Hydrostatic test automatic test system

An automatic test system, a technology of hydrostatic testing, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring the acceleration and deceleration rate of fluids, and using liquid/vacuum for liquid tightness measurement, etc. There are many impurities, hidden dangers to workers' safety, and test failures, etc., to reduce the cost of pressure measurement, improve the efficiency of pressure measurement, and have a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

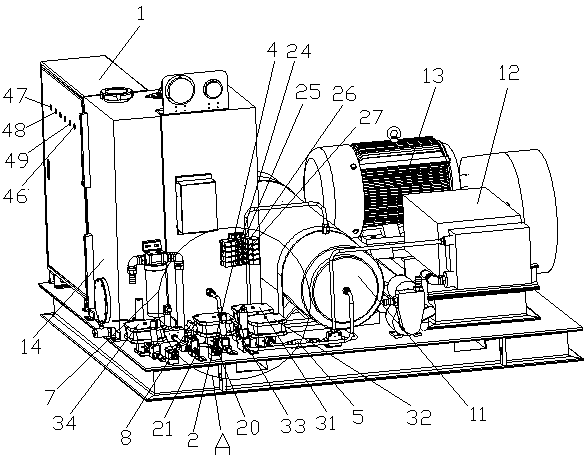

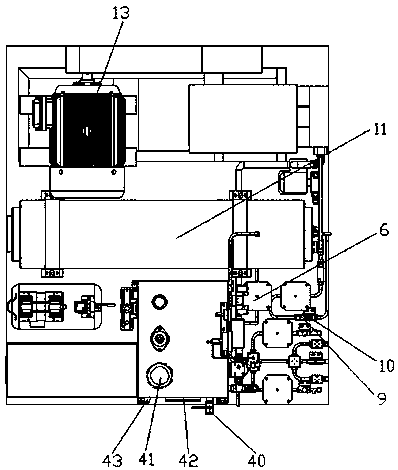

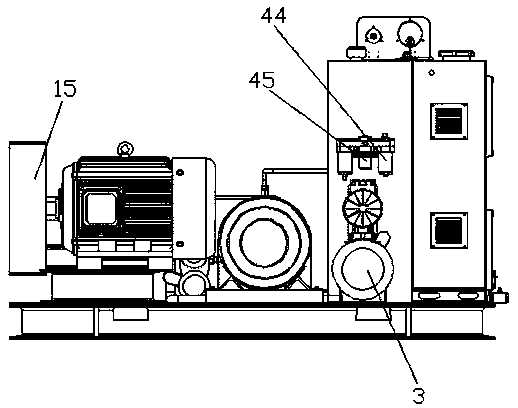

[0035] See Figure 1-Figure 6 , A hydraulic test automatic test system, including a frame and a pressure holding device, a pressure relief device, and an electric control cabinet 1 installed on the frame. The pressure holding device includes a gas source integrated control valve group 2 and a pressure holding plate Valve group, the air source integrated control valve group 2 is sequentially connected with an air pump 3, a first air source reversing valve group 4, a one-way valve 5, a container unloading valve 6, a high pressure filter 7, and The manual shut-off valve 8, the pressure sensor 9, the overflow valve 10, the surge tank 11, the high-pressure pump 12, the electric motor 13 and the water tank 14. The electric motor 13 is connected to the high-pressure pump 12 through the transmission belt 15, and the high-pressure pump 12 is connected to the pressure maintaining The plate valve group is connected; the pressure relief device includes a pressure relief plate valve group, ...

Embodiment 2

[0038] See Figure 1-Figure 6 , A hydraulic test automatic test system, including a frame and a pressure holding device, a pressure relief device, and an electric control cabinet 1 installed on the frame. The pressure holding device includes a gas source integrated control valve group 2 and a pressure holding plate The air source integrated control valve group 2 is connected to the air pump 3, the first air source reversing valve group 4, the one-way valve 5, the container unloading valve 6, the high pressure filter 7, and The manual shut-off valve 8, the pressure sensor 9, the overflow valve 10, the surge tank 11, the high-pressure pump 12, the electric motor 13 and the water tank 14. The electric motor 13 is connected to the high-pressure pump 12 through the transmission belt 15, and the high-pressure pump 12 is connected to the pressure maintaining The plate valve group is connected; the pressure relief device includes a pressure relief plate valve group, a second air source...

Embodiment 3

[0042] See Figure 1-Figure 6 , A hydraulic test automatic test system, including a frame and a pressure maintaining device, a pressure relief device, and an electric control cabinet 1 installed on the frame. The pressure maintaining device includes an air source integrated control valve group 2 and a pressure maintaining plate The air source integrated control valve group 2 is connected to the air pump 3, the first air source reversing valve group 4, the one-way valve 5, the container unloading valve 6, the high pressure filter 7, and The manual shut-off valve 8, the pressure sensor 9, the overflow valve 10, the surge tank 11, the high-pressure pump 12, the electric motor 13 and the water tank 14. The electric motor 13 is connected to the high-pressure pump 12 through the transmission belt 15, and the high-pressure pump 12 is connected to the pressure maintaining The plate valve group is connected; the pressure relief device includes a pressure relief plate valve group, a seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com