Integrated self-locking intelligent informationized hydraulic cylinder device

A self-locking, integrated technology, applied in the direction of fluid pressure actuation devices, etc., can solve the problems that the pressurization value depends on the operator's experience and responsibility control, support failure, support axial force attenuation, etc., to achieve real-time dynamic Monitoring and intelligent automatic control, improving construction efficiency and reducing the effect of foundation pit deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

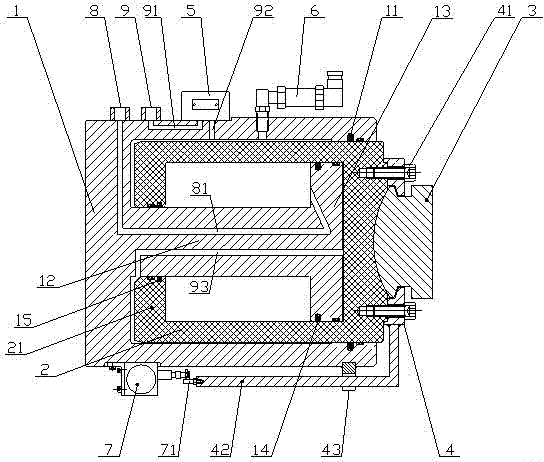

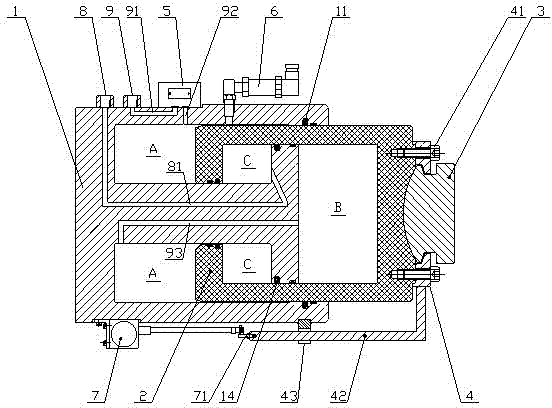

[0050] figure 1 It is a sectional view of the integrated self-locking intelligent informationized oil cylinder device of the present invention. Such as figure 1As shown, an integrated self-locking intelligent information oil cylinder device of the present invention includes an outer cylinder body 1 and an inner cylinder body 2; the opening of the inner cylinder body 2 surrounds an inner shrinkage shoulder 21, and the outer cylinder body The bottom of the body 1 is provided with a cylinder boss 12, the cylinder boss 12 stretches into the opening of the inner cylinder body 2, and the end of the cylinder boss 12 is provided with a circumferentially expanding shoulder 13 , the first oil chamber A is formed between the bottom of the outer cylinder 1 and the retracted shoulder 21 of the inner cylinder 2, the inner side of the bottom of the inner cylinder 2 and the end of the cylinder boss 12 The second oil chamber B is formed between the parts, and the oil return oil chamber C is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com