Limiting jig and limiting press-fit device

A limit and fixture technology, applied in the direction of material gluing, connecting components, electrical components, etc., can solve the problems of high mold cost and high demand for dimensional accuracy of workpiece alignment, to improve product quality, reduce dimensional accuracy requirements, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

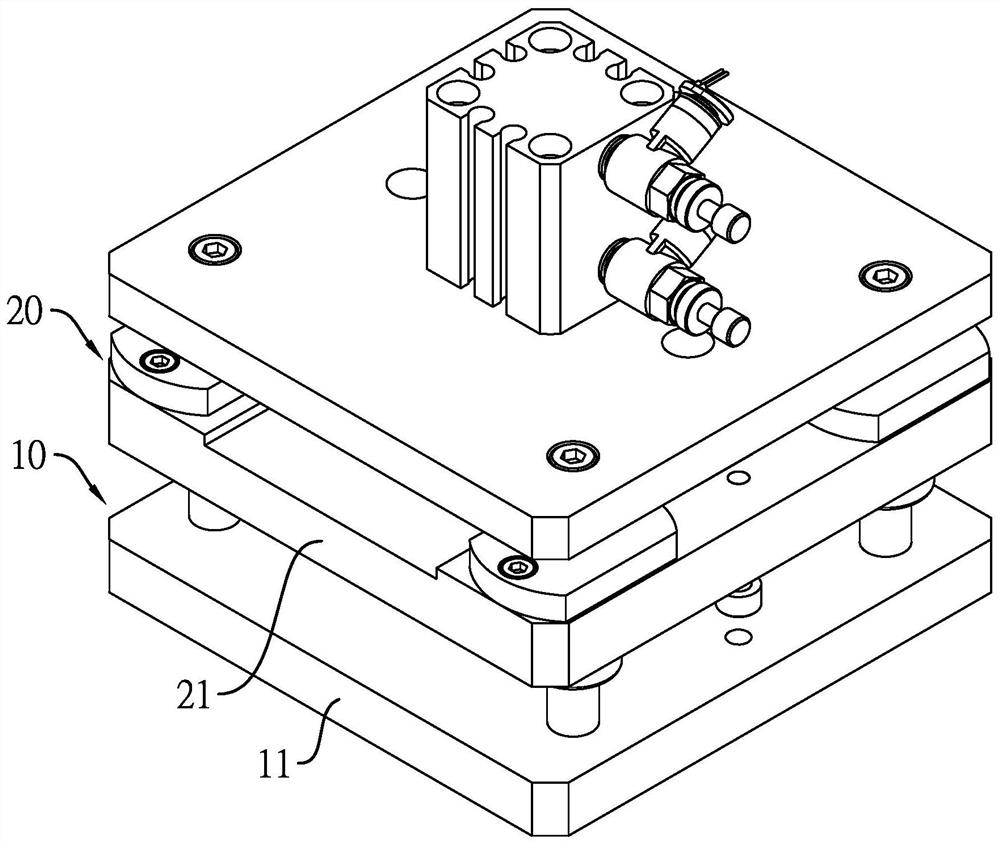

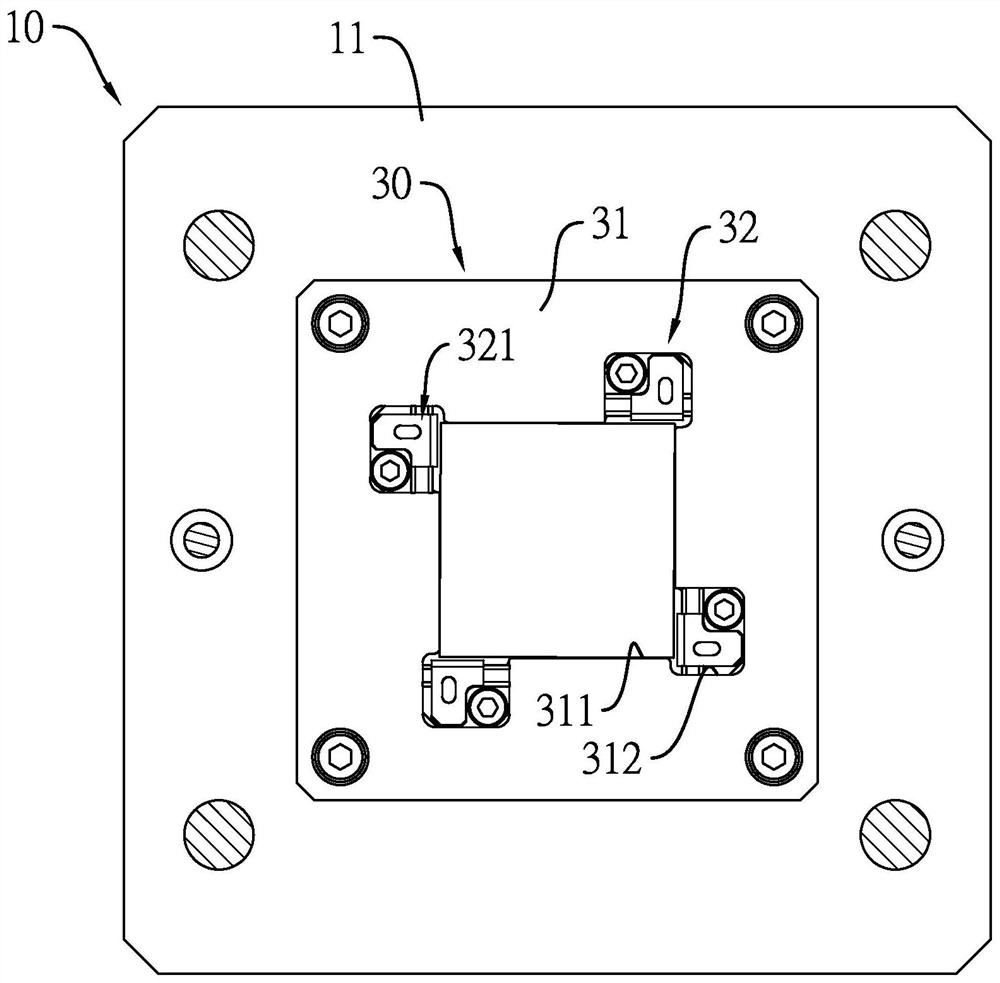

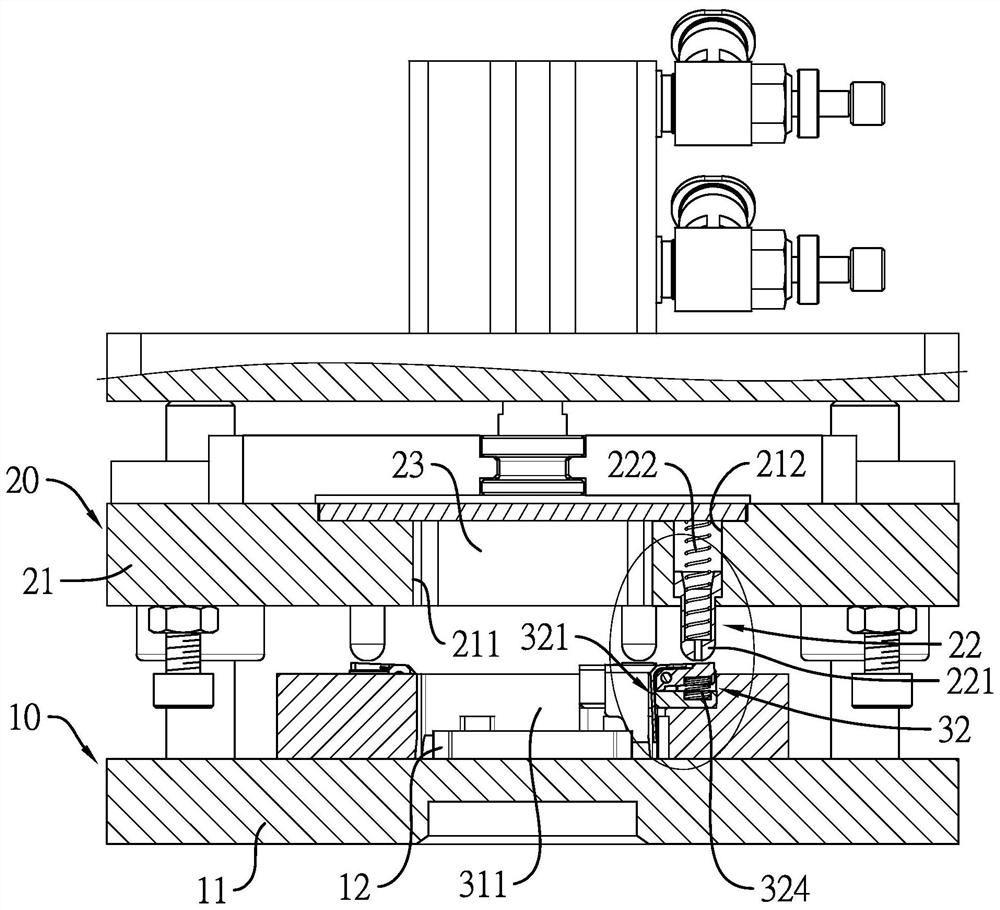

[0029] see Figure 1 to Figure 4 , is a preferred embodiment of the position-limiting jig of the present invention, which includes a lower mold 10 , an upper mold 20 and a position-limiting mechanism 30 .

[0030] Such as Figure 1 to Figure 3 As shown, the upper mold 20 is installed above the lower mold 10, the upper mold 20 has at least one pressing component, and the pressing component includes a plurality of pressing structures 22, and the plurality of pressing structures 22 can stretch It is arranged at the bottom of the upper mold 20.

[0031] Wherein, the upper mold 20 includes an upper template 21, the upper template 21 forms a plurality of assembly holes 212, the pressing component is arranged on the upper template 21, each pressing structure 22 of the pressing component It includes a push post 221 and a push post reset part 222, the push posts 221 are respectively arranged in the plurality of assembly holes 212, and the push post 221 protrudes from the correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com