Forming method of flat ultra-thin MnZn ferrite core

A technology of manganese-zinc ferrite and forming method, applied in the field of magnetic core forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

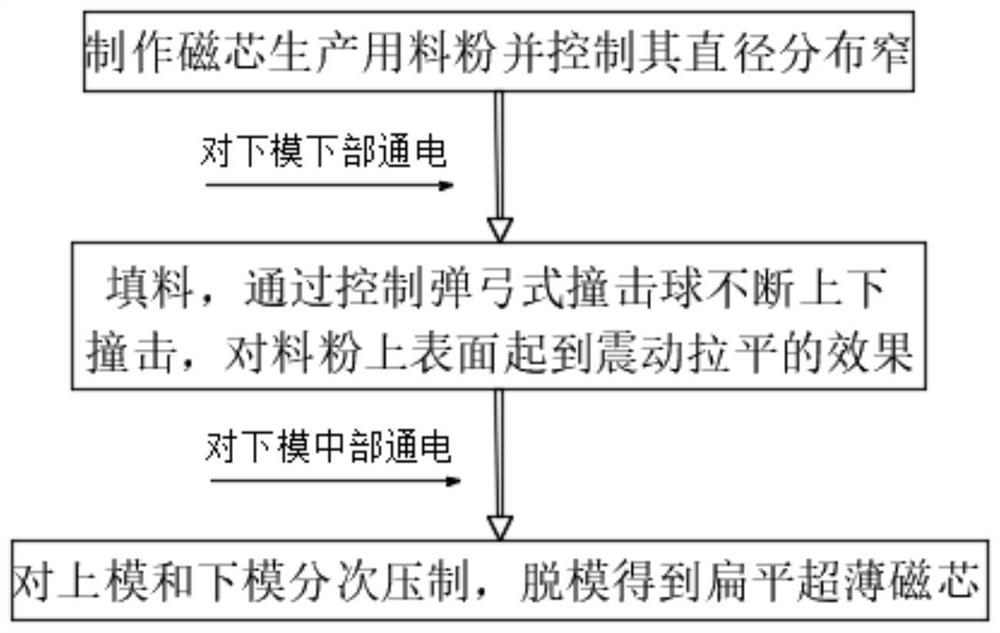

[0046] see figure 1 , a method for forming a flat ultra-thin manganese-zinc ferrite core, comprising the following steps:

[0047] S1. Make manganese-zinc-ferrite material powder for magnetic core production, and control the particle diameter distribution of the material powder to be narrow;

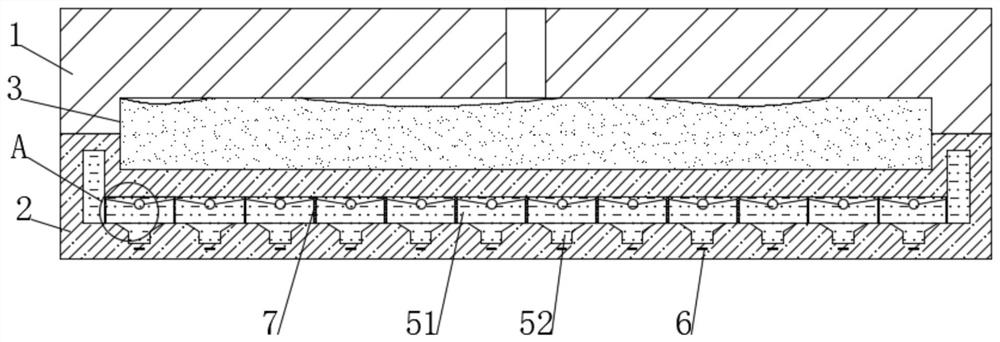

[0048] S2. Fill the powder into the mold cavity of the mold, and energize the bottom of the lower mold 2 to make it attractive, thereby attracting the slingshot impact ball to move downward. After 1-2 seconds, the power is turned off, and the slingshot impact ball moves upward. Restore the deformation, so that it hits the bottom of the mold cavity 3 multiple times, and has the effect of vibrating and leveling the upper surface of the powder;

[0049] S3, first electrify the middle part of the lower mold 2, so that the middle part of the lower mold 2 and the slingshot impact ball coagulate and harden, that is, the electrorheological fluid in the vibrating smoothing chamber 51 is energize...

Embodiment 2

[0055] see Figure 6-8 The impact smoothing ball 8 also includes a position control ball 84 embedded in the impact smoothing ball 8, the position control ball 84 is located directly below the inner magnetic block 82, and through the setting of the position control ball 84, the impact smoothing ball 8 as a whole The center is close to the position control ball 84, so that when the impact smoothing ball 8 falls to the bottom of the extension limiting groove 52, the position control ball 84 can always be at the bottom, thereby effectively ensuring that the inner magnetic block 82 is always facing the electromagnet 6. It is the same end, and the inner magnetic block 82 and the electromagnet 6 after electrification are close to each other with the same magnetic pole. In this embodiment, the bumping and smoothing ball 8 is directly placed inside the extension limiting groove 52. Hitting the smoothing ball 8 produces a repulsive force to make it rise, thereby also playing the effect ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com