Patents

Literature

38results about How to "Conducive to maintaining pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

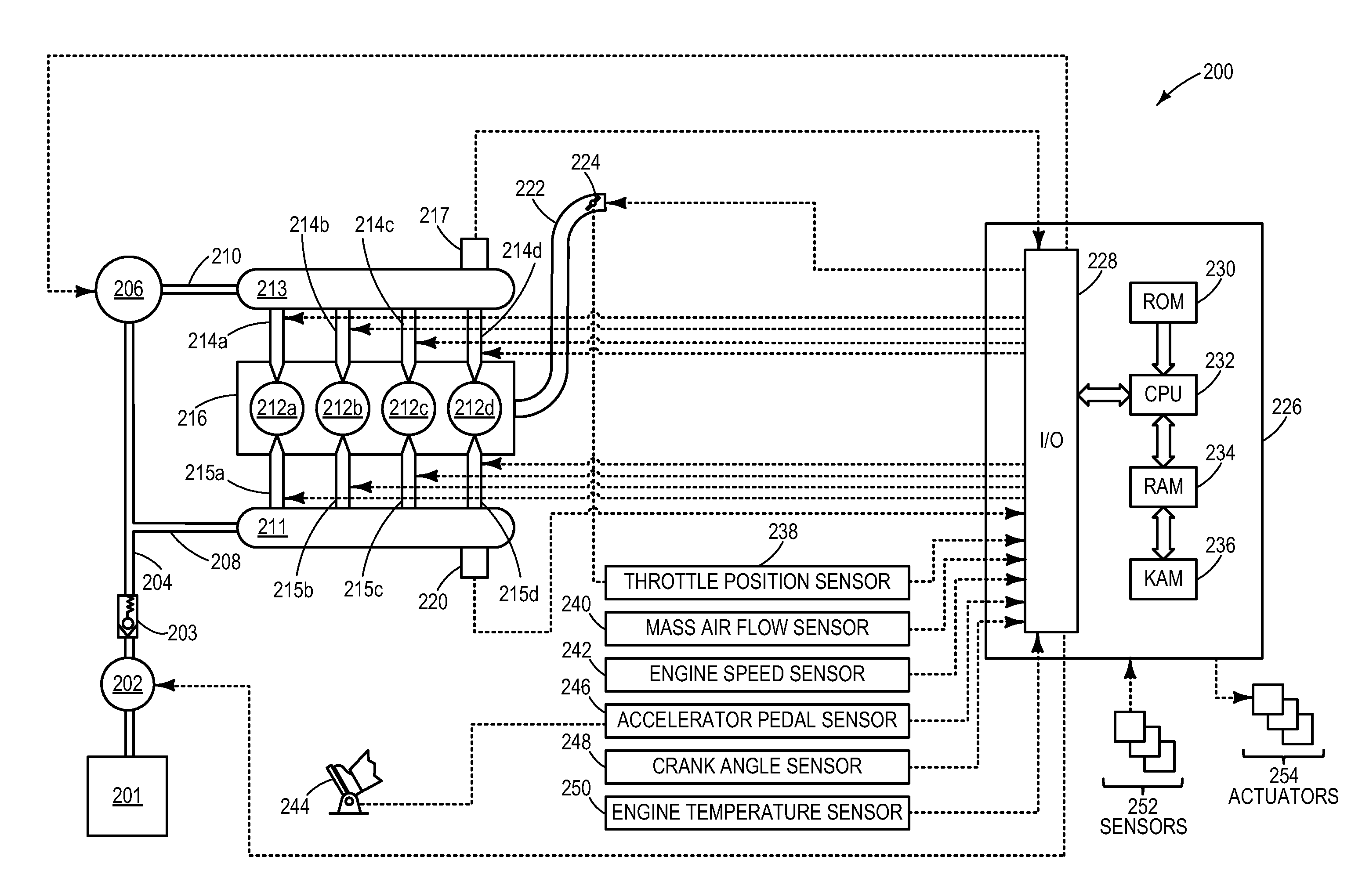

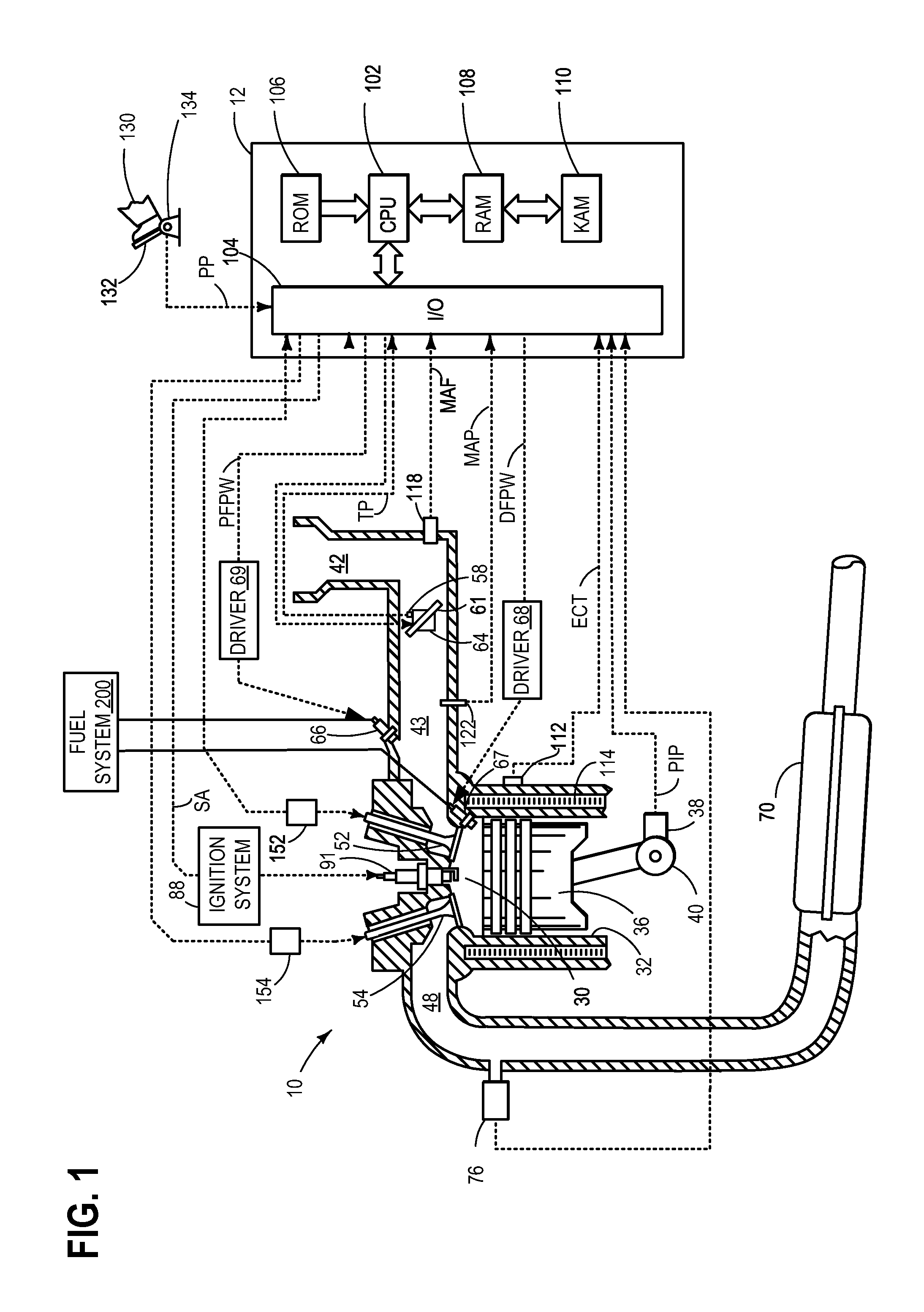

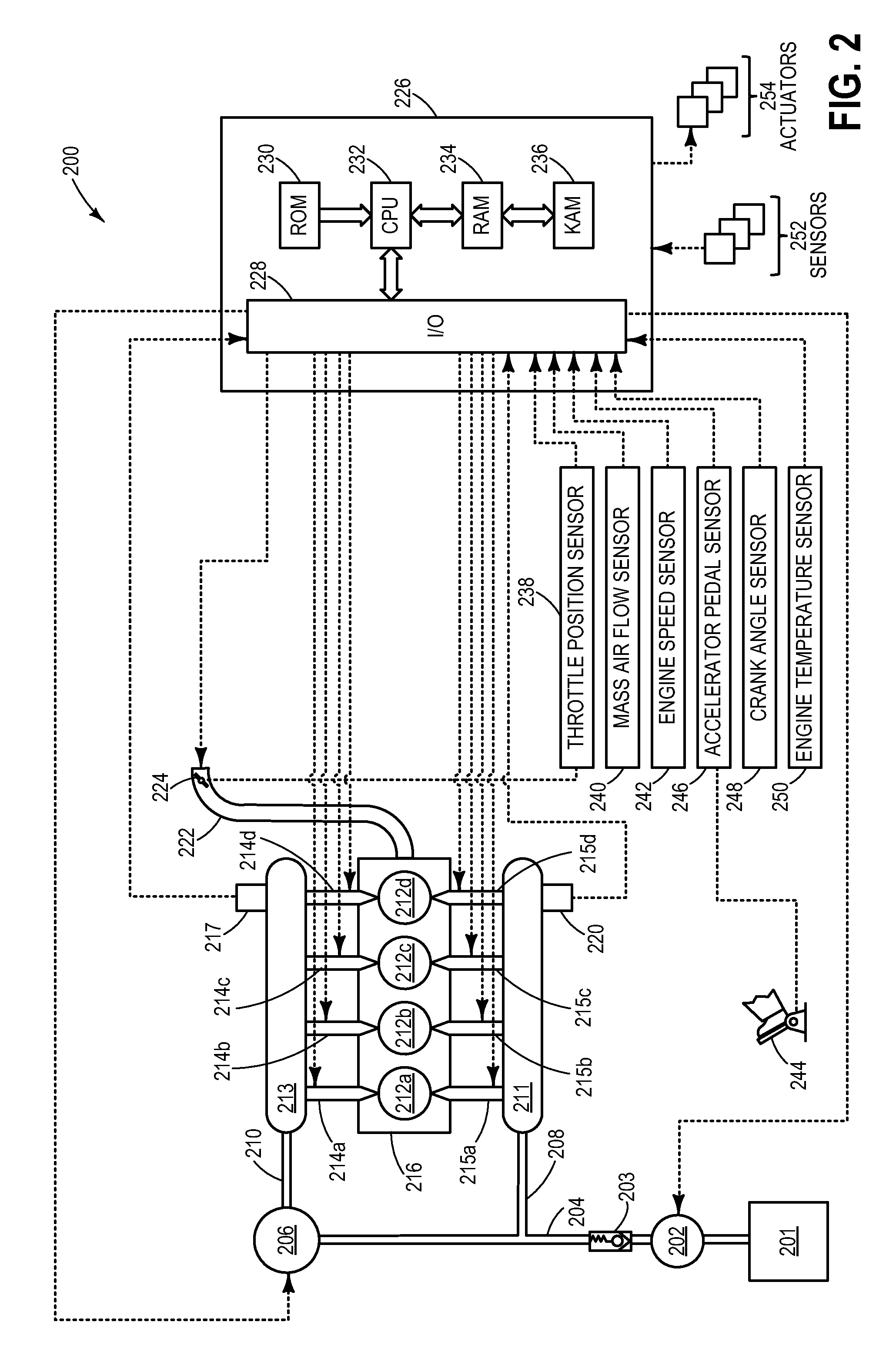

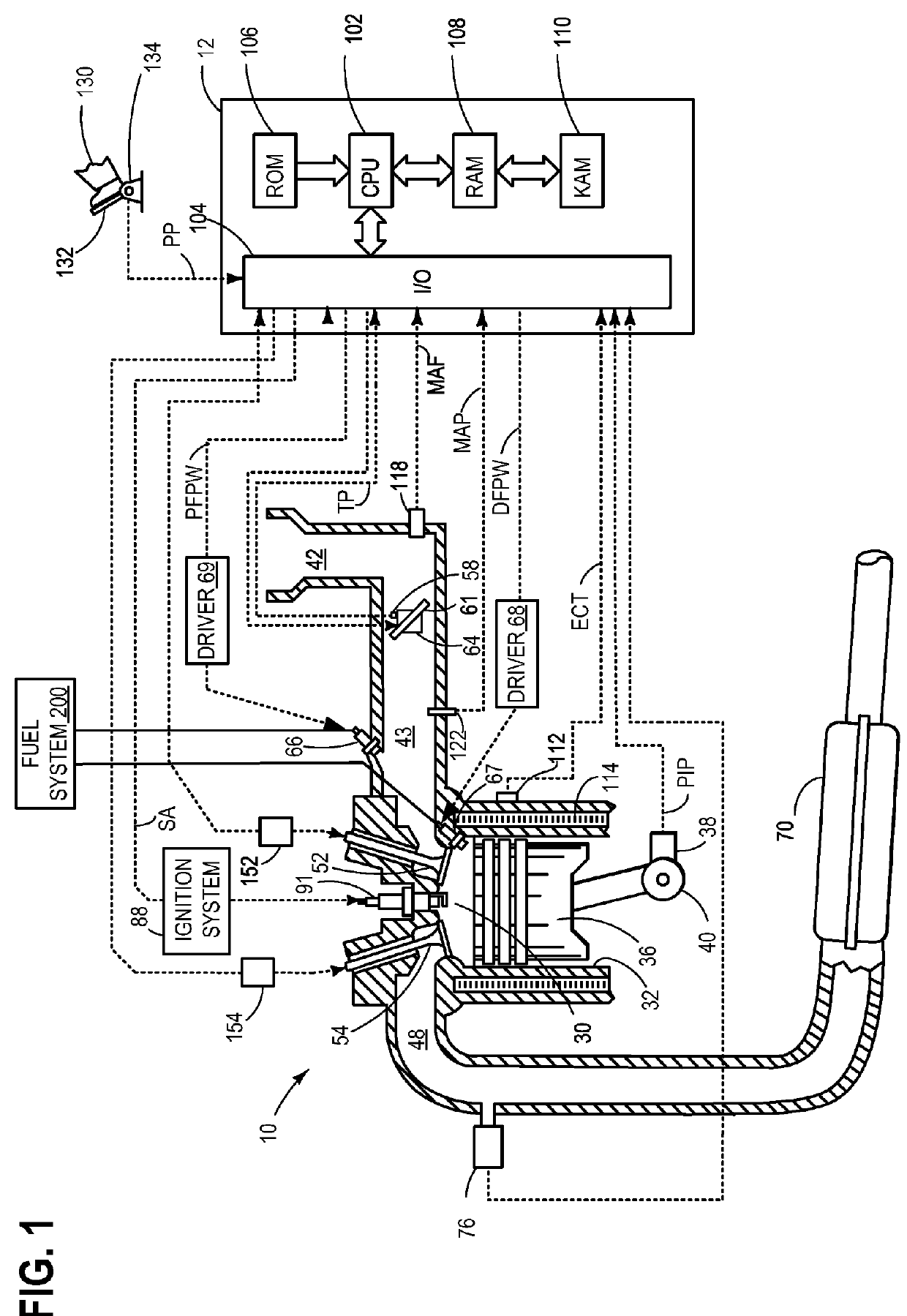

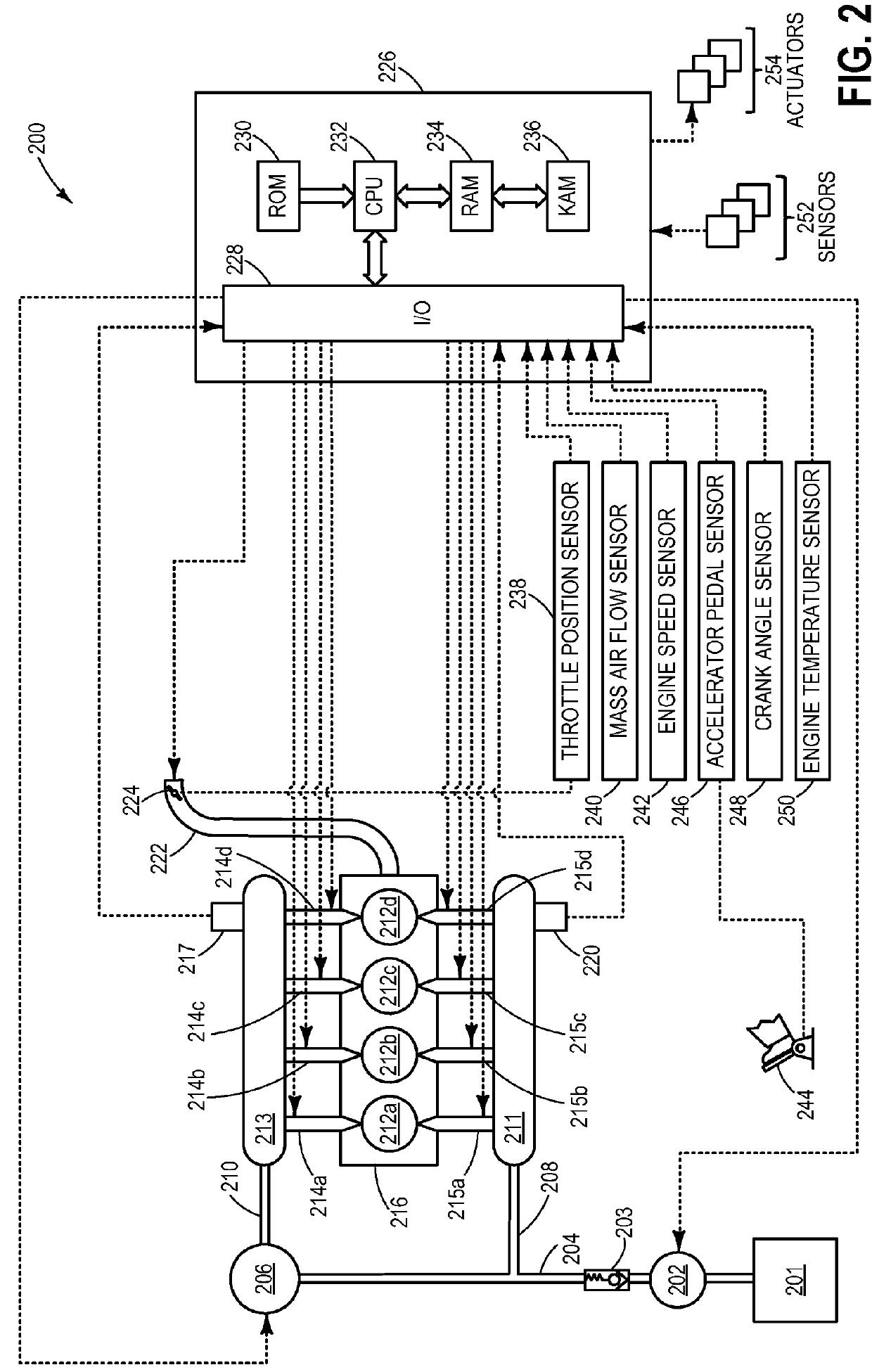

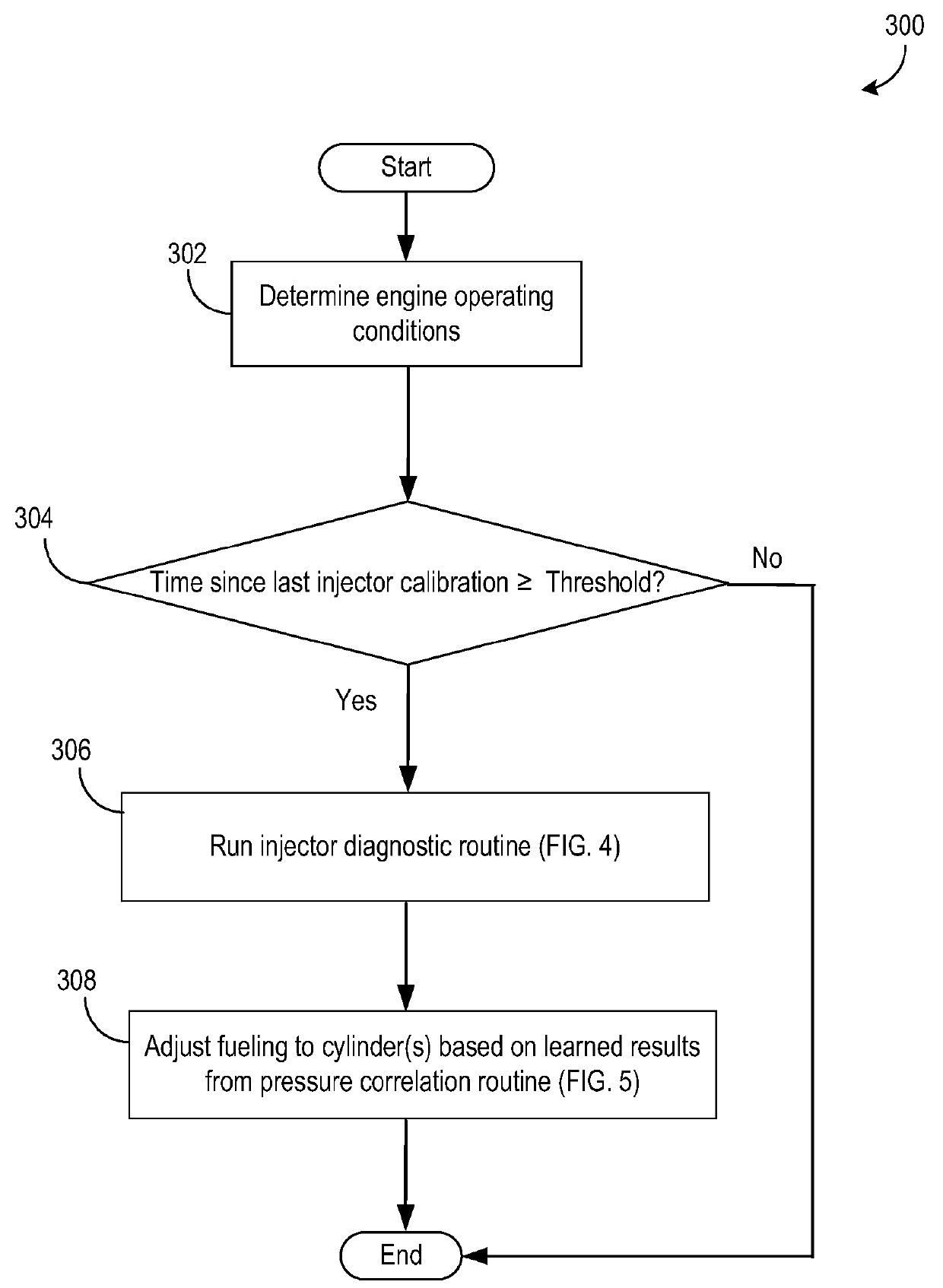

Method and system for characterizing a port fuel injector

ActiveUS20150240739A1Increase variabilityReduce fuel economyElectrical controlLow pressure fuel injectionInjectorRail pressure

Various systems and methods are described for calibrating a port injector of a common fuel, dual injector per cylinder engine which includes first and second fuel rails and first and second fuel pumps. In one example, after pressurizing both fuel rails and suspending operation of the two pumps simultaneously, a single cylinder is fueled by a port injector while the remaining cylinders are fueled via their respective direct injectors. Fuel rail pressure drops are measured in the rail coupled to the port injector and correlated to port injector performance.

Owner:FORD GLOBAL TECH LLC

Method and system for characterizing a port fuel injector

ActiveUS9334824B2Increase variabilityReduced fuel economyElectrical controlMachines/enginesRail pressureEngineering

Various systems and methods are described for calibrating a port injector of a common fuel, dual injector per cylinder engine which includes first and second fuel rails and first and second fuel pumps. In one example, after pressurizing both fuel rails and suspending operation of the two pumps simultaneously, a single cylinder is fueled by a port injector while the remaining cylinders are fueled via their respective direct injectors. Fuel rail pressure drops are measured in the rail coupled to the port injector and correlated to port injector performance.

Owner:FORD GLOBAL TECH LLC

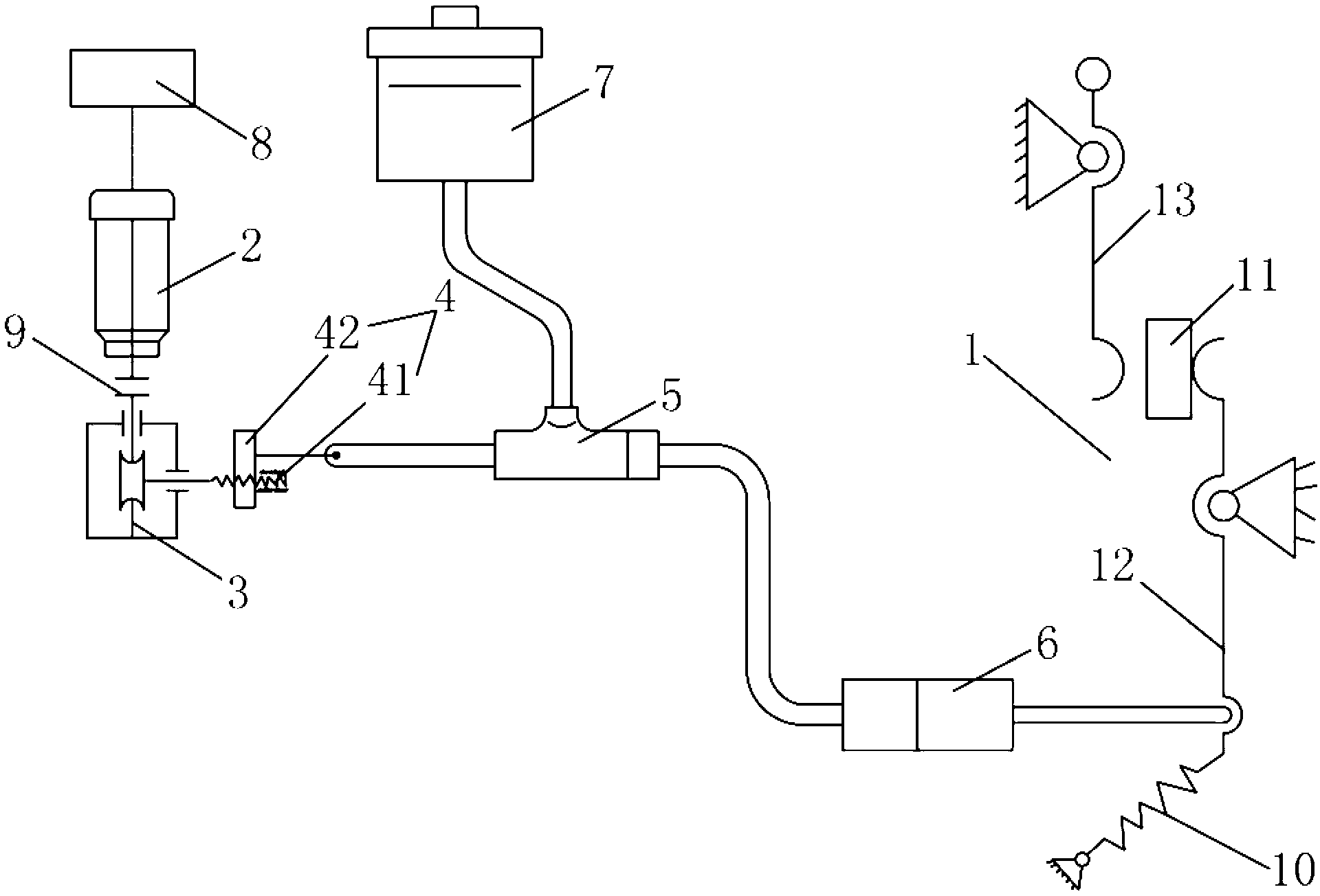

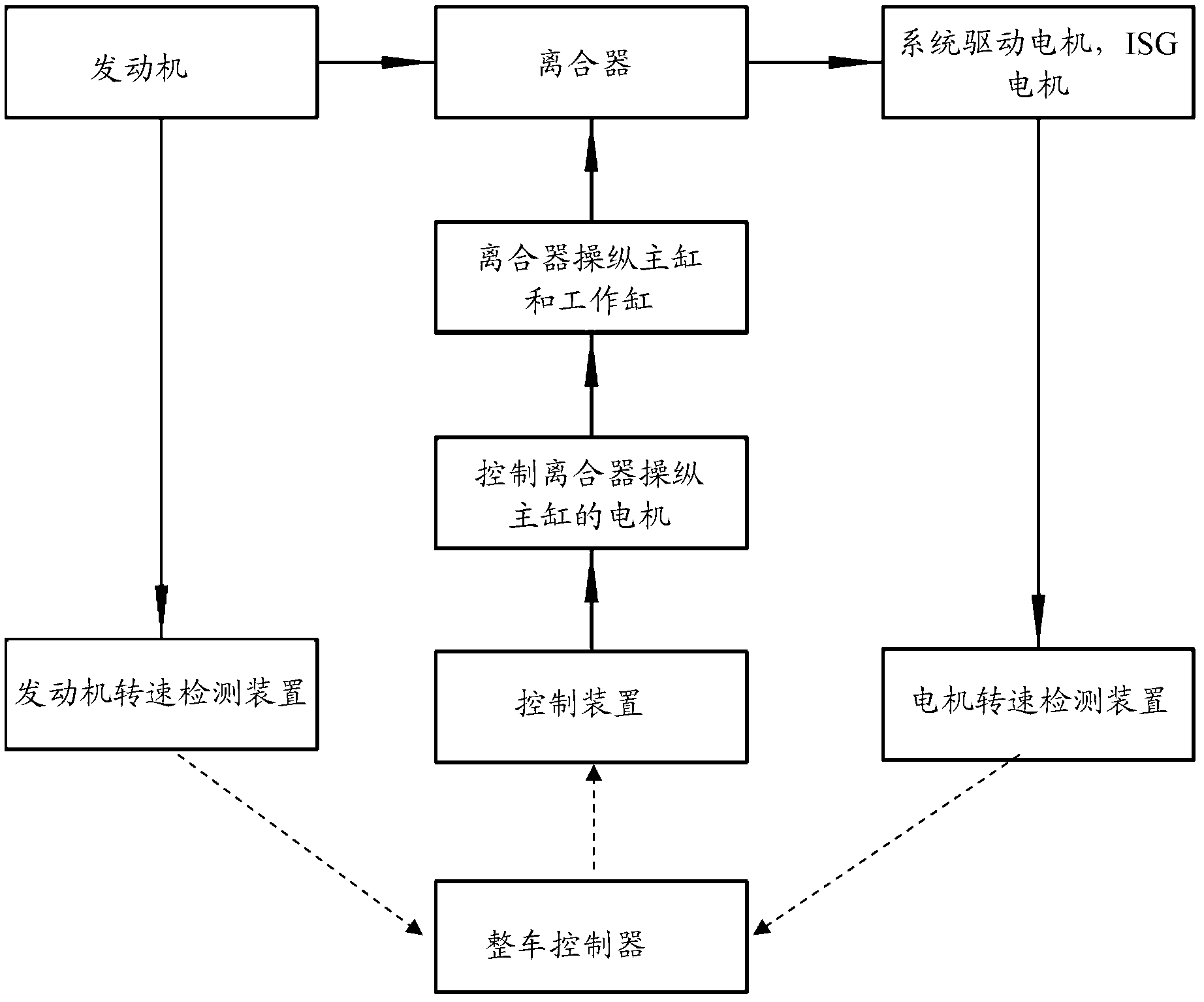

Automatic clutch control system

The invention relates to an automatic clutch control system which comprises a clutch, a motor, a speed reducer, a transmission element, a main clutch control cylinder, a working cylinder, a fluid source and a control device. The motor is connected with the transmission element through a speed reducer, the transmission element is connected with a piston rod of the main clutch control cylinder and used for pushing the piston rod to move, the fluid source is communicated with the working cylinder through the main clutch control cylinder, a piston rod of the working cylinder is connected with a release fork of the clutch to push the release fork to move, and the control device is in signal connection with the motor. Preferably, the speed reducer is a worm-gear reducer, the transmission element is a cam mechanism or screw transmission mechanism, and two clutch rotating-speed detecting devices are positioned at two ends of the clutch respectively to detect rotating speeds of the two ends of the clutch, and are in signal connection with the control device. The automatic clutch control system is ingenious in design, suitable for controlling of automatic clutches of hybrid electric vehicles, compact in structure, reliable in operation, low in cost and suitable for wide popularization and application.

Owner:JIANGXI B ENERGY SHANGRAO COACH

Turned edge press-fit device

ActiveCN105752373AAutomate operationIncrease productivityWrapper folding/bending apparatusWrappingEngineeringMechanical engineering

The invention relates to a turned edge press-fit device. Felt is positioned on a carrier assembly. An ejecting assembly is arranged on a bottom plate of a machine frame assembly. The left side and the right side of the upper portion of a carrier of the carrier assembly are each provided with a step block so that a groove can be formed between each step block and the carrier. An ejecting column which can be inserted in a positioning hole in a carrier bottom plate to position the carrier assembly is arranged on an ejecting plate of the ejecting assembly. A downward pressing assembly which can grab a product and downwards press the product is arranged at the upper portion of the bottom plate. The size of the product is smaller than that of the felt. The product is downward pressed into the grooves so that the left side and the right side of the felt can be vertically turned up. The left side and the right side of the upper portion of the bottom plate are each provided with a lateral pressing assembly which pushes and presses the corresponding vertically-turned side of the felt flat from the side face of the felt so that the corresponding vertically-turned part can be turned up again to form a horizontal turned edge. The ejecting assembly which can control the stroke of the ejecting plate and pressurize the horizontal turned edges is arranged between the ejecting assembly and the bottom plate. Two times of edge turning of the felt are achieved, and the left side and the right side of the product are wrapped.

Owner:BOZHON PRECISION IND TECH CO LTD

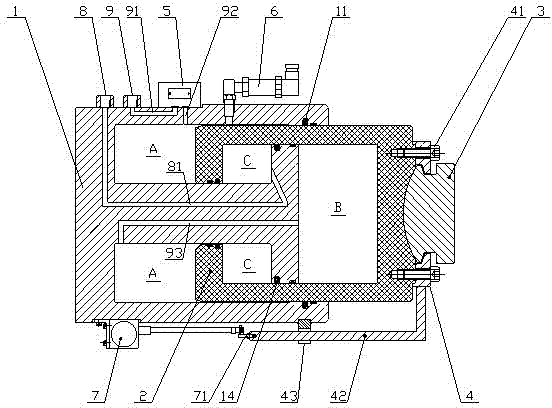

Integrated self-locking intelligent informationized hydraulic cylinder device

InactiveCN103883581AReduce distortionEasy loadingFluid-pressure actuatorsHydraulic cylinderCylinder block

The invention discloses an integrated self-locking intelligent informationized hydraulic cylinder device. The integrated self-locking intelligent informationized hydraulic cylinder device comprises an outer cylinder body and an inner cylinder body. An inward-contracting shoulder surrounds the opening of the inner cavity body, a columnar boss is arranged at the bottom of the outer cylinder body and stretches into the opening of the inner cylinder body, a peripheral outward-expanding shoulder is arranged at the end of the columnar boss, a first oil cavity is formed between the bottom of the outer cylinder body and the inward-contracting shoulder of the inner cylinder body, a second oil cavity is formed between the inner side of the bottom of the inner cylinder body and the end of the columnar boss, and an oil return cavity is formed between the outward-expanding shoulder of the outer cylinder body and the inward-contracting shoulder of the inner cylinder body. An oil cylinder clamping ring is connected with an oil cylinder skid shoe in a pressing mode and is connected to the outside of the bottom of the inner cylinder body through a bolt in a threaded mode. An oil return pipe connector is communicated with the oil return cavity through an oil return pipe, an oil inlet pipe connector is connected to a hydraulic lock through an oil inlet pipeline, the hydraulic lock is connected to the first oil cavity through an oil inlet pipeline, an oil pressure sensor is communicated with the first oil cavity, a displacement sensor is connected with a connecting rod through a bolt in a threaded mode, the connecting rod is connected with the oil cylinder clamping ring, and the first oil cavity is communicated with the second oil cavity through an oil pipe.

Owner:庄筱凤

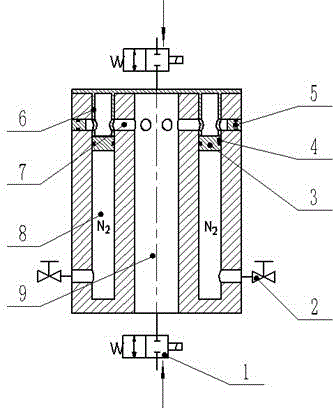

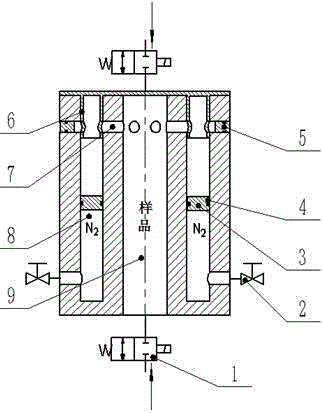

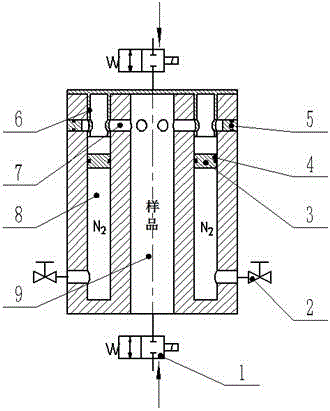

Deep-sea integrated energy-accumulator pressure-maintaining sampler mechanism

The invention relates to a deep-sea integrated energy-accumulator pressure-maintaining sampler mechanism. The mechanism comprises sampling valves, gas cutoff valves, a piston, an O-shaped sealing ring, a hydraulic plug, a stopper, a throttling port, an energy accumulation chamber and a sampling chamber, wherein the sampling valves are separately mounted at the two sides of the sampling chamber, the circumferential throttling port is formed in the chamber wall of the sampling chamber, a part, directly facing to external wall, of the throttling port is sealed through the hydraulic plug, the energy accumulation chamber is pre-charged with high-pressure nitrogen gas through the gas cutoff valve at one side, the piston is arranged at the upper end of the energy accumulation chamber, and the stopper is mounted at the upper end of the piston so as to limit displacement. According to the mechanism, an energy accumulator and a sampling tube adopt an integrated structure, so that the structure is compact, the size is small, the energy accumulator can be used for carrying out pressure compensation on the sampling tube, and thus an effective pressure maintaining effect is achieved.

Owner:ZHEJIANG UNIV

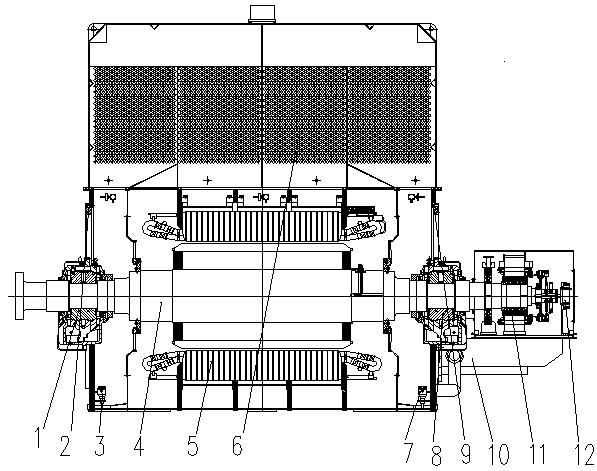

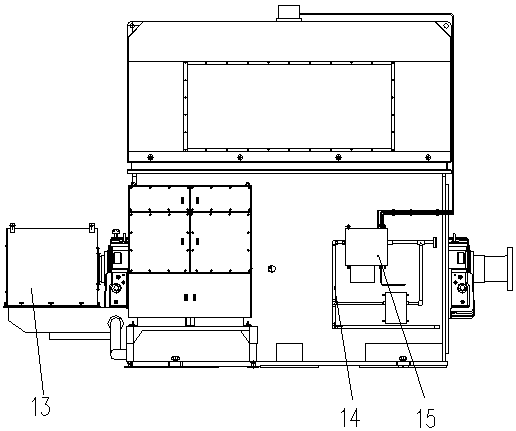

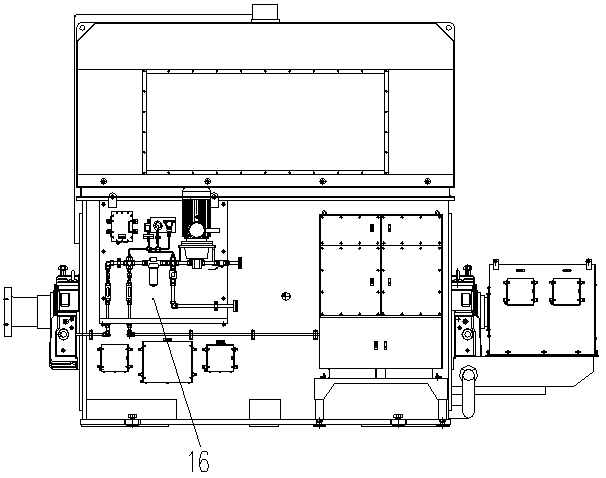

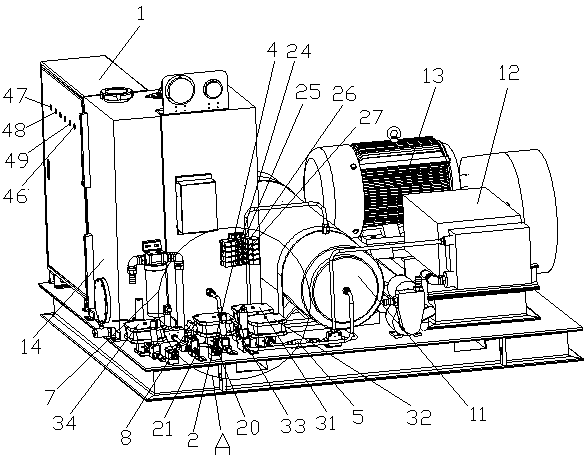

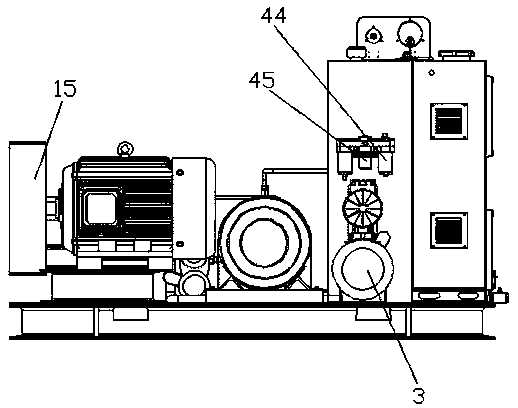

Positive-pressure and explosionproof power generator

PendingCN108023451ARealize zero-meter layoutImprove applicable environmentSynchronous machine detailsCooling/ventillation arrangementPositive pressureAir cooling system

The invention discloses a positive-pressure and explosionproof power generator. The positive-pressure and explosionproof power generator comprises a power generator body, a positive-pressure purging pipeline, a wiring cabinet, a neutral point cabinet, an excitation system and a positive-pressure purging device and is characterized in that the power generator body comprise a stator, a rotor and anair-air cooler and employs a light box-type structure of an end cover-type bearing, an integral end cover and a steel plate welding engine base, the air-air cooler is placed at the top of the power generator body and employs a pipeline forced ventilation air-air-cooling system, at a steam end of the power generator, a power generator body positive-pressure sealing space is formed by the light box-type structure and the air-air cooler, and at an excitation end of the power generator, an excitation magnetic system positive-pressure sealing space is formed by an excitation machine support and anexcitation machine outer cover. By the structure, the explosionproof performance of the power generator can be effectively improved; and moreover, the positive-pressure and explosionproof power generator is simple to operate and maintain and convenient to install and connect and is good in air tightness, and long-time and safe running of the power generator set in a flammable and combustible environment can be achieved.

Owner:WOLONG ELECTRIC GRP CO LTD +1

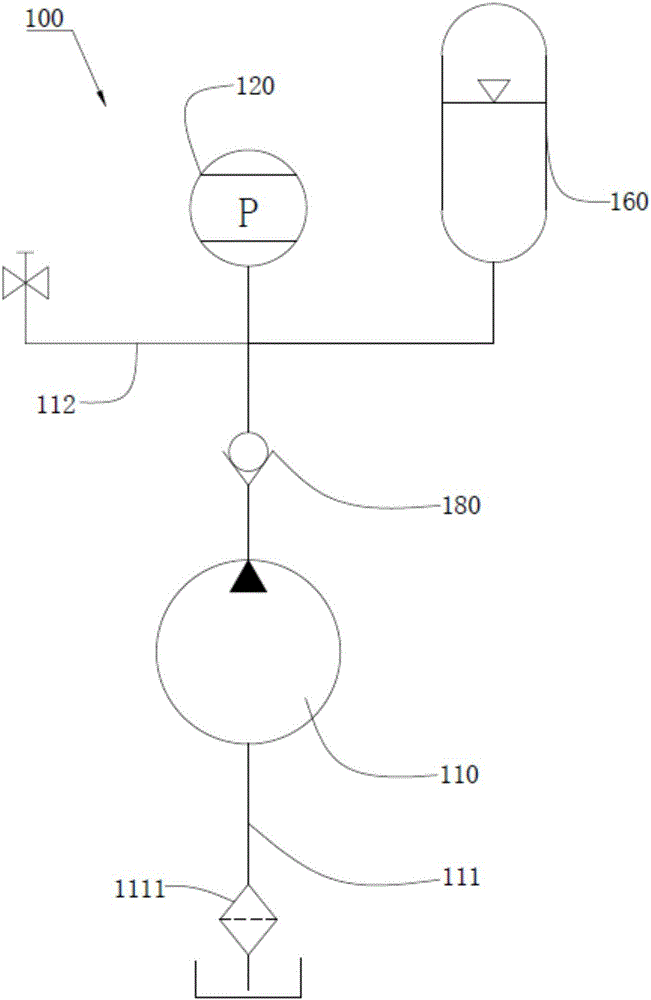

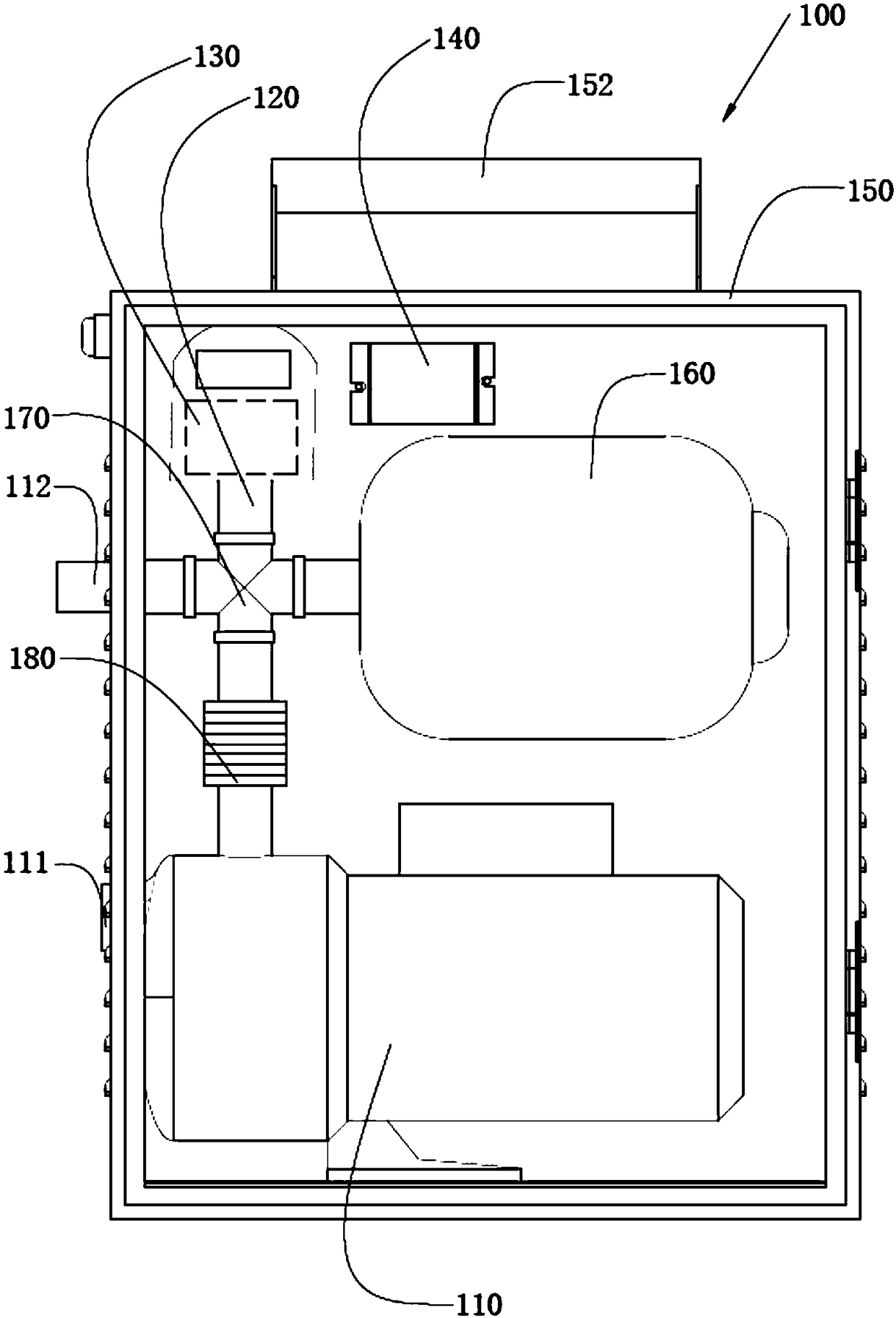

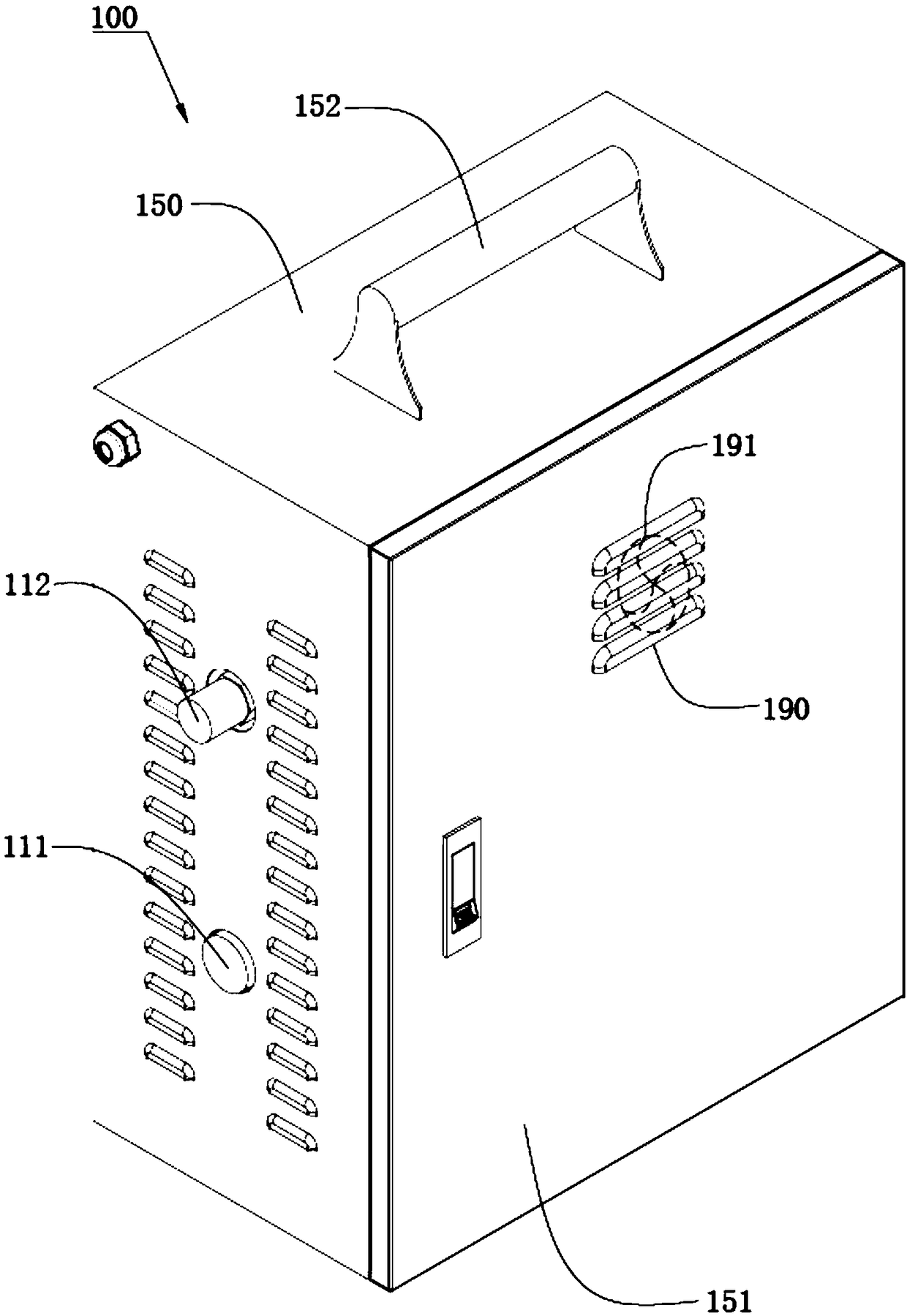

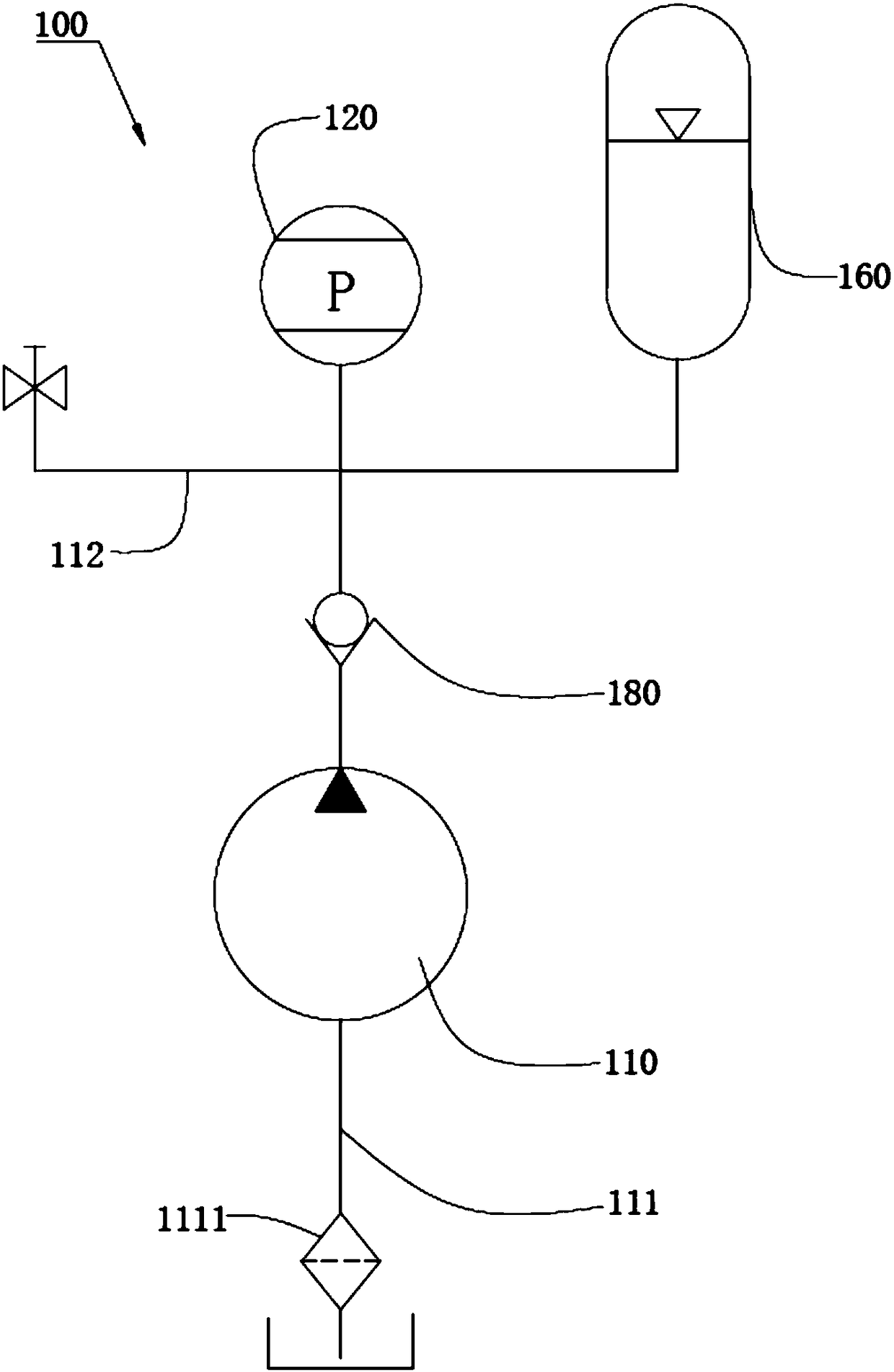

Water supply machine

ActiveCN106088240AReduce lagExtended service lifeService pipe systemsWater mainsPressure senseEngineering

The invention provides a water supply machine, and belongs to the field of water supply equipment. The water supply machine comprises a water pump, a pressure sensor, a controller and a machine box, wherein the pressure sensor is electrically connected with the controller; a contactless switch is arranged on the water pump; the controller is electrically connected with the water pump through the contactless switch; the pressure sensor is used for sensing the water supply pressure of the water pump; the controller contacts the on-off state of the contactless switch according to the pressure sensed by the pressure sensor. The water supply machine belongs to a water supply machine with the advantages that the water pressure is adjustable; the service life is long; the pressure regulation starting is fast.

Owner:阳志华

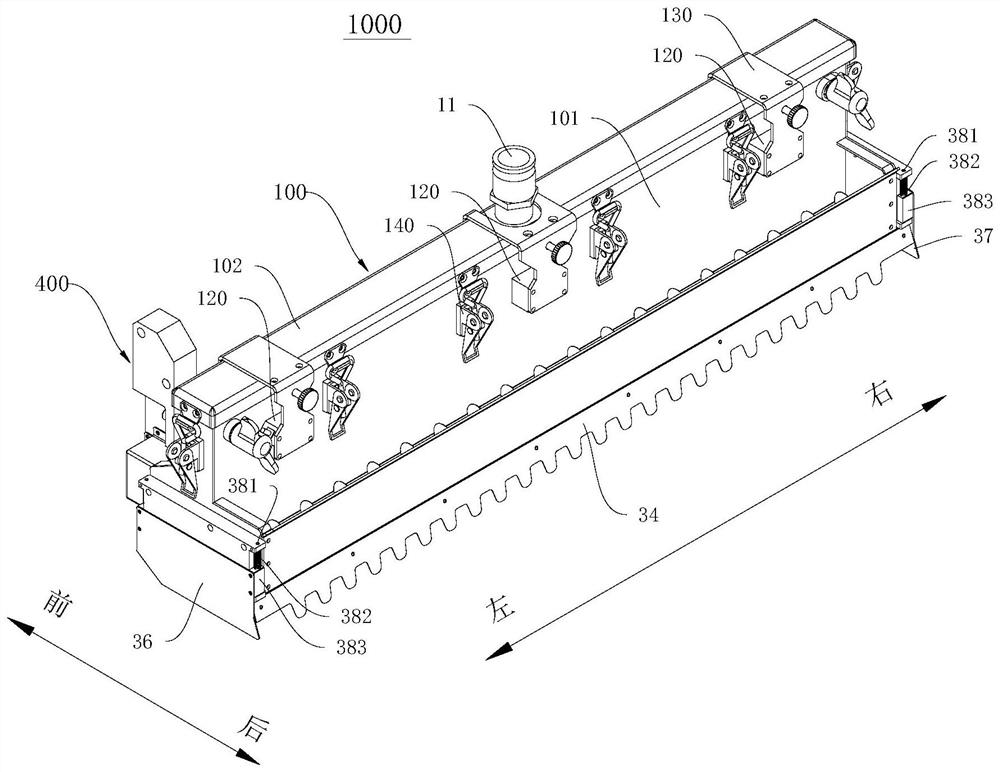

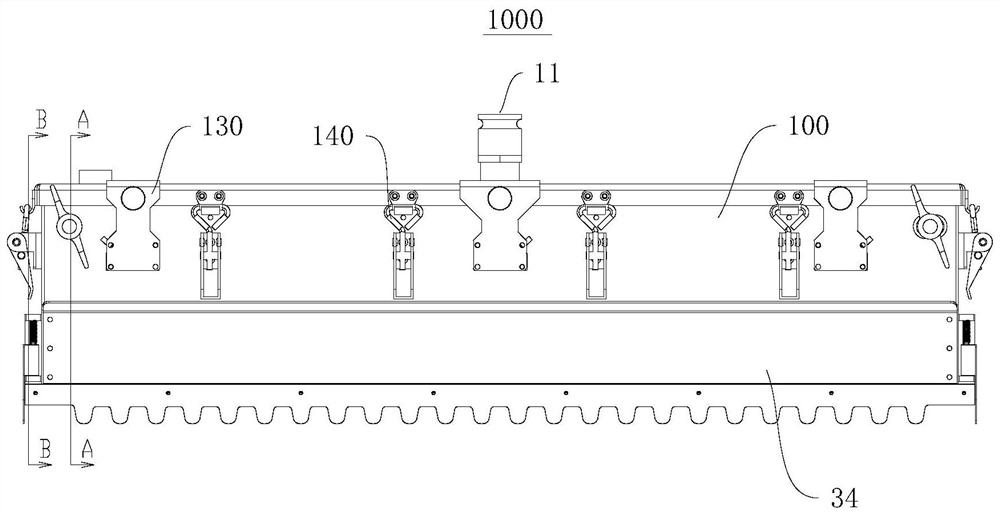

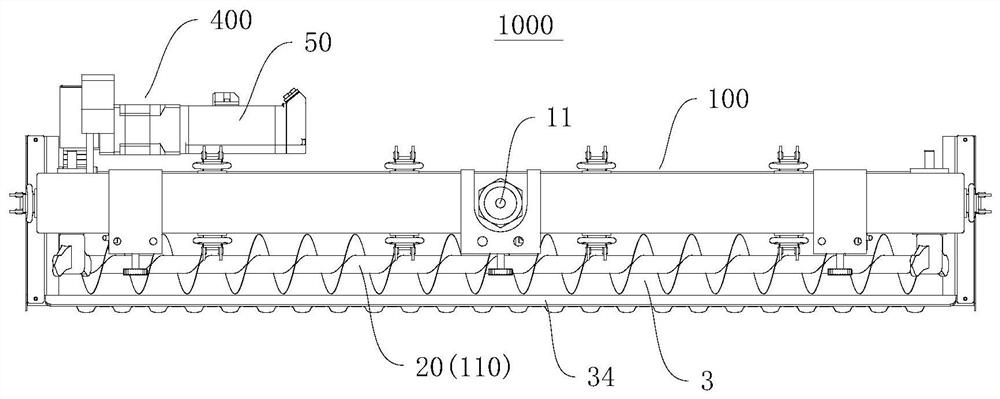

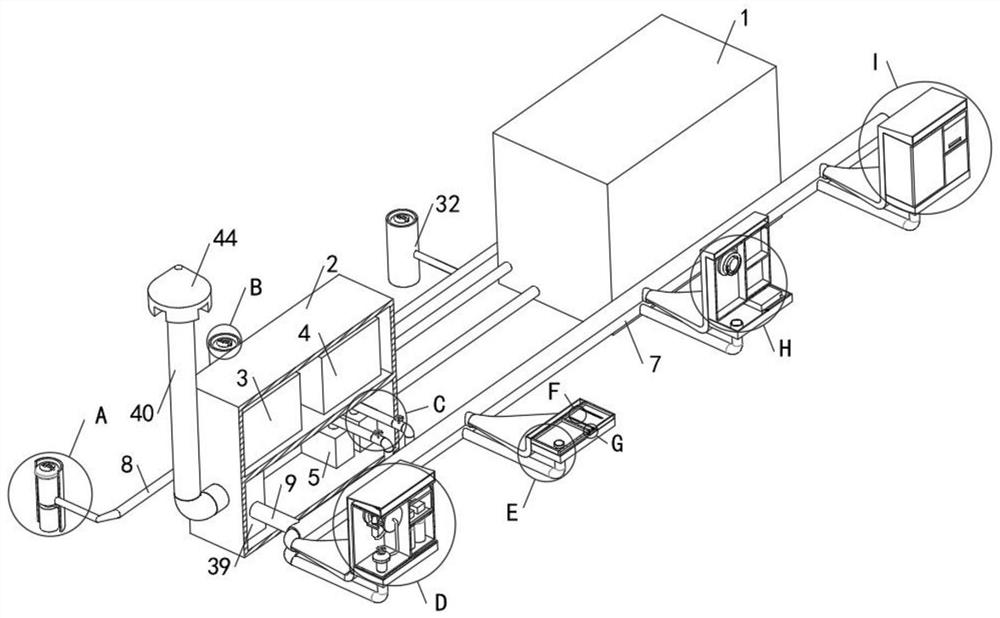

Hopper, slurry spreading terminal and slurry spreading equipment

The invention relates to a hopper, a slurry spreading terminal and slurry spreading equipment. The hopper is provided with a slurry storage chamber, the upper end of the slurry storage chamber is provided with a slurry inlet of the slurry storage chamber, the lower end of the slurry storage chamber is provided with a slurry outlet of the slurry storage chamber, the area of the slurry inlet of theslurry storage chamber is larger than that of the slurry outlet of the slurry storage chamber, at least one pressurizing cavity is arranged between the slurry inlet and the slurry outlet of the slurrystorage chamber, and the sectional area of the pressurizing cavity is gradually reduced from top to bottom. The slurry storage chamber is of a big-end-up structure, the design of the large-size slurry inlet and the small-size slurry storage outlet is adopted, slurry gathering is facilitated, and the slurry outlet uniformity of the slurry storage chamber can be improved. The pressurizing cavity isformed, so that the pressure of the slurry discharged from the slurry storage chamber is increased, the contact force between slurry and the ground is increased, the amount of air retained between the slurry and the ground is reduced, the bonding force between the slurry and the ground is improved, and tiles are not prone to hollowing after being installed. Moreover, a small opening has certain pressure maintaining capacity, and compared with a large outlet, the small outlet is beneficial to pressure maintaining in the slurry storage chamber when no external pressure exists.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

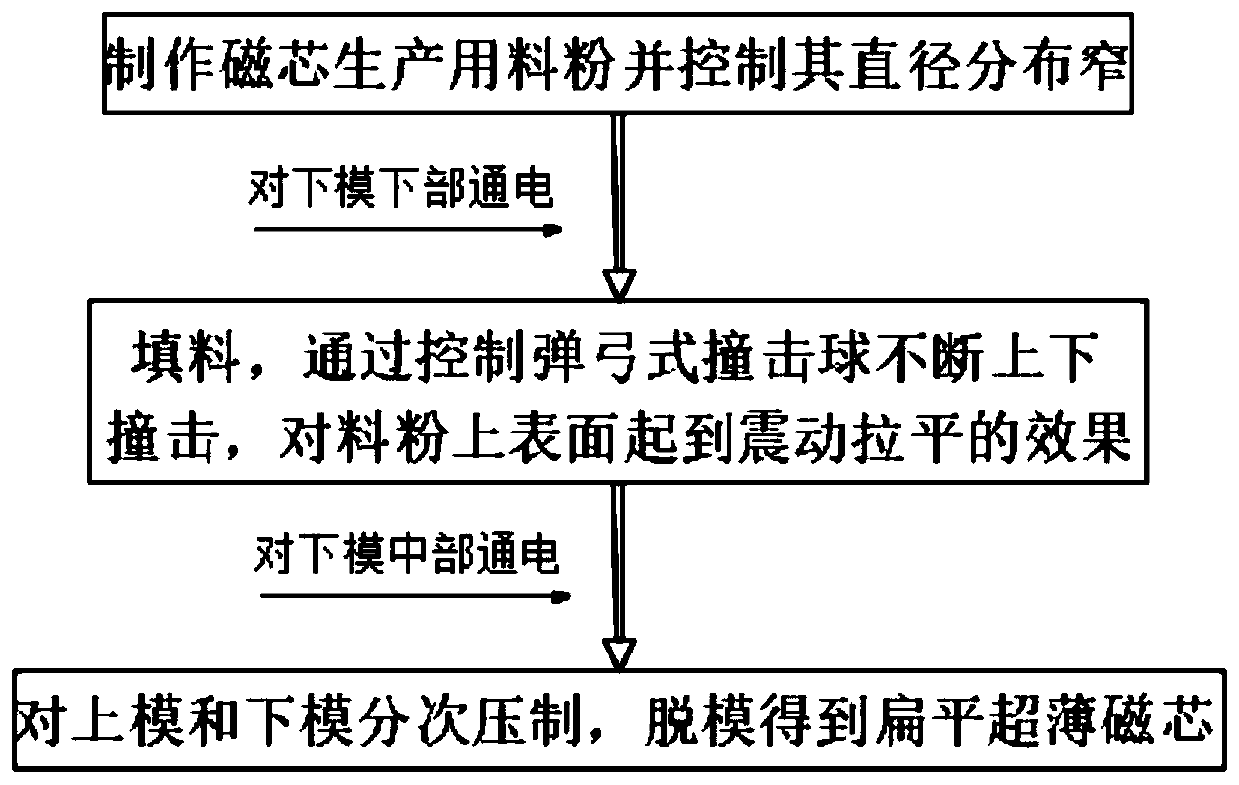

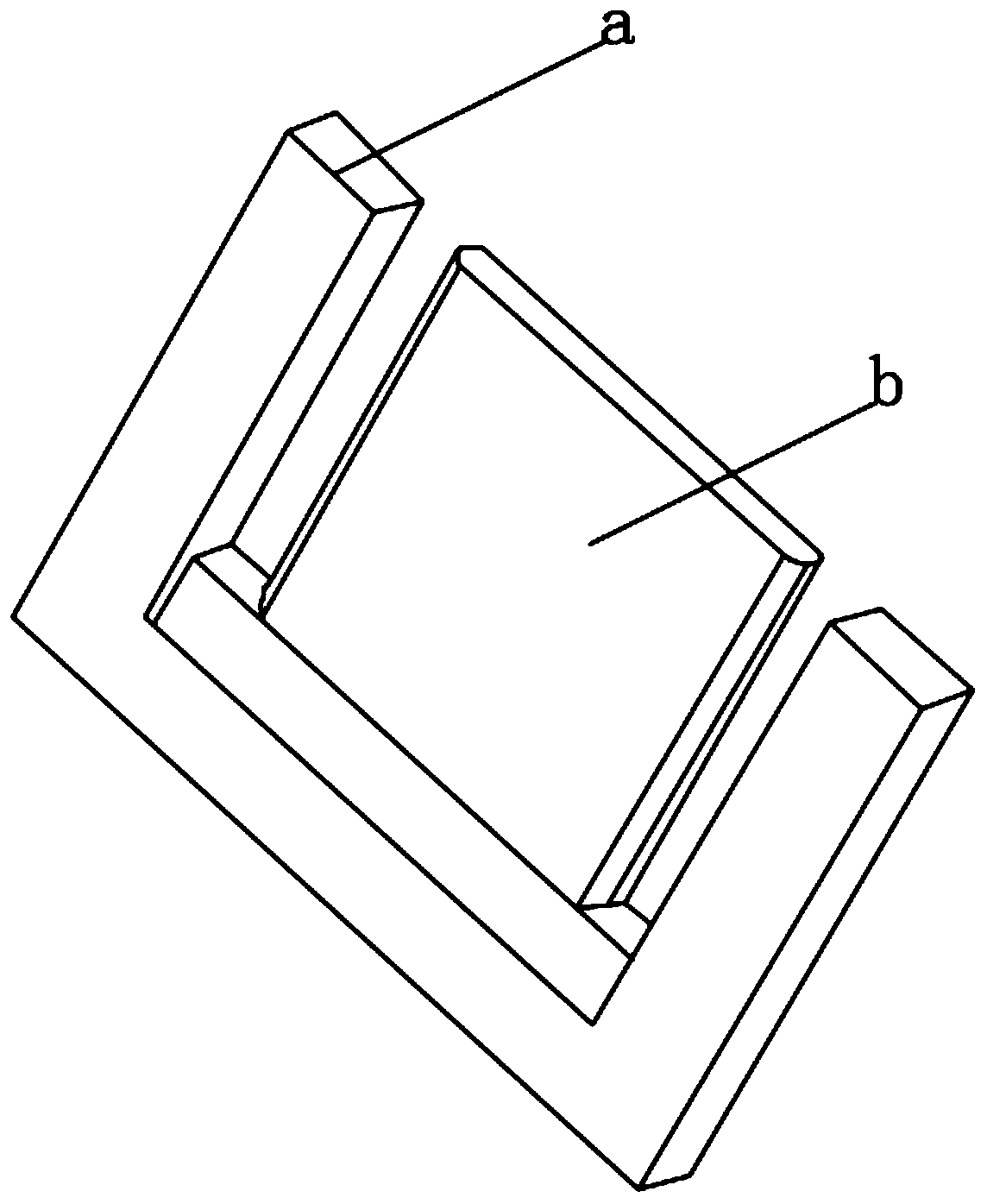

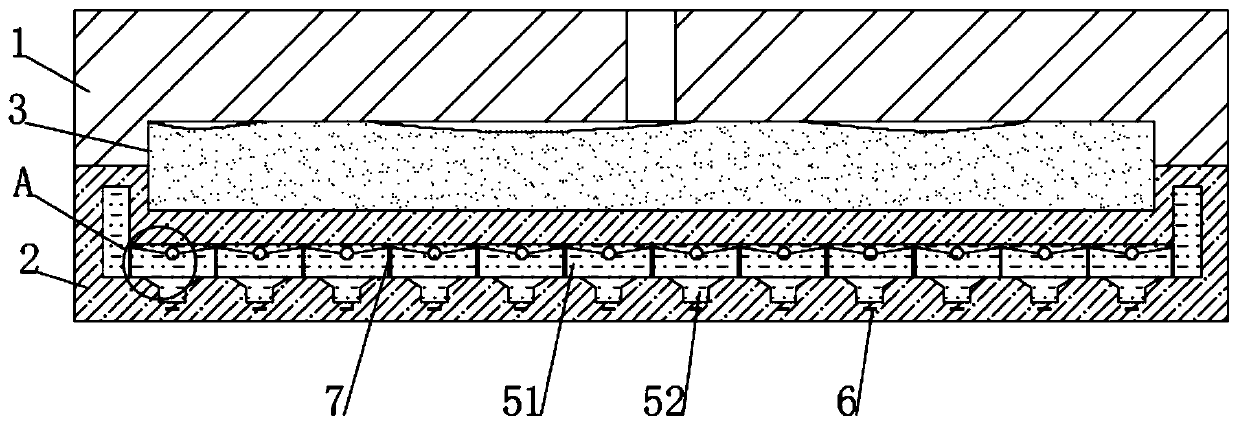

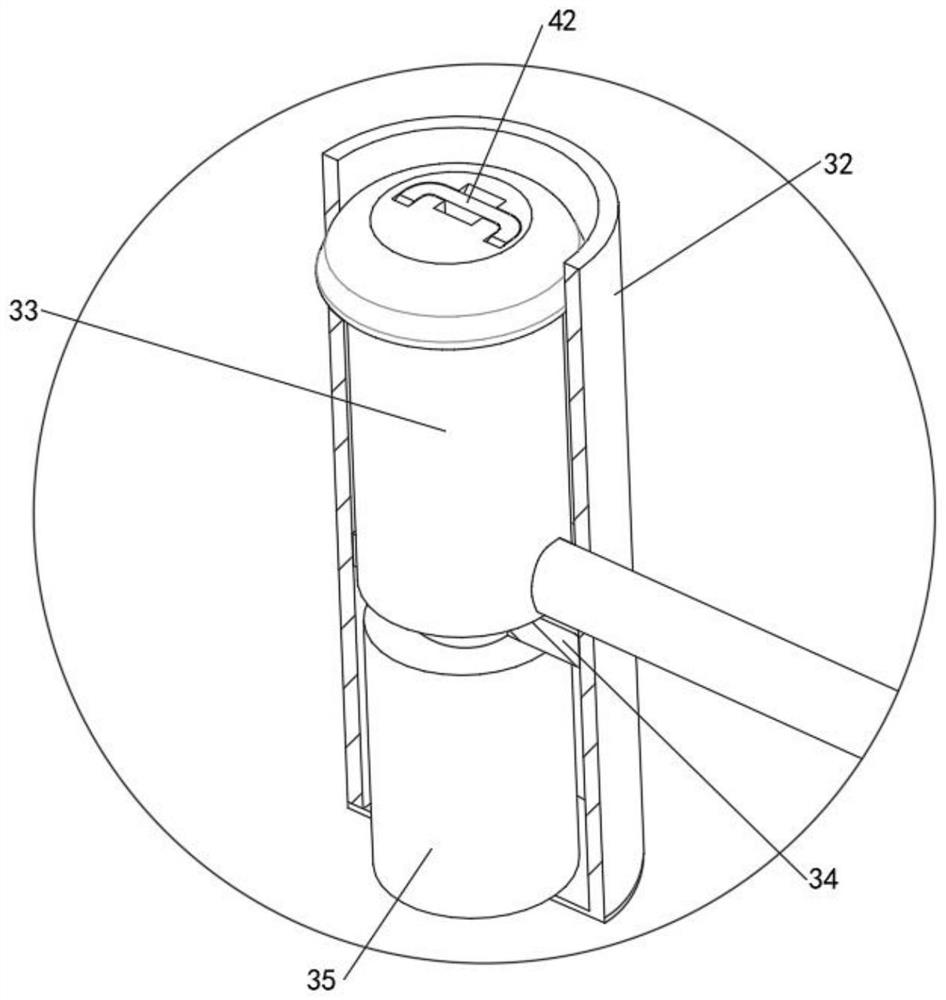

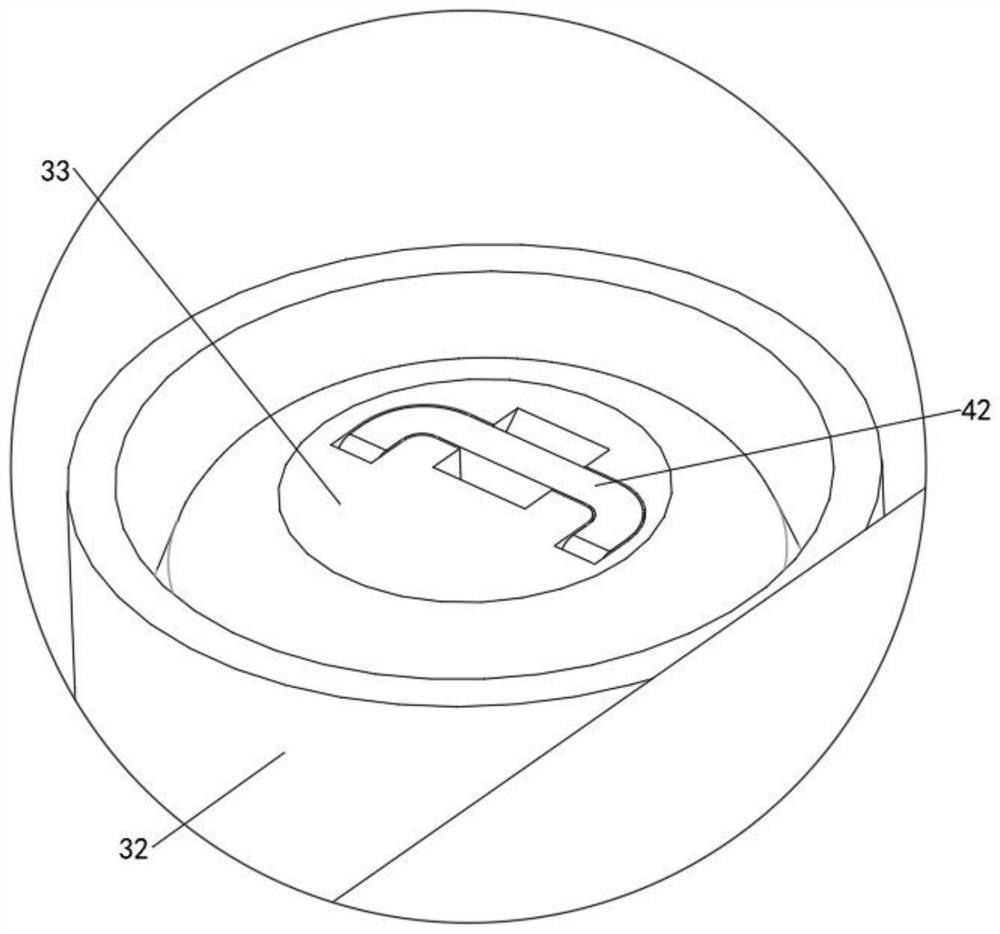

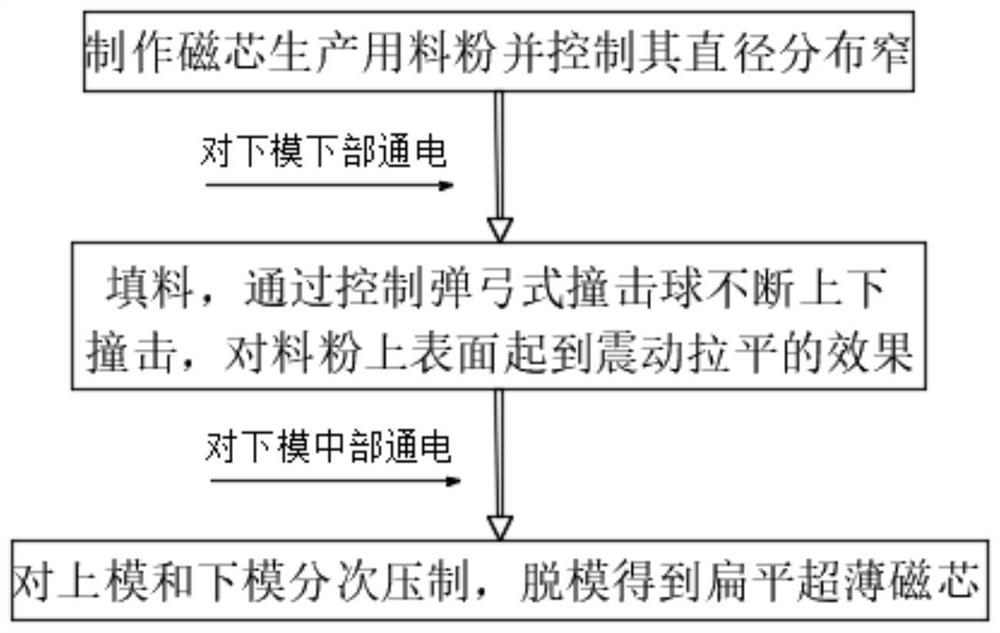

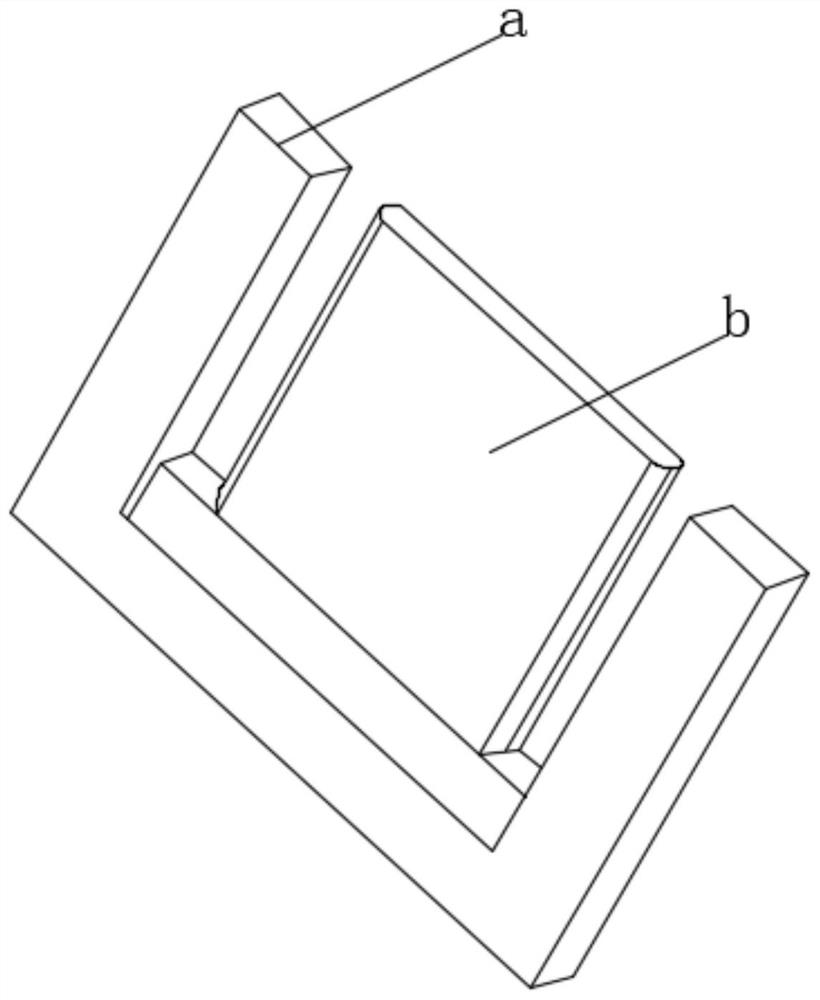

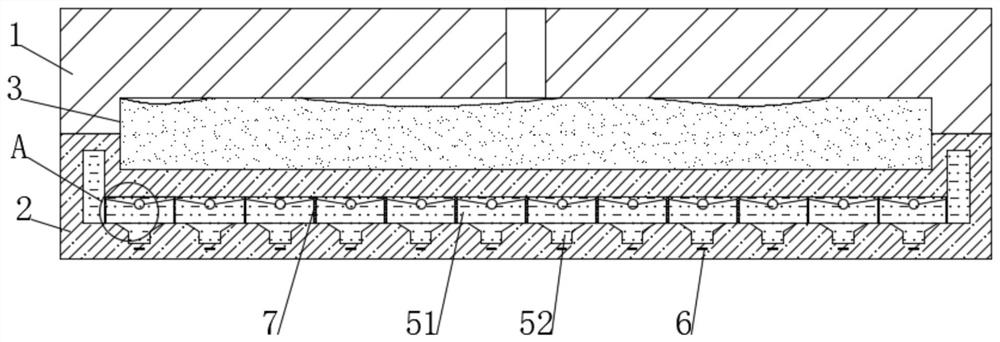

Flat and ultrathin manganese zinc ferrite magnetic core forming method

ActiveCN111483034AImprove uniformityMake up for uneven densityCeramic shaping apparatusManganeseZinc

The invention discloses a flat and ultrathin manganese zinc ferrite magnetic core forming method and belongs to the technical field of magnetic core forming. According to the flat and ultrathin manganese zinc ferrite magnetic core forming method, a certain impact effect to a lower die below a die cavity can be generated continuously by arranging a slingshot impact ball during power filling, so that a condition that the thickness of a pressed blank is non-uniform as a gap exists locally in powder of the die cavity is reduced effectively, and meanwhile, the radial uniformity of the powder can beimproved effectively. The pressing process is split by pressing at many times, the distributing uniformity of the powder is adjusted continuously while pressing, and a condition of non-uniform density in radial and axial directions of the powder due to pressing stress is compensated effectively, so that deformation generated by a formed blank is avoided effectively, the percent of pass of the magnetic core is improved obviously, and the cost input of production is lowered.

Owner:NANTONG HUAXING MAGNETIC MATERIAL

Glue feeding device and method for injection molding water tank

The invention provides a glue feeding device for an injection molding water tank. The glue feeding device comprises at least four needle valve nozzles and a glue injection structure, wherein the at least four needle valve nozzles are arranged and are arranged in two rows; the needle valve nozzles comprise a first row of needle valve nozzles which are arranged at a part close to an appearance surface of the water tank and a second row of needle valve nozzles which are arranged at a part far away the appearance surface of the water tank; the needle valve nozzles are arranged at the bottom of thewater tank and are used for feeding glue; the glue injection structure is used for injecting the glue into each needle valve nozzle. A glue feeding method for the injection molding water tank, provided by the invention, comprises the following steps: a flow channel setting step: arranging four points or more than four points of flow channels at the bottom of the water tank, and arranging the flowchannels in two rows; arranging the first row at the part close to the appearance surface of the water tank and arranging the second row at the part far away the appearance surface of the water tank;a glue feeding control step: controlling the first row of flow channels and the second row of flow channels to feed the glue. By adopting the glue feeding device and method for the injection moldingwater tank, provided by the invention, the defects of flow lines, shrinkage, welding lines, mold burrs and the like on the appearance surface of the water tank can be effectively eliminated.

Owner:ZHUHAI GREE PRECISION MOLD CO LTD +2

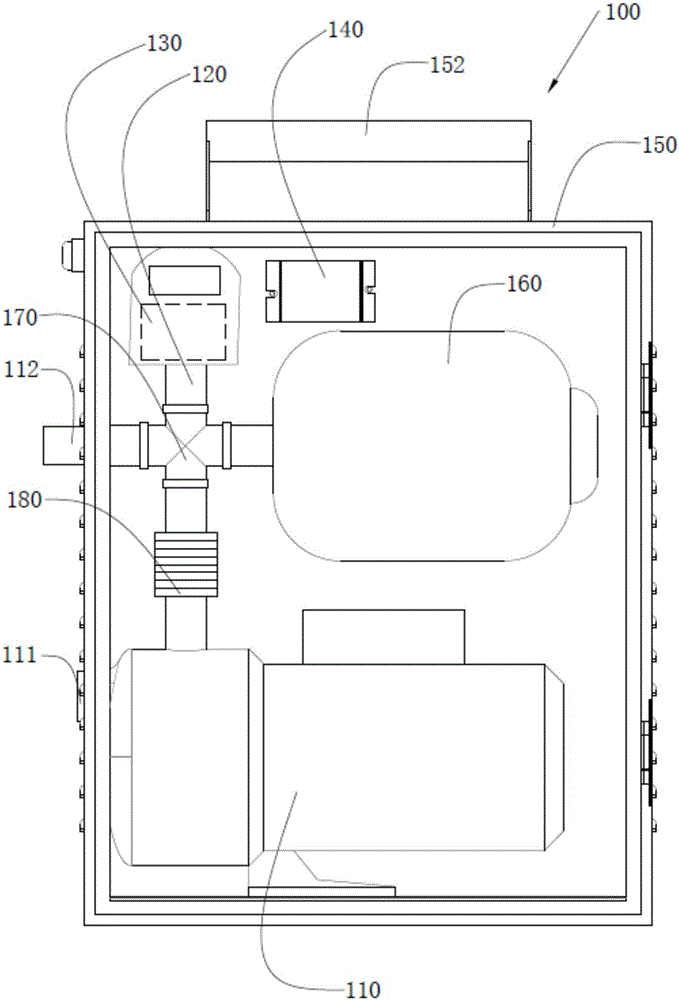

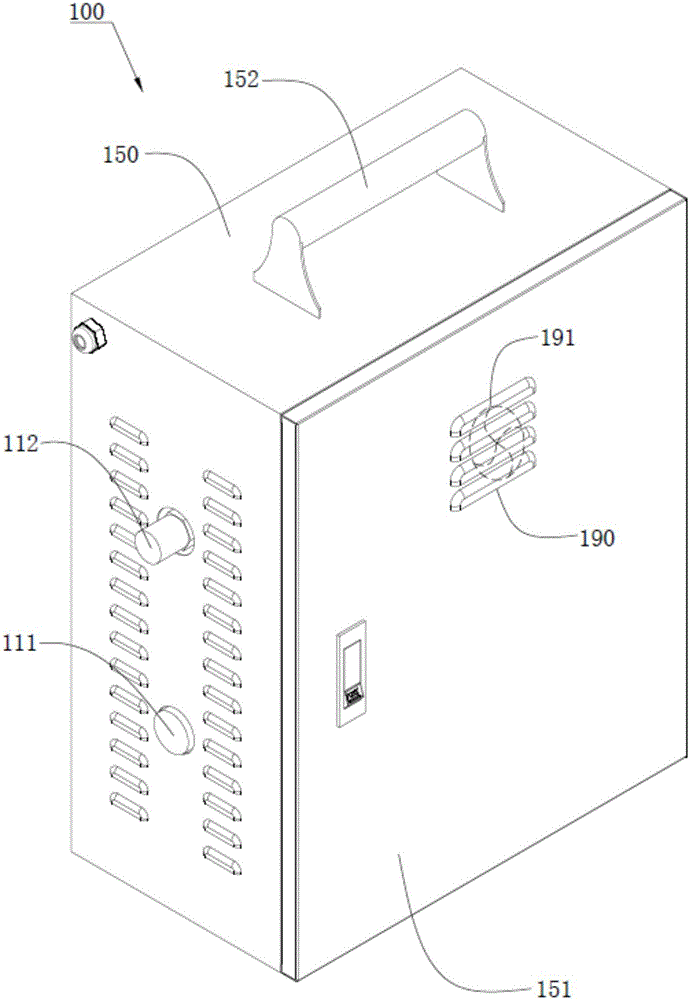

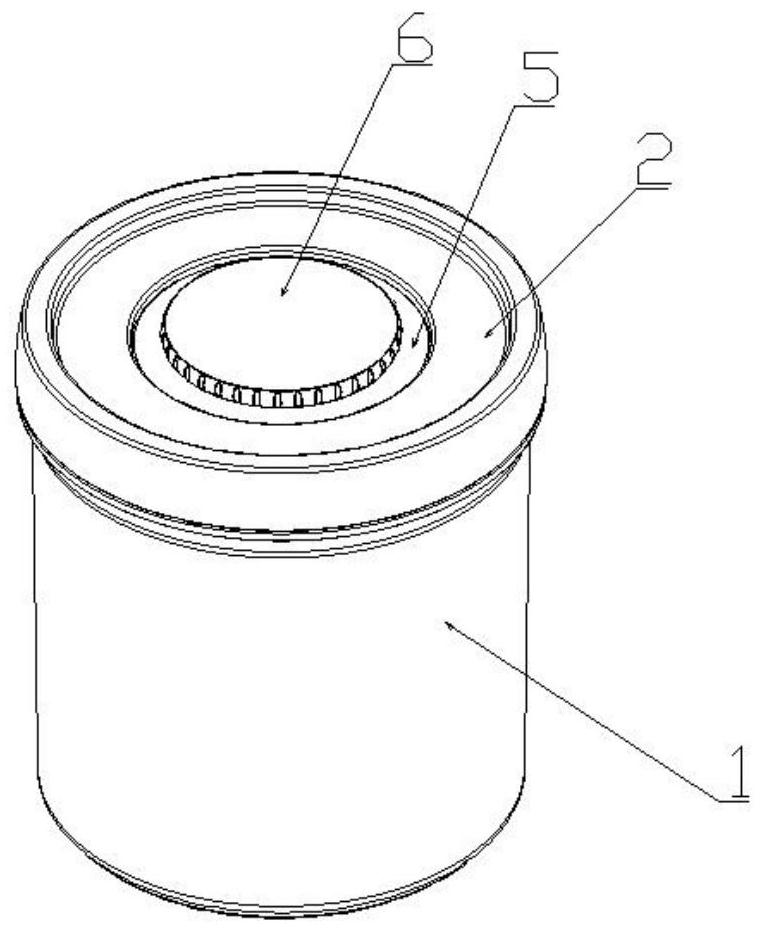

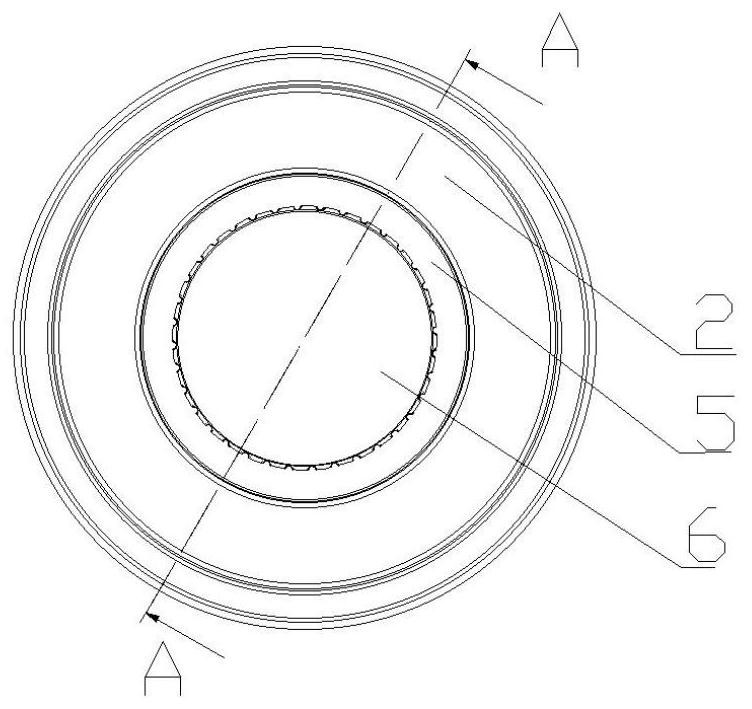

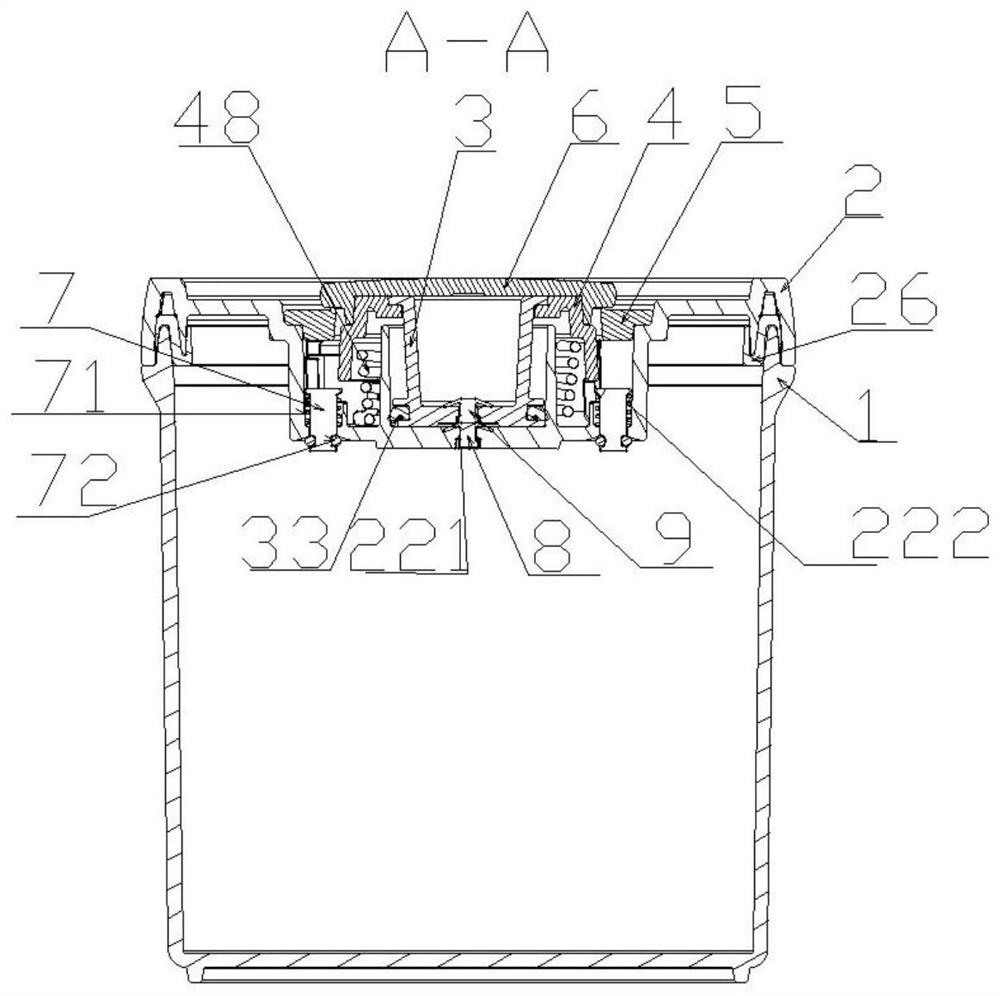

Vacuumizing device and vacuumizing container

ActiveCN112849771AEasy to store and carryConducive to maintaining pressureClosuresPackaging under vacuum/special atmospherePumping vacuumPiston

The invention relates to a vacuumizing device. The device comprises a cover body, a decoration body, a key, a piston and a key cover. The cover body comprises a base part and a concave part. The concave part protrudes upwards to form a supporting part. A first containing groove is formed between the supporting part and the concave part. A second containing groove is formed in the supporting part. The decoration body is contained in the first containing groove. The key is accommodated in an inner cavity of the decoration body and can move up and down. A key elastic piece is arranged on the supporting part in a sleeving mode. The lower portion of the piston is contained in the second containing groove, and the upper portion of the piston is contained in an inner cavity of the key and can move up and down. The key cover is arranged above the key, the key is fixedly connected with the key cover, and the key, the piston and the key cover synchronously move up and down. A first cavity is formed between a container body and the cover body, and a second cavity is formed between the piston and the bottom wall of the second containing groove. The bottom wall of the second containing groove is provided with a normally-closed exhaust hole, and the bottom wall of the piston is provided with a normally-closed exhaust hole. The vacuumizing device has the beneficial effects that vacuumizing, pressure maintaining and air inflation are realized by rotating or pressing the key cover, and the operation and the carrying are convenient.

Owner:TAIZHOU JUMA TECH CO LTD

Sealing member having good oil resistance used for brake caliper

The invention discloses a seal for a brake caliper with good oil resistance, relates to the technical field of sealing of an automobile brake caliper, and is made of the following components: nitrile rubber, EPDM rubber, dioctyl maleate, White carbon black, triallyl isocyanurate, lignin phenolic resin, aluminum oxide coated carbon fiber, vulcanizing agent, anti-aging agent, plasticizer; the seal for brake caliper prepared by the present invention has good oil resistance , heat resistance, good air tightness.

Owner:宁国市宁和密封件厂

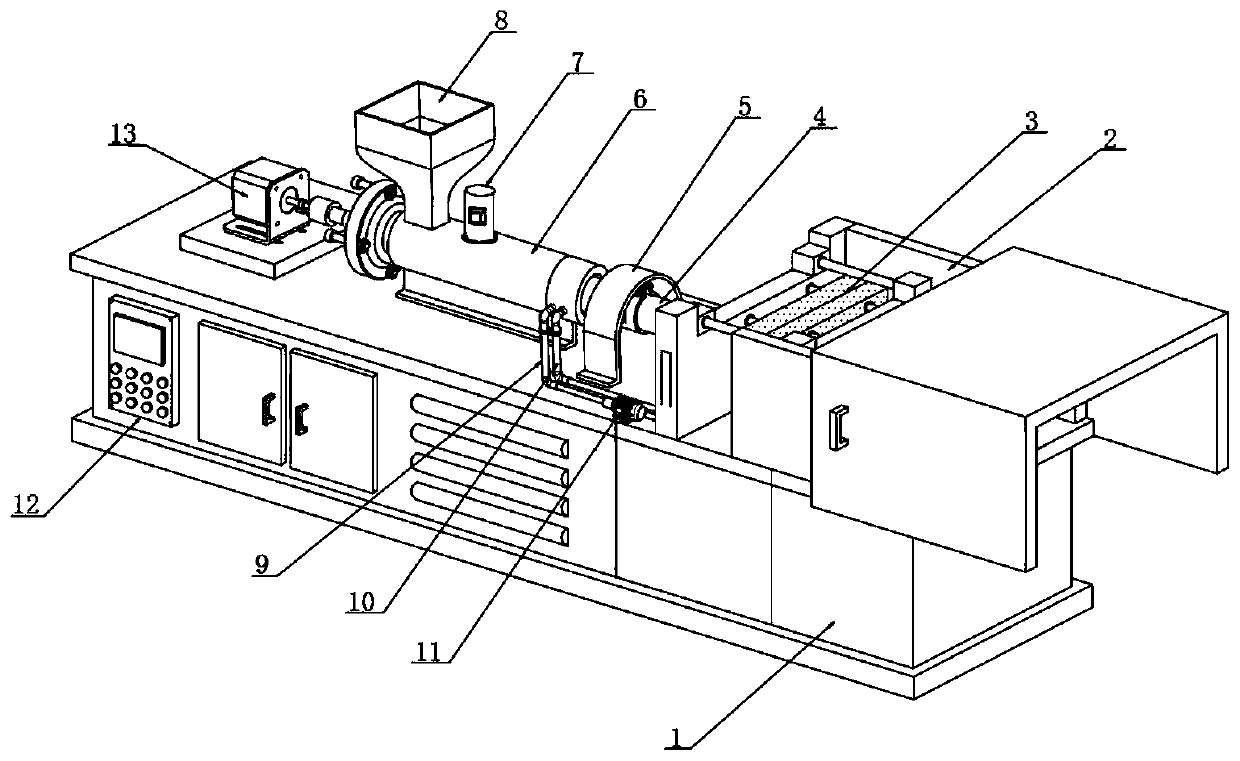

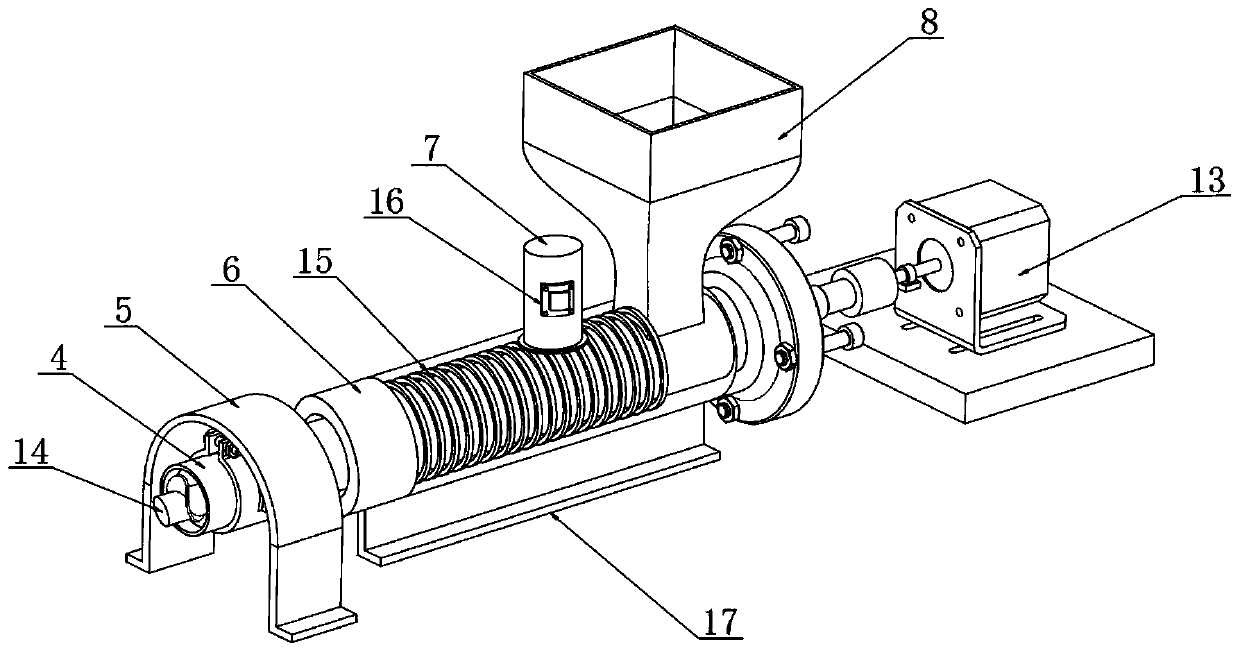

Plastic injection molding device with controllable melt injection pressure

InactiveCN111300781APrevent excessive internal pressureRealize savings and utilizationMelt temperatureHeat conservation

The invention discloses a plastic injection molding device with controllable melt injection pressure, and relates to the technical field of plastic production. The plastic injection molding device comprises a base, wherein an injection molding cavity side plate is arranged on one side of the upper end of the base, a charging barrel is arranged on one side, close to the injection molding cavity side plate, of the upper end of the base, the outer side surface of the charging barrel is wrapped with a thermal insulating tube, and a pressure control mechanism is arranged on one side, close to a feed hopper, of the upper end of the charging barrel. According to the plastic injection molding device, the melt injection pressure is controlled and adjusted by the pressure control mechanism, real-time control for the melt injection pressure is realized, the problem of overhigh internal pressure of the device is solved, a circulating pipe and a heat release pipe are adopted to cooperate with a cooling liquid and a pressure transfer pump, so that heat can be recycled, the recycled heat is applied to the outer side of the charging barrel, the problem of temperature loss of melt in the charging barrel due to too low temperature of the outer side of the charging barrel is solved, heat recycling is realized, energy waste is reduced, and resources are saved.

Owner:陈紫璇

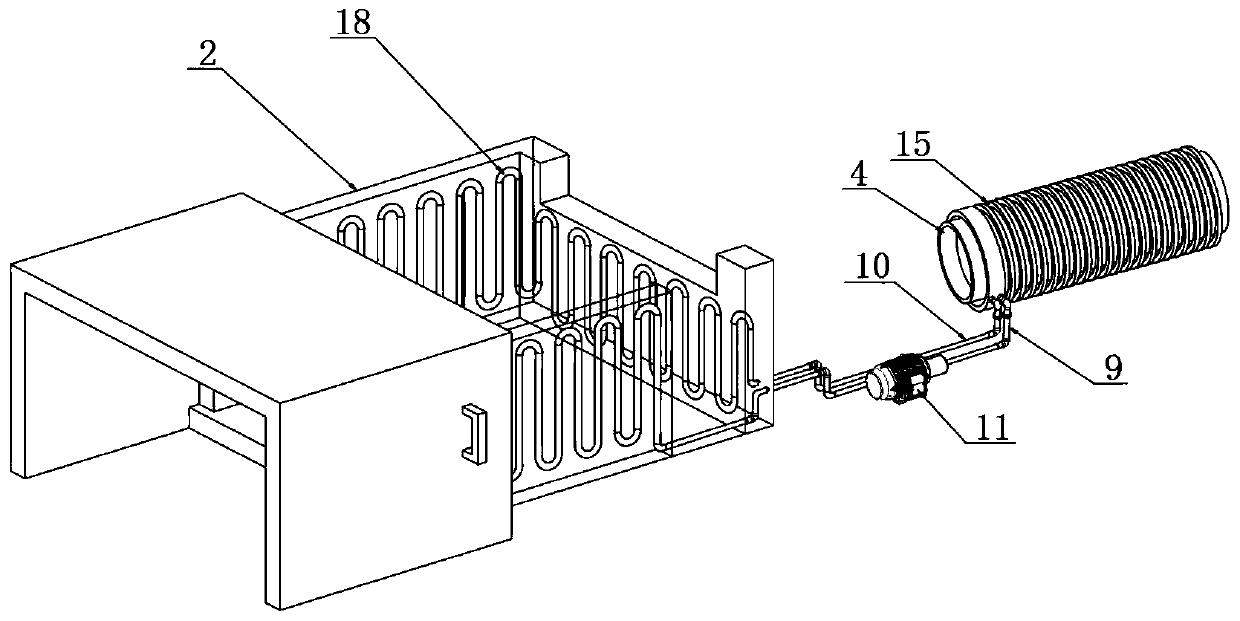

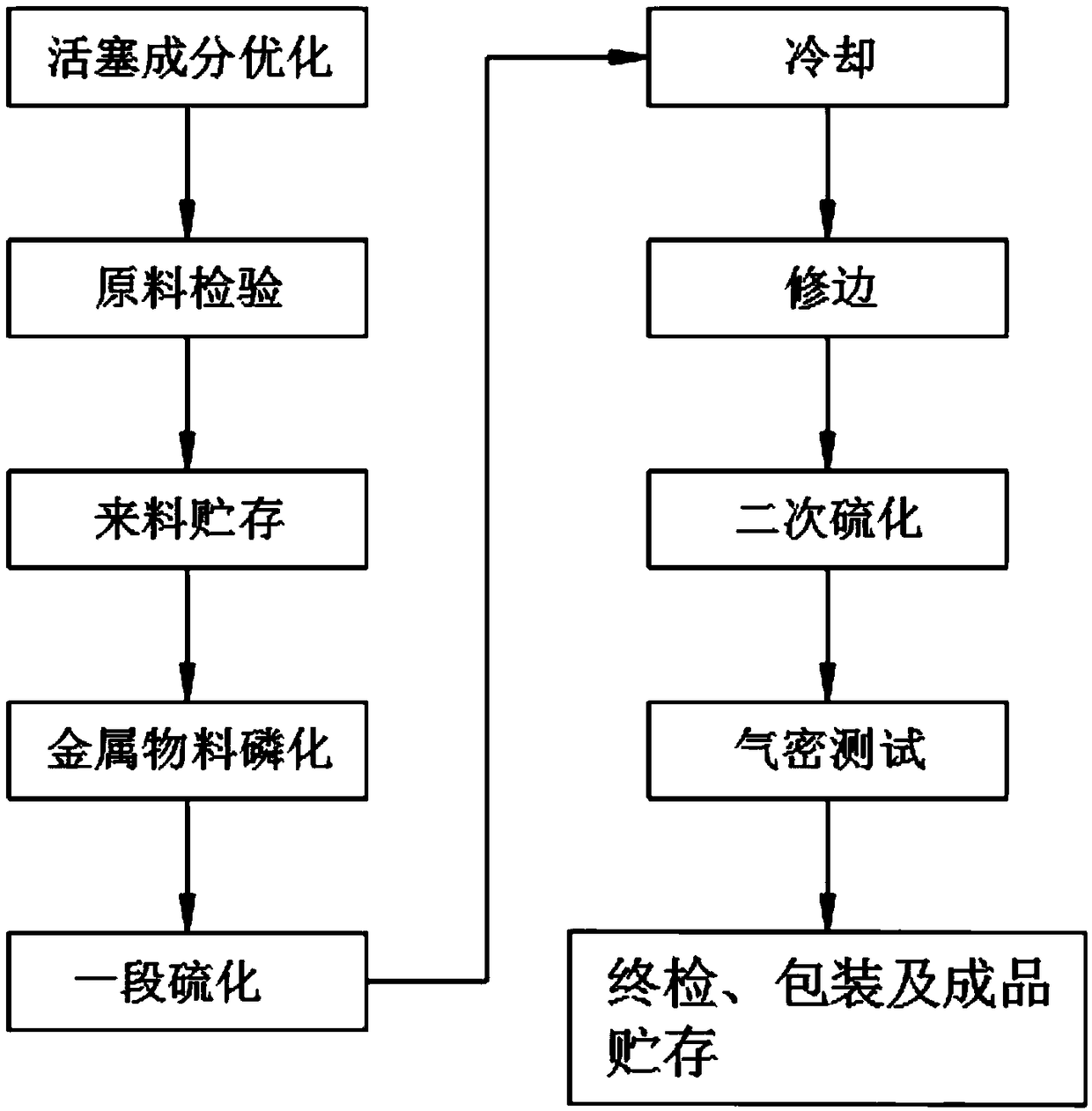

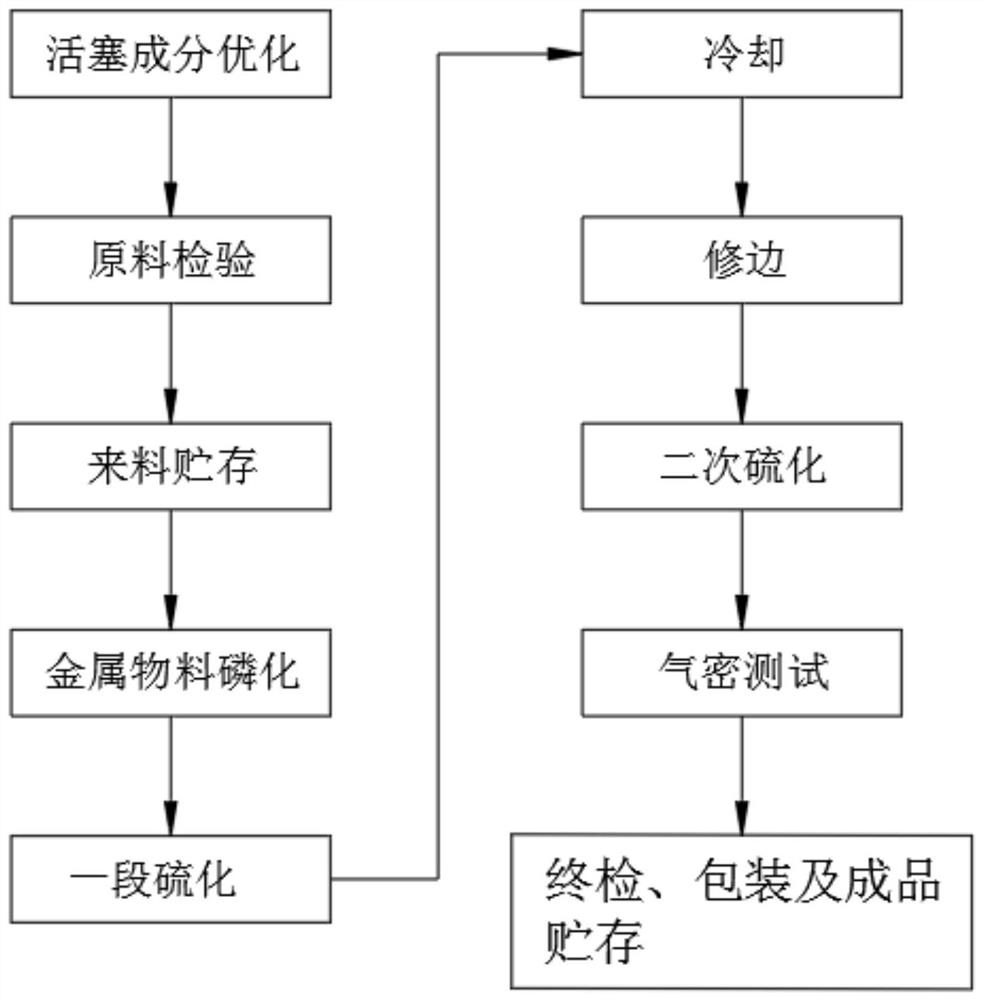

Optimal injection process for piston lip

The invention discloses an optimal injection process for a piston lip. The optimal injection process comprises the following steps: (1) optimization of piston components; (2) inspection of raw materials; (3) storage of incoming materials; (4) phosphating of metal materials: refining manganese, magnesium and lead in the raw materials respectively, proportionally adding the refined manganese, magnesium and lead into a phosphating solution for soaking for 20- / +3 minutes; (5) injection and pressure maintenance, wherein the plasticizing temperature is 60 DEG C, the temperature of an injection cylinder is 70 DEG C, the injection pressure is 120 to 130 bar, the holding pressure is 150 to 190 bar, the holding time is 3 to 7s, the ejection position of a thimble is 310 to 330mm, the ejection speed of the thimble is 150 to 190mm / s, the first-segment sulfurizing temperature is 190- / +5 DEG C, and the first-segment sulfurizing time is 90s; (6) cooling; (7) trimming; (8) second-segment sulfurizing atthe temperature of 185 DEG C for 3 hours; (9) airtight test; (10) final inspection, packaging and finished product storage. By adopting the optimal injection process, the product can keep the shape in a mold cavity during the de-molding process, the size stability of the lip is improved, and the airtightness of a piston is improved.

Owner:勃乐氏密封系统(太仓)有限公司

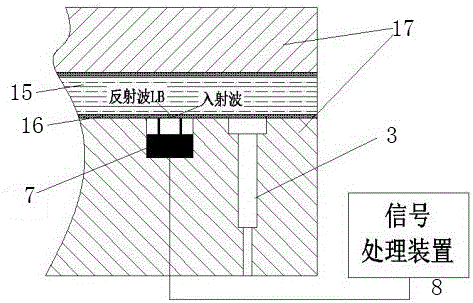

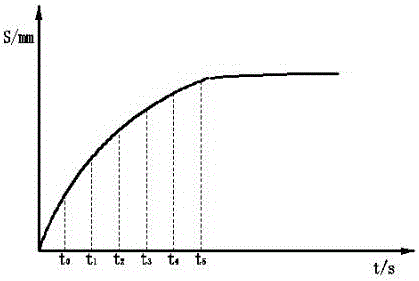

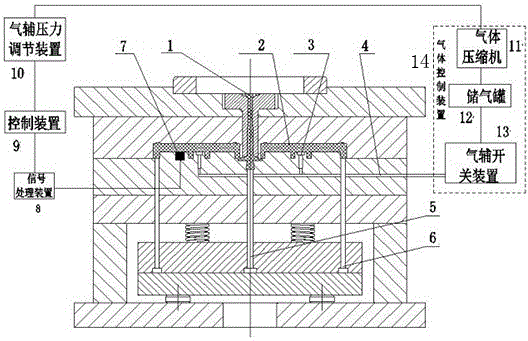

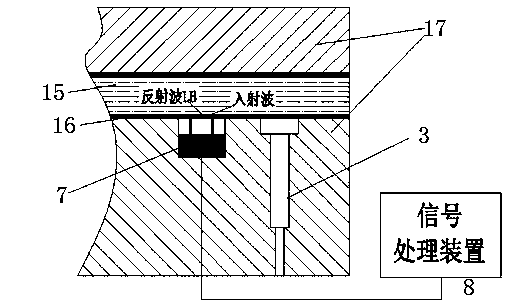

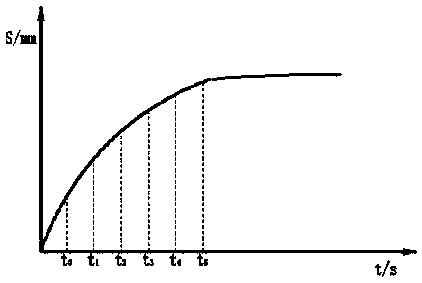

External gas assisted injection molding method based on ultrasonic measurement and molding equipment

The invention discloses an external gas assisted injection molding method based on ultrasonic measurement and molding equipment. The equipment comprises an injecting mold; the injecting mold is provided with a pouring gate, a cavity, a gas needle, a gas inlet channel, a material pulling rod and an ultrasonic probe; the ultrasonic probe is connected with a signal processing device; the signal processing device is connected with a control device and a gas assisted control device in sequence; the gas assisted control device is connected with the gas needle through the gas inlet channel; and compressed air in the gas assisted control device enters the cavity through the gas needle. According to the external gas assisted injection molding method based on the ultrasonic measurement and the molding equipment, an ultrasonic detection technology is reasonably used for external assisted molding equipment, proper gas injection time is simply and rapidly judged and the production efficiency is improved; and meanwhile, shrink marks on the surface of a molded part can also be effectively removed and the product quality is improved.

Owner:ZHEJIANG UNIV OF TECH

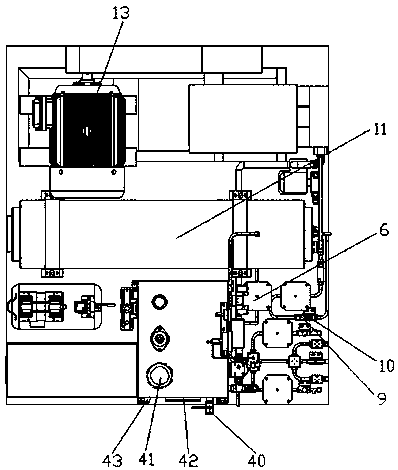

Hydrostatic test automatic test system

ActiveCN111257121AStable pressure holdingConducive to maintaining pressureMeasurement of fluid loss/gain rateMaterial strength using tensile/compressive forcesAir pumpHydraulic equipment

The invention discloses a hydrostatic test automatic test system, and belongs to the technical field of water hydraulic equipment testing. The hydrostatic test automatic test system is characterized in that an air source integrated control valve bank is sequentially connected with an air pump, a first air source reversing valve bank, a one-way valve, a container unloading valve, a high-pressure filter, a manual stop valve, a pressure sensor, an overflow valve, a pressure stabilizing tank, a high pressure pump, a motor and a water tank through connecting pipelines; the high pressure pump is connected with a pressure maintaining flat valve bank. A pressure relief device comprises a pressure relief flat valve bank, a second air source reversing valve bank, an electric throttle valve and a high-pressure sensor; the pressure maintaining flat valve bank and the pressure relief flat valve bank are connected in parallel; a high-pressure input interface, a high-pressure output interface, a pressure relief input port and a pressure relief output port are fixed on the rack, and the electric throttle valve and the high-pressure sensor are respectively connected with the pressure relief input port. The pressure resistance of various pipelines, high-pressure and low-pressure pressure vessels and equipment can be tested, and the system has the characteristics of high pollution resistance, high pressure maintaining precision, safety and reliability in testing and long service life.

Owner:中国东方电气集团有限公司

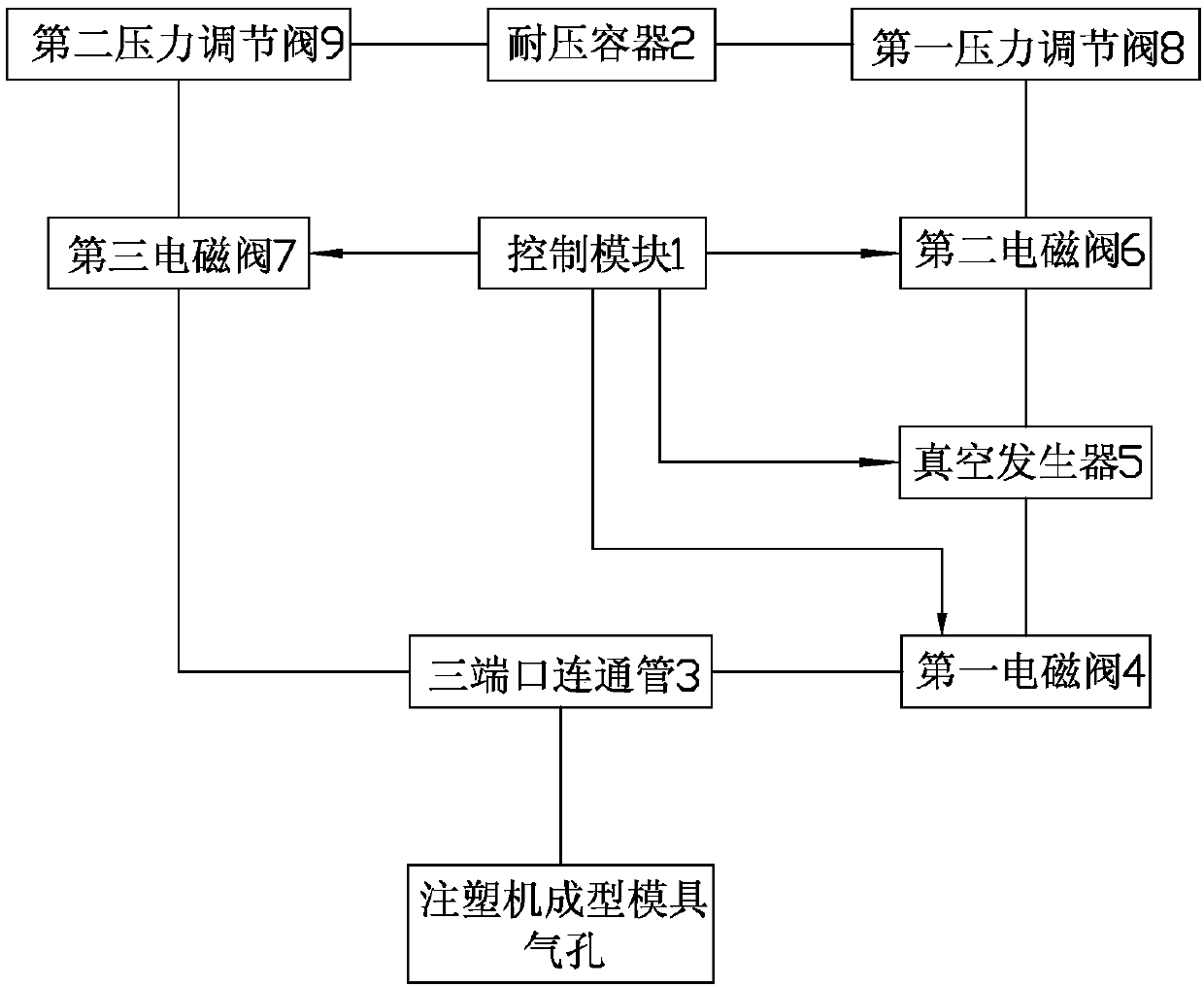

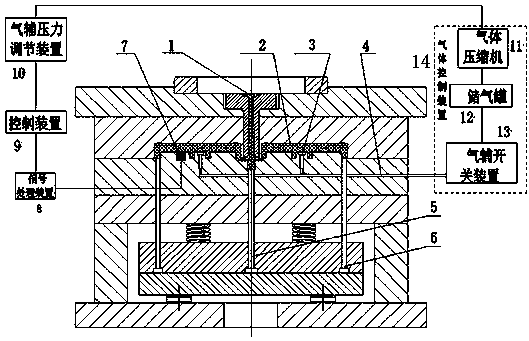

Air suction and air supply control system for injection molding machine molding die

InactiveCN107856266ASimple structureConducive to maintaining pressureControl systemAtmospheric pressure

The invention discloses an air suction and air supply control system for an injection molding machine molding die. According to the air suction and air supply control system for the injection moldingmachine molding die, a three-port communicating pipe is adopted to be connected with an air hole in the injection molding machine molding die, namely, the air suction and the air supply share the samethree-port communicating pipe, and the three-port communicating pipe is convenient to connect and use; a control module, through controlling a first electromagnetic valve, a vacuum generator, a second electromagnetic valve and a third electromagnetic valve, is used for temporarily storing air in the injection molding machine molding die in a pressure-resistant container during an air suction process and used for sending the air temporarily stored in the pressure-resistant container back into the injection molding machine molding die during an air supply process, and the control is convenient;and when the air temporarily stored in the pressure-resistant container is sent back into the injection molding machine molding die, the air pressure in the injection molding machine molding die cannot be too large, so that pressure maintaining, shaping and subsequent opening of the injection molding machine molding die are facilitated.

Owner:GUANGDONG TAIAN MOLDING TECH CO LTD

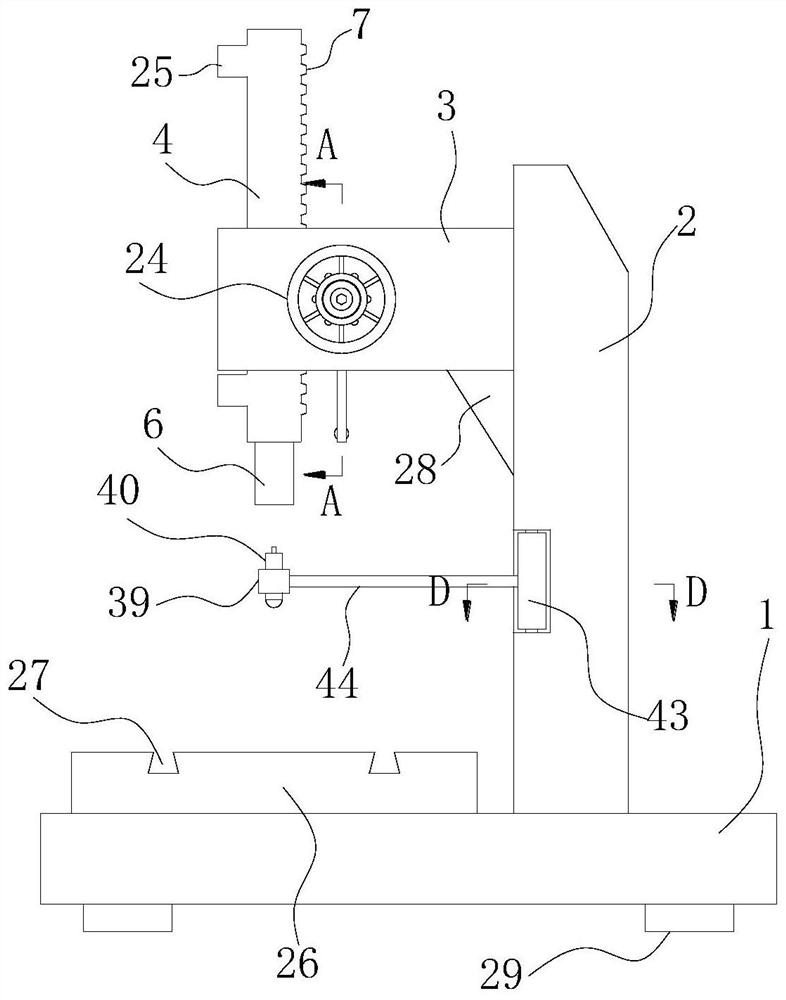

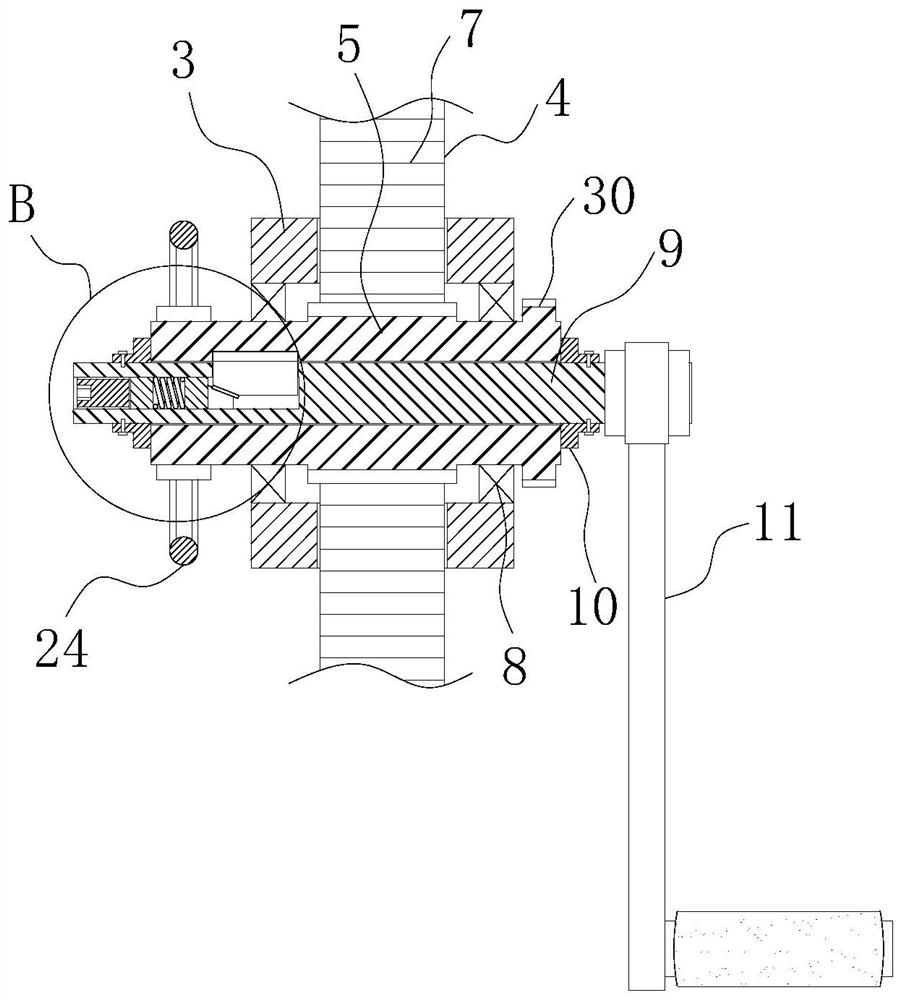

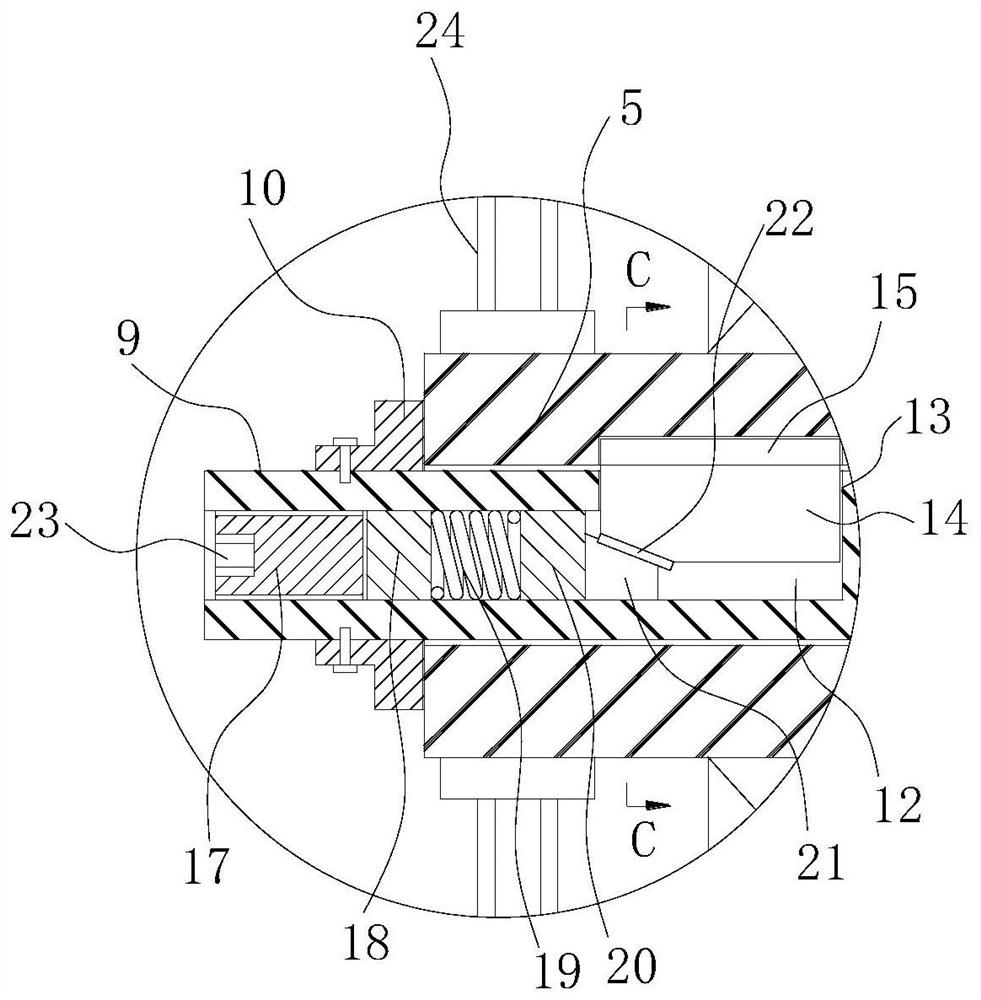

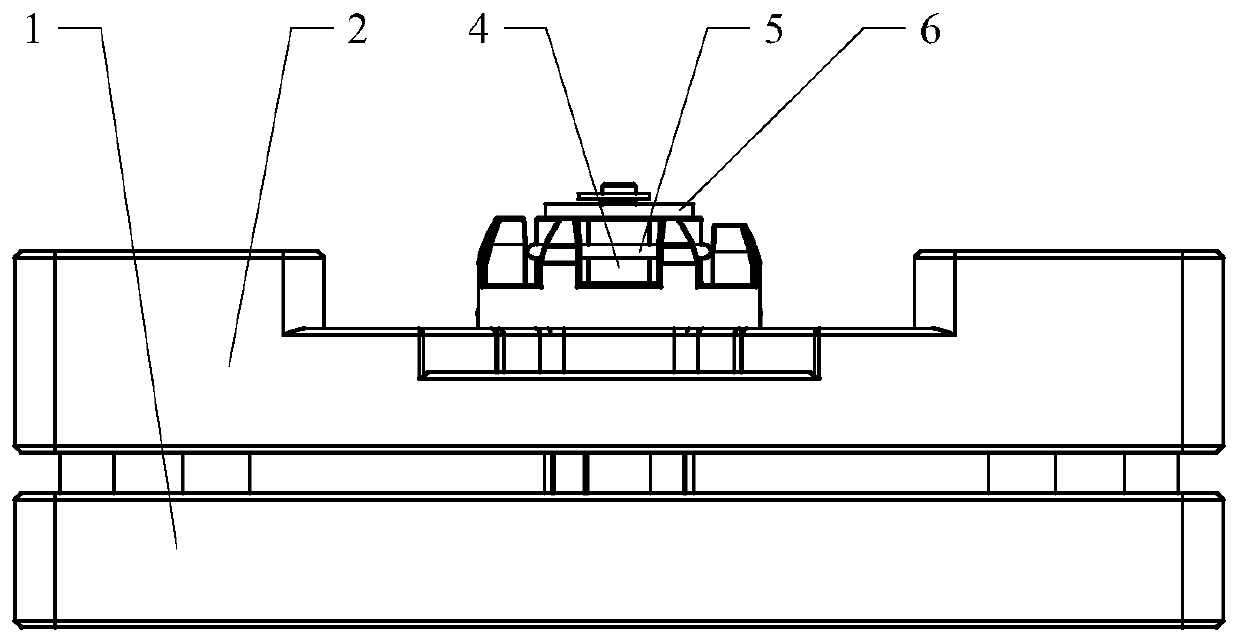

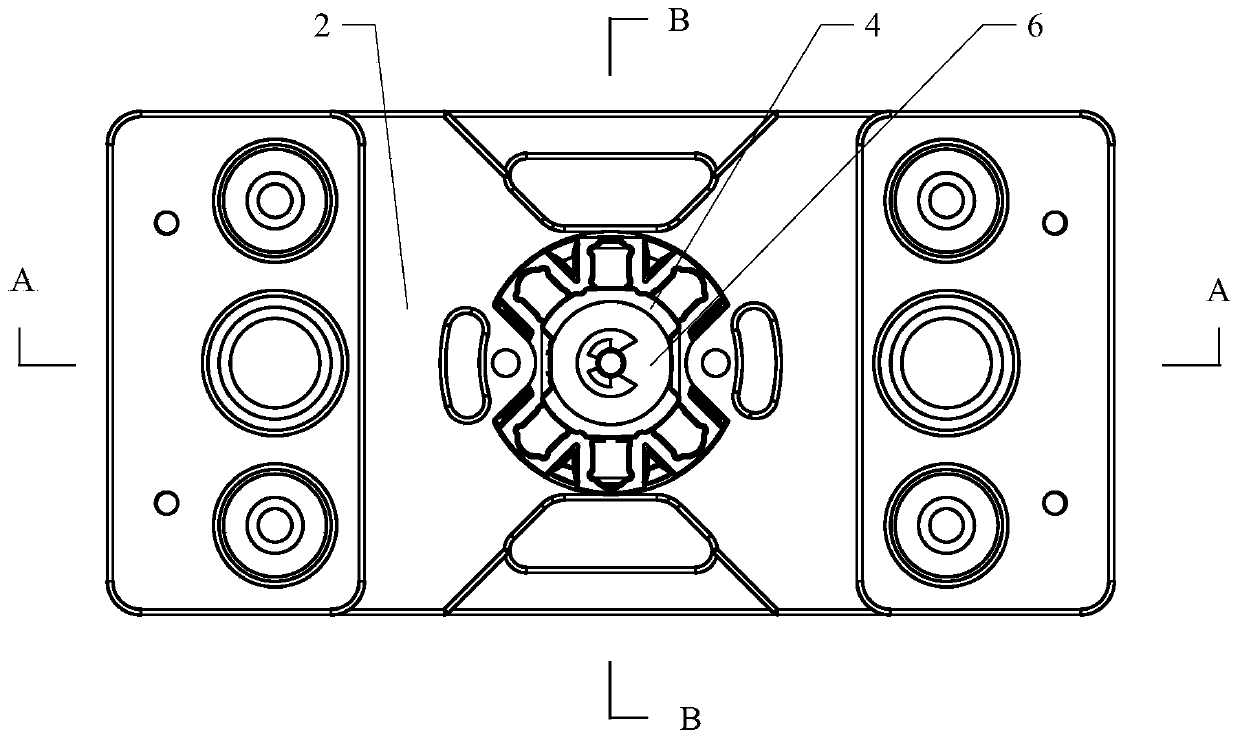

A self-locking press

The invention particularly relates to a hand press, and aims to provide a self-locking press machine capable of pressure maintaining conveniently. According to the technical scheme, the self-locking press machine comprises a machine seat and a press device located on the upper part of the machine seat, and the press device is connected with the machine seat through a supporting standing column; the press device comprises a cross beam, a lifting column, a gear shaft and a driving mechanism, a self-locking assembly is further arranged at one end of the gear shaft, the self-locking assembly comprises a ratchet wheel and a pawl, the ratchet wheel sleeves the circumferential surface of one end of the gear shaft and is fixedly connected with the gear shaft; the middle of the pawl is hinged to the side wall of the cross beam through a hinged shaft, one end of the pawl abuts against the ratchet wheel, the other end of the pawl extends into a U-shaped limiting clamp; and a guiding casing is further fixedly arranged on the side wall of the cross beam on the rear part of the pawl, and the guiding casing is internally provided with a sliding rod matched with the guiding casing in a penetratingmode. According to the self-locking press machine, the hand press can be self-locked, pressure maintaining is convenient, and meanwhile, after pressure maintaining is completed, unlocking can also beconducted conveniently and quickly.

Owner:SHANDONG LUDA TEST INSTR

An external gas-assisted injection molding method and molding equipment based on ultrasonic measurement

The invention discloses an external gas assisted injection molding method based on ultrasonic measurement and molding equipment. The equipment comprises an injecting mold; the injecting mold is provided with a pouring gate, a cavity, a gas needle, a gas inlet channel, a material pulling rod and an ultrasonic probe; the ultrasonic probe is connected with a signal processing device; the signal processing device is connected with a control device and a gas assisted control device in sequence; the gas assisted control device is connected with the gas needle through the gas inlet channel; and compressed air in the gas assisted control device enters the cavity through the gas needle. According to the external gas assisted injection molding method based on the ultrasonic measurement and the molding equipment, an ultrasonic detection technology is reasonably used for external assisted molding equipment, proper gas injection time is simply and rapidly judged and the production efficiency is improved; and meanwhile, shrink marks on the surface of a molded part can also be effectively removed and the product quality is improved.

Owner:ZHEJIANG UNIV OF TECH

Intelligent network control device for fire extinguishing system

ActiveCN113368429AHigh degree of automationConducive to maintaining pressureLighting and heating apparatusVentilation arrangementIntelligent NetworkElectric power system

The invention relates to the technical field of fire-fighting systems, in particular to an intelligent network control device for a fire extinguishing system. The device comprises a fire-fighting pool, a machine room, a plurality of indoor fire-fighting devices and a plurality of outdoor fire-fighting devices, wherein an electric power system, an intelligent control system, an air draft system and two pressure-maintaining fire-fighting water supply pumps are mounted in the machine room, the intelligent control system is connected with the electric power system, the air draft system and the two pressure-maintaining fire-fighting water supply pumps are all connected with the intelligent control system, the pressure-maintaining fire-fighting water supply pumps are communicated with the fire-fighting water pool, the pressure-maintaining fire-fighting water supply pumps are communicated with an indoor pipeline and an outdoor pipeline, and the outdoor fire-fighting device and the indoor fire-fighting device are communicated with the outdoor pipeline and the indoor pipeline respectively. The plurality of indoor fire-fighting devices are all provided with the smoke exhaust devices, so that the device is reliable to operate, more in function and more convenient to use, the influence on escape space is small, a negative pressure is easily formed indoors, fire spreading is suppressed, the requirement for the surroundings is low through installation of the outdoor fire hydrant, and the device is high in practicability.

Owner:INNER MONGOLIA FINANCE AND ECONOMICS UNIVERSITY

Forming method of flat ultra-thin MnZn ferrite core

ActiveCN111483034BImprove uniformityMake up for uneven densityCeramic shaping apparatusManganeseZinc ferrite

Owner:NANTONG HUAXING MAGNETIC MATERIAL

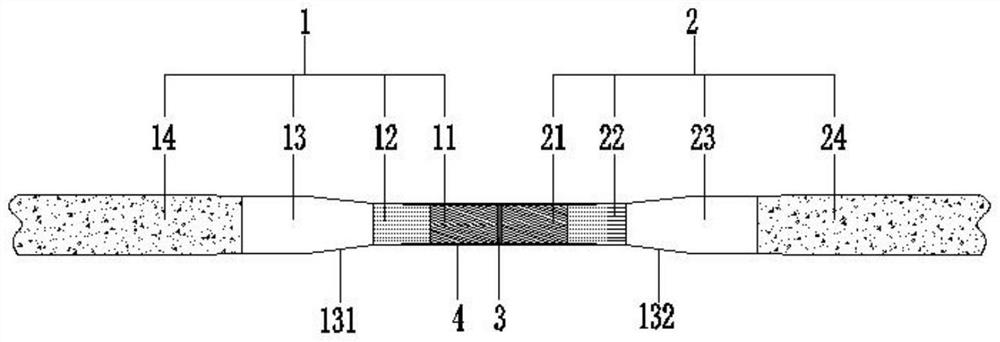

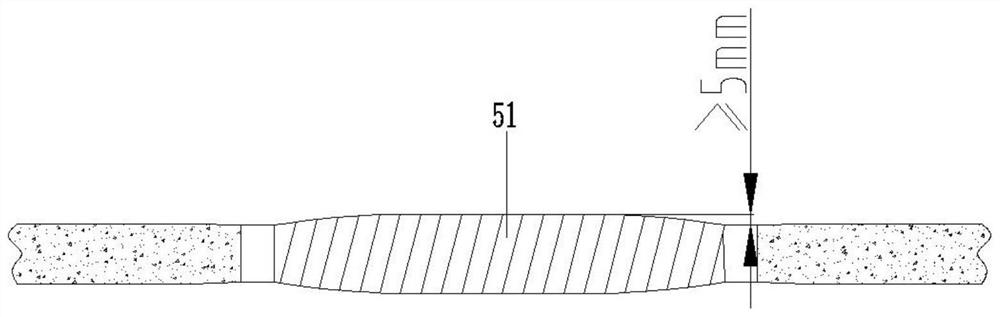

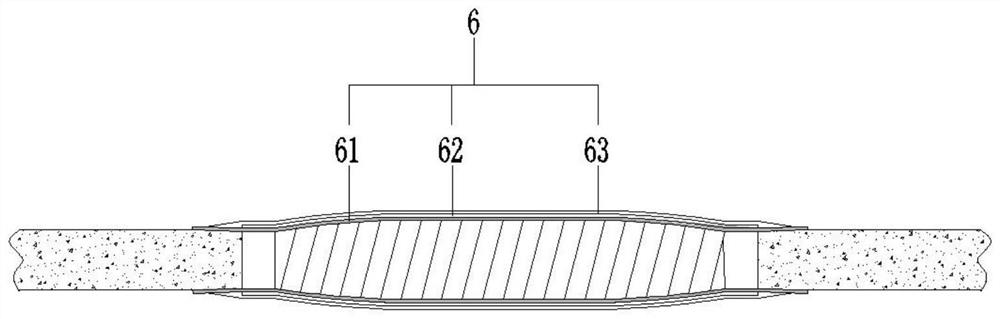

Polypropylene cable and insulating layer repairing method and application thereof

PendingCN114566312AAchieve fixGuaranteed electrical performanceInsulated cablesElectronic waste recyclingPolymer scienceInsulation layer

The invention belongs to the technical field of polypropylene cables, and particularly relates to a polypropylene cable and an insulating layer repairing method and application thereof. The invention provides a polypropylene cable and an insulating layer repairing method and application thereof, and the repairing method comprises the steps: wrapping a pencil stub slope insulating layer with a polypropylene insulating tape, then sequentially wrapping the polypropylene insulating tape with a rubber soft film, a metal foil and a polyimide film from inside to outside, and finally heating the polypropylene insulating tape to melt the polypropylene insulating tape, the polypropylene insulating tape can provide lasting radial pressure, the metal foil can uniformly transfer heat, and the polyimide film has relatively high tensile strength and relatively low load elongation, so that the polypropylene insulating tape and the to-be-repaired position of the polypropylene cable insulating layer are fused and combined, the repair of the polypropylene cable insulating layer is realized, and the service life of the polypropylene cable insulating layer is prolonged. The electrical performance of the polypropylene cable is guaranteed, and the technical problem that in the prior art, a polypropylene cable insulation layer repairing technology is lacked is solved.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

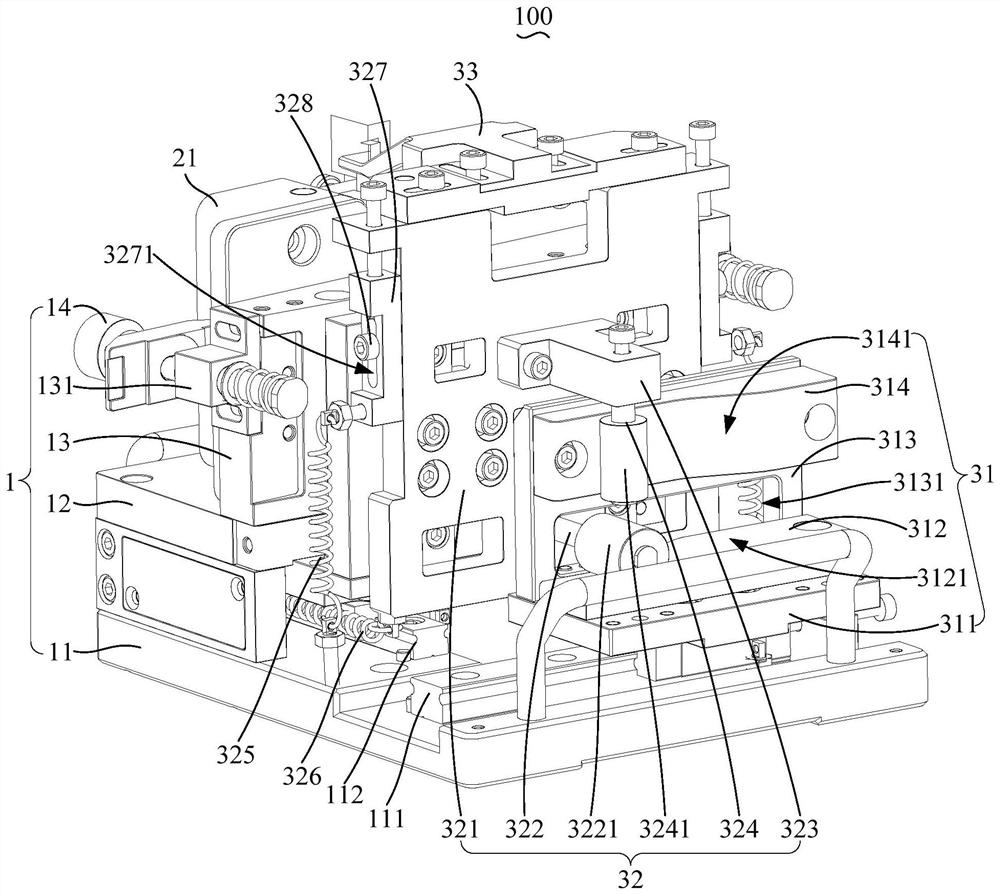

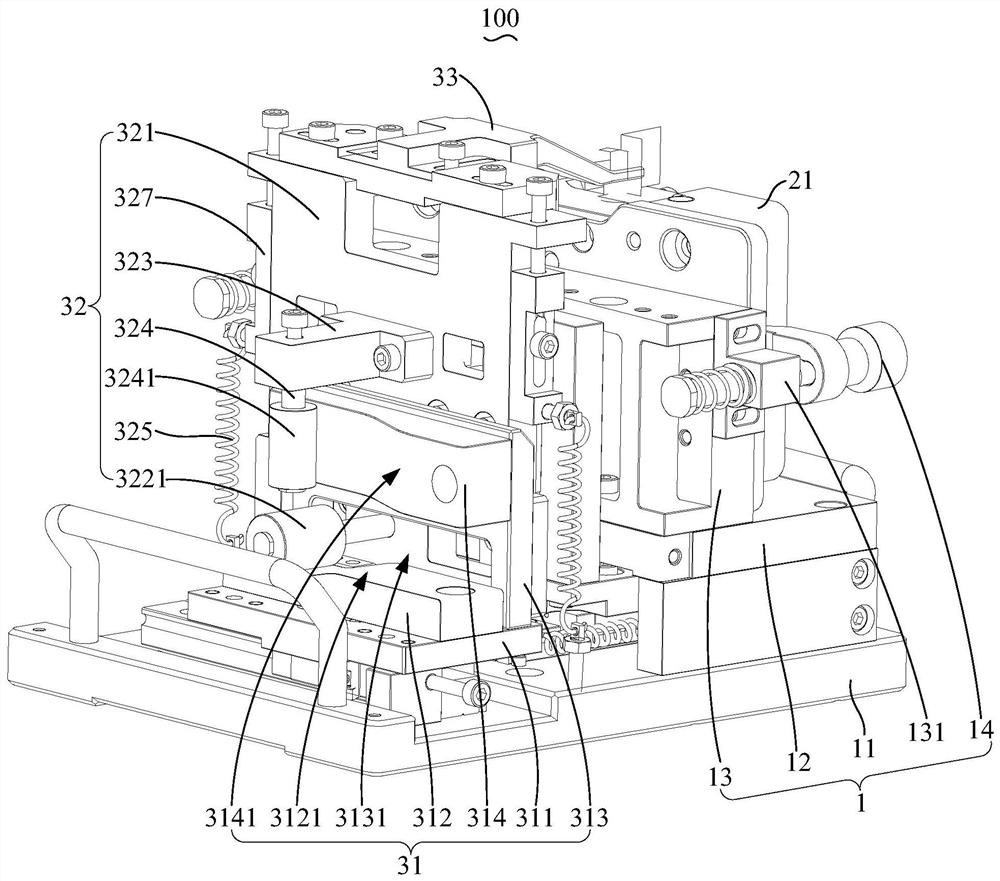

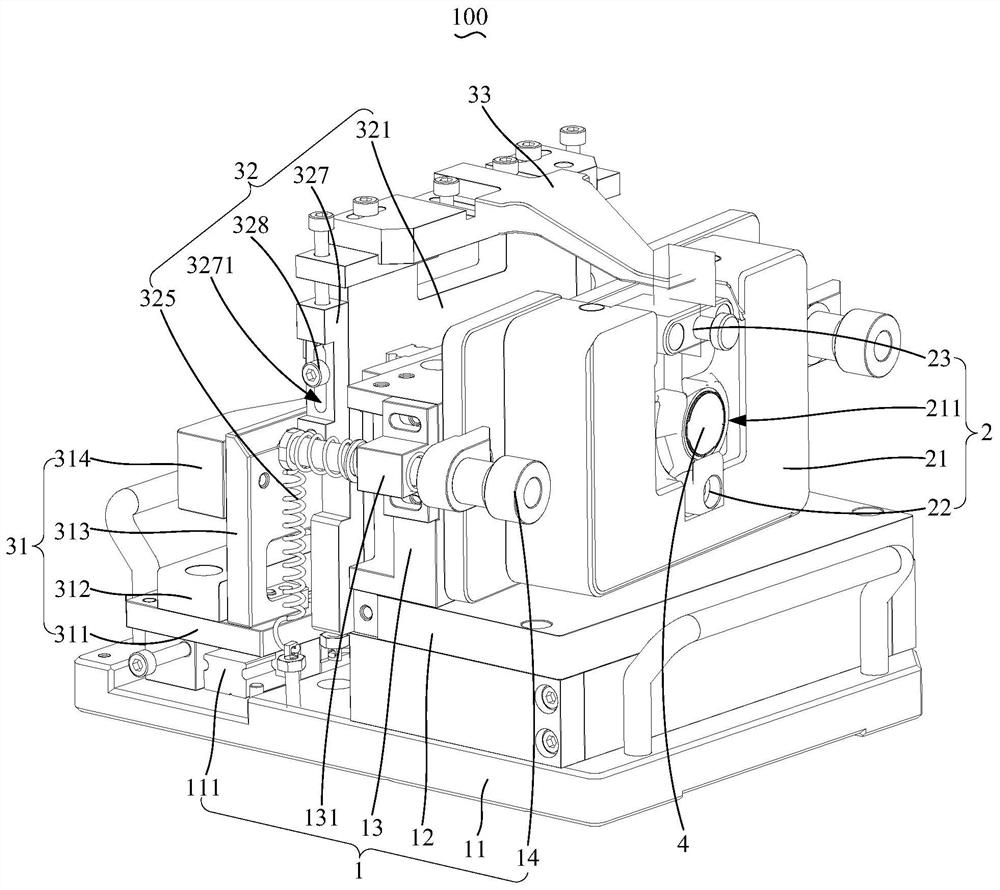

Pressure holding equipment

ActiveCN111022455BConducive to maintaining pressureEasy to installPlastic deformation fasteningMaterial gluingHeadphonesMechanical engineering

The invention discloses a pressure maintaining device, which is used for pressure maintaining earphones. The pressure maintaining device includes: a base; It includes a sliding platform assembly slidably arranged on the base, a pressure maintaining assembly and a pressure head, the pressure maintaining assembly is movably arranged between the carrier and the sliding platform assembly, and the sliding platform assembly is set There is a first slope surface, and the side of the pressure maintaining component facing the slide assembly is rotatably provided with a first roller, the first roller abuts against the first slope surface, and the pressure head is set on The end of the pressure maintaining component away from the base is used for pressure maintaining the earphone. The present invention aims to provide a pressure-holding device capable of maintaining pressure well on small-volume electronic products, and the pressure-holding device can effectively provide assembly stability of the product.

Owner:GOERTEK INC

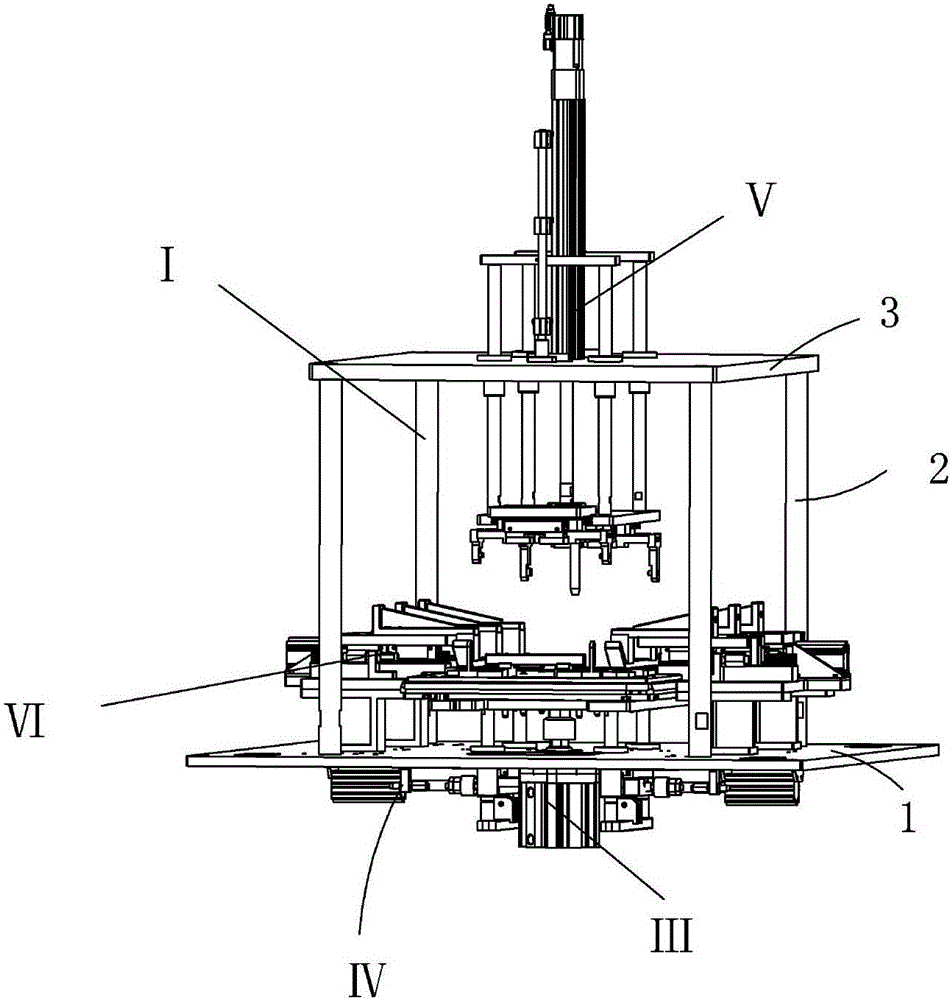

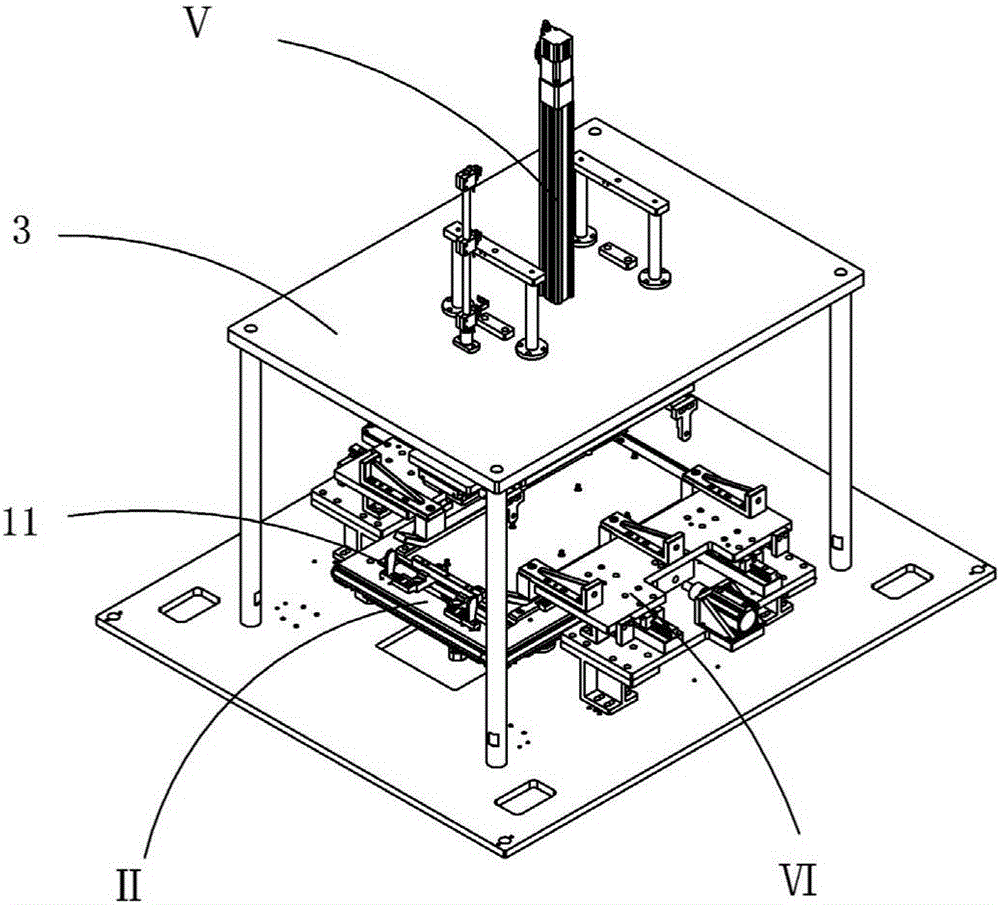

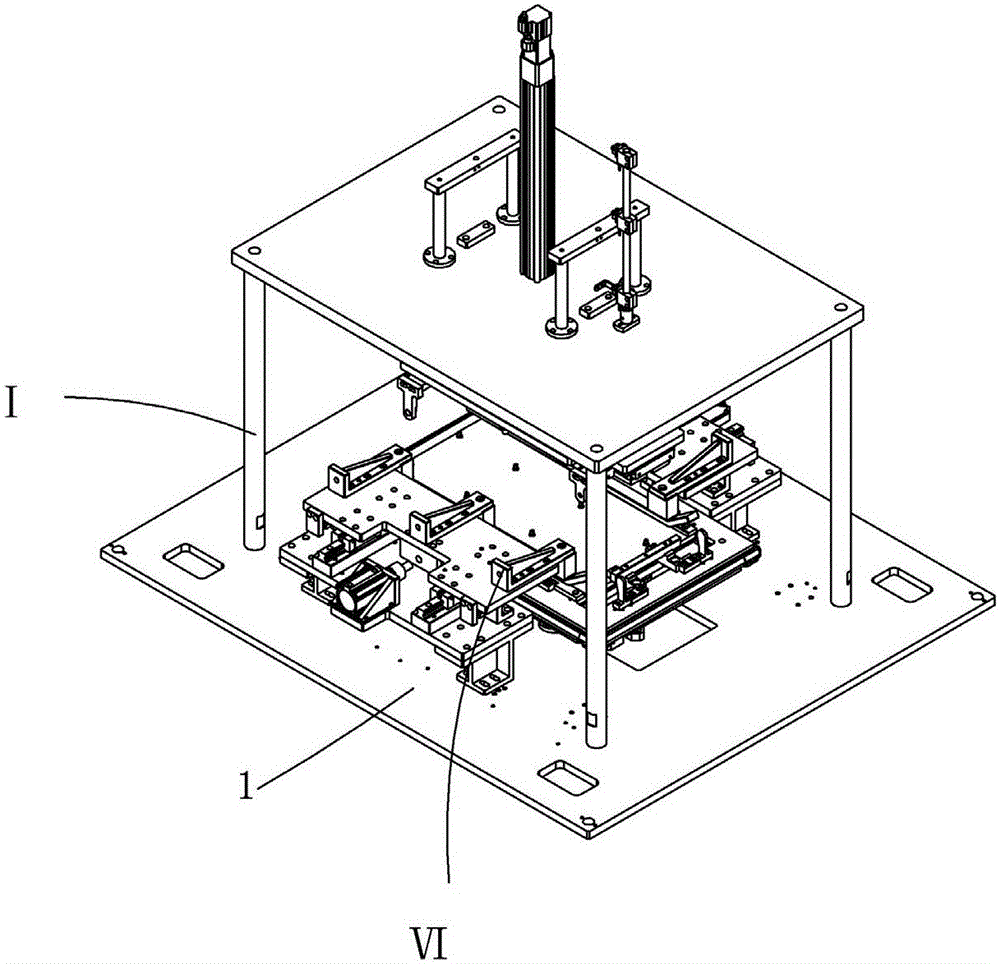

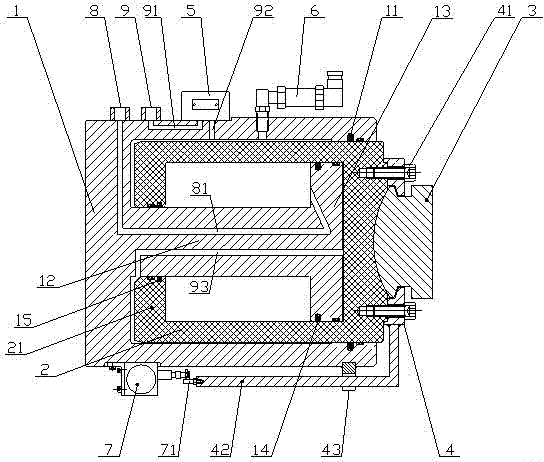

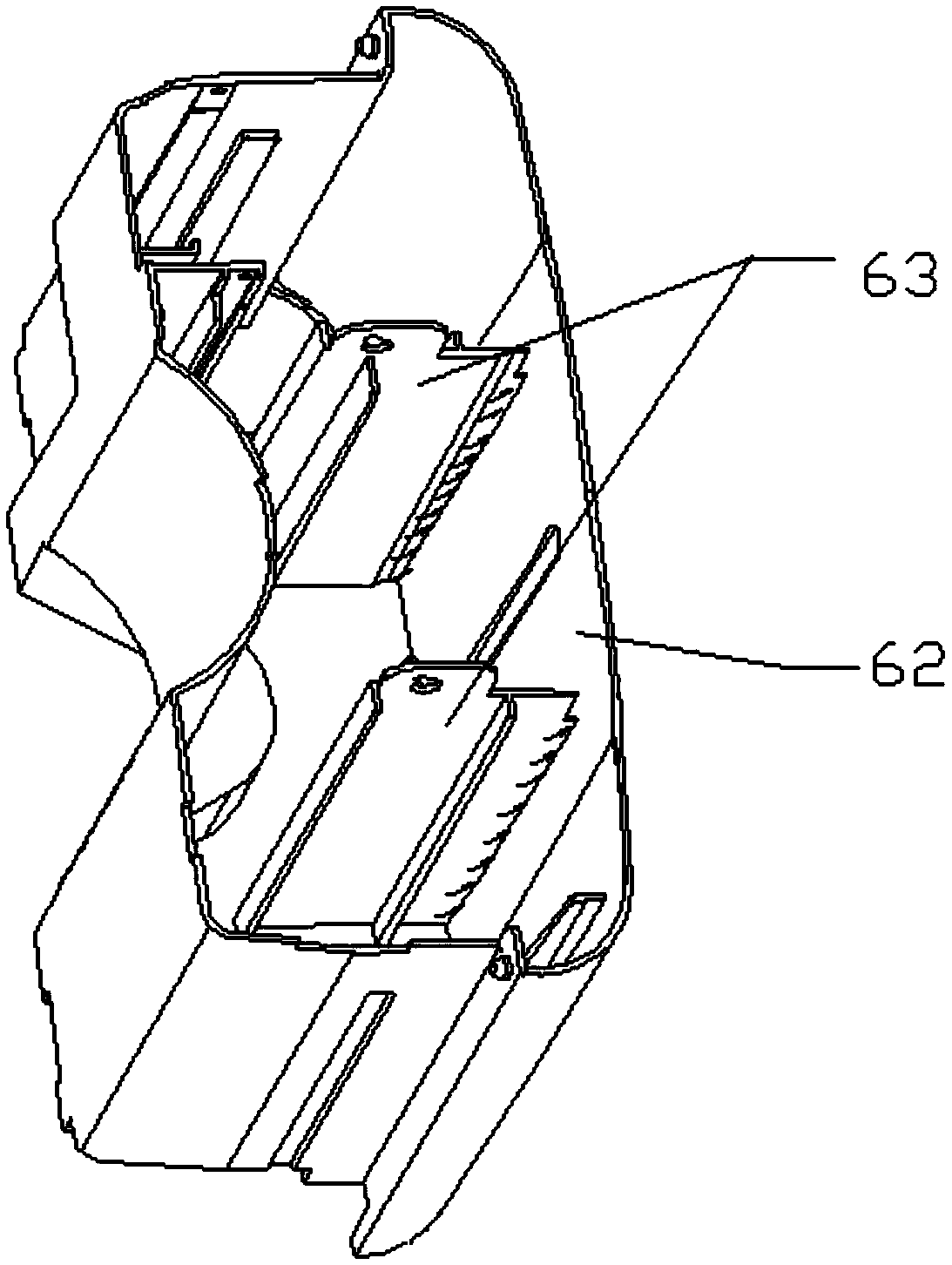

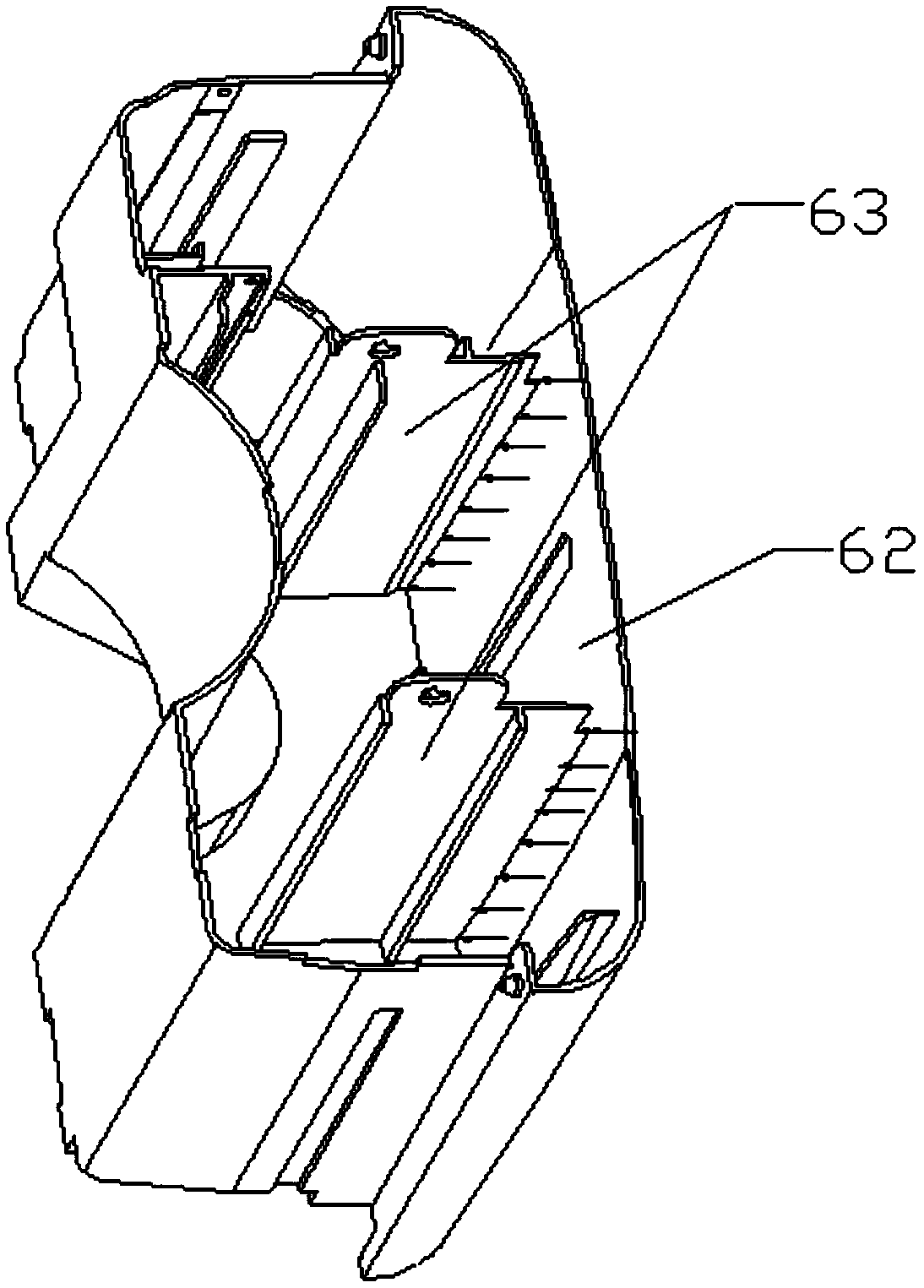

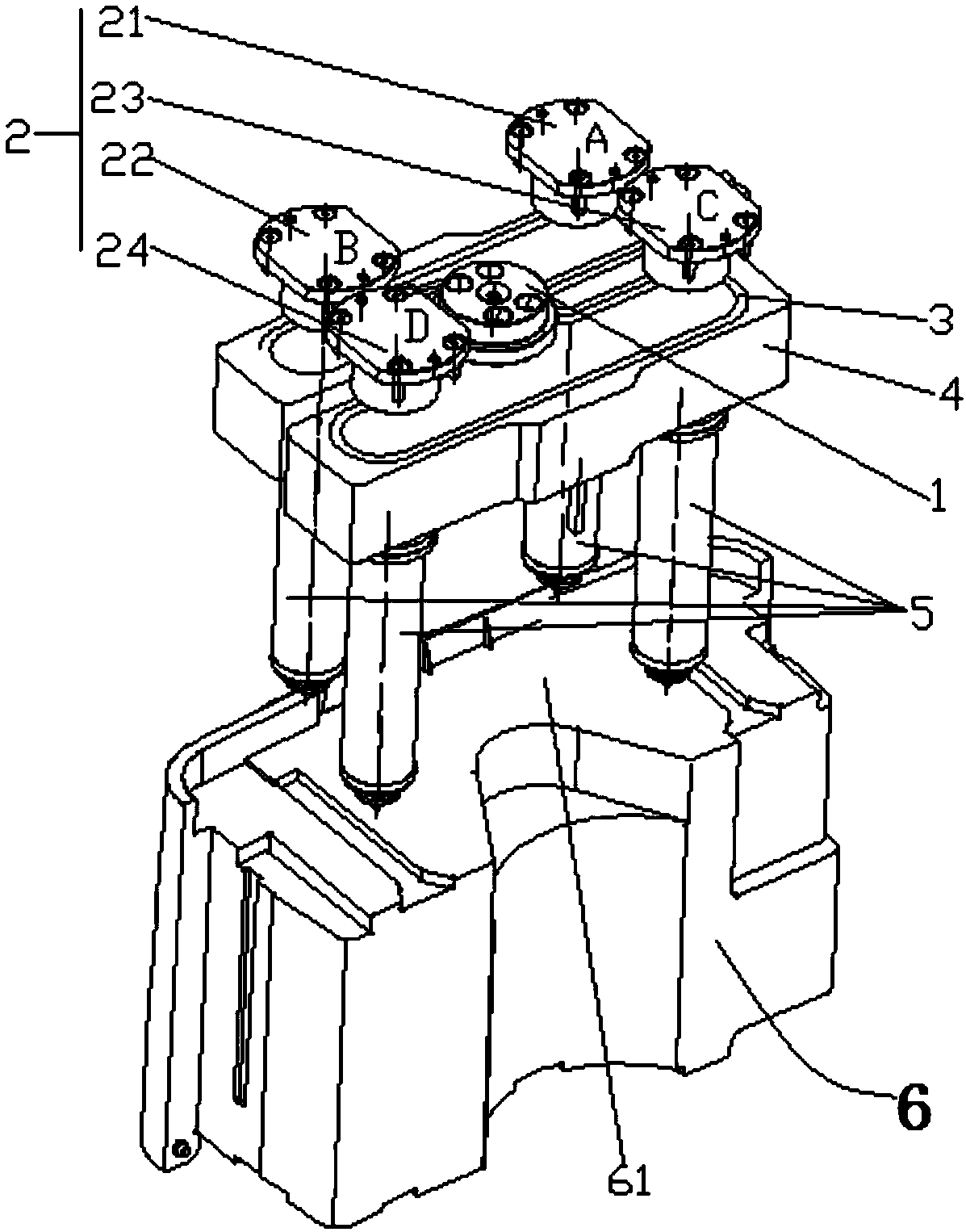

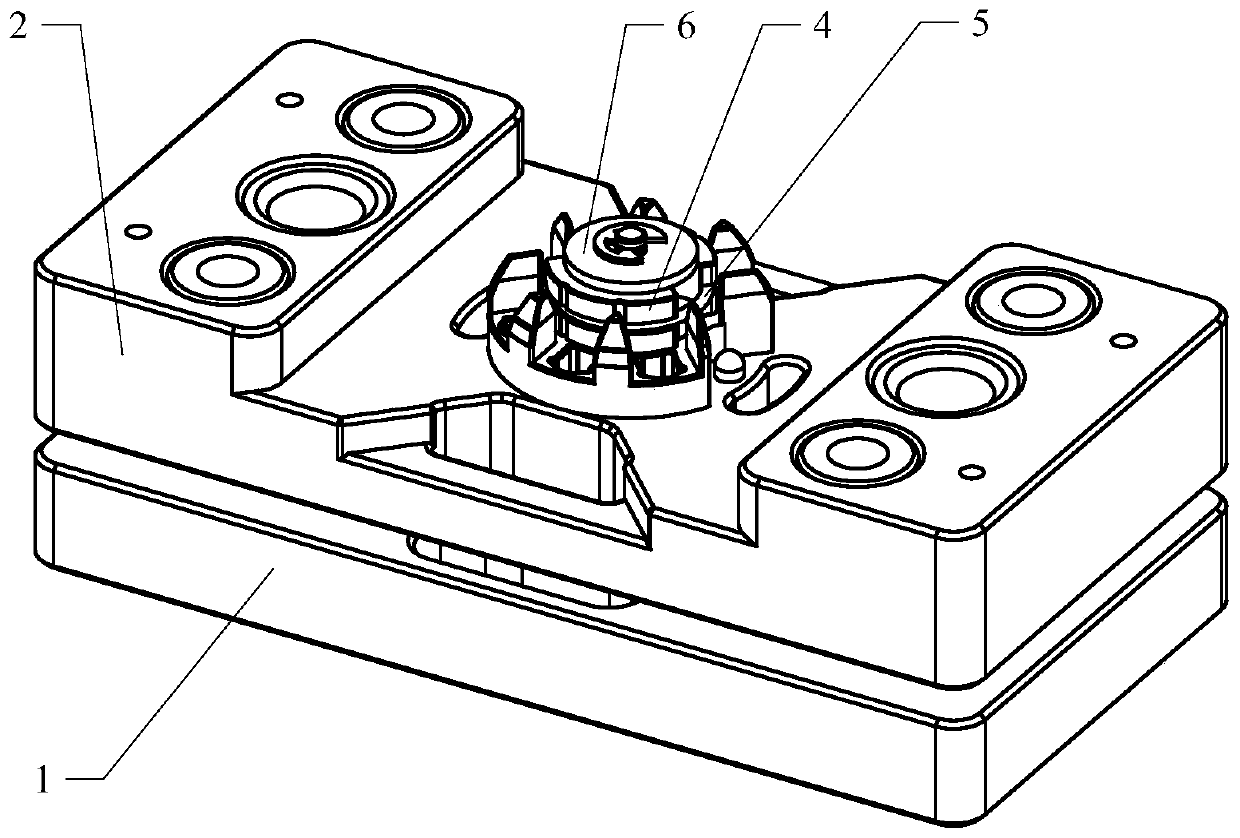

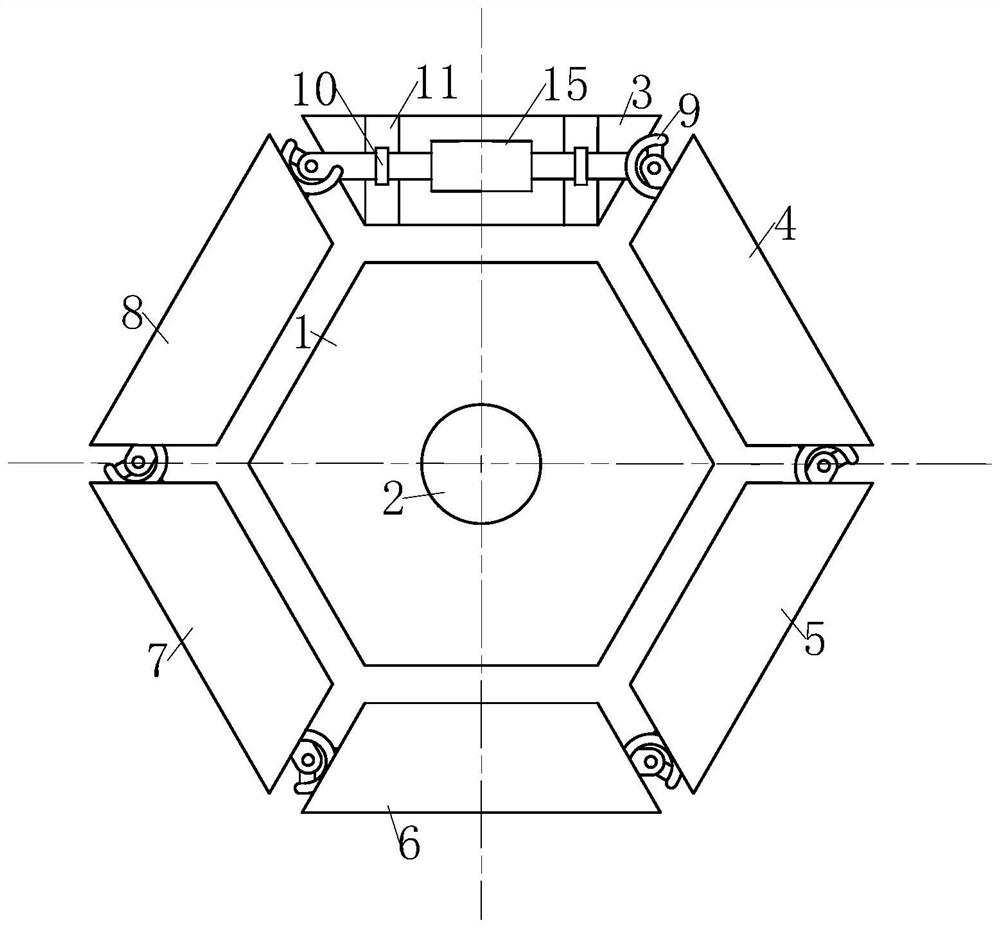

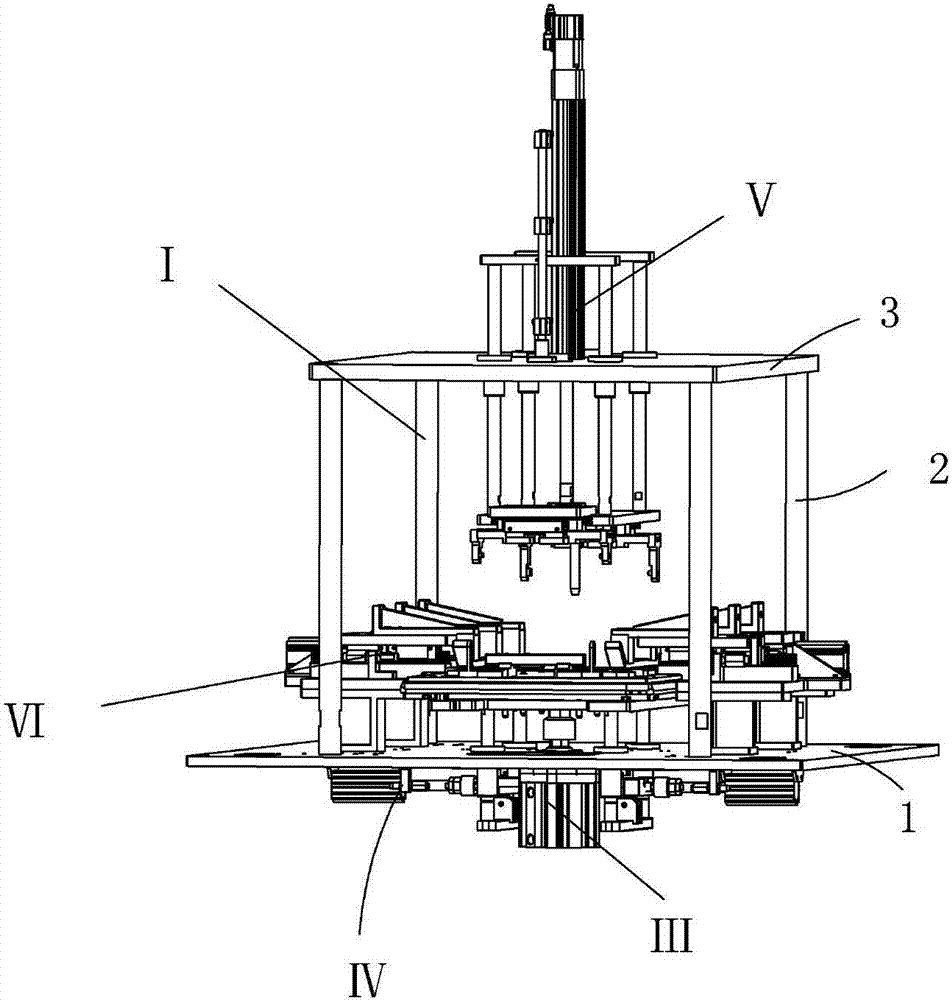

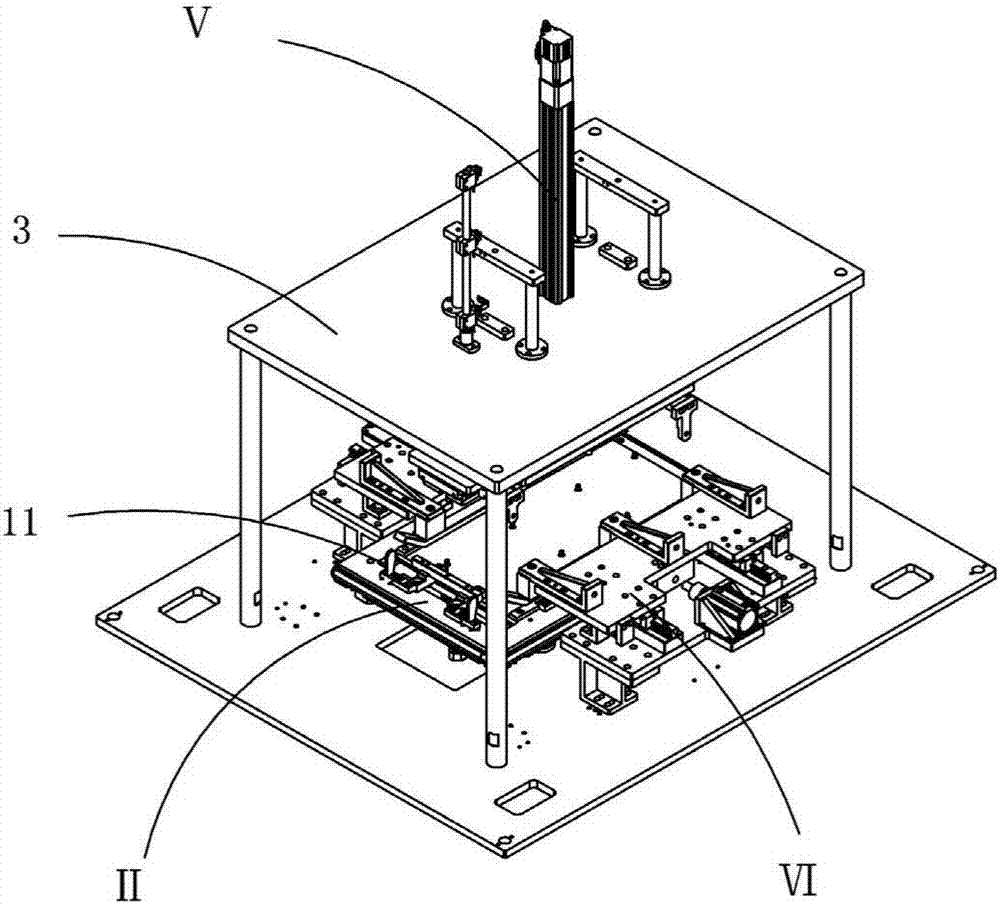

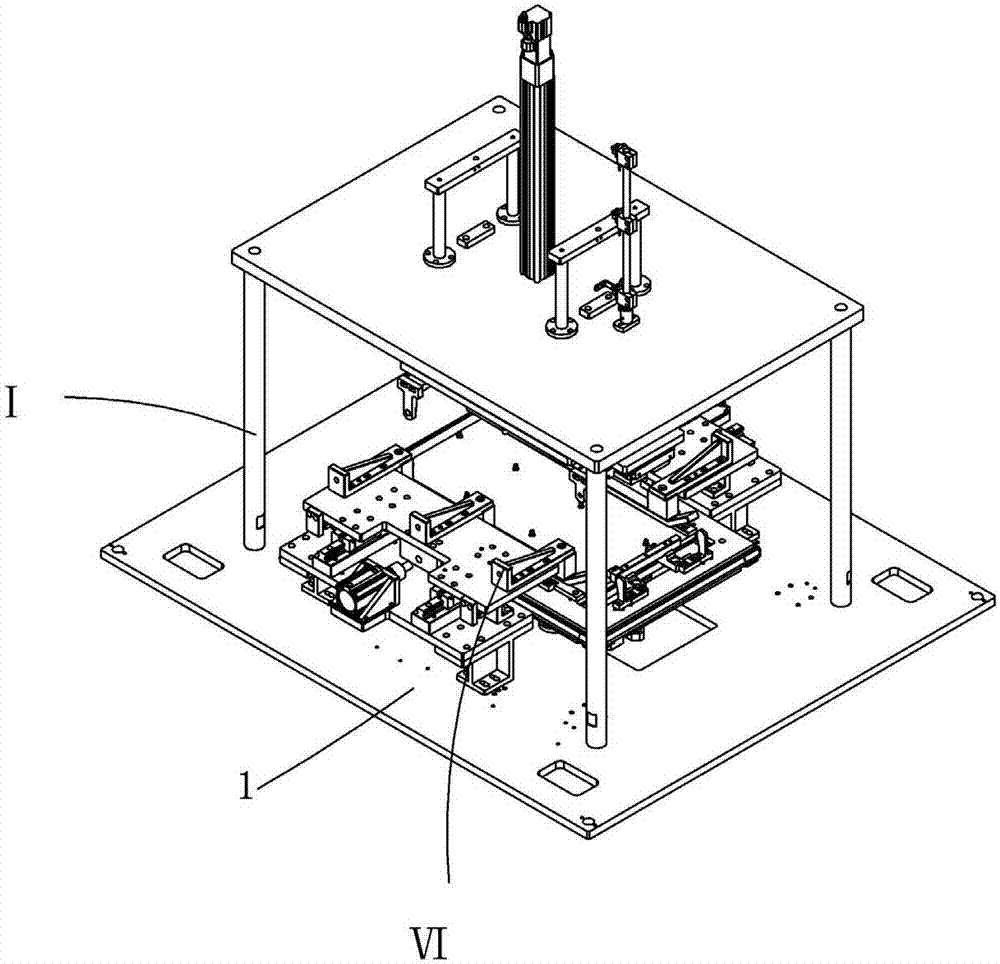

Radial expansion mechanism and assembly jig

InactiveCN111283072AEasy to assembleConducive to maintaining pressureEngineeringMechanical engineering

The embodiment of the invention discloses a radial expansion mechanism and an assembly jig. A push block (3) is fixedly connected with a base (1) and is provided with at least one first inclined surface (31), wherein at least two sliding blocks (4) are arranged on the outer side of the push block (3); a pressing disc (6) is arranged above the sliding blocks (4) and is fixedly connected with an objective table (2); and when the objective table (2) moves, the pressing disc (6) moves along with the objective table (2) to push the sliding blocks (4) to move along the first inclined surface (31) ofthe push block (3), so that the distance between the sliding blocks (4) and the center of the push block (3) is changed, the outer contours of the sliding blocks (4) are expanded in the radial direction, and workpieces arranged on the outer sides of the sliding blocks (4) are driven to move. Therefore, according to the technical scheme of the embodiment of the invention, a plurality of radial external forces can be applied to the workpieces on the outer sides of the sliding blocks (4) at the same time, so that the products can be conveniently assembled and subjected to pressure maintaining.

Owner:LUXSHARE ELECTRONICS TECH (KUNSHAN) LTD

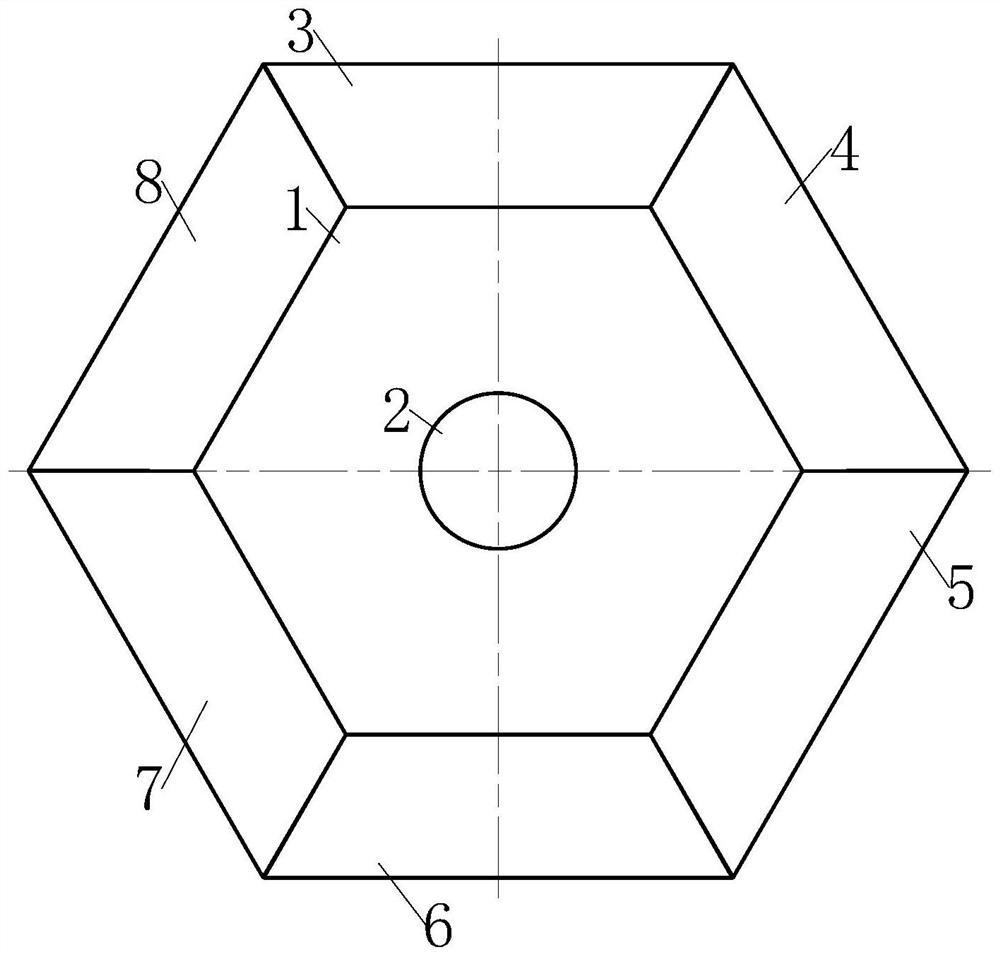

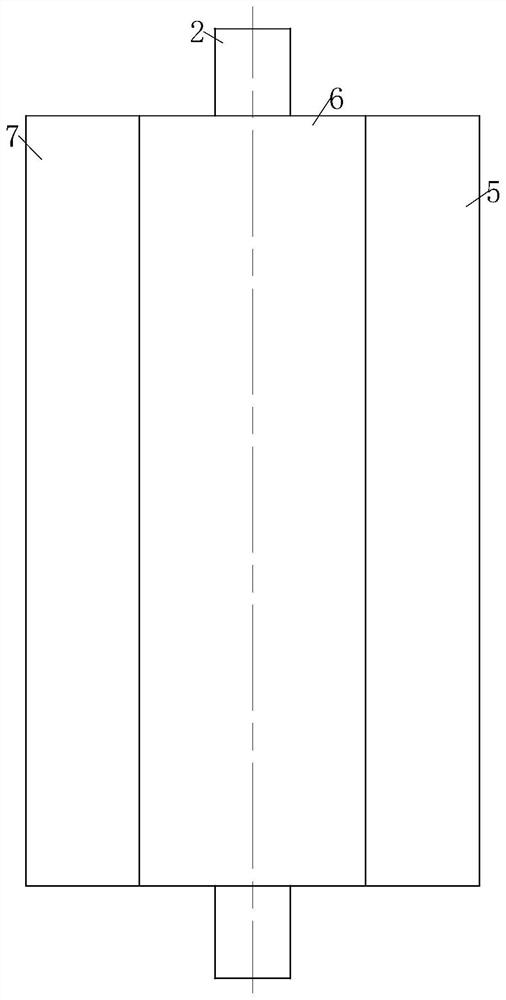

Injection mold for engineering plastics

PendingCN114506019AIncrease productivityTo achieve the effect of synchronous controlEngineering plasticEngineering

The invention relates to the field of injection molds, in particular to an injection mold for engineering plastics, which comprises a rotating male mold, a rotating shaft, a first female mold, a second female mold, a third female mold, a fourth female mold, a fifth female mold and a sixth female mold, the two ends of the rotating shaft are located outside the upper outer surface and the lower outer surface of the rotating male die, and the rotating male die is matched with the first female die, the second female die, the third female die, the fourth female die, the fifth female die and the sixth female die. According to the invention, the injection mold is changed from a traditional square structure consisting of a convex mold and a concave mold into an integral mold consisting of a hexagonal columnar rotary convex mold, a first concave mold, a second concave mold, a third concave mold, a fourth concave mold, a fifth concave mold and a sixth concave mold; and the number of one-time injection molding products is increased, so that the purpose of increasing the production efficiency is achieved.

Owner:滕沛鑫

A flanging pressing device

ActiveCN105752373BConducive to maintaining pressureAutomate operationWrapper folding/bending apparatusWrappingEngineeringMechanical engineering

The invention relates to a turned edge press-fit device. Felt is positioned on a carrier assembly. An ejecting assembly is arranged on a bottom plate of a machine frame assembly. The left side and the right side of the upper portion of a carrier of the carrier assembly are each provided with a step block so that a groove can be formed between each step block and the carrier. An ejecting column which can be inserted in a positioning hole in a carrier bottom plate to position the carrier assembly is arranged on an ejecting plate of the ejecting assembly. A downward pressing assembly which can grab a product and downwards press the product is arranged at the upper portion of the bottom plate. The size of the product is smaller than that of the felt. The product is downward pressed into the grooves so that the left side and the right side of the felt can be vertically turned up. The left side and the right side of the upper portion of the bottom plate are each provided with a lateral pressing assembly which pushes and presses the corresponding vertically-turned side of the felt flat from the side face of the felt so that the corresponding vertically-turned part can be turned up again to form a horizontal turned edge. The ejecting assembly which can control the stroke of the ejecting plate and pressurize the horizontal turned edges is arranged between the ejecting assembly and the bottom plate. Two times of edge turning of the felt are achieved, and the left side and the right side of the product are wrapped.

Owner:BOZHON PRECISION IND TECH CO LTD

portable water dispenser

ActiveCN106088240BReduce lagExtended service lifeService pipe systemsWater mainsPulse controlPressure sense

The invention provides a water supply machine, and belongs to the field of water supply equipment. The water supply machine comprises a water pump, a pressure sensor, a controller and a machine box, wherein the pressure sensor is electrically connected with the controller; a contactless switch is arranged on the water pump; the controller is electrically connected with the water pump through the contactless switch; the pressure sensor is used for sensing the water supply pressure of the water pump; the controller contacts the on-off state of the contactless switch according to the pressure sensed by the pressure sensor. The water supply machine belongs to a water supply machine with the advantages that the water pressure is adjustable; the service life is long; the pressure regulation starting is fast.

Owner:阳志华

Optimal Injection Process of Piston Lip

Owner:勃乐氏密封系统(太仓)有限公司

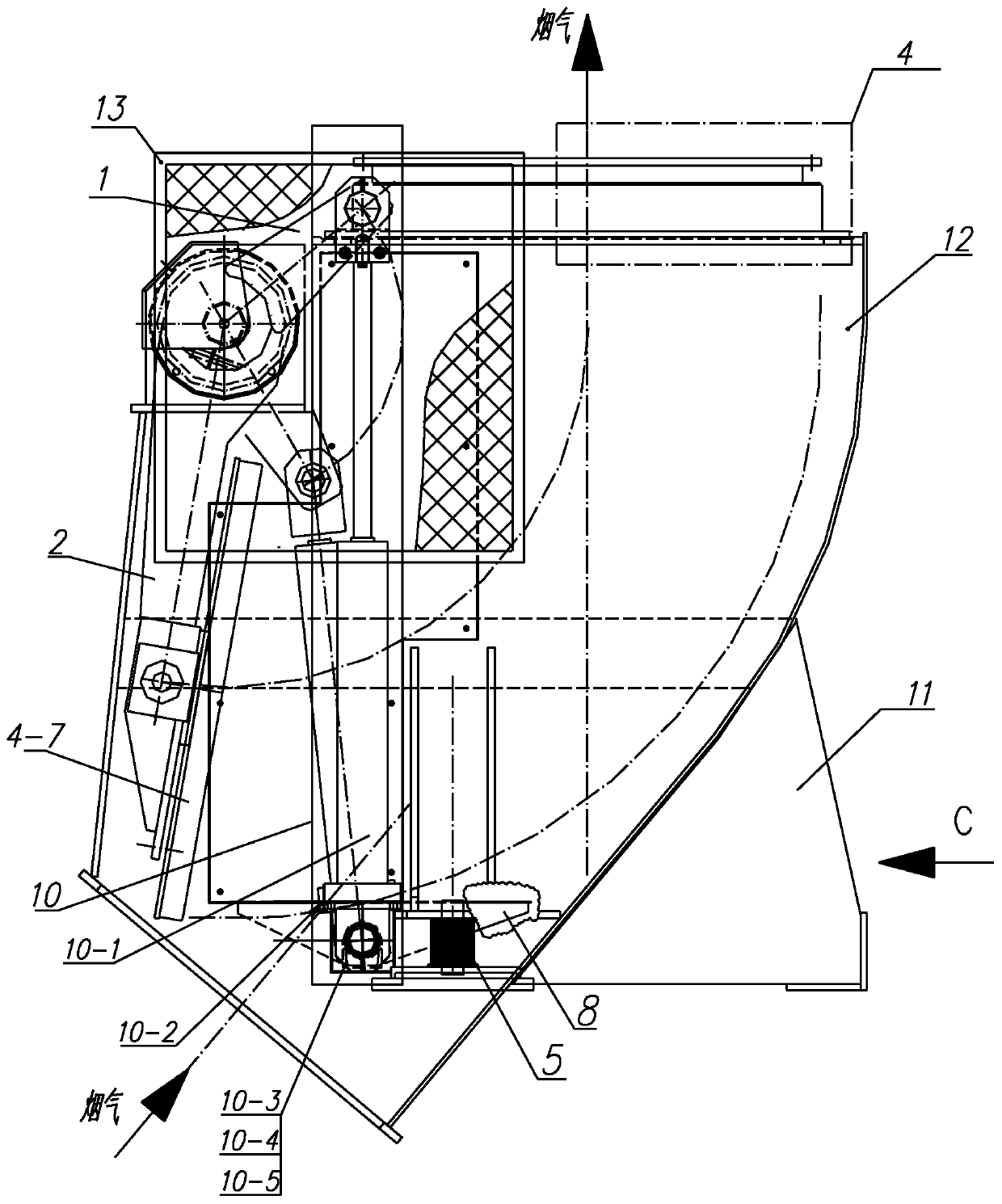

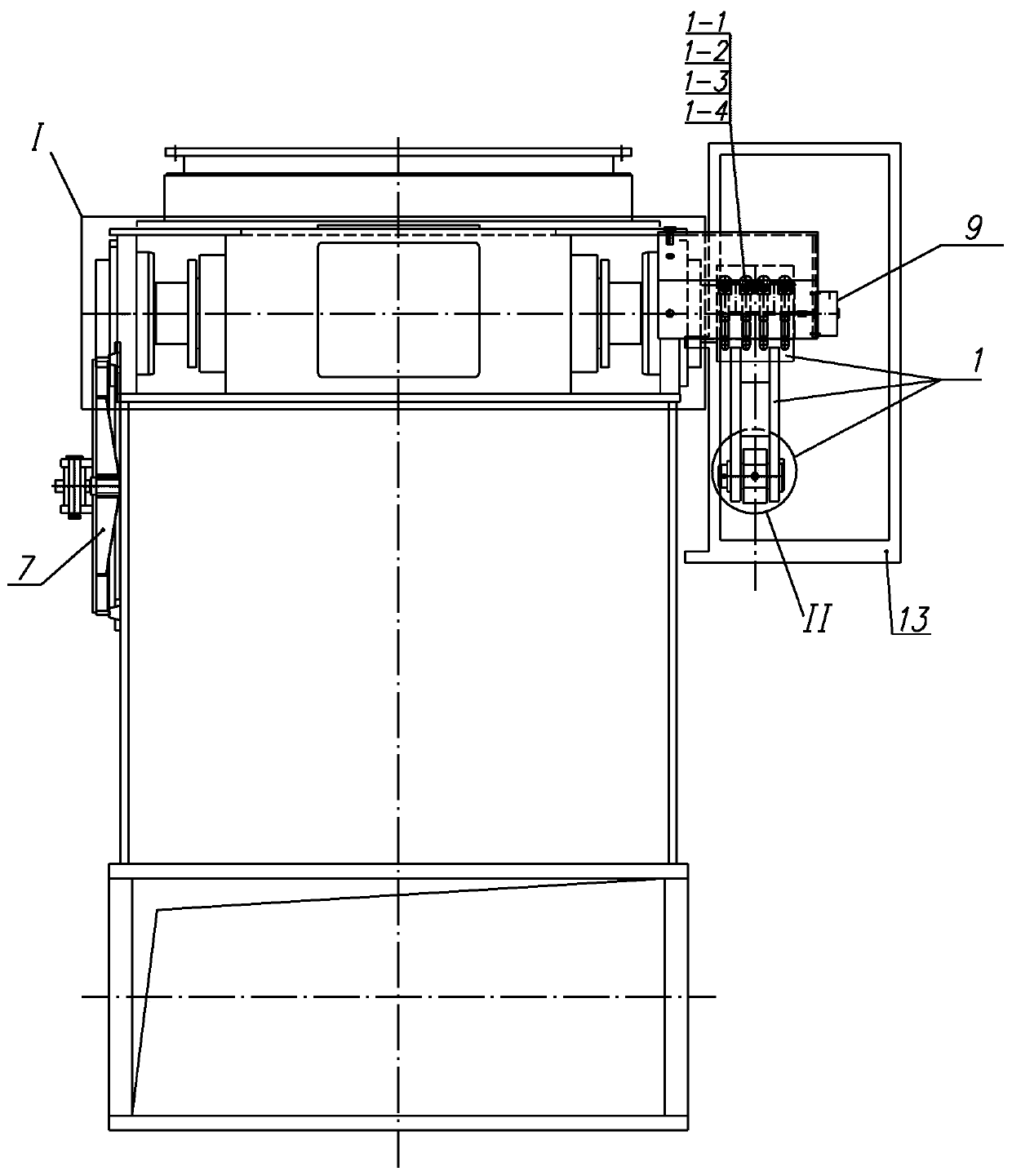

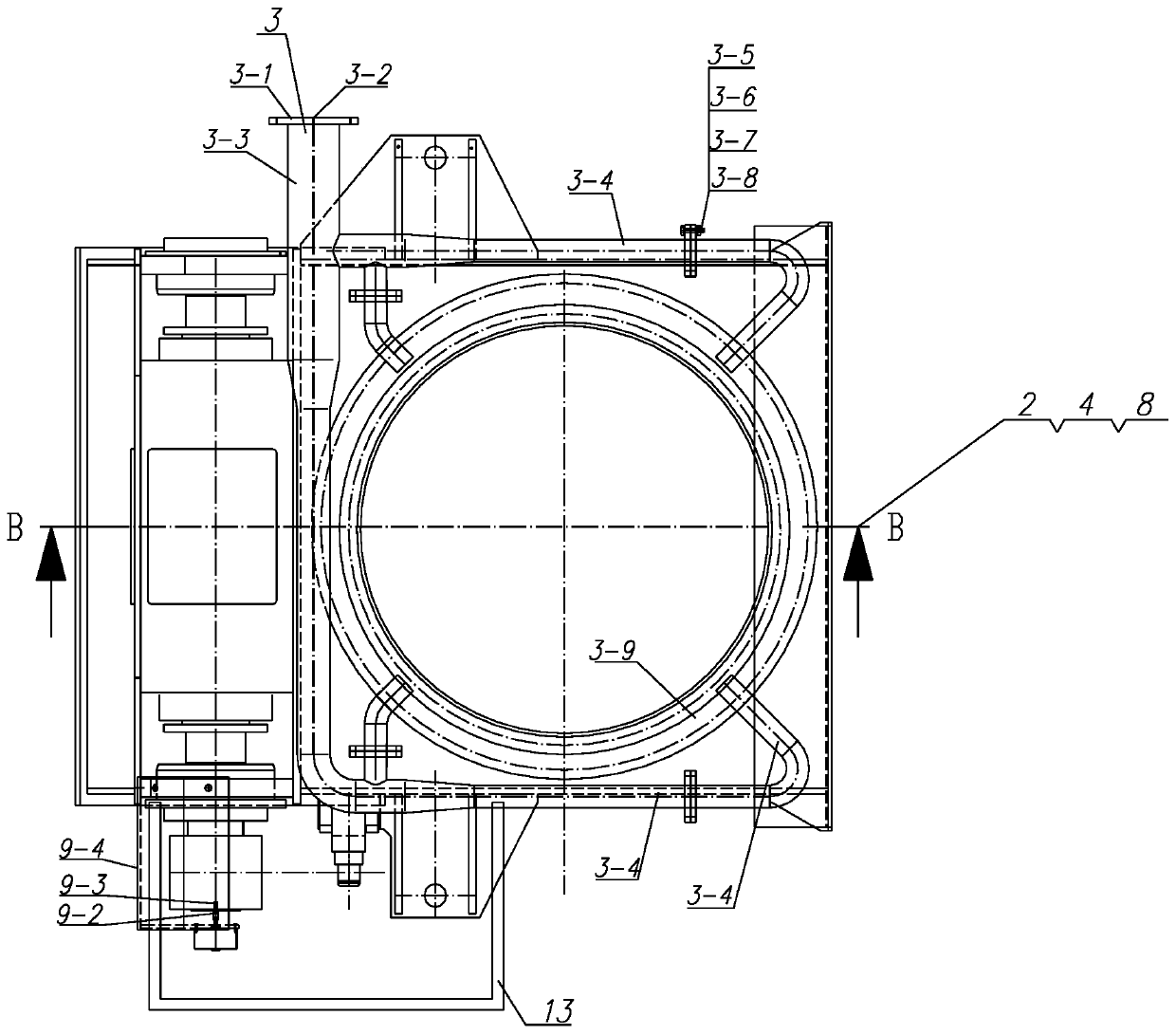

Large high-temperature releasing valve capable of rapidly replacing drive device

PendingCN111457107AQuick releaseSolve the difficulty of replacementOperating means/releasing devices for valvesValve members for heating/coolingDrive shaftControl engineering

The invention relates to a large high-temperature releasing valve capable of rapidly replacing a drive device. A valve body, a valve plate and a valve plate drive mechanism are included. The valve plate drive mechanism is composed of a both-way buffering drive device, a transmission shaft, a drive arm and a connection arm. A push rod of the both-way buffering drive device is hinged to one end of the drive arm, and the other end of the drive arm is connected with the transmission shaft through an opening elastic shaft hub. One end of the connection arm is connected with the transmission shaft through a split shaft hub, and the connection arm is fixedly connected with one half shaft hub. The other end of the connection arm is connected with the valve plate. Under driving of the both-way buffering drive device, the drive arm drives the transmission shaft to rotate, and then the connection arm and the valve plate are driven to integrally rotate. The large high-temperature releasing valve can achieve integral rapid replacement of the transmission shaft, the connection arm and the valve plate, the service life of a transmission shaft bearing and a valve port rubber seal ring can be further prolonged, the valve plate rotation position precision is improved, and safety of operation personnel is guaranteed.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com