Preparation method for coating material for strengthening and repairing airplane landing gear

A technology for aircraft landing gear and coating materials, which is applied in the direction of coating and metal material coating technology, and can solve the problems of corrosion failure of landing gear and its components, and failure of landing gear retraction and deployment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

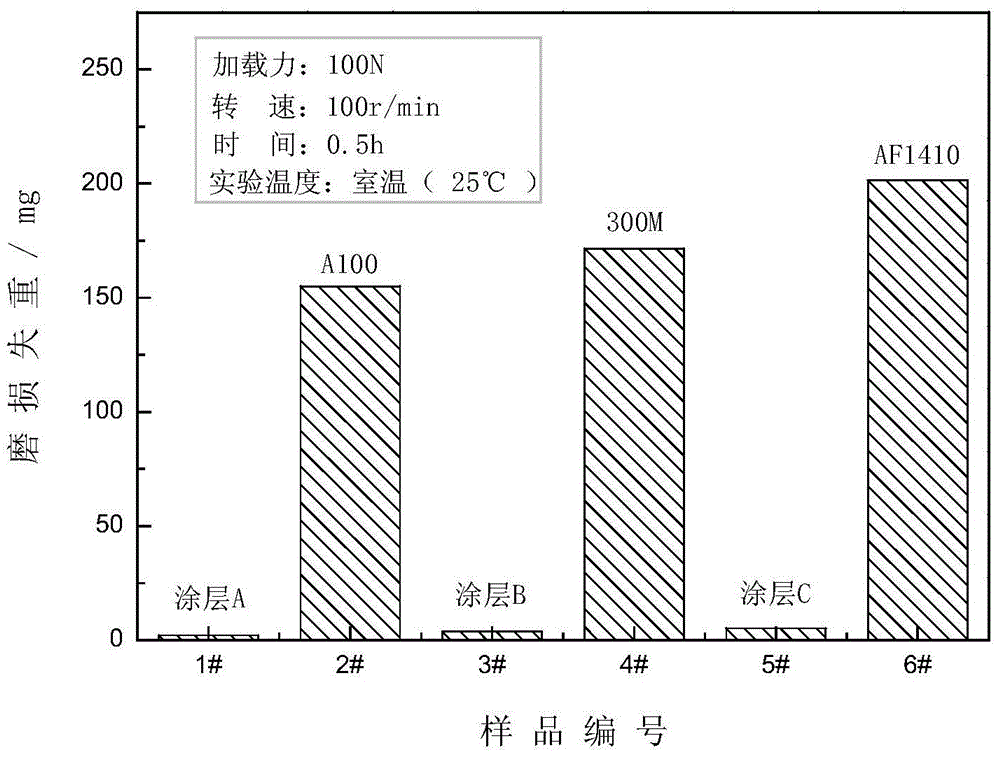

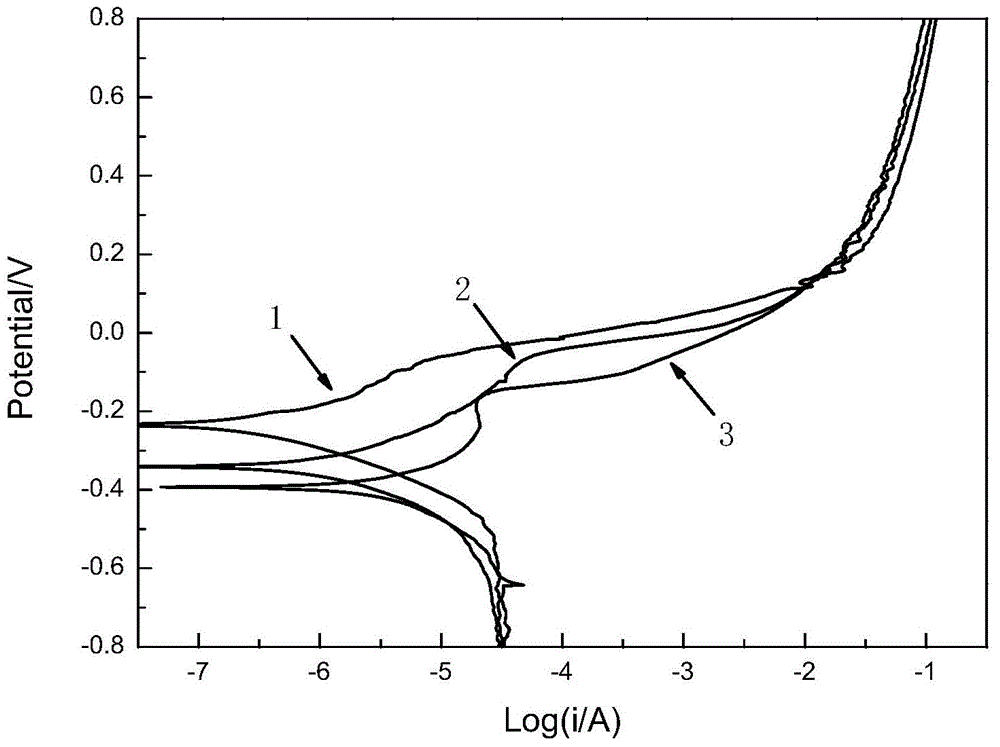

Embodiment 1

[0013] Including the following steps:

[0014] (1) The components of the alloy powder are designed according to mass percentage: C: 1.45wt%; Co: 6.93wt%; Cr: 10.27wt%; Ni: 5.53wt%; Mo: 5.64wt%; W: 5.74wt% ; Mn: 0.99wt%, Nb: 1.15wt%; V: 1.11wt%; Ti: 1.45wt%; Fe: 59.74wt%. Weigh the proportioned single-element powder according to the mass percentage of the above components, mix the powder in a ball mill for 1.5 hours, and obtain a uniform powder after mixing;

[0015] (2) Dry the powder in a drying oven for 2.5 hours at a drying temperature of 100 degrees Celsius;

[0016] (3) Clean and wipe the area of the Aermet100 high-strength steel landing gear with a diameter of 200mm to be repaired with acetone to remove oil and impurities on the surface;

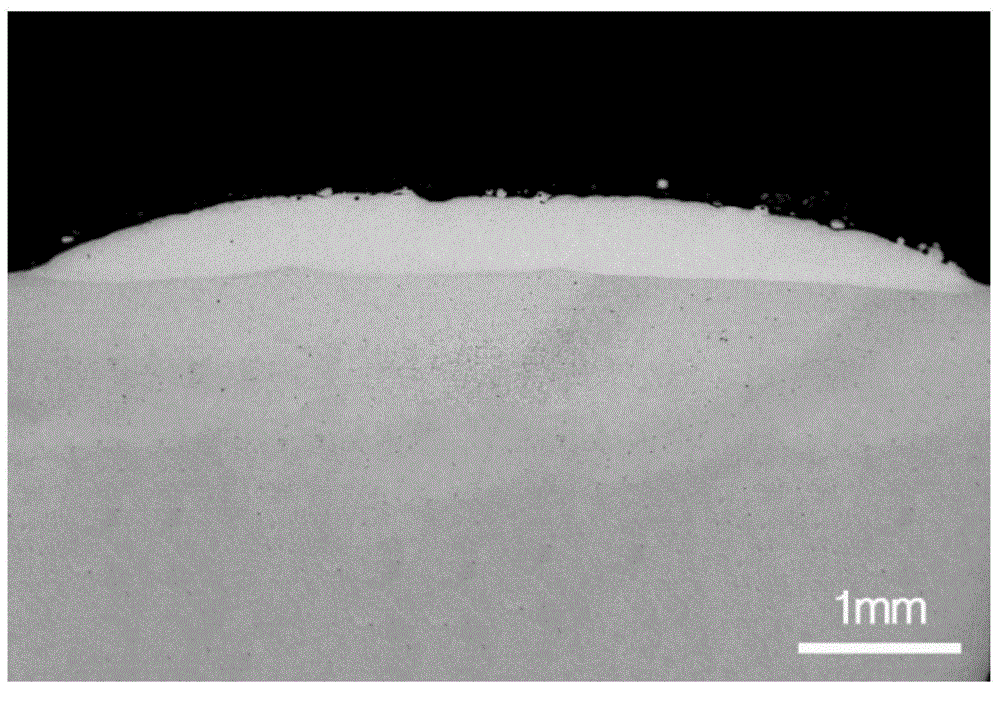

[0017] (4) A semiconductor laser is used to prepare an alloy cladding layer on the surface of the Aermet100 material. The laser cladding process parameters are: the conveyed powder beam and the laser beam are at 55°, the powder bea...

Embodiment 2

[0026] Including the following steps:

[0027] (1) The components of the alloy powder are designed according to mass percentage: C: 0.75wt%; Co: 6.53wt%; Cr: 10.05wt%; Ni: 5.25wt%; Mo: 5.34wt%; W: 5.52wt% ; Mn: 0.89wt%, Nb: 1.05wt%; V: 1.01wt%; Ti: 1.35wt%; Fe: 62.26wt%. Weigh the proportioned single element powder according to the mass percentage of the above components, mix the powder in a ball mill for 3 hours, and obtain a uniform powder after mixing;

[0028] (2) Dry the powder in a drying oven for 3 hours at a drying temperature of 110 degrees Celsius;

[0029] (3) Clean and wipe the 300M high-strength steel undercarriage area with a diameter of 170mm to be repaired with acetone to remove oil and impurities on the surface;

[0030] (4) A fiber laser is used to prepare an alloy cladding layer on the surface of the landing gear with a material of 300M. The process parameters of the laser cladding preparation process are: the conveyed powder beam and the laser beam are at...

Embodiment 3

[0039] (1) The components of the alloy powder are designed according to mass percentage: C: 0.65wt%; Co: 5.24wt%; Cr: 8.72wt%; Ni: 4.02wt%; Mo: 4.11wt%; W: 4.31wt% ; Mn: 0.79wt%, Nb: 0.95wt%; V: 0.91wt%; Ti: 1.25wt%; Fe: 69.05wt%. Weigh the proportioned single-element powder according to the mass percentage of the above components, mix the powder in a ball mill for 4.5 hours, and obtain a uniform powder after mixing;

[0040] (2) Dry the powder in a drying oven for 3.5 hours at a drying temperature of 120 degrees Celsius;

[0041] (3) Clean and wipe the area of the AF1410 high-strength steel landing gear with a diameter of 150mm to be repaired with acetone to remove oil and impurities on the surface;

[0042](4) Using CO 2 The laser prepares the Ni-based alloy cladding layer on the surface of the AF1410 landing gear material. The process parameters of the laser cladding preparation process are: the delivered powder beam and the laser beam are at 45°, the powder beam and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com