GaN-based light emitting diode epitaxial wafer and preparation method thereof

A technology of light-emitting diodes and epitaxial wafers, applied in chemical instruments and methods, crystal growth, polycrystalline material growth, etc., can solve problems affecting the luminous efficiency of light-emitting diodes, affecting the luminous brightness of light-emitting diodes, serious In segregation, etc., to improve the interface Effects of crystal quality, crystal quality improvement, and defect reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

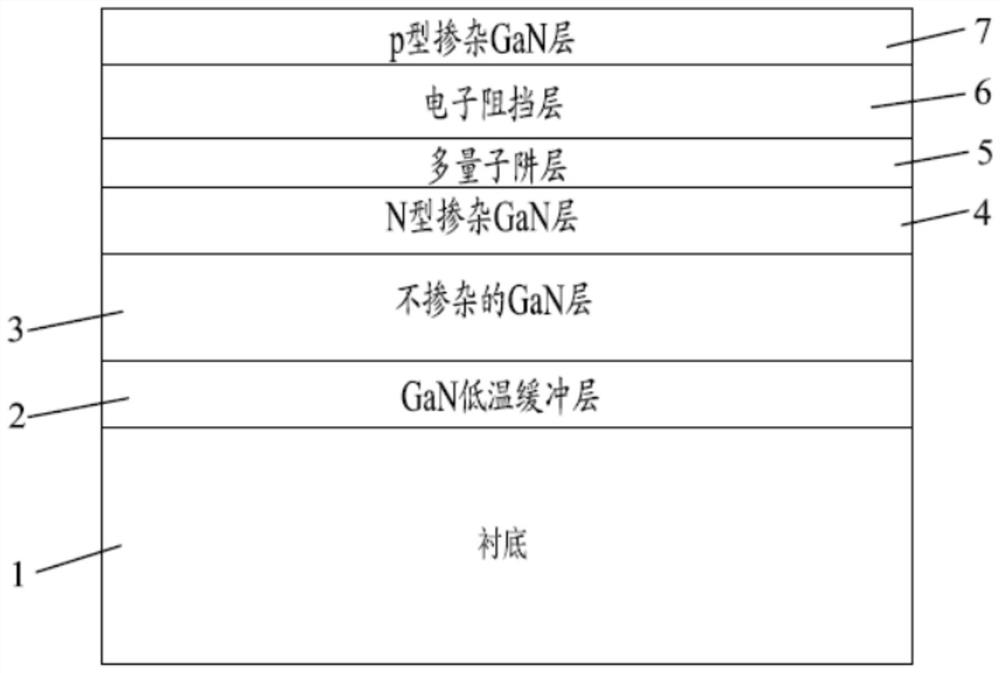

[0036] see Figure 1-Figure 3 , shows the GaN-based light-emitting diode epitaxial wafer in the first embodiment of the present invention, including a substrate 1, and a GaN low-temperature buffer layer 2 epitaxially grown on the substrate 1 in turn, an undoped GaN layer 3, and an N-type doped GaN layer. Hetero GaN layer 4 , multiple quantum well layer 5 , electron blocking layer 6 and p-type doped GaN layer 7 .

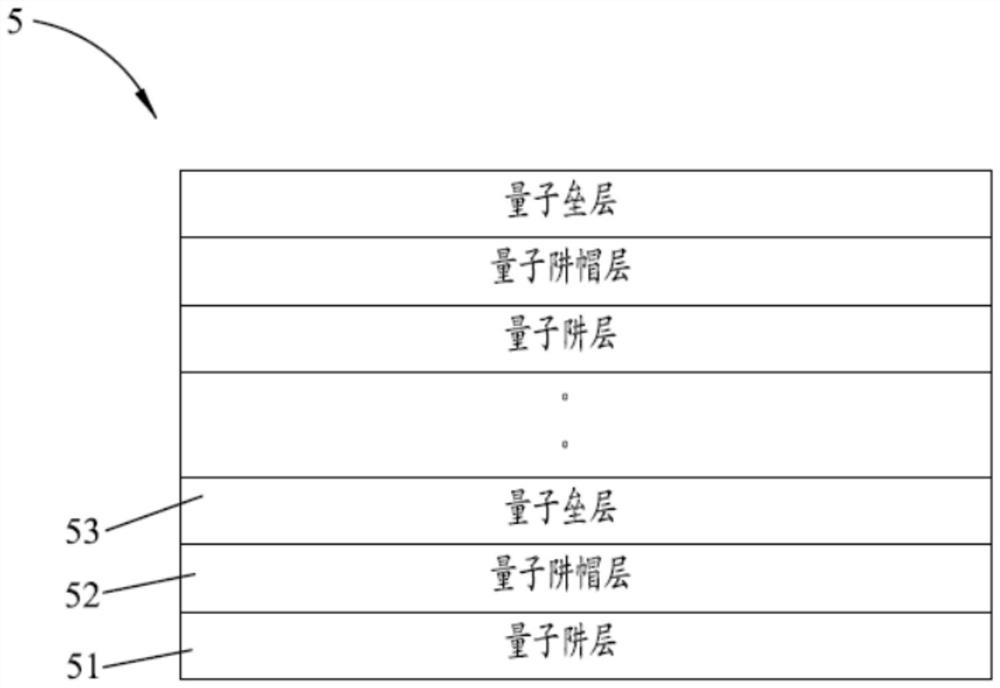

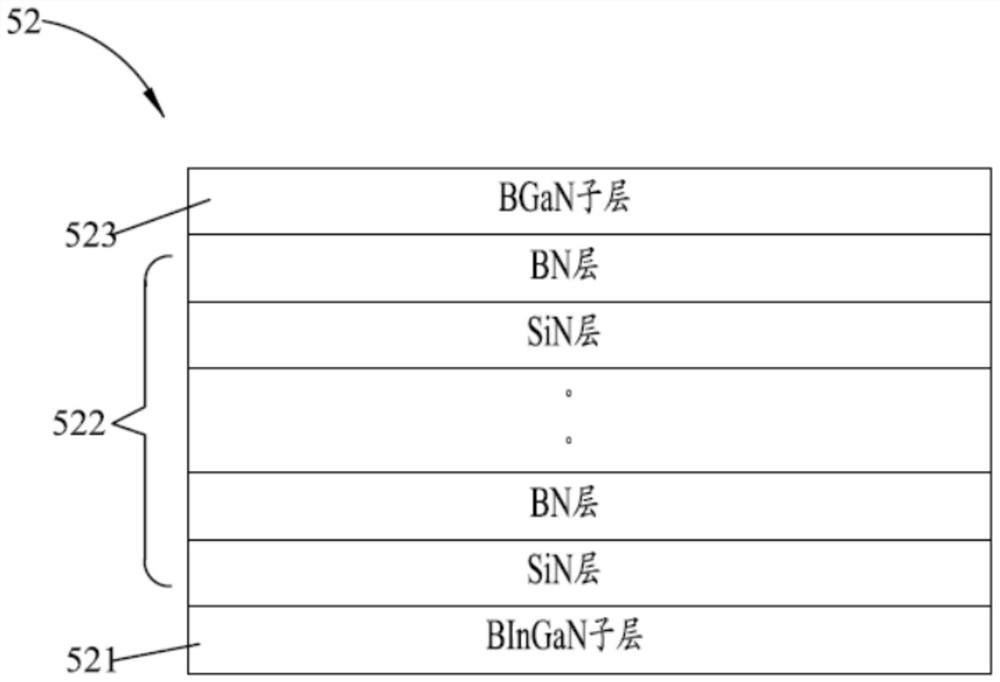

[0037] In this embodiment, as figure 2 As shown, the multiple quantum well layer 5 is a periodic structure in which quantum well layers 51 , quantum well cap layers 52 and quantum barrier layers 53 are alternately stacked. The quantum well layer 51 may be an InGaN quantum well layer, and the quantum barrier layer 53 may be a GaN quantum barrier layer. The quantum well cap layer 52 is inserted between the quantum well layer 51 and the quantum barrier layer 53, and is mainly used for the purpose of protecting the In composition of the quantum well and reducing the l...

Embodiment 2

[0058] The second embodiment of the present invention also provides a GaN-based light-emitting diode epitaxial wafer and a preparation method thereof. The GaN-based light-emitting diode epitaxial wafer and its preparation method in this embodiment are the same as the GaN-based light-emitting diode epitaxial wafer and its preparation in the first embodiment. The methods differ in that:

[0059] The BInGaN sublayer still does not pass H during the growth 2 , the H introduced during the growth of the composite sublayer 2 The amount is 2L, and the H introduced during the growth of the BGaN sublayer 2 The volume is 8L.

Embodiment 3

[0061] The third embodiment of the present invention also provides a GaN-based light-emitting diode epitaxial wafer and a preparation method thereof. The GaN-based light-emitting diode epitaxial wafer and its preparation method in this embodiment are the same as the GaN-based light-emitting diode epitaxial wafer and its preparation in the first embodiment. The methods differ in that:

[0062] The BInGaN sublayer still does not pass H during the growth 2 , the H introduced during the growth of the composite sublayer 2 The amount is 3L, and the H introduced during the growth of the BGaN sublayer 2 The volume is 10L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com