Pen type auxiliary tool in resistance strain gauge pasting process

A resistance strain gage and auxiliary tool technology, applied in the direction of electric/magnetic solid deformation measurement, plastic deformation fastening, electromagnetic measurement device, etc. , easy to achieve, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

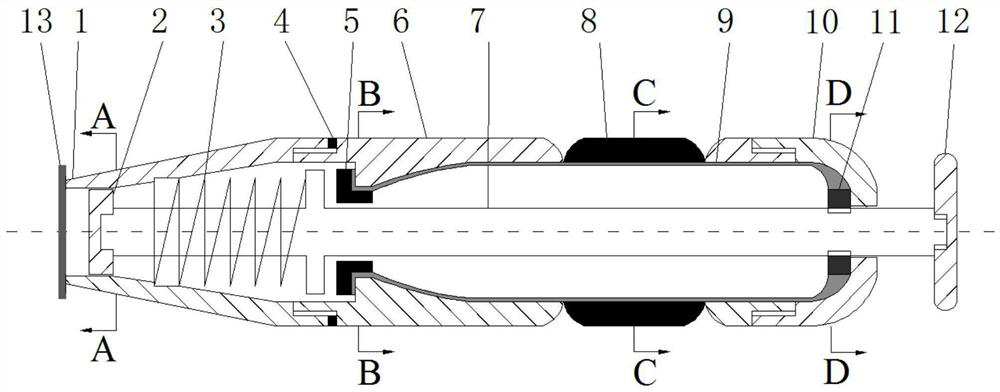

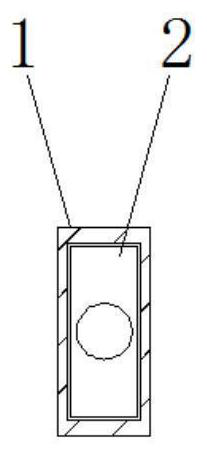

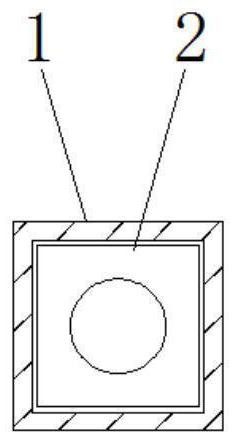

[0025] Such as figure 1 Shown, the present invention comprises nib 1, spring 3, pen body 6, center pen holder 7 and pen tail 10, and nib 1 is connected with pen body 6 by screw thread, and rubber sealing ring 4 is connected between nib 1 and pen body 6. The pen tail 10 is connected with the pen body 6 by threads.

[0026] The present invention also includes a strain gauge pressing head 2, a rubber sealing ring 4, an air bag front compression ring 5, an air bag compression button 8, an air bag 9, an air bag rear end sealing ring 11 and a penholder pressing button 12, and the air bag 9 is placed in the pen body 6 and In the cavity inside the pen tail 10.

[0027] Such as Figure 4 As shown, the front end of the airbag 9 is compressed on the step flange of the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com