A method and device for measuring the lateral thermal conductivity of a thin film

A technology of thermal conductivity and thin film, applied in the field of thermal physical property testing of thin film materials, can solve the problems of short test time, large measurement error of multimeter, inability to accurately determine the transverse heat transfer distance of thin film, etc., so as to avoid process difficulties and achieve high accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with specific examples and accompanying drawings.

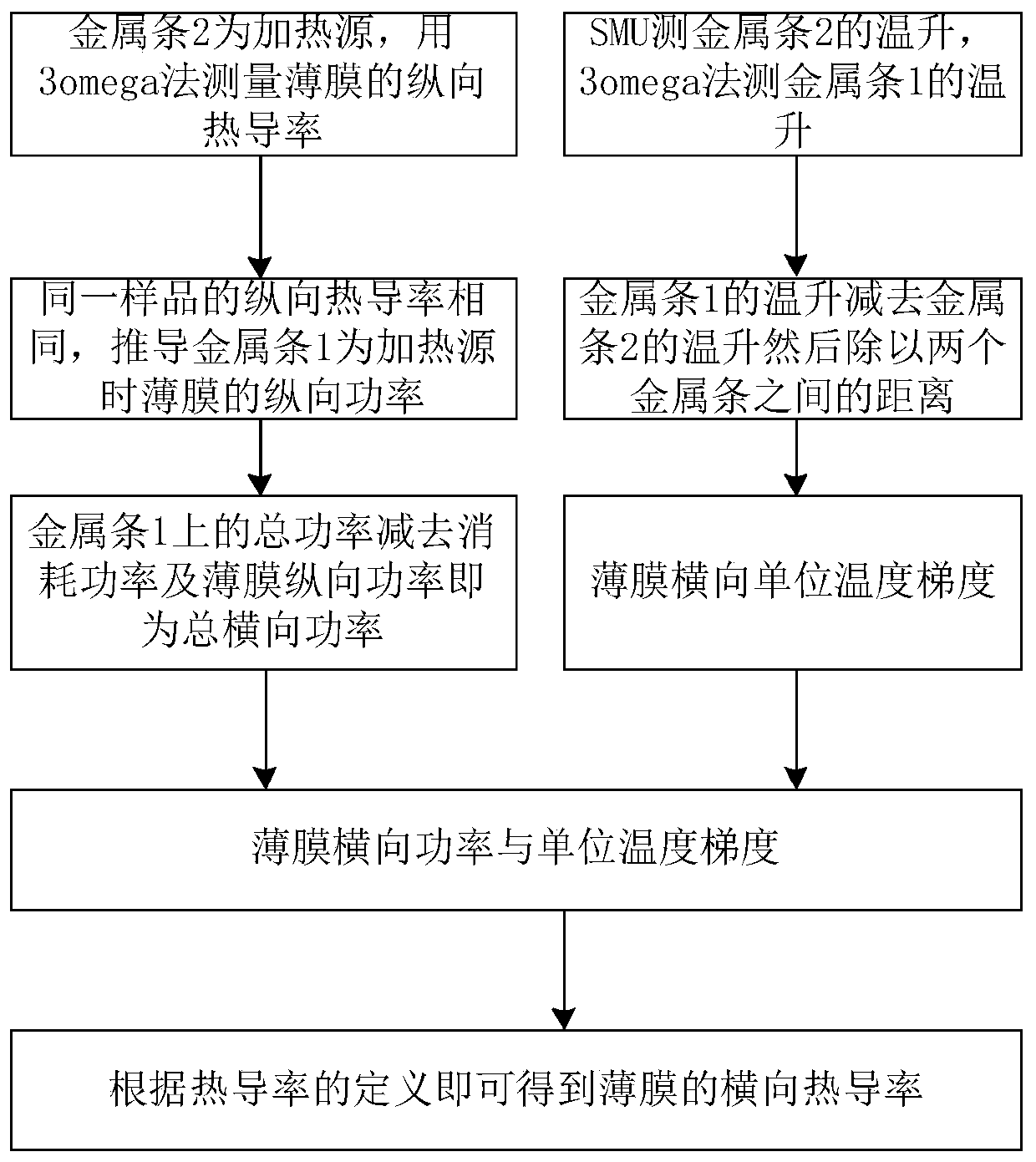

[0043] The invention provides a method for measuring the lateral thermal conductivity of a thin film, such as figure 1 As shown, it includes the following steps:

[0044] S1, using the 3ω method, with the second metal strip as the heating source, measure the longitudinal thermal conductivity K of the film to be tested Y ; The second metal strip is deposited on the surface of the film to be tested, the bottom of the film to be tested is provided with a substrate, the film to be tested and the substrate constitute a sample, and the sample is non-suspended; the vertical direction is the direction perpendicular to the film to be measured, such as Figure 8 shown.

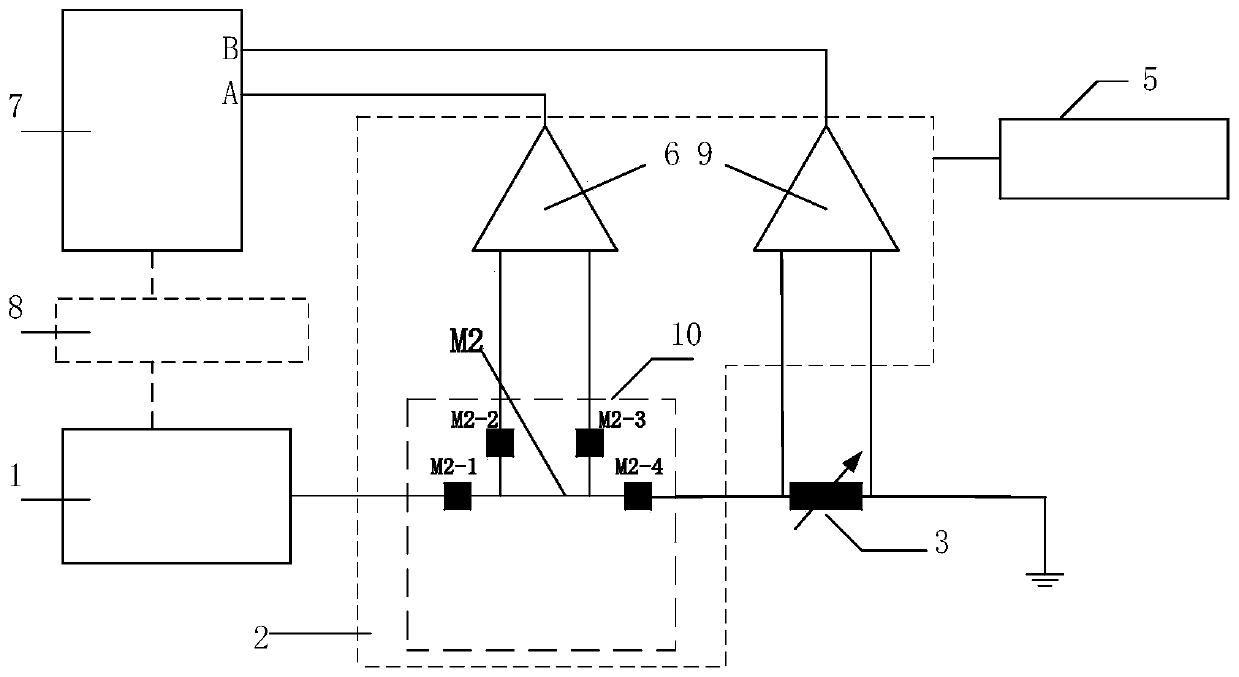

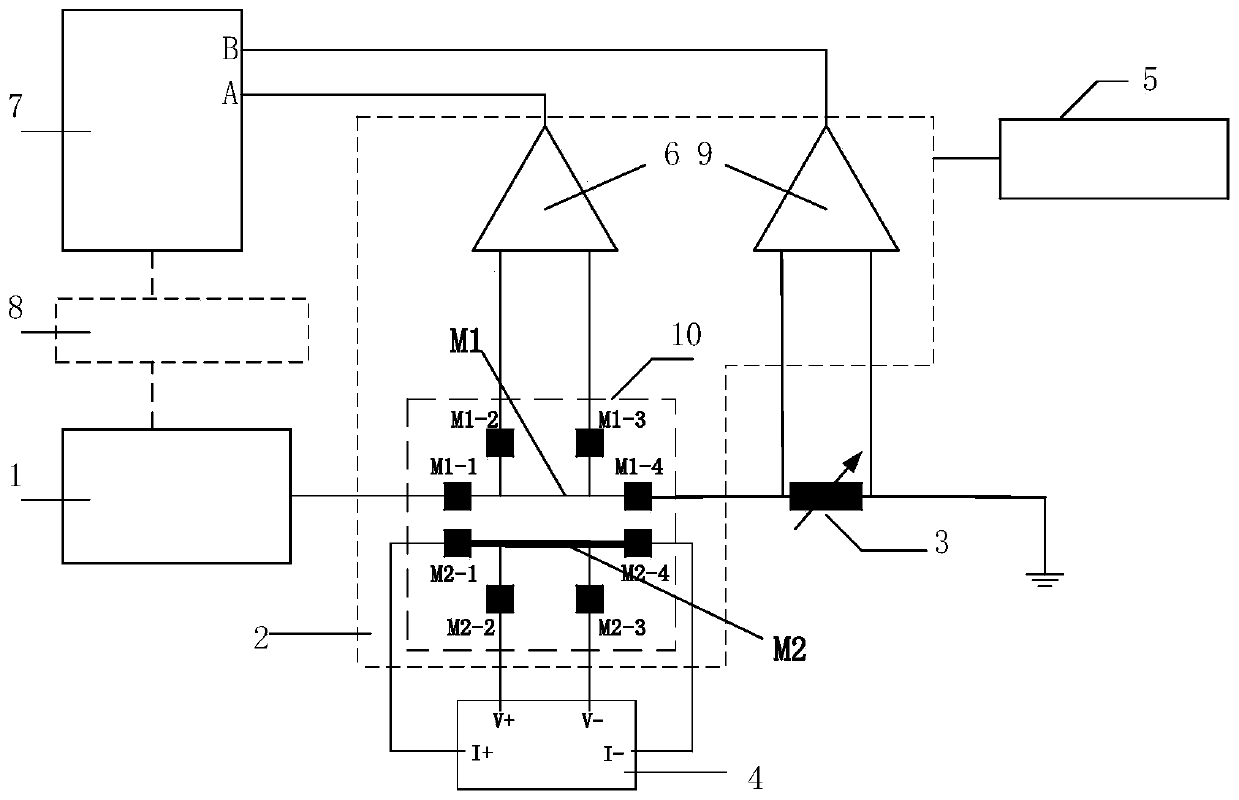

[0045] In this embodiment, the film to be tested is a silicon dioxide film. according to figure 2 Connecting device, the second metal strip M2 with a line width of 40 μm is provided with 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com