Heat dissipation device for liquid fuel cell system

A liquid fuel cell and heat sink technology, which is applied in the directions of fuel cell heat exchange, fuel cell, fuel cell auxiliary, etc. The effect of simplicity, reduced processing difficulty, and compact layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

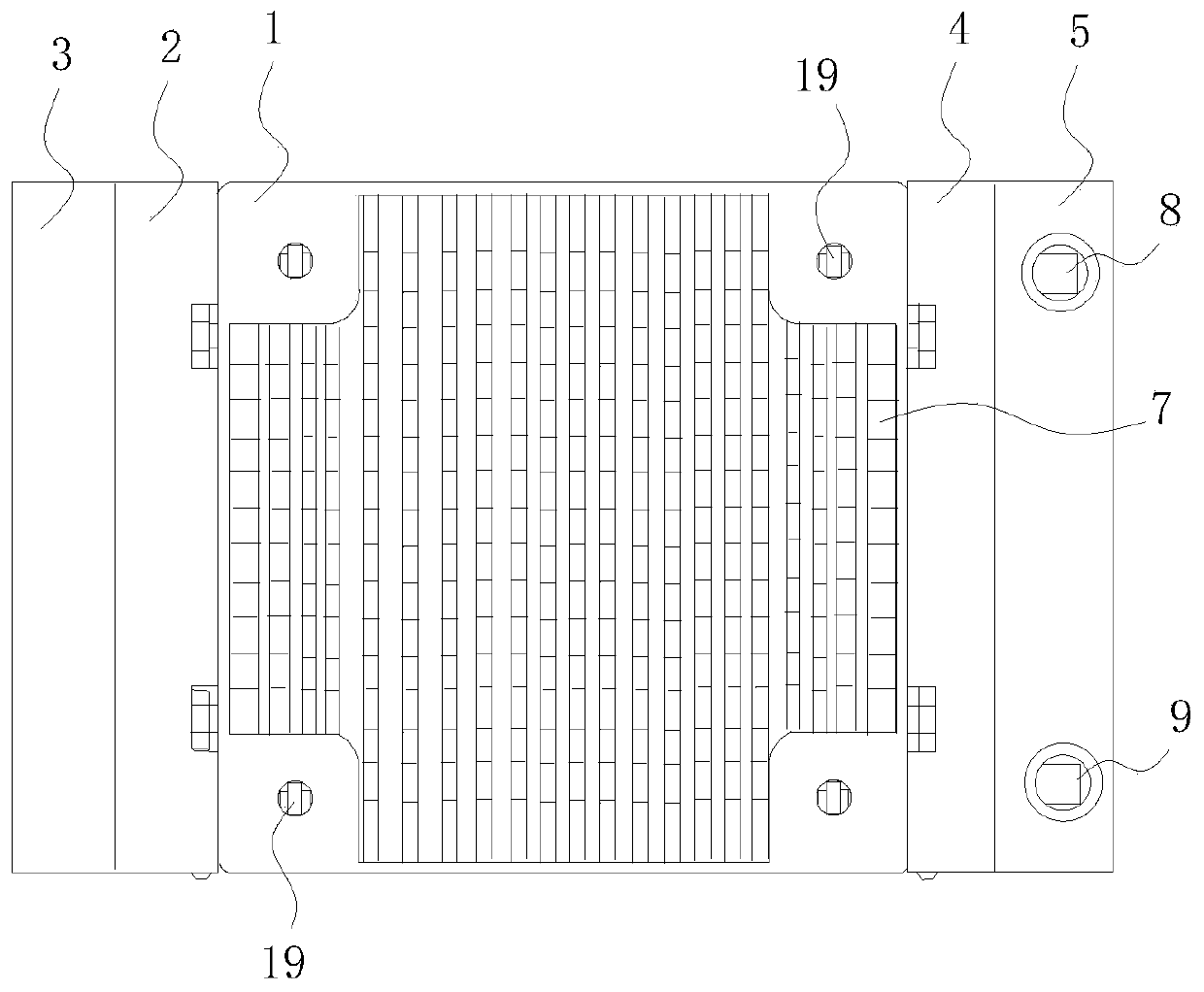

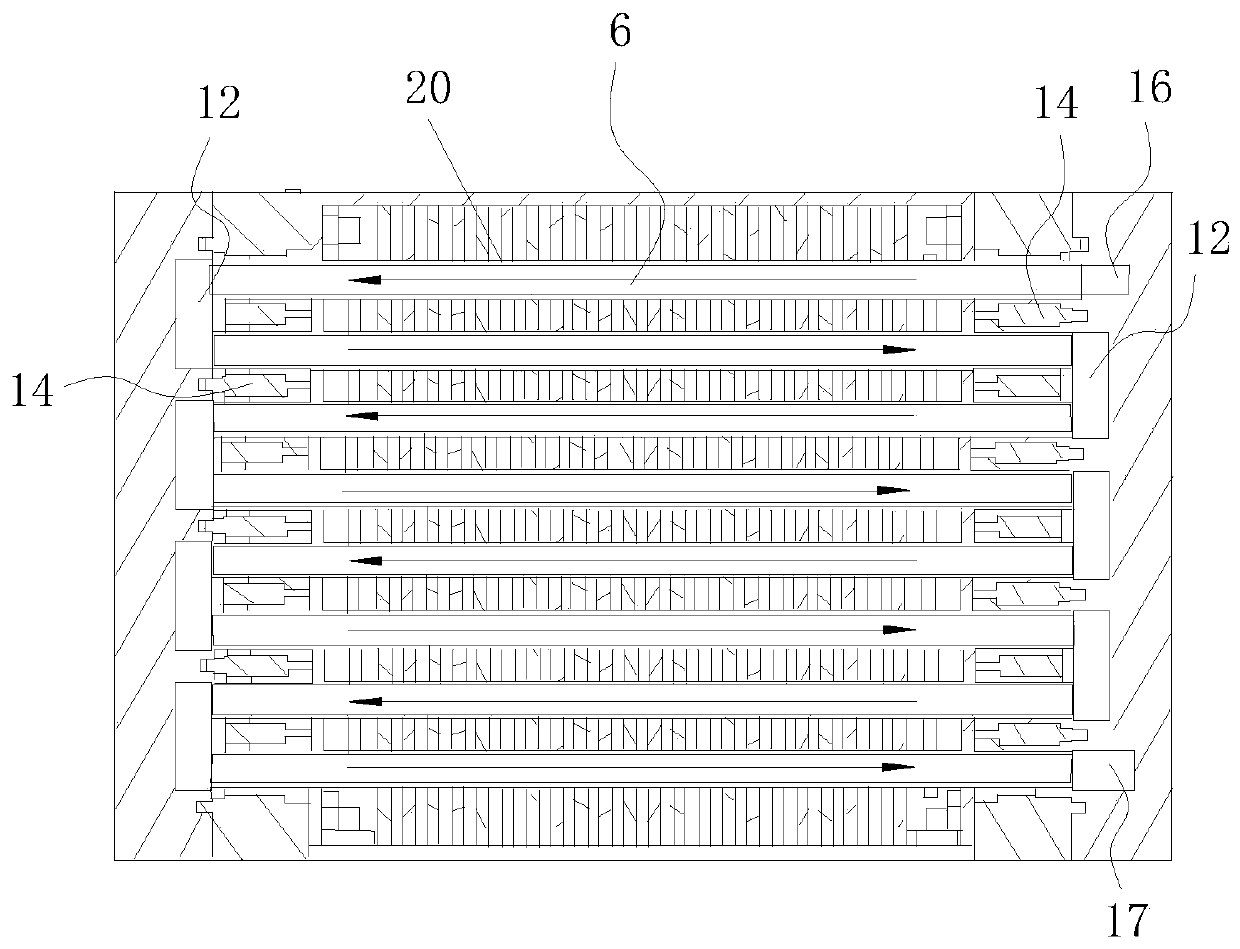

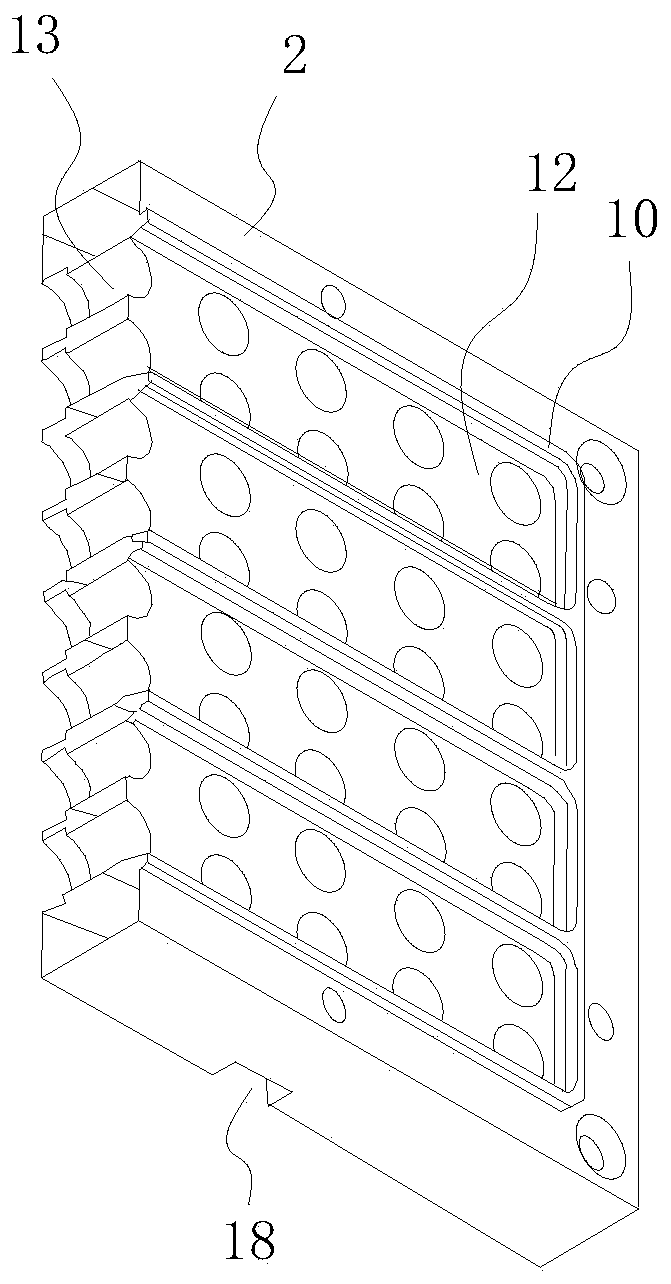

[0028] Such as Figure 1-6 As shown, the cooling device for the liquid fuel cell system of this embodiment includes a fixed frame 1, a left end plate 3 arranged on the left side of the fixed frame 1 through a left fixed plate 2, and a left end plate 3 arranged on the left side of the fixed frame 1 through a right fixed plate 4. The right end plate 5 on the right side of the fixed frame 1, several pipes 6 arranged in the fixed frame 1, several fins 7 arranged in the fixed frame 1, and the feed inlet 8 arranged on the right end plate 5 and the discharge port 9, the pipe 6 passes through the fin 7, the pipe 6 connects the feed port 8 and the discharge port 9, several pipes 6 are arranged in several layers in the fixed frame 1, the left fixed plate 2 and the right The fixed plates 4 are provided with grooved rectangular channels 12 for communicating with t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com