Wedge welding method and welding structure for large-calibre plastic pipes

A plastic pipe and large-diameter technology, which is applied in the direction of pipeline connection arrangement, pipe/pipe joint/pipe fitting, mechanical equipment, etc., can solve the problem of smaller contact area between two pipe bodies, difficulty in welding large-diameter pipes, poor connection strength of pipes, etc. problems, to achieve the effect of increased strength, stable pressure holding and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

[0088] In the primary welding and the secondary welding, the welding hole and the taper pin are heated separately, and the specific steps b3 and c3 are the same, including the following steps:

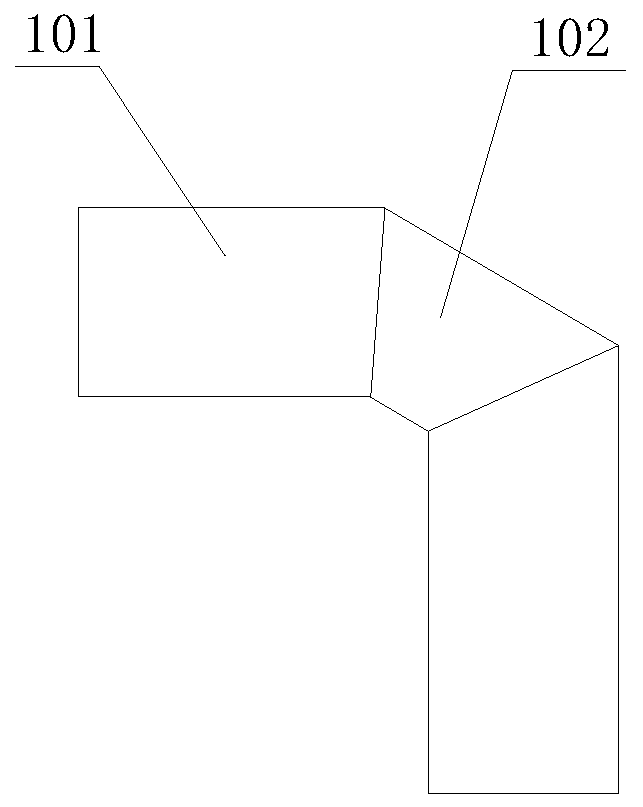

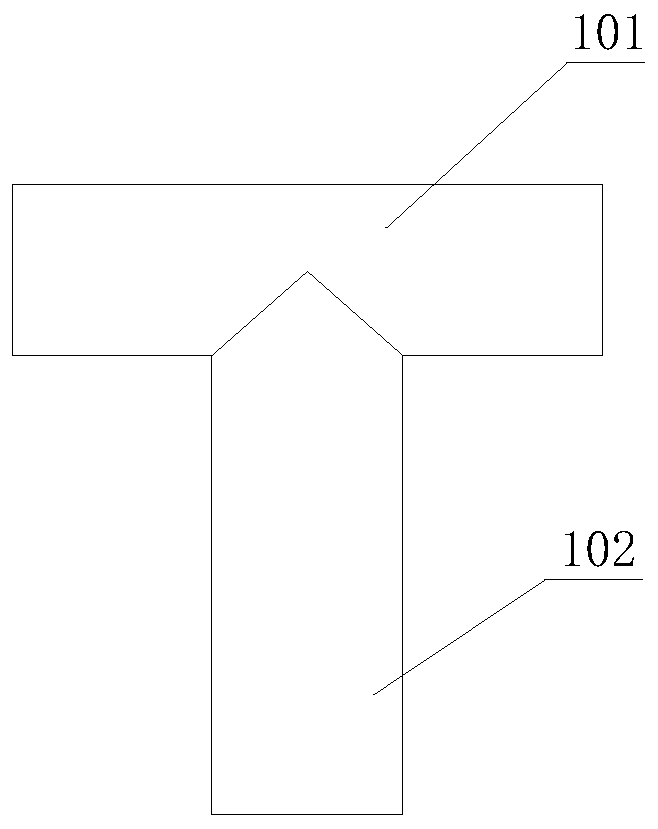

[0089] e1. Separately heat the inner surfaces of the primary welding hole 11 and the secondary welding hole 12, and the outer surfaces of the primary cone pin 13 and the secondary cone pin 14, so that they all have a softening layer with a thickness of 2-5mm;

[0090] e2. Place the primary taper pin 13 and the secondary taper pin 14 in the corresponding primary welding hole 11 and secondary welding hole 12;

[0091] e3. Squeeze from the large end of the primary taper pin 13 and the secondary taper pin 14 to the small end, or pull from the small end.

Embodiment 12

[0093] In the primary welding, the primary welding hole 11 and the primary taper pin 13 are heated simultaneously, and in the secondary welding, the secondary welding hole 12 and the secondary taper pin 14 are heated separately.

[0094] The specific step b3 includes the following steps: f1. Helically winding the heating wire on the surface of the primary cone pin 13;

[0095] f2. Place the primary taper pin 13 in the corresponding primary welding hole 11, and energize the heating wire to melt the contact surface to achieve welding;

[0096] f3. Squeeze from the large end of the primary taper pin 13 to the small end, or pull it from the small end.

[0097] Step c3 includes the following steps:

[0098] e1. Separately heat the inner surface of the secondary welding hole 12 and the outer surface of the secondary taper pin 14 so that they all have a 2-5mm thick softening layer;

[0099] e2. Place the secondary taper pin 14 in the corresponding secondary welding hole 12;

[010...

Embodiment 13

[0102] In the primary welding, the primary welding hole 11 and the primary taper pin 13 are heated separately, and in the secondary welding, the secondary welding hole 12 and the secondary taper pin 14 are heated simultaneously.

[0103] Concrete step b3 comprises the following steps:

[0104] e1. Separately heat the inner surface of the primary welding hole 11 and the outer surface of the primary taper pin 13 so that they all have a 2-5mm thick softening layer;

[0105] e2. Place the primary taper pin 13 in the corresponding primary welding hole 11;

[0106] e3. Squeeze from the large end of the primary taper pin 13 to the small end, or pull it from the small end.

[0107] Step c3 includes the following steps:

[0108] f1. Helically wind the heating wire on the surface of the secondary cone pin 14;

[0109] f2. Place the secondary cone pin 14 in the corresponding secondary welding hole 12, and energize the heating wire to melt the contact surface to achieve welding;

[01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com