Polypropylene cable and insulating layer repairing method and application thereof

A repair method and cable insulation technology, applied in the direction of conductor/cable insulation, insulated conductors, insulated cables, etc., can solve problems such as high environmental pressure, low energy consumption, and unsatisfactory green power grids

Pending Publication Date: 2022-05-31

ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] However, cross-linked polyethylene is a thermosetting material that cannot be degraded by itself. It can only be recycled by incineration and crushed to landfill, and some harmful cross-linked by-products will be produced during the cross-linking reaction. Environmental pressure Large, does not meet the requirements of the green grid

Different from cross-linked polyethylene, the production process of polypropylene is simple, without cross-linking and degassing process, low energy consumption, small plant area, and can be recycled after reaching the service life, and polypropylene has excellent electrical properties, melting temperature High temperature resistance and good water resistance. Therefore, polypropylene insulation materials have been used as power cable insulation layers, such as the 10kv polypropylene cables currently used in production. When the polypropylene cable insulation layer is bulged and deformed, the electrical properties of the cable are affected. , when the electric energy cannot be stably transmitted, the cable needs to be repaired, but polypropylene is a thermoplastic material, and the material properties of polypropylene, such as melting point and fluidity, are different from those of cross-linked polyethylene. Thermoplastic polypropylene will flow after heating and melting, so , the repair process of XLPE cables is not suitable for polypropylene cables, and there is no repair process for polypropylene cable insulation in the prior art

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

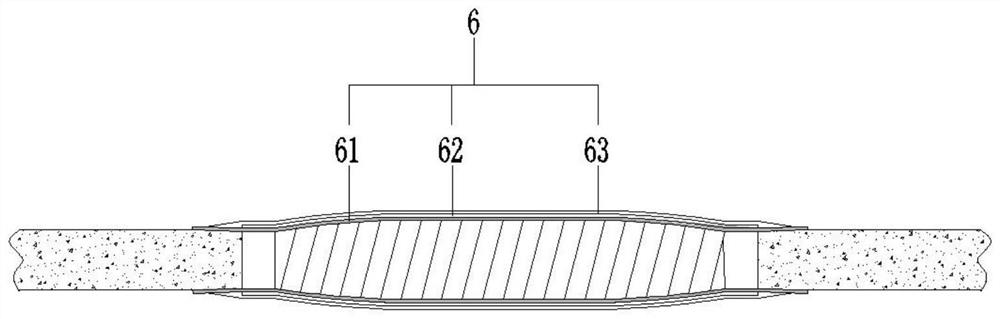

[0047] Step 4, wrapping the metal tin foil, wrapping the metal tin foil on the surface of the polypropylene insulating tape.

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistivity | aaaaa | aaaaa |

Login to View More

Abstract

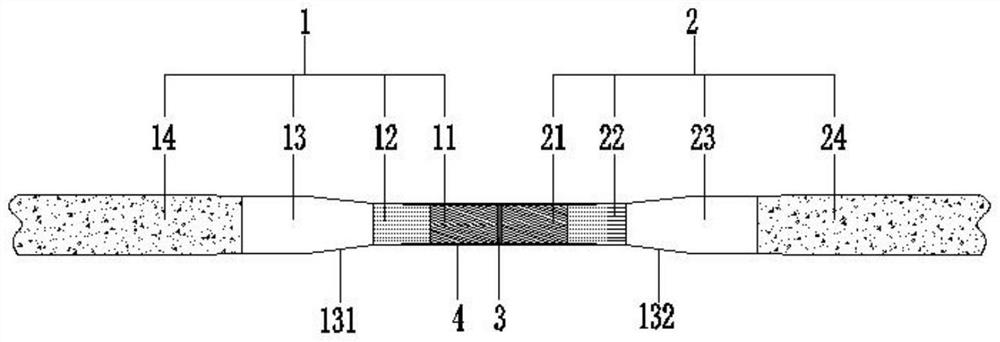

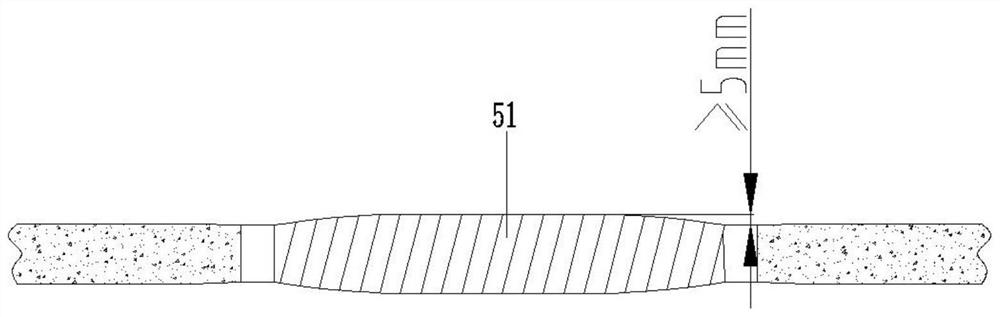

The invention belongs to the technical field of polypropylene cables, and particularly relates to a polypropylene cable and an insulating layer repairing method and application thereof. The invention provides a polypropylene cable and an insulating layer repairing method and application thereof, and the repairing method comprises the steps: wrapping a pencil stub slope insulating layer with a polypropylene insulating tape, then sequentially wrapping the polypropylene insulating tape with a rubber soft film, a metal foil and a polyimide film from inside to outside, and finally heating the polypropylene insulating tape to melt the polypropylene insulating tape, the polypropylene insulating tape can provide lasting radial pressure, the metal foil can uniformly transfer heat, and the polyimide film has relatively high tensile strength and relatively low load elongation, so that the polypropylene insulating tape and the to-be-repaired position of the polypropylene cable insulating layer are fused and combined, the repair of the polypropylene cable insulating layer is realized, and the service life of the polypropylene cable insulating layer is prolonged. The electrical performance of the polypropylene cable is guaranteed, and the technical problem that in the prior art, a polypropylene cable insulation layer repairing technology is lacked is solved.

Description

A polypropylene cable and its insulating layer repair method and application technical field The application belongs to polypropylene cable technical field, relate in particular to a kind of polypropylene cable and insulation layer repair method thereof and application. Background technique The excellent electrical properties of cross-linked polyethylene (XLPE) make cross-linked polyethylene insulating material as a long-distance transmission frame. The insulating layer of empty lines and the insulating layer of urban underground cables are widely used. But the polyethylene after the cross-linking is a kind of thermosetting material, cannot rely on self-degradation, can only adopt incineration during recycling And the way of crushing and landfilling, and some harmful cross-linking by-products will be produced in the process of cross-linking reaction, environmental protection pressure is high, dissatisfaction meet the requirements of green grid. Unlike cross-linked...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01B7/02H01B7/17H01B7/29H01B7/18H01B7/42H01B13/10

CPCH01B7/02H01B7/17H01B7/29H01B7/18H01B7/428H01B13/10Y02W30/82

Inventor 侯帅展云鹏傅明利黎小林刘唱陈珂馨朱闻博惠宝军陈俊张逸凡冯宾蒋毅恺赵丽媛

Owner ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com