Vehicle stabilizer and method for manufacturing said stabilizer

A manufacturing method and stabilizer technology, applied to vehicle springs, vehicle parts, springs/shock absorbers, etc., can solve problems such as increased component loads, inability to bear component loads, and detachment of restricting rings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

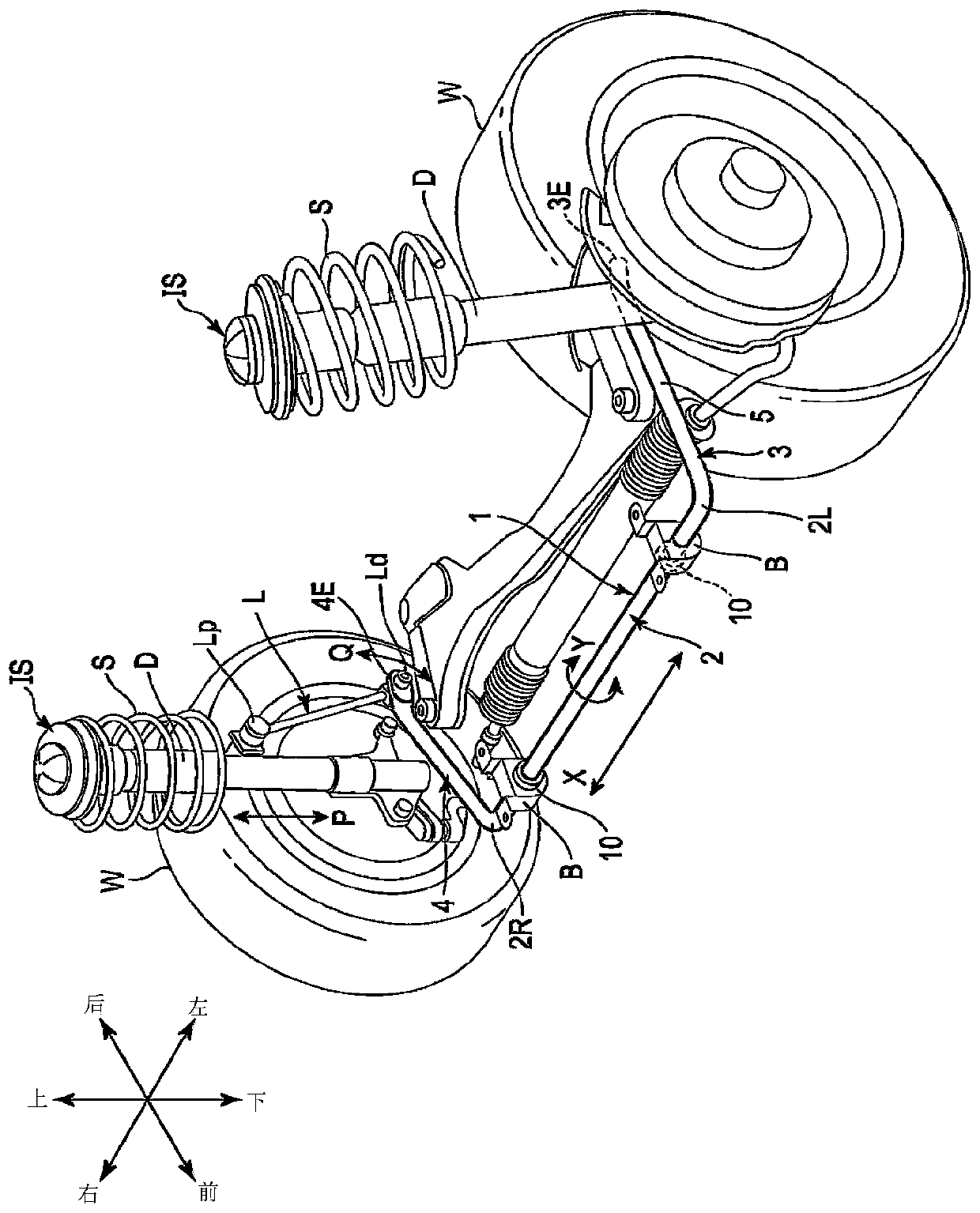

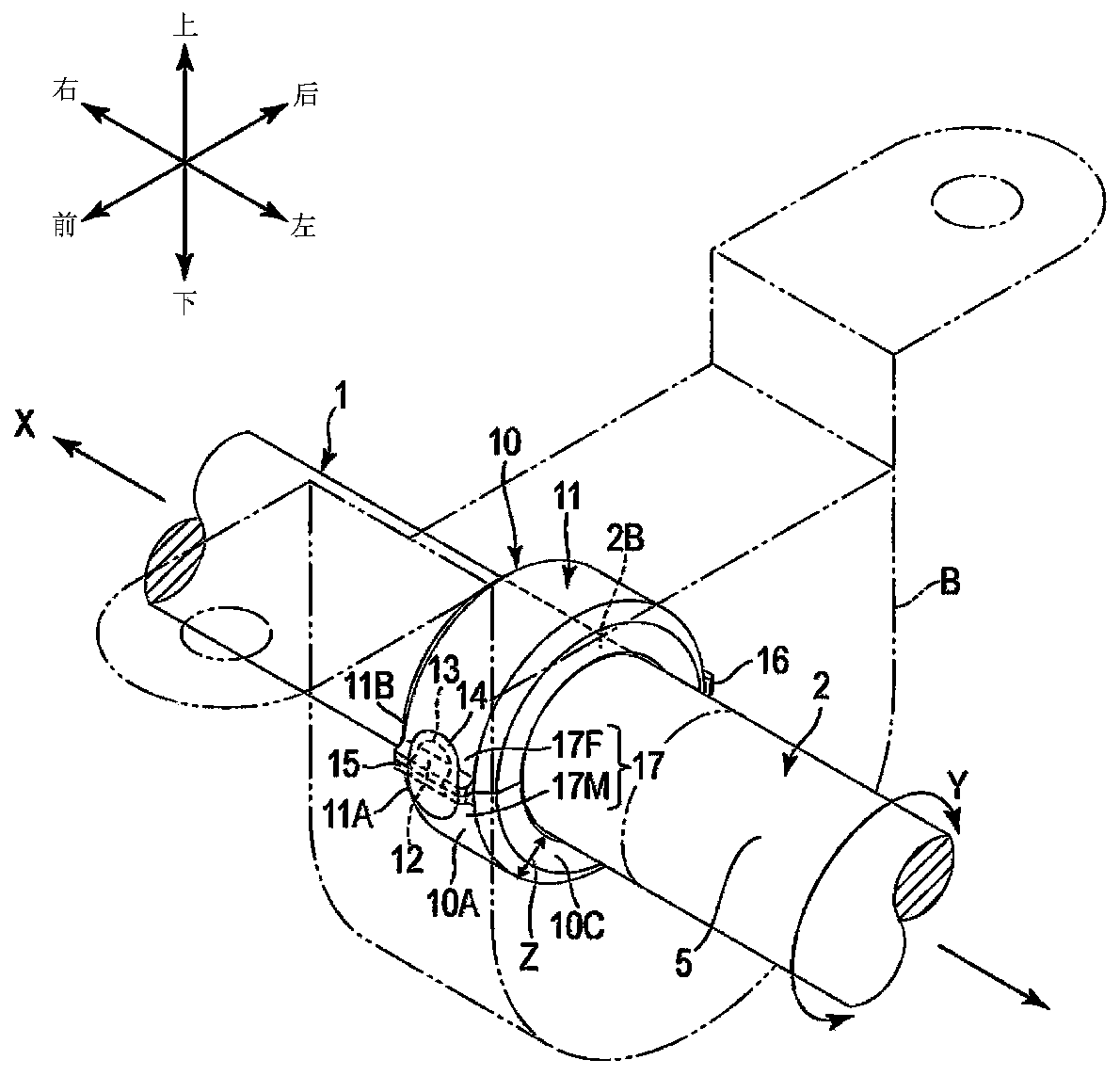

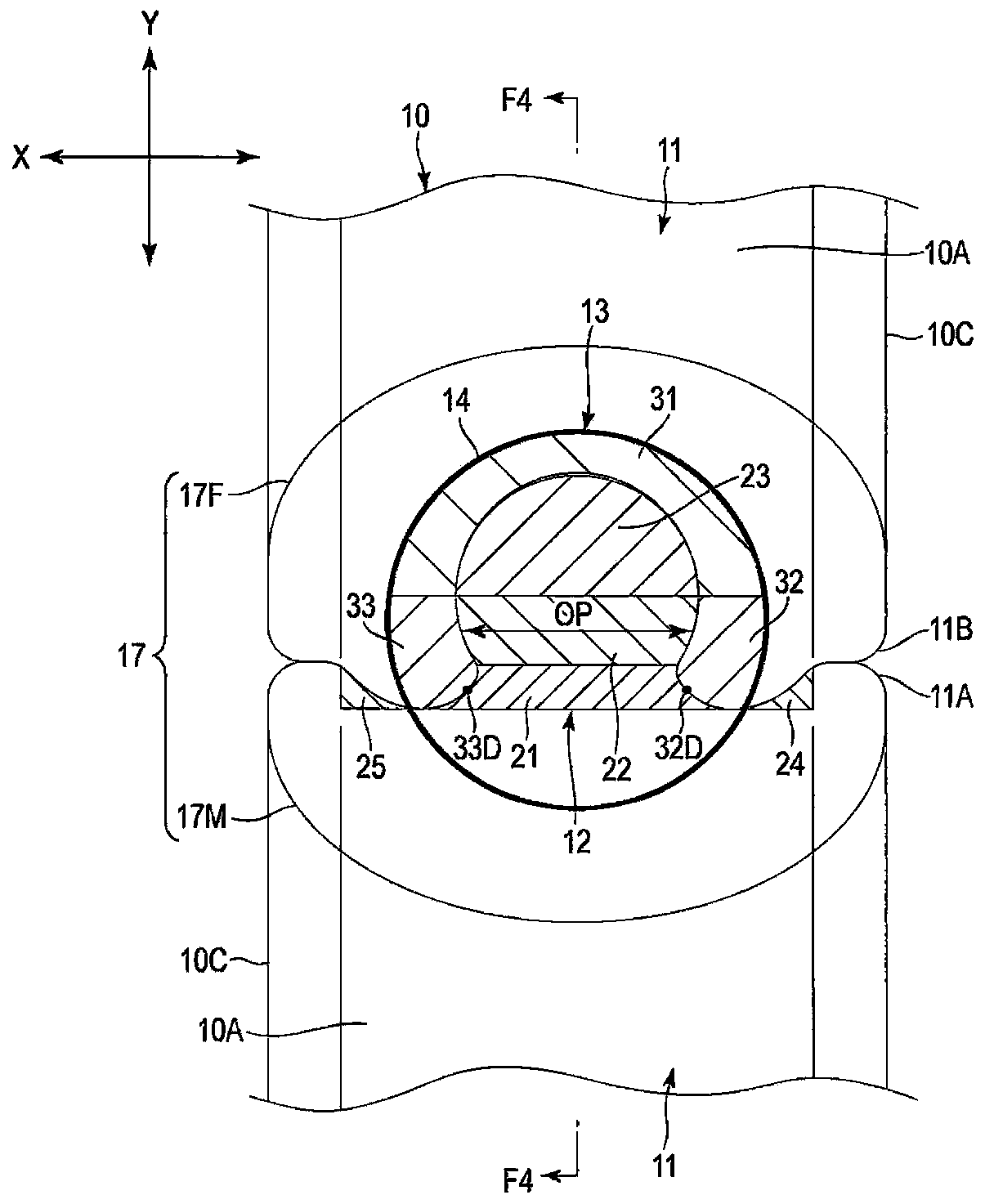

[0027] Below, refer to Figure 1 to Figure 14 A stabilizer 1 according to an embodiment of the present invention will be described. figure 1 An example perspective view of the stabilizer 1 mounted on a vehicle is shown. The stabilizer 1 is formed by bending a bar of spring steel into a U shape.

[0028] Examples of steel grades include SAE10B21, SAE15B26, SAE5160, etc. according to SAE, SUP9, etc., such as 26MnB5, 34MnB5, etc. according to JIS. The steel type of the stabilizer 1 is not limited to spring steel, and may also be high-strength steel or carbon-impregnated steel. The stabilizer 1 is covered with a coating film 5 such as epoxy resin containing a corrosion-resistant component.

[0029] The stabilizer 1 includes a torsion portion 2 , a pair of arm portions 3 and 4 , and a restraint ring 10 . The torsion portion 2 has a substantially linear shape and extends in the width direction (left-right direction) of the vehicle. A pair of arm portions 3 and 4 extend from bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com