Air suction and air supply control system for injection molding machine molding die

A molding die and control system technology, which is applied in the field of air extraction and air supply control system for molding dies of injection molding machines, can solve the problems of small air, inconvenient opening of molding dies, etc., so as to facilitate pressure maintaining and shaping, highlight substantive features, and facilitate control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The features of the present invention and other relevant features are described in further detail below through the embodiments, so as to facilitate the understanding of those skilled in the art:

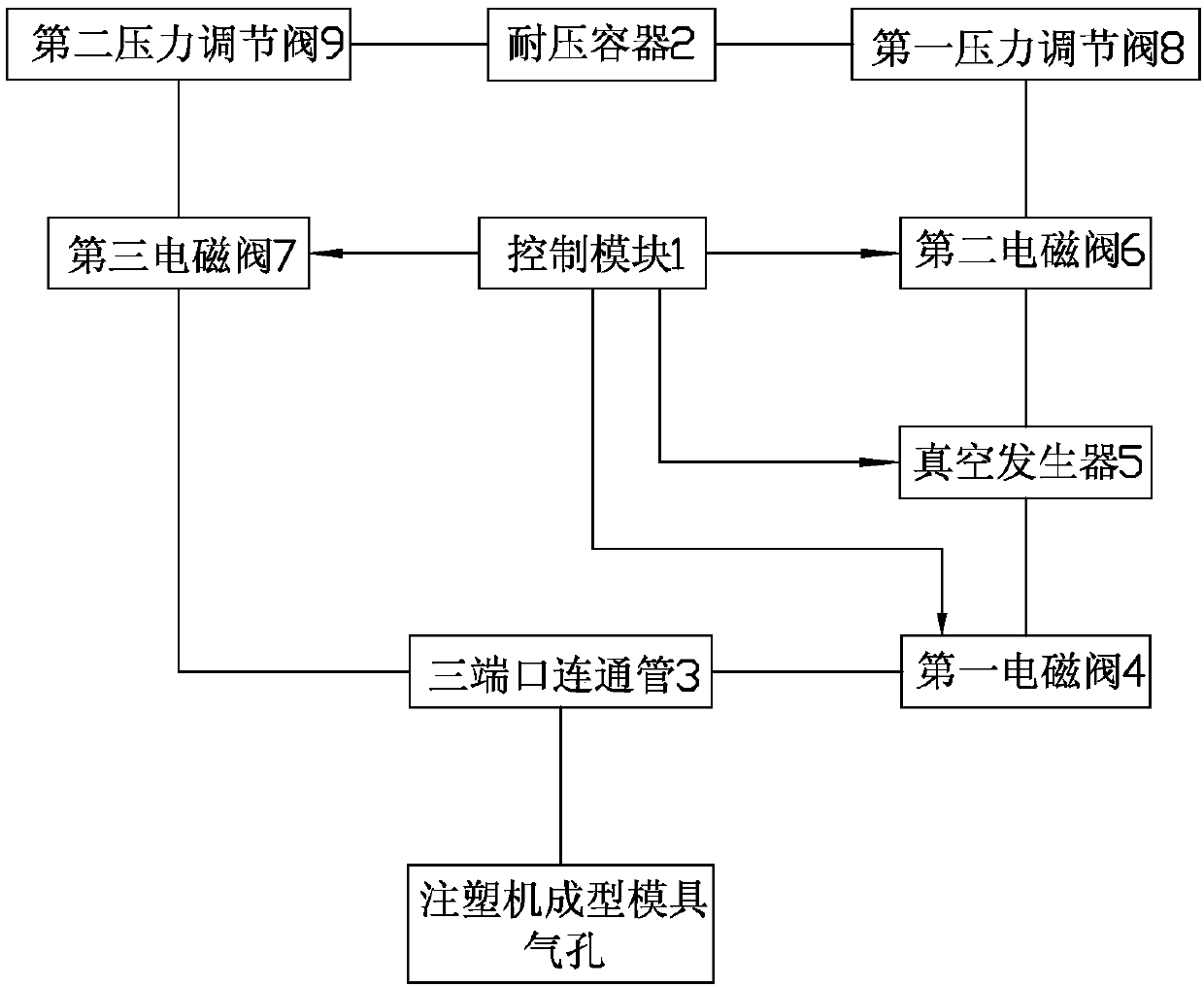

[0014] Such as figure 1 As shown, a control system for pumping and supplying air to the mold of an injection molding machine includes a control module 1, a pressure-resistant container 2 for buffering gas, and a three-port communication pipe 3 with one port connected to the air hole on the molding mold of the injection molding machine. Between the second port of the three-port communicating pipe 3 and the pressure-resistant container 2, a first electromagnetic valve 4, a vacuum generator 5 for evacuating the mold of the injection molding machine, and a second electromagnetic valve are arranged in sequence. Valve 6, a third solenoid valve 7 for controlling the gas in the pressure-resistant container 2 to be sent back to the mold of the injection molding machine is provided bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com