Tooth blank finish turning hydraulic tool system

A technology of finish turning and tooth blank, which is applied in the field of gear blank finish turning hydraulic tooling system, can solve the problems of unsatisfactory pass rate of accuracy and low efficiency, and meet the requirements of tooth blank finish turning, high work efficiency, and tight tension force adjustable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

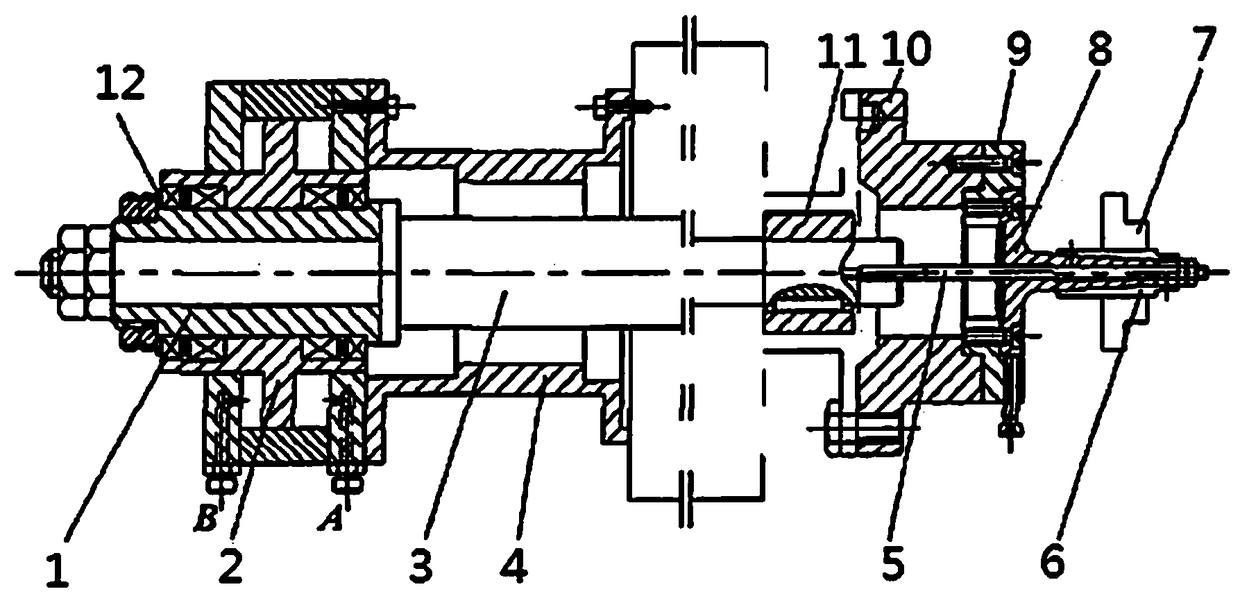

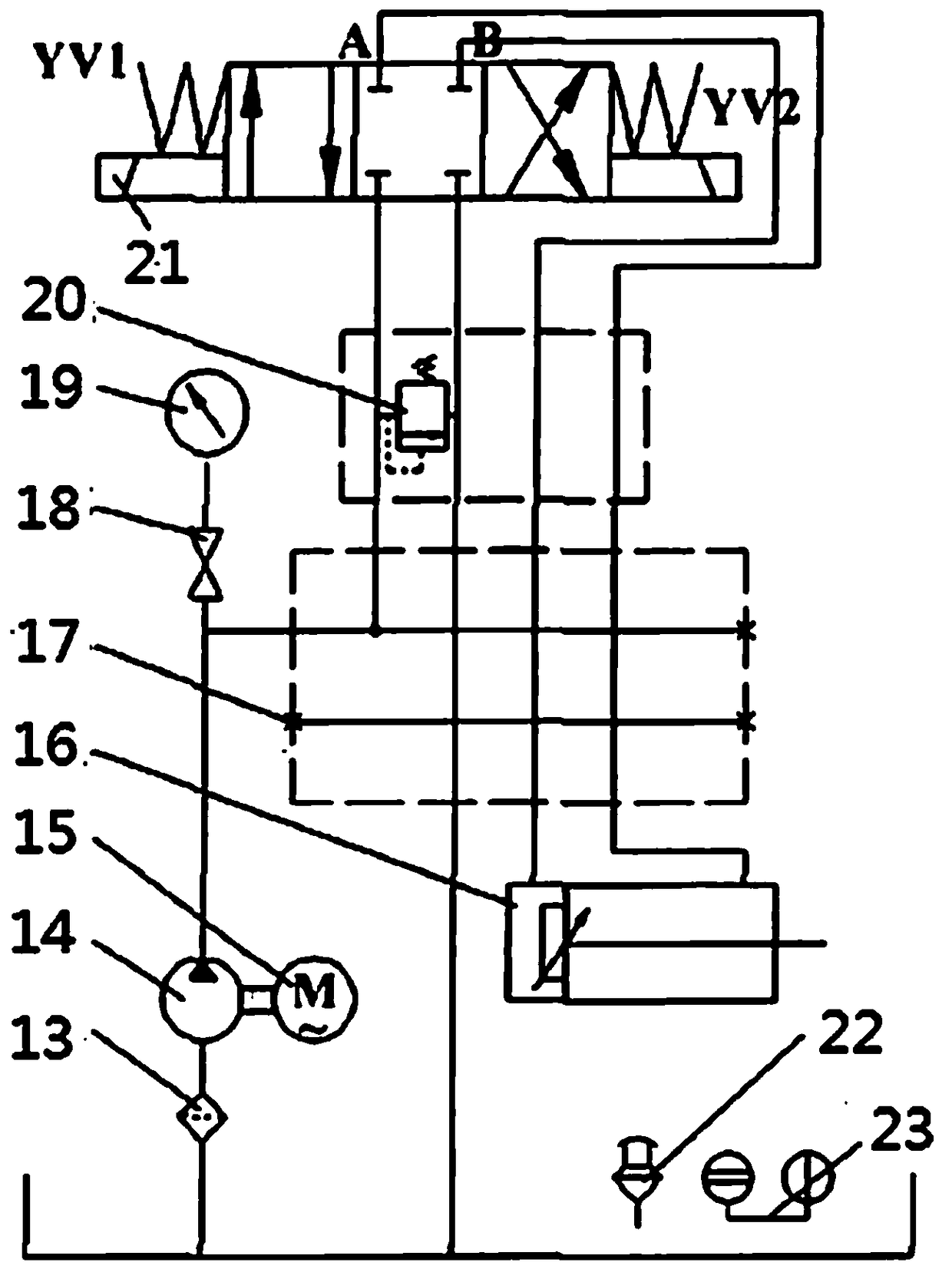

[0015] figure 1 Medium-tooth billet finishing hydraulic tooling system, mainly composed of bearing sleeve, rotary cylinder, tie rod, connecting sleeve, connecting rod, finishing tire cover, finishing tire seat, flange plate, connecting plate, positioning sleeve, spacer sleeve and corresponding hydraulic system etc.; the front end of the pull rod is connected to the connecting rod; the connecting sleeve is installed at the tail of the main shaft; The front end of the main shaft of the lathe; the finish car tire seat can be installed with different specifications of finish car tire covers according to the needs, so as to meet the needs of processing various specifications of gear blanks; the finish car tire seat is aligned and installed on the flange plate; the described A flange is installed on the connecting plate after being aligned; the positioning sleeve is put into the front hole of the main shaft, and the positioning sleeve and the pull rod are connected by a key.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com