Radial expansion mechanism and assembly jig

A technology for assembling jigs and jigs, which is applied in the field of machinery and can solve problems such as improper assembly, displacement of parts, and difficulty in controlling tolerances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

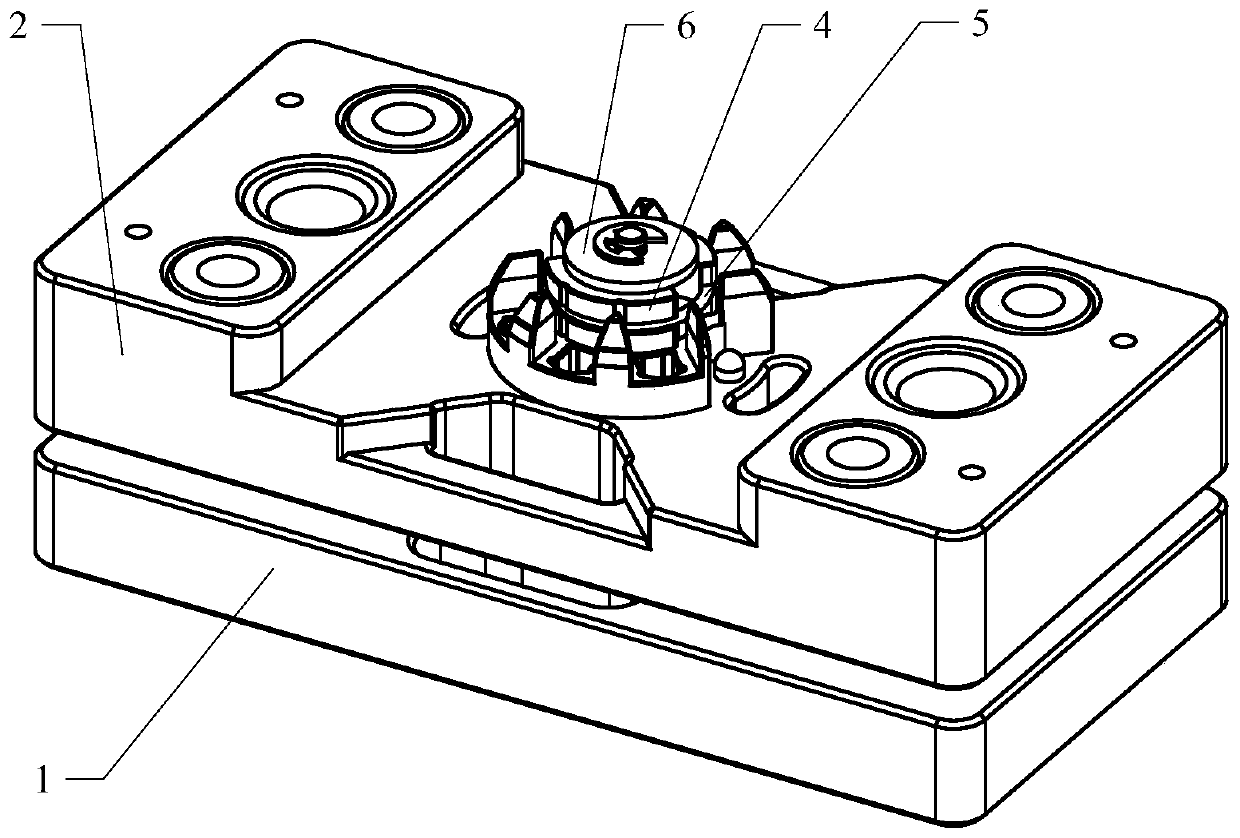

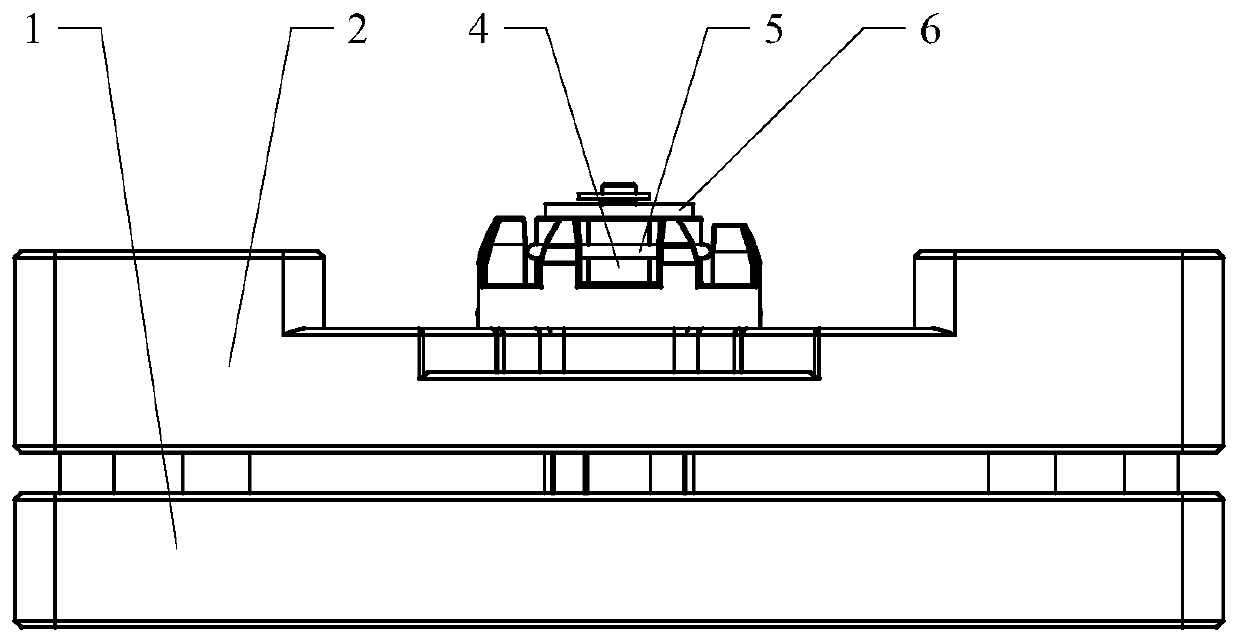

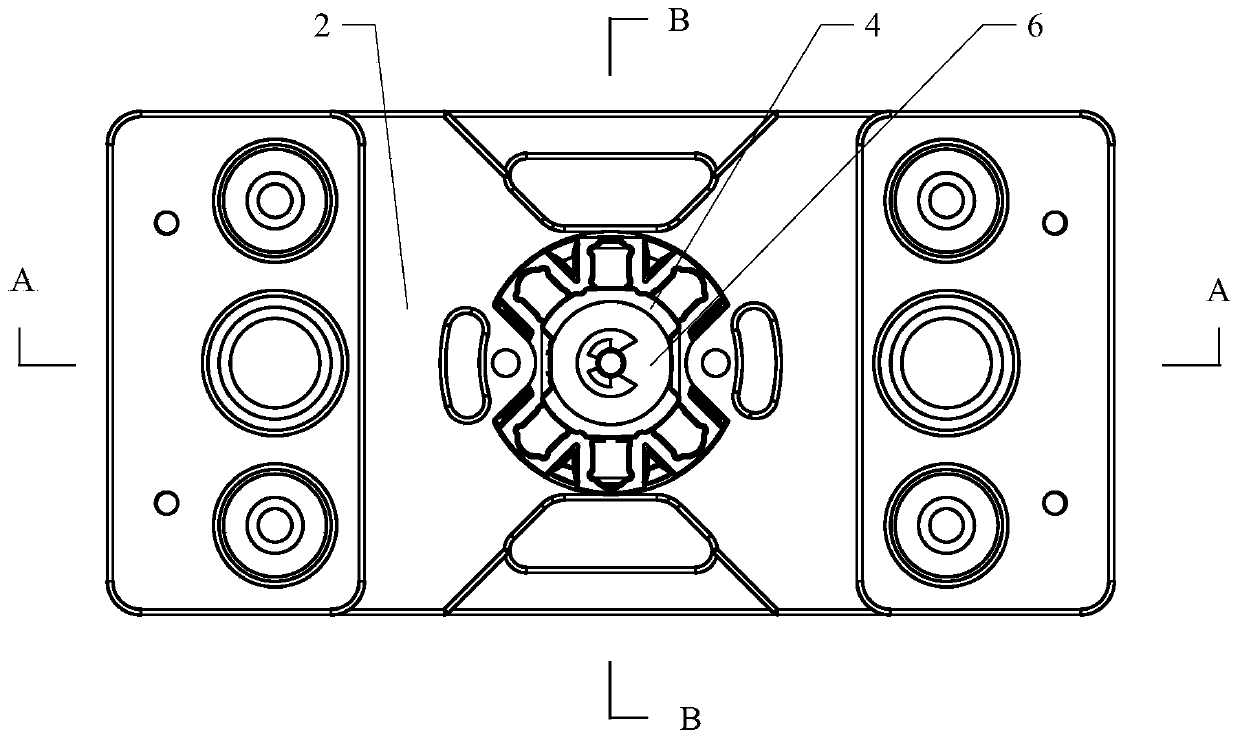

[0040] Figure 1-Figure 3 They are respectively the three-dimensional structure schematic diagram, the front view and the top view of the radial expansion mechanism of this embodiment, Figure 4 and Figure 5 respectively image 3 Schematic cross-sectional views of the radial expansion mechanism in A-A direction and B-B direction. Such as Figure 1-Figure 5 As shown, the radial expansion mechanism of this embodiment includes a base 1 , a stage 2 , a push block 3 , at least two slide blocks 4 , a reset device and a pressure plate 6 . The stage 2 is arranged above the base 1 and is movably connected with the upper end surface of the base 1 . The lower end of the push block 3 is fixedly connected to the base 1 , the push block 3 has at least one first slope 31 , and the slide block 4 is arranged outside the push block 3 . The reset device is connected with the sliding block 4 and is used to keep the sliding block 4 in contact with the first slope 31 of the push block 3 . Th...

Embodiment 2

[0053] The radial expansion mechanism in Embodiment 1 can cooperate with other components to form an assembly jig. Figure 8 is a schematic structural view of the assembly jig of this embodiment. In an alternative embodiment, such as Figure 8 As shown, the assembly jig of this embodiment includes the indenter 91 and the radial expansion mechanism in the first embodiment.

[0054] During the assembly process of the product, it is often necessary to install other workpieces on the inner side of the housing and the ring-shaped workpiece by bonding, welding or the like. This embodiment takes assembling the anti-theft buckle, that is, bonding a plurality of magnets inside the hemispherical casing 8 as an example, to describe the structure and usage of the assembling jig.

[0055] The stage 2 can be provided with profiling grooves corresponding to the shape of the magnets, a plurality of magnets are placed in the corresponding profiling grooves, and there can be a certain interva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com