Injection mold for engineering plastics

A technology for injection molds and engineering plastics, applied in the field of injection molds for engineering plastics, can solve the problems of not being able to meet the needs of mass production and low efficiency, and achieve good sealing and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

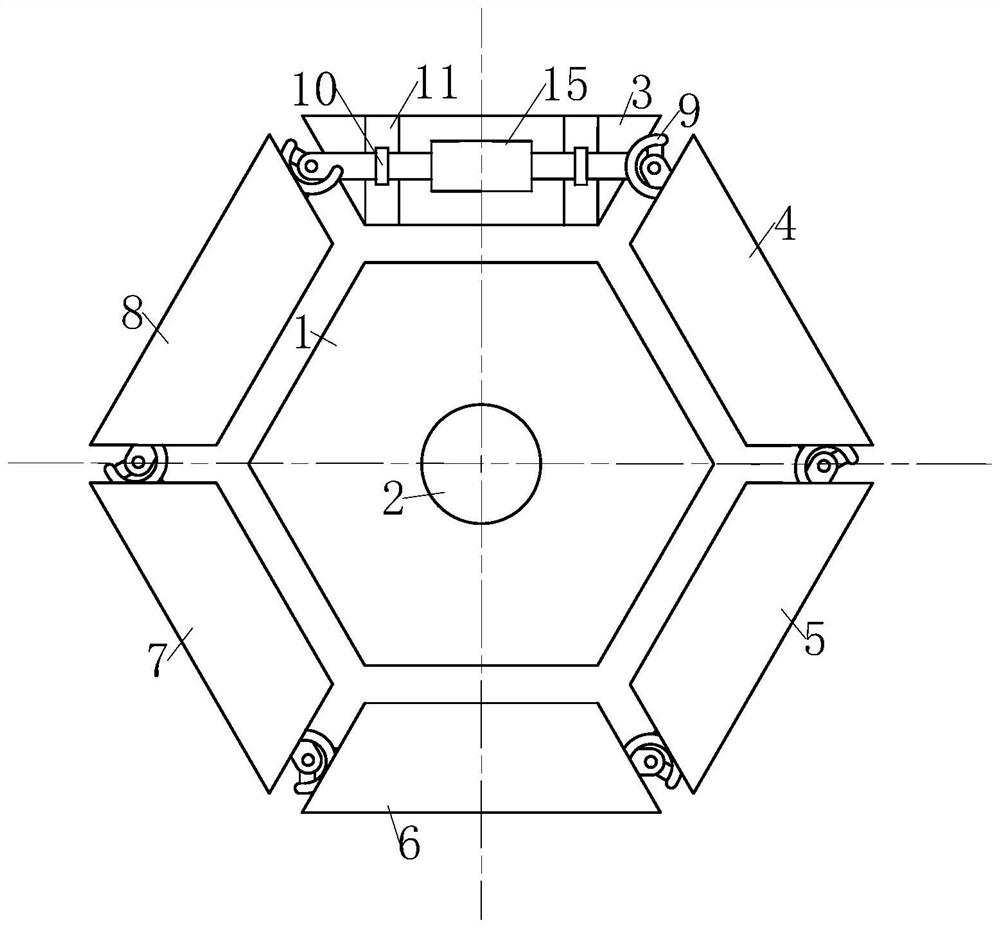

[0034] As a specific embodiment of the present invention, the cardan shaft 9 is provided with a chute 92, the chute 92 is located on the upper and lower sides of the threaded hole 91 and through the threaded hole 91, the sliding connection within the chute 92 is connected to the slider 13, the outer surface chute 92 on the cardan shaft 92 is fixedly connected to the magnetic controller 14, the outer surface of the screw 12 is provided with grooves 121 at both ends of the outer surface.

[0035]After adjusting the screw 12, since the screw 12 and the cardan axis 9 is connected by thread rotation, and the cardan axis 9 itself also has to rotate, the screw 12 will often rotate together with the rotation of the cardan axis 9, the present invention opens a chute 92 within the cardan shaft 9, places a slider 13 in the chute 92, and then opens a groove 121 at both ends of the screw 12, when it is necessary to adjust the screw 12, the control magnetic controller 14 makes the magnetic con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com