Underground controllable self-expansion casing patching pipe

A casing subsidy and controllable technology, applied in wellbore/well parts, earthwork drilling and production, etc., can solve the problems of complex hydraulic cold extrusion expansion device, lack of subsidy, high construction risk, etc., and achieve high cost performance, The effect of convenient operation and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

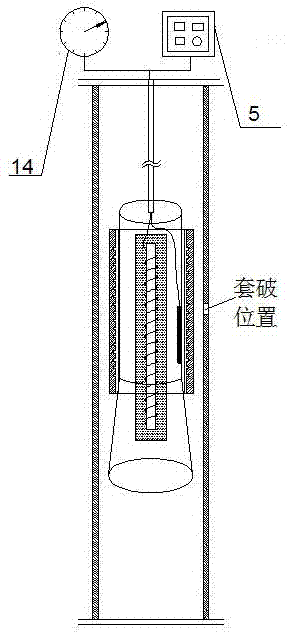

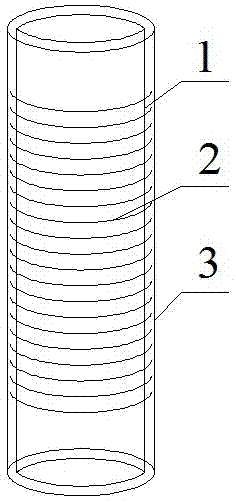

[0034] Such as figure 1 A downhole controllable self-expanding casing supplementary pipe shown, including such as figure 2 , 3 Subsidize the pipe body and as Figure 4 Controllable downhole tool release device;

[0035] Such as figure 2 The subsidy pipe body is composed of a rubber liner 1, a memory alloy ring 2, and a plugging rubber tube 3. The inner surface of the plugging rubber tube 3 is bonded to the outer surface of the rubber liner 1 through a temperature-resistant adhesive. knot, and the outer surface of the plugging rubber cylinder 3 is also coated with a temperature-resistant adhesive; the memory alloy ring 2 is located between the plugging rubber cylinder 3 and the rubber liner 1; the memory alloy ring 2 is made of shape memory alloy The material is processed. Shape memory alloy material can produce shape memory effect after component design, preparation and repeated training treatment, and can quickly return to the original memory shape at a specific high t...

Embodiment 2

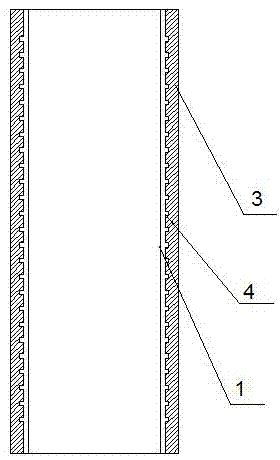

[0040] On the basis of Example 1, such as image 3 Trapezoidal grooves 4 are evenly distributed on the inner wall of the leak-stopping rubber cylinder 3, and the memory alloy ring 2 is embedded in the trapezoidal grooves 4; to the limiting effect. The memory alloy ring 2 is embedded in the trapezoidal groove 4, and the rubber liner 1 and the plugging rubber cylinder 3 are firmly bonded by the temperature-resistant adhesive 4; the shape memory alloy material mainly includes titanium-nickel alloy, iron-nickel alloy, and chromium-nickel alloy Wait. The outer diameter of the shape memory alloy ring 2 is generally Φ38mm-Φ244.5mm. According to the specifications and strength requirements of the bushing to be subsidized, the wall thickness of the memory alloy ring is 3mm-10mm; It is fixedly connected by welding; the controllable downhole tool release device also includes a manometer 14 for detecting the pressure in the well; the centralizing cylinder 12 and the conical limit cylin...

Embodiment 3

[0043] Well Wang X-Y in an oilfield, the well depth is 2130m, the casing size is 139.7mm×9.17mm, the casing damage position is 1580-1582m, and the well temperature is about 55℃. The total length of the downhole tool release device is 10m, the size of the centralizing cylinder is 95mm×3mm, the outer diameter of the upper part of the conical limiting cylinder is 95mm, and the outer diameter of the lower part is 110mm.

[0044] Firstly, according to the service environment such as well temperature, qualified subsidy pipes are processed and trained. The subsidy pipes have a size of 106mm×3mm before self-expansion. After expansion, the outer diameter of the free state can be changed to 125mm and the length is 8 meters. In order to prevent accidents such as sudden expansion due to abnormal well temperature when the subsidy pipe was run in, the self-expansion thixotropic temperature was set at 80°C during the training, which was much higher than the wellbore temperature at the casing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com