A self-locking press

A press and self-locking technology, which is applied in the field of presses, can solve problems that affect production quality, easily cause mistakes, and high pressure, and achieve the effects of easy operation, easy pressure maintenance, and self-locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

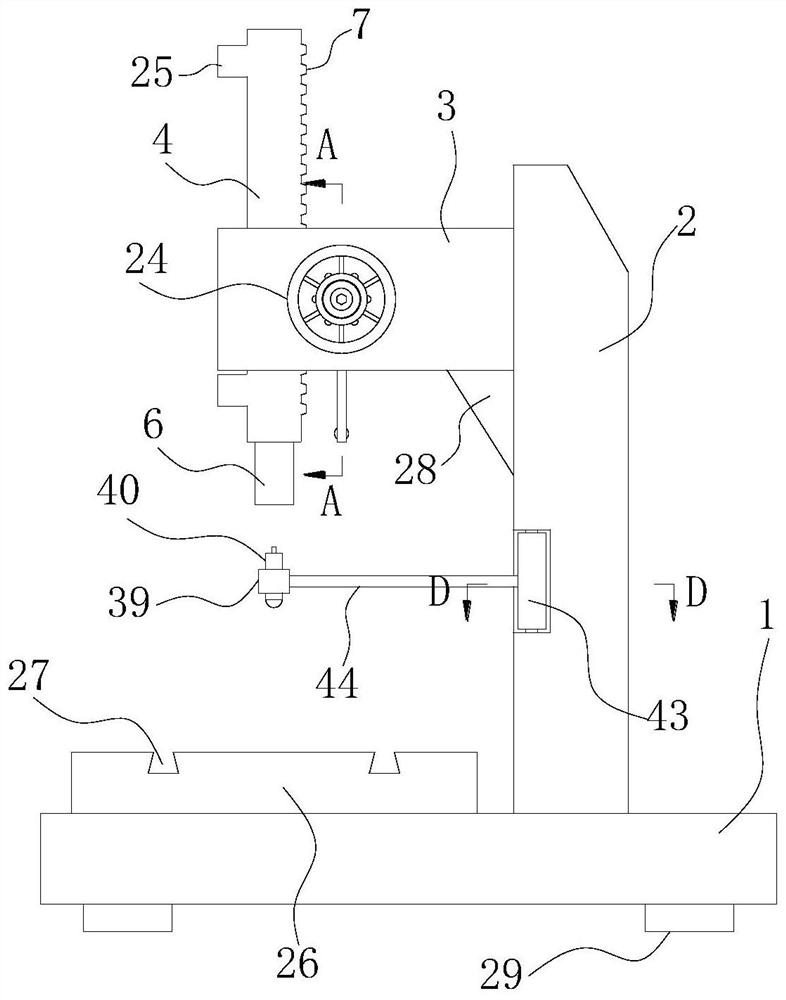

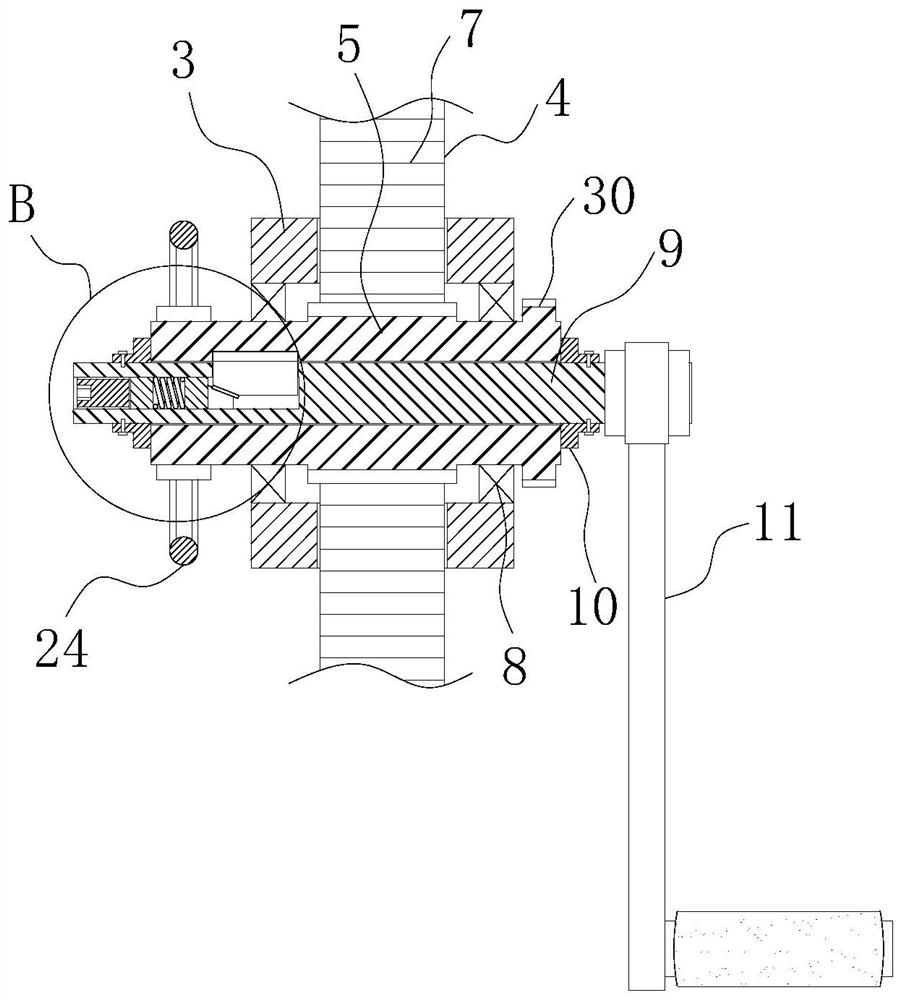

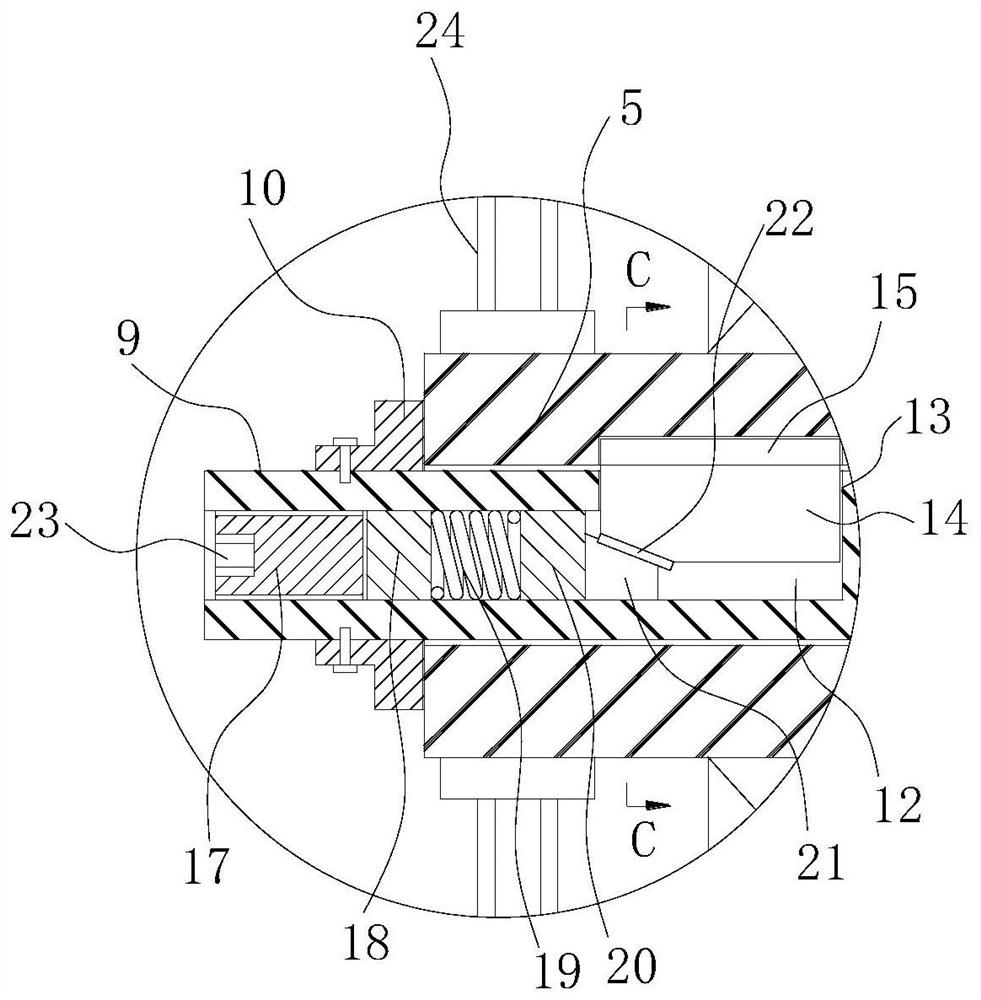

[0024] combine Figure 1-8 The press machine shown is the same as the existing press machine, and it includes a base 1 and a pressing device positioned above the base 1. The pressing device is connected to the base 1 through a support column 2, in order to improve the installation of the base 1. stability, as figure 1 As shown, a plurality of non-slip rubber blocks 29 are arranged on the bottom surface of the base 1 . The base 1 is used to place and fix the workpiece, and the pressing device is provided with a pressure head for applying pressure to the workpiece to process the workpiece. The present invention intends to improve the existing manual press from various aspects in order to obtain better comprehensive performance.

[0025] In the existing manual press, the positioning of the workpiece on the machine base 1 is mainly observed by the user with the naked eye, and its accuracy is difficult to guarantee. Therefore, an auxiliary positioning component is also provided d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com