An external gas-assisted injection molding method and molding equipment based on ultrasonic measurement

An external gas and ultrasonic measurement technology, applied in the field of external gas assisted injection molding, can solve the problems of complex judgment method of external auxiliary molding equipment, unable to prepare to judge the timing of gas injection, unable to significantly eliminate sink marks, etc., and achieve simple and fast gas injection time. , The effect of improving product quality and removing sink marks on the surface of plastic parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

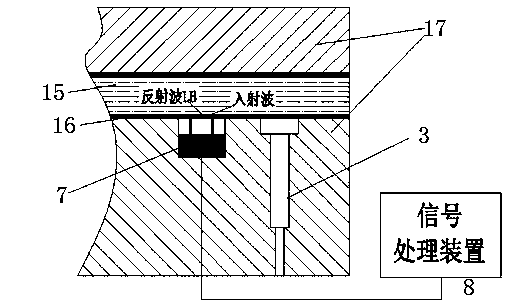

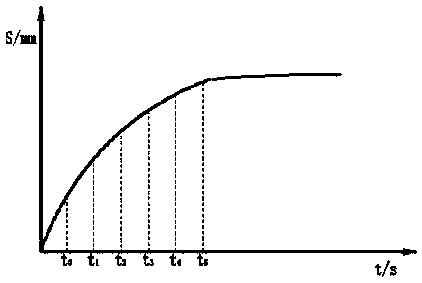

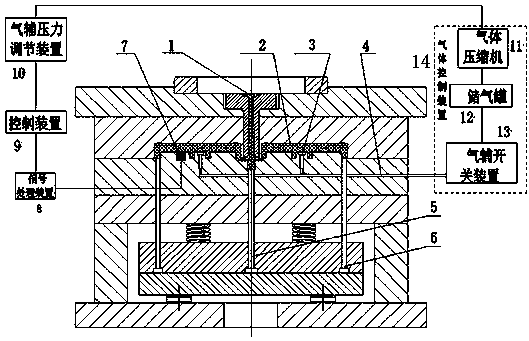

[0052] Such as figure 2 As shown, the schematic diagram is a graph of the relationship between the thickness of the condensate layer and the time in the pressure-holding cooling stage without the intervention of external air. At this time, the melt 15 in the cavity is injected to complete the mold filling, the melt in the cavity begins to cool and shrink, and the condensation layer begins to form. At the same time, the distance between the inner wall of the mold cavity and the condensation layer begins to grow and gradually increases. In the figure, t0-t5 represents the pre-stage of pressure-holding cooling. The control device divides the pre-stage of pressure-holding cooling according to the time interval of ultrasonic emission, namely t0-t1; t1-t2; t2-t3; t3-t4; t4-t5; A total of 5 time intervals, t6 means that the melt is basically solidified and not shrinking in the later stage of the pressure-holding cooling. At this time, the distance between the mold cavity and the conde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com