A medium-temperature high-strength adhesive wear-resistant material and its preparation method

A wear-resistant material and high-strength technology, which is applied in the field of adhesive wear-resistant materials, can solve problems such as failure to consider, adhesive coating damage and peeling, and achieve the effects of reducing area, prolonging service life, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

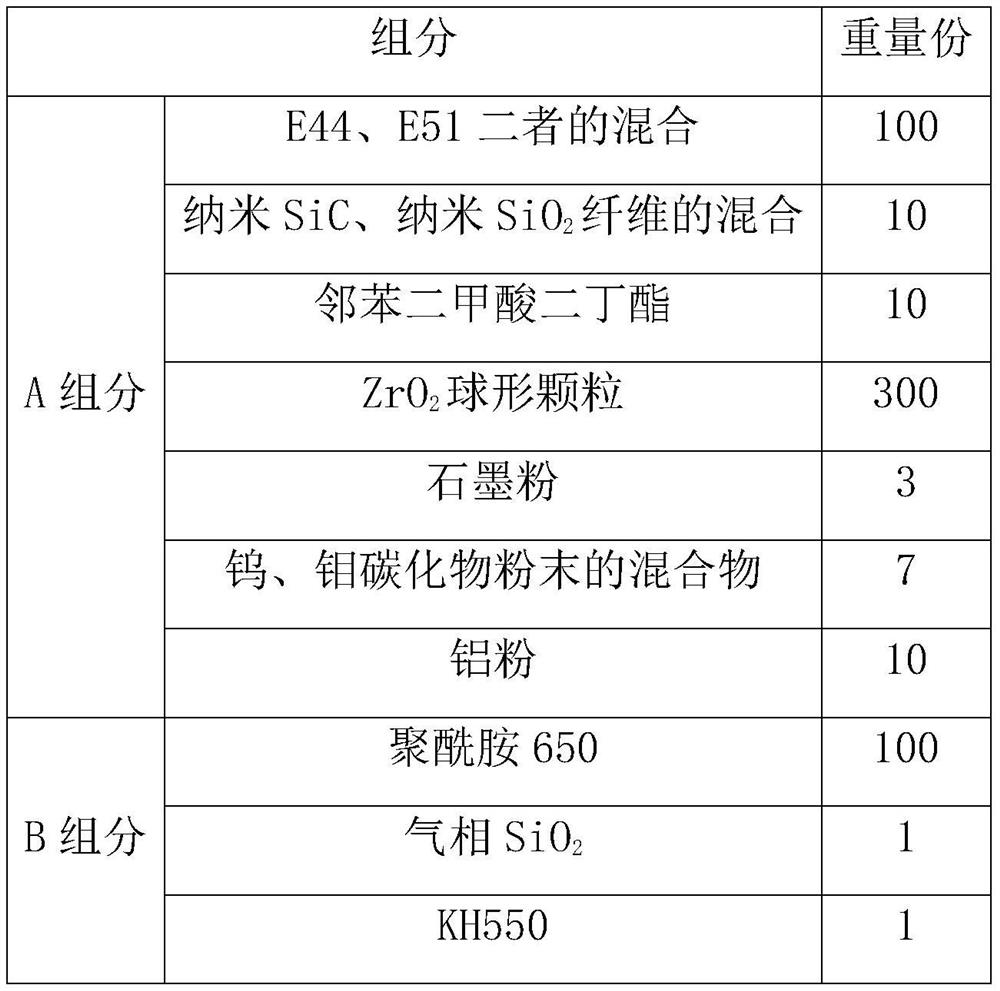

[0049] A medium-temperature high-strength adhesive wear-resistant material, composed of A and B components.

[0050] The composition of A component and the parts by weight of each composition are as follows:

[0051] Mixture of E44 and E51 100 parts

[0052] Nano-SiC, Nano-SiO 2 fiber blend 10 parts

[0053] 10 parts of dibutyl phthalate

[0054] ZrO 2 300 parts of spherical particles

[0055] 3 parts graphite powder

[0056] 7 parts mixture of tungsten and molybdenum carbide powder

[0057] 10 parts of aluminum powder;

[0058] The composition of B component and the parts by weight of each composition are as follows:

[0059] Polyamide 650100 parts

[0060] Vapor SiO 2 1 copy

[0061] KH5505 copies.

[0062] Among them, ZrO 2 The purity of spherical particles is above 95%, and its particle size specifications are composed of: 2.0mm 90 parts by weight, 1.0mm 120 parts by weight, 0.5mm 90 parts by weight; the particle size range of graphite powder is 100-400 mesh; ...

Embodiment 2

[0070] A medium-temperature high-strength adhesive wear-resistant material, composed of A and B components.

[0071] The composition of A component and the parts by weight of each composition are as follows:

[0072] E51 120 copies

[0073] Nano-ZrO 2 , Nano TiO 2 fiber blend 5 parts

[0074] Polyether polyol N300 30 parts

[0075] Al 2 o 3 200 parts of spherical particles

[0076] 5 parts of graphite powder and talcum powder mixture

[0077] 5 parts of mixture of titanium and iron carbide powder

[0078] 15 parts of aluminum powder;

[0079] The composition of B component and the parts by weight of each composition are as follows:

[0080] 20 parts m-xylylenediamine

[0081] Vapor SiO 2 5 copies

[0082] 1 copy of KH560;

[0083] Among them, Al 2 o 3 The purity of the spherical particles is above 95%, and its particle size specifications are composed of: 3.5mm 60 parts by weight, 2.0mm 80 parts by weight, 1.0mm 60 parts by weight; nano ZrO 2 , Nano TiO 2 Th...

Embodiment 3

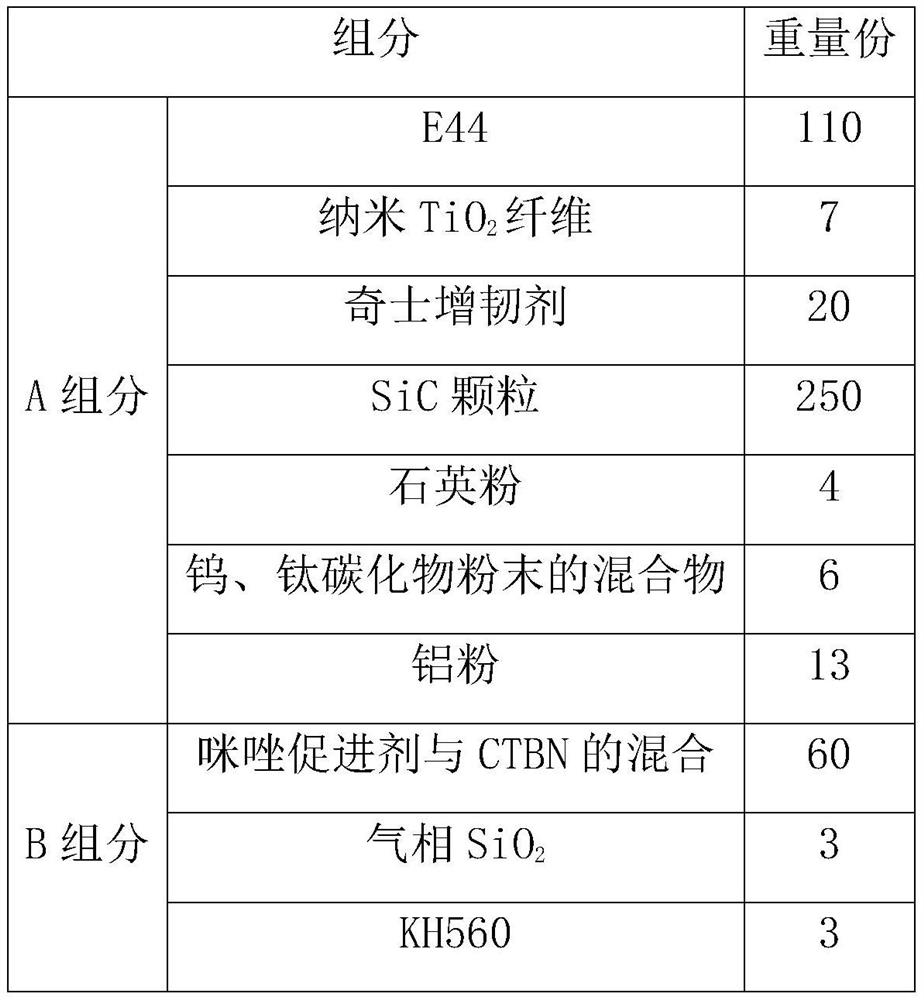

[0091] A medium-temperature high-strength adhesive wear-resistant material, composed of A and B components.

[0092] The composition of A component and the parts by weight of each composition are as follows:

[0093] E44 110 copies

[0094] Nano-TiO 2 7 servings of fiber

[0095] Qishi toughening agent 20 parts

[0096] SiC particles 250 parts

[0097] Quartz powder 4 parts

[0098] 6 parts mixture of tungsten and titanium carbide powder

[0099] 13 parts of aluminum powder;

[0100] The composition of B component and the parts by weight of each composition are as follows:

[0101] Mixture of imidazole accelerator and CTBN 60 parts

[0102] Vapor SiO 2 3 copies

[0103] KH560 3 copies;

[0104] Among them, the particle size specifications of SiC particles are composed of: 60 parts by weight for 5 mesh, 80 parts by weight for 6 mesh, 60 parts by weight for 8 mesh, 37.5 parts by weight for 30 mesh, 12.5 parts by weight for 100 mesh; 2 The particle size range of the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com