Pattern-segmented sapphire substrate used for AlGaInN material system film growth

A sapphire substrate and thin film growth technology, which is applied in semiconductor devices, stone processing equipment, fine working devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

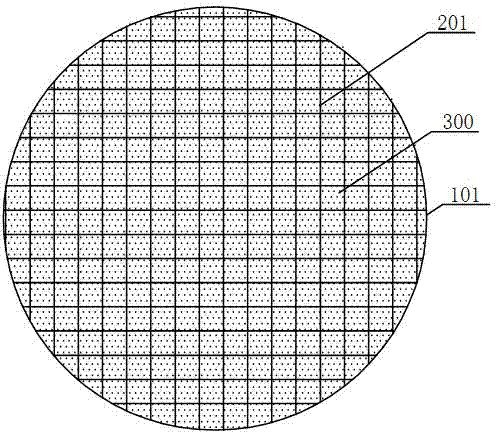

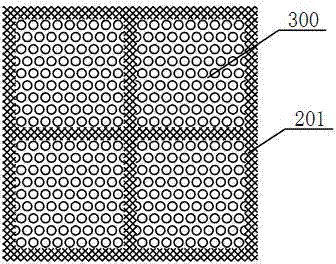

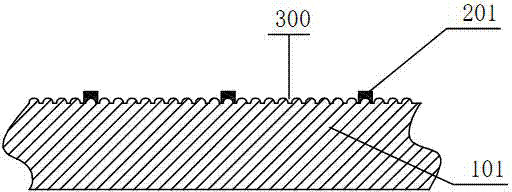

[0040] Such as Figure 1 to Figure 4 As shown, a split pattern sapphire substrate for AlGaInN material system film growth includes: a sapphire substrate body 100, a pattern split groove 200 is processed on the upper surface of the sapphire substrate body 100, and the pattern split groove 200 will The upper surface of the sapphire substrate body 100 is divided into a plurality of independent and non-connected repeated pattern units 300 , and the AlGaInN thin film 400 is grown on the pattern units 300 .

[0041] In this embodiment, the sapphire substrate body 100 adopts a patterned sapphire substrate body 101 , and the pattern dividing groove 200 adopts a second medium type pattern dividing groove 201 .

[0042] Wherein: the second dielectric pattern dividing groove 201 can be obtained by first depositing a dielectric film on the sapphire substrate, and then using photolithography technology, the width of the second dielectric pattern dividing groove 201 is 10 microns, and the h...

Embodiment 2

[0047] The structure of embodiment 2 is basically the same as embodiment 1, the difference is: as Figure 5 to Figure 8 As shown, the sapphire substrate body 100 adopts a planar sapphire substrate body 102 .

[0048] The width of the second dielectric pattern dividing groove 201 is 20 microns, and the height is 0.1 microns.

[0049] The graphics unit 300 is a rectangle with a size of 2mm×3mm.

Embodiment 3

[0051] The structure of embodiment 3 is basically the same as embodiment 1, the difference is: as Figure 9 to Figure 12 As shown, the sapphire substrate body 100 adopts a planar sapphire substrate body 102 , and the pattern dividing groove 200 adopts a groove type pattern dividing groove 202 .

[0052] The trench-type pattern dividing groove 202 can be obtained by dry or wet etching of the sapphire substrate using photolithography technology. The width of the groove-type pattern dividing groove 202 is 20 microns, and the depth is 20 microns.

[0053] The graphics unit 300 is a square with a size of 2mm×2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com