Large-size light emitting diode epitaxial wafer and growing method thereof

A technology for light emitting diodes and a growth method, which is applied in the production of light emitting diode epitaxial structures and in the field of semiconductors, can solve the problems of poor uniformity of epitaxial slivers and epitaxial wafers, and achieve the effects of improving wavelength uniformity, improving quality, and solving process difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

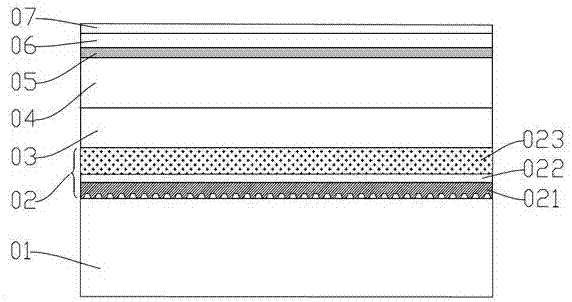

[0021] 1. Production process:

[0022] The epitaxial structure of the present invention is grown by MOCVD, H 2 , N 2 Carrier gas as organometallic source, SiH 4 Provides N-type doping, magnesiumocene (Cp 2 Mg) provides P-type doping, NH 3 As group V source, trimethylgallium (TMGa), triethylgallium (TEGa), trimethylaluminum (TMAl), trimethylindium (TMIn), as group III organometallic source.

[0023] Such as figure 1 As shown, the growth steps are as follows:

[0024] Step 1: Raise the temperature of the MOCVD reaction chamber to 250°C and feed NH 3 and trimethylindium (TMIn), grow InN with a thickness of 100nm on the substrate 01 as the first buffer layer 021, and the growth pressure is 300mbar.

[0025] The substrate 01 can be selected from sapphire, Si, SiC, GaN, etc. In this example, a 6-inch sapphire substrate is preferred.

[0026] Step 2: In H 2 Under ambient conditions, raise the temperature of the MOCVD reaction chamber to 1200°C to perform a high-temperature c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com