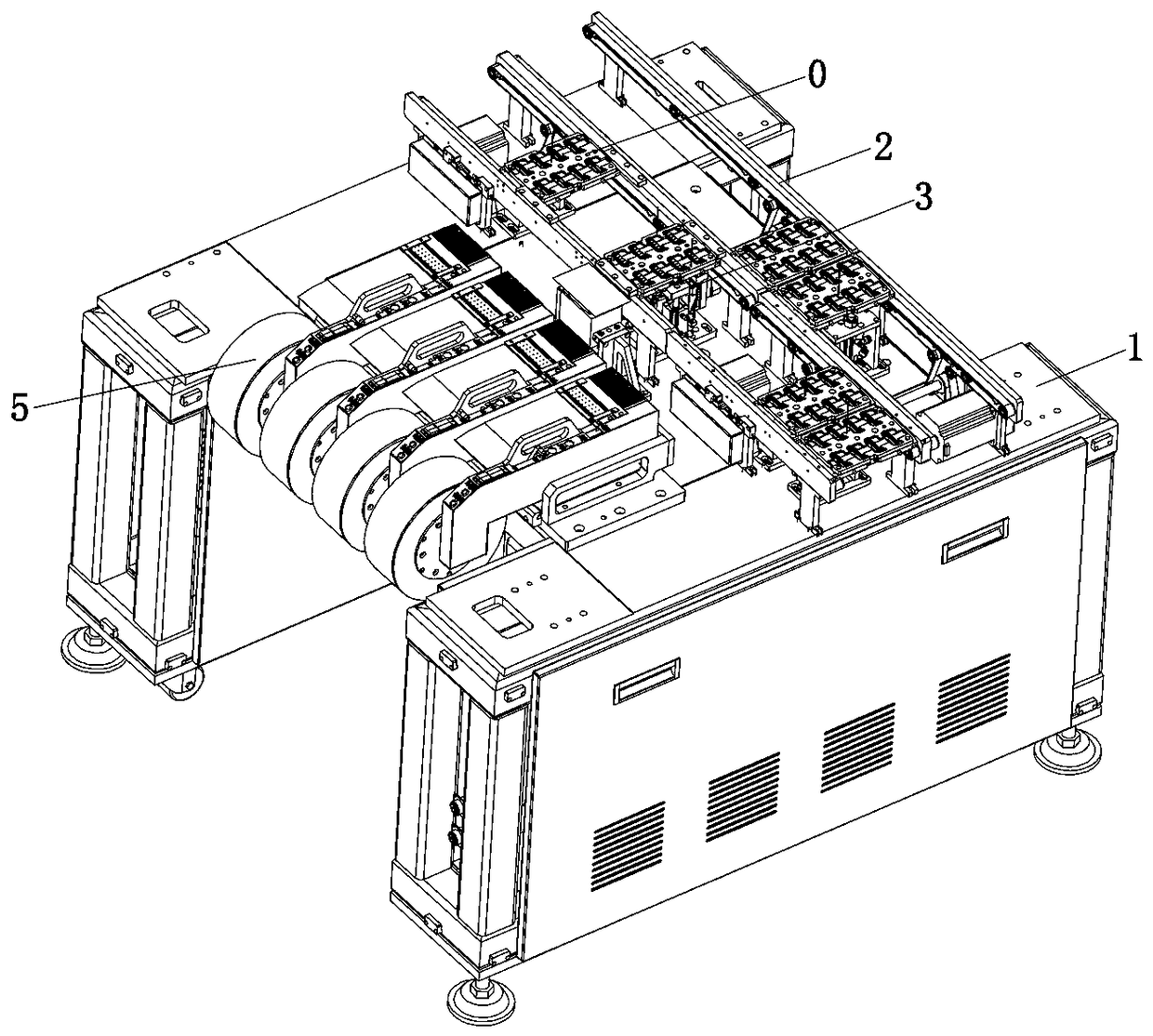

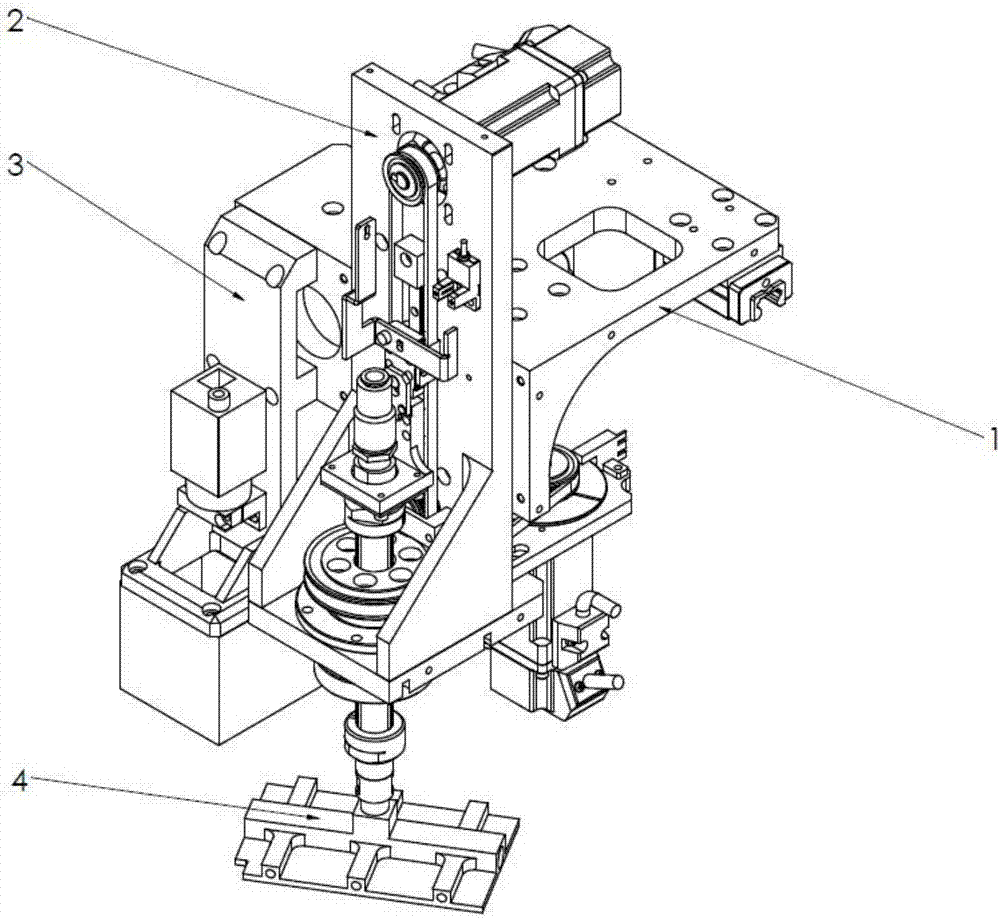

Automatic attaching machine for electronic product auxiliary materials

PendingCN109340233AReduce stuck and broken situationsHigh replaceabilityPlastic deformation fasteningMaterial gluingMulti materialEngineering

The invention discloses an automatic attaching machine for electronic product auxiliary materials. The automatic attaching machine comprises a conveying mechanism, a positioning and supporting mechanism, an attaching mechanism and a material supplying mechanism; the conveying mechanism is horizontally arranged on a rack; the positioning and supporting mechanism is arranged at an attaching stationin the conveying mechanism, when a fixture moves to the attaching station, the fixture is positioned by the positioning and supporting mechanism, and a product in the fixture penetrates through the fixture upwards to be jacked and supported and adsorbed and fixed downwards through the positioning and supporting mechanism; the material supplying mechanism is arranged on one side of the conveying mechanism and used for guiding out at least two auxiliary materials; and the attaching mechanism is arranged between the attaching station and the material supplying mechanism in a crossing mode and used for attaching the auxiliary materials to the product after the auxiliary materials guided out of the material supplying mechanism are adsorbed, fixed and moved to the attaching station. According tothe automatic attaching machine for the electronic product auxiliary materials, the functions of multi-product bearing, fixture positioning, product jacking and supporting and adsorbing and heating are achieved, the material supplying assembly achieves quick disassembling and replacing, the condition that a material belt is jammed and pulled to be broken is reduced, a multi-material automatic material taking and attaching function is achieved, the universality is high, and the part replaceability is high.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

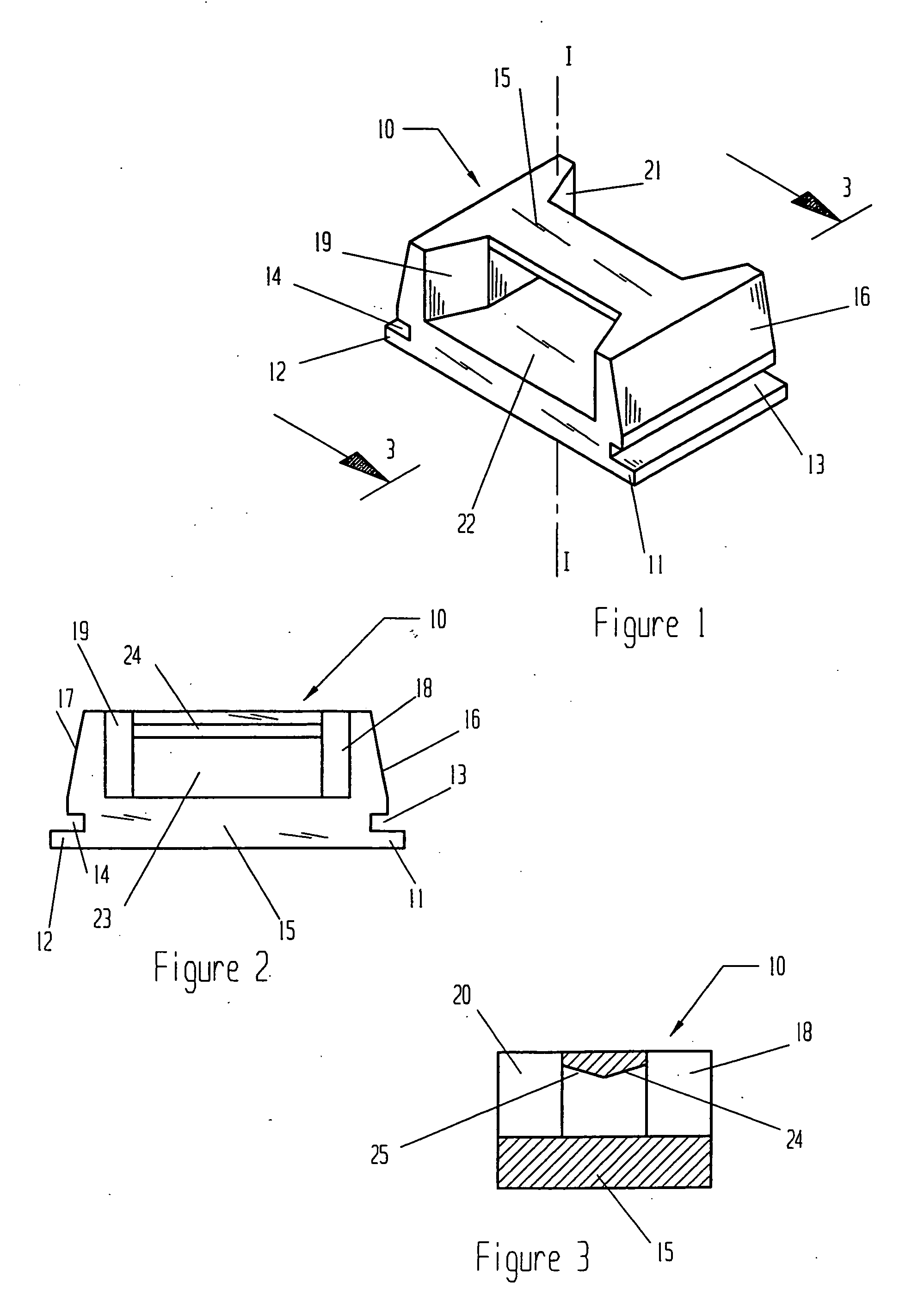

Self-clinching cable tie mount

InactiveUS6981683B2Low profileImprove carrying capacityPipe supportsPlastic deformation fasteningEngineeringThin sheet

A self-clinching fastener that when pressed into a thin sheet panel provides for a strong attachment point for a cable tie. The inventive fastener relies on the self-clinching process to carry external loads and thus carries larger loads when compared to adhesive backed cable tie mounts. When installed, the self-clinching fastener becomes flush with the far side of the sheet panel.

Owner:WINTON III GEORGE R

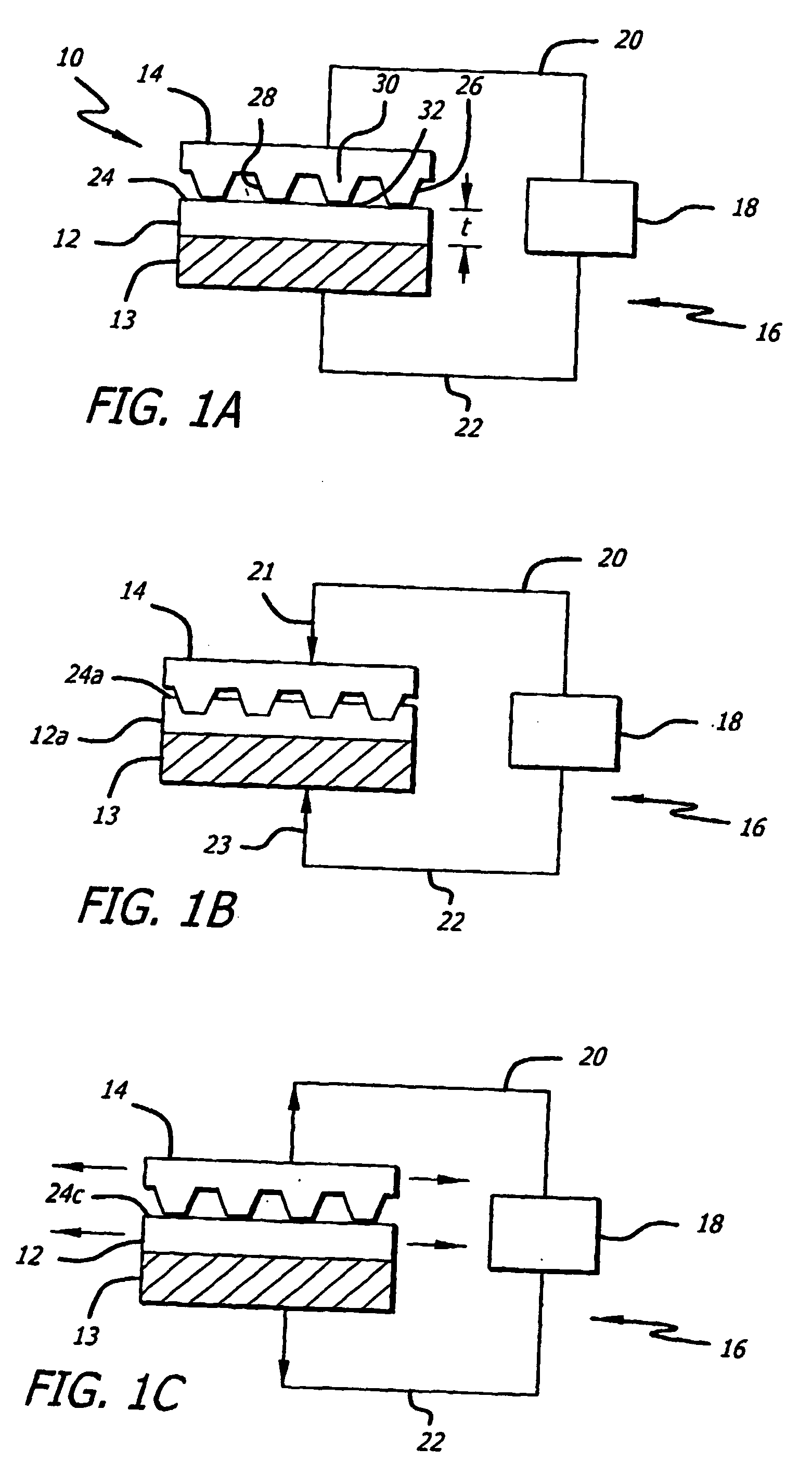

Infinitely adjustable engagement system and method

InactiveUS20060110211A1Prolong lifePlastic deformation fasteningRopes and cables for vehicles/pulleyEngineeringMartensite

A system for releasable engagement of two bodies where one of the bodies deforms the other body during the engagement process. The system includes a first body having an engagement surface that is made from a pseudo-elastic mater pseudo-elastic material is maintained at an operating temperature that is above the martensite-austenite transition temperature for the material. The second body has an indenter surface that contacts the pseudo-elastic material and exerts sufficient stress to convert the material from the relatively hard austenite state to the relatively soft martensite state wherein the material conforms to the indenter shape. Upon release of the indenter contact stress, the pseudo-elastic material changes back to its original shape.

Owner:CARMAN GREGORY P +2

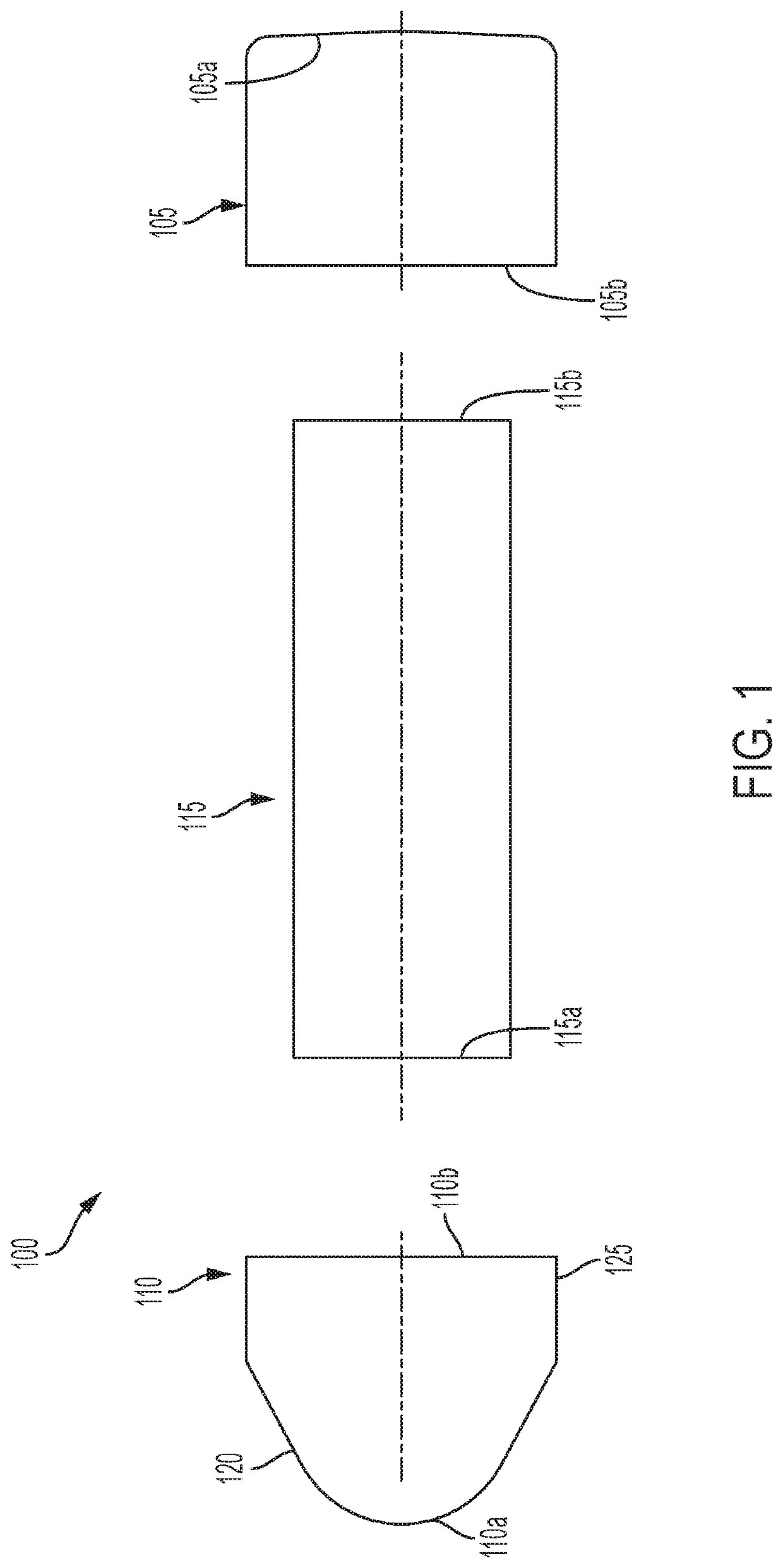

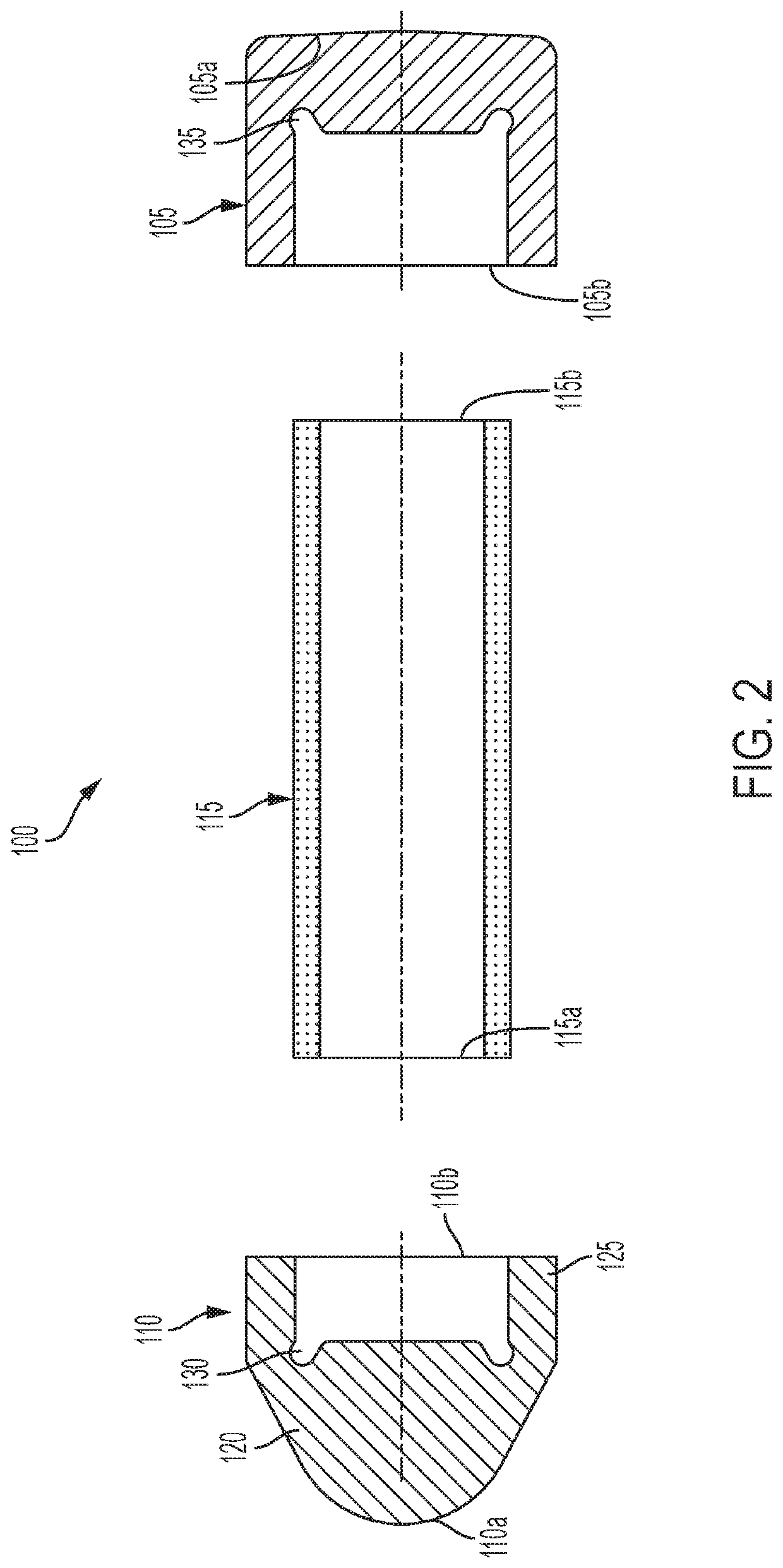

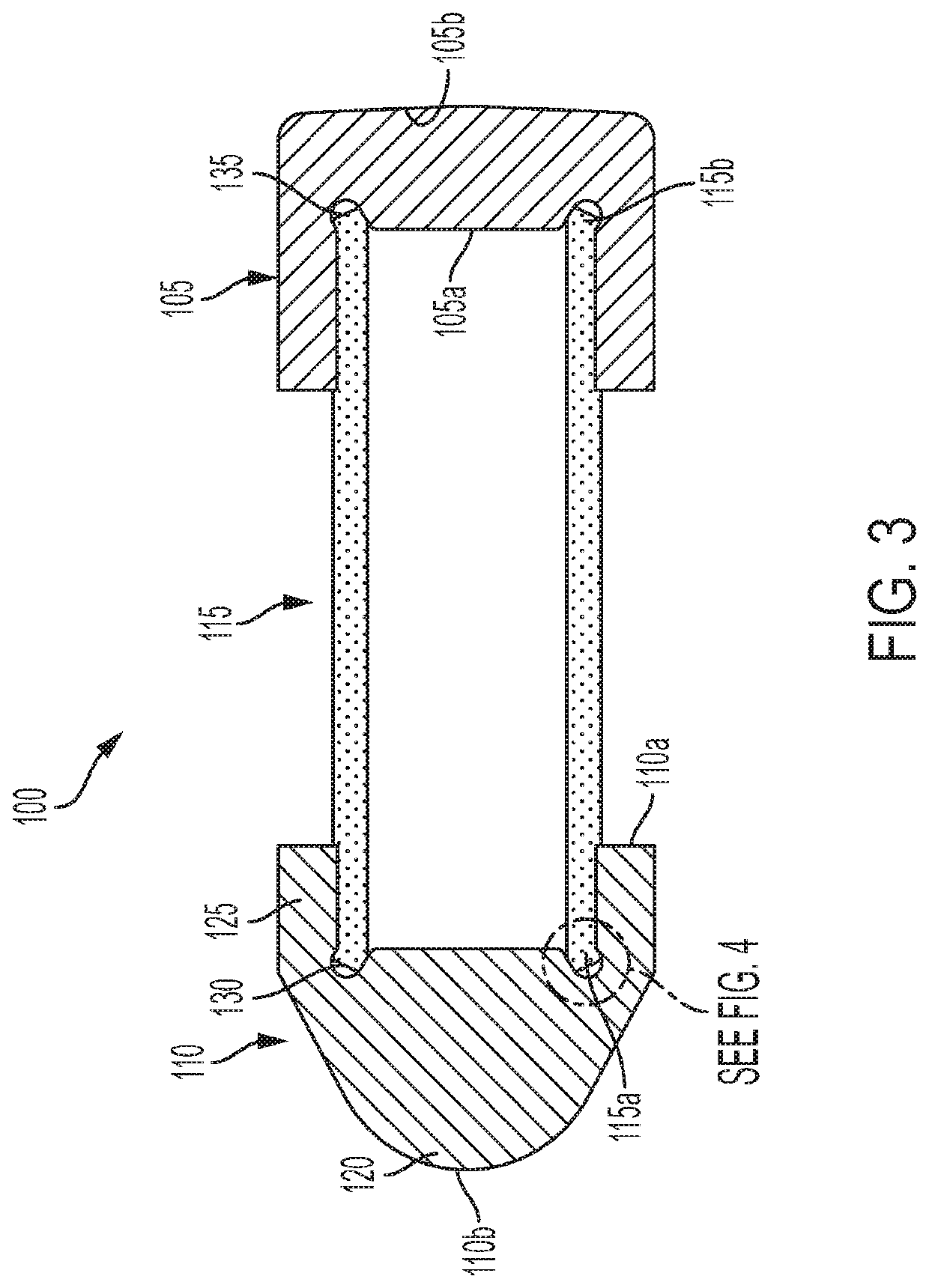

Joint assembly and method of forming thereof

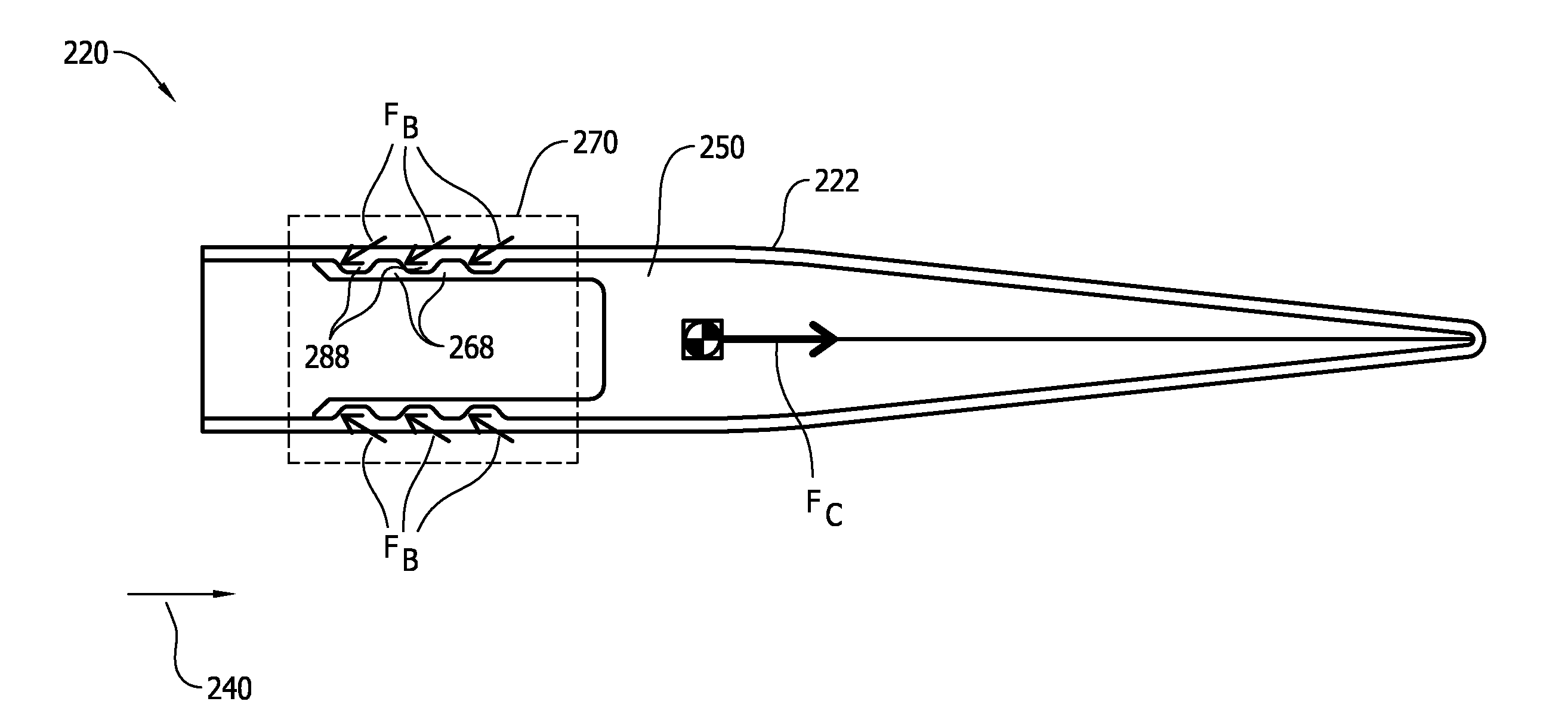

ActiveUS20140377076A1Facilitate restricting movement of tipFacilitate restricting movementPropellersPlastic deformation fasteningEngineering

A joint assembly is provided. The joint assembly includes a first component formed from a first material and a second component including a portion that extends at least partially into the first component and that has an uneven outer profile. The first material is configured to form the first component into a shape that is substantially complementary to a shape of the portion to facilitate restricting movement of the second component in an axial direction.

Owner:THE BOEING CO

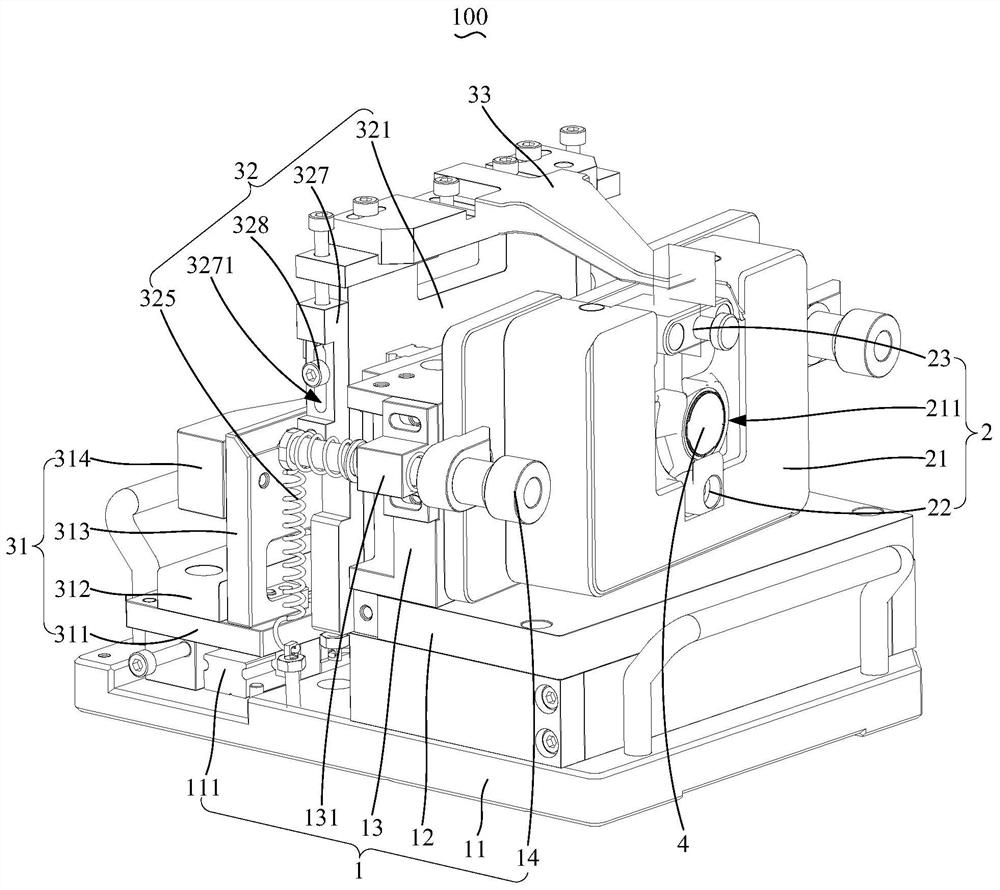

Large-size special-shaped material pasting device and pasting control method

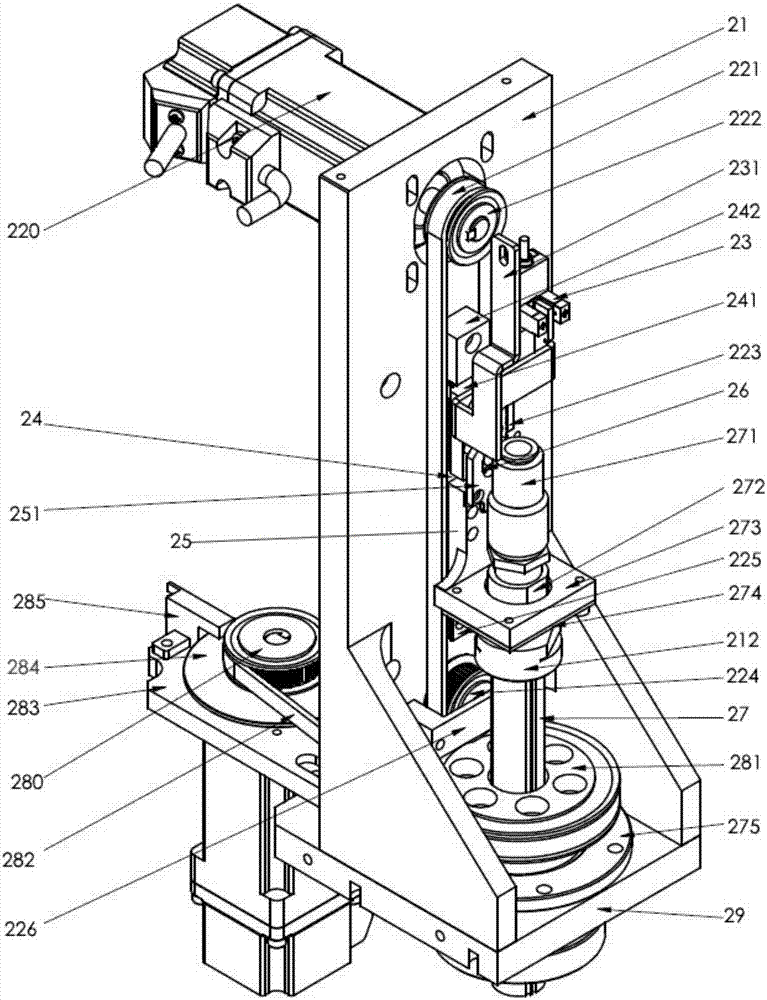

InactiveCN106907381AImprove placement accuracyImprove stabilityPlastic deformation fasteningEngineeringVisual recognition

The invention discloses a large-size special-shaped material pasting device. The pasting device is composed of an installation base assembly, a pasting assembly, a visual recognition assembly and a special-shaped material taking assembly. The pasting assembly comprises a driving assembly, a Z-axis pasting assembly and an R-axis rotating assembly, wherein the driving assembly and the Z-axis pasting assembly are installed on a spline installation base, and the R-axis rotating assembly is arranged on a bottom fixing seat. The Z-axis pasting assembly is fixed through a three point and one line over-positioning type Z-axis spline, and pasting angle errors caused by rotation deviation are reduced by using various Z-axis buffering or pressure control connecting structures based on a single-sliding-rail and double-sliding-block fixing manner. The large-size special-shaped material pasting device has the beneficial effects that by the adoption of the large-size special-shaped material pasting head and a matched pasting control method, the pasting precision and pasting stability of large-size special-shaped materials can be improved, the material throwing rate is reduced, and the product pasting yield is increased; and the technical difficulty that automatic equipment is used for replacing manual work is overcome, manual work is saved, the production cost is reduced, and the production efficiency is improved.

Owner:深圳逻辑自动化科技有限公司

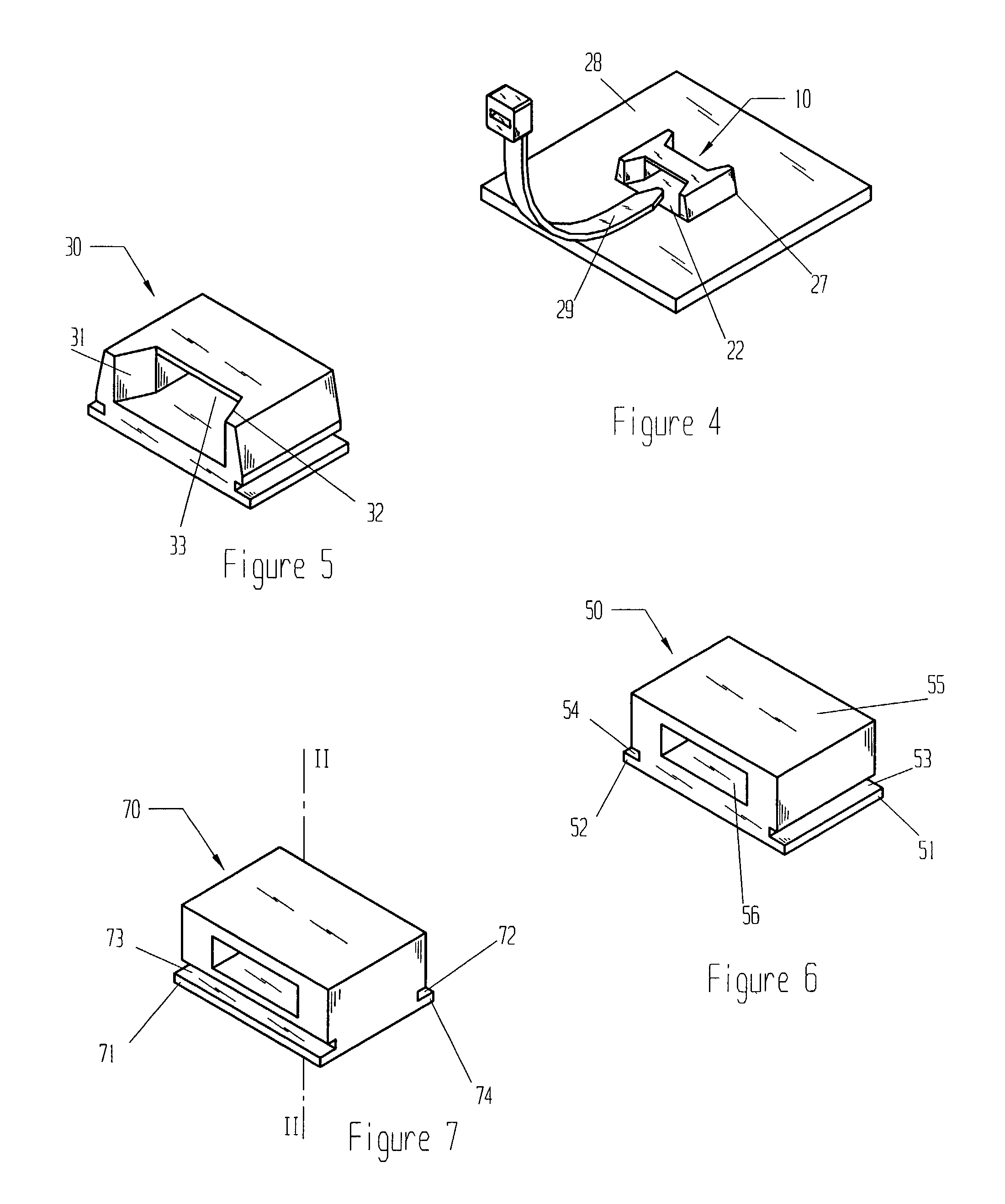

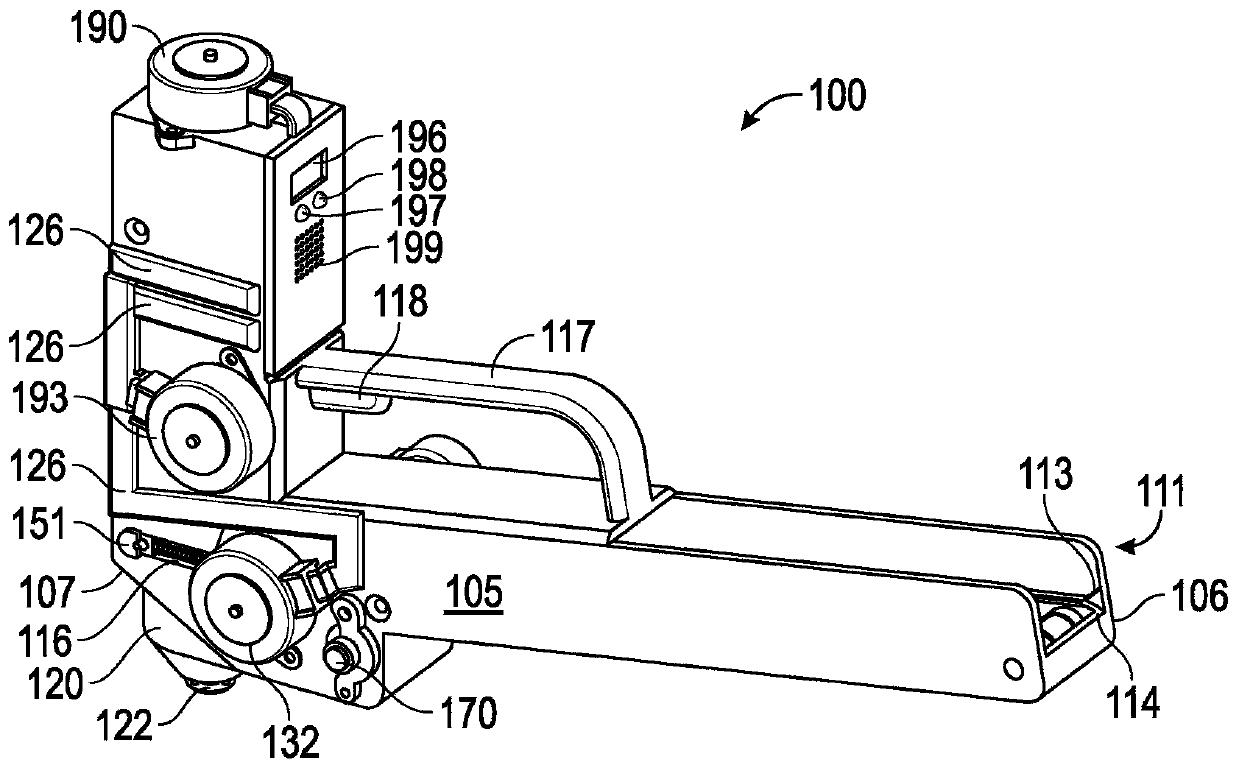

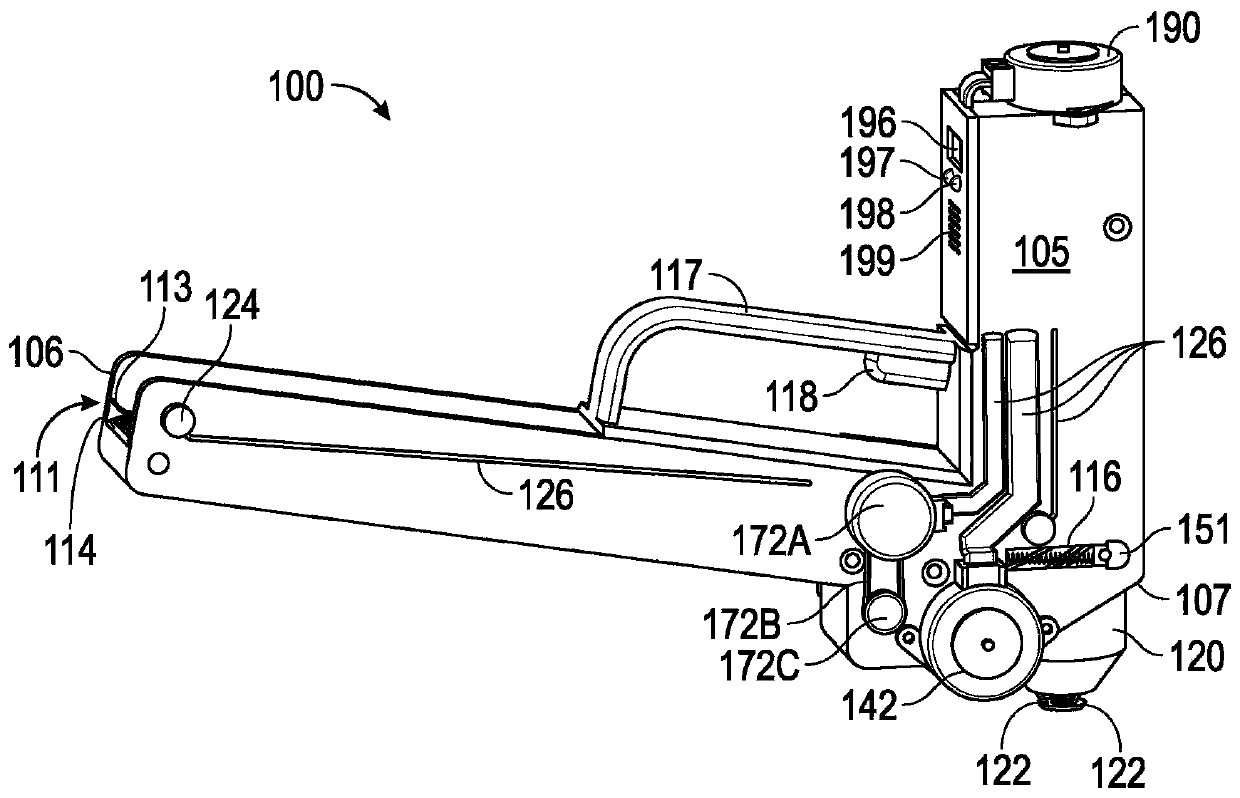

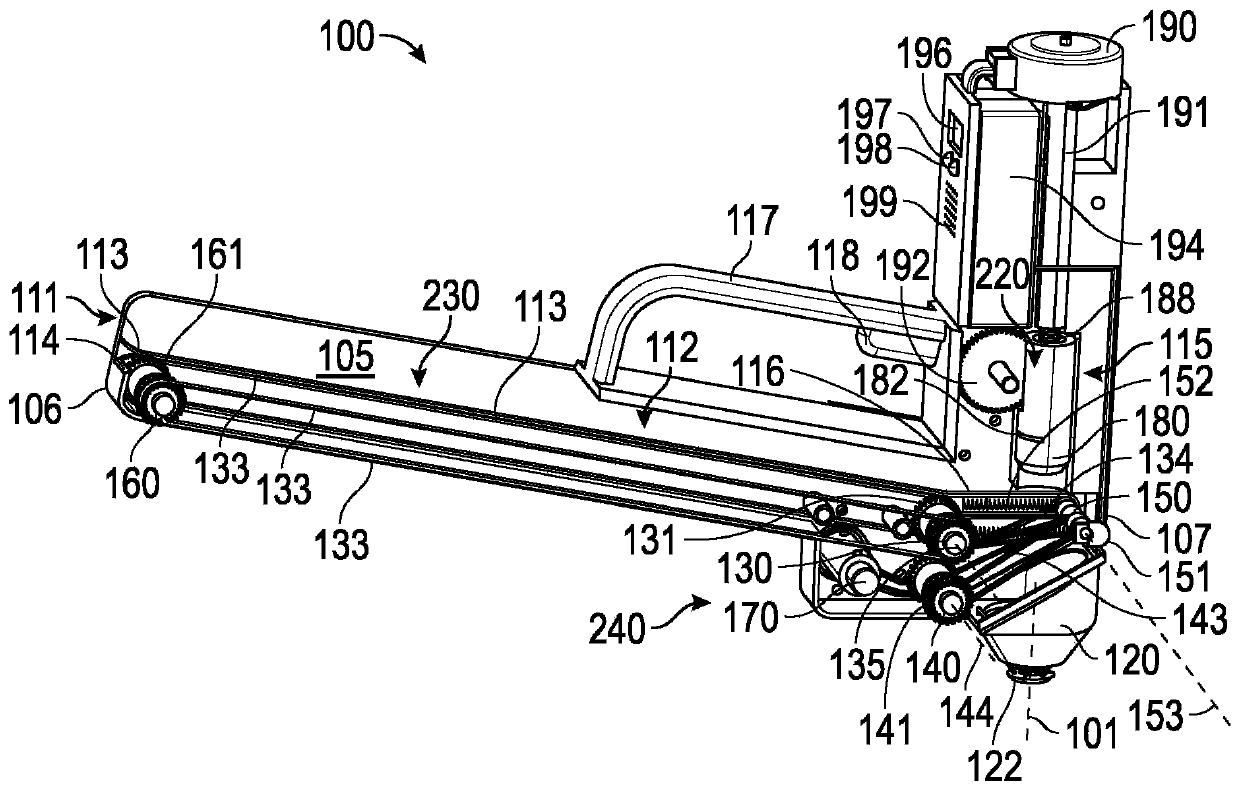

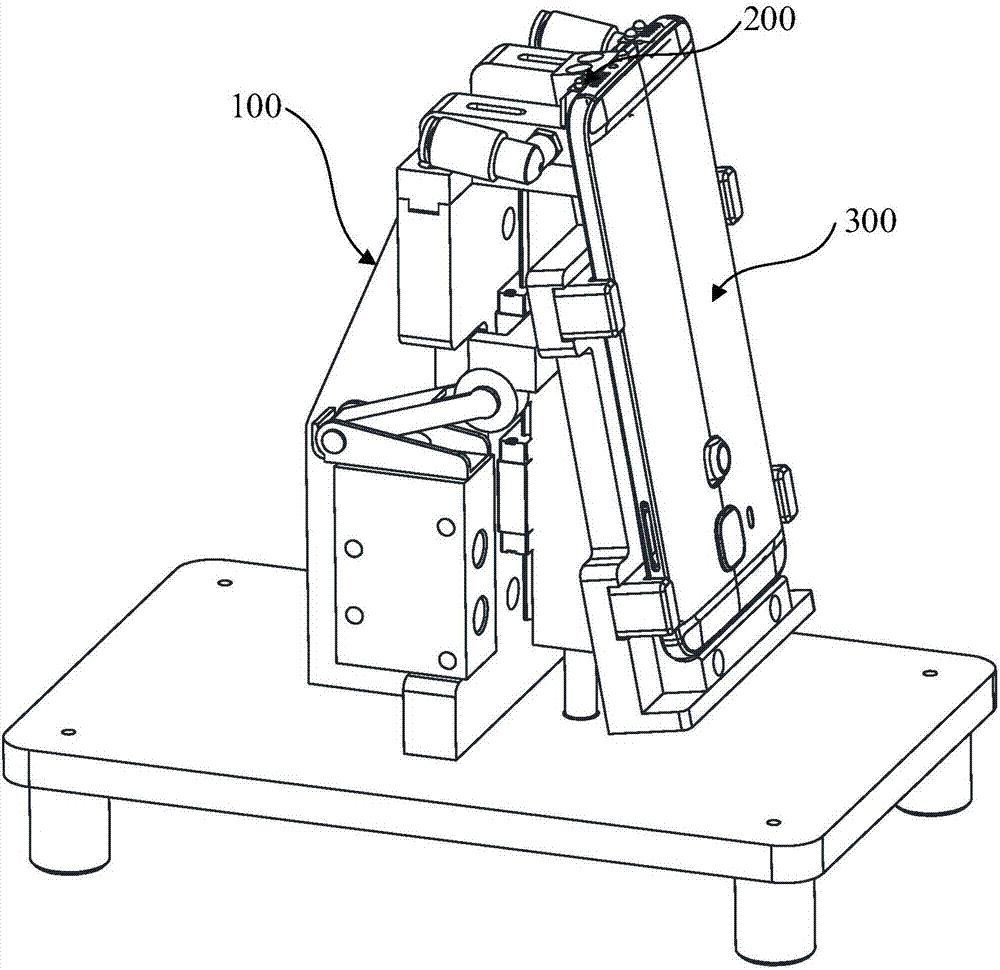

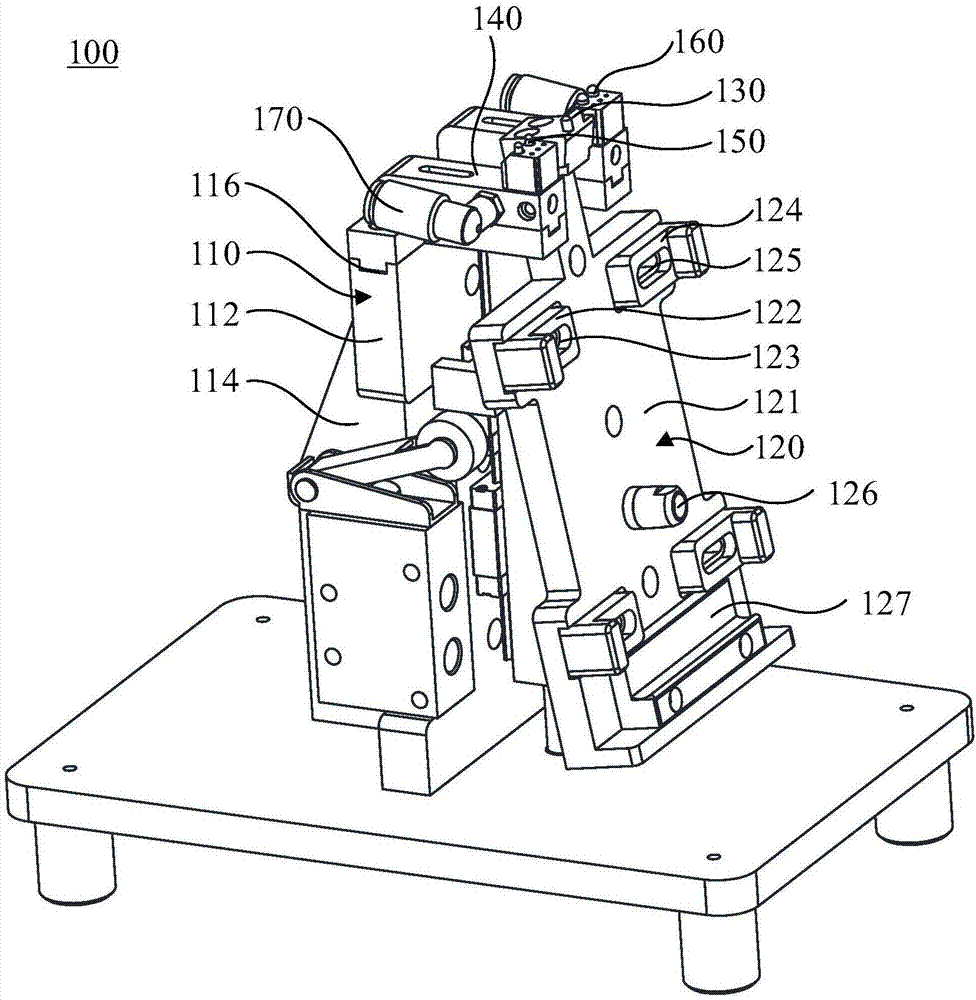

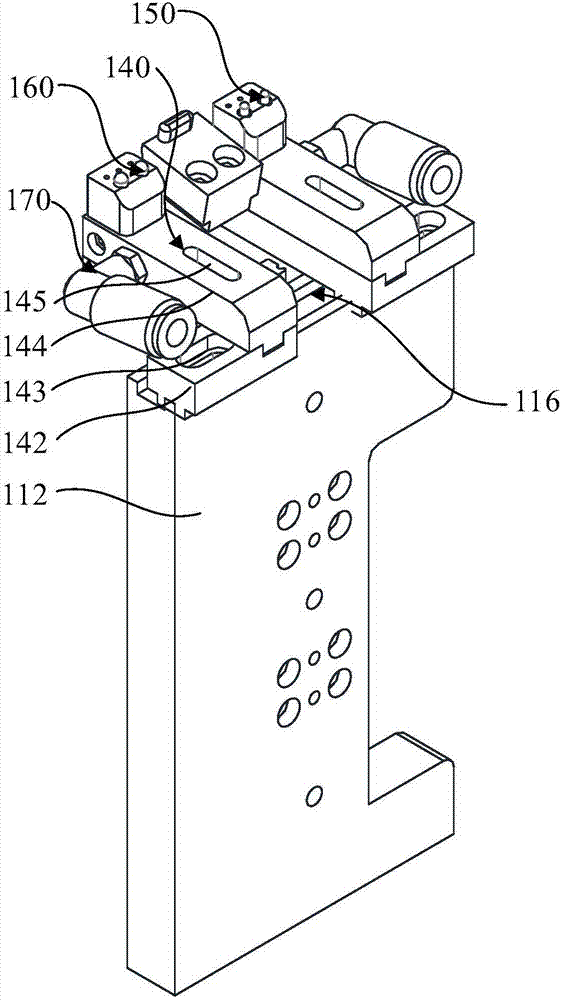

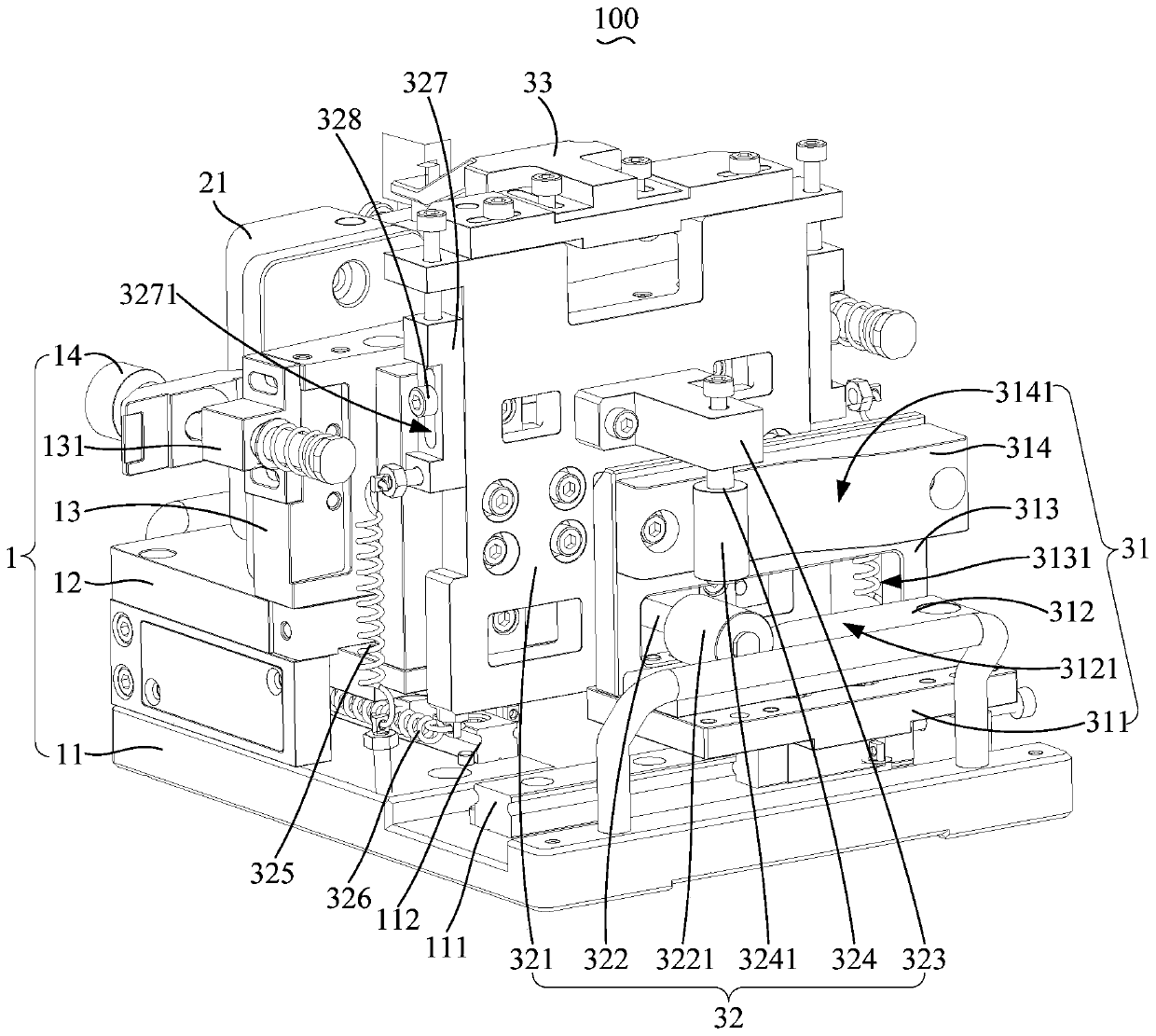

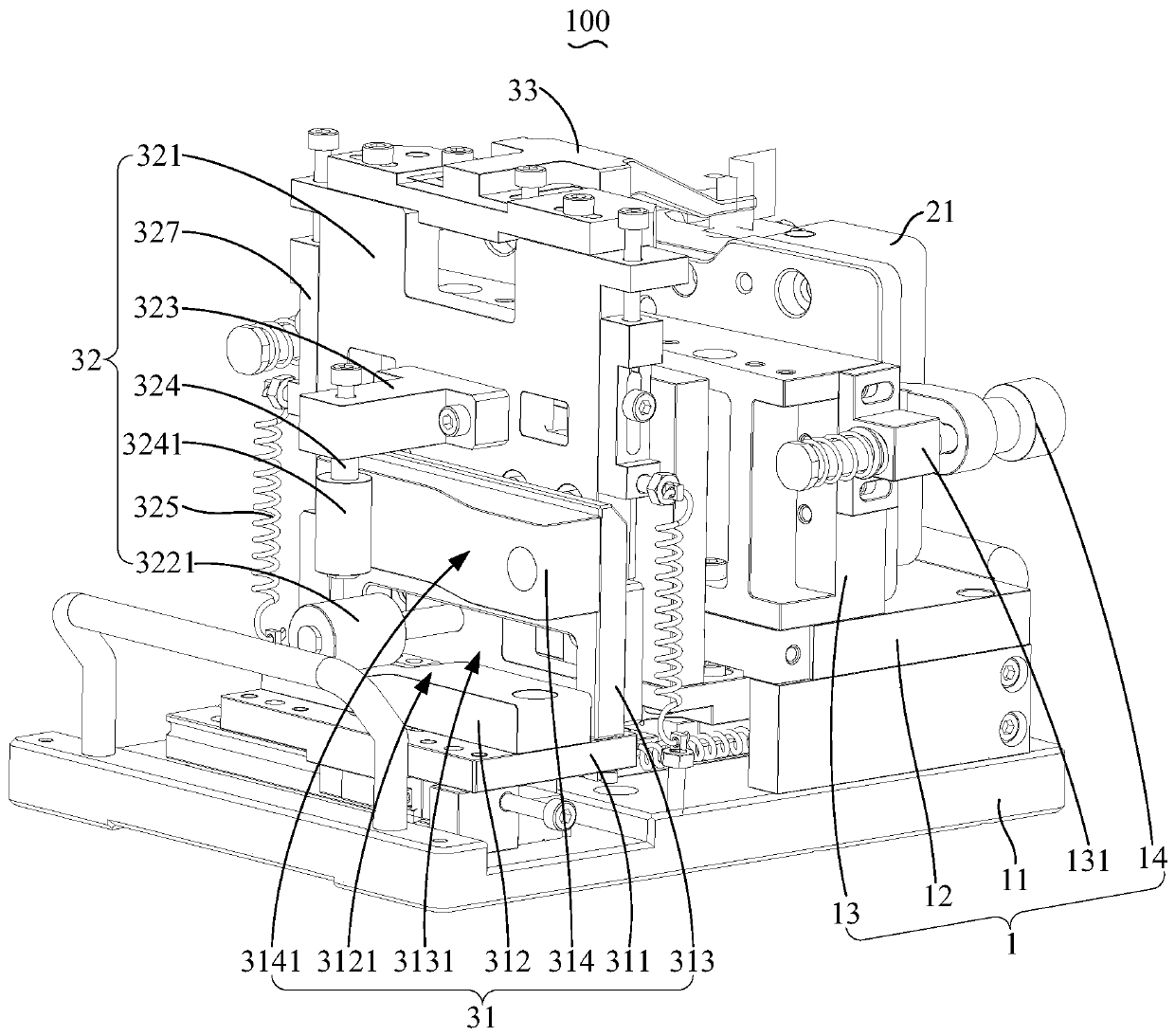

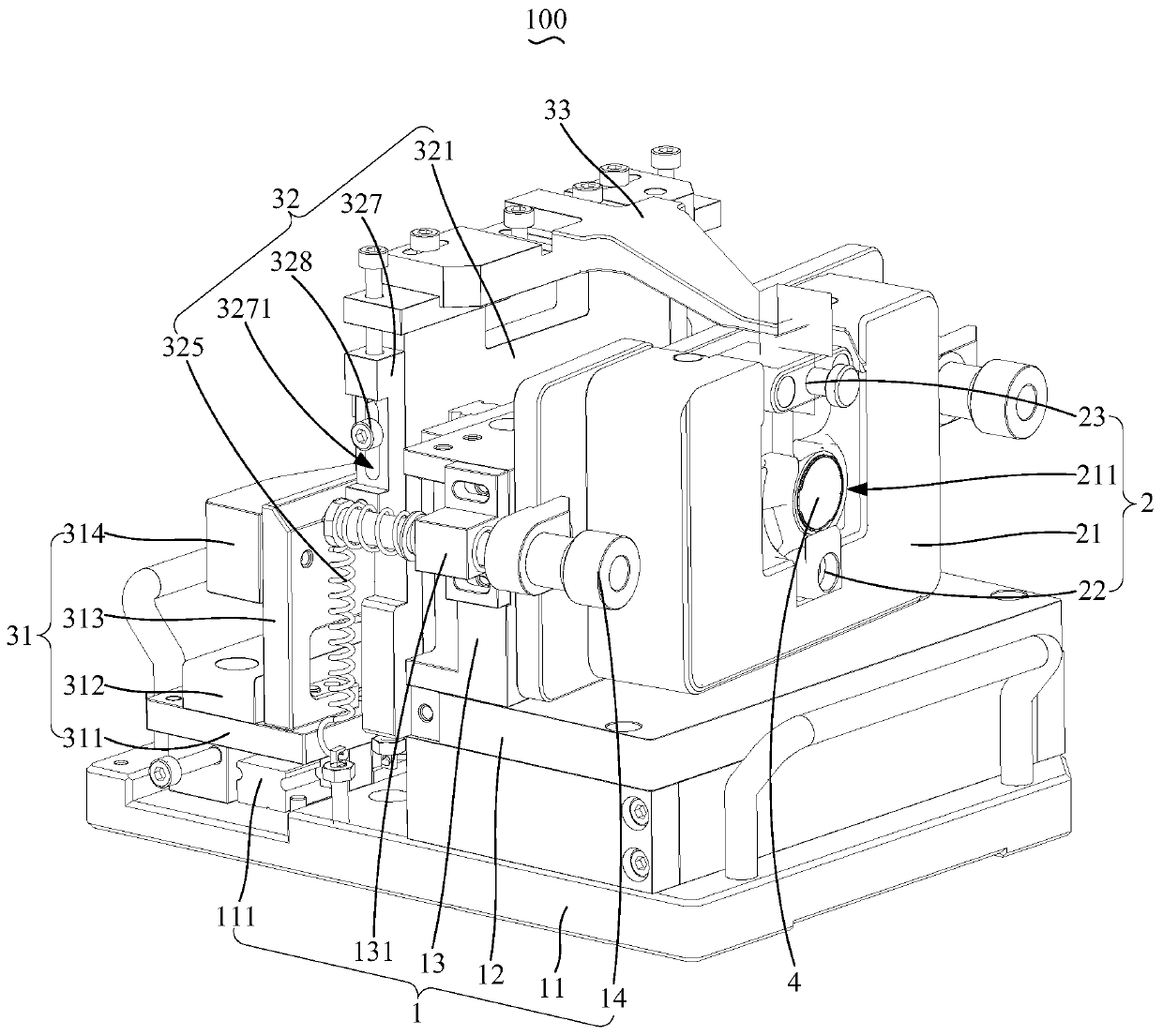

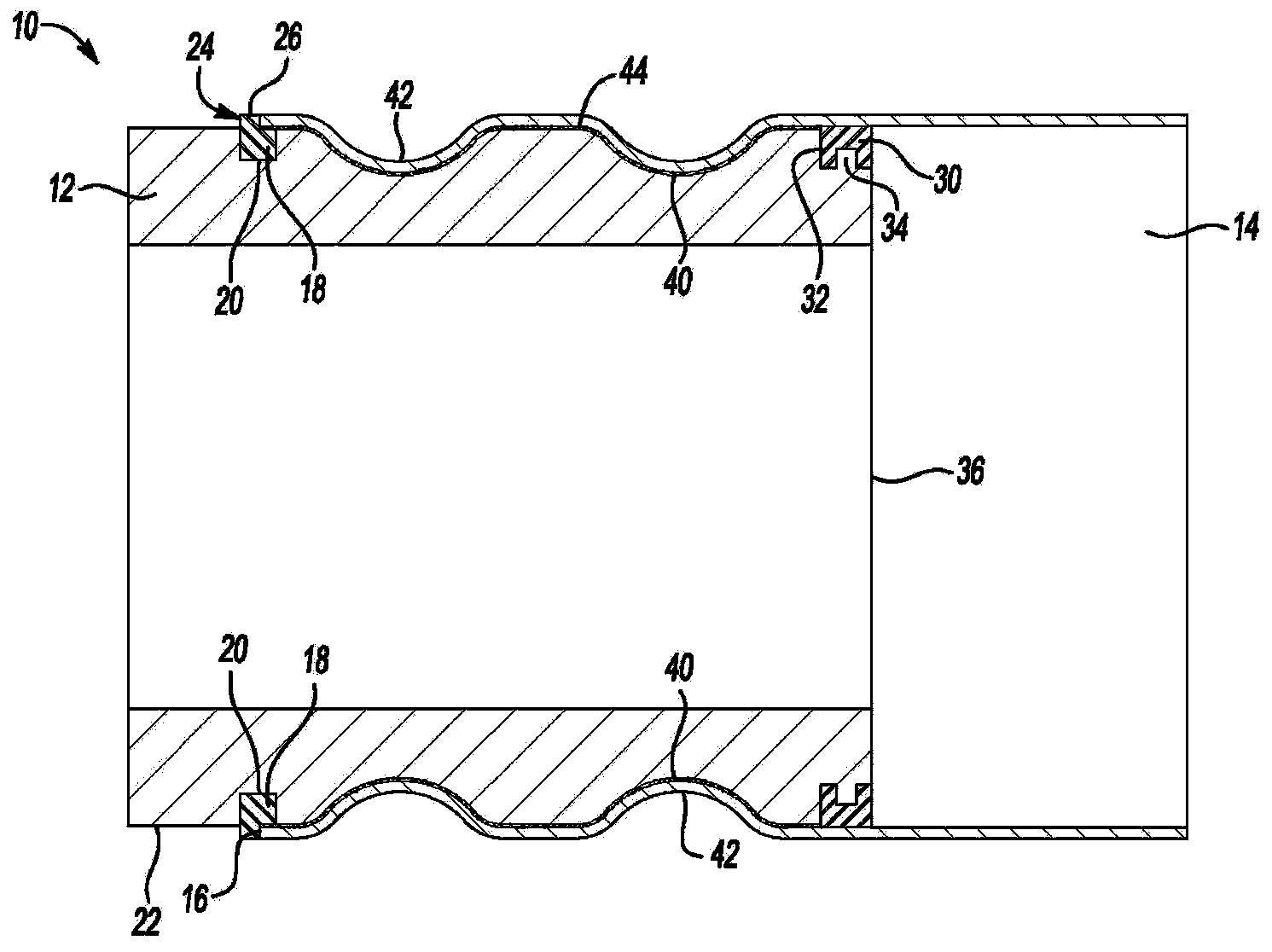

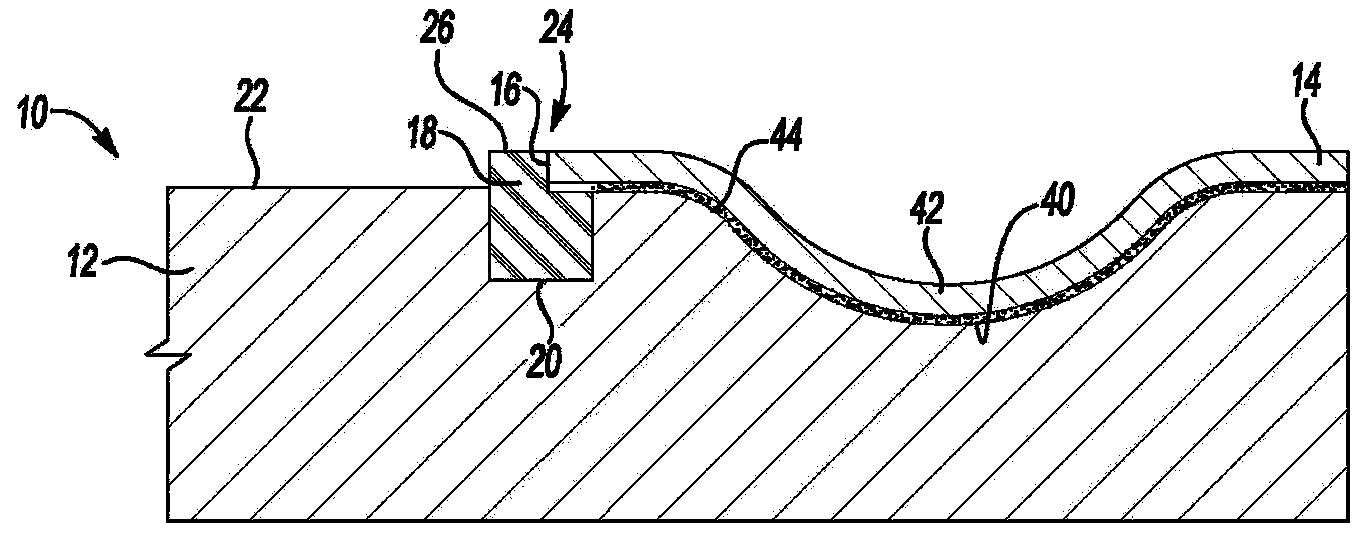

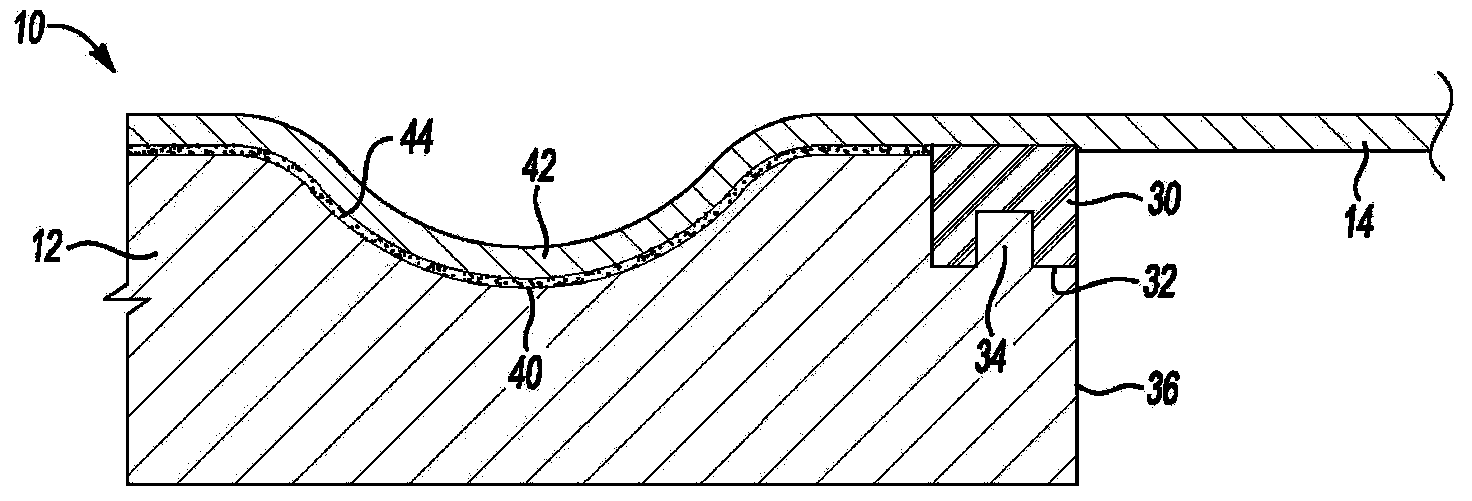

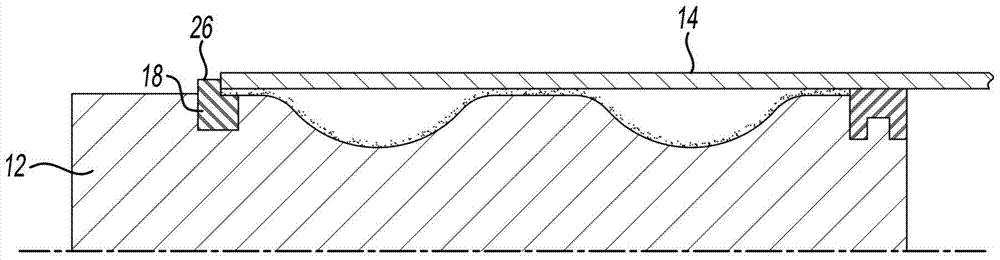

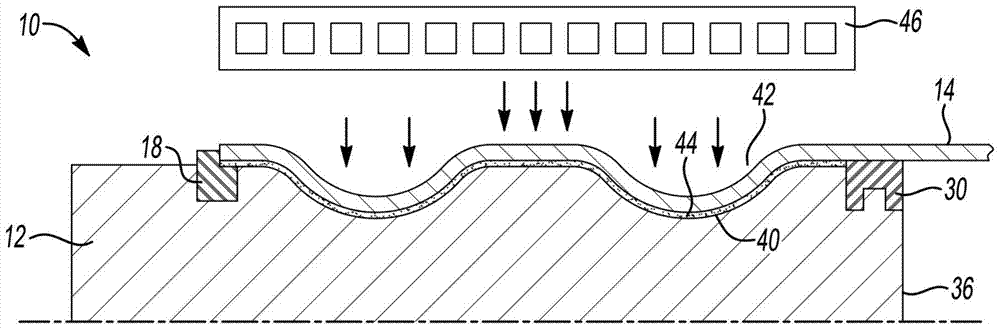

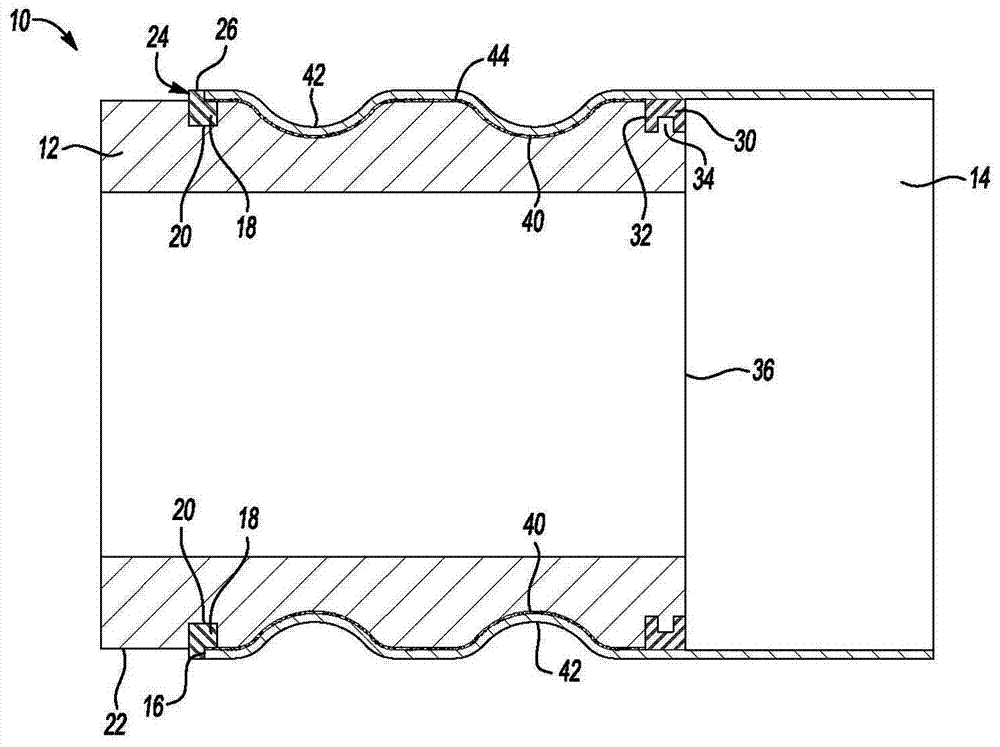

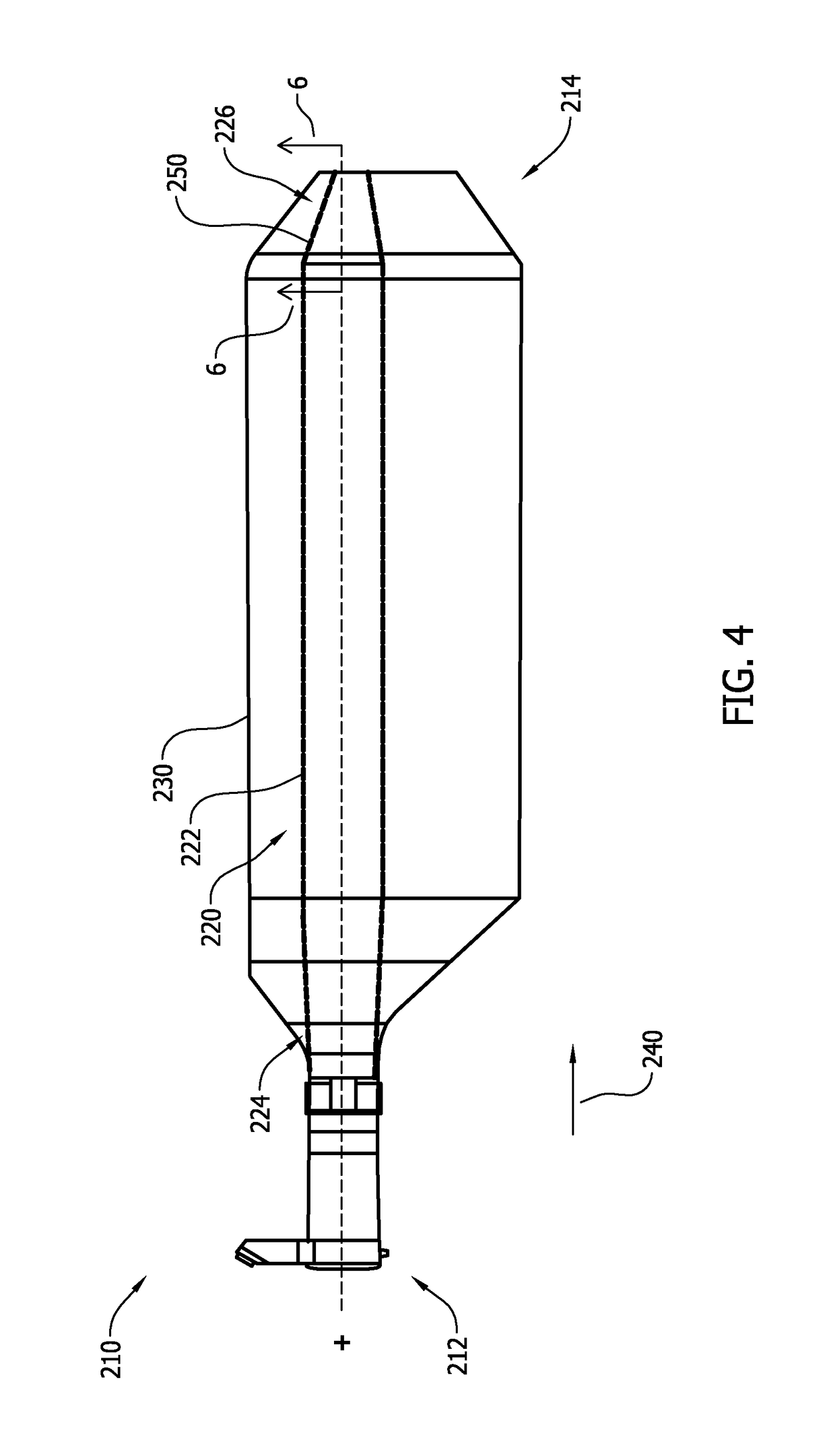

Apparatus and method of installing pre-molded seal caps

An apparatus (100) and method for mounting preformed seal covers (210) to a fastener (301) extending from a surface (300) is disclosed. The apparatus (100) includes a plunger mechanism (220) configured to individually mount the preformed seal cover (210) to a selected one of a plurality of fasteners (301). The apparatus (100) also includes a feed system (230) configured to sequentially convey thepreformed sealing covers (210) disposed on the carrier tape (200) to the plunger mechanism (220). The apparatus (100) additionally includes a collection mechanism (240) configured to collect the carrier tape (200) as the preformed sealing cover (210) are sequentially removed from the carrier tape (200). The plunger mechanism (220) is further configured to cooperate with the feed system (230) to sequentially remove the preformed seal covers (210) from the carrier tape (200).

Owner:THE BOEING CO

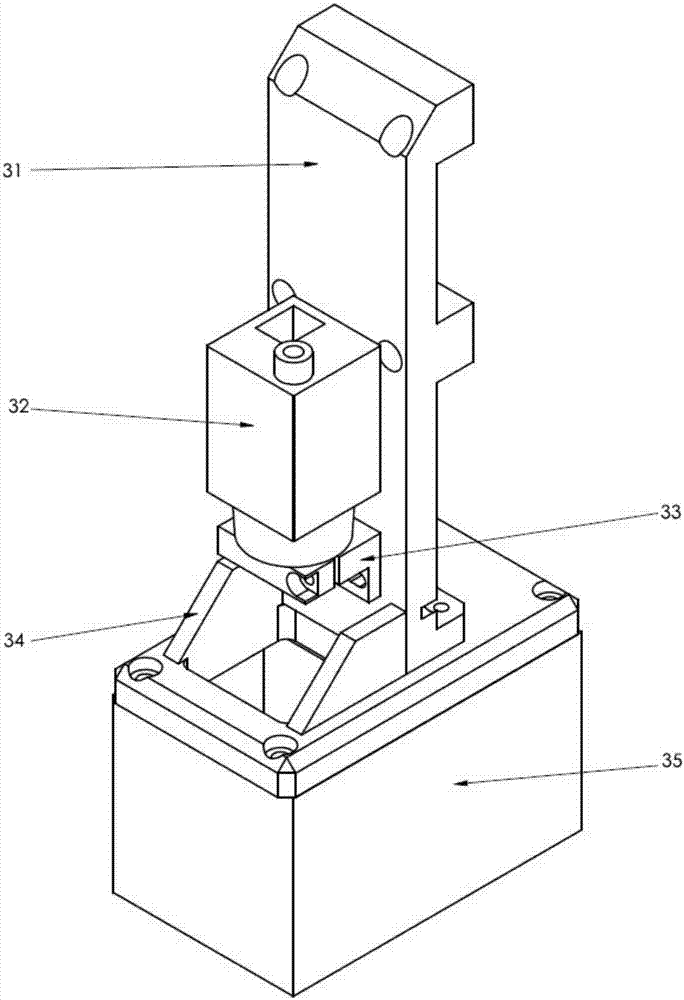

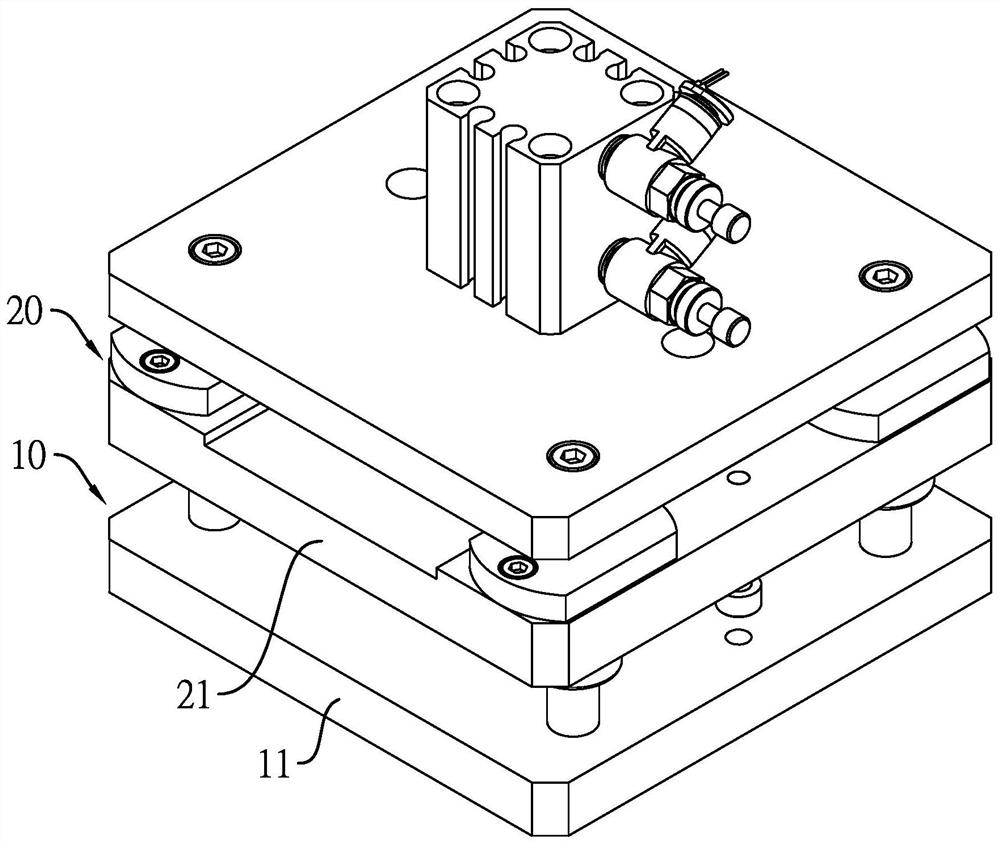

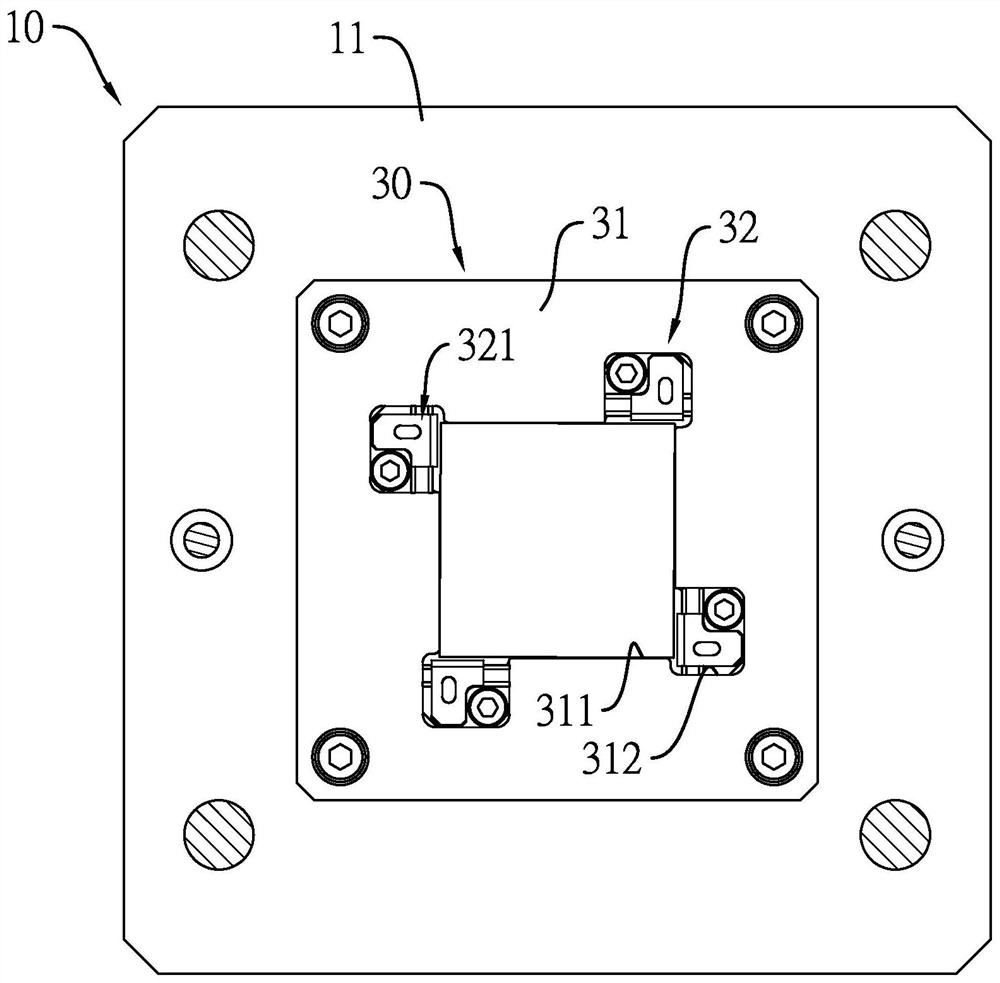

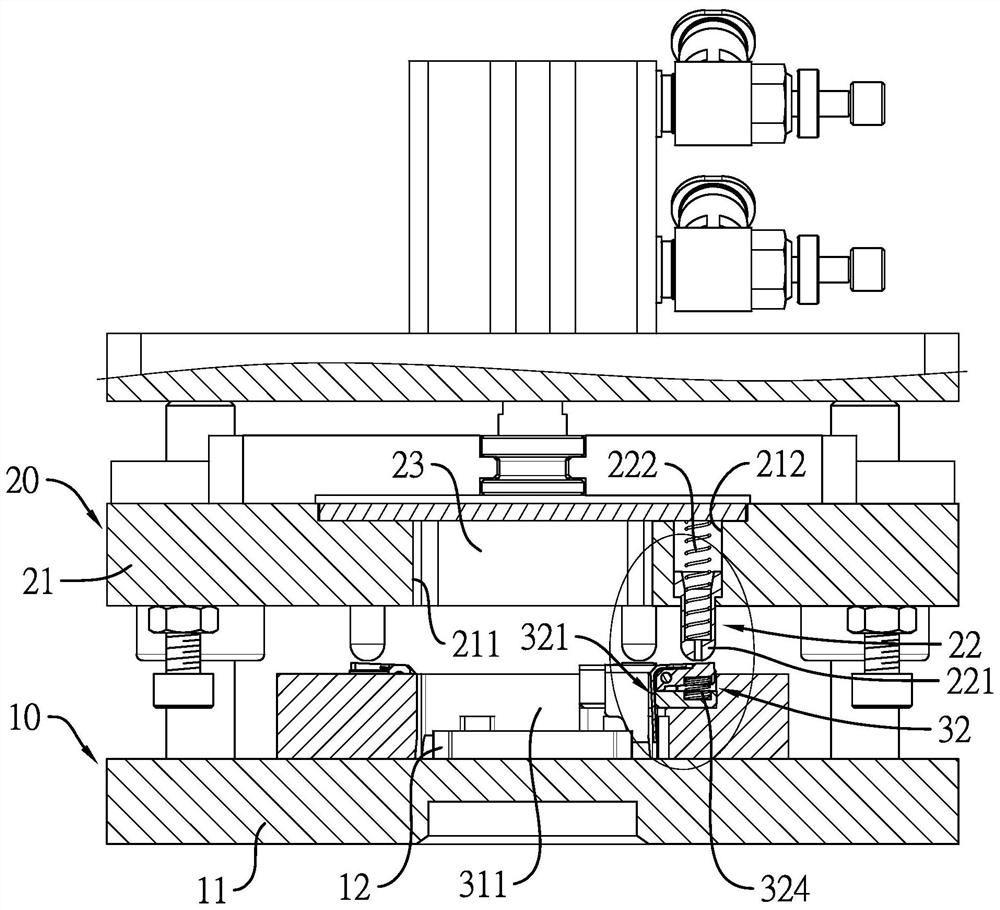

Attaching jig

ActiveCN107023544AImprove fitting accuracyAccurate fitPlastic deformation fasteningEngineeringMechanical engineering

The invention relates to an attaching jig which is used for attaching a dustproof net to a mobile phone shell. The attaching jig comprises a connecting seat, an installation seat which is used for carrying the mobile phone shell and is arranged on the connecting seat in a sliding manner, a first positioning pillar which is arranged on the installation seat and can be matched with an auxiliary hole of the mobile phone shell to position the mobile phone shell, an adjusting assembly arranged on the connecting seat and used for carrying the dustproof net, and a second positioning pillar which is used for positioning the dustproof net, arranged on the adjusting assembly and can be matched with a connecting hole of the dustproof net so that the carrying position of the dustproof net can be aligned with the position, used for installing the dustproof net, on the mobile phone shell; and the installation seat drives the mobile phone shell to slide relative to the connecting seat so that the mobile phone shell can extrude the dustproof net, and then the dustproof net is attached to the mobile phone shell. By means of the above attaching jig, due to the cooperation use of the first positioning pillar and the second positioning pillar, the dustproof net can be accurately attached to the mobile phone shell, and the attaching precision of the dustproof net is greatly improved.

Owner:GUANGDONG EVERWIN PRECISION TECH

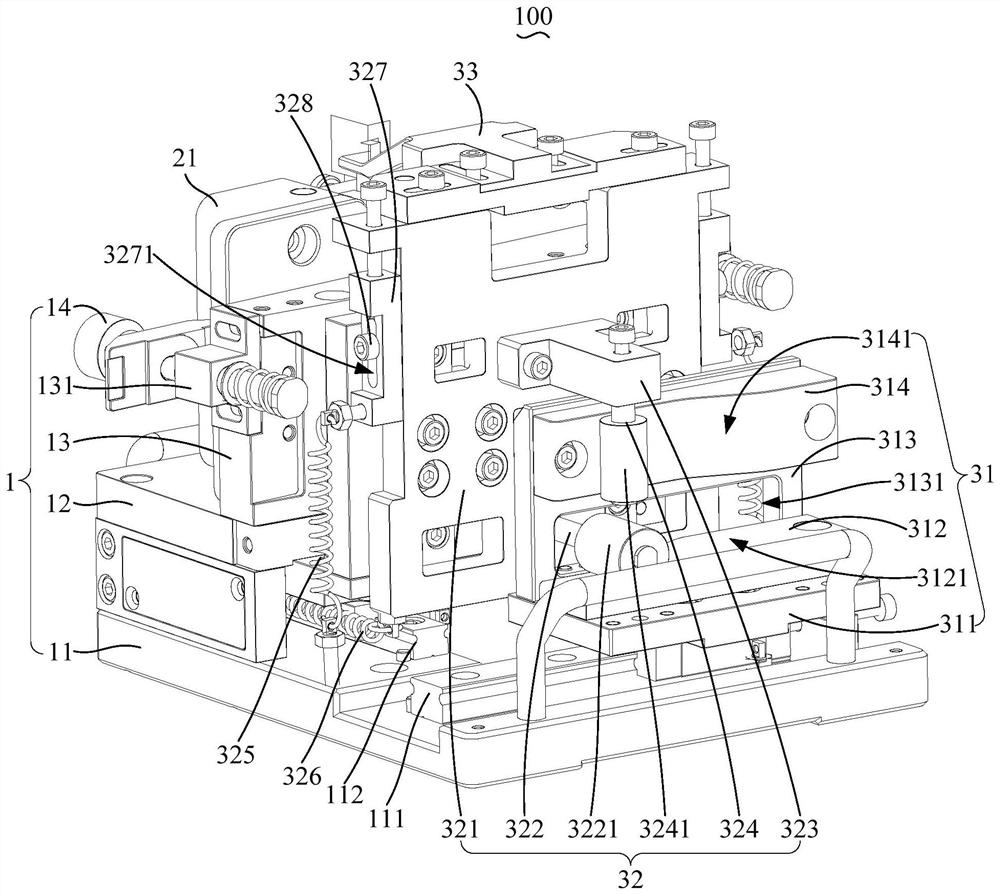

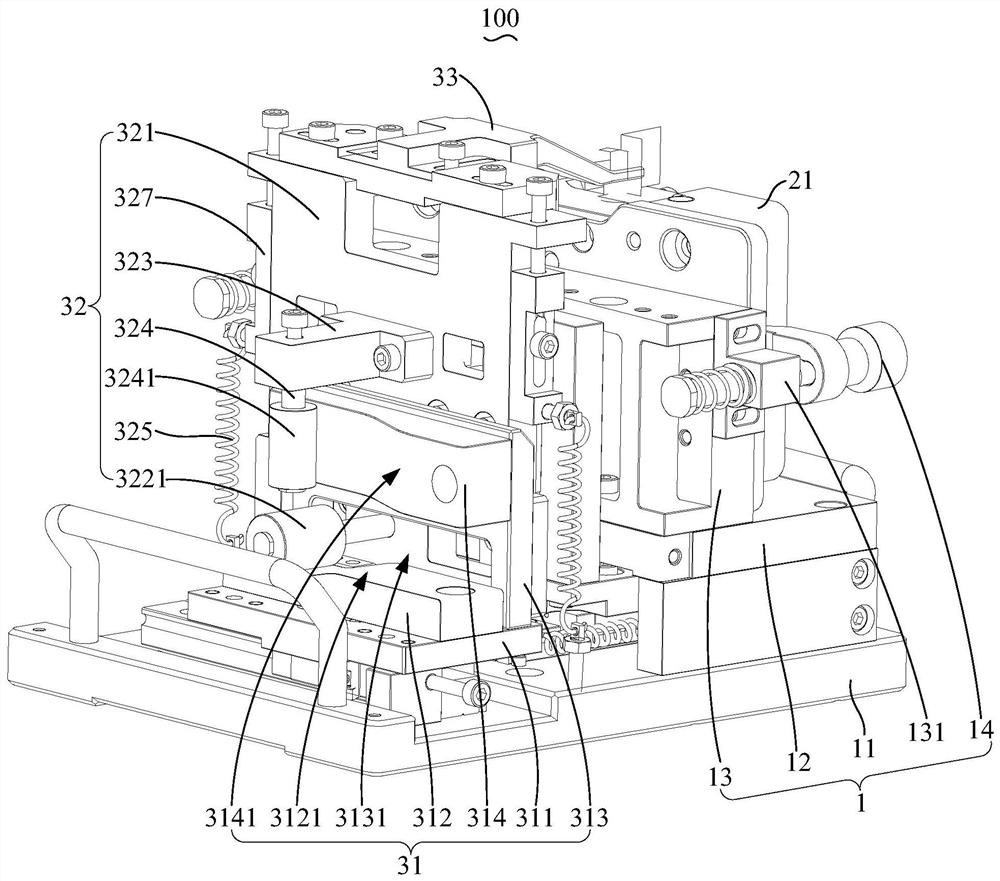

Pressure maintaining equipment

ActiveCN111022455AConducive to maintaining pressureEasy to installPlastic deformation fasteningMaterial gluingMechanical engineeringPhysics

The invention discloses pressure maintaining equipment for pressure maintaining an earphone. The pressure maintaining equipment comprises a base, a carrier, and a pressure maintaining structure, wherein the carrier is arranged on the base, and the carrier is provided with a mounting groove for fixing the earphone; the pressure maintaining structure comprises a sliding table assembly which is slidably arranged on the base, a pressure maintaining assembly and a pressing head, wherein the pressure maintaining assembly is movably arranged between the carrier and the sliding table assembly; and thesliding table assembly is provided with a first slope face, one side, facing the sliding table assembly, of the pressure maintaining assembly is rotatably provided with a first rolling wheel, the first rolling wheel abuts against the first slope face, and the pressing head is arranged at one end, away from the base, of the pressure maintaining assembly and is used for pressure maintaining the earphone. The invention aims to provide pressure maintaining equipment capable of carrying out good pressure maintaining on a small-volume electronic product, and the pressure maintaining equipment can effectively provide the assembly stability of the product.

Owner:GOERTEK INC

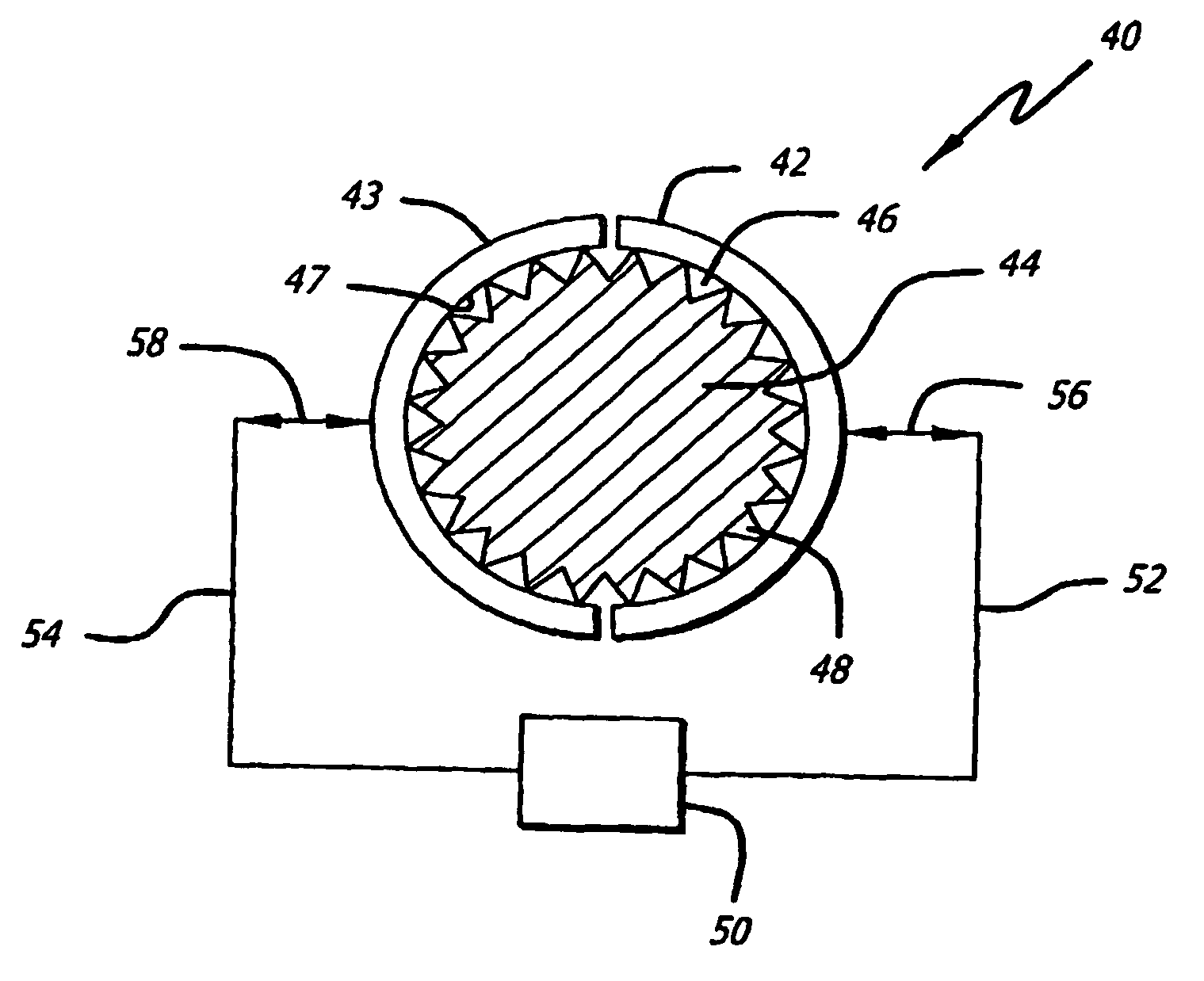

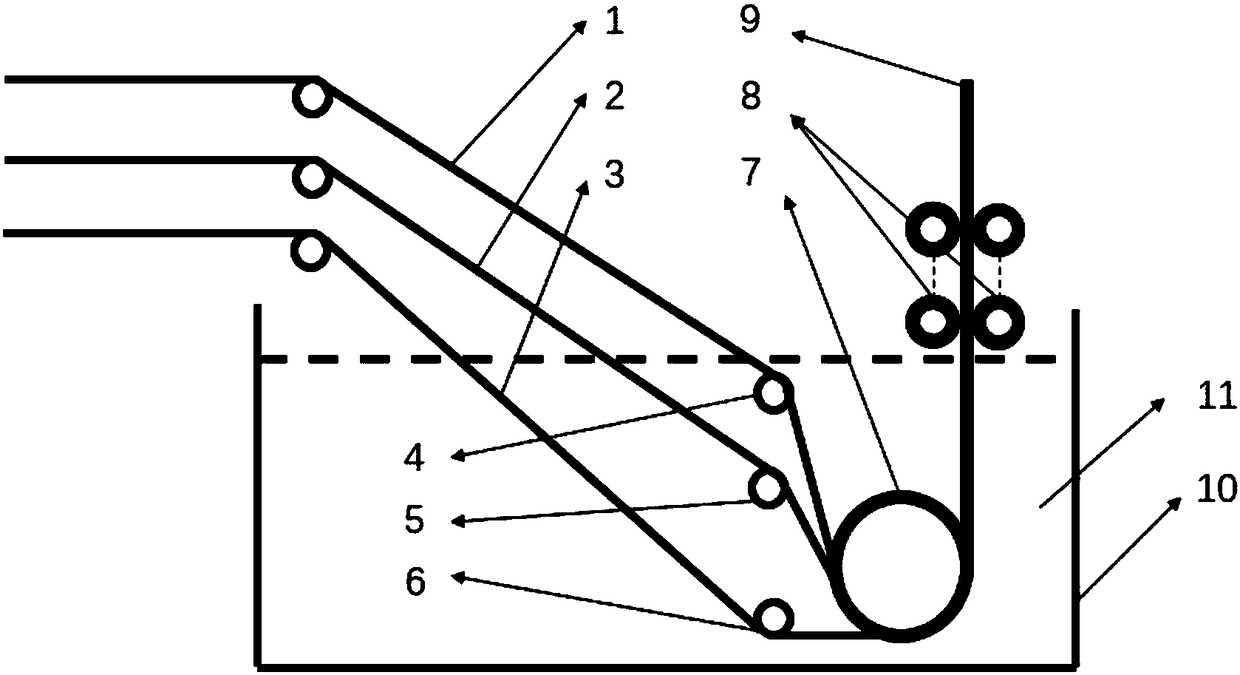

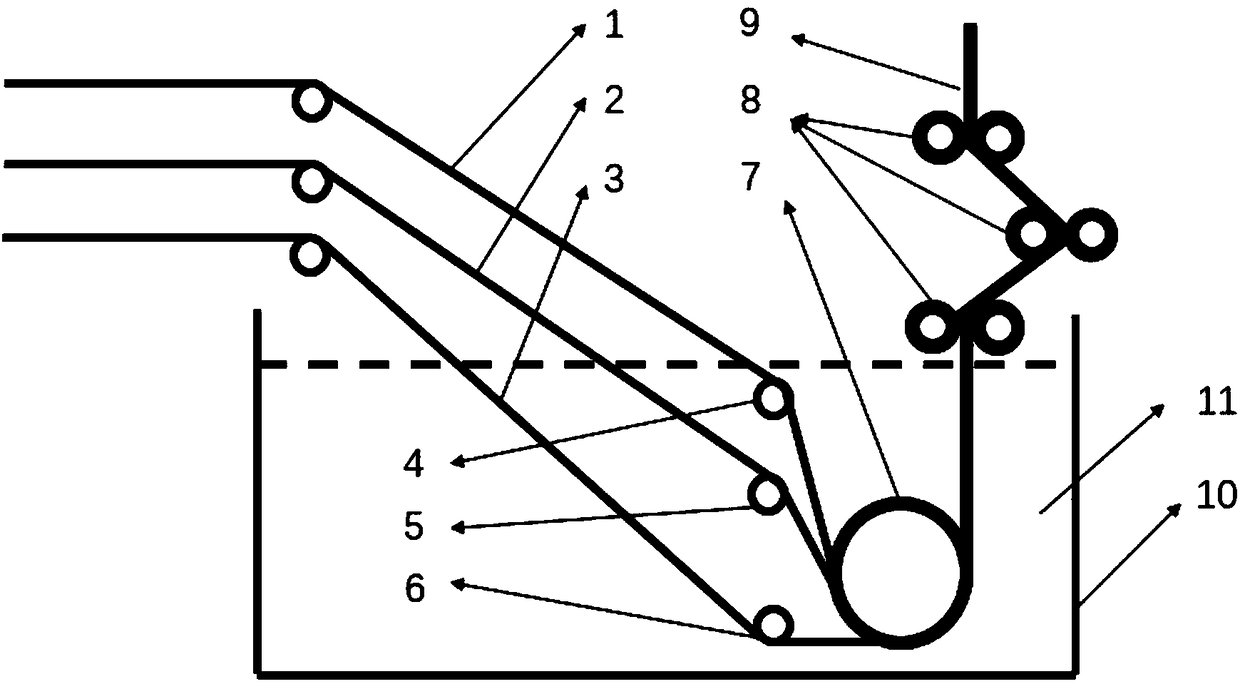

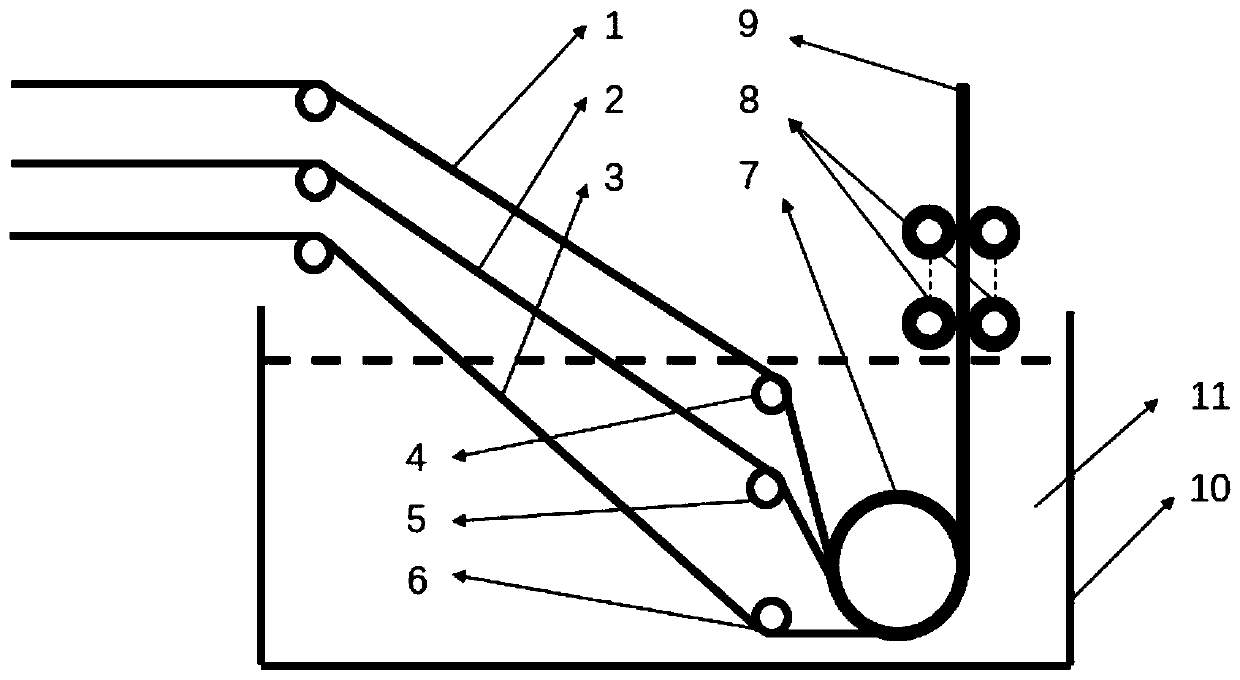

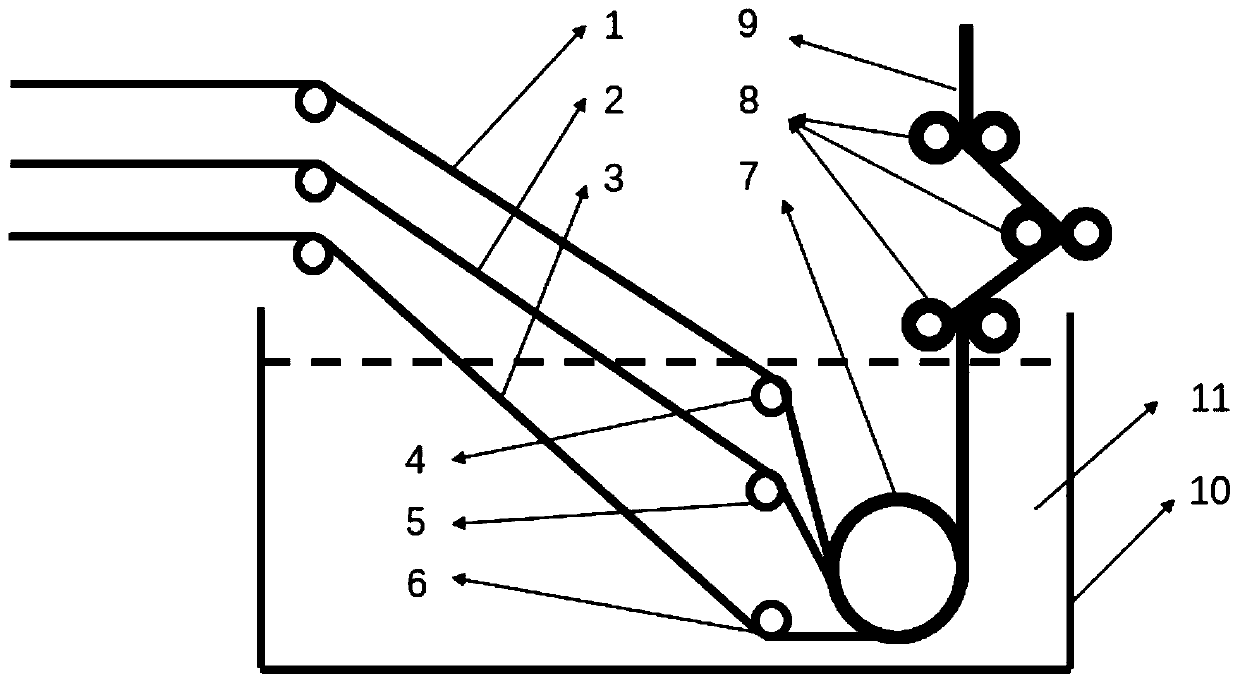

Pressure welding device and method for high-temperature superconducting strips

ActiveCN108223518AAchieve continuous and stable preparationGood effectSuperconductors/hyperconductorsPlastic deformation fasteningHigh temperature superconductingEngineering

The invention relates to a pressure welding device and method for high-temperature superconducting strips. The device and the method are used for carrying out pressure welding on at least two strips.The pressure welding device is composed of one or more groups of rolling wheels arranged in different ways, wherein the core part rolling wheel adopts a non-metal elastic wheel or a metal wheel with anon-metal elastic coating layer on the surface; and on one hand, the elastic rolling compression design ensures that the resistance and the pressure borne in the whole strip width direction are uniform, and on the other hand, the design of carrying out pressure welding by the plurality of groups of rolling wheels enables stainless steel strips to be packaged continuously and reliably. Meanwhile,the invention further provides the pressure welding method. The superconducting strip manufactured by the pressure welding method and device has the beneficial effects of being low in cost, high in yield and the like; and stable preparation of the superconducting thin strip and the stainless steel packaged superconducting strip can be further realized.

Owner:NORTHEASTERN UNIV

Assembly including parts made of dissimilar metals and the method of manufacturing the assembly

A method of joining parts with an electromagnetic joining process and an assembly made according to the process. Seals are assembled to a first part and a second part is assembled over the first part and the seals. A lubricant is applied to the first part between the seals to preoccupy or partially fill the area within the joint to prevent moisture from penetrating into the joint and causing corrosion. A portion of the second part is deformed into recesses formed in the first part to join the first and second parts.

Owner:FORD GLOBAL TECH LLC

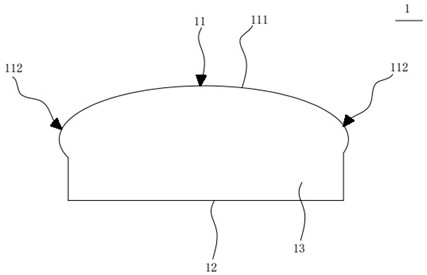

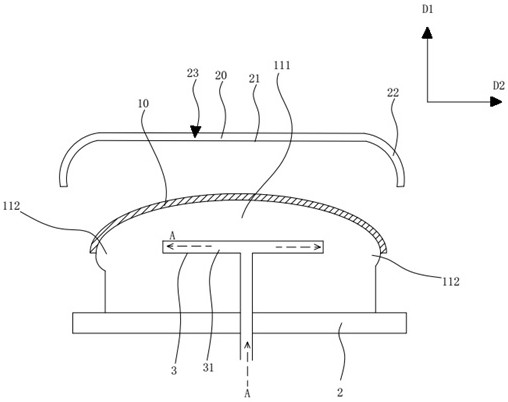

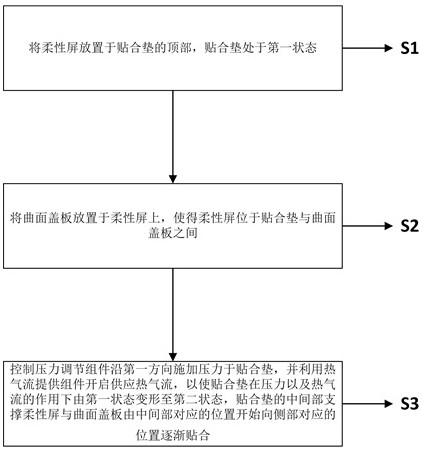

Attaching device and attaching method

ActiveCN113153876AGood fitIncrease plane attachment effectPlastic deformation fasteningGas bubbleMaterials science

The invention provides an attaching device and an attaching method. The attaching device is used for attaching a flexible screen to a curved surface cover plate, the attaching device comprises an attaching pad, a pressure adjusting assembly and a hot air flow providing assembly; the attaching pad comprises a top and a bottom which are oppositely arranged; the top is used for supporting the flexible screen to be stacked and attached to the curved surface cover plate in the first direction, and a gap is formed in the attaching pad; the pressure adjusting assembly makes contact with the bottom of the attaching pad and is used for applying pressure to the attaching pad in the first direction; the hot air flow providing assembly is used for providing hot air flow to the gap in the attaching pad; and wherein the attaching pad is made of a thermoplastic material. The problems of screen body tearing, bubbles and the like occurring in the process of attaching the curved surface cover plate to the flexible screen can be solved.

Owner:BAZHOU YUNGU ELECTRONICS TECH CO LTD

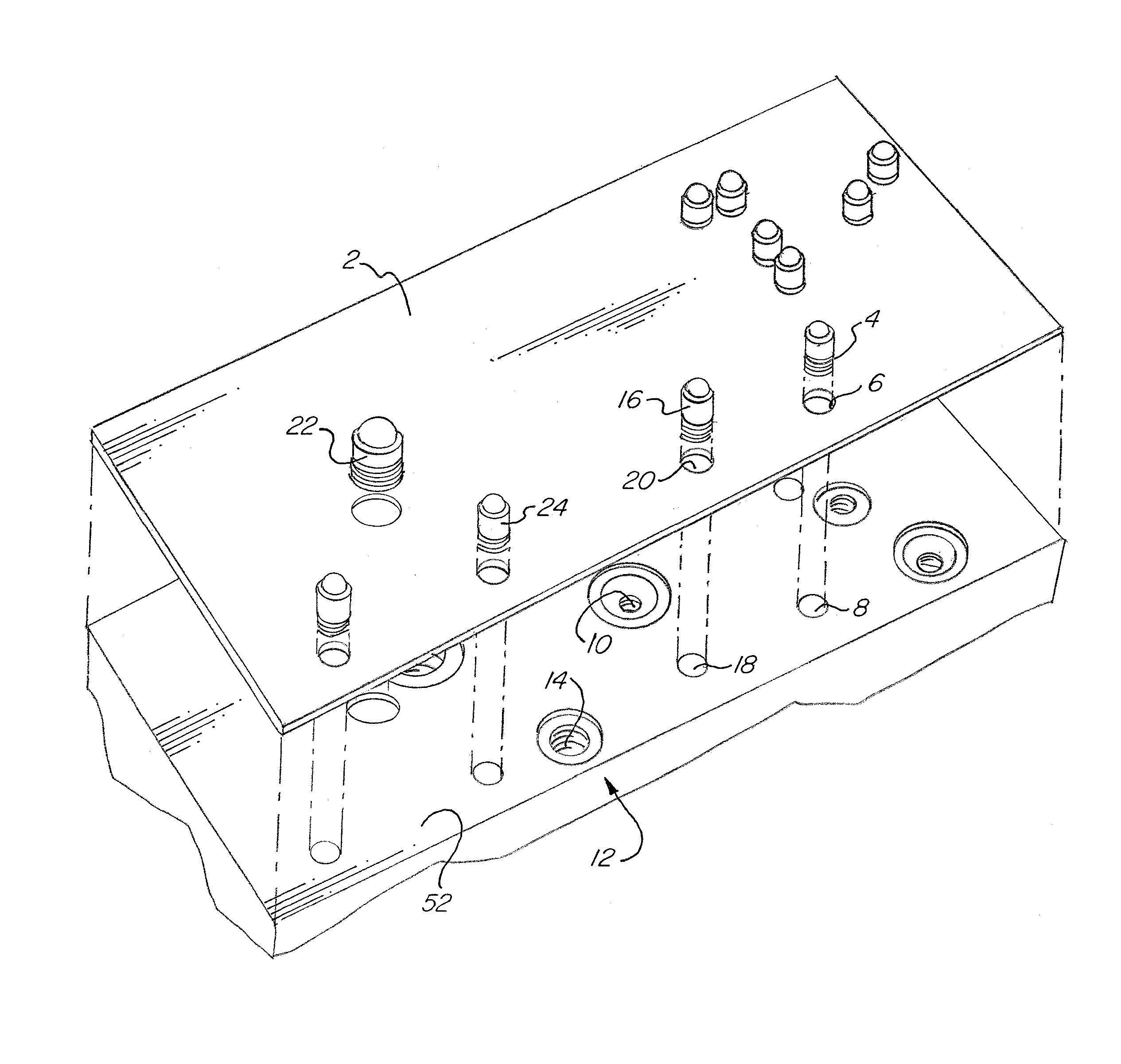

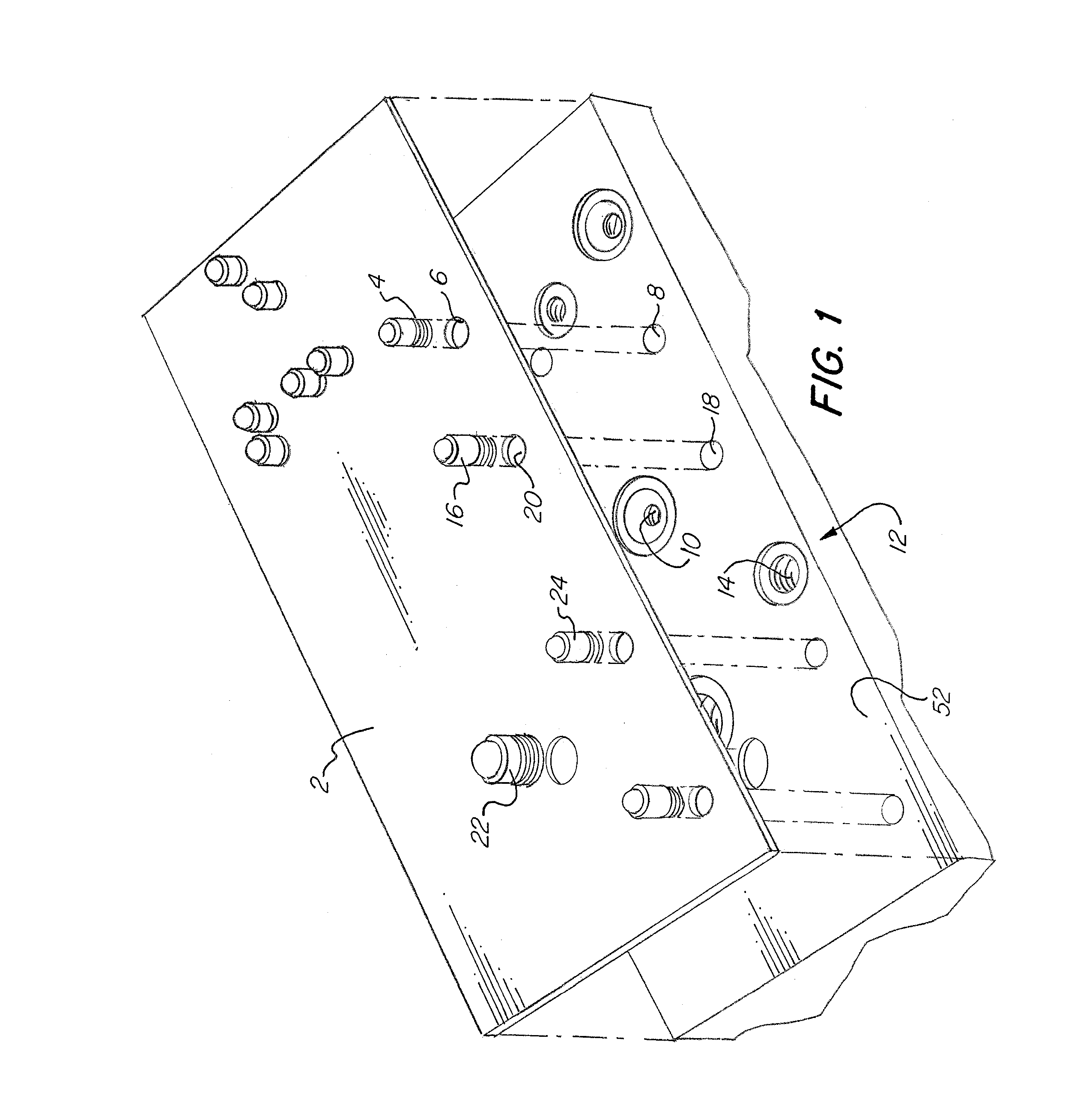

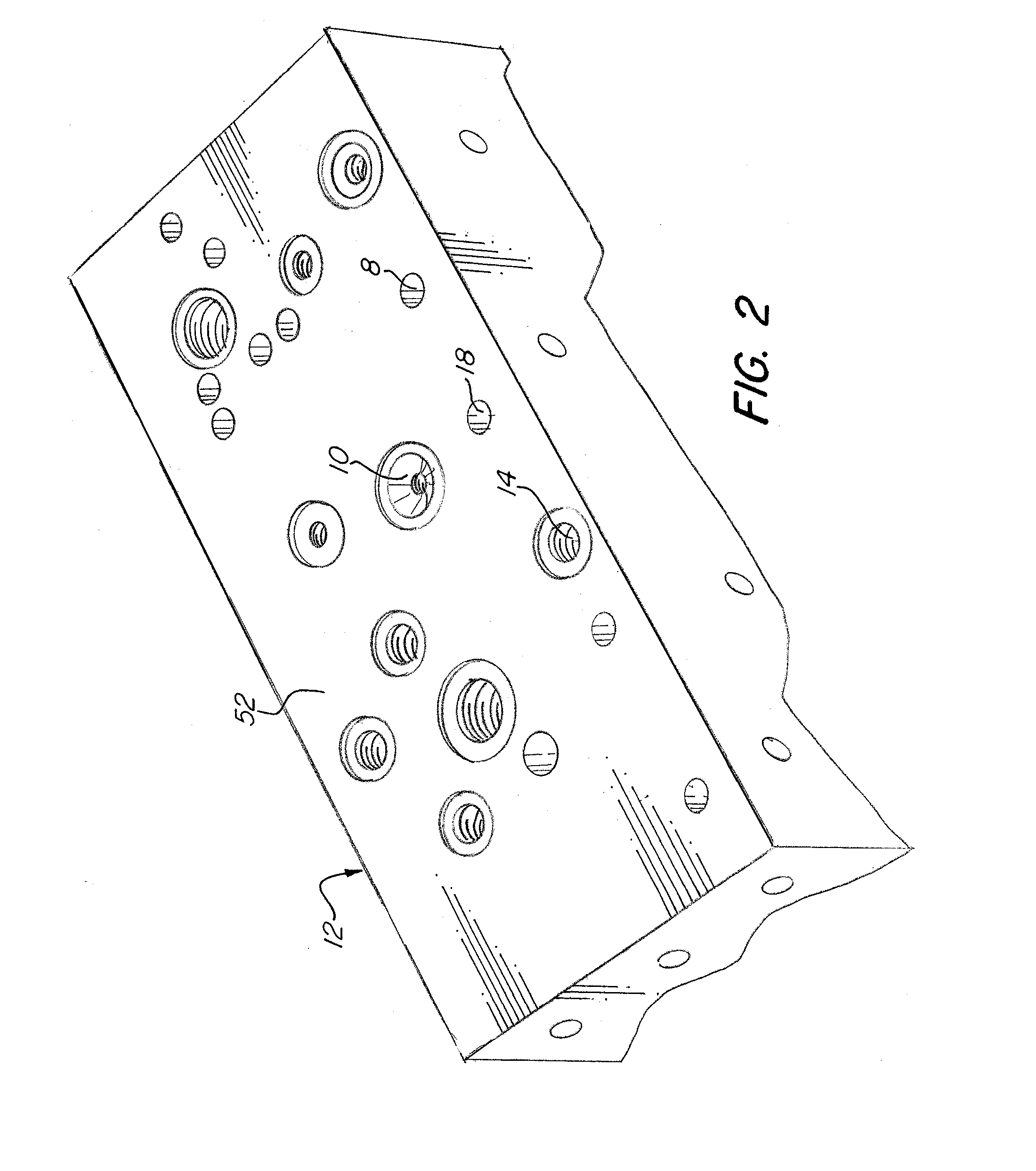

Insert Alignment and Installation Devices and Methods

ActiveUS20170058931A1Easy alignmentEasy to placePlastic deformation fasteningPipe elementsEngineeringCylinder block

Owner:ENGINEERED INSERTS & SYST

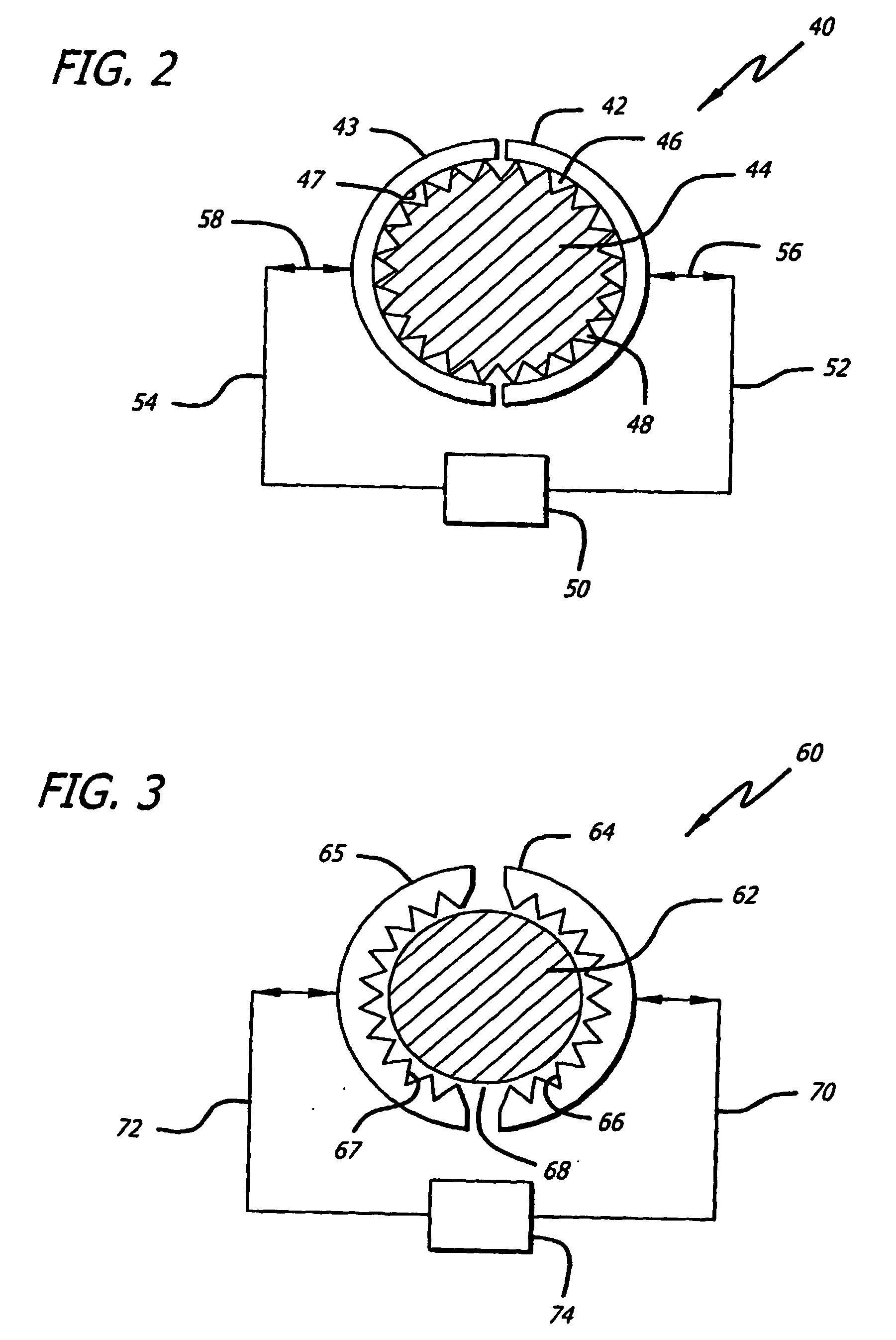

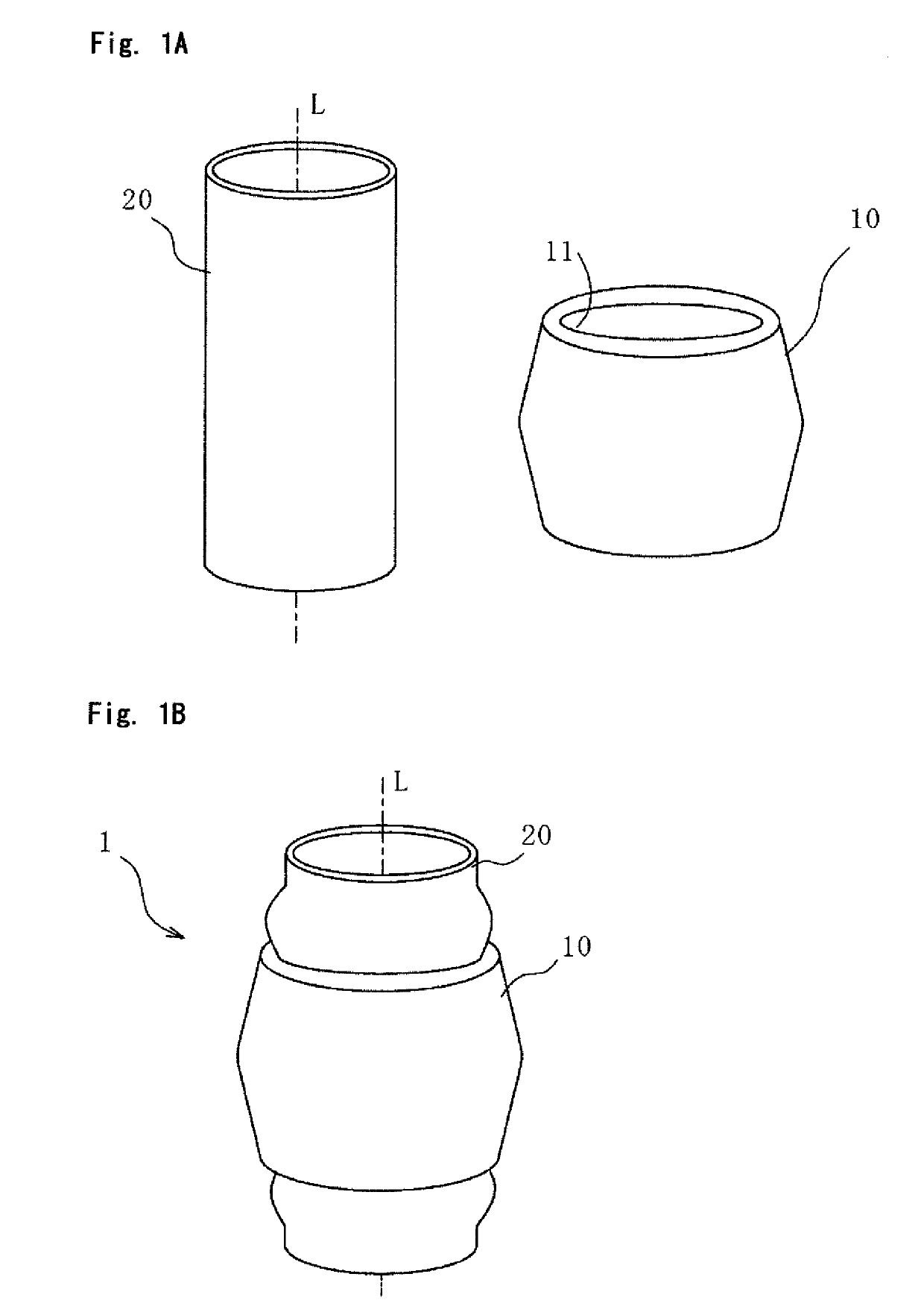

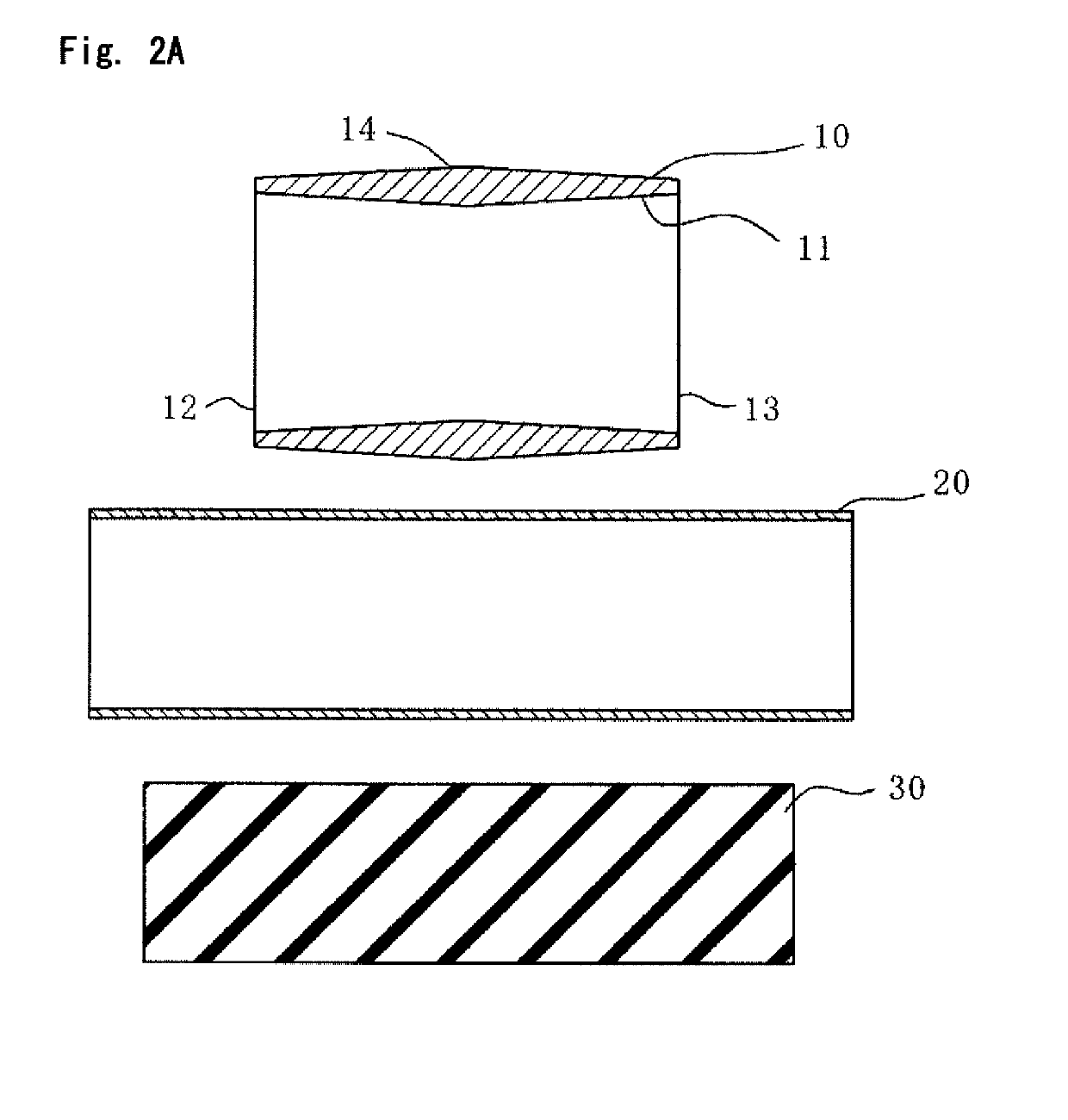

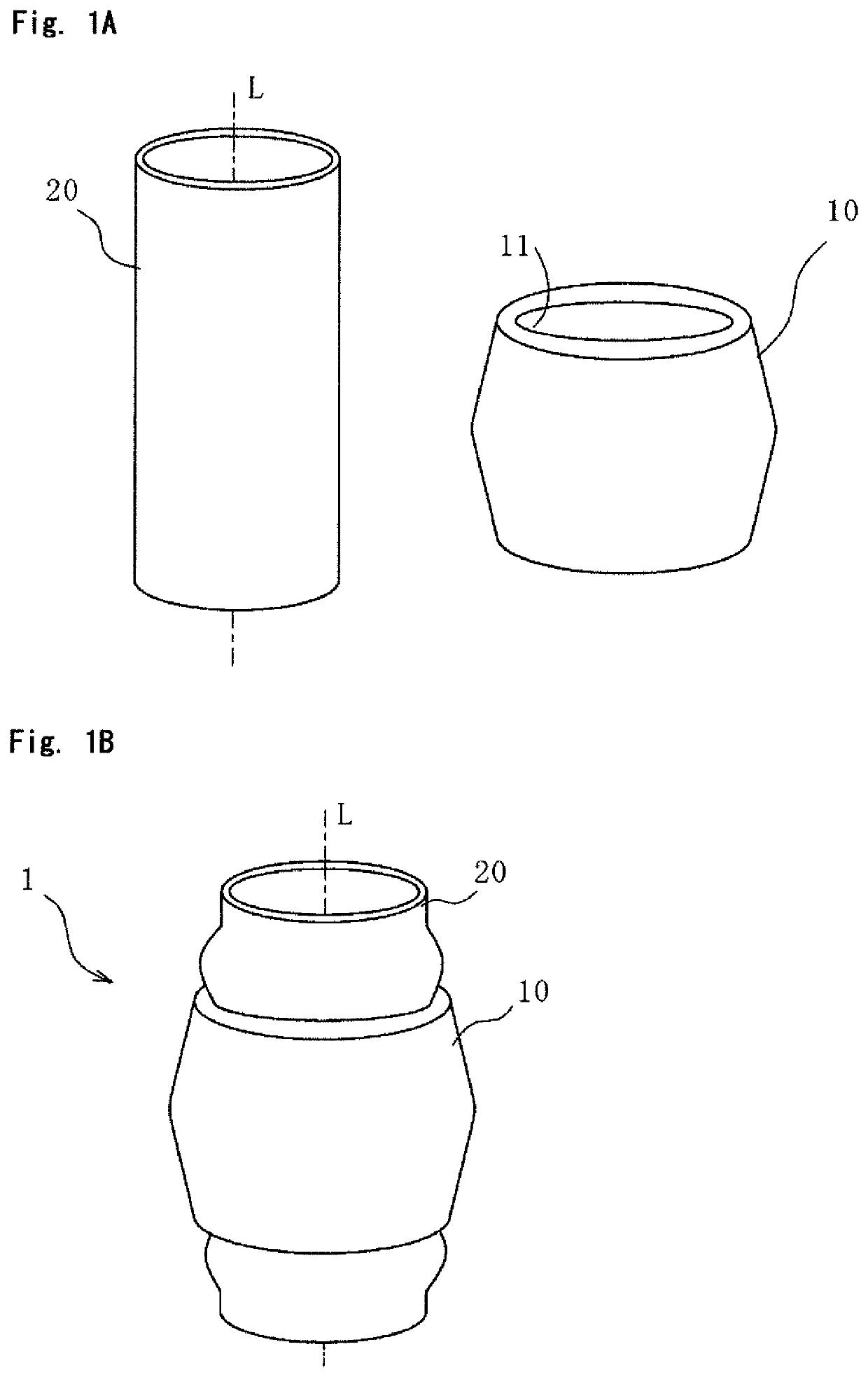

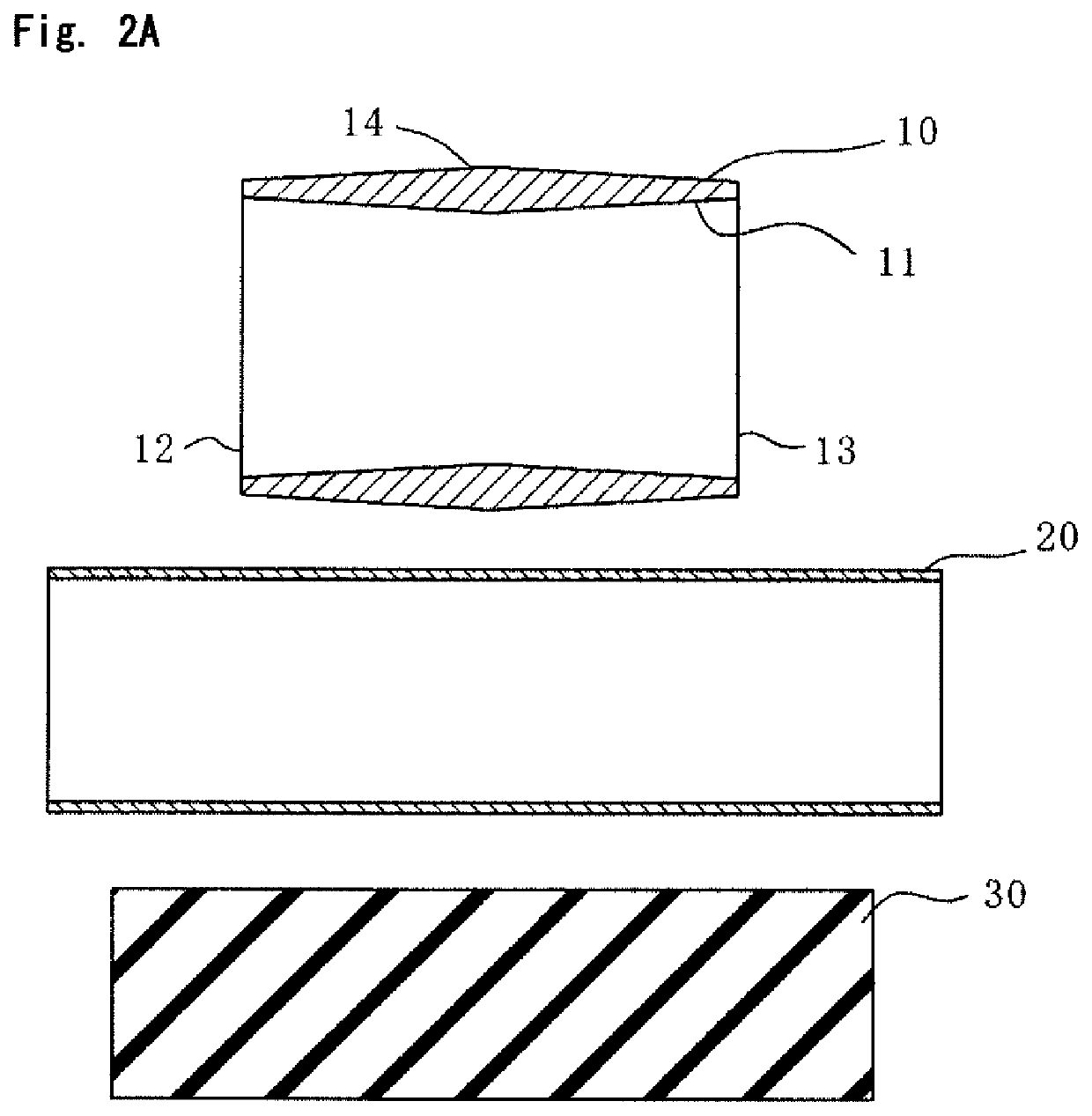

Method for joining members, and joint body

ActiveUS20190210087A1High joining strengthDeformation burdenPlastic deformation fasteningShrinkage connectionsEngineeringHollow shape

A method for joining members includes: providing a wall surface body which is a die-molded article provided with a hole portion with a draft angle provided from its opposite end portions toward its center portion, a tubular body with a hollow shape, and an elastic body; inserting the tubular body into the hole portion in the wall surface body; inserting the elastic body into the inside of the tubular body; and compressing the elastic body in the direction of an axial line L of the tubular body to expand the elastic body outwardly in the radial direction of the axial line L, thereby deforming and expanding the tubular body to joint the tubular body to the wall surface body by press-fitting.

Owner:KOBE STEEL LTD

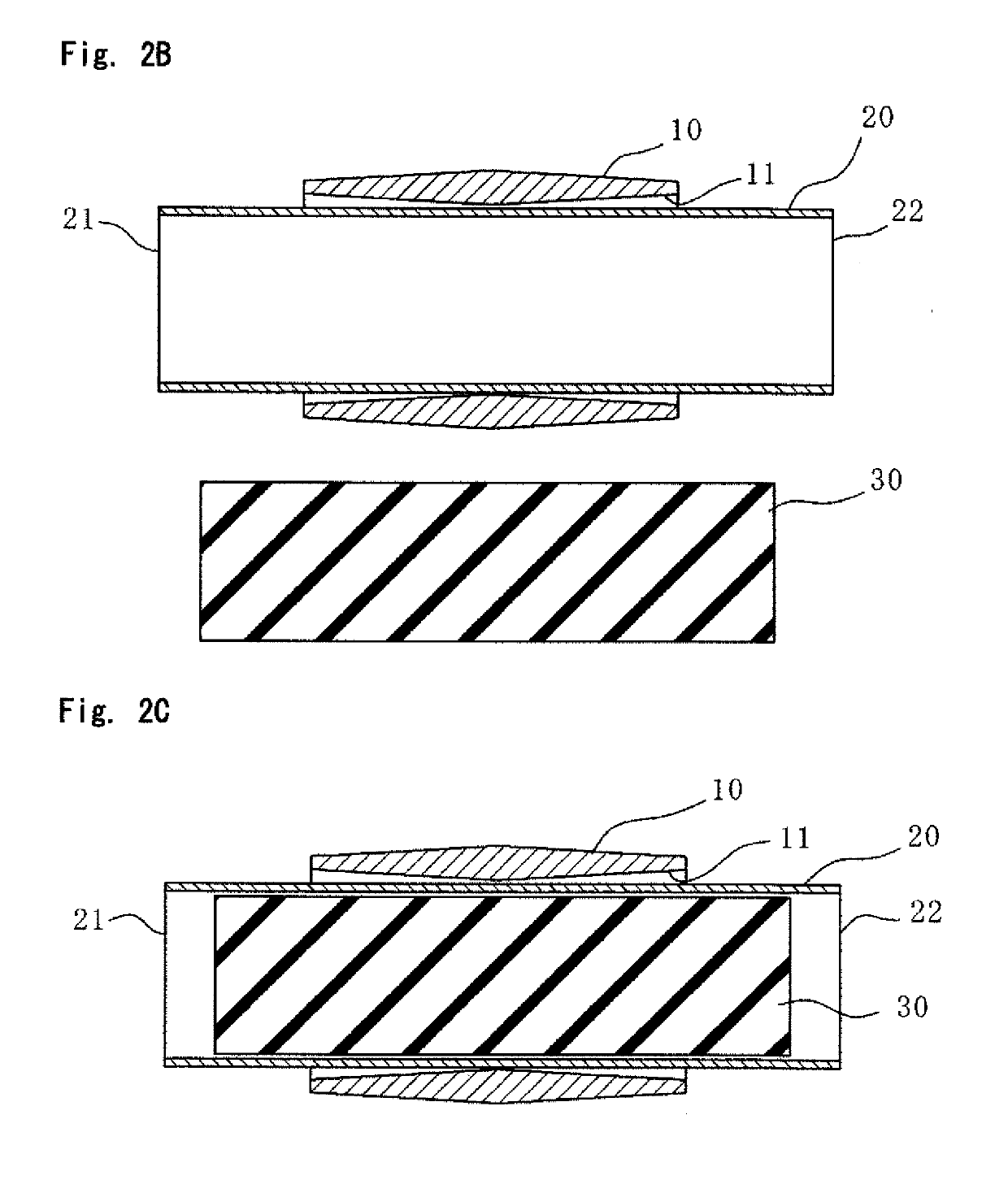

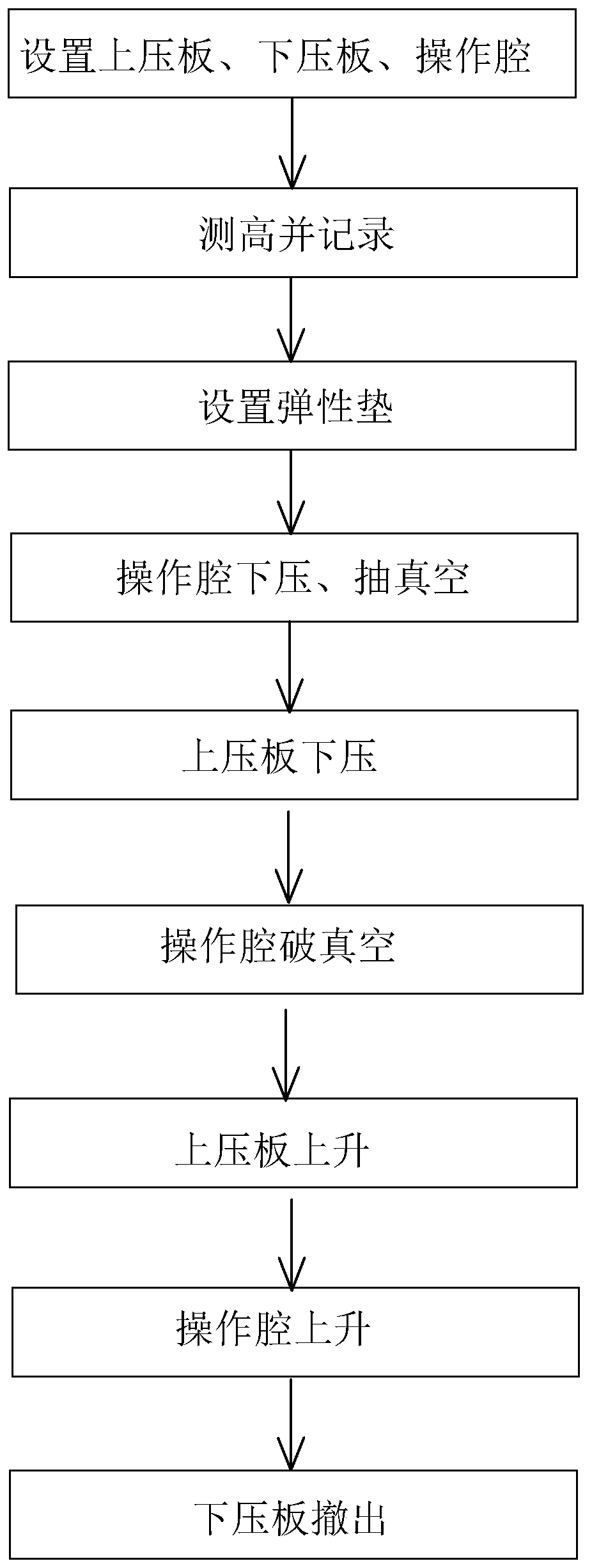

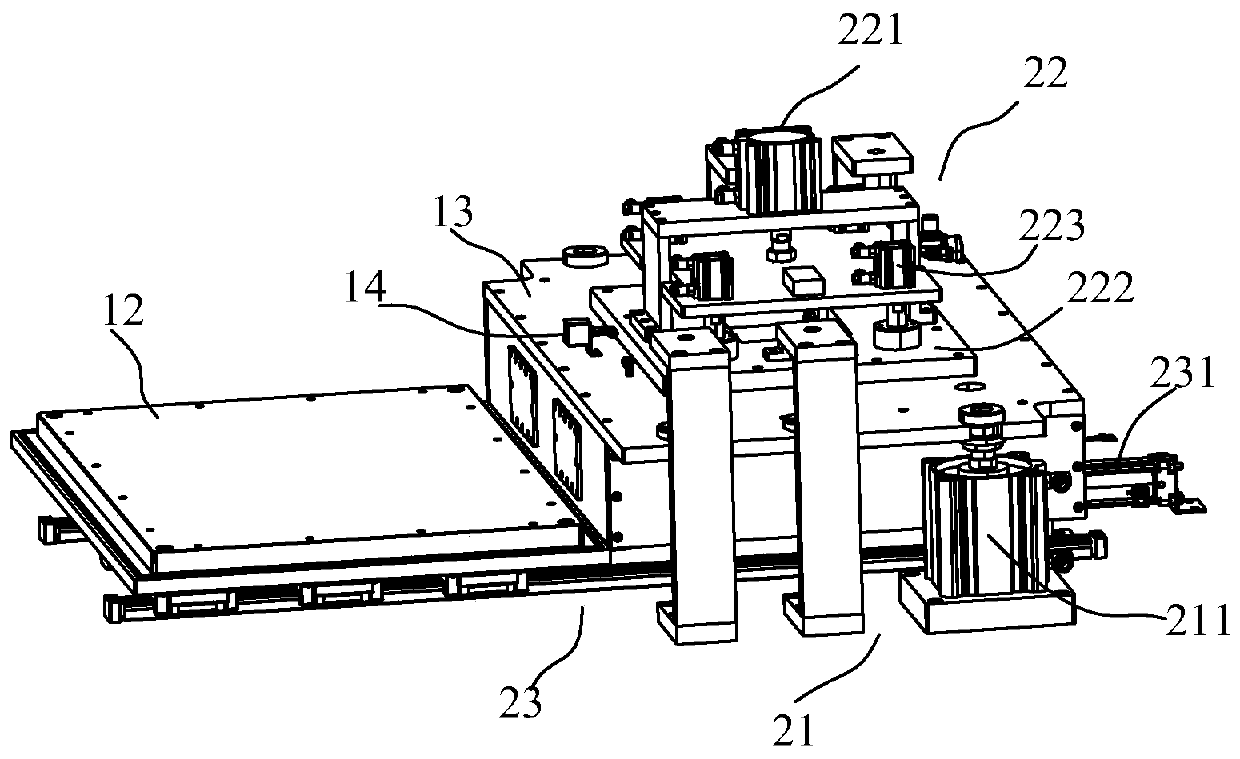

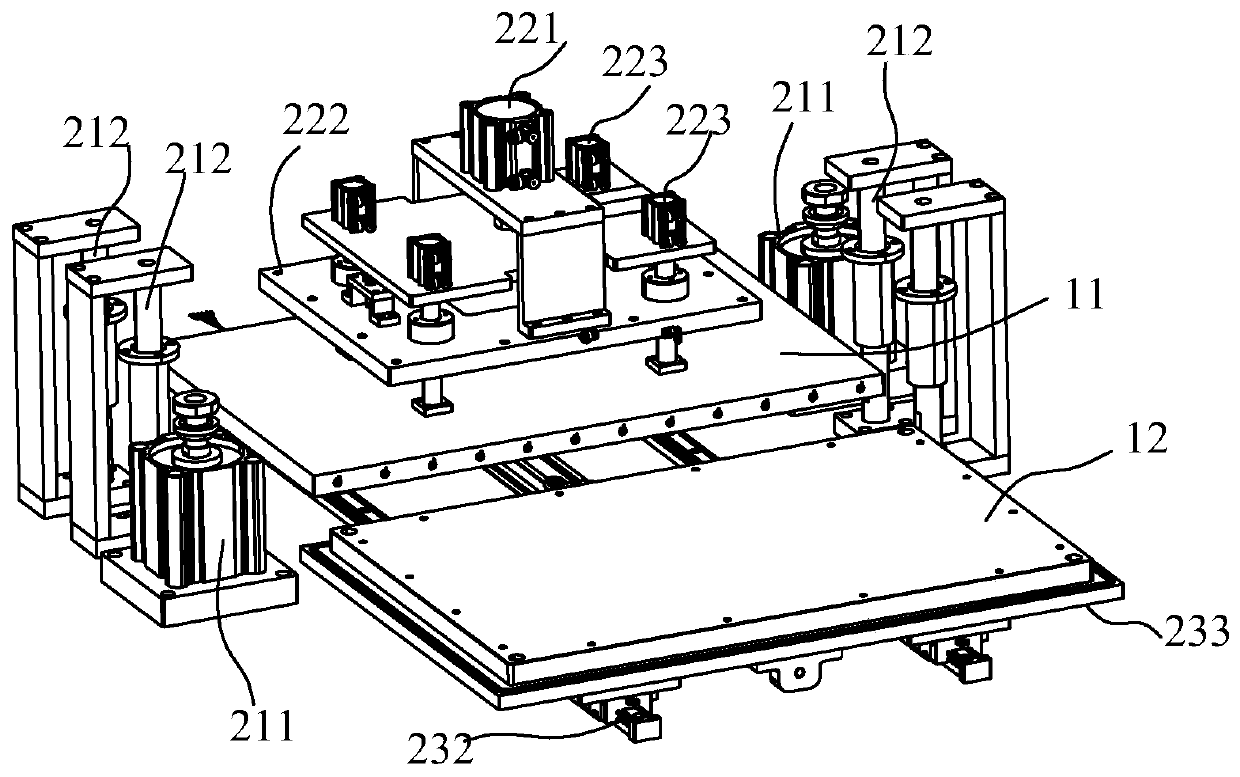

Display adhering technology and device

PendingCN110118217AOvercome the defect of uncontrollable moving distanceImprove fitPlastic deformation fasteningIdentification meansElastomerMeasuring instrument

The invention relates to a display adhering technology and device. The technology comprises the steps of measuring the height of an upper pressing plate, the height of a product positioned on a lowerpressing plate, arranging an elastic cushion between the product and the lower pressing plate, downwards pressing an operating chamber and vacuumizing the operating chamber, downwards pressing a pressing plate, etc. The display adhering device comprises the upper pressing plate, the lower pressing plate, the operating chamber and a height measuring instrument, wherein a vacuumizing device is connected to the operating chamber; the elastic cushion is arranged on the lower pressing plate; and the upper pressing plate is driven by a second conveying assembly to be close to or far away from the elastic cushion. According to the display adhering technology and device, the height of the upper pressing plate and the product is measured; an elastomer with corresponding thickness is arranged to meet the product adhering requirement; the defect that the moving distance of the upper pressing plate cannot be controlled is overcome; in addition, the product adhering effect is improved under the springing-back effect of the elastomer; the adhering stability and the firmness are optimized; the problem that the product is damaged due to excessively high pressure of the upper pressing plate can beavoided; and the yield is increased.

Owner:深圳市一鑫智化科技有限公司

Hammer head with interference fit

ActiveUS20200171641A1Maximizes surface area overlapAvoid stress concentrationPlastic deformation fasteningShrinkage connectionsInterference fitStress concentration

A dead blow hammer head with end caps coupled to a central body through an interference fit. The ends of the body can be flared axially and radially outward and interference fit with the recesses to maximize the surface area overlap between the ends of the body and the recesses. By maximizing the surface area overlap, stress concentrations and failure are reduced. The hammer head can also include a shot or other mass that is unobstructed by screws or pins due to the interference fit of the hammer head components. The interference fit can become stronger during use with each impact further solidifying the surface area overlap between the ends and central portion of the hammer head.

Owner:SNAP ON INC

Bonding objects together

Owner:MULTIMATERIAL WELDING AG

Assembly comprising parts made of dissimilar metals and method of manufacturing same

Method of connecting process of the connecting member and the electromagnetic assembly made according to the process.A sealing member is fitted to the first member and the second member is fitted over the first member and the seal member.Lubricant is applied to the first member between the seal member to partially fill or occupy the region within the junction to prevent moisture from entering the connector and cause corrosion.Portion of the second member is deformed into a recess formed in a first member, to connect the first member and the second member.

Owner:FORD GLOBAL TECH LLC

Limiting jig and limiting press-fit device

ActiveCN113757237AImprove qualityReduced dimensional accuracy requirementsPlastic deformation fasteningMaterial gluingDimensional precisionPhysics

The invention relates to a limiting jig and a limiting press-fit device. The limiting press-fit device comprises the limiting jig and a pressure supply mechanism connected with the limiting jig, and the limiting jig comprises an upper die, a lower die and a limiting mechanism, wherein the upper die and the lower die are opposite up and down and can move up and down, and the limiting mechanism is arranged between the upper die and the lower die. The limiting jig is mainly provided with a limiting assembly at a workpiece alignment opening of a limiting module, and the upper die is provided with corresponding pressing and abutting assemblies at the positions corresponding to limiting assemblies. Therefore, the limiting jig and the limiting press-fit device can mainly utilize limiting structures of the limiting mechanism to be matched with pressing and abutting structures of the upper die, and thus in the press-fit operation process, the upper part and the lower part of a workpiece can be respectively pushed and positioned through pushing parts of the limiting structures, so that not only can the device be suitable for the press-fit operation of workpieces with various sizes, but also the size precision requirement of the workpiece alignment opening can be reduced, and the production cost of the dies can be further reduced.

Owner:HORNG TERNG AUTOMATION

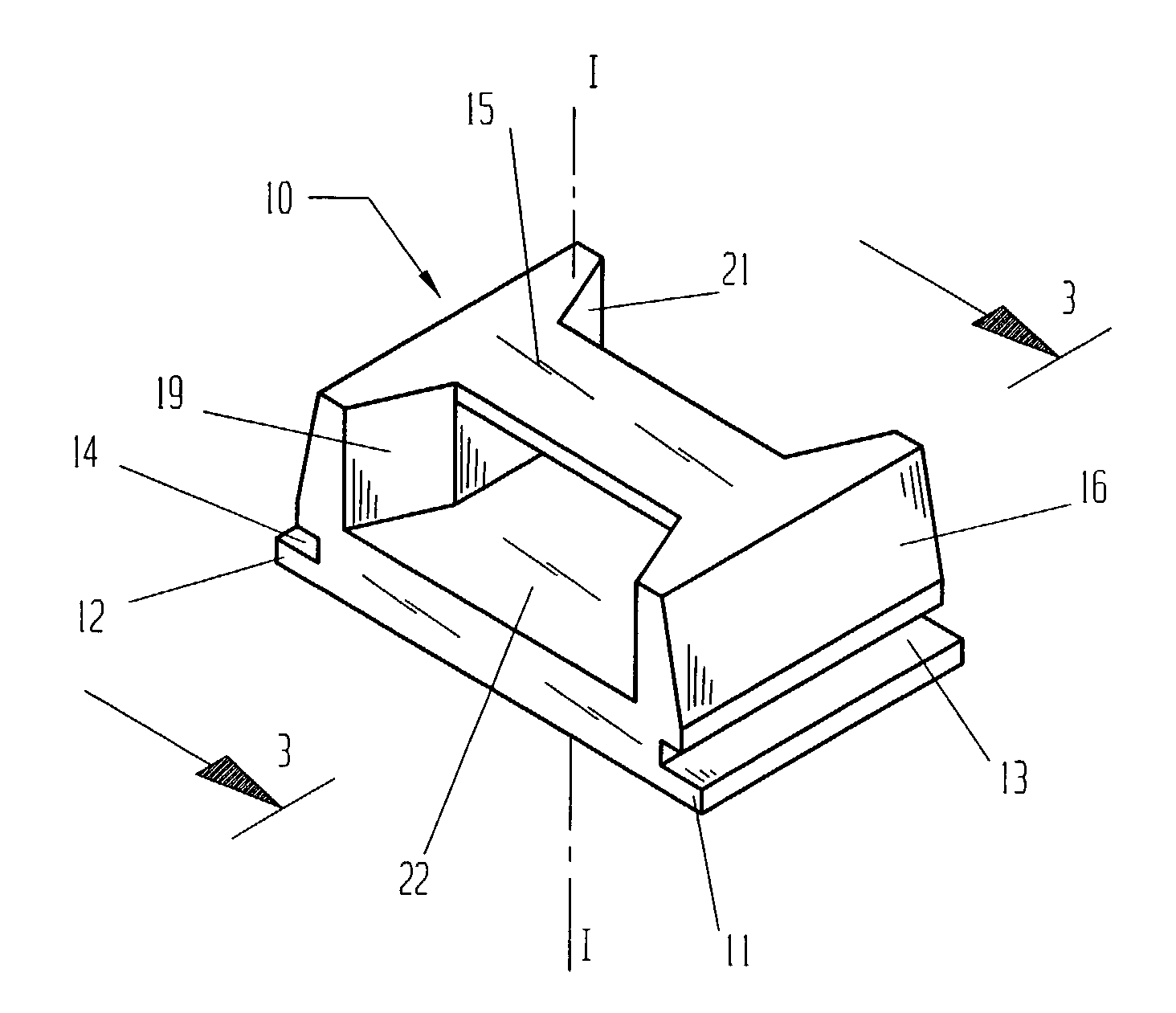

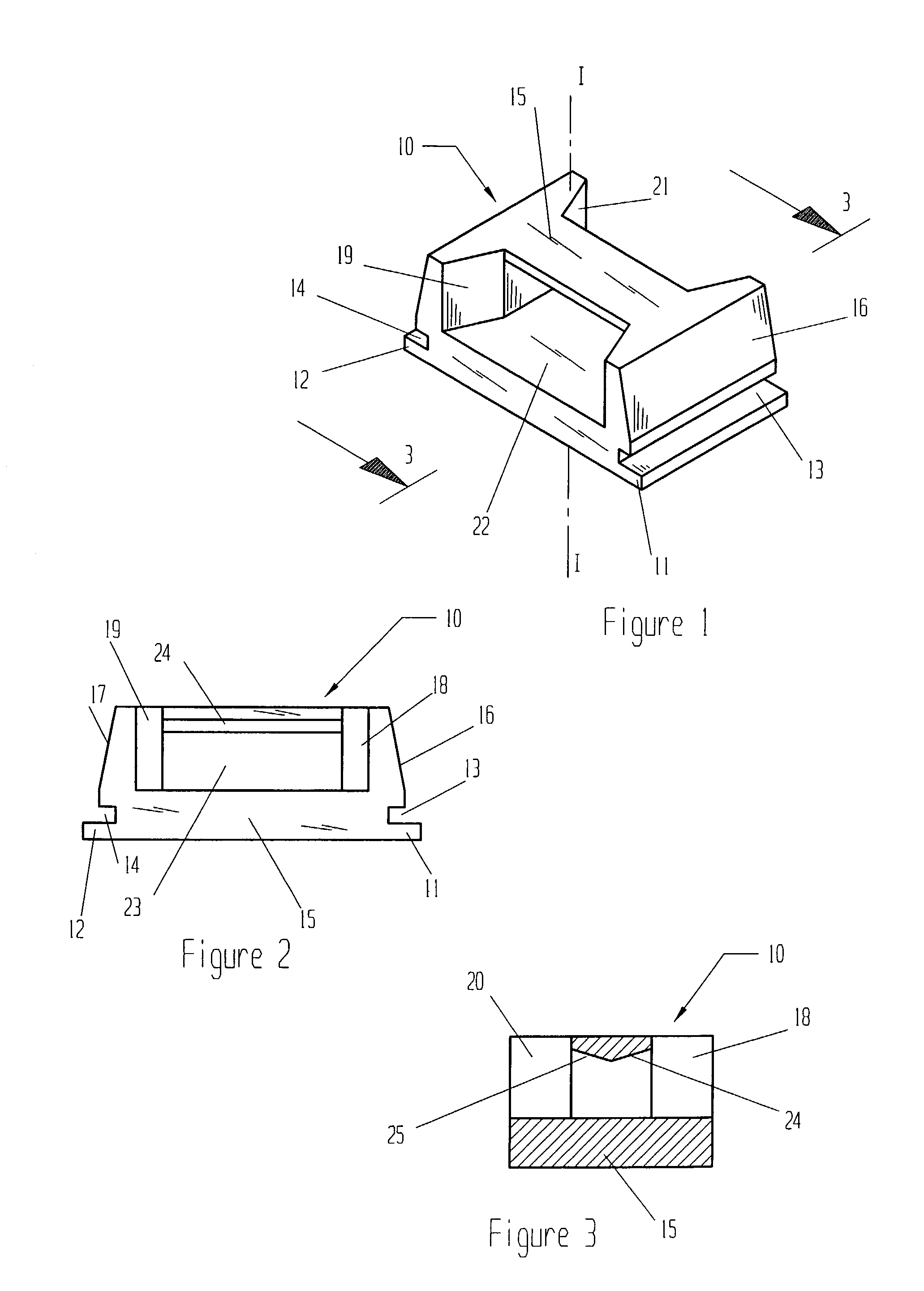

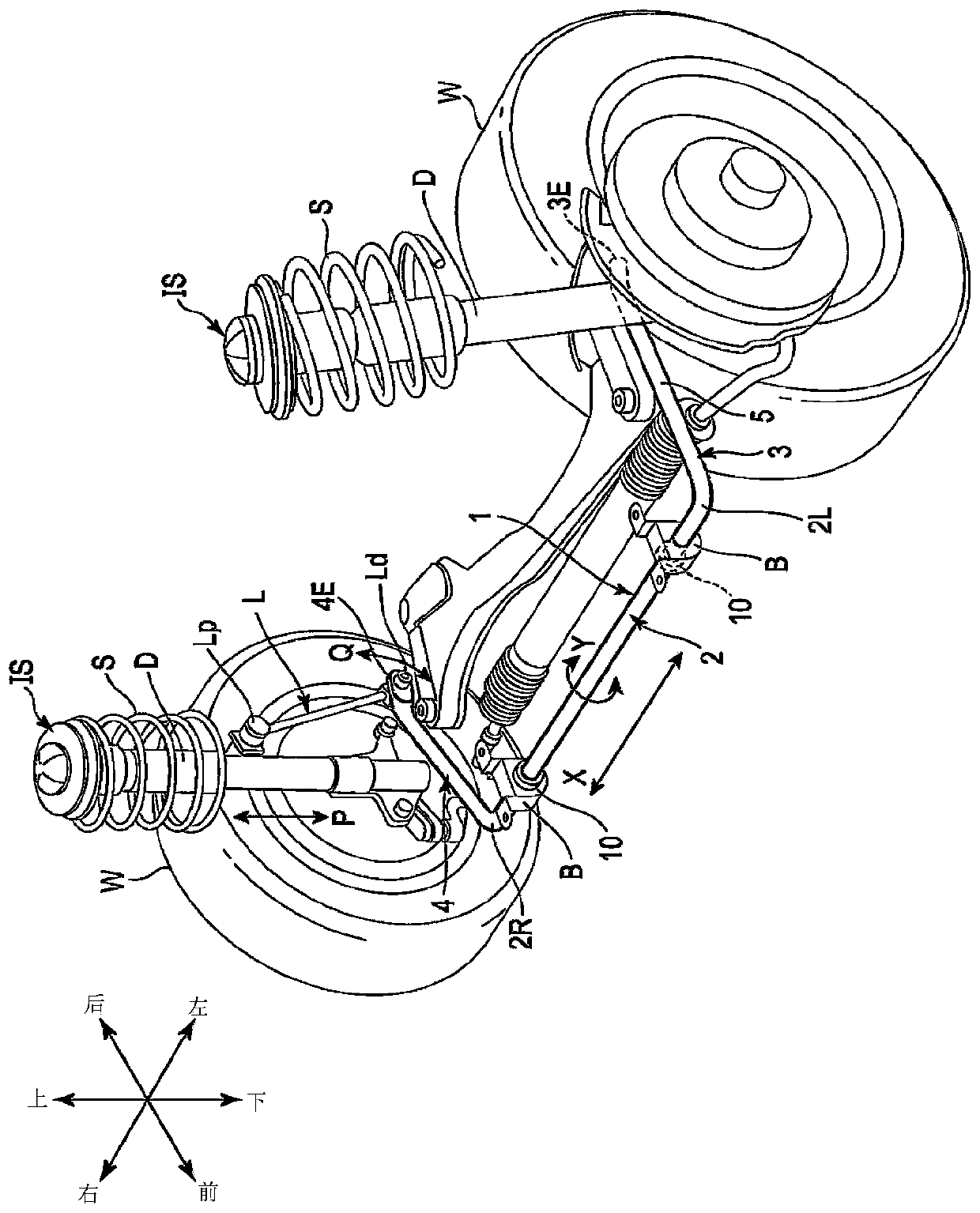

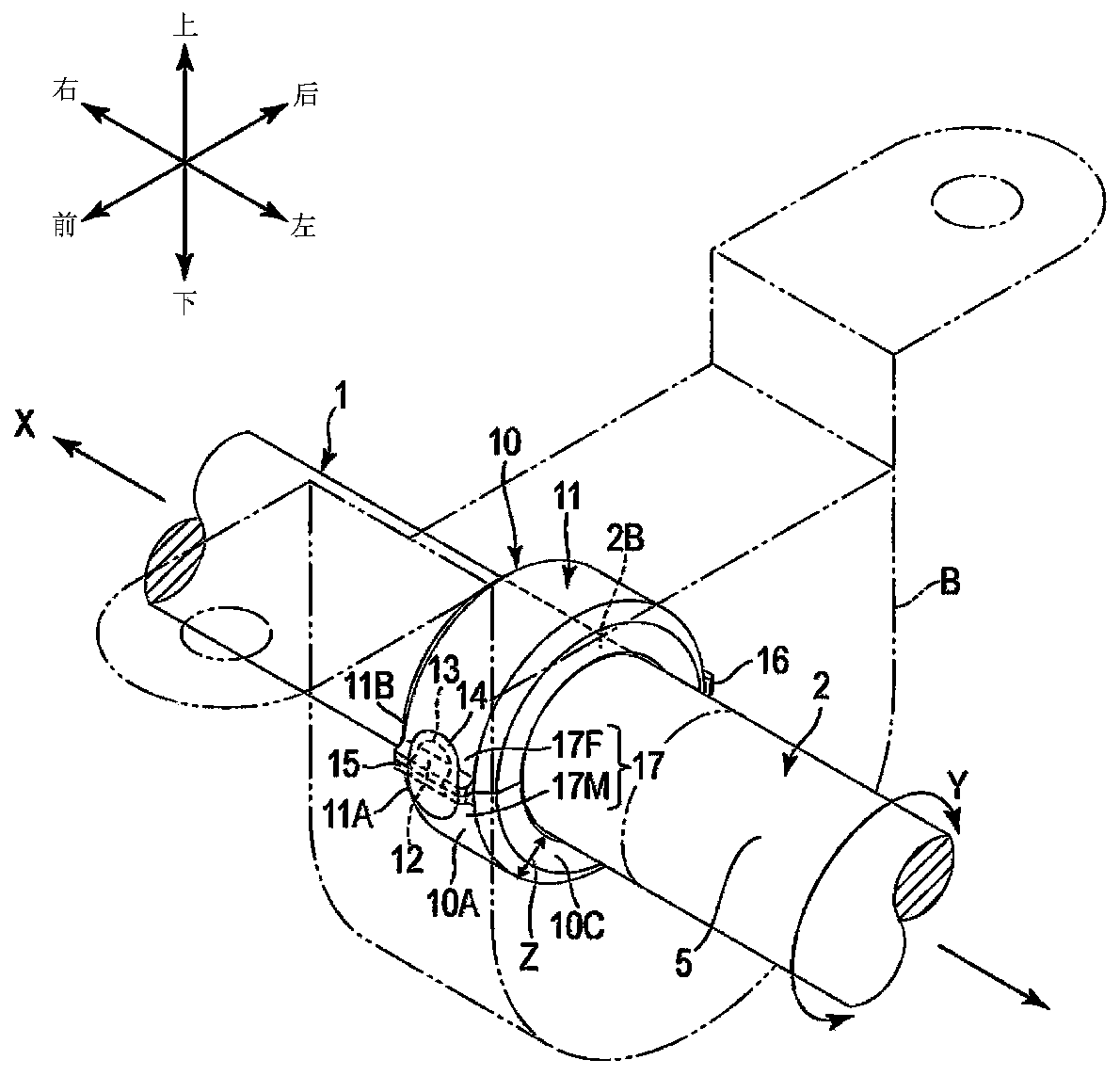

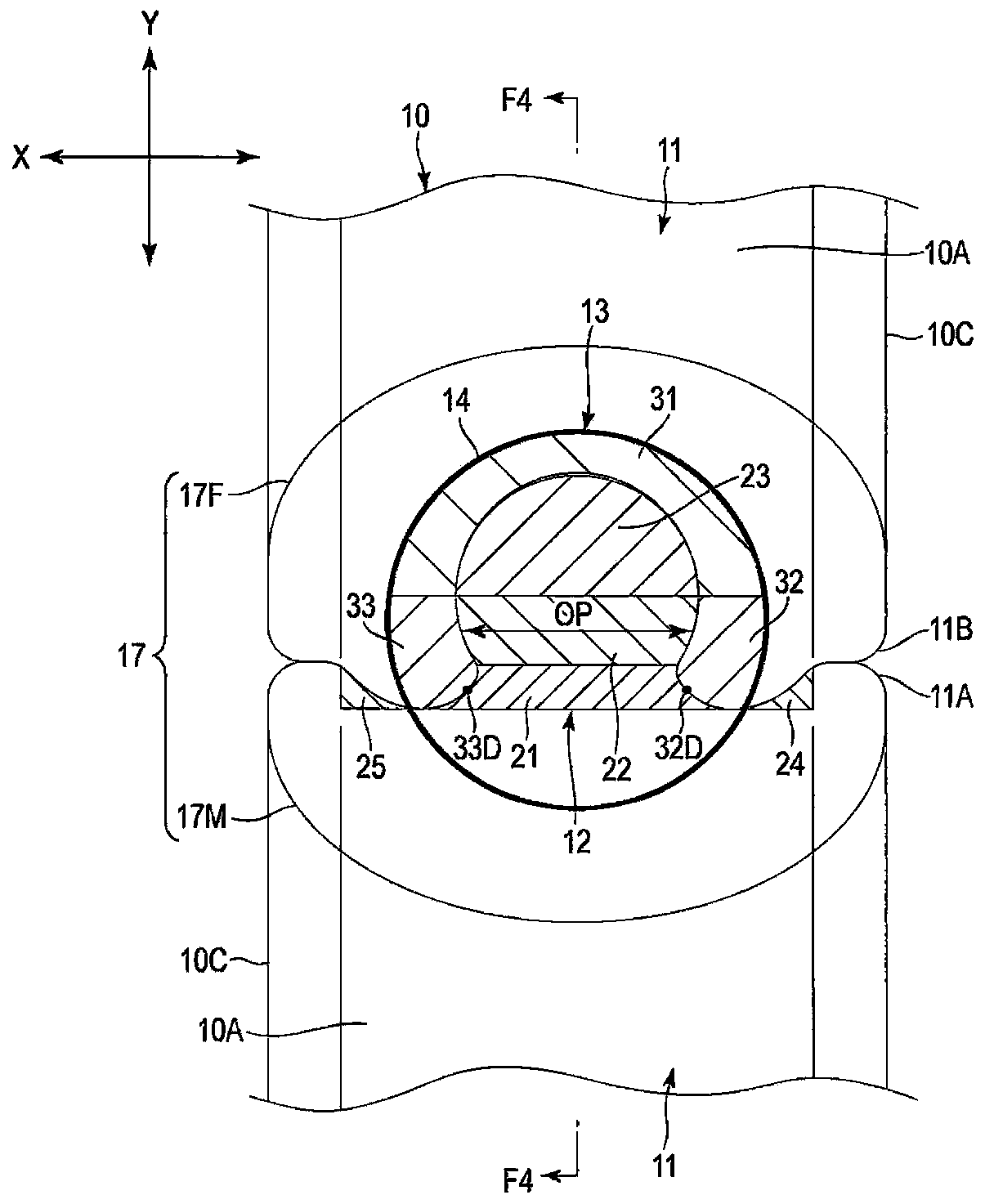

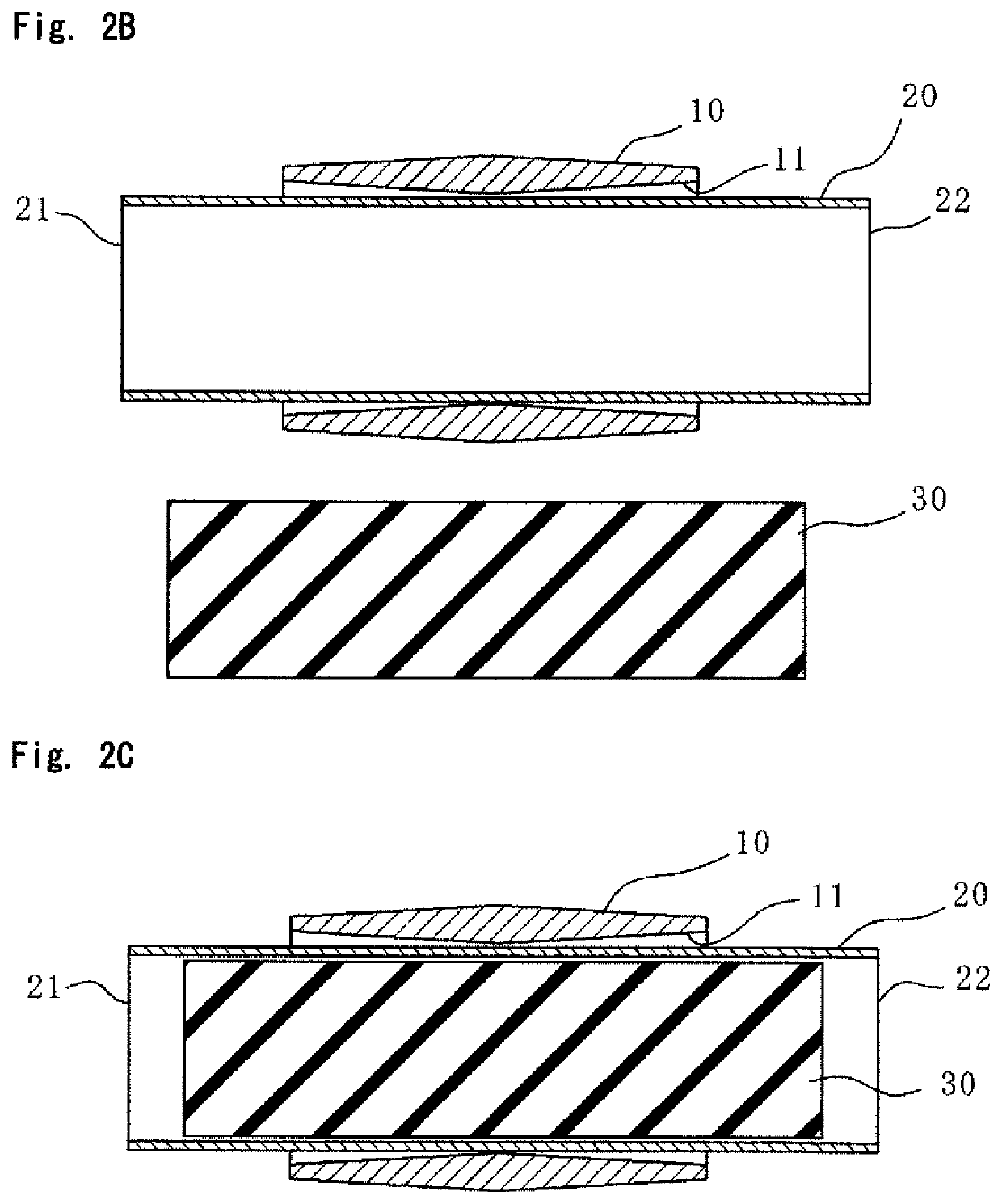

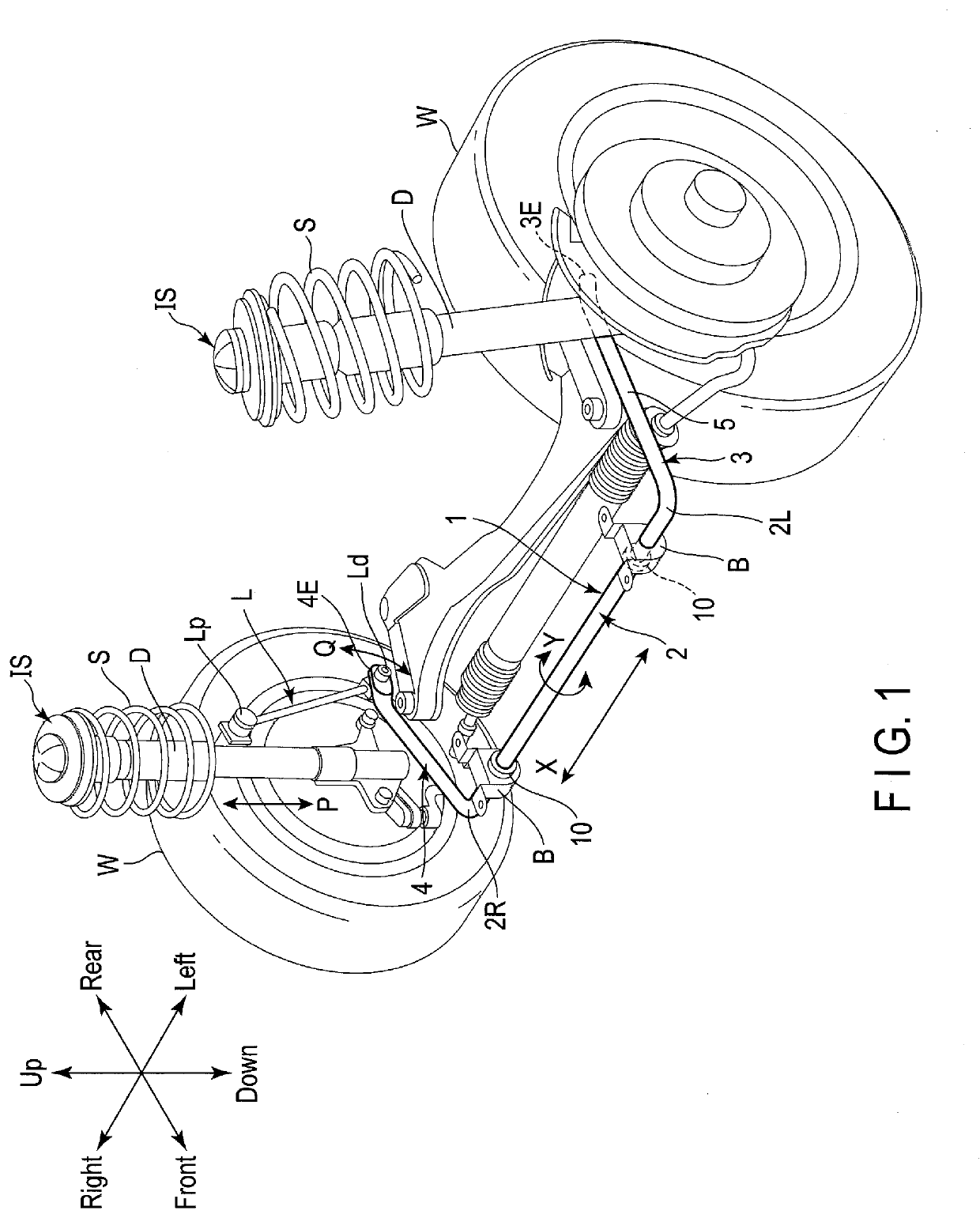

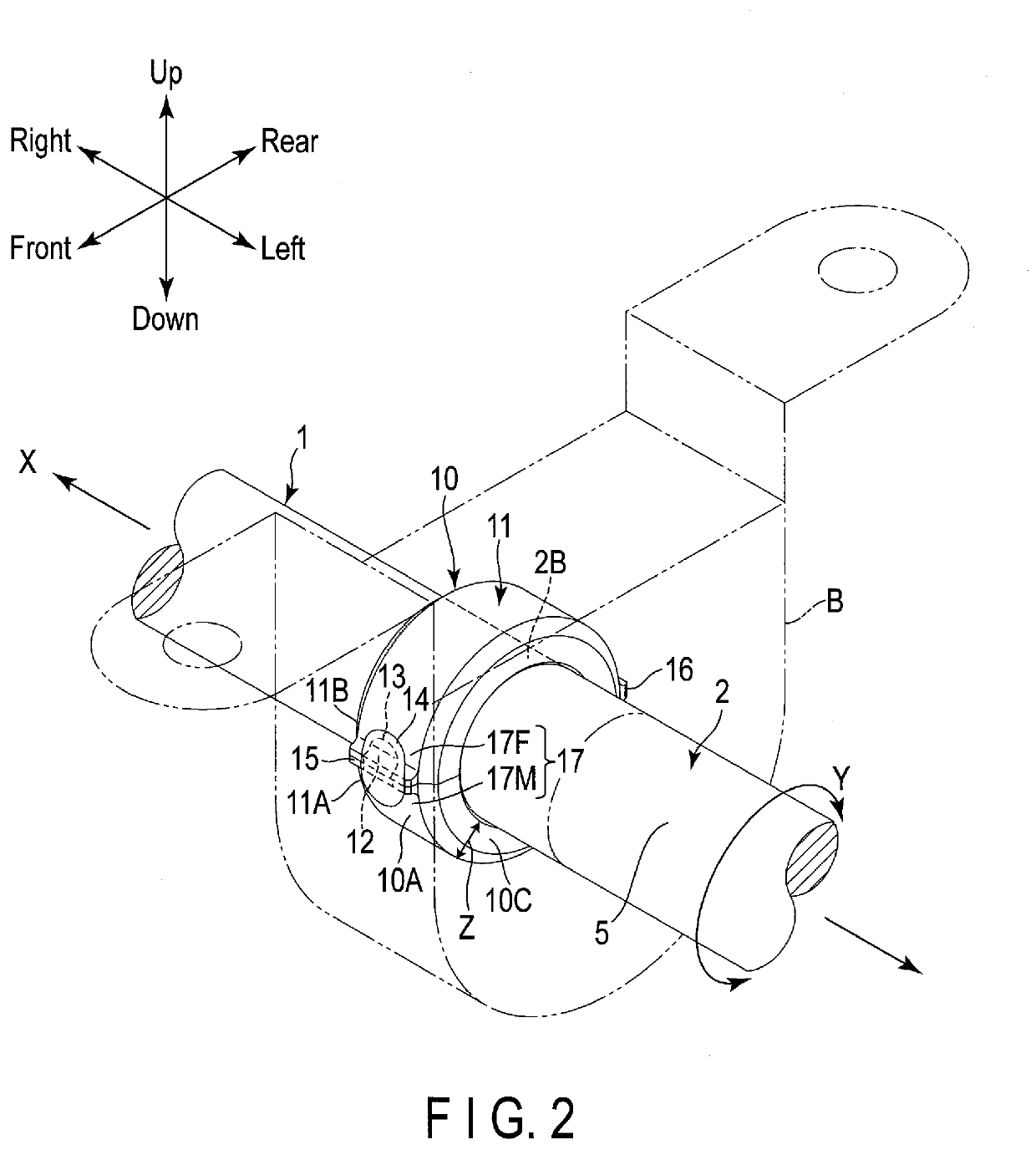

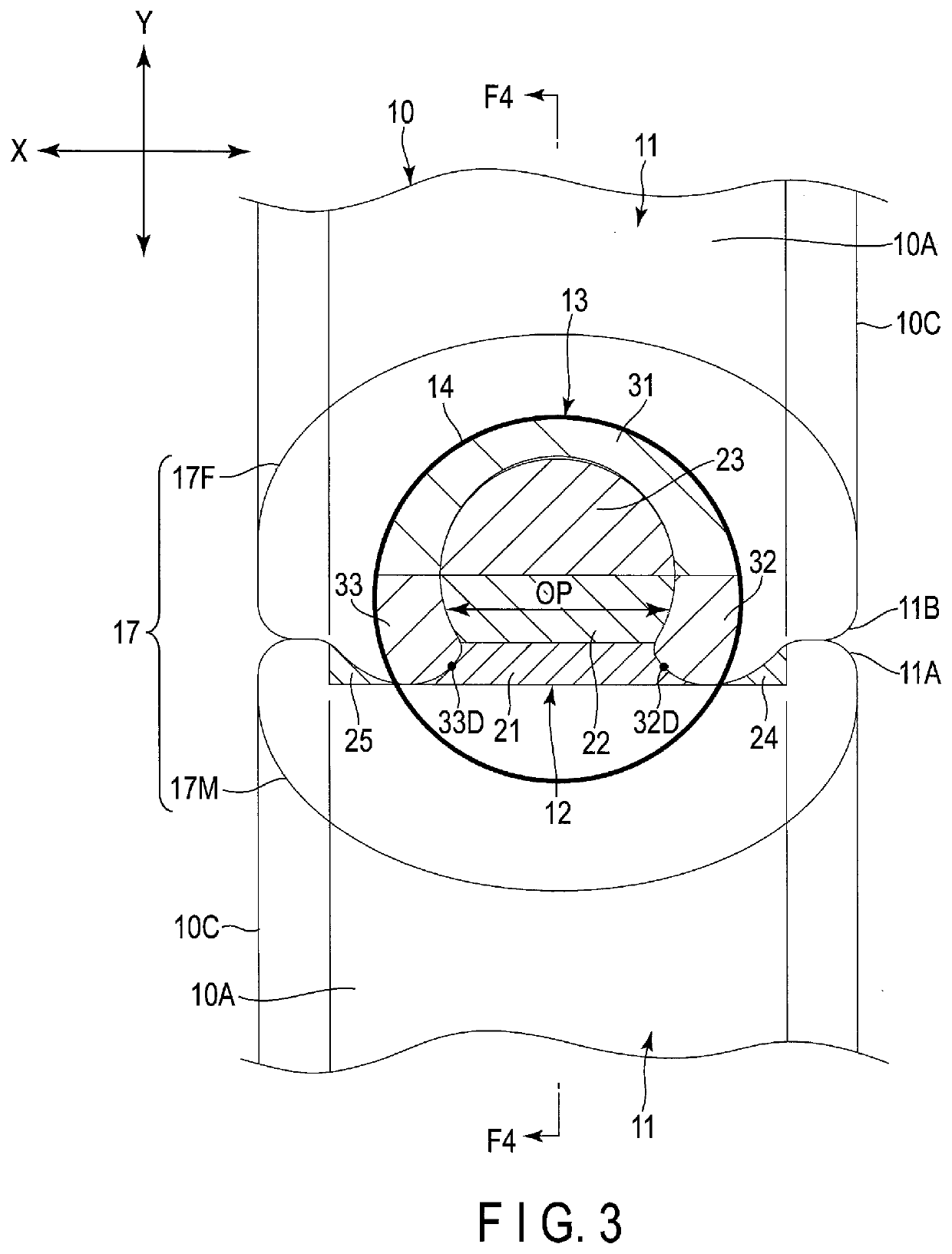

Vehicle stabilizer and method for manufacturing said stabilizer

ActiveCN110392639AAvoid position shiftPlastic deformation fasteningTorsion springsMechanical engineeringElectrical and Electronics engineering

The present invention provides a stabilizer (1) equipped with a restriction ring (10) that can withstand a large component force load. The stabilizer (1) is provided with a restriction ring (10) connected to a torsion portion (2) at a connection portion (2B) adjacent to a bush (B). The restriction ring (10) has a body (11), a female portion (13), a male portion (12), and a welded portion (14). Thefemale portion (13) has a pair of gripping portions (32, 33) with a spacing therebetween decreasing in the direction away from a valley bottom portion (31). The male portion (12) has a neck portion (21), an expansion portion (22), and a contraction portion (23). The welded portion (14) covers at least the range of the contraction portion (23) and the valley bottom portion (31) and melts in the plate thickness direction (Z) from the outer peripheral surface (10A).

Owner:NHK SPRING CO LTD

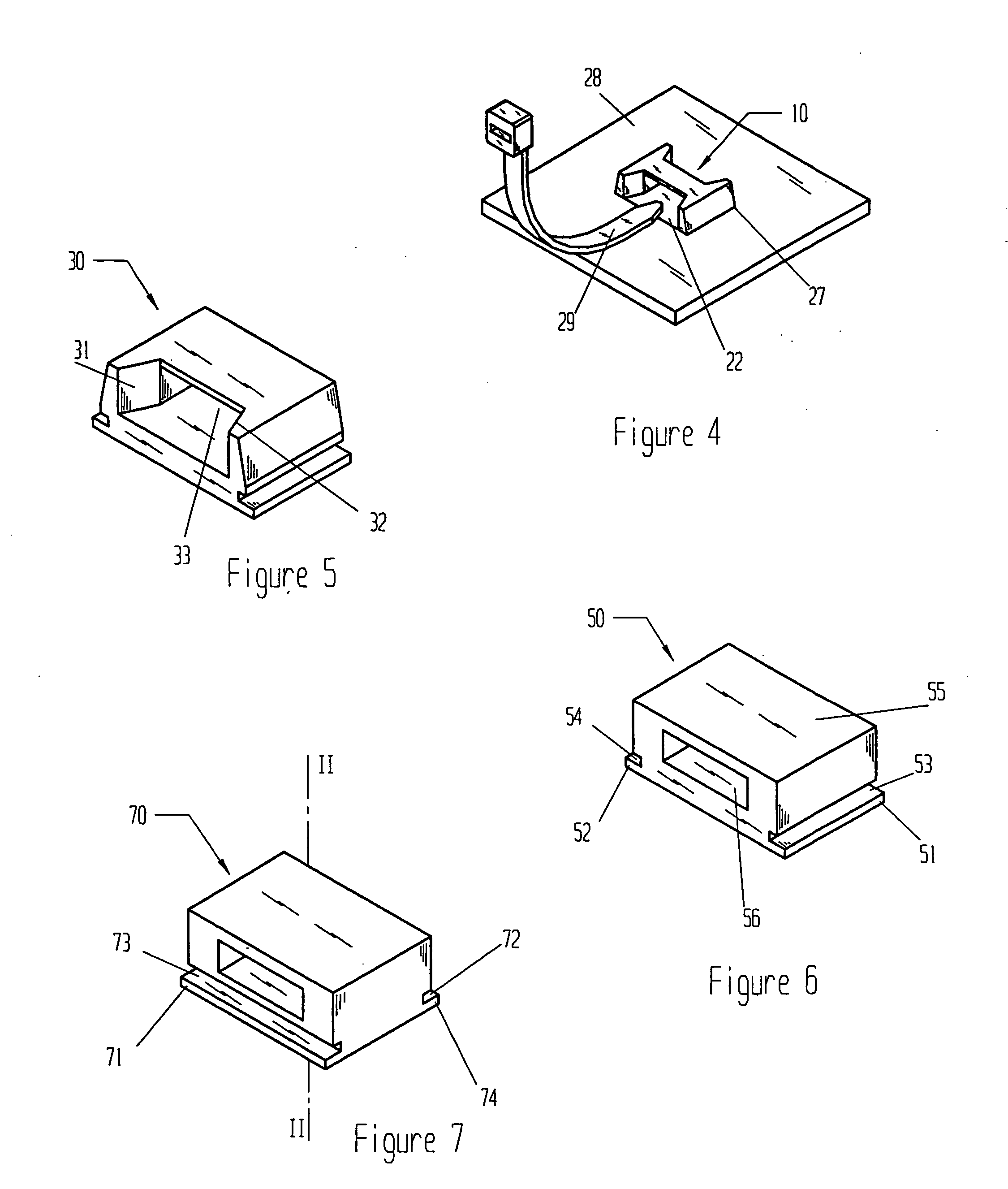

Self-clinching cable tie mount

InactiveUS20060027717A1Improve carrying capacityShorten assembly timePipe supportsPlastic deformation fasteningThin sheetElectrical and Electronics engineering

A self-clinching fastener that when pressed into a thin sheet panel provides for a strong attachment point for a cable tie. The inventive fastener relies on the self-clinching process to carry external loads and thus carries larger loads when compared to adhesive backed cable tie mounts. When installed, the self-clinching fastener becomes flush with the far side of the sheet panel.

Owner:WINTON GEORGE R III

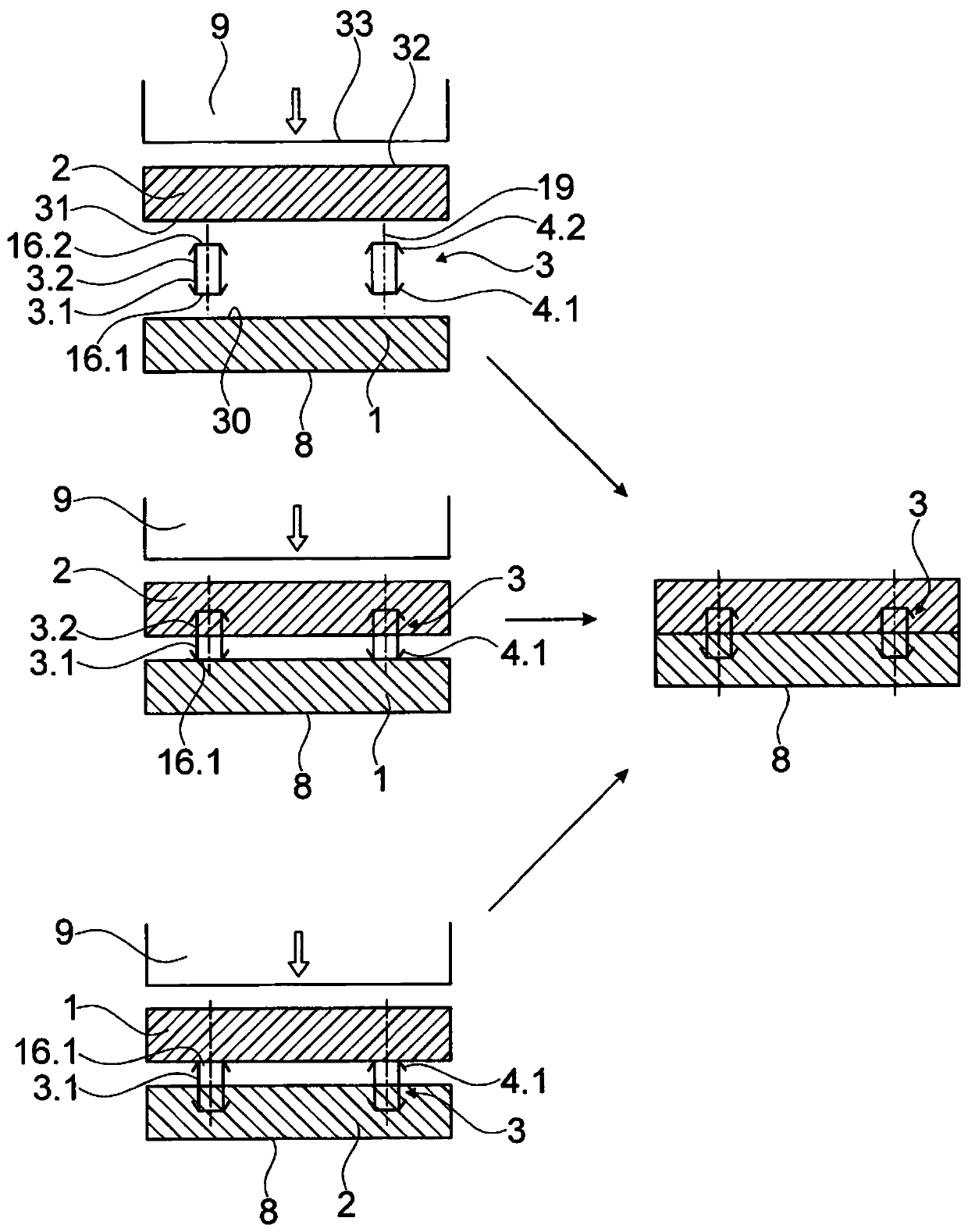

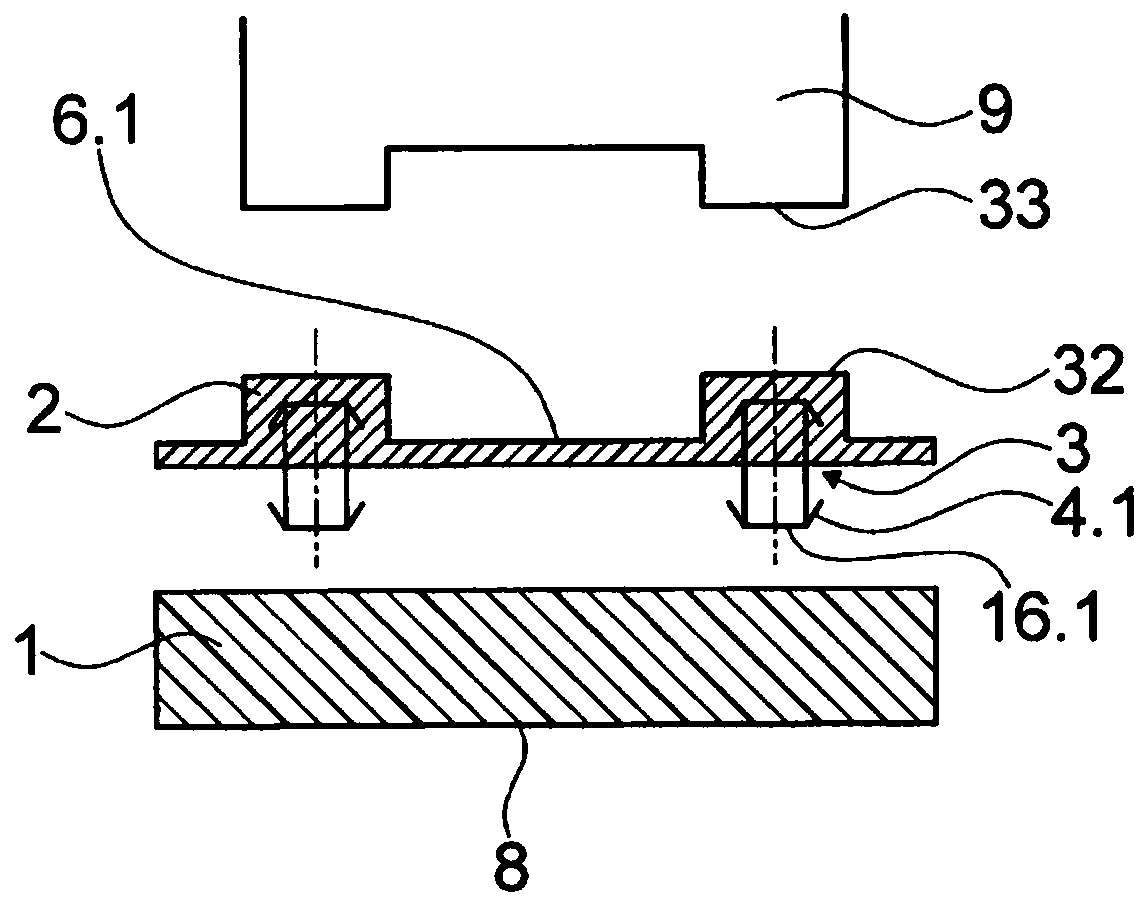

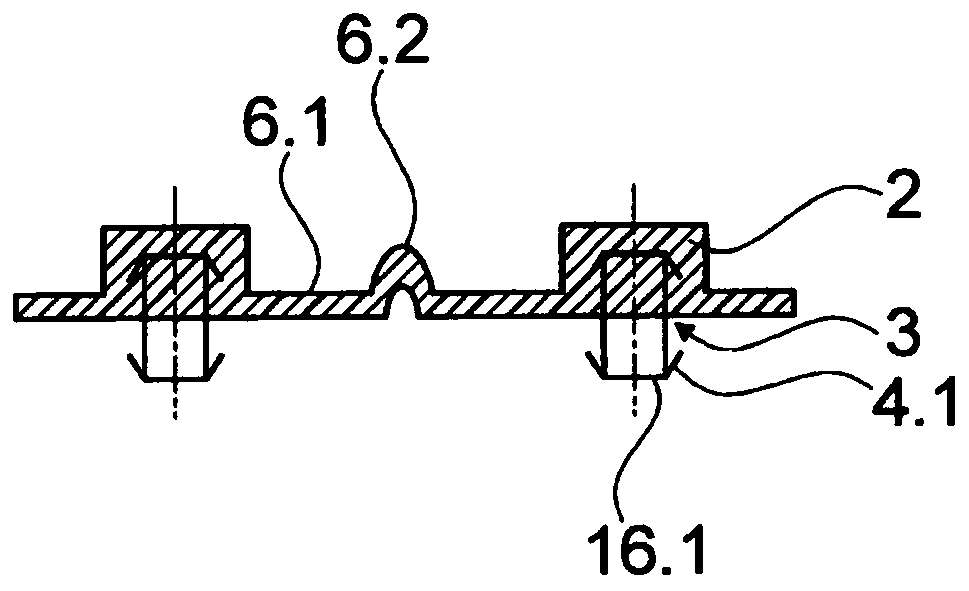

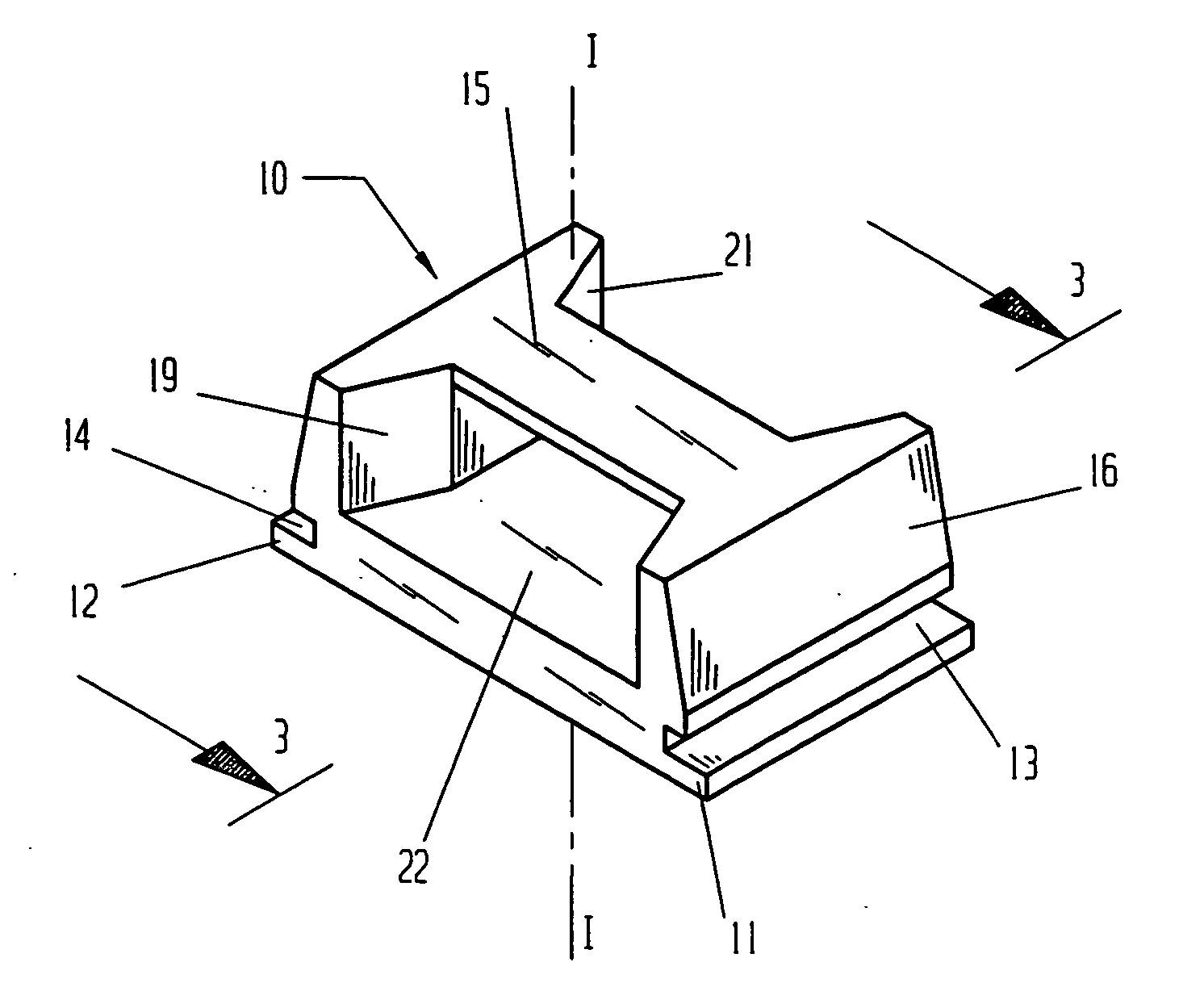

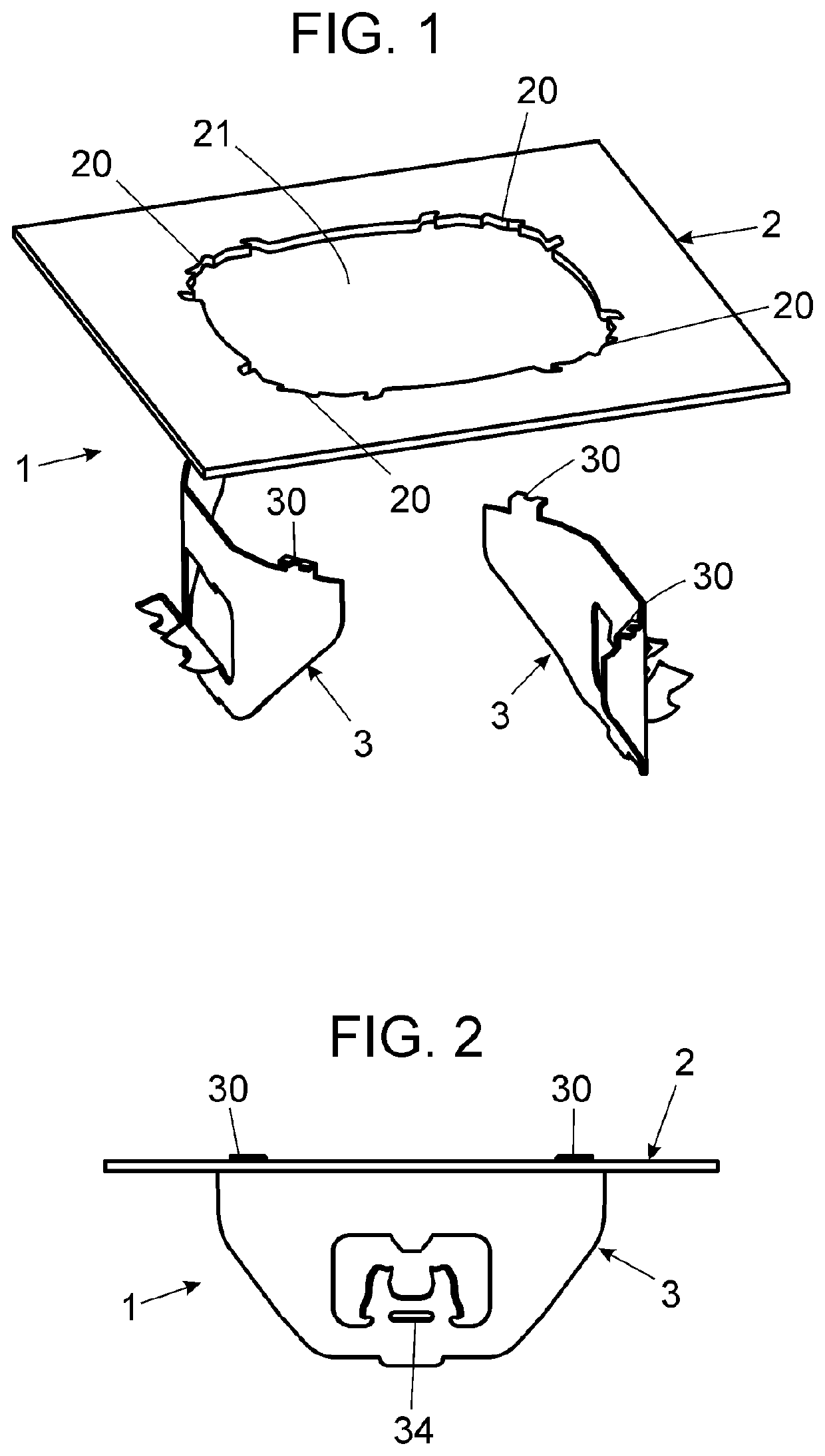

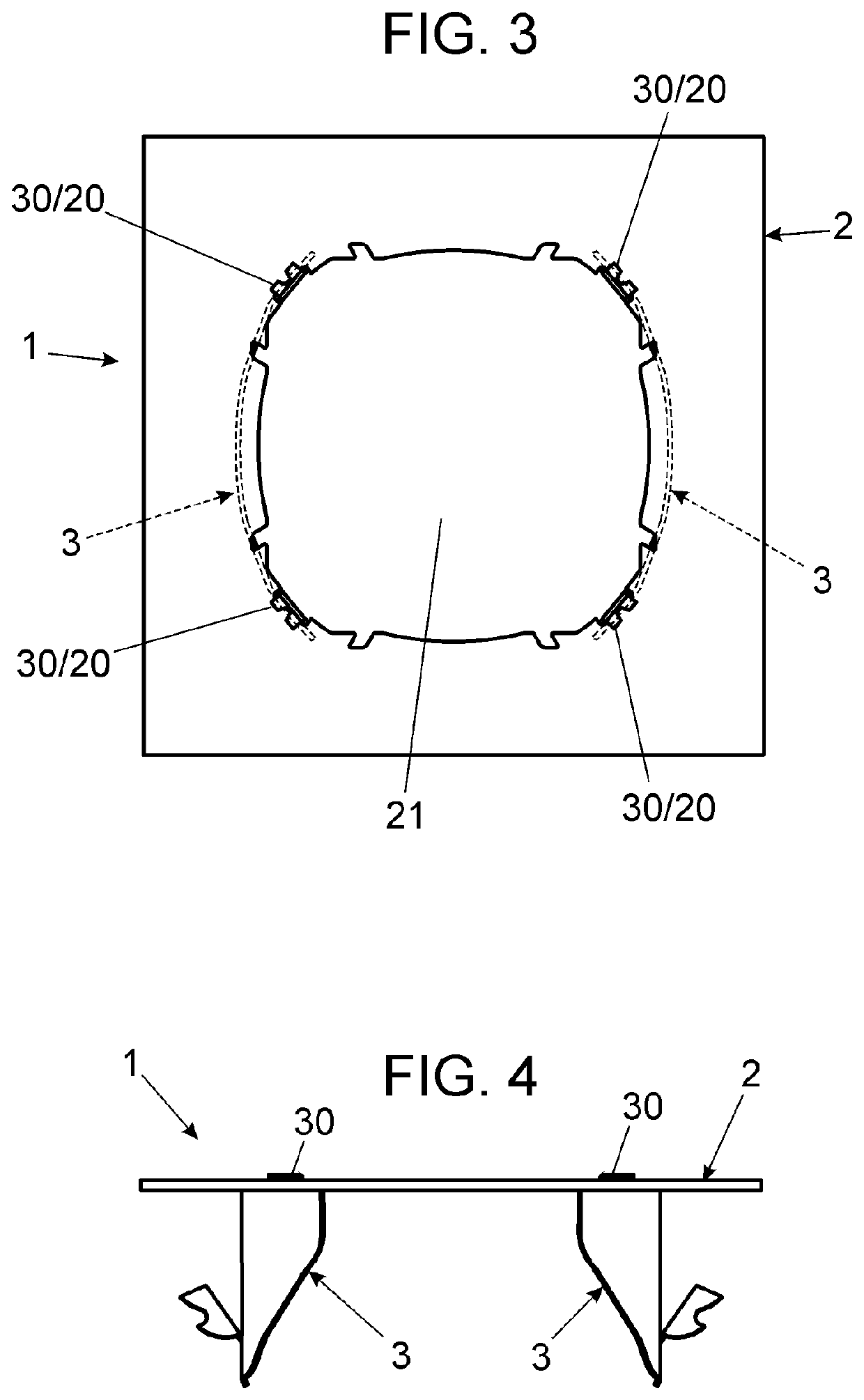

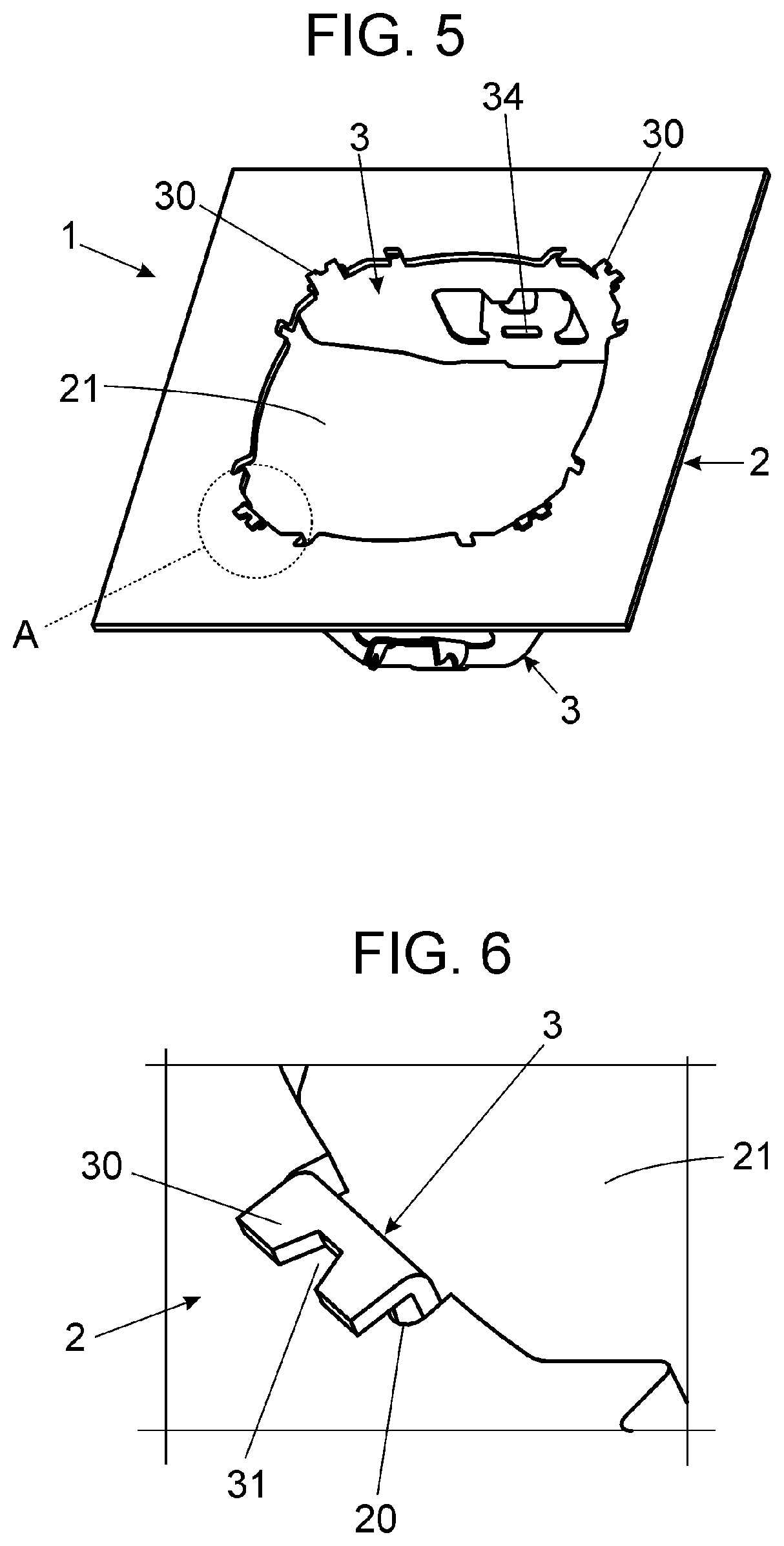

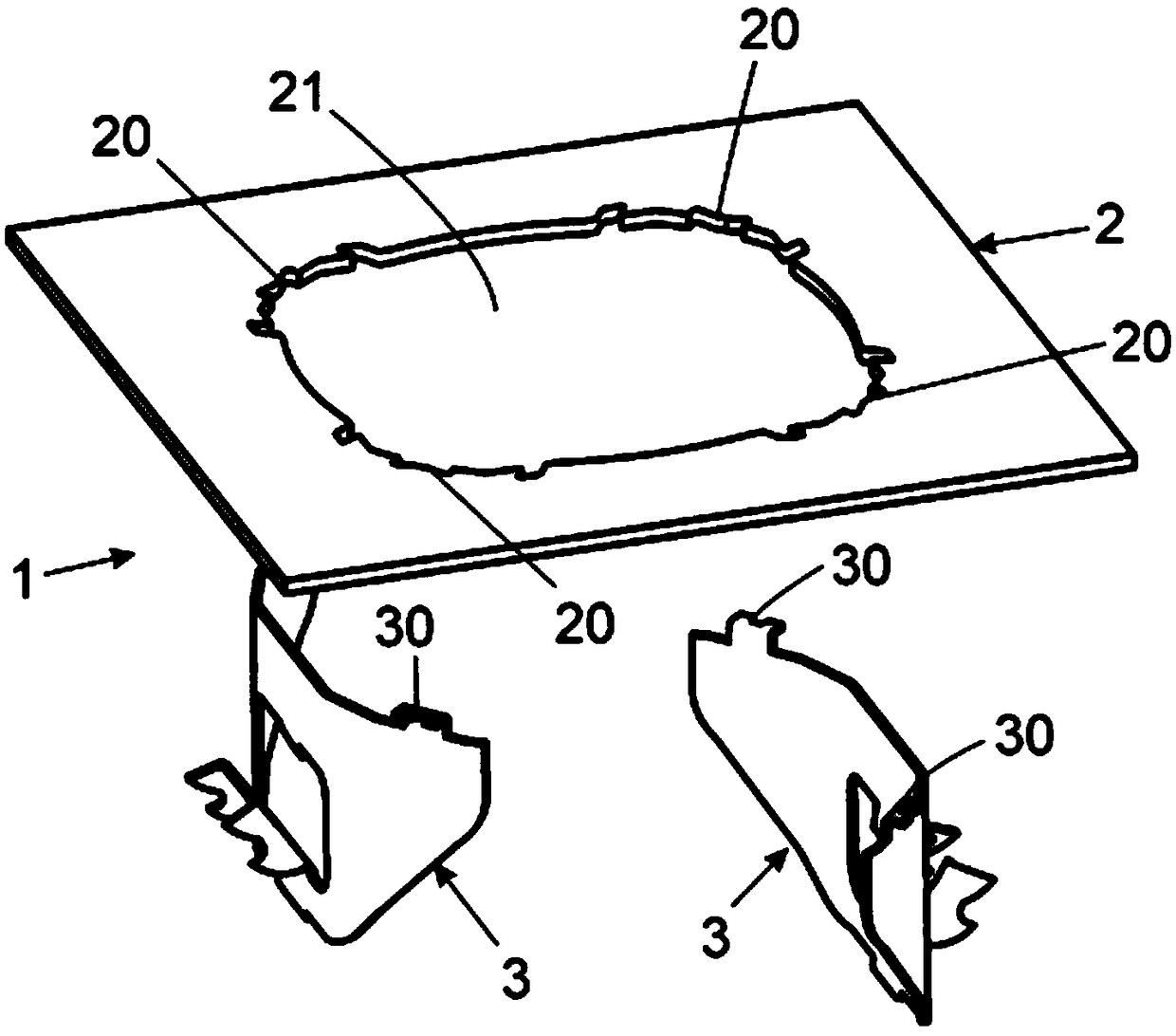

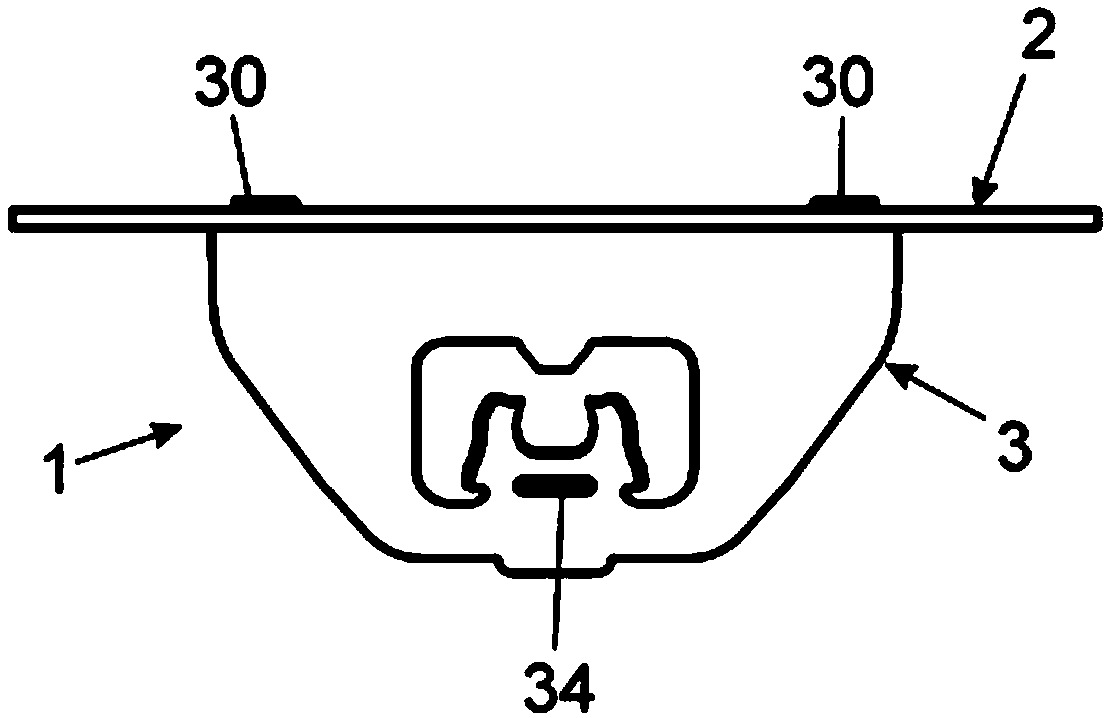

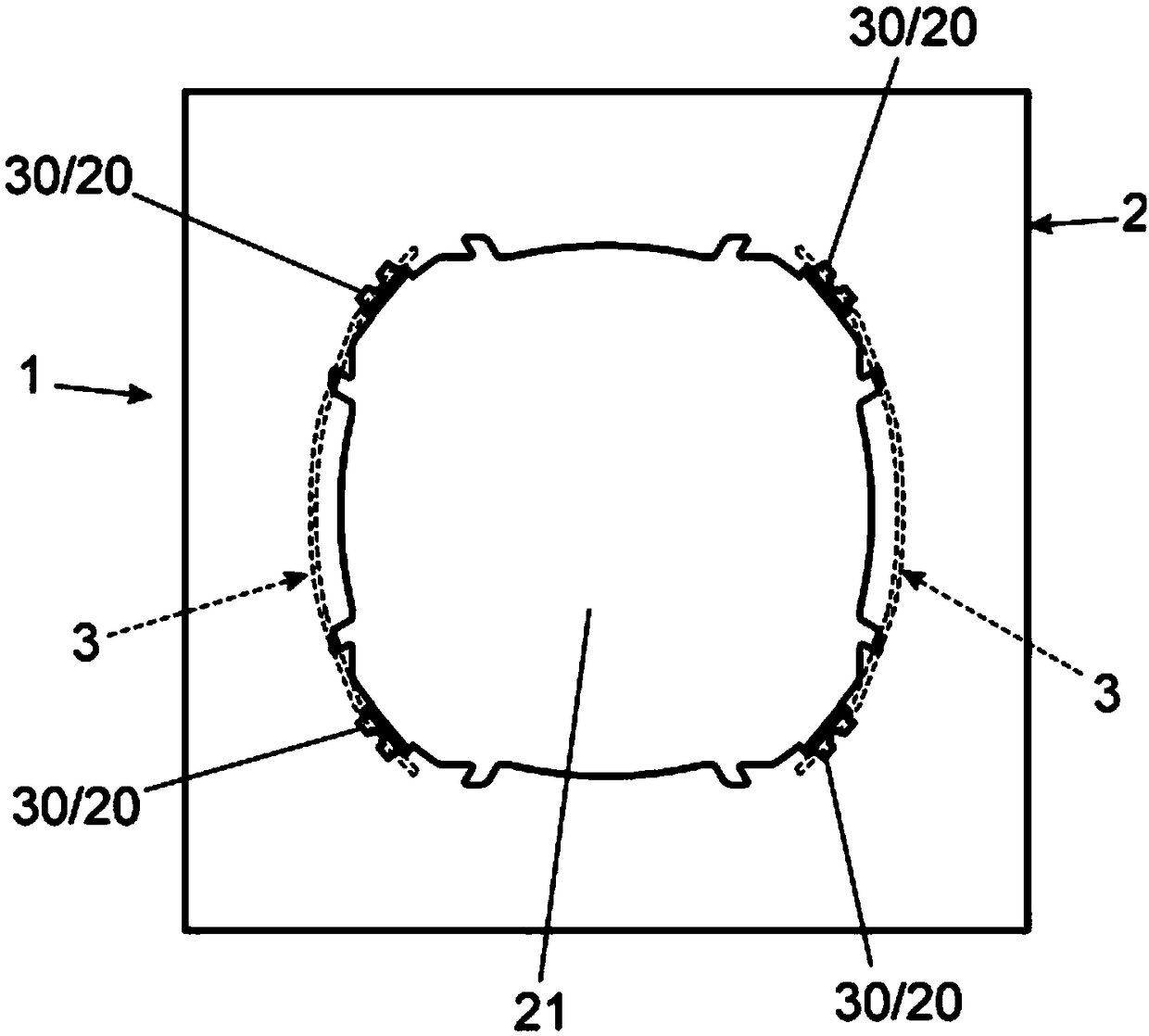

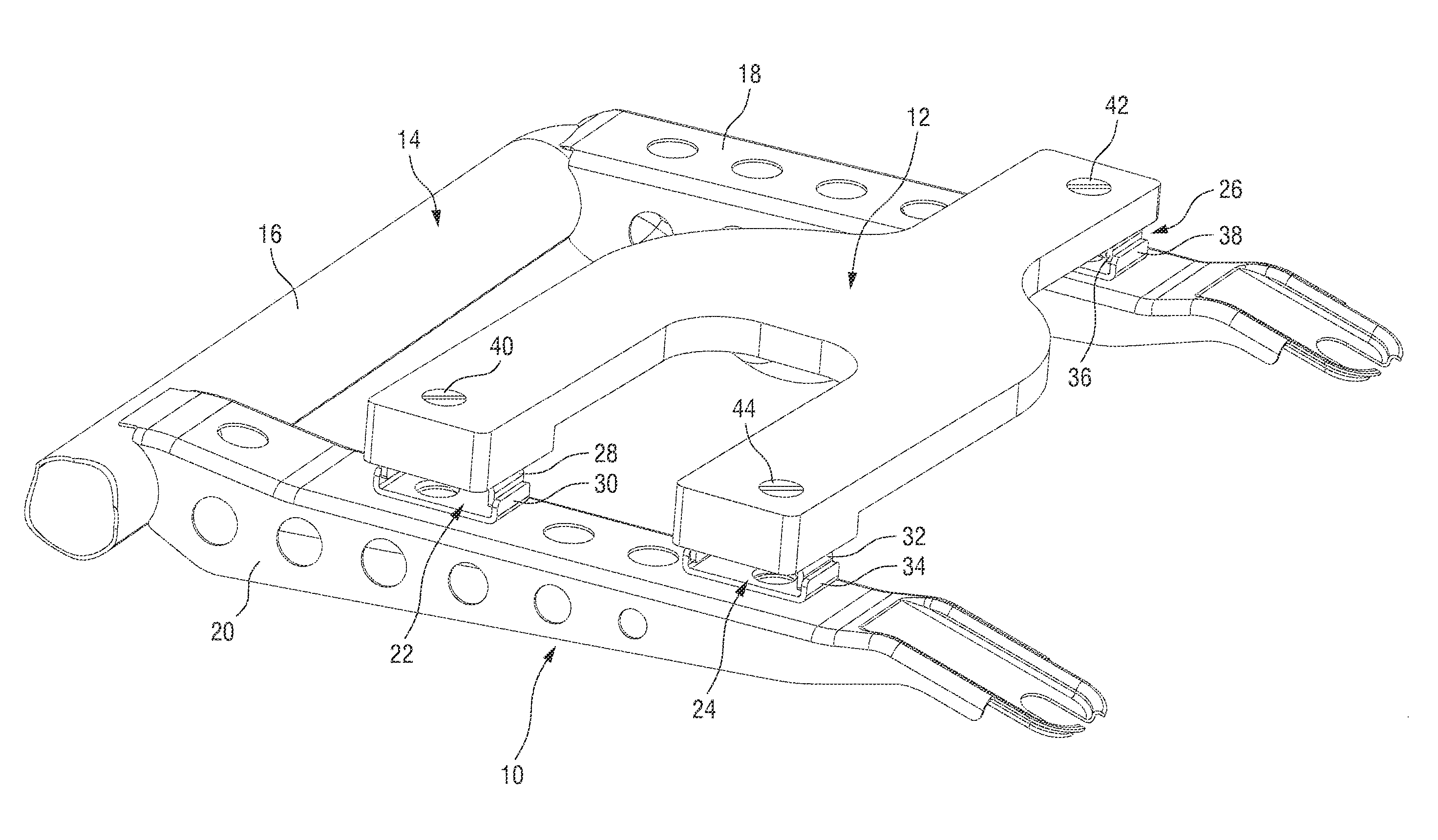

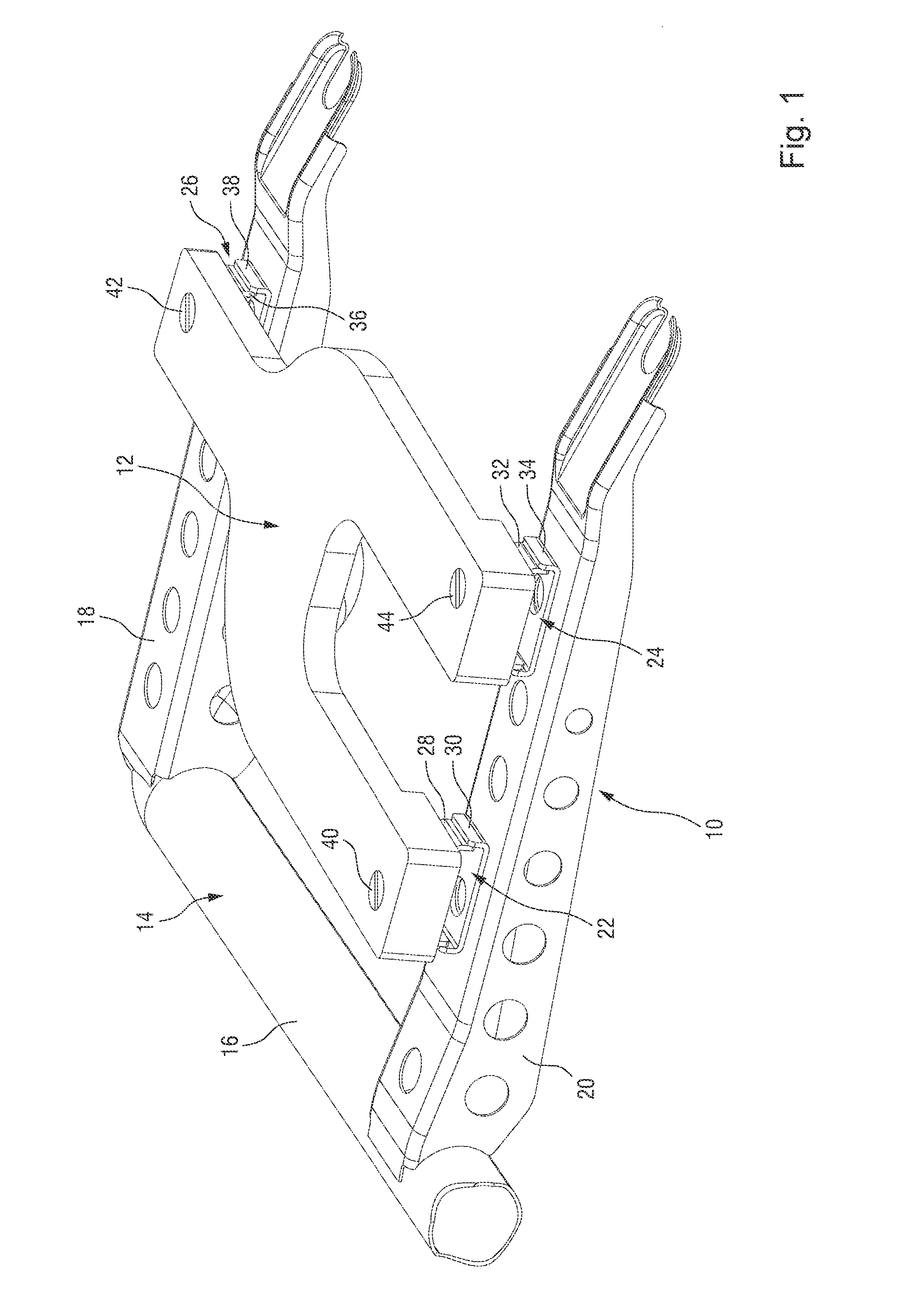

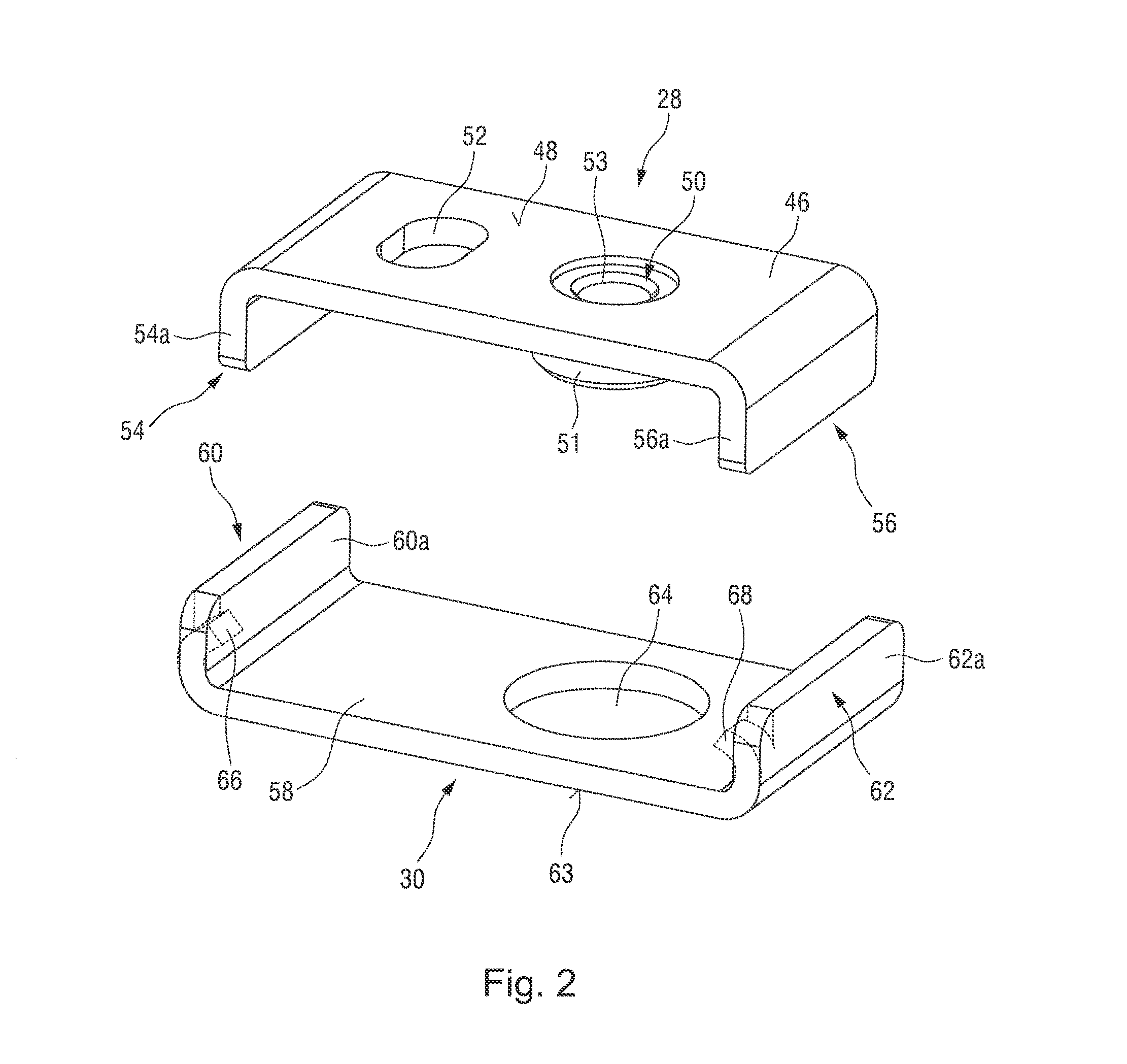

Fastening assembly for electric and/or electronic devices that can be built-in

InactiveUS20210222715A1Avoid the needOptimizing effectivityPlastic deformation fasteningCoupling device detailsElectric devicesSupport point

A fastening assembly for electric and / or electronic devices that can be built in includes a frame (2) and claws (3) adapted to secure the frame (2) to the wall or box where it is built-in, showing at least two claws (3) of which at least one is flexible and independent from the frame (2) and can be joined to the frame (2) by temporarily deforming the claw (3) generating when joined to the frame (2) at least three unaligned bearing points between the claw (3) and the frame (2). The frame (2) includes at least one hollow (21) and at least two supporting points (20), and the claw (3) two bearing points (30), can be introduced in the hollow (21) of the frame (2) and when the claw (3) is released, the the bearing points (30) or clipping flanges are coincident with the supporting points or mortises (20) of the frame (2).

Owner:SIMON SA

Method for joining members, and joint body

ActiveUS11052446B2Plastic deformation fasteningShrinkage connectionsEngineeringStructural engineering

A method for joining members includes: providing a wall surface body which is a die-molded article provided with a hole portion with a draft angle provided from its opposite end portions toward its center portion, a tubular body with a hollow shape, and an elastic body; inserting the tubular body into the hole portion in the wall surface body; inserting the elastic body into the inside of the tubular body; and compressing the elastic body in the direction of an axial line L of the tubular body to expand the elastic body outwardly in the radial direction of the axial line L, thereby deforming and expanding the tubular body to joint the tubular body to the wall surface body by press-fitting.

Owner:KOBE STEEL LTD

Pressure holding equipment

ActiveCN111022455BConducive to maintaining pressureEasy to installPlastic deformation fasteningMaterial gluingHeadphonesMechanical engineering

The invention discloses a pressure maintaining device, which is used for pressure maintaining earphones. The pressure maintaining device includes: a base; It includes a sliding platform assembly slidably arranged on the base, a pressure maintaining assembly and a pressure head, the pressure maintaining assembly is movably arranged between the carrier and the sliding platform assembly, and the sliding platform assembly is set There is a first slope surface, and the side of the pressure maintaining component facing the slide assembly is rotatably provided with a first roller, the first roller abuts against the first slope surface, and the pressure head is set on The end of the pressure maintaining component away from the base is used for pressure maintaining the earphone. The present invention aims to provide a pressure-holding device capable of maintaining pressure well on small-volume electronic products, and the pressure-holding device can effectively provide assembly stability of the product.

Owner:GOERTEK INC

Assembly for securing built-in electronic and electrical devices

InactiveCN109155511APromote technical levelPlastic deformation fasteningCoupling device detailsElectrical devicesEngineering

The invention relates to an assembly for securing built-in electronic and electrical devices. The assembly comprises a frame (2) suitable for securing an electrical and / or electronic device and claws(3) suitable for fixing the frame (2) to the wall or box into which it is built. The assembly has at least two claws (3) of which at least one is flexible and independent of the frame (2) and can be attached to the frame (2) by means of the temporary deformation of the claw (3), thus generating, once attached to the frame (2), at least three non-aligned support points between the claw (3) and theframe (2). The frame (2) comprises at least one hole (21) and at least two holding points (20), and the claw (3) comprises two support points (30) which can be inserted into the hole (21) of the frame(2) when the claw is deformed, and when the claw (3) is released, the support points (30) or clipping tabs coincide with the holding points (20) or slots of the frame (2). The claw (3) has a U-shapedcross section that reduces when pressure is applied, and when the pressure is released, the distance increases and the clipping tabs (30) remain fixed in the slots (20). The tabs (30) have a recess (31). The claw (3) has a groove (34).

Owner:SIMON SA

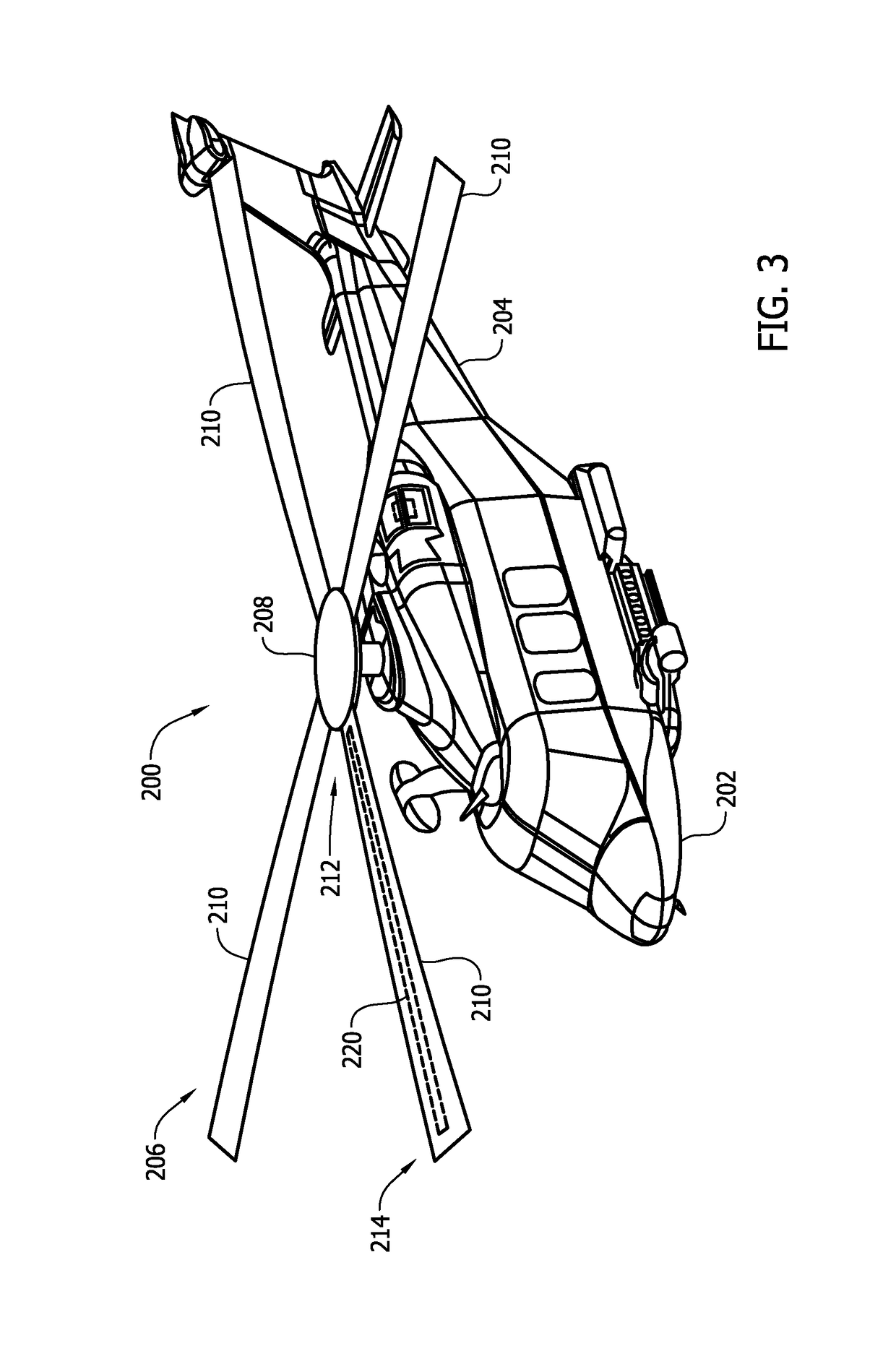

Joint assembly and method of forming thereof

ActiveUS10167075B2Facilitate restricting movementFacilitate restricting movement of tipPropellersPlastic deformation fasteningEngineering

A joint assembly includes a first component formed from a first material and a second component including a portion that extends at least partially into the first component and that has an uneven outer profile. The first material is configured to form the first component into a shape that is substantially complementary to a shape of the portion to facilitate restricting movement of the second component in an axial direction.

Owner:THE BOEING CO

A high-temperature superconducting tape packaging device and method

ActiveCN108223518BAchieve continuous and stable preparationGood effectSuperconductors/hyperconductorsPlastic deformation fasteningMetalWelding

The invention relates to a packaging device and method for high-temperature superconducting strips, which are used for packaging at least two strips together. The packaging device is composed of one or more groups of rollers arranged in different ways, in which the core component roller is a non-metallic elastic wheel or a metal wheel with a non-metallic elastic coating on the surface. On the one hand, the elastic rolling design ensures uniform resistance and pressure in the entire strip width direction. On the other hand, the multi-set roller packaging design ensures continuous and reliable packaging of stainless steel strips. Encapsulation methods are also provided. The superconducting strip produced by the packaging method and device provided by the present invention has the beneficial effects of low cost, high yield, etc., and can also achieve stable preparation of superconducting thin strips and stainless steel encapsulated superconducting strips.

Owner:NORTHEASTERN UNIV LIAONING

Vehicle stabilizer and method of manufacturing the same

ActiveUS20200009937A1Heavy loadAvoid displacementTorsion springsPlastic deformation fasteningStructural engineeringMechanical engineering

A stabilizer is provided with a restriction ring connected to a torsion portion at a connection portion adjacent to a bush. The restriction ring has a body, a female portion, a male portion, and a welded portion. The female portion has gripping portions with a spacing therebetween decreasing in the direction away from a valley bottom portion. The male portion has a neck portion, an expansion portion, and a contraction portion. The welded portion covers at least the range of the contraction portion and the valley bottom portion and melts in the plate thickness direction from the outer peripheral surface.

Owner:NHK SPRING CO LTD

Pen type auxiliary tool in resistance strain gauge pasting process

ActiveCN112361951AUncontrollableFixes an issue where strain gages would slip when pressedPlastic deformation fasteningMaterial gluingEngineeringStrain gauge

The invention discloses a pen type auxiliary tool in a resistance strain gauge pasting process. A pen point is connected with a pen body through threads, a pen tail is connected with the pen body through threads, an air bag is arranged in a cavity in the pen body and the pen tail, the front end of the air bag is pressed on a step flange on the inner wall of the pen body through an air bag front end pressing ring, a through notch is formed in the middle of the pen body,an air bag compression button is arranged in the circumferential direction of the air bag, and the air bag compression button is embedded in and penetrates out of the notch. According to the invention, the problems of difficulty in controlling the sticking direction of a strain gauge and sliding of the strain gauge during pressing in the traditional strain gauge sticking process in engineering test are effectively solved, and the pen type auxiliary tool is simple in structure, common in material, low in cost, easy to realize, novel and unique, and solves the problems in the traditional strain gauge sticking process in engineering test conveniently and quickly, and the pasting quality of the strain gauge is ensured.

Owner:水利部产品质量标准研究所

Method for producing a fastening arrangement, and such fastening arrangement

ActiveUS20160023690A1Reduce expenditurePlastic deformation fasteningNutsEngineeringMechanical engineering

Owner:PROGRESS WERK OBERKIRCH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com