Apparatus for packaging flat articles

a technology for flat articles and packaging, applied in the field of accessories for packaging, can solve the problems of relatively complicated handling, and achieve the effect of eliminating and malfunctioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

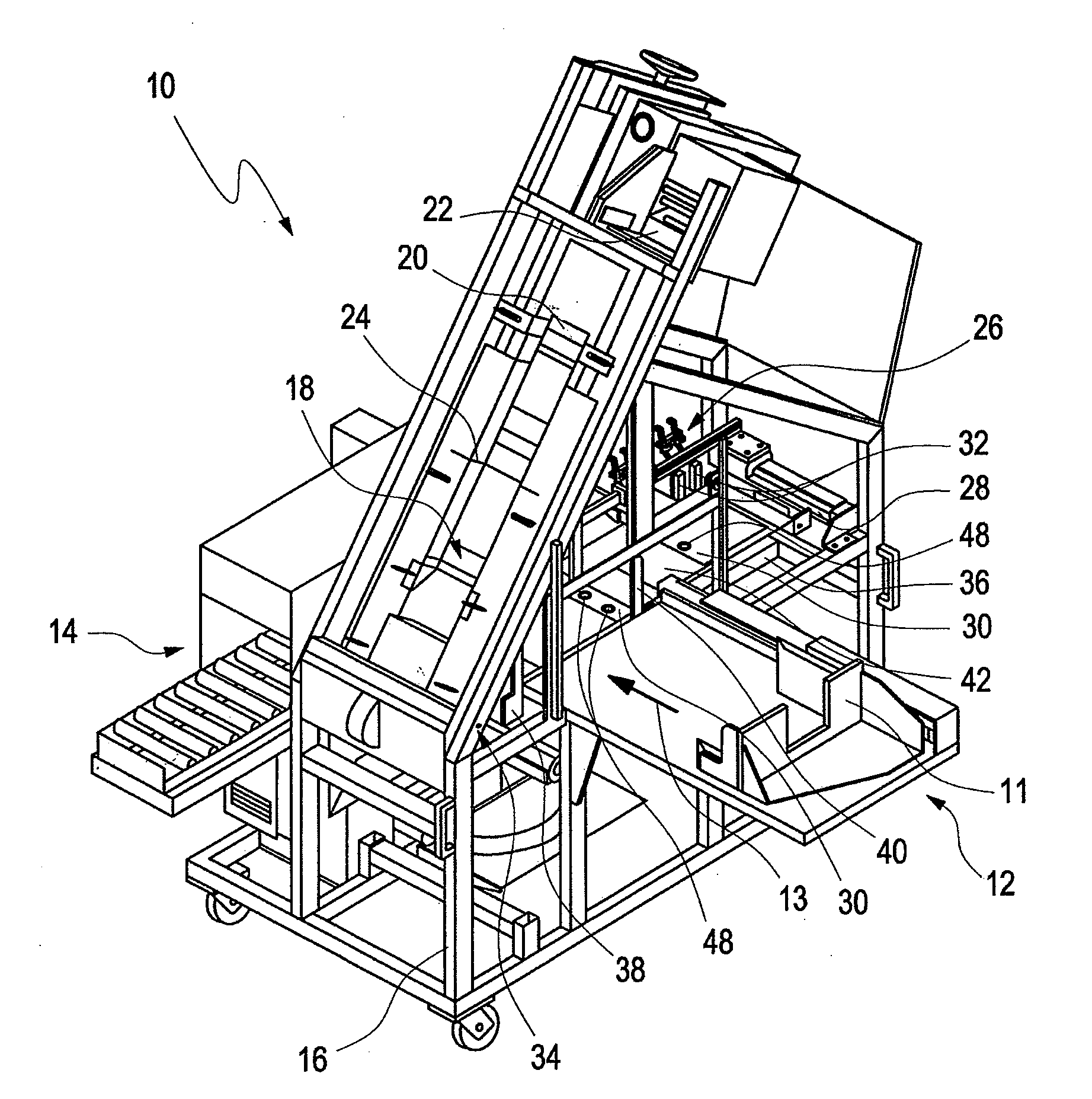

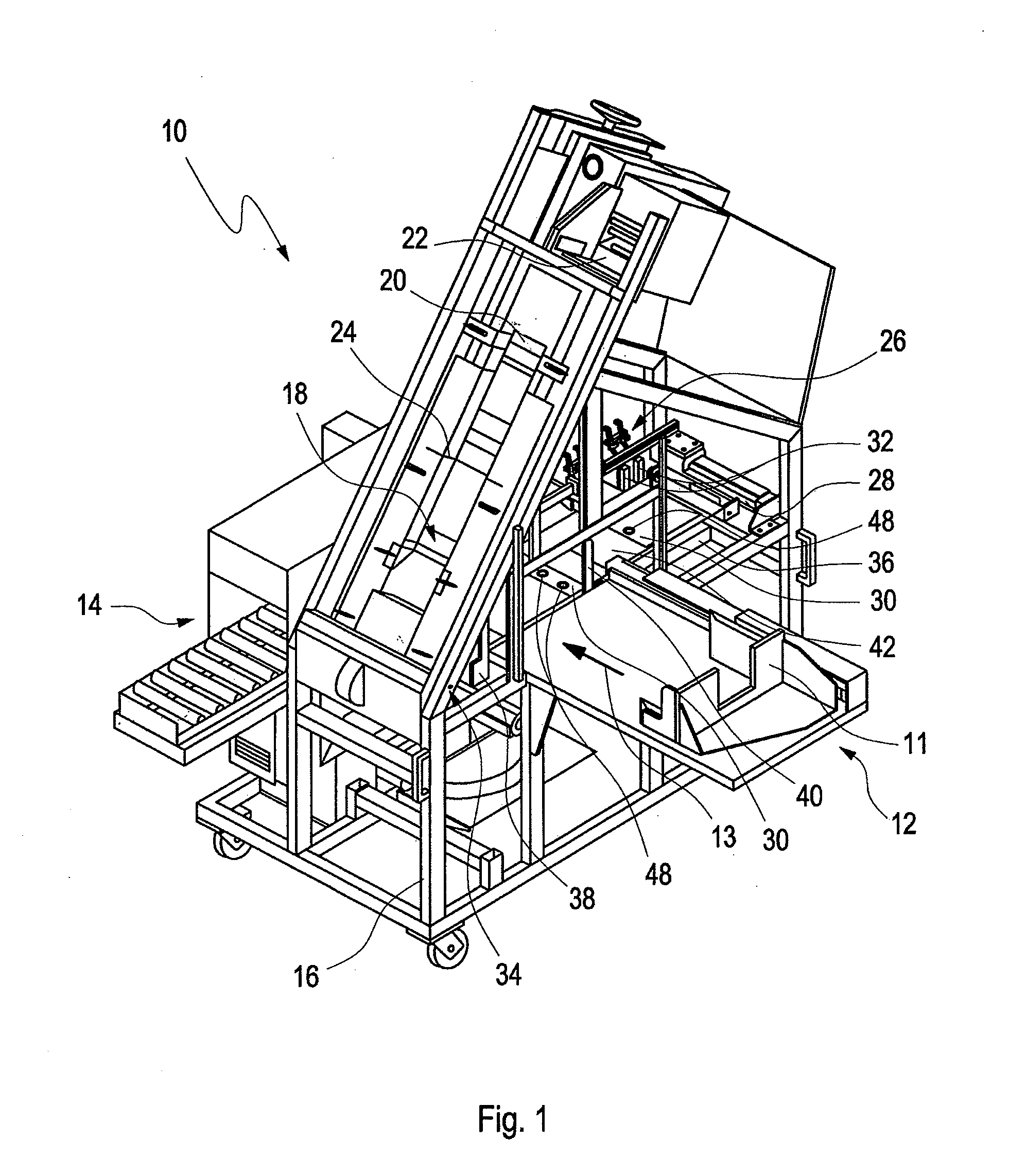

[0034]A perspective view of the essential components of the packaging unit proposed according to the invention can be seen in the illustration according to FIG. 1. The illustration according to FIG. 1 reveals that a packaging unit 10, in particular a banding unit, has a feeding region 12 which comprises a lateral pushing-in means 13 into a processing plane 30. The feeding region is understood below as meaning a feeding table, a feeding plane or else a working plane of a handling unit.

[0035]The magazine 18 which is arranged in an inclined manner is accommodated in the machine frame 16 of the packaging unit 10, with a number of preferably tape-shaped banding tapes 20 being stored lying one above another in the magazine 18. An applicator 22 which can be controlled by a commercially available PC is located above the magazine 18. The applicator 22 is part of a labeller or other printing head, such as, for example, an inkjet printer. When a label which is pre-printed or is printed online ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com