Patents

Literature

61results about How to "Improve wavelength uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

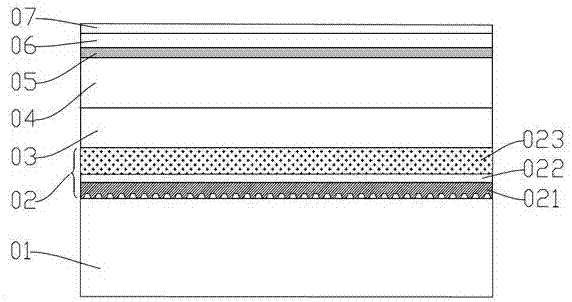

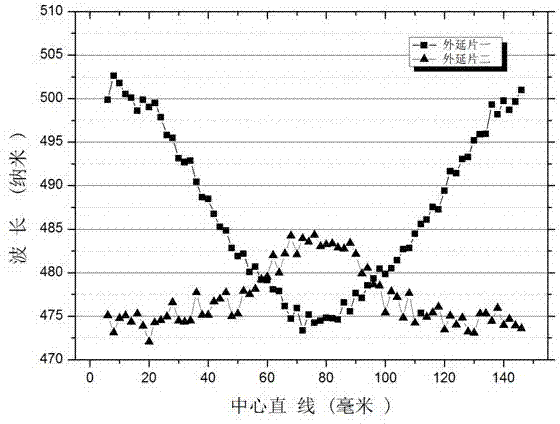

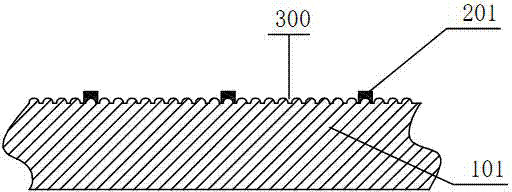

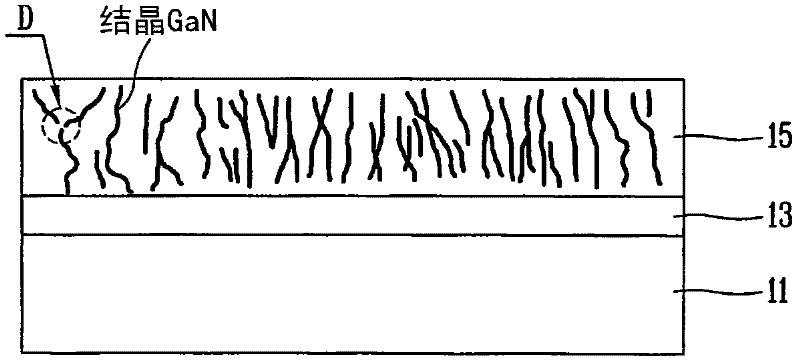

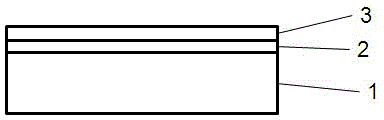

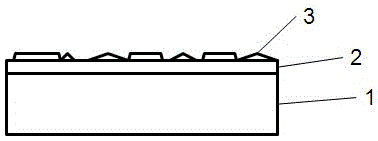

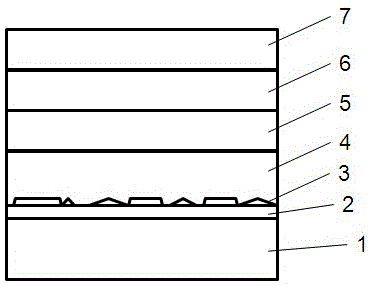

Method for reducing warping stress of LED epitaxy

InactiveCN103296151AImprove wavelength uniformityImprove wavelength yieldSemiconductor devicesLength waveSapphire substrate

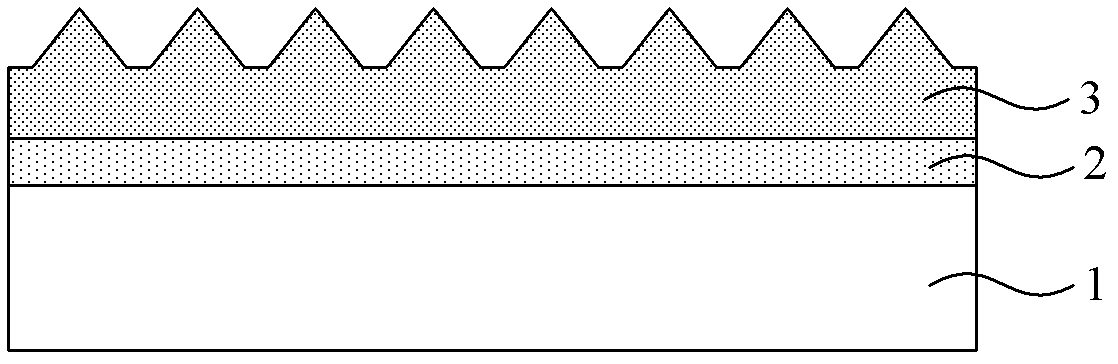

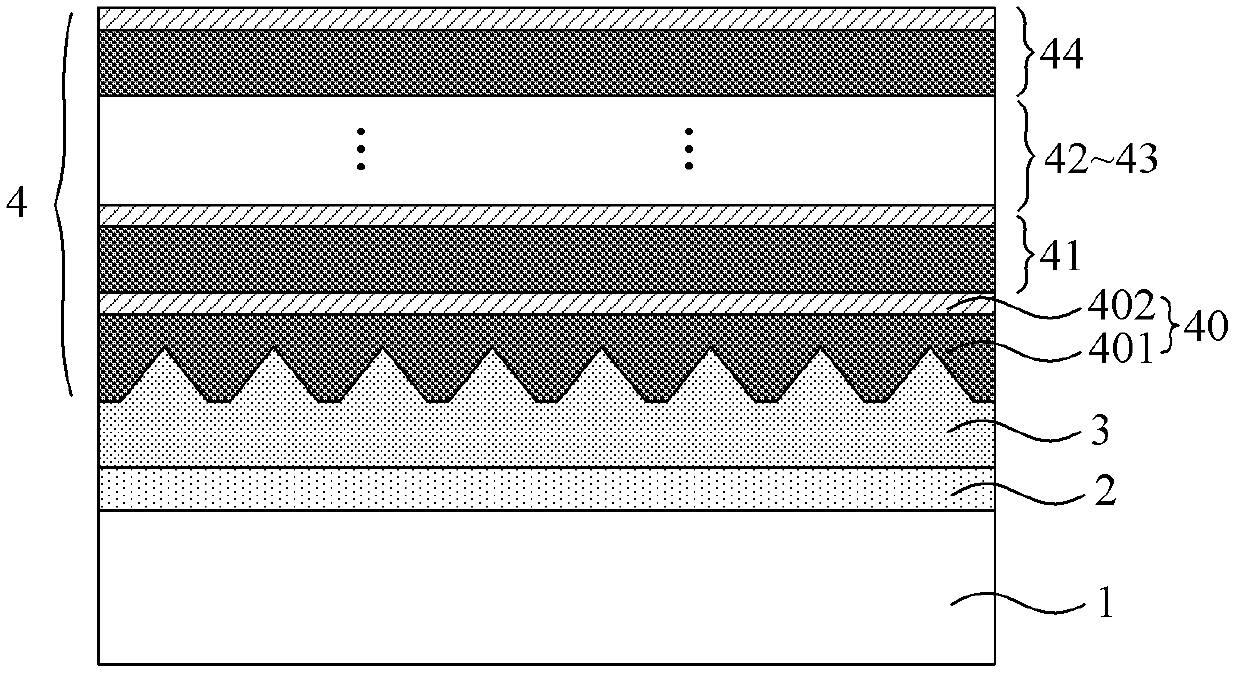

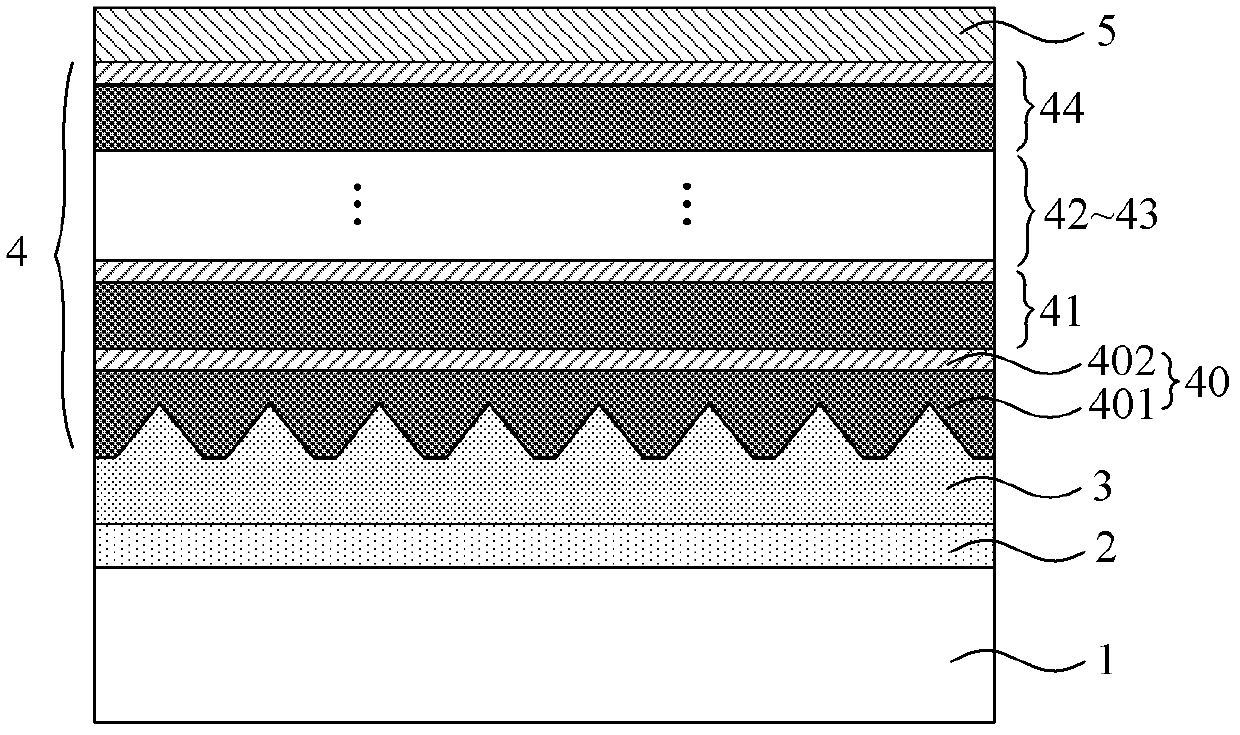

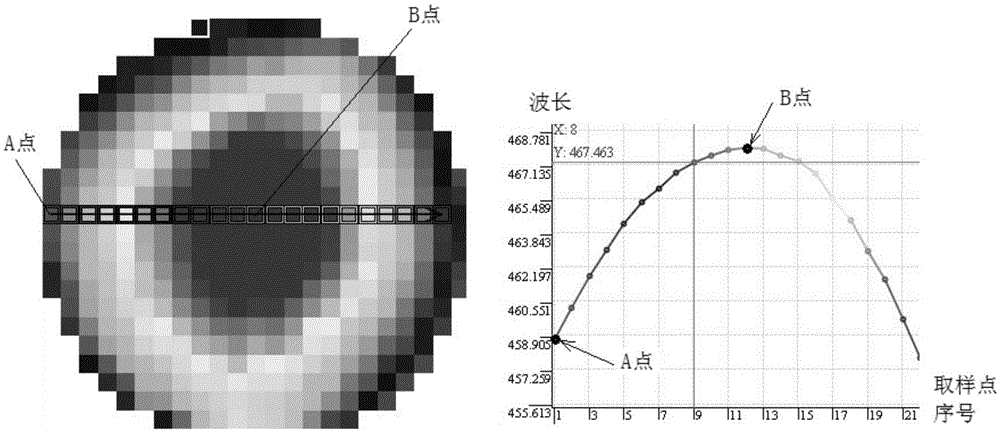

The invention provides a method for reducing warping stress of LED epitaxy. The method comprises the steps of forming a GaN buffer layer on a sapphire substrate in an epitaxial mode, then growing a GaN layer on the GaN buffer layer in a three-dimensional mode, and forming a GaN epitaxial wafer which is provided with an island-shaped surface; after cooling is conducted, forming a double-layer thin film on the GaN epitaxial wafer provided with the island-shaped surface in an epitaxial mode, wherein the double-layer thin film comprises the GaN layer and an All-xGaxN layer, and forming double-layer thin films repeatedly in the epitaxial mode so as to form a superlattice on the GaN epitaxial wafer provided with the island-shaped surface; growing the GaN layer on the superlattice in a two-dimensional mode, and finishing preparation of a GaN base layer on the sapphire substrate. A superlattice inserting layer structure is adopted to adjust and release the warping stress between the GaN epitaxial layer growing in the two-dimensional mode and the sapphire substrate, accordingly, the warping degree when a light-emitting layer is grown on the epitaxial wafer is improved, wavelength difference between the central part and the edge part of the epitaxial wafer after the light-emitting layer is grown can be reduced, uniformity of the wavelength of the epitaxial wafer is improved, and accordingly the wave length yield of the epitaxial wafer is improved.

Owner:EPILIGHT TECH

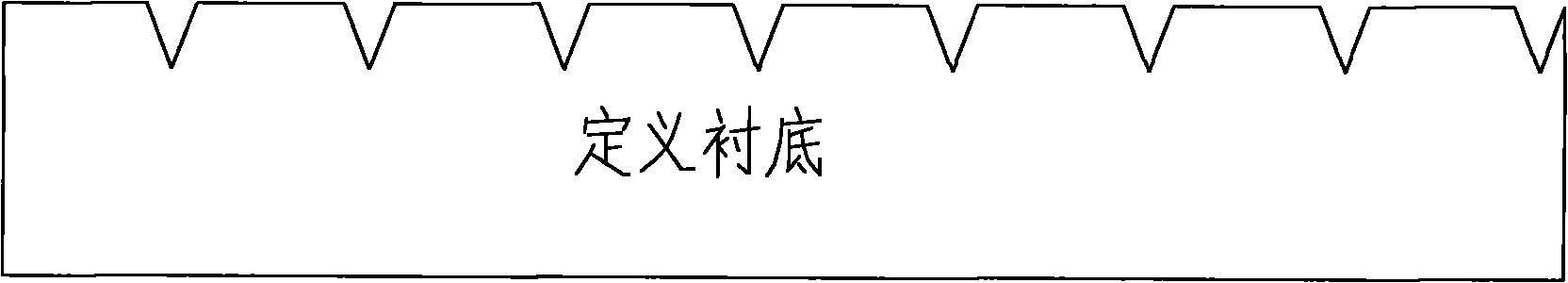

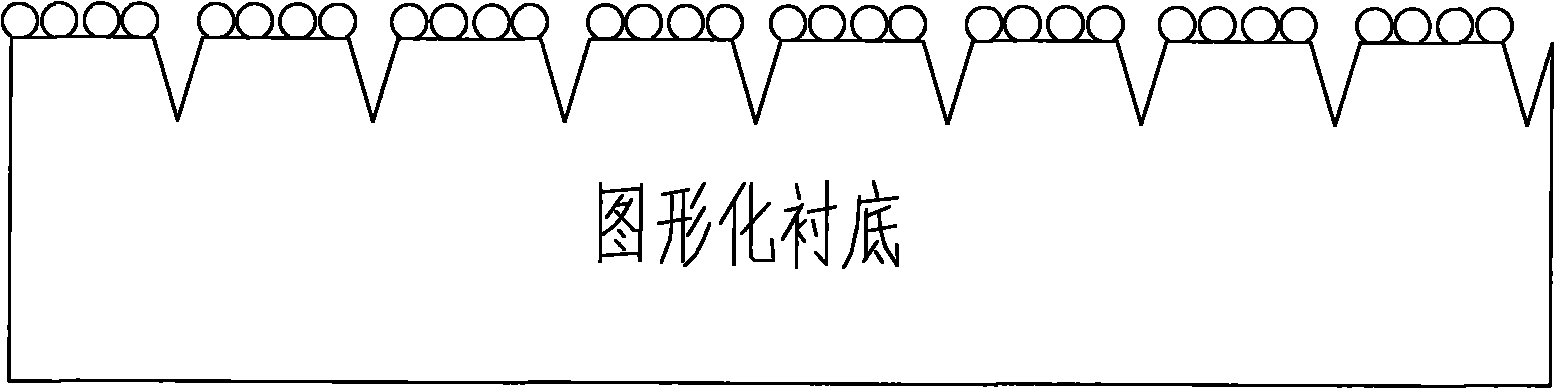

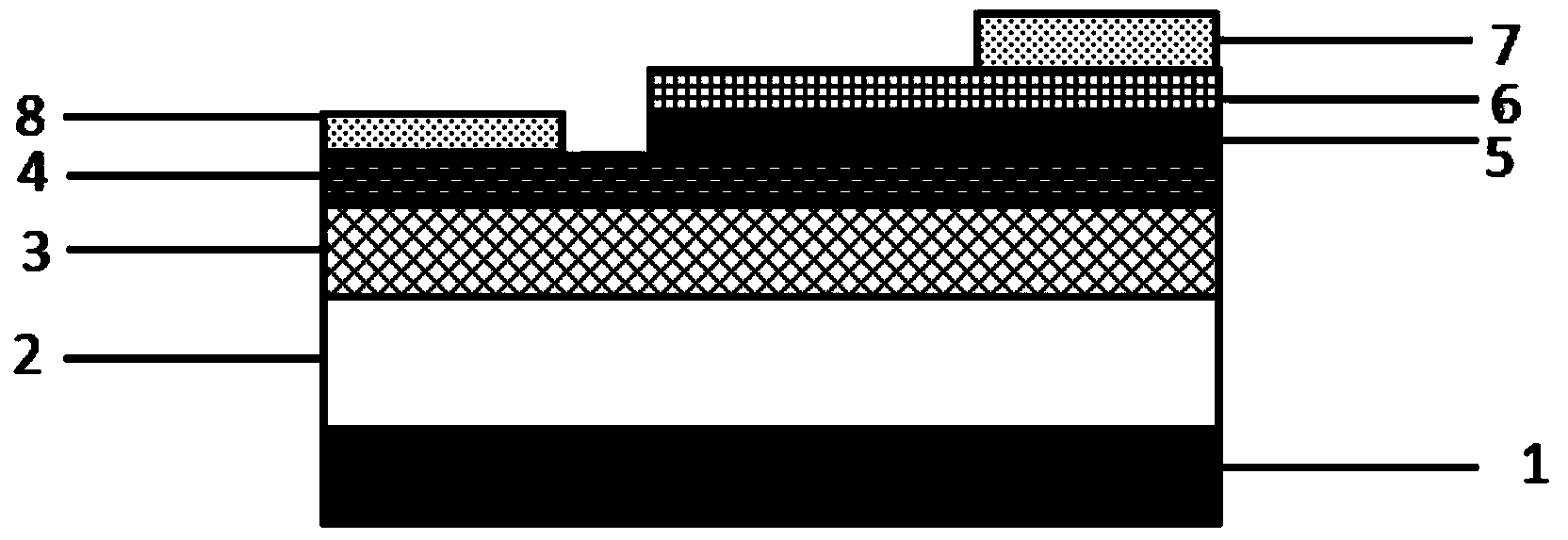

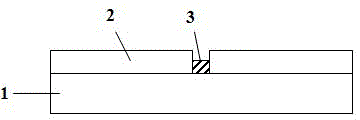

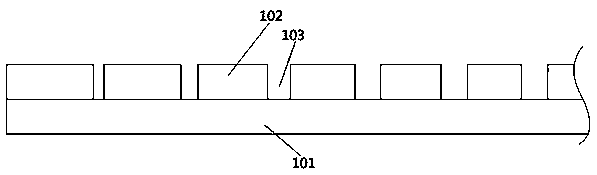

Method for manufacturing light-emitting diode chip

The invention discloses a method for manufacturing a light-emitting diode chip, which comprises the following steps: firstly forming a corridor on the surface of a growth substrate, dividing the surface of the growth substrate into a small region which is in the same size with the final chip, and defining the size of the chip; then cleaning the growth substrate, and removing dirt in a ditch of the growth substrate; further producing a patterned substrate on the growth substrate after dividing; and finally sequentially growing an N-type semiconductor layer, an active layer and a P-type semiconductor layer on the patterned substrate for forming a single chip structure consisting of the mutually separated N-type semiconductor layer, the active layer and the P-type semiconductor layer. The process method can reduce the residual stress during the epitaxial growth process, reduce the crystal defects and be further conductive to improving the wavelength uniformity of the chip, improving the electric leakage of the chip and improving the brightness of the chip.

Owner:EPILIGHT TECH

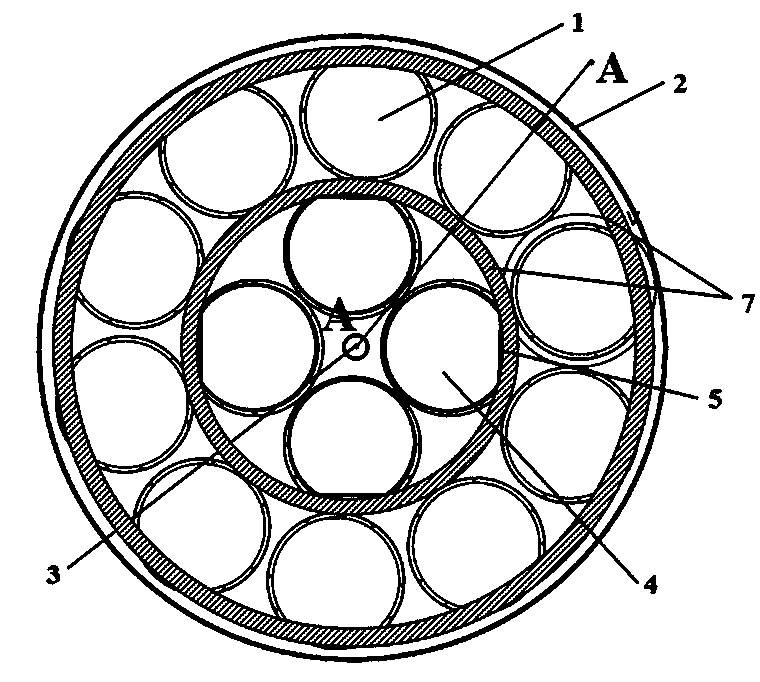

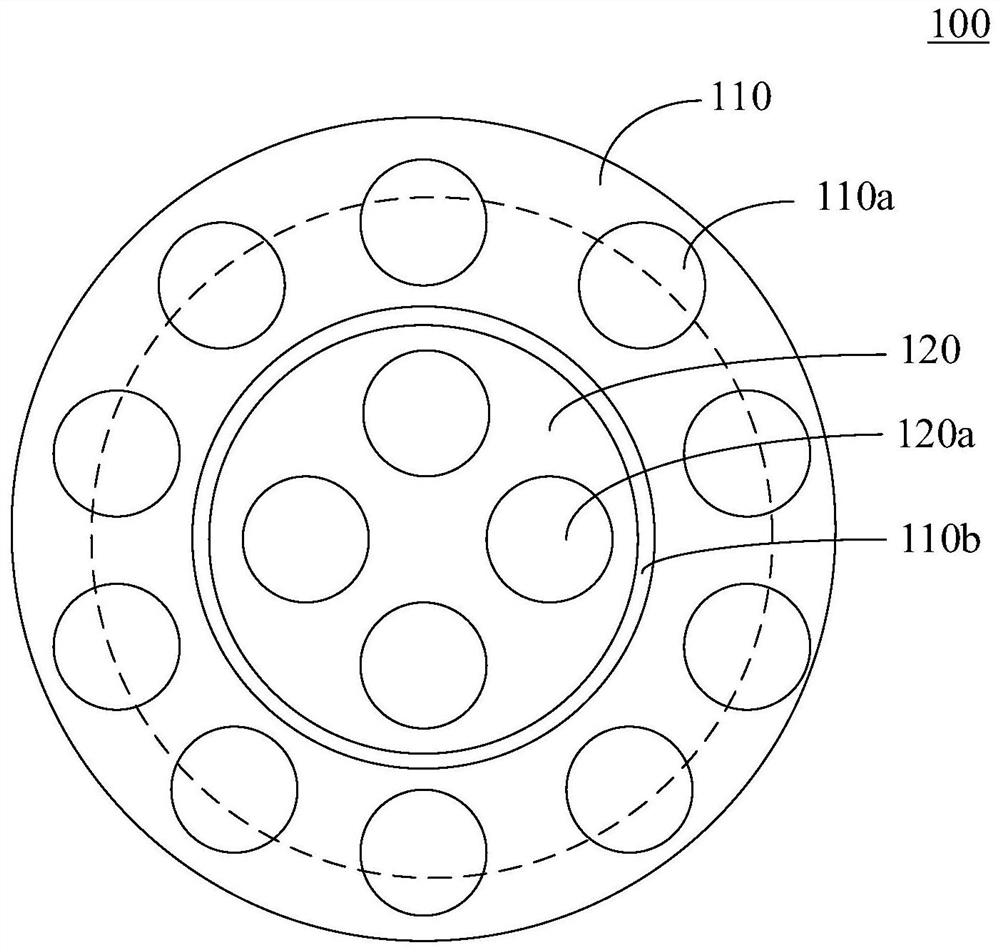

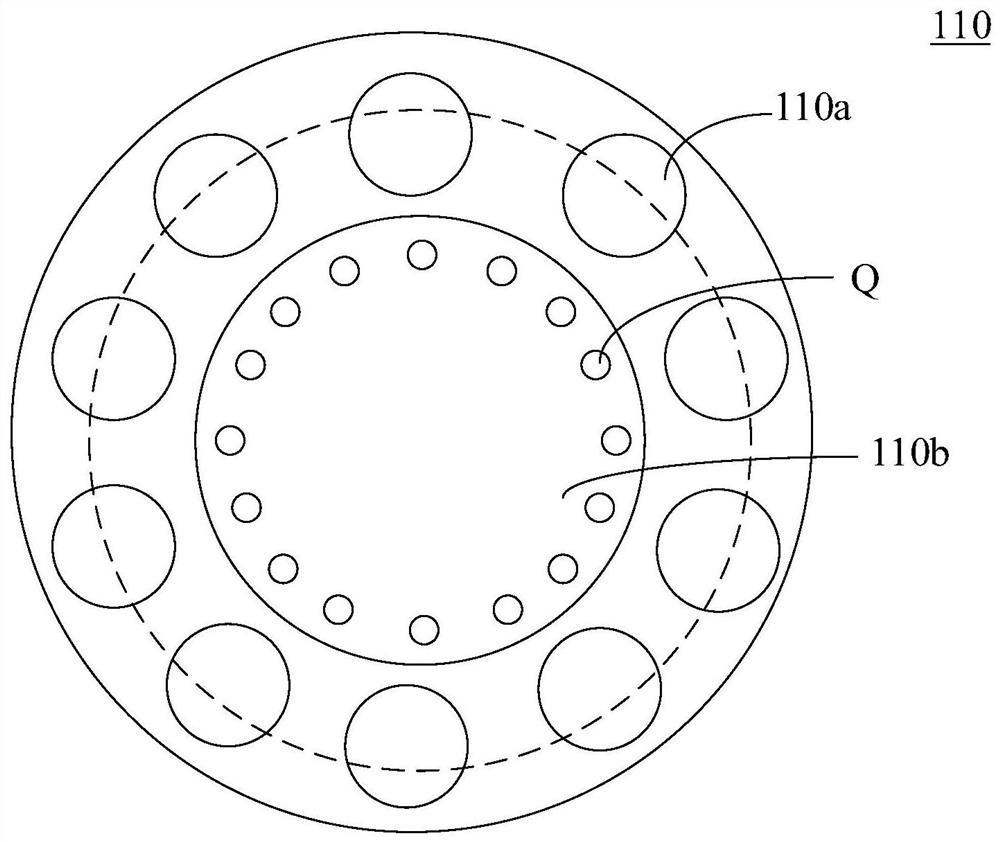

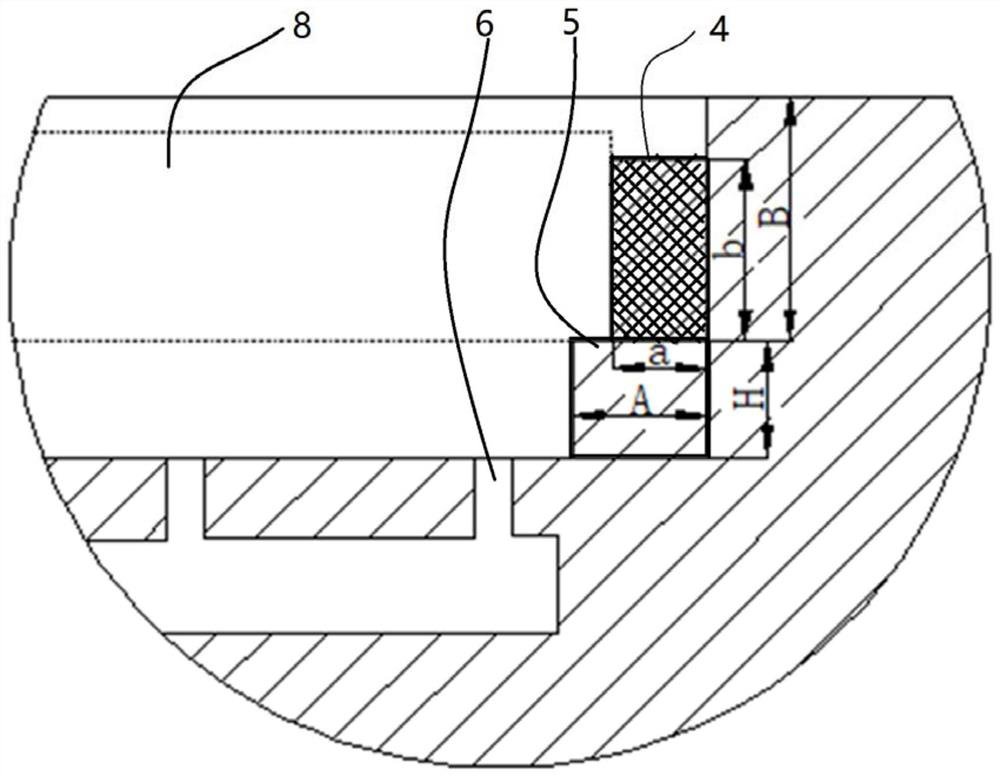

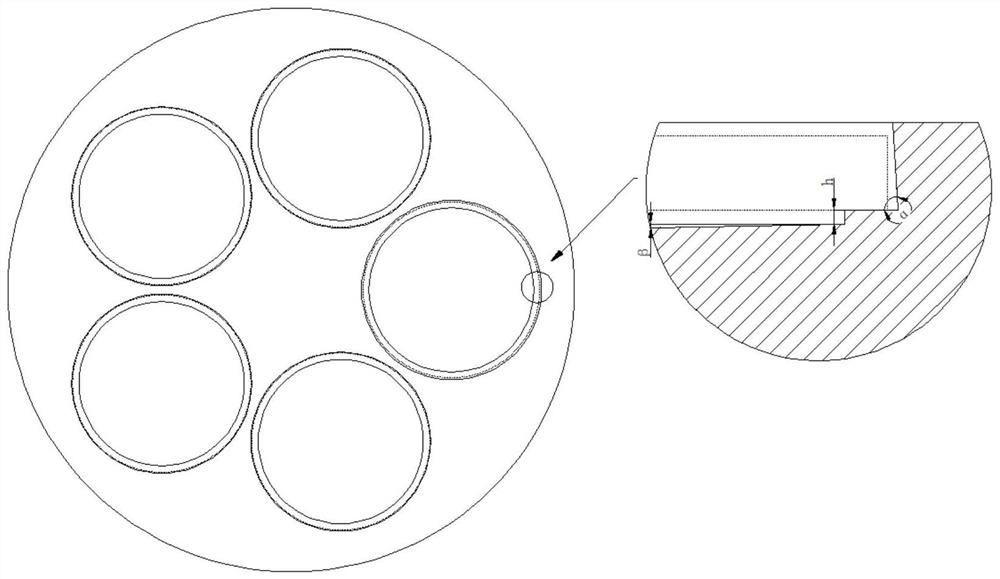

Graphite bearing tray capable of regulating and controlling local temperature field

ActiveCN104051316AImprove edge yieldImprove uniformitySemiconductor/solid-state device manufacturingSemiconductor devicesWaferGraphite

The invention provides a graphite bearing tray capable of regulating and controlling a local temperature field. The graphite bearing tray comprises a plurality of wafer grooves which are formed above the bearing tray and used for storing epitaxial wafer substrates, one grooving structure is at least arranged on the back face of the wafer grooves, and the grooving structure and the graphite bearing tray are concentric. The grooving structure is filled with a leading-in material or only the grooving structure is arranged, the local temperature filed of the graphite bearing tray can be regulated and controlled in the epitaxial growth process, hence, the entire temperature field of the graphite bearing tray is balanced, the edge yield of epitaxial wafers is improved, and the wave length evenness and the overall yield of the epitaxial wafers are improved.

Owner:QUANZHOU SANAN SEMICON TECH CO LTD

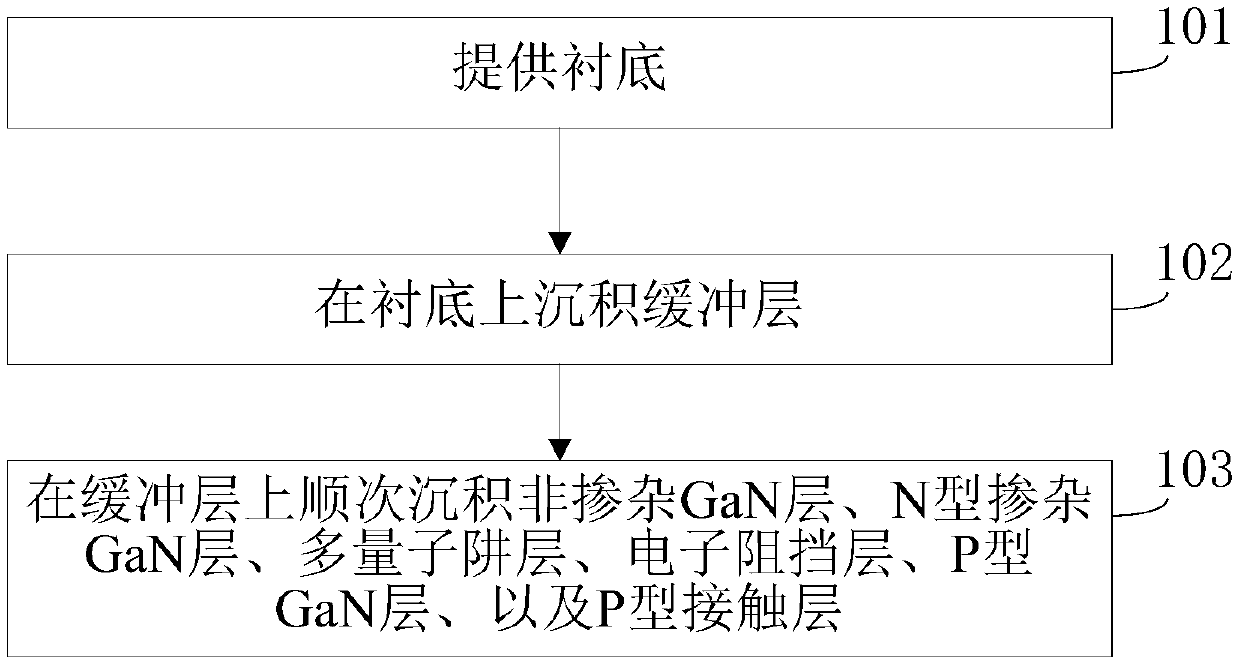

AlN template, preparation method of AlN template and semiconductor device on AlN template

ActiveCN105633233AIncrease the lattice constantThe lattice constant is close toSemiconductor devicesDevice materialSemiconductor technology

The invention discloses an AlN template, a preparation method of the AlN template and a semiconductor device on the AlN template, and belongs to the field of semiconductor technology. The AlN template comprises a substrate and an AlN thin film deposited on the substrate. The AlN thin film comprises a first AlN layer deposited on the substrate. The first AlN layer is mixed with oxygen. The content of the oxygen in the first AlN layer is gradually reduced from an interface of the first AlN layer and the substrate to the surface of the first AlN layer. The semiconductor device comprises the AlN template and a nitride semiconductor layer. The AlN template comprises the substrate and the AlN thin film deposited on the substrate. The nitride semiconductor layer is deposited on the AlN thin film. The AlN template is the aforesaid AlN template. The method comprises steps of providing the substrate; and depositing the AlN thin film on the substrate. The AlN thin film comprises a first AlN layer deposited on the substrate. The first AlN layer is mixed with oxygen. The content of the oxygen in the first AlN layer is gradually reduced from an interface of the first AlN layer and the substrate to the surface of the first AlN layer.

Owner:HC SEMITEK SUZHOU

AlGaN template, preparation method of AlGaN template and semiconductor device on AlGaN template

ActiveCN105633223ARelieve compressive stressReduce accumulated stressSemiconductor devicesSemiconductor technologyNitride semiconductors

The invention discloses an AlGaN template, a preparation method of the AlGaN template and a semiconductor device on the AlGaN template, and belongs to the field of semiconductor technology. The AlGaN template comprises a substrate and an Al<1-x>Ga<x>N crystallization thin film deposited on the substrate, wherein 0<x<1. The semiconductor device comprises a template and a nitride semiconductor layer. The template is the aforesaid AlGaN template. The nitride semiconductor layer is deposited on the Al<1-x>Ga<x>N crystallization thin film. The method comprises steps of providing the substrate; and depositing the Al<1-x>Ga<x>N crystallization thin film on the substrate, wherein 0<x<1.

Owner:HC SEMITEK SUZHOU

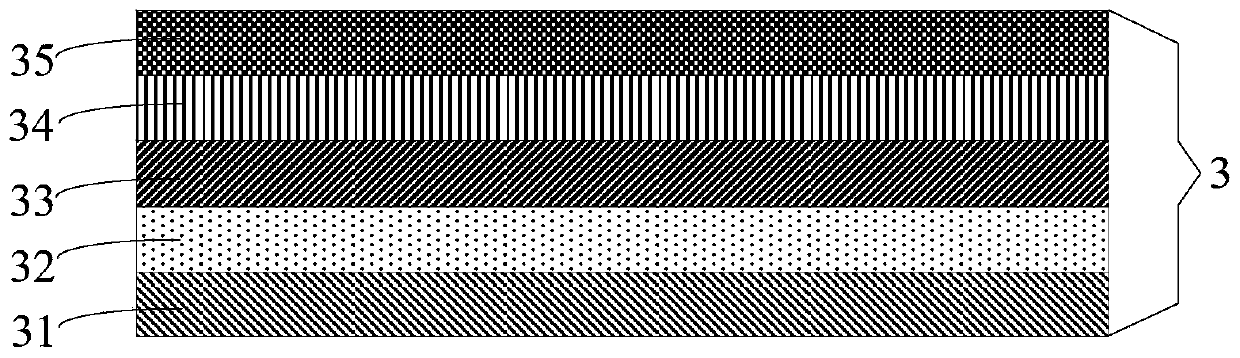

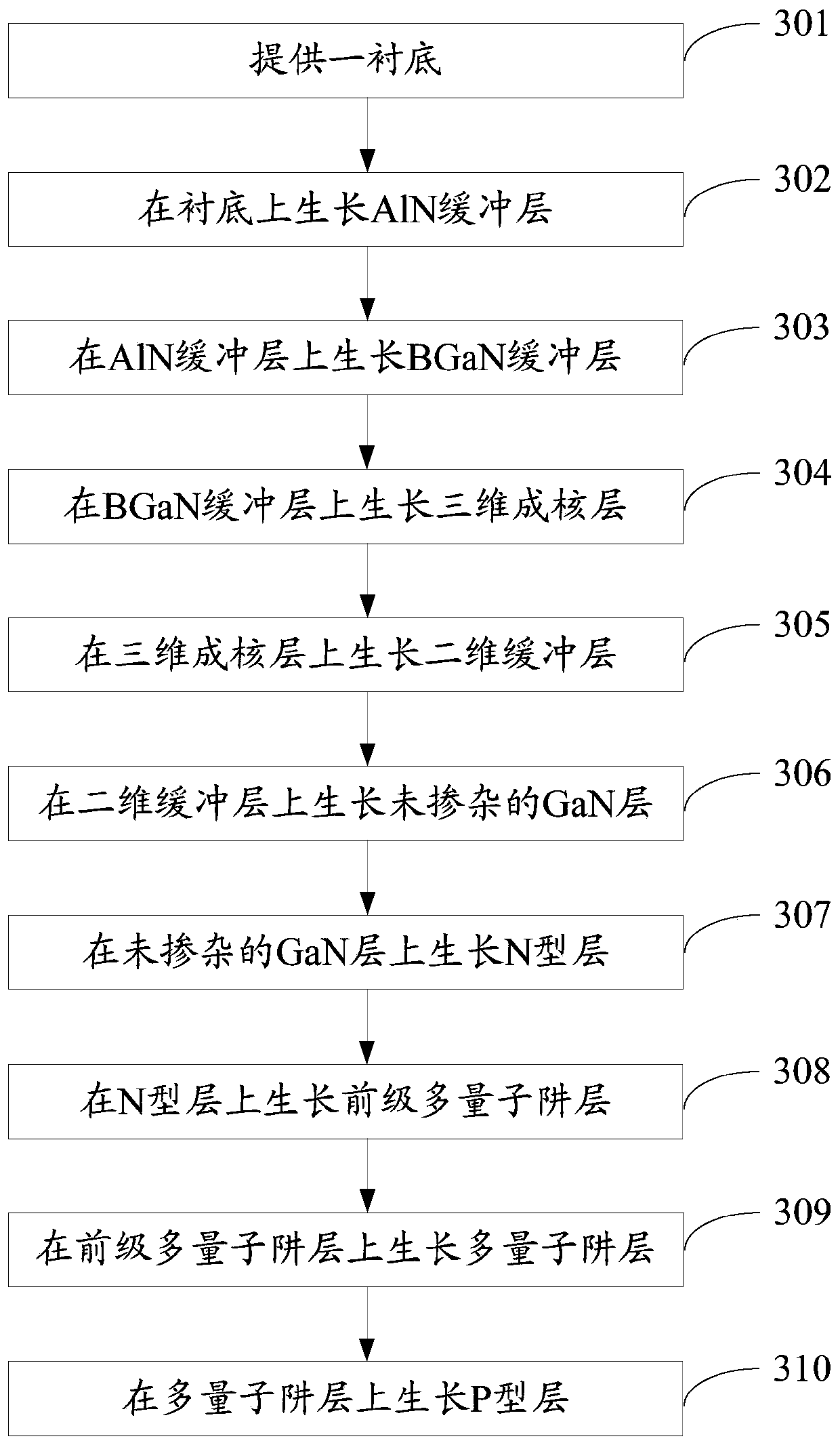

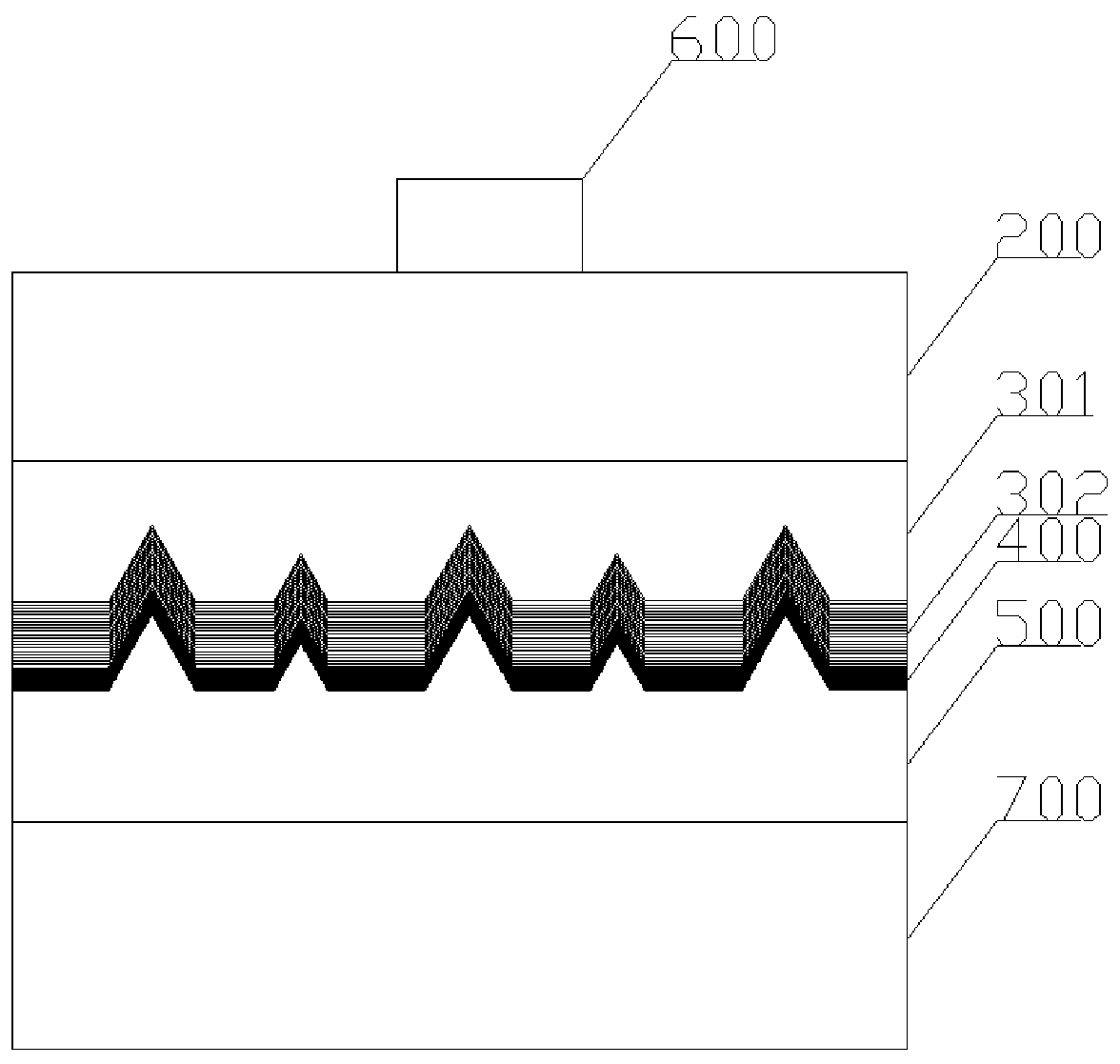

Light-emitting diode epitaxial wafer and manufacturing method thereof

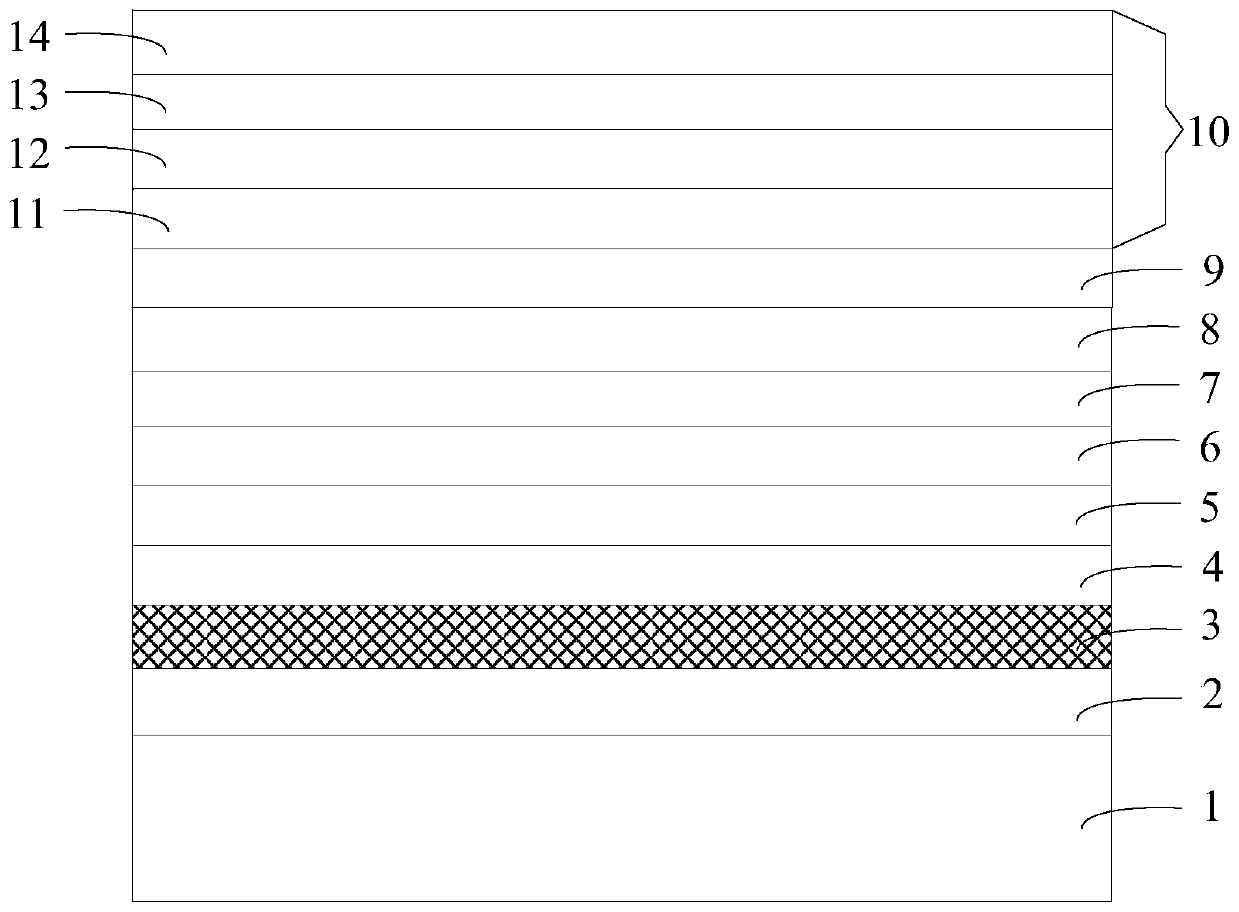

ActiveCN109786527AImprove wavelength uniformityThe lattice constant decreasesSemiconductor devicesLattice mismatchQuantum well

The invention discloses a light-emitting diode epitaxial wafer and a manufacturing method thereof, and belongs to the technical field of semiconductors. The light-emitting diode epitaxial wafer comprises a substrate, and an AlN buffer layer, a three-dimensional nucleation layer, a two-dimensional recovery layer, an undoped GaN layer, an N-type layer, a multi-quantum well layer and a P-type layer which are sequentially grown on the substrate, wherein the three-dimensional nucleation layer is a GaN layer; the light-emitting diode epitaxial wafer further comprises a BGaN buffer layer arranged between the AlN buffer layer and the three-dimensional nucleation layer; and the B component in the BGaN buffer layer is gradually reduced in the stacking direction of the light-emitting diode epitaxialwafer. By virtue of the BGaN buffer layer, lattice mismatch between the AlN buffer layer and the GaN epitaxial layer can be gradually reduced, the crystal quality of the grown epitaxial layer is improved, the warping of the epitaxial layer is optimized, and the wavelength uniformity of the LED is improved.

Owner:HC SEMITEK ZHEJIANG CO LTD

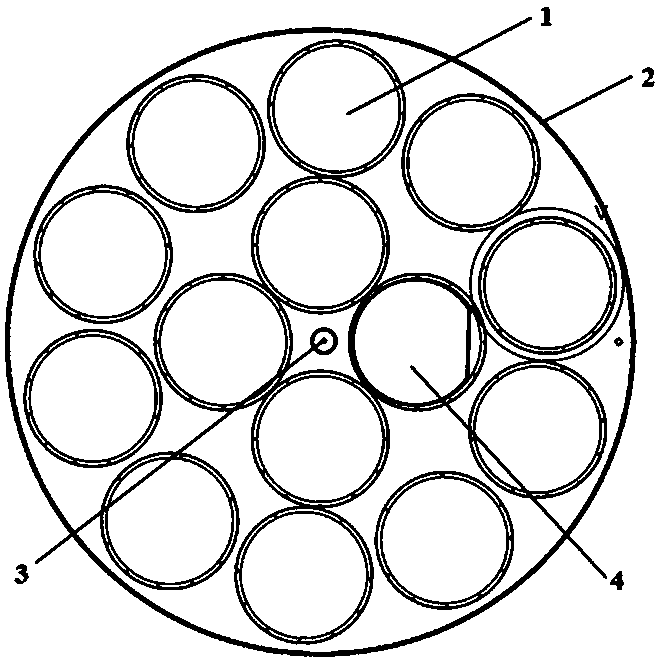

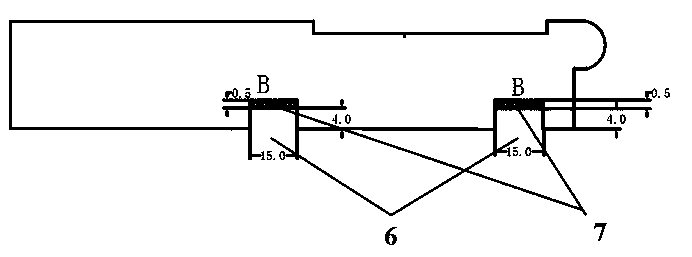

Graphite bearing disc for LED epitaxial process, and matching substrate thereof

InactiveCN103824796AImprove yieldReduce warpageSemiconductor/solid-state device manufacturingGraphiteEngineering

The invention provides a graphite bearing disc for an LED epitaxial wafer process, and a matching substrate thereof. The bearing disc comprises a bearing disc body. The body is uniformly provided with wafer grooves; the center of the body is provided with a shaft hole; the edge inner sides of the wafer grooves are provided with erection bench surfaces; there are distances between the erection bench surfaces and the edge top portions of the wafer grooves; and the erection bench surfaces are uniformly distributed at the edges of the wafer grooves. The substrate comprises a substrate body and wings erected on the erection bench surfaces. The advantages are mainly reflected as follows: the bearing disc provided by the invention overcomes the disadvantages of not high overall epitaxial wafer yield rate and unstable uniform distribution of epitaxial wafer wavelengths due to uneven heating by use of a conventional graphite bearing disc, the overall yield rate of grown LED epitaxial wafers is high, the wavelength uniformity is good, and the problems of the epitaxial wavelengths and standard deviation yield rate of the LED epitaxial wafers are well solved.

Owner:SUZHOU NANOJOIN PHOTONICS

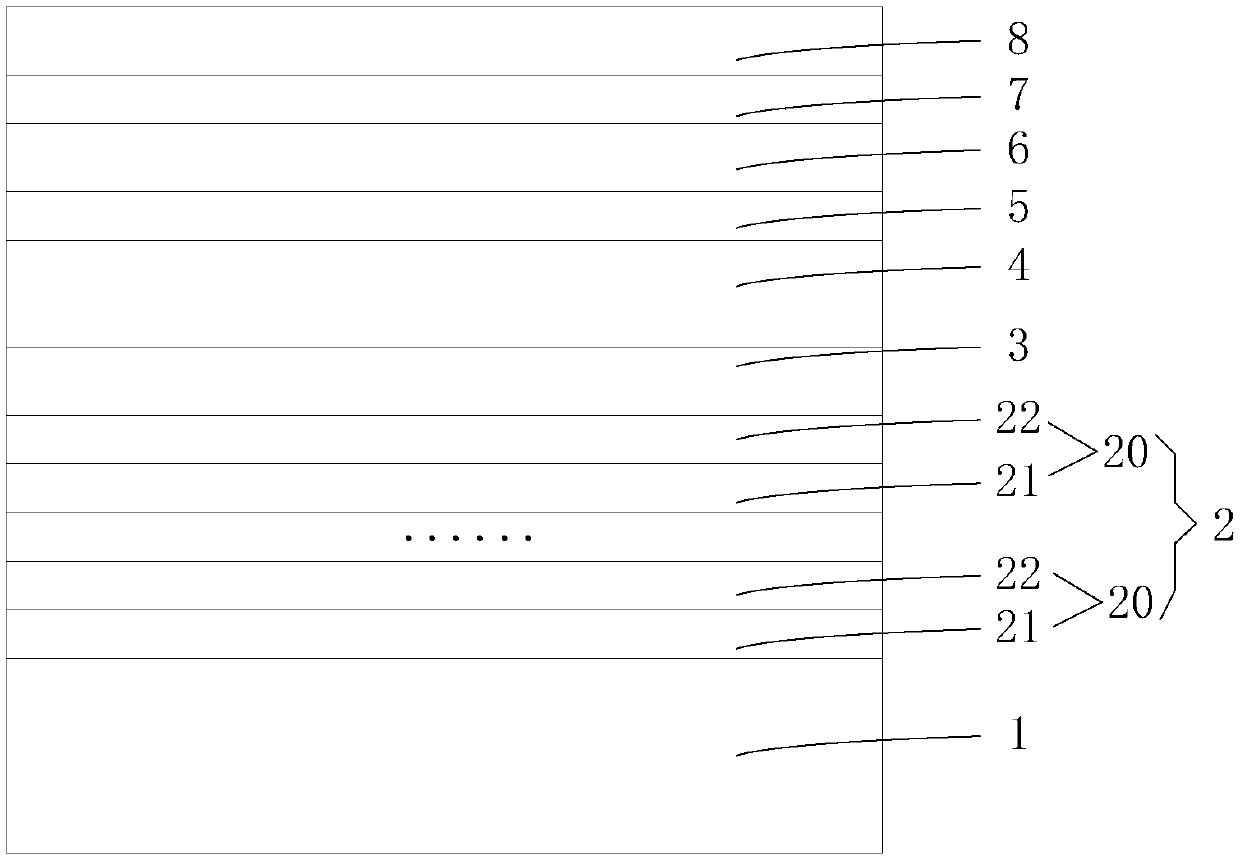

Large-size light emitting diode epitaxial wafer and growing method thereof

InactiveCN107452845AFacilitated releaseImprove crystal qualitySemiconductor devicesEpitaxial materialThermal expansion

The invention discloses a large-size light emitting diode epitaxial wafer and a growing method thereof, and belongs to the technical field of semiconductors. A substrate is provided with a buffer layer, an unintentional doped GaN layer, an N-type doped GaN layer, a multiple quantum well layer, an electronic blocking layer and a P-type doped GaN layer which successfully and epitaxially grows on the substrate, wherein the buffer layer growth includes the successful growth of a first, a second and a third buffer layer on the substrate. According to the invention, three buffer layers are employed to effectively release the stress which is generated due to the differences of coefficients of thermal expansion between the substrate and the GaN, to reduce the stress which is generated due to the differences of lattice constants between the substrate and the GaN, to reduce the probability of tattering and shredding of the substrate when the large-size epitaxial wafer grows at high temperature, provides sound basis for the growth of the unintentional doped GaN layer and active layer structure in a nitride thin film structure layer. The substrate herein can increase the quality of large-size epitaxial material, improve the uniformity of the wavelength of the epitaxial wafer and adjusts the warpage of the epitaxial wafer.

Owner:YANGZHOU ZHONGKE SEMICON LIGHTING

LED chip structure of graphene structure and manufacturing method thereof

InactiveCN104300052AAlleviate problems such as horizontal expansion difficultiesAvoid epitaxial growthSemiconductor devicesQuantum efficiencyDoped graphene

The invention discloses an LED chip structure of a graphene structure and a manufacturing method of the LED chip structure. A nucleating layer, a non-doped GaN layer, an N-type doped GaN layer and an InGaN / GaN multiple-quantum-well structure are formed on a substrate in an epitaxial mode; after the multiple-quantum-well structure grows in the epitaxial mode, growth is stopped, and a P-type doped graphene layer is adopted for replacing a P-type GaN epitaxial layer; a P electrode is manufactured on the P-type doped graphene layer, the N-type doped GaN layer is formed through etching and an N electrode is manufactured on the N-type doped GaN layer; the P electrode is correspondingly arranged on the P-type doped graphene layer; an epitaxial wafer is etched, and the N electrode is manufactured on the N-type doped GaN layer. Through the LED chip structure of the graphene structure and the manufacturing method of the LED chip structure, maldistribution of In groups caused by P-GaN growing after the InGaN / GaN multiple-quantum-well structure through temperature rise can be avoided, and wavelength homogeneity can be improved easily; epitaxial growth of the P-GaN is avoided, cost is reduced, and productivity is improved; an ultrathin graphene layer high in light transmission and conductivity is adopted as a P-type current expanding layer, the light outgoing efficiency can be effectively improved, and the external quantum efficiency can be improved.

Owner:华芯半导体科技有限公司

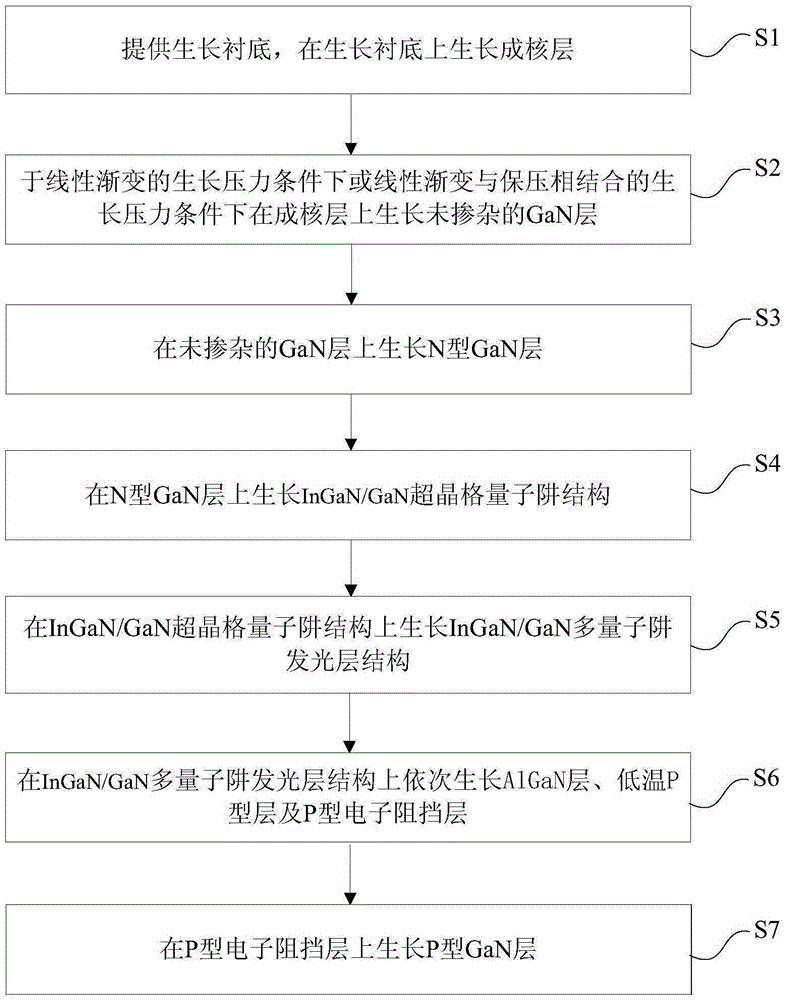

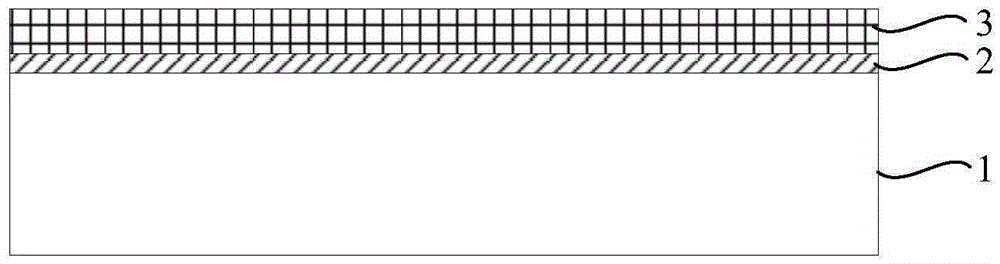

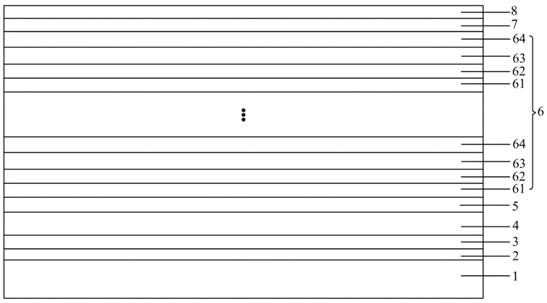

GaN-based LED epitaxy structure and preparation method thereof

InactiveCN105206714AImprove wavelength uniformityImprove matchSemiconductor devicesQuantum wellLength wave

The invention provides a GaN-based LED epitaxy structure and a preparation method thereof. The method comprises the following steps: providing a growth substrate, and growing a nucleating layer on the growth substrate; growing an undoped GaN layer on the nucleating layer under a condition of linear-gradient growth pressure or a condition of the growth pressure with linear gradient and pressure maintaining being combined; growing an N-type GaN layer on the undoped GaN layer; growing an InGaN / GaN superlattice quantum well structure on the N-type GaN layer; growing an InGaN / GaN multi-quantum-well luminescent layer structure on the InGaN / GaN superlattice quantum well structure; growing an AlGaN layer, a low-temperature P-type layer and a P-type electron blocking layer on the InGaN / GaN multi-quantum-well luminescent layer structure in sequence; and growing a P-type GaN layer on the P-type electron blocking layer. Warpage degree of the epitaxy structure in the growing process can be changed by adjusting the growth pressure conditions; and the method is large in amplitude in adjusting the warpage degree, so that it is convenient to find an appropriate warpage degree to enable the epitaxy structure to be well matched with a carrier disc when growing the multi-quantum-well luminescent layer structure, and wavelength uniformity of the single epitaxy structure is effectively improved.

Owner:ENRAYTEK OPTOELECTRONICS

Light emitting diode epitaxial wafer and manufacturing method thereof

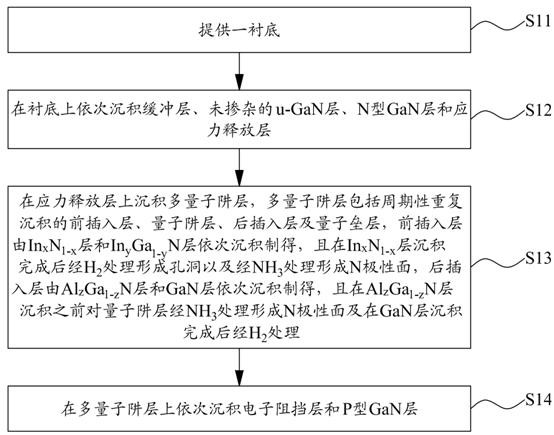

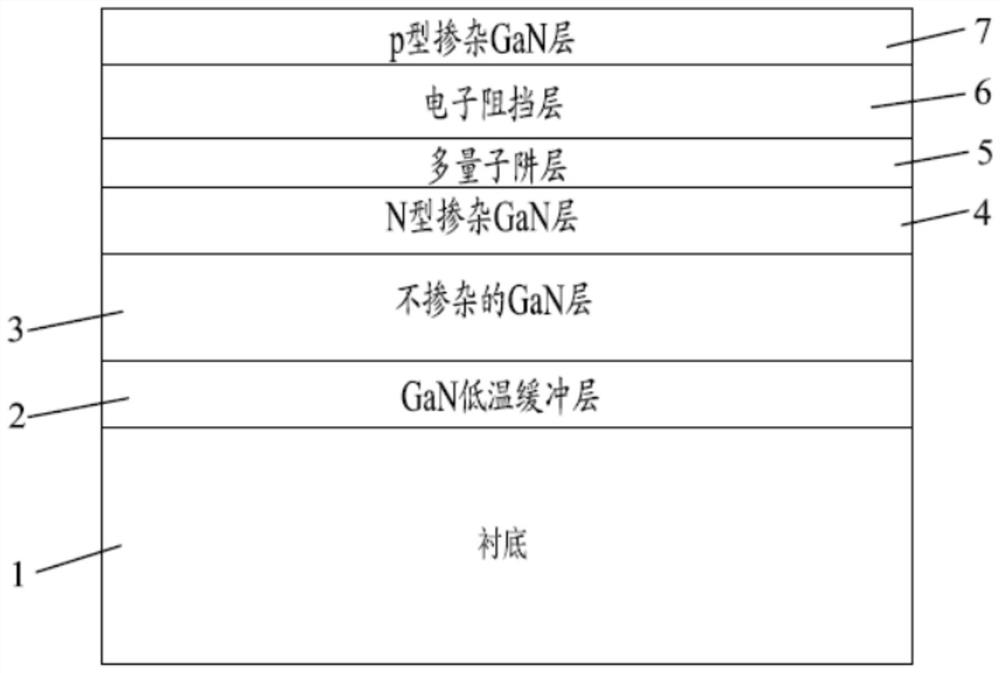

ActiveCN114824003AEvenly distributedFit tightlySemiconductor devicesElectrical polarityElectron blocking layer

The invention provides a light emitting diode epitaxial wafer and a manufacturing method thereof. The epitaxial wafer comprises a substrate, a buffer layer, an undoped u-GaN layer, an N-type GaN layer, a stress release layer, a multi-quantum well layer, an electron barrier layer and a P-type GaN layer, the multi-quantum well layer comprises a front insertion layer, a quantum well layer, a rear insertion layer and a quantum barrier layer; the front insertion layer comprises an In < x > N < 1-x > layer and an In < y > Ga < 1-y > N layer, and the contact surface of the In < x > N < 1-x > layer and the In < y > Ga < 1-y > N layer is processed by H2 to form a hole and processed by NH3 to form an N polar surface; the rear insertion layer comprises an Al < z > Ga < 1-z > N layer and a GaN layer, the surface, in contact with the Al < z > Ga < 1-z > N layer, of the quantum well layer is subjected to NH3 treatment to form an N polar surface, and the surface, in contact with the quantum barrier layer, of the GaN layer is subjected to H2 treatment. According to the invention, the problems of low luminous efficiency and low wavelength uniformity of the existing light-emitting diode are solved.

Owner:JIANGXI ZHAO CHI SEMICON CO LTD

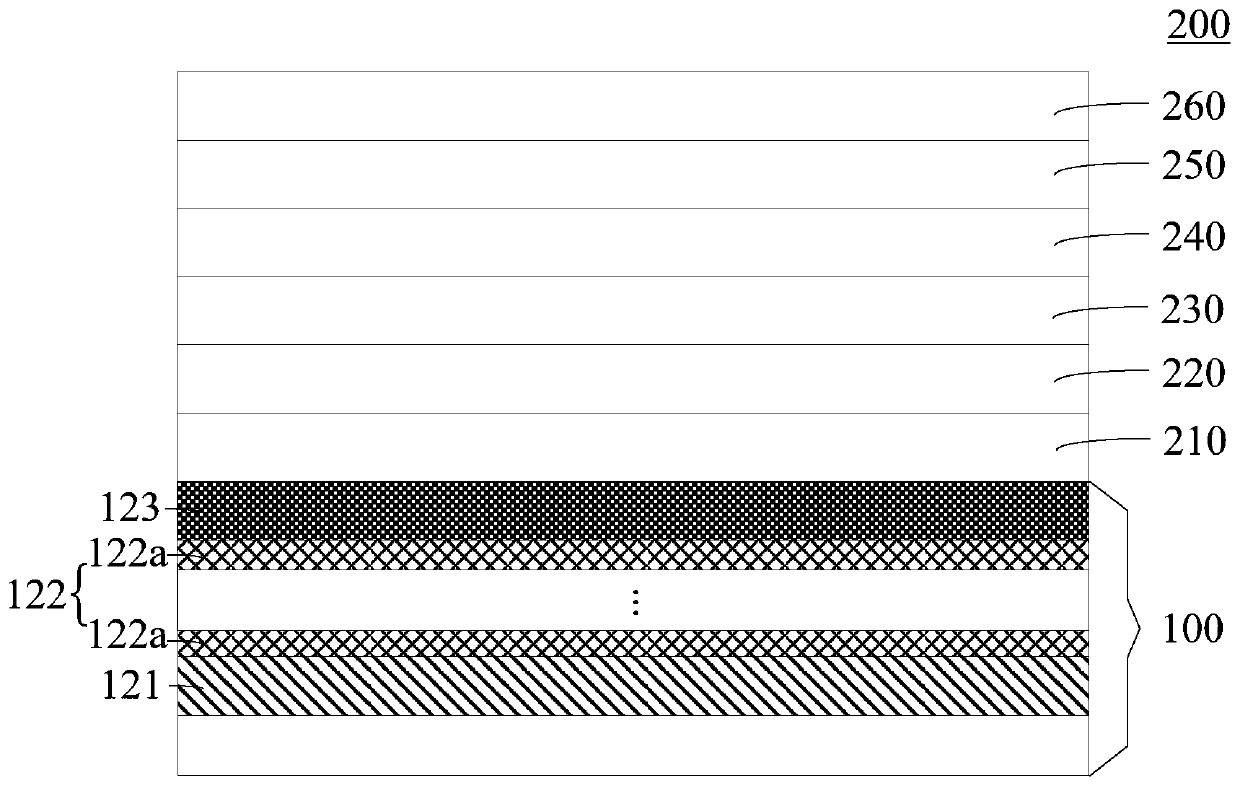

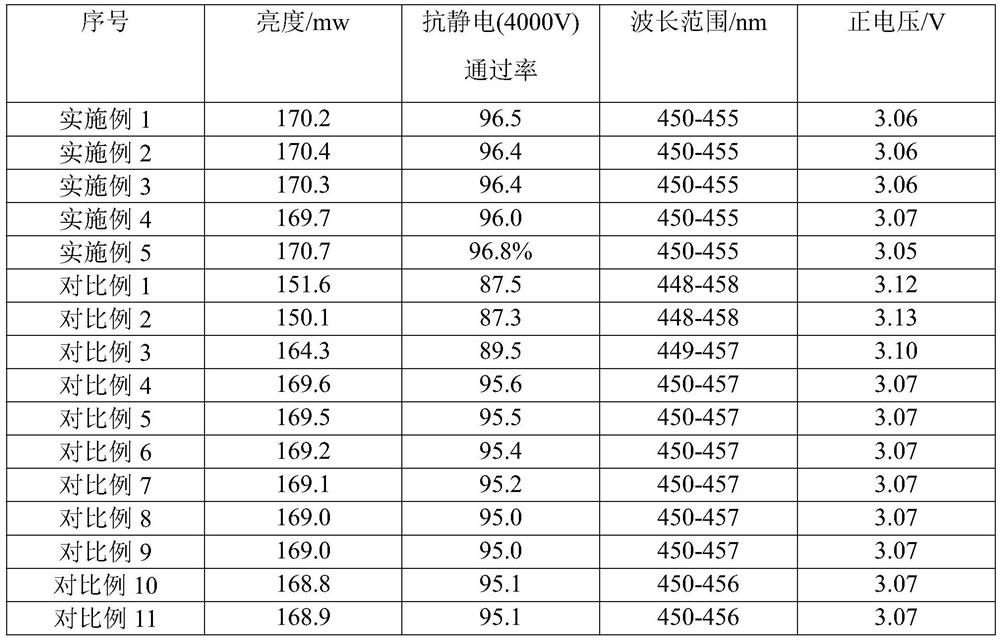

GaN-based light emitting diode epitaxial wafer and preparation method thereof

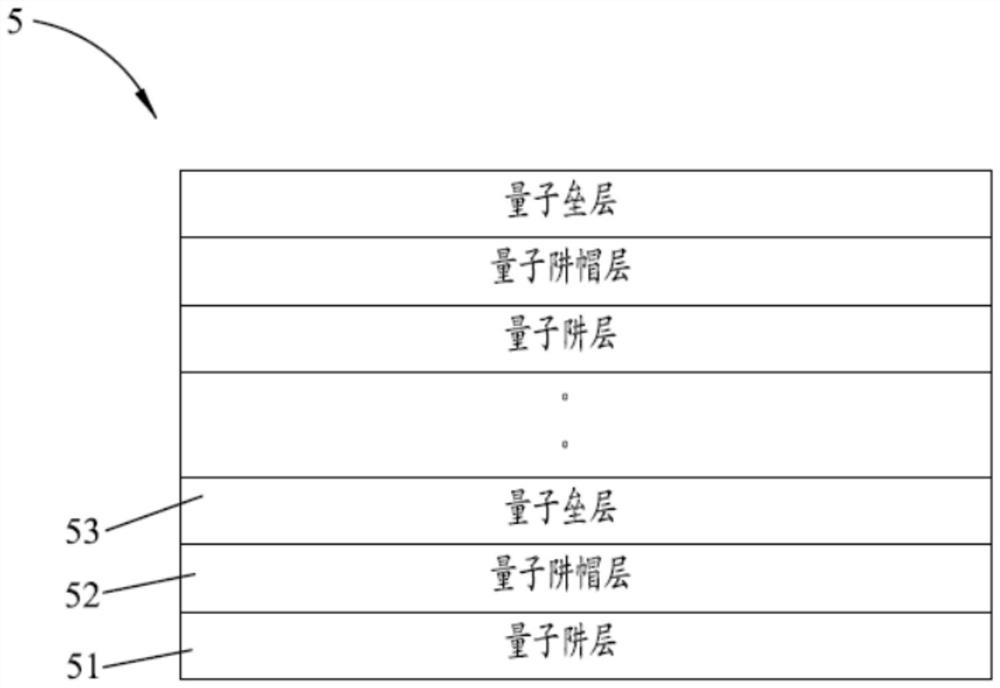

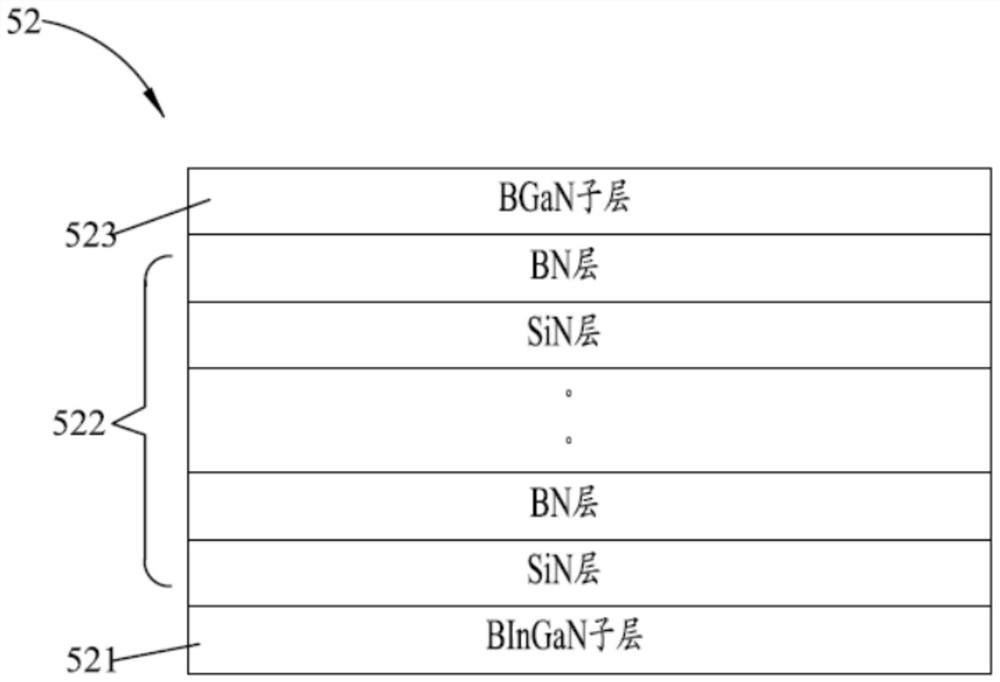

PendingCN114792749AReduce segregationImprove mobilityPolycrystalline material growthFrom chemically reactive gasesLattice mismatchLight-emitting diode

The invention provides a GaN-based light-emitting diode epitaxial wafer and a preparation method thereof, the GaN-based light-emitting diode epitaxial wafer comprises a multi-quantum well layer, and the multi-quantum well layer is of a periodic structure formed by alternately stacking quantum well layers, quantum well cap layers and quantum barrier layers; the quantum well cap layer comprises a BInGaN sub-layer, a composite sub-layer and a BGaN sub-layer which are stacked in sequence, the composite sub-layer is of a periodic structure formed by alternately stacking SiN layers and BN layers, the growth temperature gradient of the BInGaN sub-layer, the growth temperature gradient of the composite sub-layer and the growth temperature gradient of the BGaN sub-layer are increased, and the In component content of the BInGaN sub-layer is gradually reduced. The cap layer in the multi-quantum well layer is specially designed, so that the aim of protecting the In component of the quantum well is well fulfilled, well-barrier lattice mismatch is reduced, In segregation at a quantum well-barrier interface is relieved, the interface crystal quality at the quantum well-barrier is improved, the well-barrier interface is steeper, and the performance of the device is improved. The improvement of wavelength uniformity and the acquisition of better antistatic capability are facilitated, and the luminous efficiency of the light-emitting diode is successfully improved.

Owner:JIANGXI ZHAO CHI SEMICON CO LTD

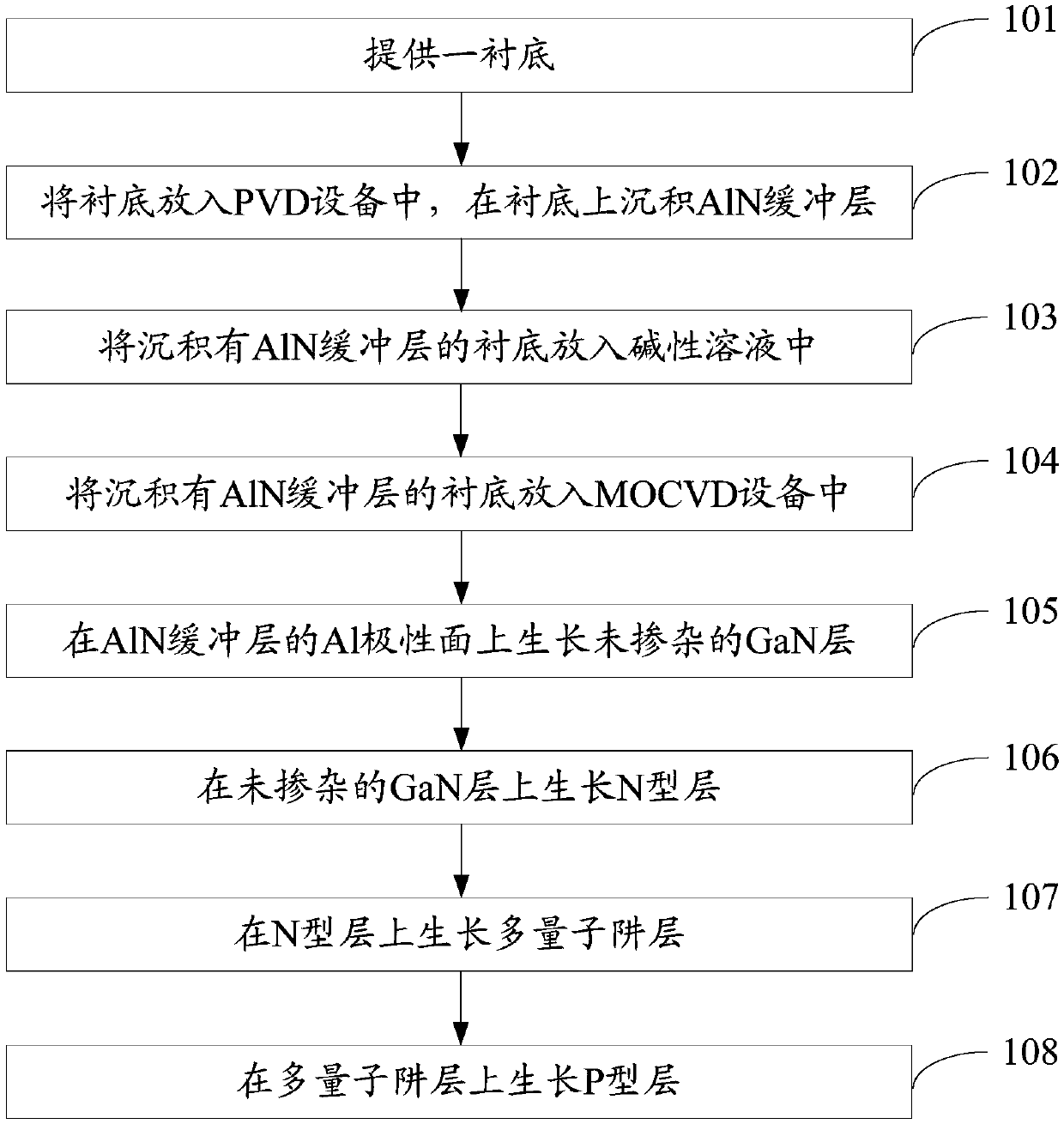

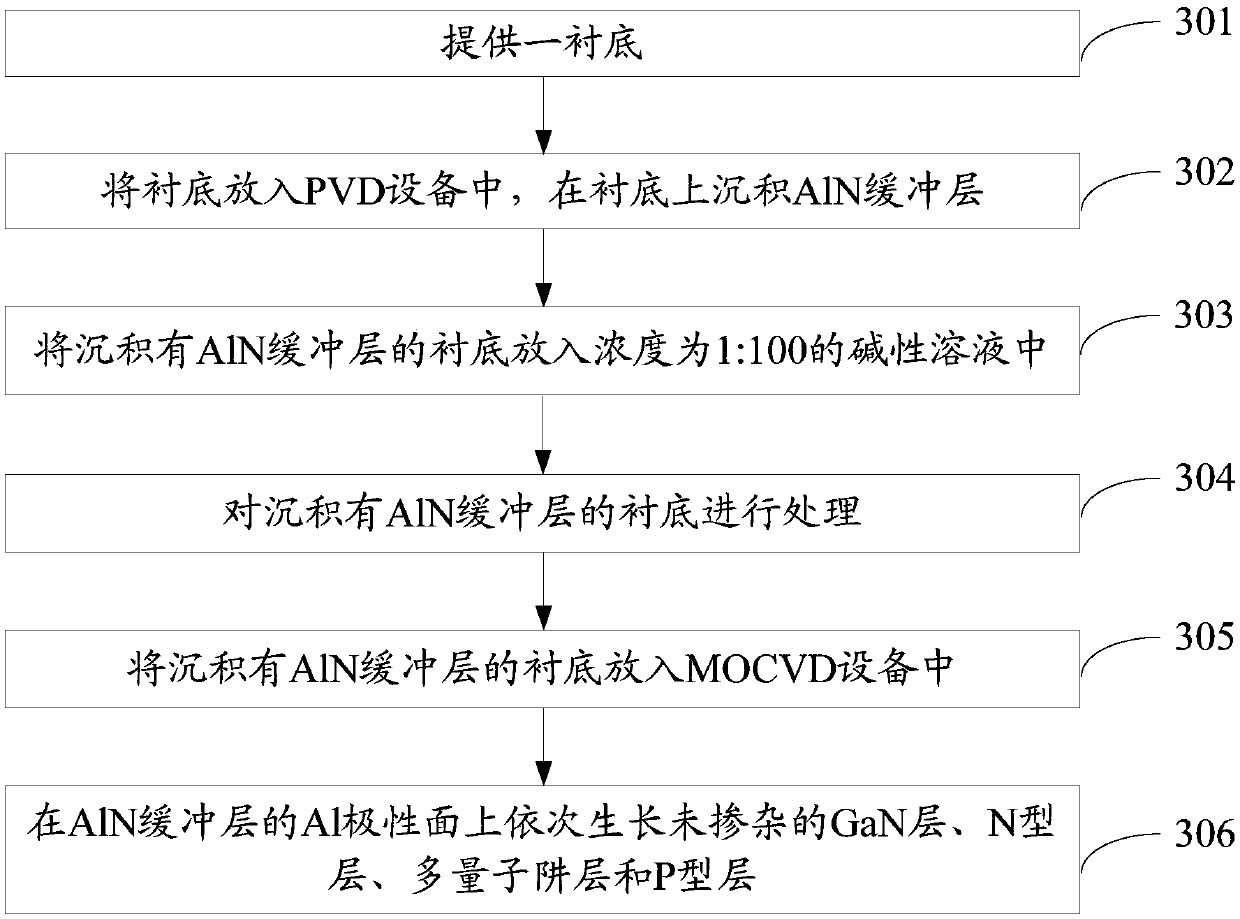

Manufacturing method of light-emitting diode epitaxial wafer

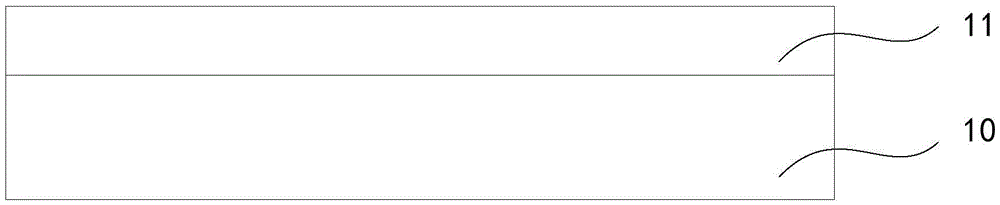

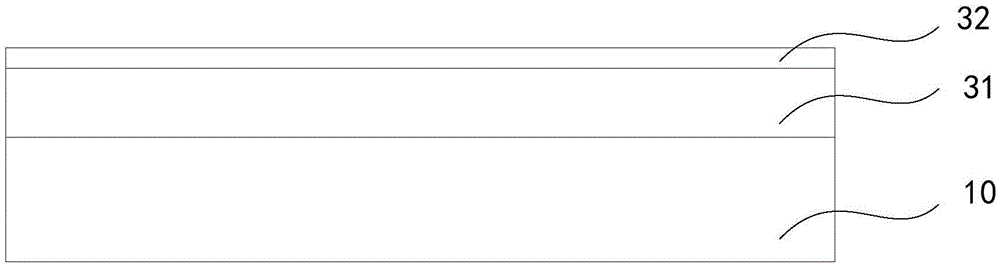

ActiveCN109686820AImprove lattice matchingReduce stressSemiconductor devicesQuantum wellSemiconductor

The invention discloses a manufacturing method of a light-emitting diode epitaxial wafer, and belongs to the technical field of semiconductors. The manufacturing method comprises the following steps:providing a substrate; putting the substrate into PVD equipment, and depositing an AlN buffer layer on the substrate; putting the substrate deposited with the AlN buffer layer into an alkaline solution, and reacting the alkaline solution with the AlN buffer layer to ensure that the surface of the AlN buffer layer is an Al polar surface; putting the substrate deposited with the AlN buffer layer into MOCVD equipment, and sequentially growing an undoped GaN layer, an N-type layer, a multi-quantum well layer and a P-type layer on the Al polar surface of the AlN buffer layer. When the surface of the AlN buffer layer is an Al polar surface, the lattice matching degree between the AlN buffer layer and the undoped GaN layer is higher. Therefore, the manufacturing method can improve the lattice matching degree between the AlN buffer layer and the GaN layer, thereby improving the crystal quality of the grown light-emitting diode epitaxial wafer and further improving the luminous efficiency of the LED.

Owner:HC SEMITEK ZHEJIANG CO LTD

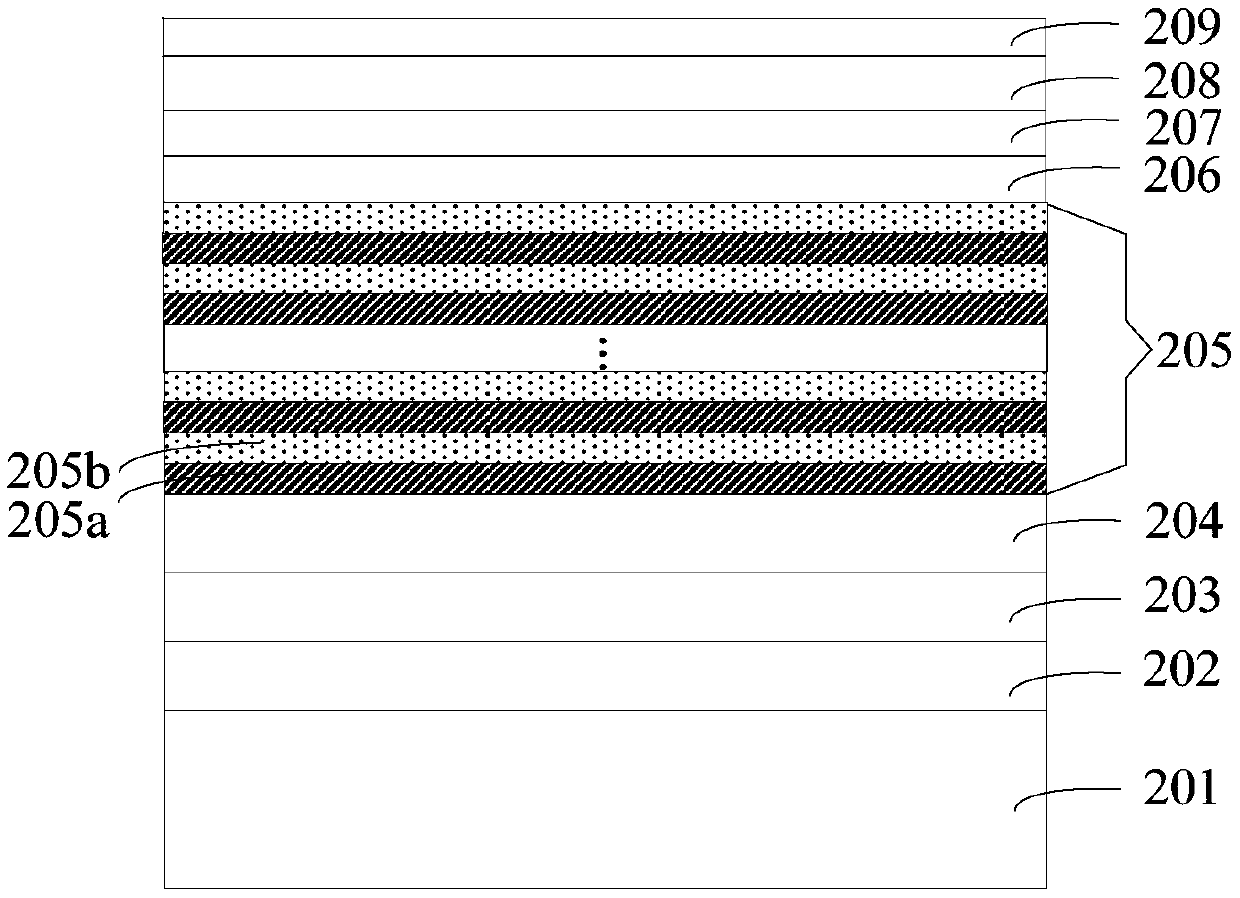

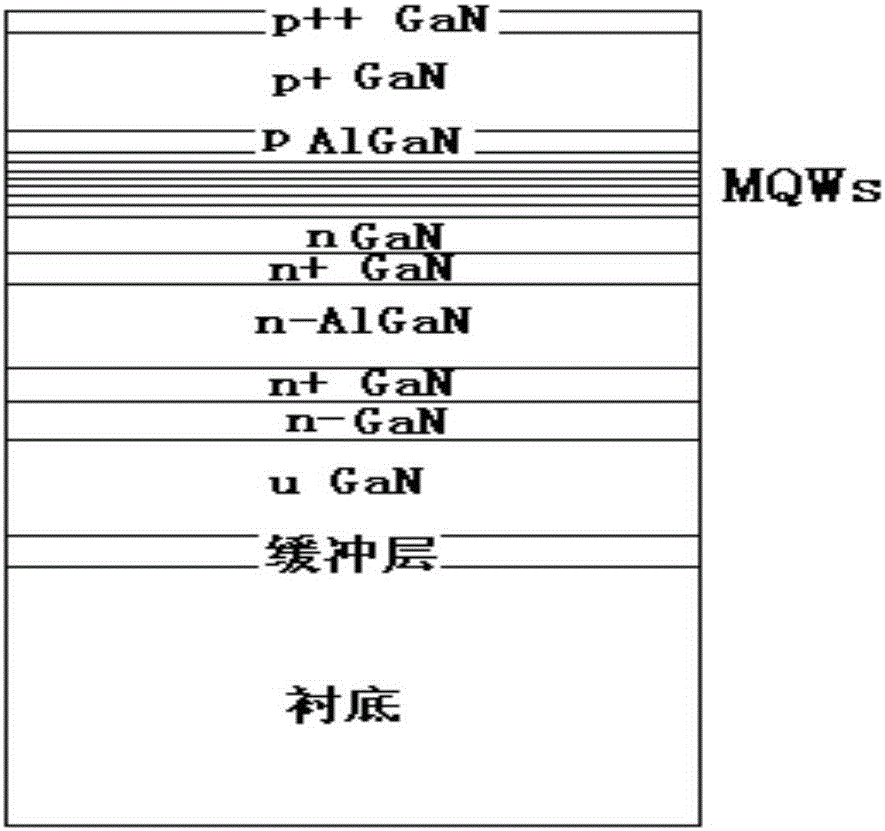

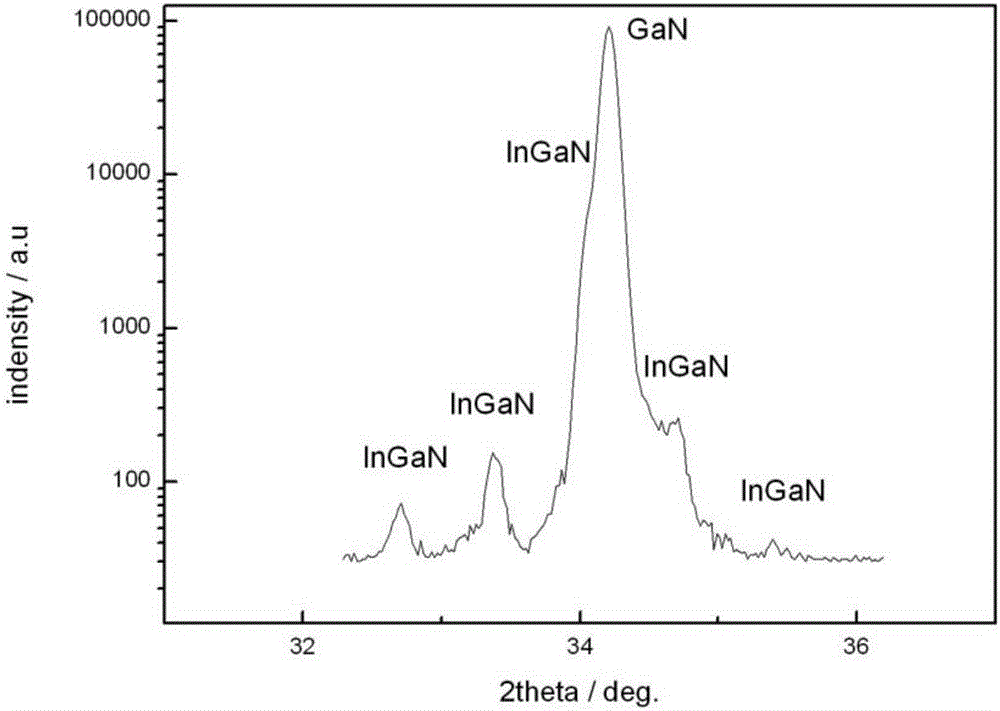

Method for preparing InGaN/AlGaN MQW ultraviolet LED

ActiveCN106206880ALarge adjustment rangeSuitable for batch growthSemiconductor devicesUltravioletP type doping

The invention discloses a method for preparing a high-performance InGaN / AlGaN MQW ultraviolet LED. Blue ammonia, high-purity trimethylindium and high-purity trimethyl gallium serve as an N source, an In source and a Ga source respectively, and SiH4 and Cp2Mg serve as an n type doping agent and a p type doping agent respectively. The method comprises the following steps that firstly, a sapphire substrate or a SiC substrate or a Si substrate is nitrided; secondly, a buffering layer is grown and crystallized, and then a uGaN nucleating layer is grown; thirdly, a low Si-doped n-GaN layer is grown first, and then a high Si-doped n+GaN layer is grown; fourthly, an n-AlGaN layer is grown; fifthly, a Si-doped n+GaN layer is grown, and then an nGaN layer without Si is grown; sixthly, three cycles of InGaN / GaN superlattices without Al are grown, and then eight cycles of Al-doped InGaN / GaN is grown; seventhly, a PAlGaN layer is grown; eighthly, a Mg-doped P+GaN layer is grown; ninthly, a high Mg-doped P++GaN layer is grown. According to the method, InGaN / AlGaN MQW ultraviolet LED epitaxy pieces of the specific structure are grown with an LP MOCVD system, the preparing cost is low, time is saved, the prepared ultraviolet LED is good in performance, and the ultraviolet LED epitaxy industrialization is promoted.

Owner:江苏晶曌半导体有限公司

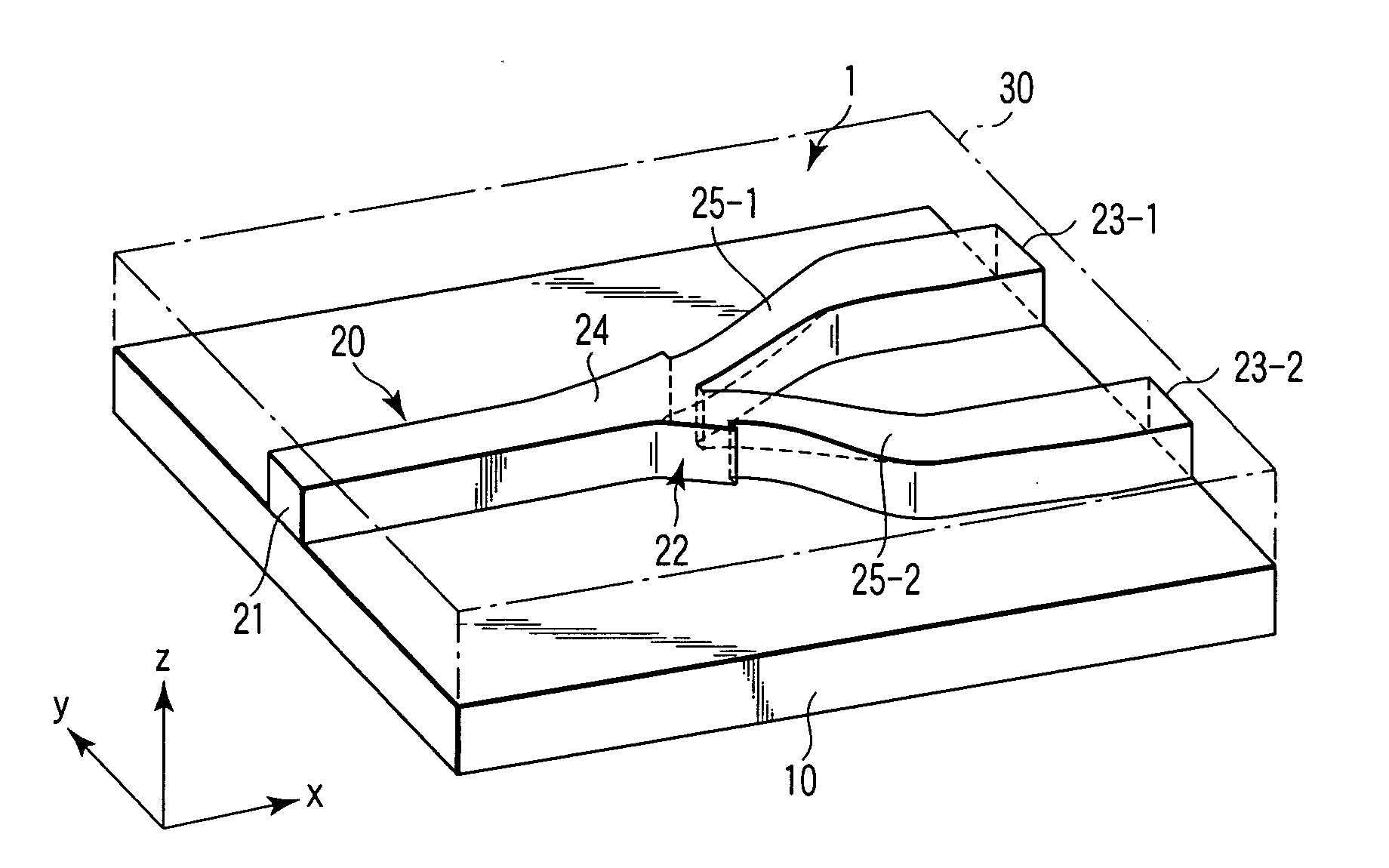

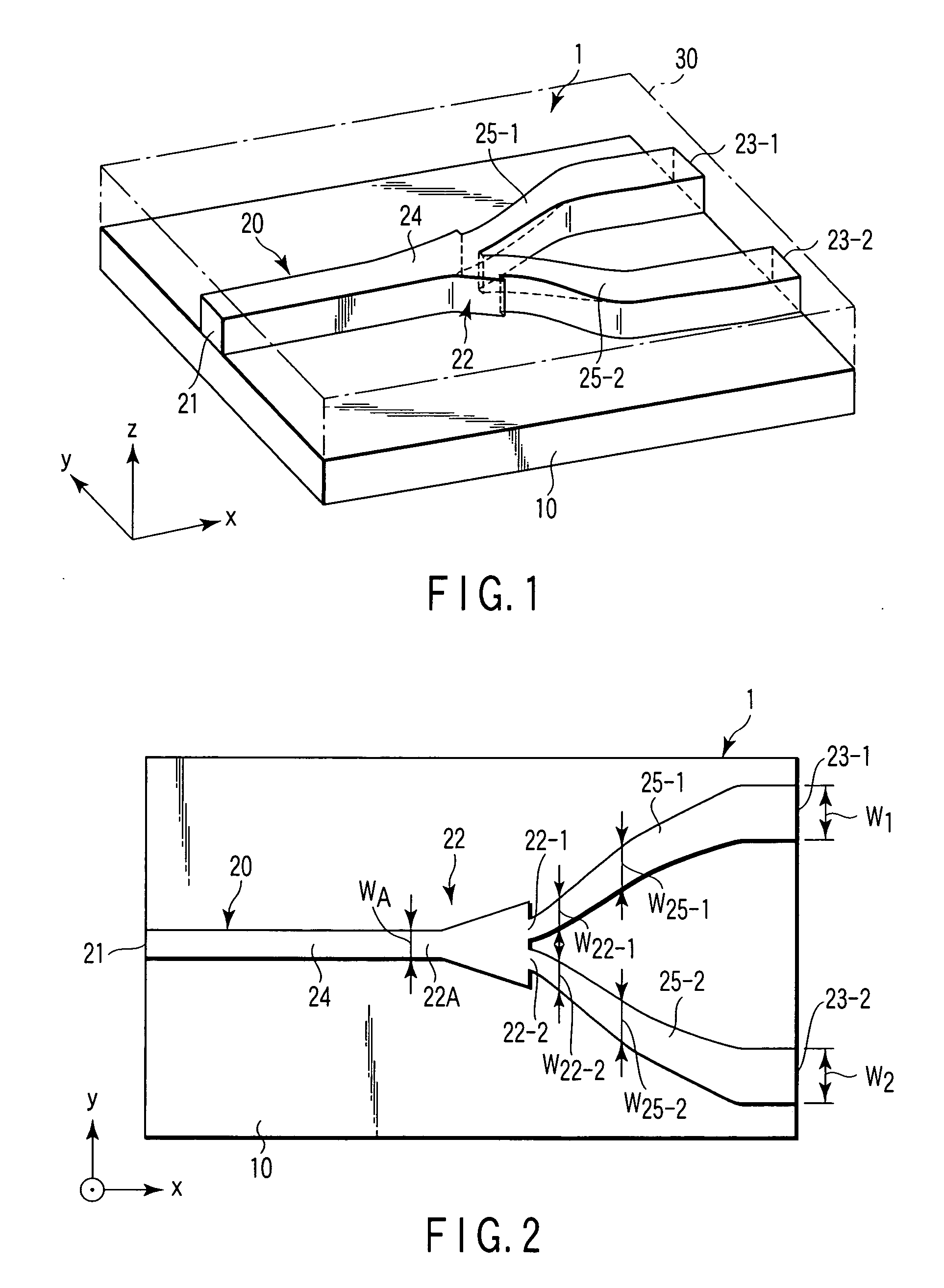

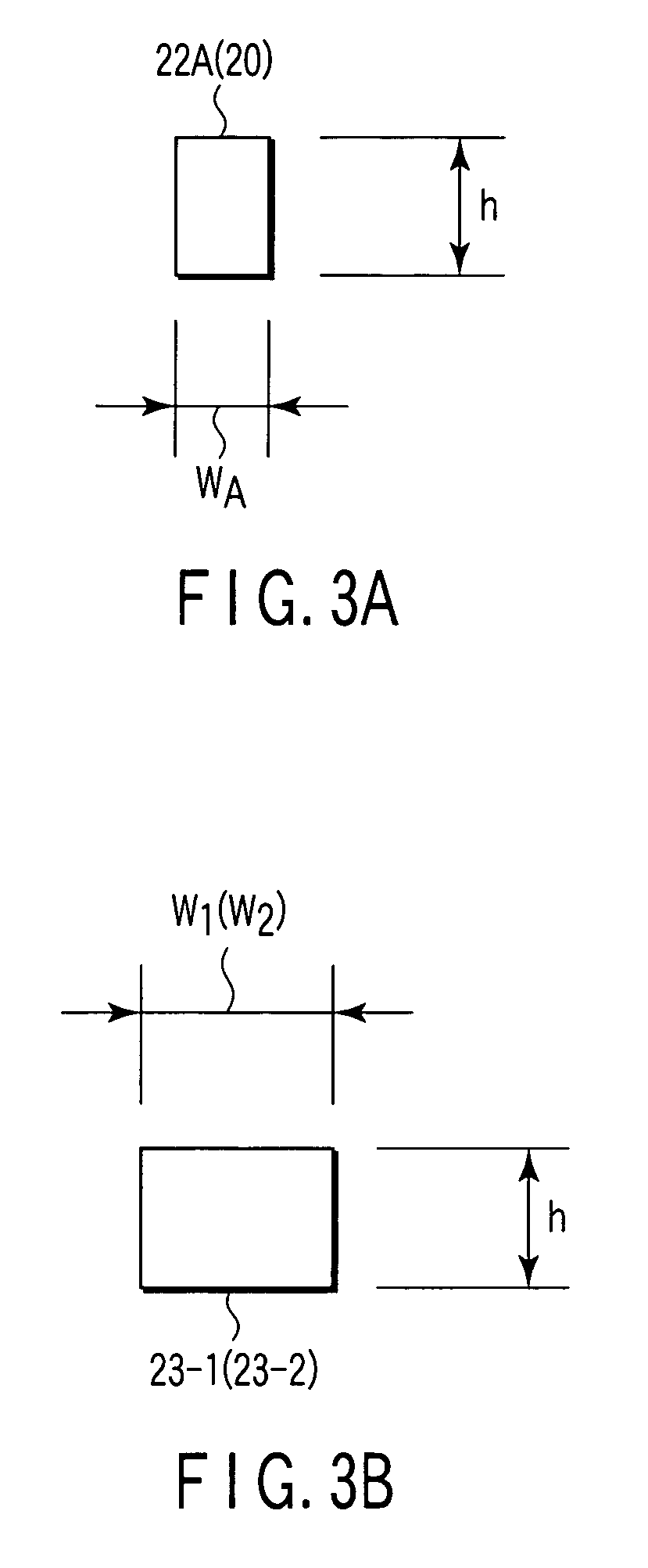

Optical branching unit

InactiveUS7362933B2Emission reductionImprove uniformityCoupling light guidesOptical waveguide light guideEngineeringWaveguide

In an optical branching unit according to the invention, the cross section shape in an area of a front stage to branch to two output waveguides in the optical branch is a rectangle or a non-circle with different vertical-to-horizontal ratio, including an area that the length along the surface of the substrate is defined to be shorter than the length in the direction orthogonal to the surface of a substrate, the cross section at the output ends of the output waveguide is a rectangle or a non-circle with a different vertical-to-horizontal ratio, where the length along the surface of the substrate is defined to be longer than the length in the direction orthogonal to the surface of the substrate.

Owner:ORMON CORP

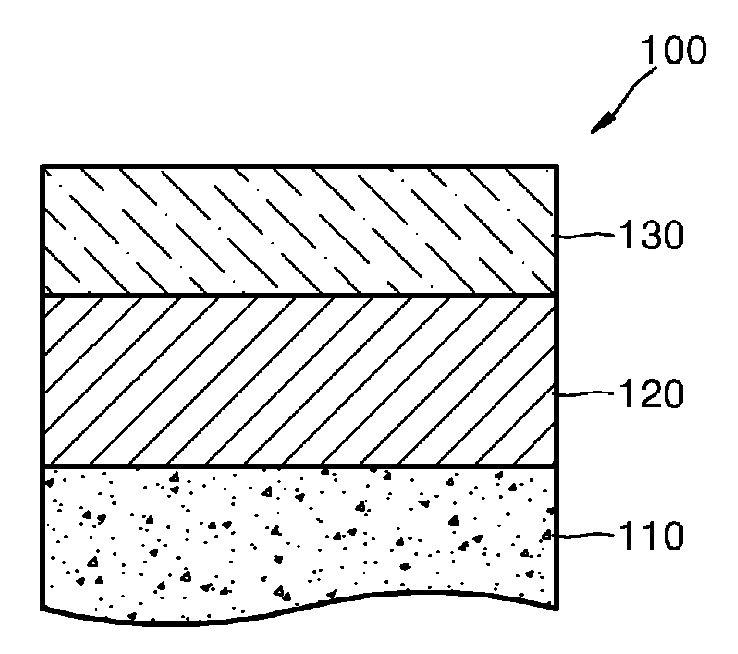

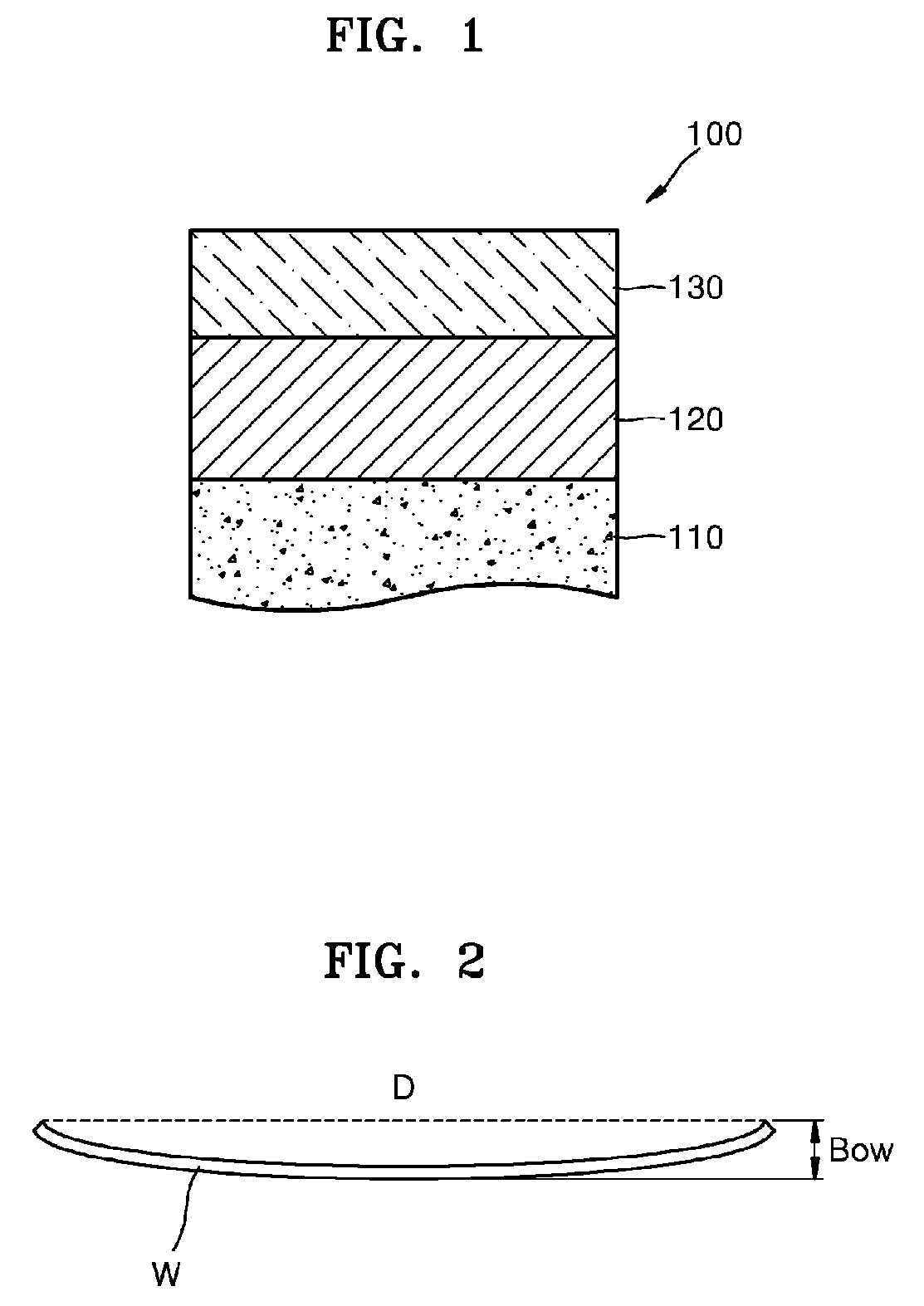

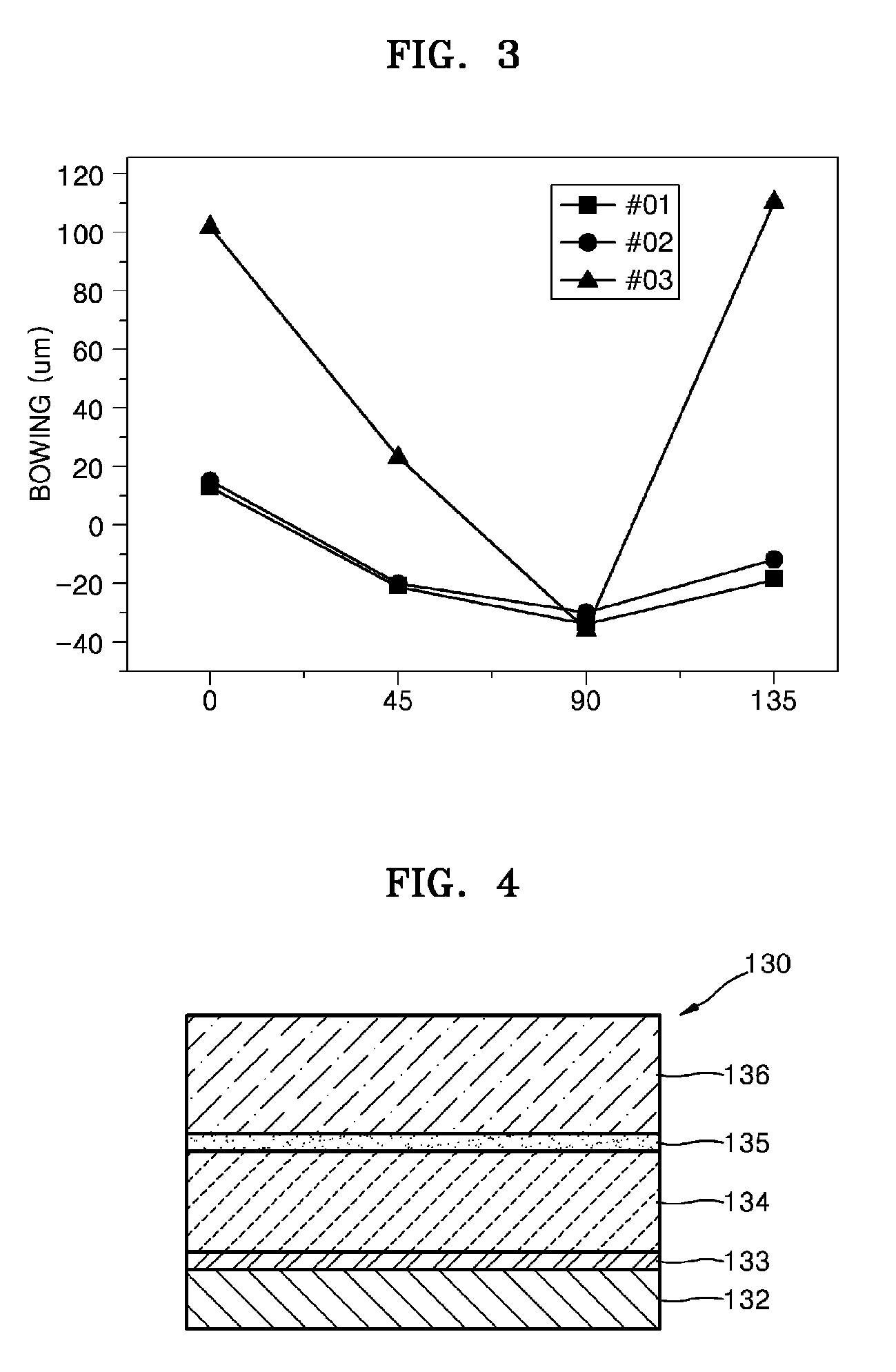

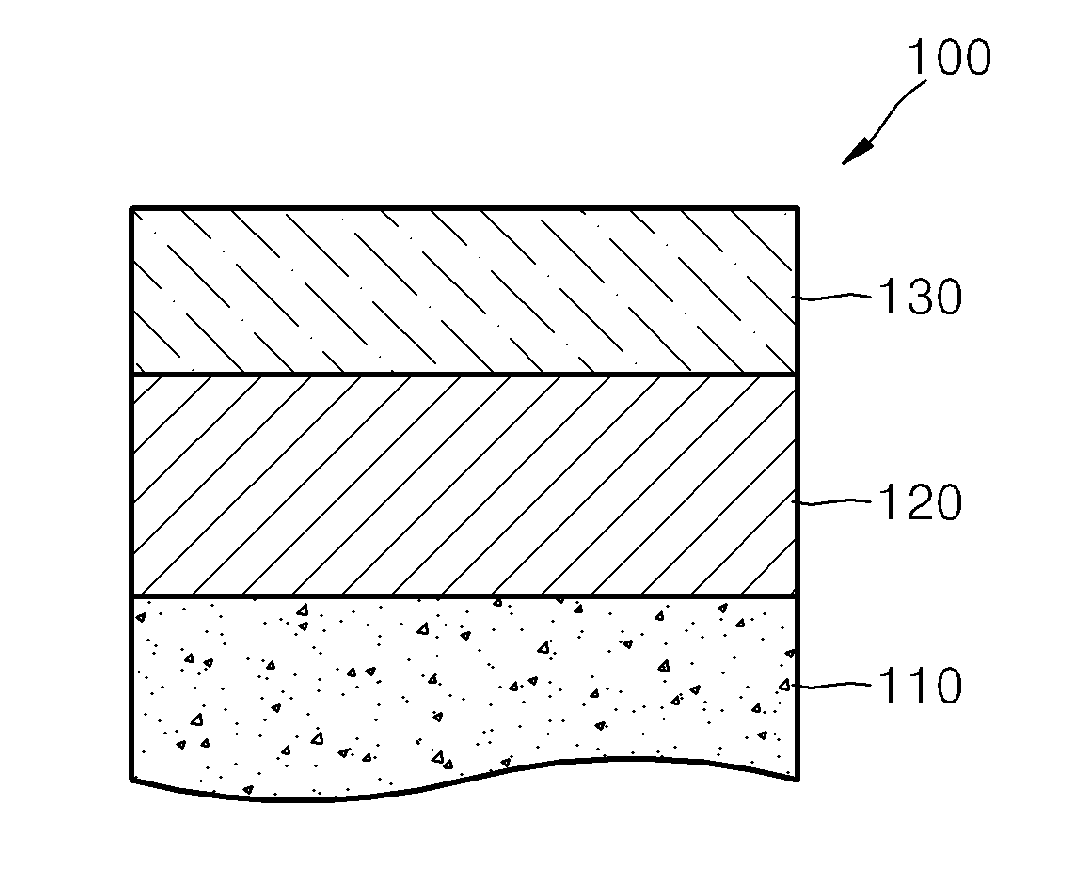

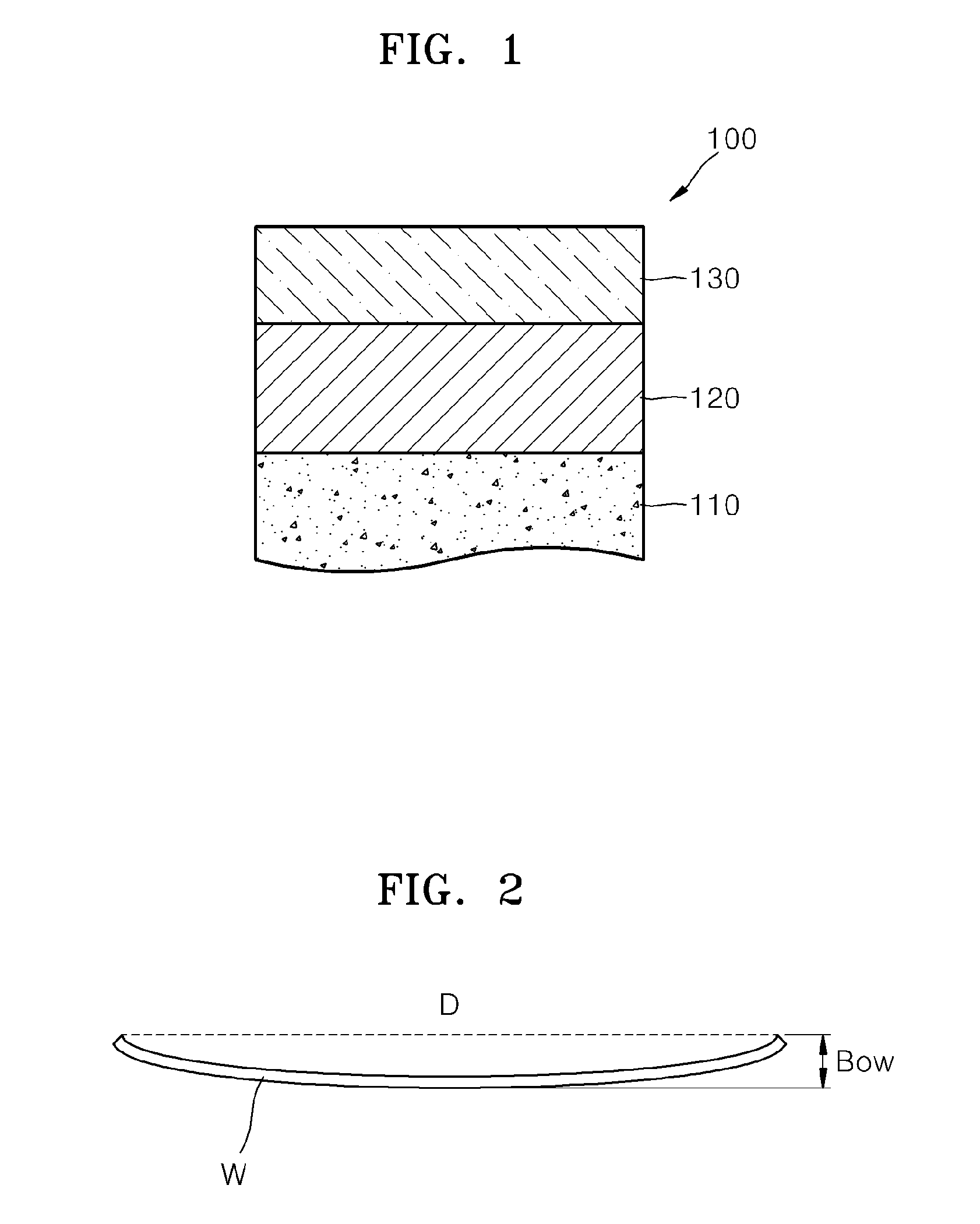

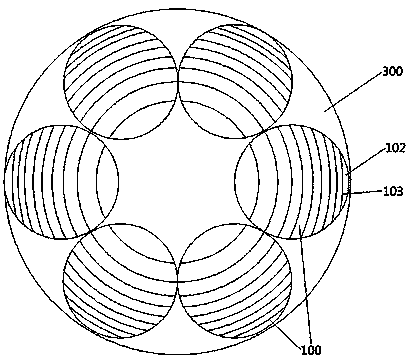

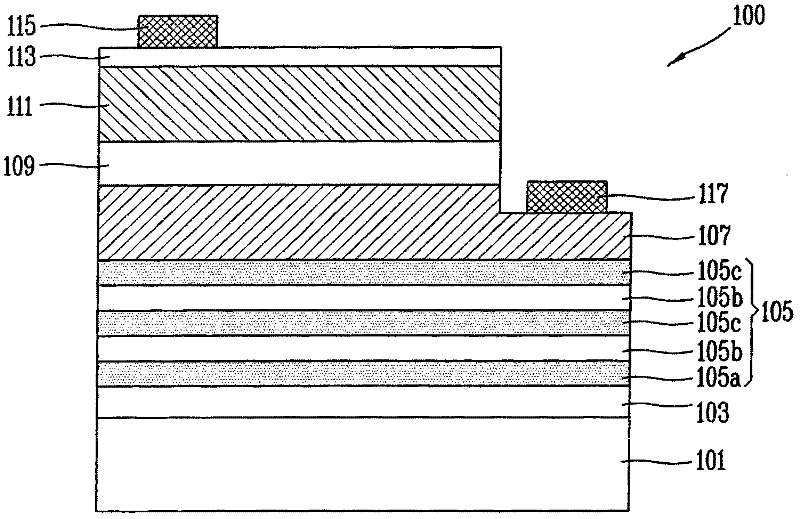

Gallium nitride based semiconductor device and method of manufacturing the same

ActiveUS9202878B2Avoid damageReduce deformationSemiconductor/solid-state device manufacturingSemiconductor devicesHigh concentrationDevice material

A gallium nitride based semiconductor device includes a silicon-based layer doped simultaneously with boron (B) and germanium (Ge) at a relatively high concentration, a buffer layer on the silicon-based layer, and a nitride stack on the buffer layer. A doping concentration of boron (B) and germanium (Ge) may be higher than 1×1019 / cm3.

Owner:SAMSUNG ELECTRONICS CO LTD

Gallium nitride based semiconductor device and method of manufacturing the same

ActiveUS20130328054A1Avoid damageReduce deformationSemiconductor/solid-state device manufacturingSemiconductor devicesHigh concentrationDevice material

A gallium nitride based semiconductor device includes a silicon-based layer doped simultaneously with boron (B) and germanium (Ge) at a relatively high concentration, a buffer layer on the silicon-based layer, and a nitride stack on the buffer layer. A doping concentration of boron (B) and germanium (Ge) may be higher than 1×1019 / cm3.

Owner:SAMSUNG ELECTRONICS CO LTD

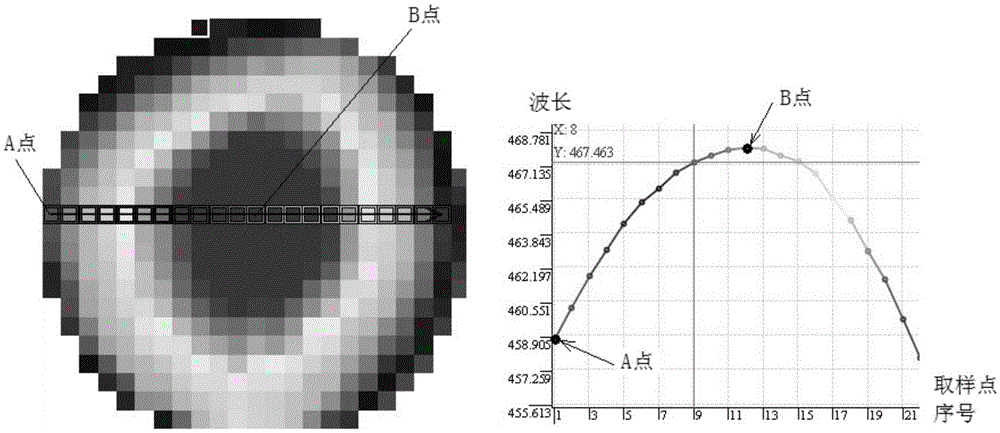

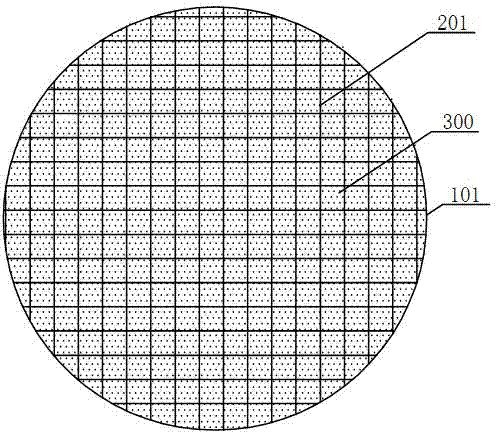

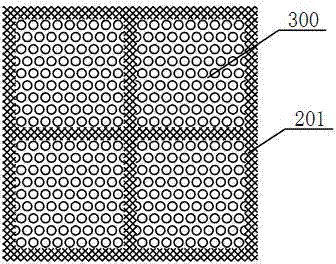

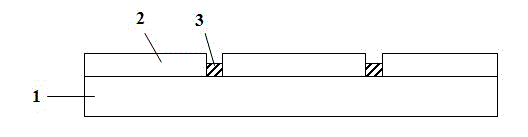

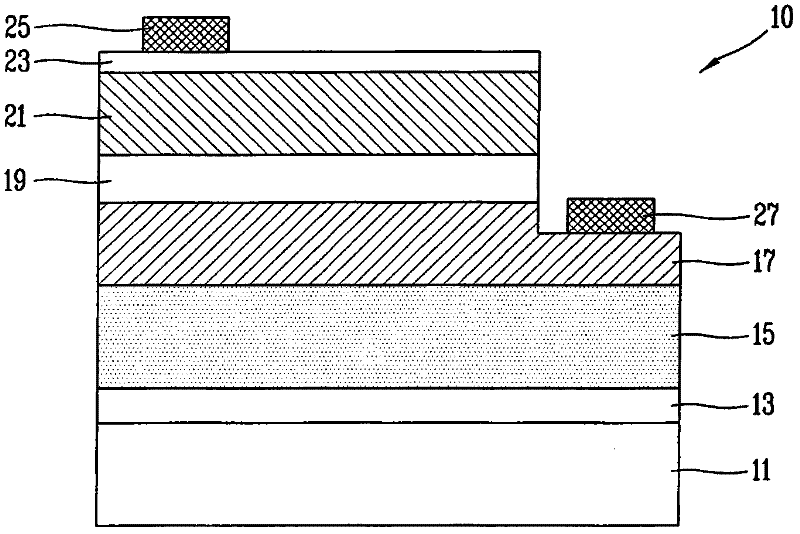

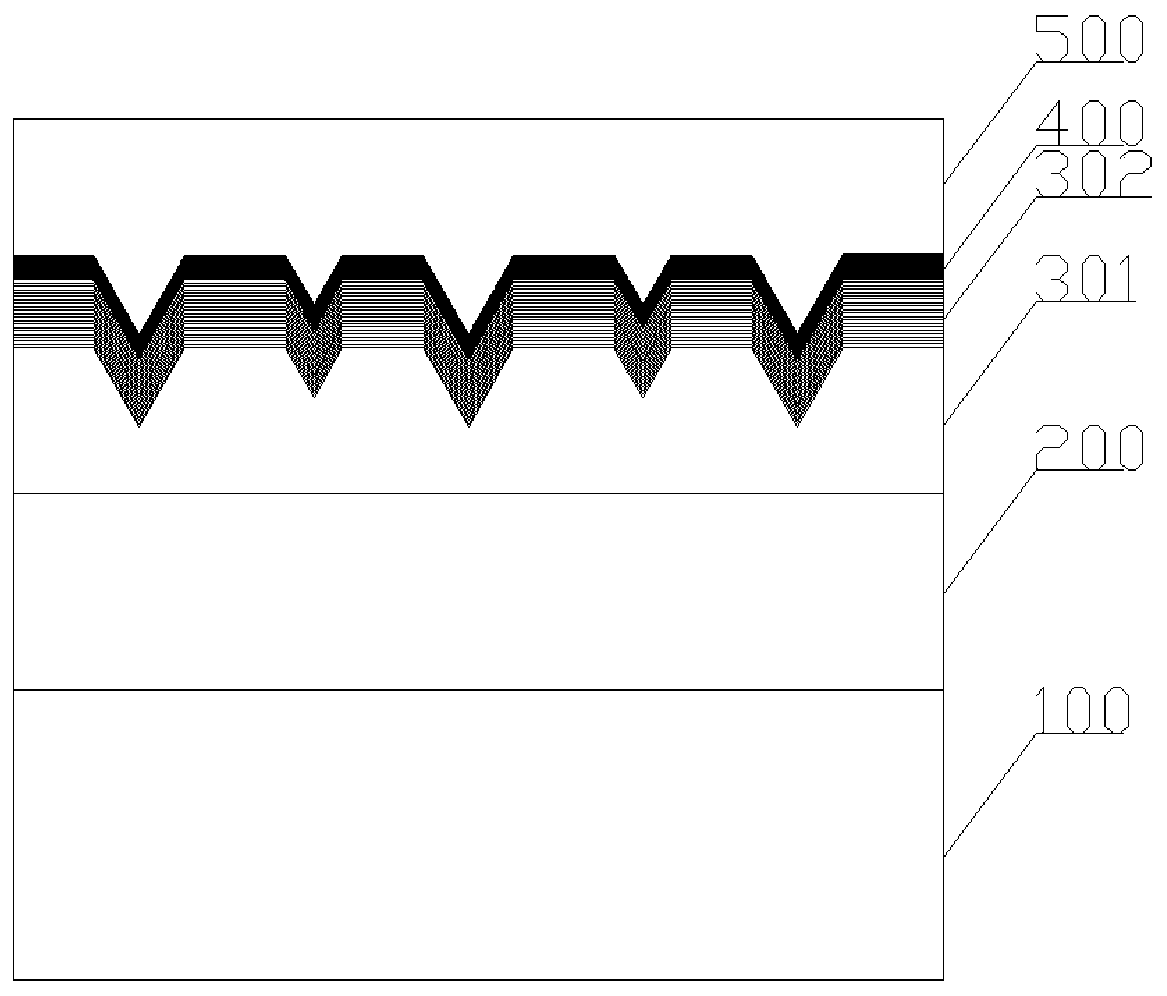

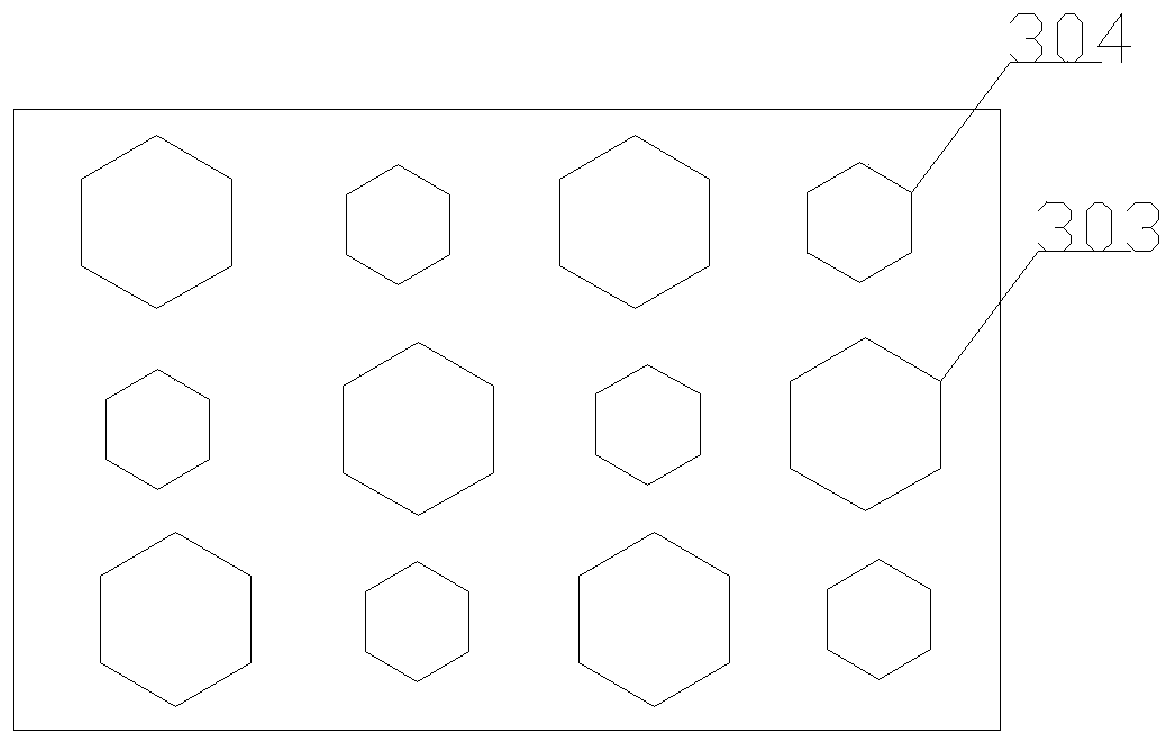

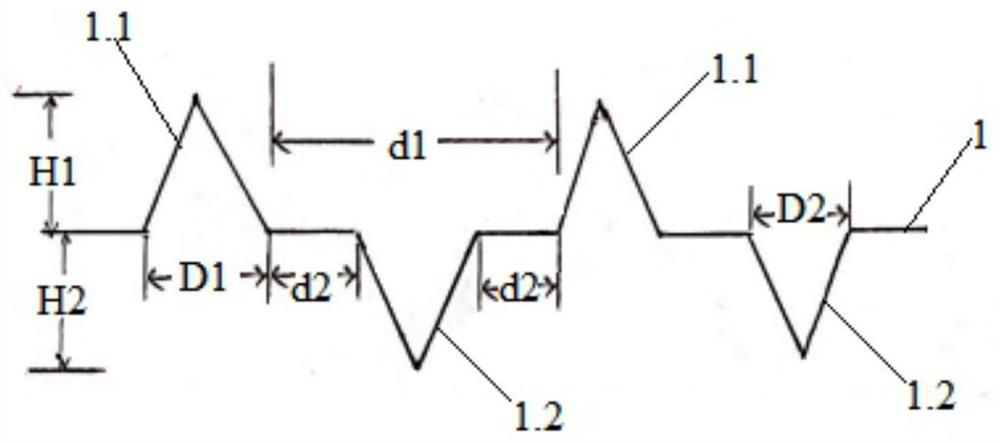

Pattern-segmented sapphire substrate used for AlGaInN material system film growth

InactiveCN103647005AImprove wavelength uniformityReduce the amount of bending deformationSemiconductor/solid-state device manufacturingFine working devicesThin membraneCondensed matter physics

The invention discloses a pattern-segmented sapphire substrate used for AlGaInN material system film growth. The pattern-segmented sapphire substrate comprises a sapphire substrate body; pattern segmentation grooves divide the upper surface of the sapphire substrate body into a plurality of mutually-independent repeated pattern units, wherein the pattern units are growing platforms of AlGaInN materials. The sapphire substrate body is a plane sapphire substrate body or a pattern sapphire substrate body. The pattern segmentation grooves are trench-type pattern segmentation grooves or second medium-type pattern segmentation grooves. The pattern-segmented sapphire substrate is formed by dividing the sapphire substrate into the plurality of mutually-independent and mutually-isolated pattern units through the grooves or second medium. According to the segmented AlGaInN epitaxial thin films, the wave length uniformity of an LED can be greatly improved, the qualified rate of an LED epitaxial wafer is improved, and the giant thermal stress and thermal shock, due to laser lift-off, between the AlGaInN epitaxial thin films and the sapphire substrate are greatly reduced, the pass rate of the laser lift-off can be greatly improved, and the qualified rate of sapphire substrate vertical structure LED chips is improved.

Owner:NANCHANG UNIV +1

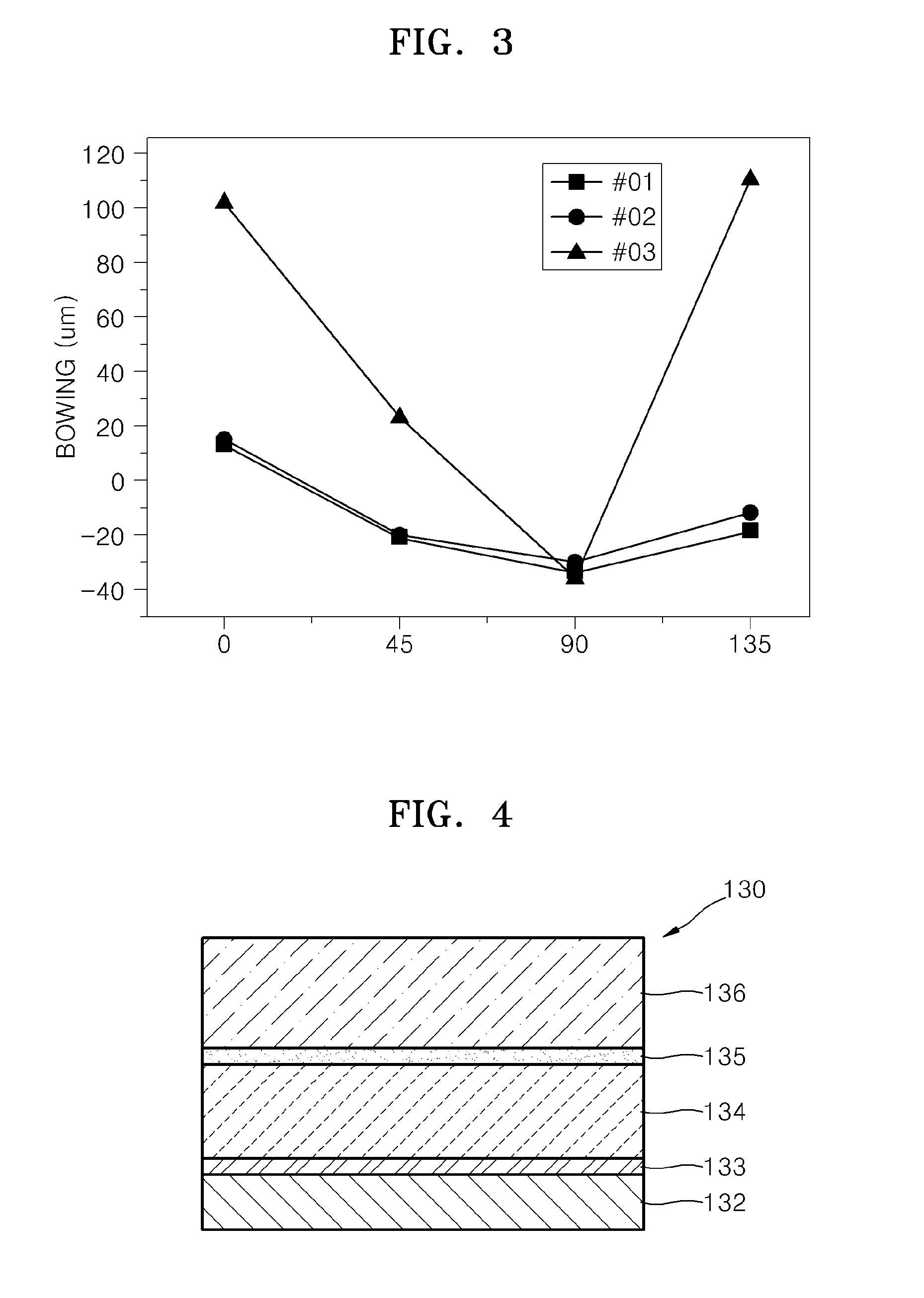

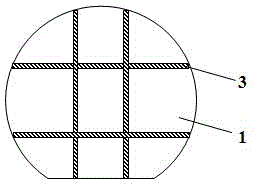

Stress-released GaN-based LED structure and manufacturing method

InactiveCN104576865AStress reliefImprove wavelength uniformitySemiconductor devicesLead structureEngineering

The invention discloses a stress-released GaN-based LED structure which comprises a sapphire substrate and a GaN-based epitaxial layer. The stress-released GaN-based LED structure is characterized in that crisscross strip-type isolation strips or crisscross strip-type isolation channels are formed in the growth plane of the sapphire substrate; the GaN-based epitaxial layer is arranged in an area, without the isolation strips or the isolation channels, on the growth plane of the sapphire substrate. The invention further discloses a manufacturing method for the GaN-based LED structure. According to the stress-released GaN-based LED structure and the manufacturing method, the internal stress of an epitaxial layer of a large-sized substrate can be simply and conveniently released, the uniformity of wavelengths in the epitaxial layer can be improved, and the yield of a GaN-based LED chip can be improved.

Owner:GUANGDONG DELI PHOTOELECTRIC

Graphic substrate, epitaxial wafer, manufacturing method, storage medium and LED chip

ActiveCN110190163AImprove uneven thicknessImprove wavelength uniformitySemiconductor devicesEpitaxial materialEngineering

The invention relates to a graphic substrate, an epitaxial wafer, a manufacturing method, a storage medium and an LED chip. The graphic substrate is applied to a Micro LED, and the body is provided with at least one accommodating groove for accommodating at least a portion of the epitaxial material dropped in the epitaxial process. The graphic substrate is advantaged in that at least a portion ofthe excess epitaxial material generated during high-speed rotational molding of the epitaxial layer in an MOCVD furnace can be dropped into the accommodating groove without remaining on the epitaxiallayer, a problem of uneven thickness of the epitaxial layer is ameliorated, wavelength uniformity is improved, and a problem of wavelength non-uniformity is at least solved.

Owner:KONKA GROUP

Semiconductor light emitting diode and manufacturing method thereof

InactiveCN102280544AAvoid growth defectsIncrease productionSemiconductor devicesActive layerLight-emitting diode

Owner:LG DISPLAY CO LTD

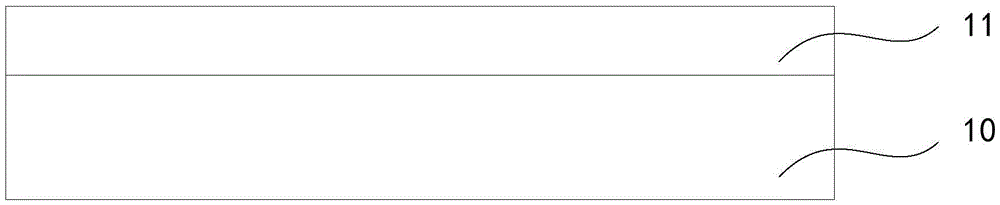

AlN template, light-emitting diode epitaxial wafer and production method thereof

InactiveCN109888070AIncrease the lattice constantImprove wavelength uniformitySemiconductor devicesOxygen contentLength wave

The invention discloses an AlN template, a light-emitting diode epitaxial wafer and a production method thereof and belongs to the field of semiconductor technologies. The AlN template comprises a substrate and an AlN thin film deposited on the substrate, wherein the AlN thin film comprises a first AlN thin film part, an inserted layer and a second AlN thin film part which are sequentially stacked, the inserted layer comprises multiple AlNO sub-layers, and oxygen content in the multiple AlNO sub-layers is increased layer by layer and then decreased layer by layer along the stacking direction of the multiple AlNO sub-layers. A part of O atoms in the AlNO sub-layers can replace N atoms, the other part of O atoms can form gap-filling atoms, both the replacing O atoms and the gap-filling O atoms can make AlN lattices distort to a certain extent, therefore, the lattice constant of the AlN thin film is increased, the lattice constant of the AlN thin film is more approximate to the lattice constant of a subsequent GaN epitaxial thin film, pressing stress in a GaN material can be reduced beneficially, warping of the epitaxial wafer is relieved, and then wavelength uniformity of an epitaxial layer is improved.

Owner:HC SEMITEK ZHEJIANG CO LTD

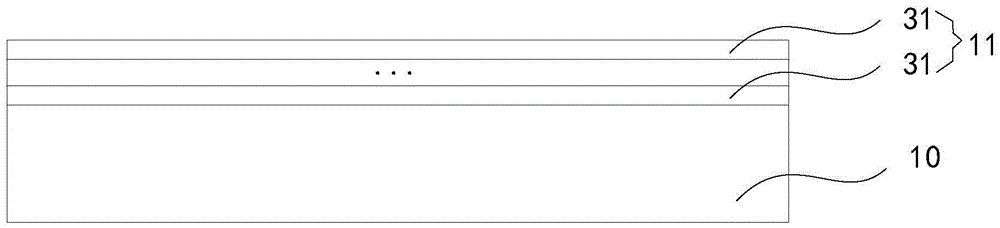

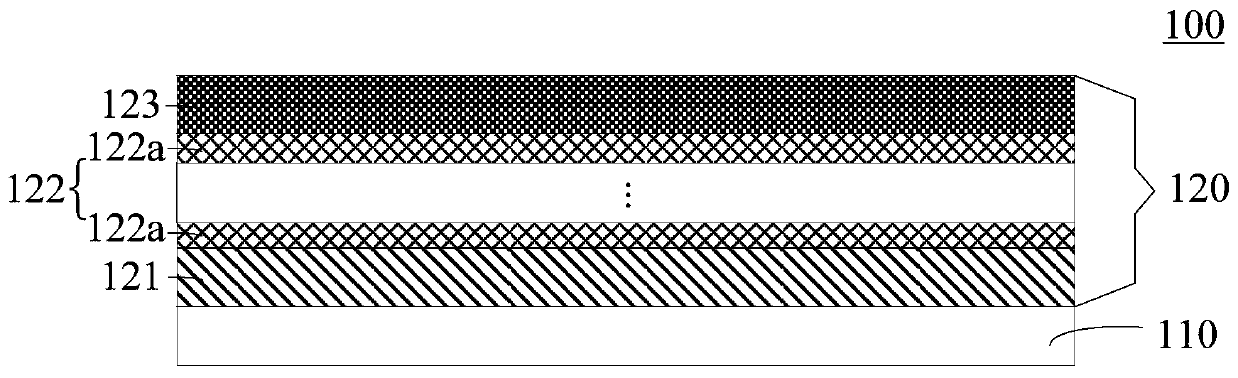

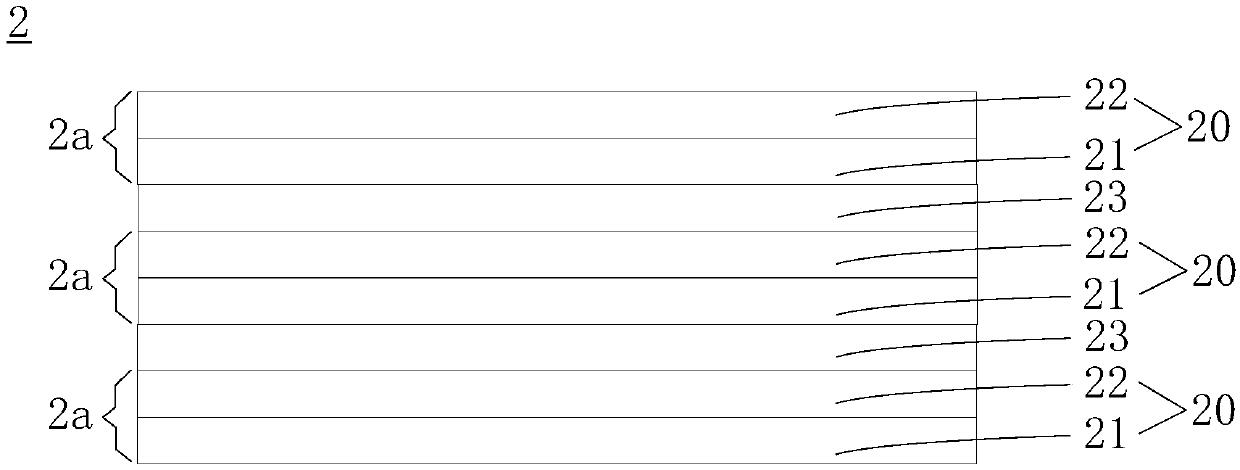

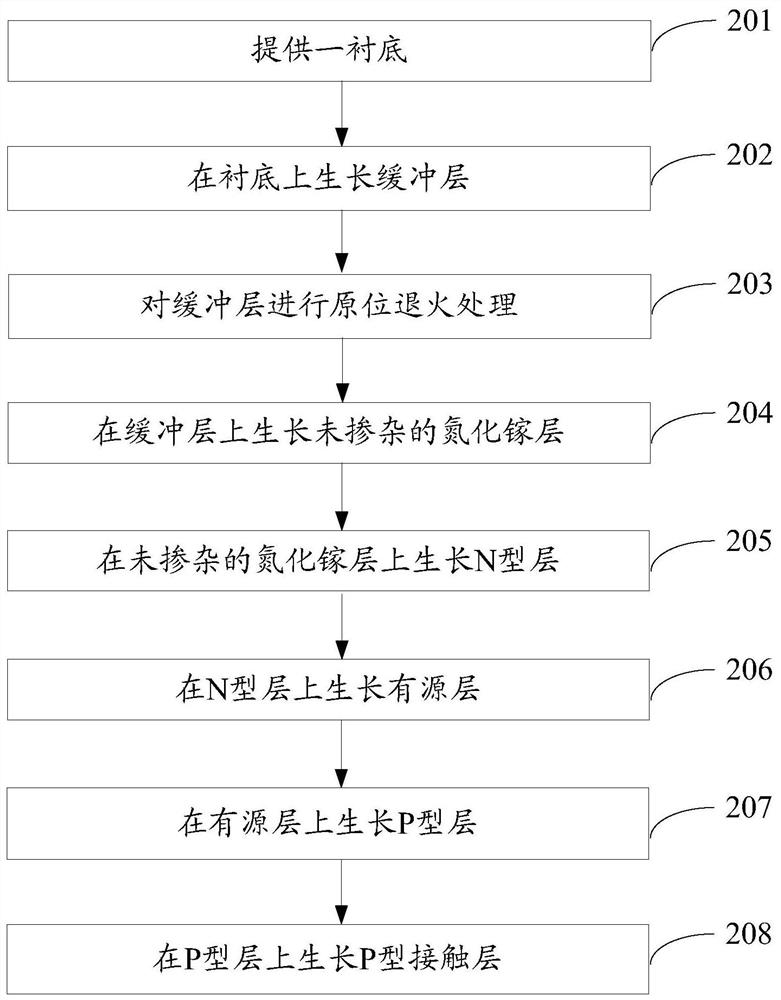

GaN-based light-emitting diode epitaxial wafer and preparation method thereof

ActiveCN109671819AAdjust warpageImprove wavelength uniformitySemiconductor devicesQuantum wellContact layer

The invention discloses a GaN-based light-emitting diode epitaxial wafer and a preparation method thereof, and belongs to the field of GaN-based light-emitting diodes. The method includes the steps of: providing a substrate; depositing a buffer layer on the substrate, the buffer layer comprising a plurality of stacked composite layers, each composite layer comprising an AlN sub-layer and an AlNO sub-layer, the oxygen content of the AlNO sub layer in each composite layer is gradually increased from a composite layer being closet to the substrate to a composite layer being farthest to the substrate; and depositing an undoped GaN layer, an N-doped GaN layer, a quantum well layer, an electron blocking layer, a P-type GaN layer and a P-type contact layer on the buffer layer in order.

Owner:HC SEMITEK ZHEJIANG CO LTD

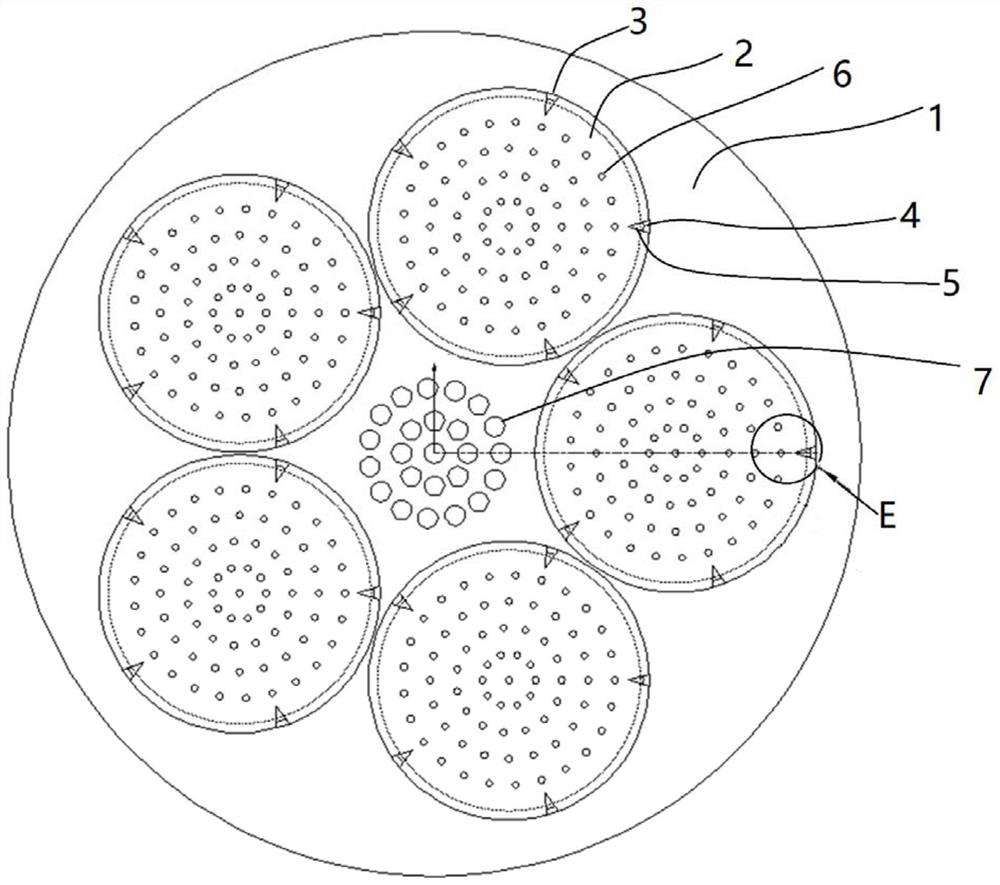

Graphite substrate for improving wavelength uniformity of epitaxial wafer

PendingCN114134563AReduce volumeEvenly distributedFrom chemically reactive gasesCircular discEngineering

The invention provides a graphite substrate for improving the wavelength uniformity of an epitaxial wafer, and belongs to the technical field of semiconductors. The graphite base plate comprises a first base plate, a second base plate and an exhaust device, and the first base plate and the second base plate are both discs; the upper surface of the first substrate is provided with a plurality of circles of first grooves for accommodating substrates, the middle part of the first substrate is provided with a circular pit, and the bottom of the circular pit is provided with a plurality of air holes; the second substrate is coaxially arranged in the circular pit, and the upper surface of the second substrate is provided with a plurality of circles of second grooves for accommodating the substrate; and the exhaust device is configured to provide gas with set flow for the plurality of gas holes in different working states, so that the second substrate is suspended in the circular pit and is separated from the first substrate, and the second substrate and the first substrate rotate in the same direction or in the opposite direction at a set rotating speed. The epitaxial wafer grows on the graphite substrate provided by the invention, so that the wavelength uniformity of the epitaxial wafer growing in each groove of the graphite substrate can be improved.

Owner:HC SEMITEK ZHEJIANG CO LTD

Tray with air bridge structure and epitaxial growth method

ActiveCN113699586ASpeed up circulationImprove temperature consistencyPolycrystalline material growthElectric discharge tubesFluid transportAir bridge

The invention discloses a tray with an air bridge structure and an epitaxial growth method. The tray comprises a tray main body, the end face of the tray main body is provided with a plurality of grooves, a plurality of composite steps are distributed in each groove, and after a substrate is placed, the air bridge structure is naturally formed between the edge of the substrate and the inner walls of the grooves. Benefited from the fluid transport strengthening effect of the air bridge structure, the back surface of an epitaxial wafer grown by the technical scheme does not have a decomposition phenomenon, the circulation of reaction fluid on the back surface of the epitaxial wafer is further strengthened by virtue of the air bridge formed by the first step and a spray hole structure at the bottom of the grooves, and the deep height of the second step is matched so that the back fluid flowing space is enlarged, so that the heat exchange is more uniform, and the temperature consistency of the substrate is better. The design of the tray is particularly suitable for homoepitaxy, and the wavelength uniformity of the homogeneous LED epitaxial wafer growing on the tray is remarkably improved.

Owner:JIANGSU INST OF ADVANCED SEMICON CO LTD

Wide-spectrum semiconductor active device and manufacturing method thereof

ActiveCN109755363AImprove injection efficiencyIncrease the number of cyclesSemiconductor devicesElectrical conductorSemiconductor structure

The invention discloses a wide-spectrum semiconductor active device and a manufacturing method thereof; the active device comprises an epitaxial substrate and a multi-layer semiconductor structure formed on the epitaxial substrate; the multi-layer semiconductor structure comprises a first semiconductor layer, an active layer and a second semiconductor layer which are sequentially formed on the epitaxial substrate, and a first electrode and a second electrode which are electrically connected with the first semiconductor layer and the second semiconductor layer in a direct or indirect mode respectively. The manufacturing method comprises the following steps of manufacturing the epitaxial structure; exposing all or part of the first semiconductor layer, manufacturing the first electrode on the exposed first semiconductor layer, and manufacturing the second electrode on the surface of the second semiconductor layer. According to the method, the wide spectrum and multi-spectral radiation ofthe semiconductor active device can be realized.

Owner:XI AN JIAOTONG UNIV

A kind of preparation method of light-emitting element

ActiveCN104393125BEnhanced buffer rangeEasy to handleSemiconductor devicesGallium nitrideMaterials science

Owner:ANHUI SANAN OPTOELECTRONICS CO LTD

Method for manufacturing light-emitting diode chip

ActiveCN101789476BReduce defectsIncrease brightnessSemiconductor devicesPatterned substrateLength wave

Owner:EPILIGHT TECH

A kind of manufacturing method of LED epitaxial wafer

ActiveCN113097351BImprove luminous efficiencyImprove antistatic performanceSemiconductor devicesEngineeringConical cavity

Owner:XIANGNENG HUALEI OPTOELECTRONICS

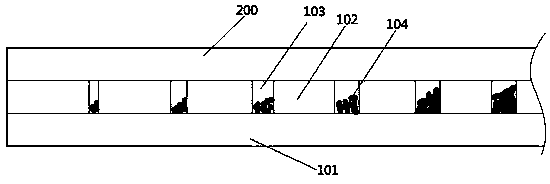

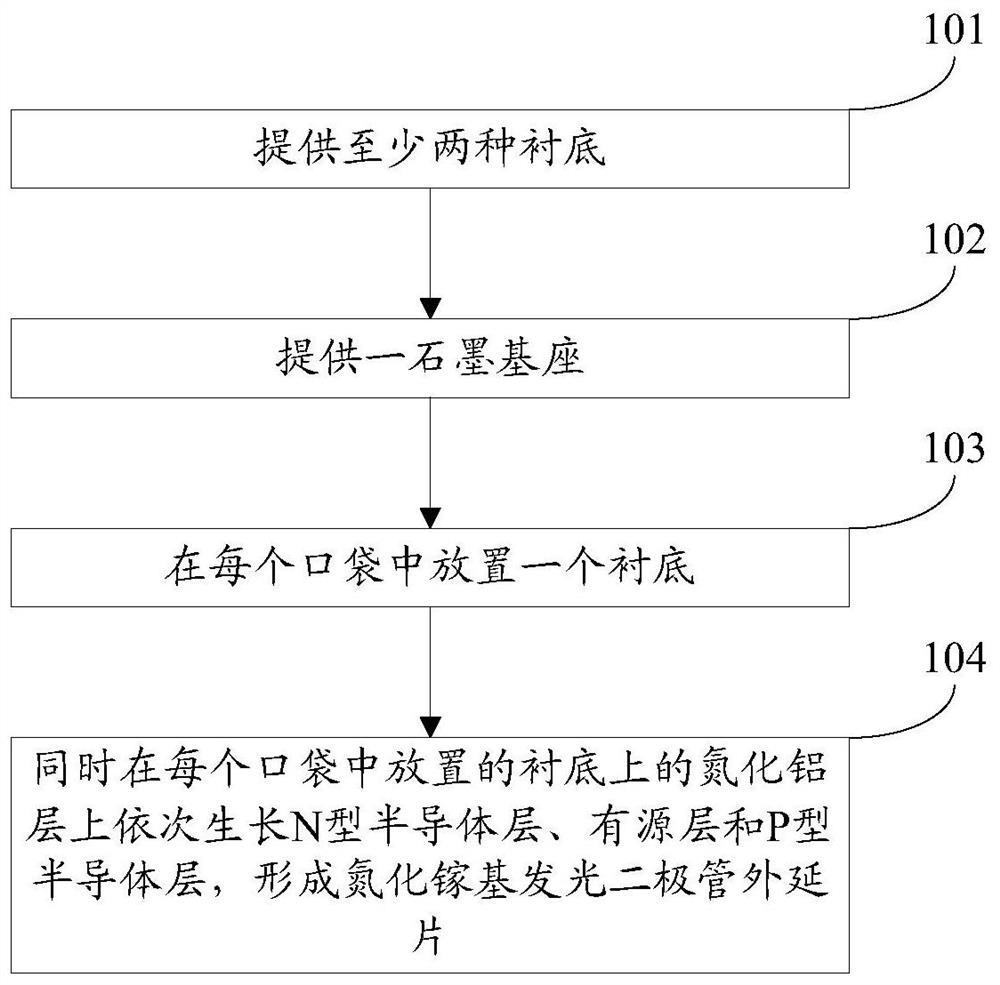

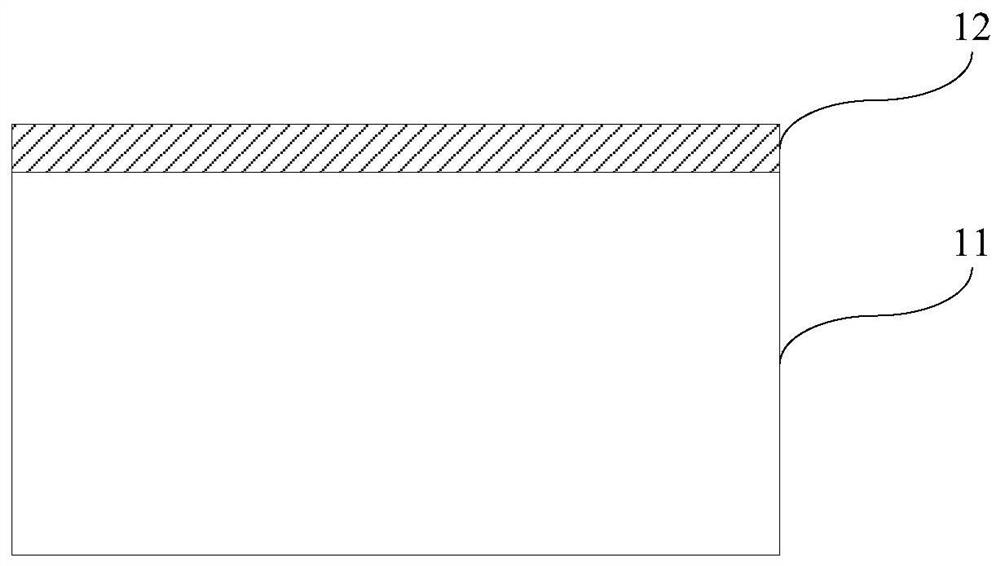

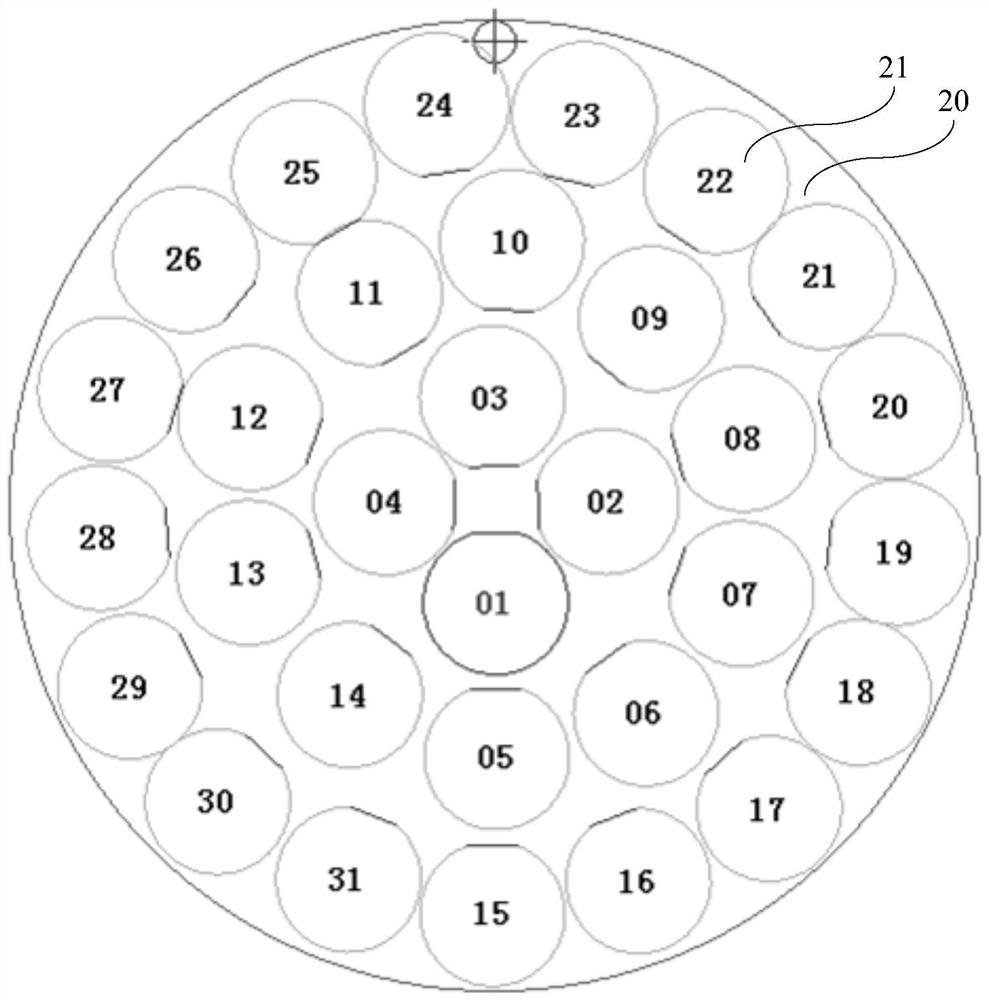

A method for growing gallium nitride-based light-emitting diode epitaxial wafers

ActiveCN109440063BIncreased warpageConsistent warpingVacuum evaporation coatingSputtering coatingCrystallographyGraphite

The invention discloses a gallium nitride-based light-emitting diode epitaxial wafer growing method, and belongs to the technical field of semiconductors. The method comprises the following steps thatat least two substrates are provided, wherein an aluminum nitride layer doped with oxygen elements is arranged on each substrate, and the doping concentrations of the oxygen elements in the aluminumnitride layers on the at least two substrates are different; a graphite base is provided, wherein a plurality of pockets are arranged on the graphite base; one substrate is placed in each pocket, wherein the doping concentrations of the oxygen elements in the aluminum nitride layers on the substrates placed in the pockets distributed on the same circle are the same, and the doping concentrations of the oxygen elements in the aluminum nitride layers on the substrates placed in the pockets distributed on at least two concentric circles are gradually reduced along the radial directions of the atleast two concentric circles from the circle centers of the at least two concentric circles; and meanwhile, an N-type semiconductor layer, an active layer and a P-type semiconductor layer are sequentially grown on the aluminum nitride layer on the substrate placed in each pocket, and thus gallium nitride-based light-emitting diode epitaxial wafers are formed. According to the method, the warping of the epitaxial wafers formed in all the pockets can be consistent.

Owner:HC SEMITEK SUZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com