Large high-temperature releasing valve capable of rapidly replacing drive device

A driving device and release valve technology, applied in the direction of valve device, valve operation/release device, valve heating/cooling device, etc., can solve the problem of time-consuming and labor-intensive overhaul, service life of rubber sealing ring, and difficulty in replacement and other issues, to achieve the effect of environmental protection, prolonging the service life and preventing the leakage of smoke and dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

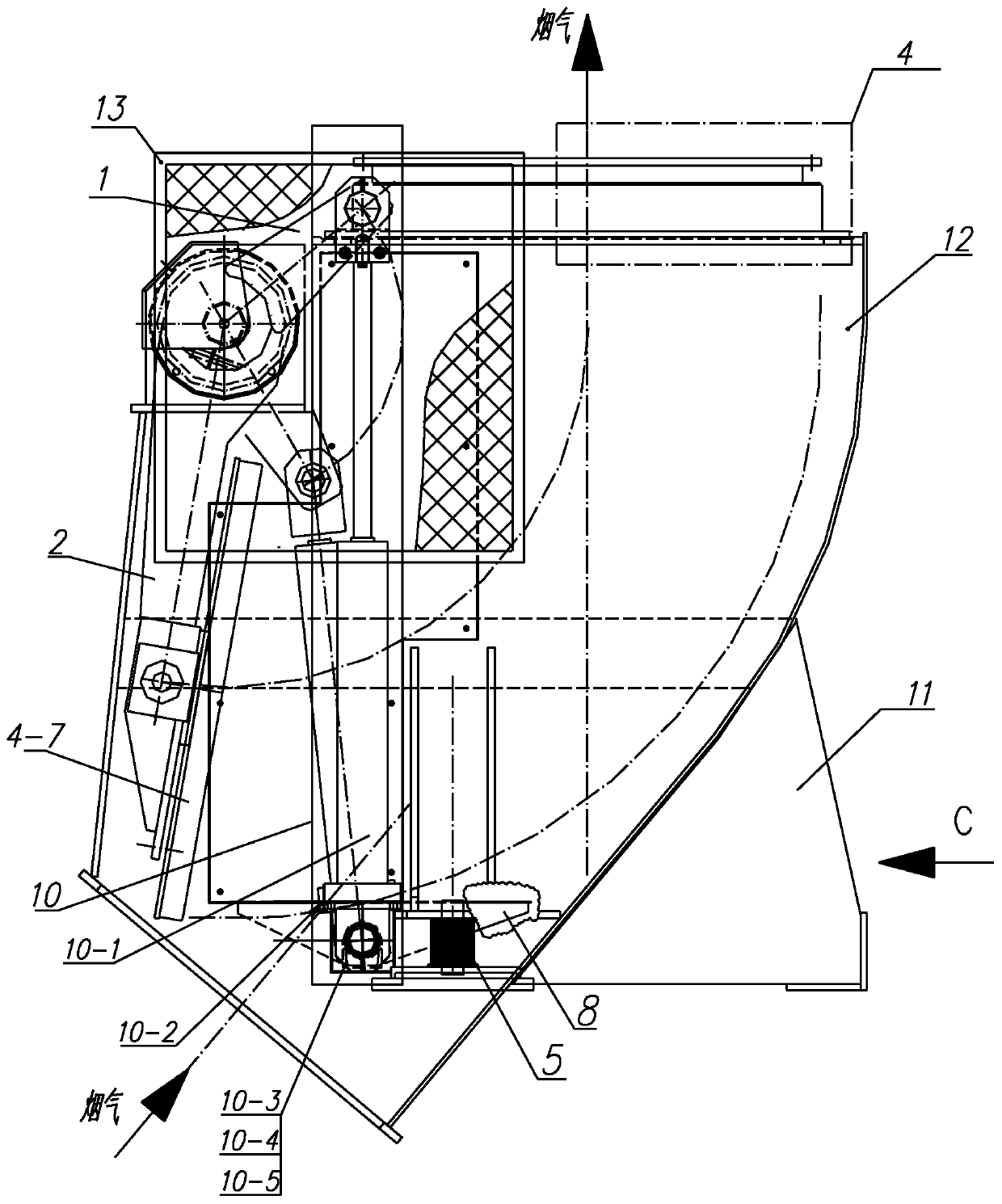

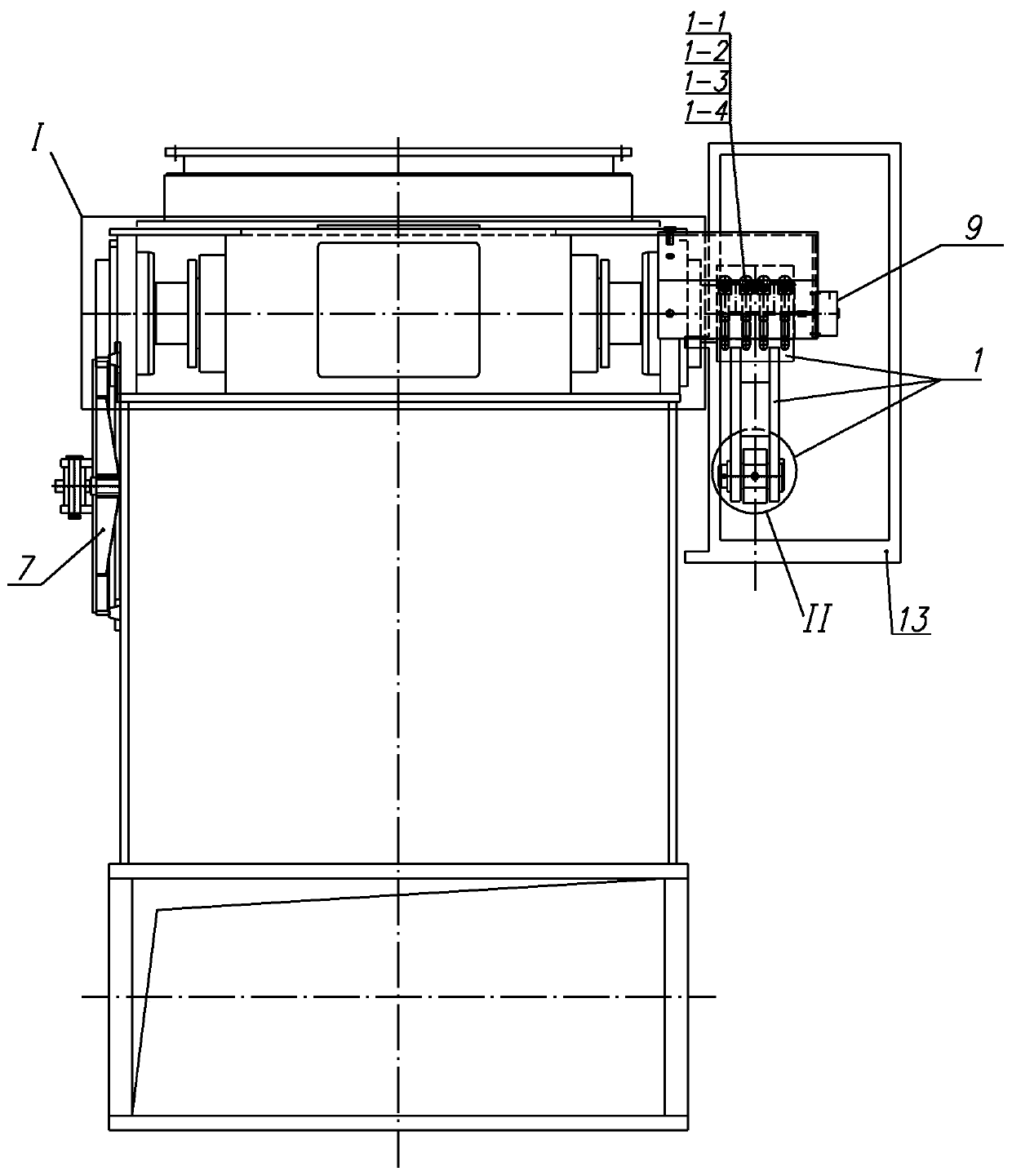

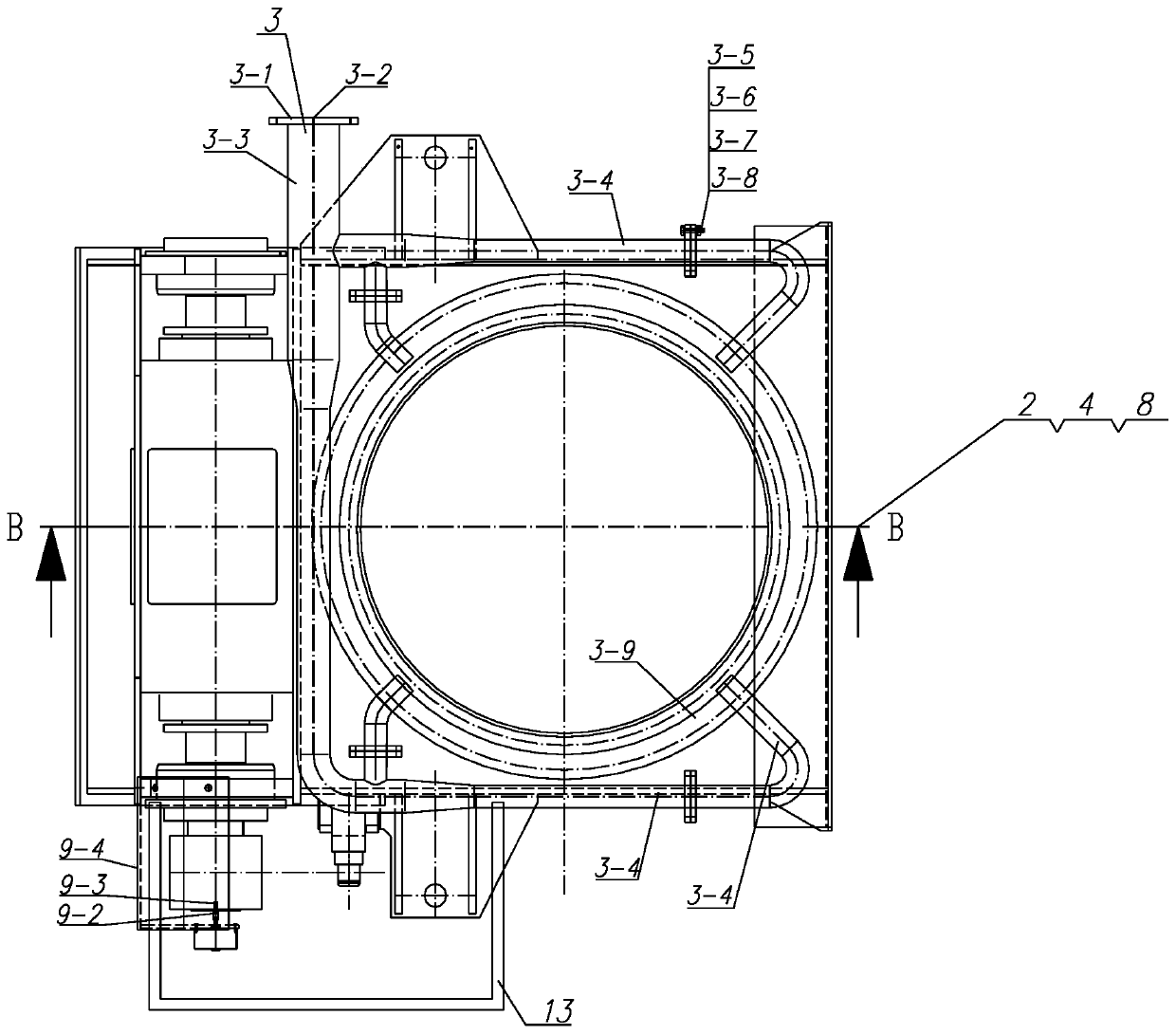

[0040] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0041] Such as Figure 1-Figure 3 As shown in the present invention, a large-scale high-temperature relief valve that can quickly replace the driving device includes a valve body, a valve plate 4-7, and a valve plate driving mechanism; one end of the valve body is provided with a smoke inlet, and the other end is provided with a smoke inlet. The gas outlet, the valve plate 4-7 is located in the valve body, the valve plate 4-7 can rotate under the drive of the valve plate driving mechanism, and close or open the flue gas outlet; the valve plate driving mechanism is controlled by a two-way buffer driving device 10 , transmission shaft 6-16, drive arm 1 and connecting arm 2; The other end of 1 passes through opening elastic axle hub 1-5 (as Figure 4 shown) is connected to the transmission shaft 6-16, and the opening of the open elastic hub 1-5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com