Hopper, slurry spreading terminal and slurry spreading equipment

A hopper and grouting technology, which is applied in construction, building construction, etc., can solve the problems of poor uniformity of manual grouting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

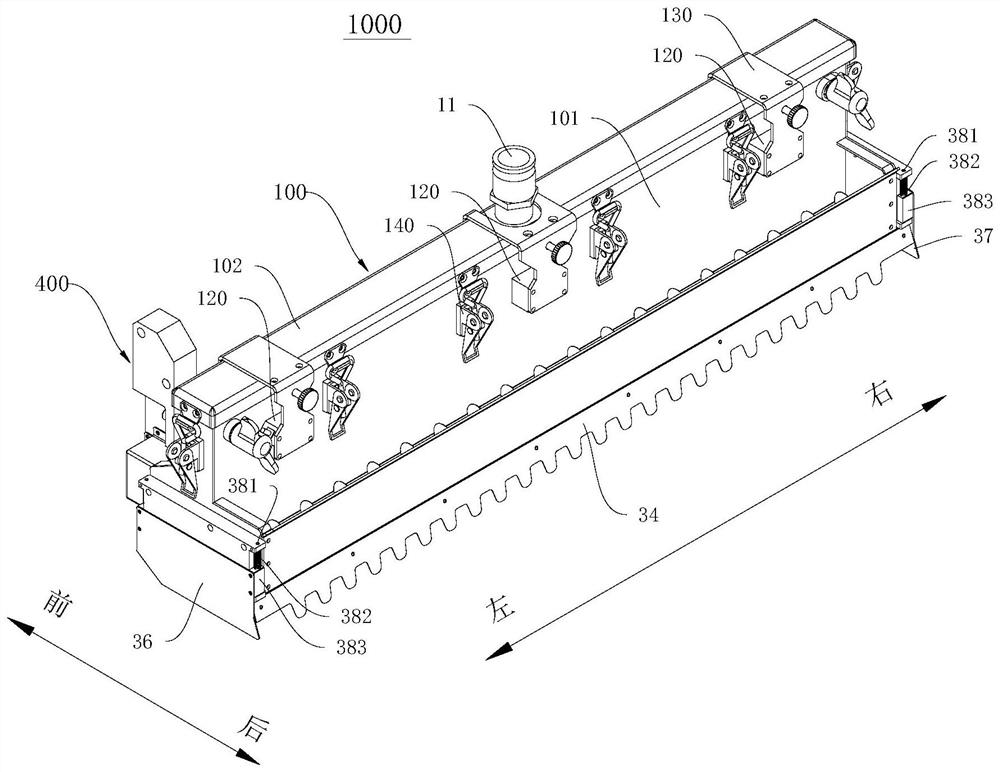

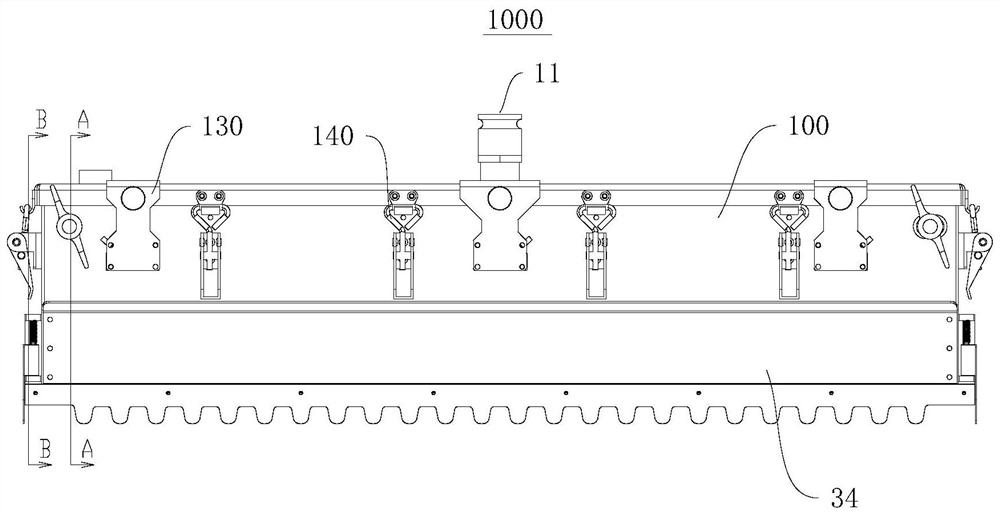

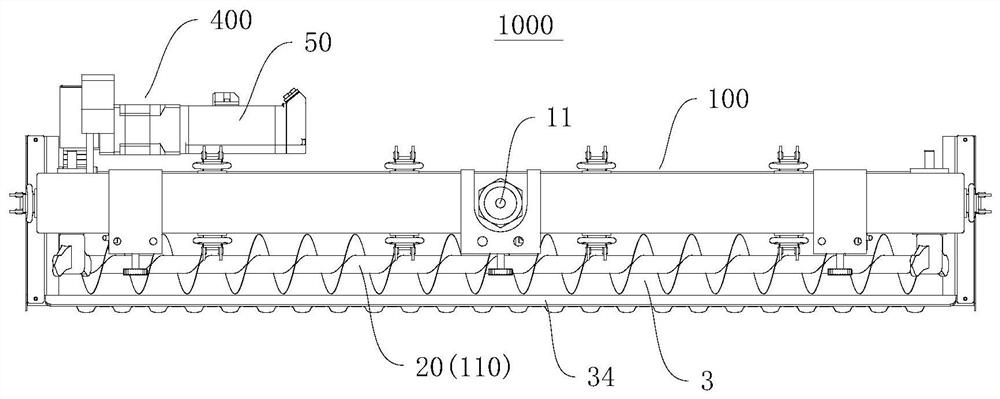

[0037] Such as Figure 1 to Figure 12 As shown, the embodiment of the first aspect of the present application provides a hopper, which can be used in the slurry-laying terminal 100 , the slurry-laying mechanism 1000 and the slurry-laying equipment 10000 . The paving terminal can perform automatic pumping, separating, storing, controlling and laying of pulp. For example, in the process of laying floor tiles, the grouting mechanism 1000 can be used to automatically pump grout, separate grout, store grout, control grout and spread grout to the tile adhesive 2000.

[0038] Such as Image 6 As shown, the hopper 10 has a slurry storage chamber 2, the upper end of the slurry storage chamber 2 is the slurry inlet 21 of the slurry storage chamber, and the lower end is the slurry outlet 22 of the slurry storage chamber, and the size of the slurry inlet 21 of the slurry storage chamber is larger than that of the storage The area of the pulp outlet 22 of the pulp chamber has at least ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com