Patents

Literature

47results about How to "Reduce the amount of bending deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

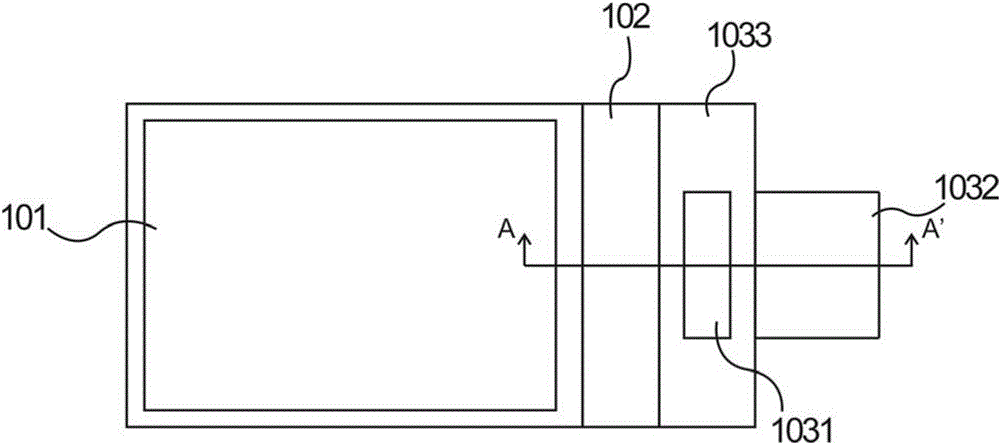

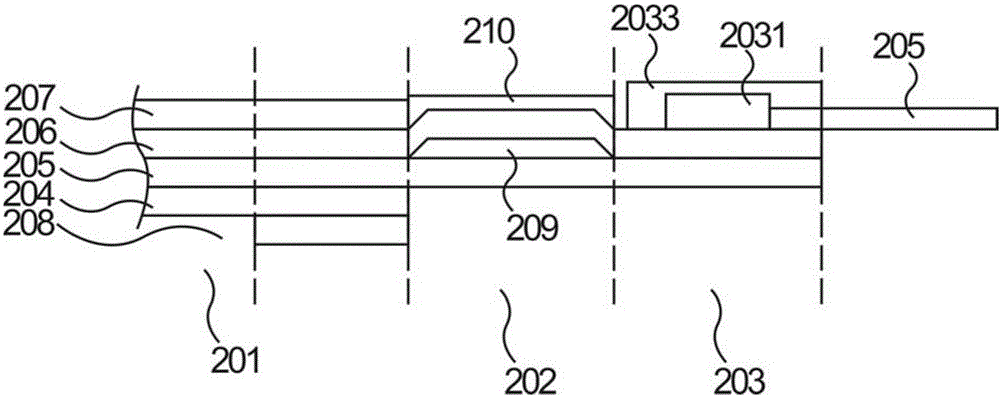

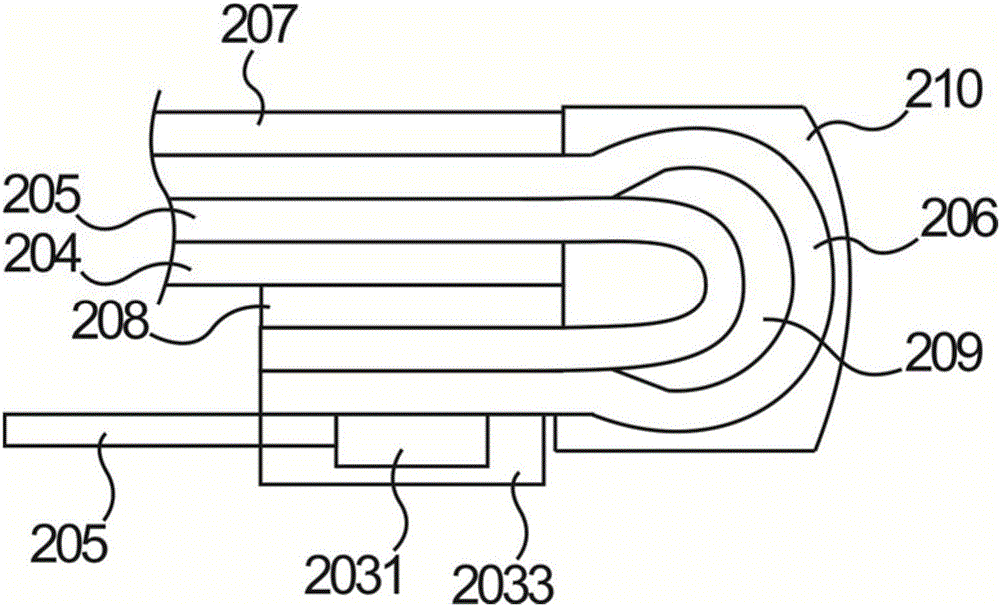

OLED display panel and display device thereof

ActiveCN106847871APlay a protective effectImprove toughnessSolid-state devicesSemiconductor/solid-state device manufacturingFlexible circuitsDisplay device

The invention provides an OLED display panel and a display device thereof. The display panel is defined as a display area, a bending area and a driving binding area, wherein the driving binding area is provided with a driving chip, a flexible circuit board for realizing the connection between the driving chip and a mainboard, and a reinforcing plate adhered on a surface of a substrate wiring layer located in the driving binding area and covering the surface of the substrate wiring layer of the driving binding layer; a cavity is formed in the bottom of the reinforcing plate, and the driving chip is arranged in the cavity. The OLED display panel provided by the invention has the advantages that the reinforcing plate is arranged at the driving area of the OLED display panel so as to increase the tenacity of part of a flexible substrate, the bending is convenient, the bending deformation of the flexible substrate is reduced, the attachment precision is improved, and the protection effect is provided for the driving chip.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Welding method for carriage side plate of self-dumper

ActiveCN103008901ASmall amount of deformationReduce the amount of bending deformationWelding/cutting auxillary devicesAuxillary welding devicesSlagWeld bead

The invention discloses a welding method for a carriage side plate of a self-dumper, which relates to the technical field of welding. The method comprises the following steps of: welding a carriage side plate; welding a weld bead on the inner plate surface of the welded carriage side plate; performing slag removal and milling on the carriage side plate for which the weld bead on the inner plate surface is welded; overturning the carriage side plate for which the weld bead on the inner plate surface is welded, and transferring onto a platform on a fourth working station; applying pressures to the two ends of the carriage side plate by using a bending device and welding a weld bead on an outer plate surface; performing slag removal and milling on the carriage side plate for which the weld bead on the outer plate surface is welded to finish welding of the carriage side plate. Compared with the prior art, the method has the advantage that the problem of large welding bending deflection of the carriage side plate can be solved.

Owner:SINOTRUK LIUZHOU YUNLI SPECIAL PURPOSE VEHICLES

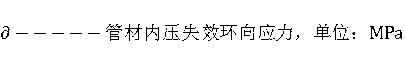

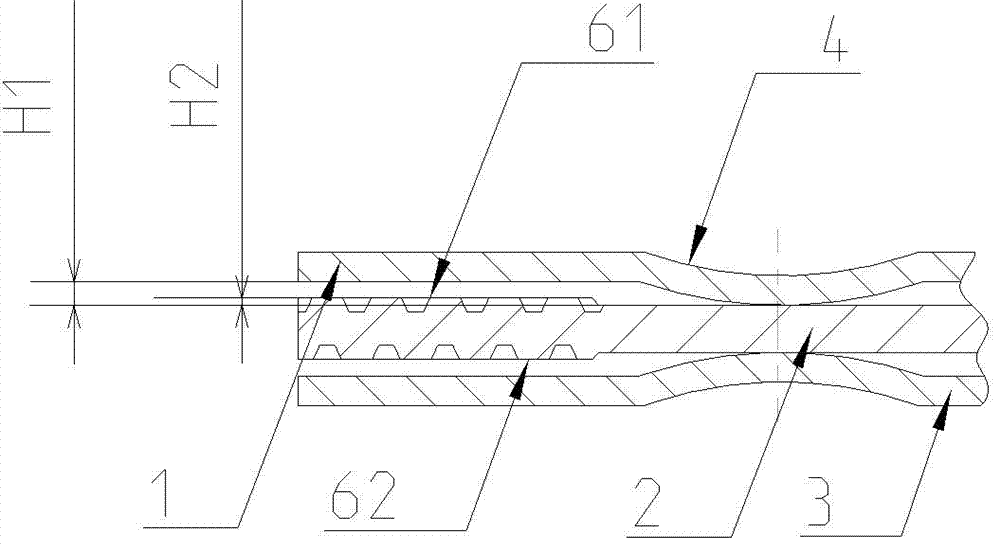

Anti-static flame-retardant steel skeleton fiber reinforced resin pipe and preparation technology thereof

ActiveCN103104754AGood mechanical propertiesReduce dosageRigid pipesTubular articlesEpoxyFine structure

The invention belongs to the technical field of mine conveying pipe bodies, and discloses an anti-static flame-retardant steel skeleton fiber reinforced resin pipe and a preparation technology of the anti-static flame-retardant steel skeleton fiber reinforced resin pipe. The anti-static flame-retardant steel skeleton fiber reinforced resin pipe is technically characterized in that the anti-static flame-retardant steel skeleton fiber reinforced resin pipe comprises a pipe body which comprises a seepage-proof flame-retardant conductive inner lining layer and a pressure-bearing flame-retardant conductive structural layer from inside to outside, wherein the seepage-proof flame-retardant conductive inner lining layer comprises glass fiber solidified on an inner base body, and the pressure-bearing flame-retardant conductive structural layer comprises an outer base body which is synchronously provided with a zinc-coated steel wire and glass fiber direct roving in a winding mode, wherein epoxy resin is coated on the outer surface of the zinc-coated steel wire. According to the anti-static flame-retardant steel skeleton fiber reinforced resin pipe, matching among all layers of fiber is reasonable, mechanical property is strengthened, meanwhile, weight of the tube body is lightened, multi-wall carbon nanotubes and nanometer aluminium hydroxide are filled, fine structures of all layers are changed, meanwhile, bending resistant strength and shock resistance capability are enhanced, wear-resisting property and conductivity are largely improved, service life is prolonged, and cost is reduced.

Owner:河北拓安管业有限公司

Welding deformation control method of large thick-wall box body component

ActiveCN106001866AUniform welding gapImprove assembly accuracyArc welding apparatusEngineeringThick wall

The invention relates to a welding deformation control method of a large thick-wall box body component. The method comprises following five steps: firstly, before welding, an assembly reference platform is prefabricated on the welding side of a box body plate, and the influence of warping or the uneven wall thickness of the box body plate on the welding gap is removed; secondly, before welding, a welding groove is designed to be of a double-angle V-shaped structure, and the welding line metal filling amount and the welding heat input amount in the subsequent welding process can be reduced; thirdly, during pre-welding assembly, a flexible welding deformation control tool is prefabricated in a box body; fourthly, in the welding process, welding lines on the two sides of a transverse plate of the same box body are subject to symmetric welding application at the same time; and fifthly, in the welding process, according to the transverse shrinkage amount of the welding lines of the box body, the transverse elongation amount of the flexible welding deformation control tool is adjusted to control the transverse opening size of an inner cavity of the box body component, and further, the bending deformation amount of a box body vertical plate is controlled. Finally, the welding deformation control method can effectively control the welding deformation amount of the large thick-wall box body component.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

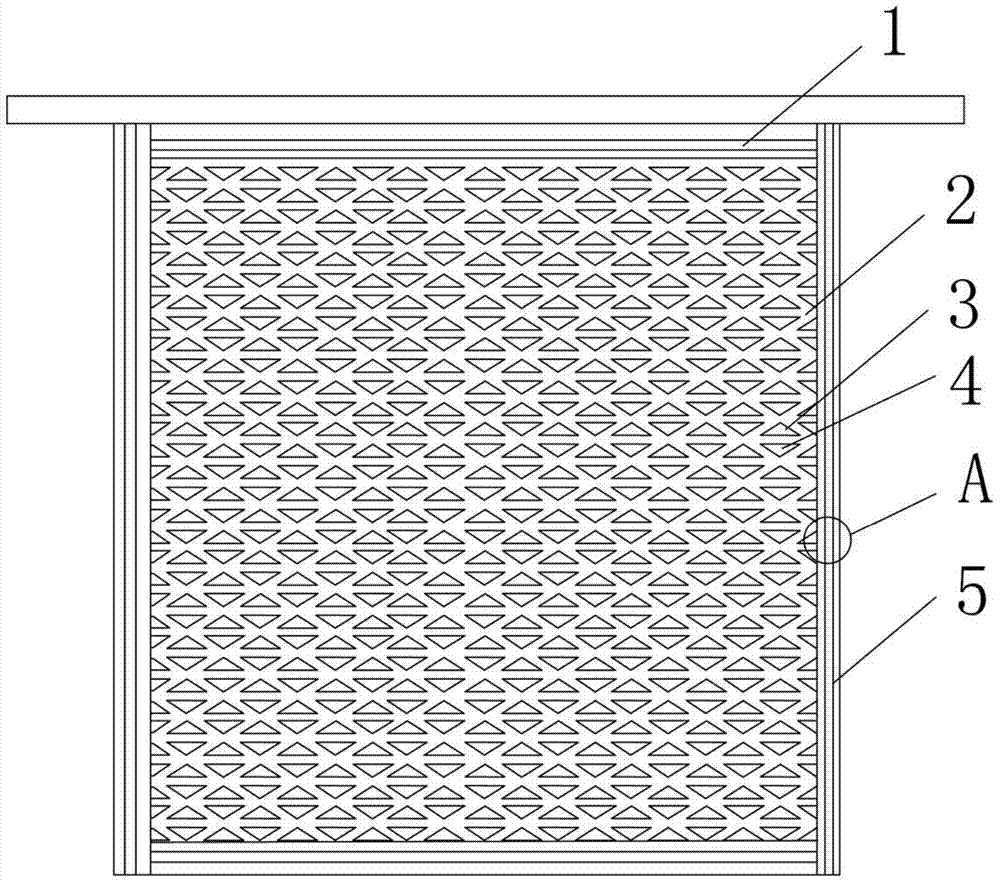

Embossed flattened rigidity-reinforced electrolytic electrode plate and preparation method thereof

ActiveCN104328459AIncreased flexural section modulusImprove rigidityElectrodesElectrolysisEngineering

The invention relates to an embossed flattened rigidity-reinforced electrolytic electrode plate and a preparation method thereof, the electrolytic electrode plate comprises an electrode plate, an embossed groove is arranged on the surface of the electrode plate, and forms a concave convex pattern to improve the electrode plate surface strength and bending resistant ability. The embossed groove is composed of a plurality of transverse embossed grooves and oblique embossed grooves to form a structure shaped like a Chinese character mi, and raised structure composed of an upper triangular convex block and a lower triangular convex block is formed on the electrode plate. The beneficial effects of the embossed flattened rigidity-reinforced electrolytic electrode plate are that: aiming at the electrode plates of different types, reinforced stripes with different specifications and different shapes are designed, through embossing and shaping of the reinforced stripes, the electrode plate rigidity is greatly enhanced, the internal stress is eliminated, the objective of improving the electrode plate surface flatness, reducing the bending deformation, and enhancing the electrode plate bending resistant ability can be achieved, anode and cathode short circuit phenomenon in the process of electrolysis due to deformation can be avoided, the power consumption in the electrolysis or plating process can be effectively reduced, at the same time, cathode product quality is improved, the labor intensity is reduced, and production efficiency is improved.

Owner:HANGZHOU EMPEROR LOSSEN TECH

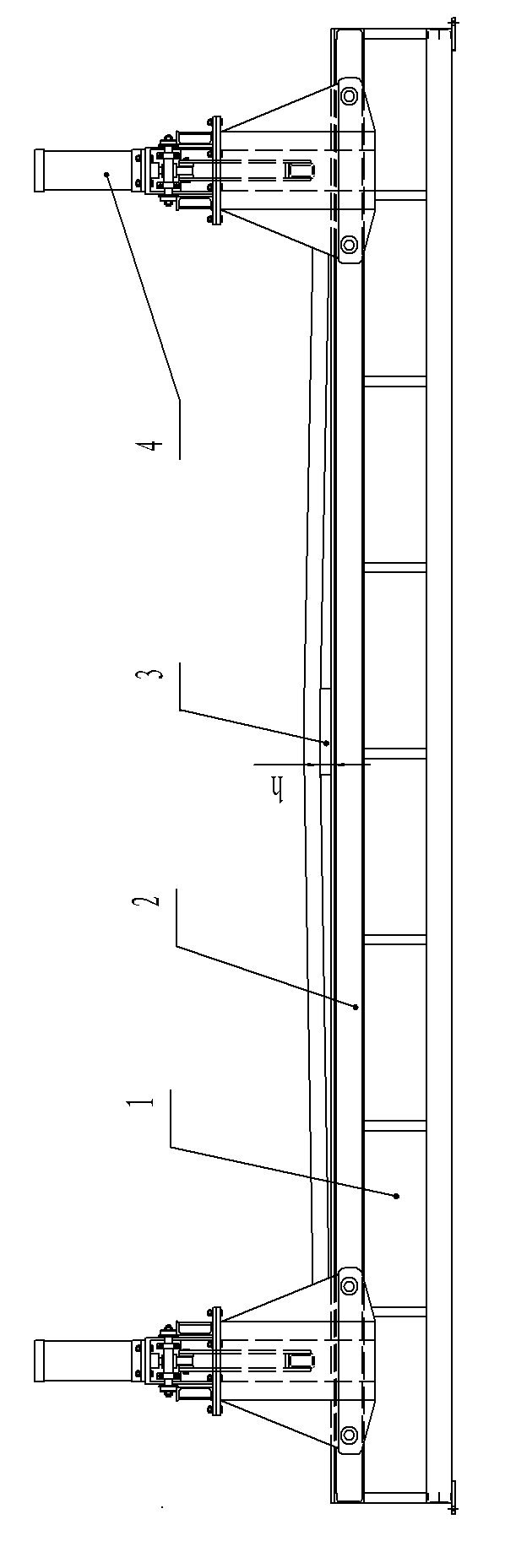

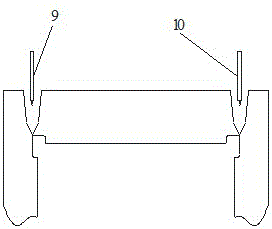

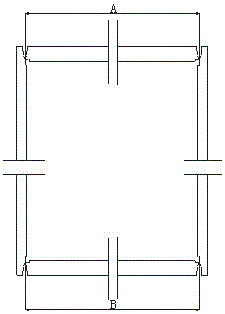

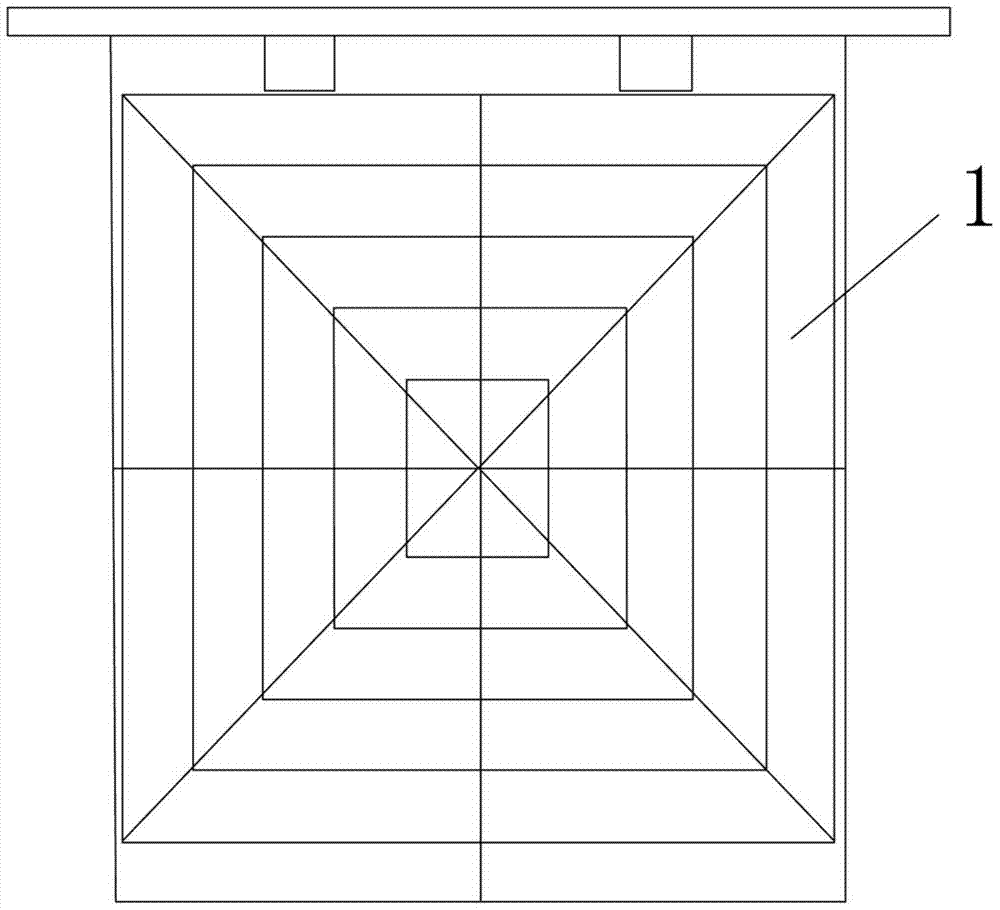

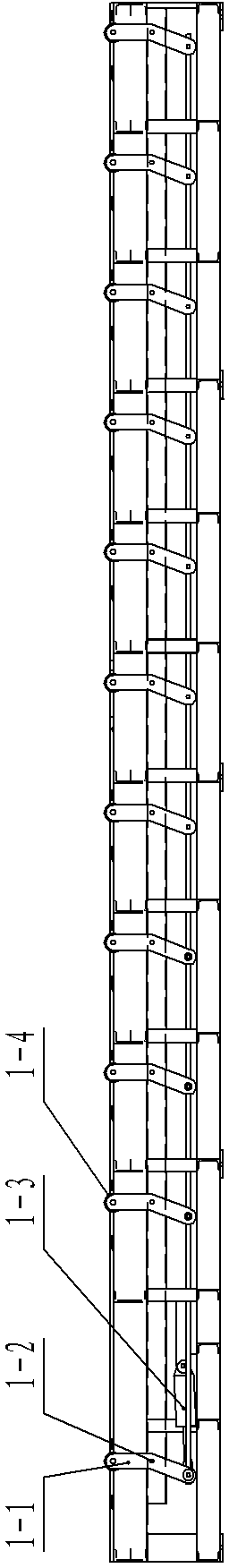

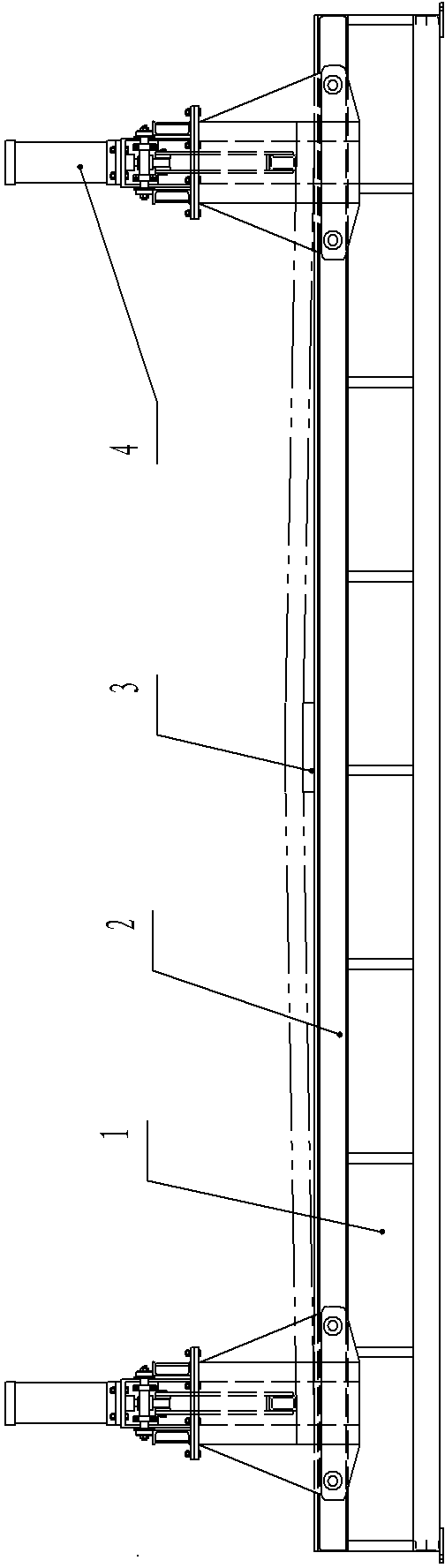

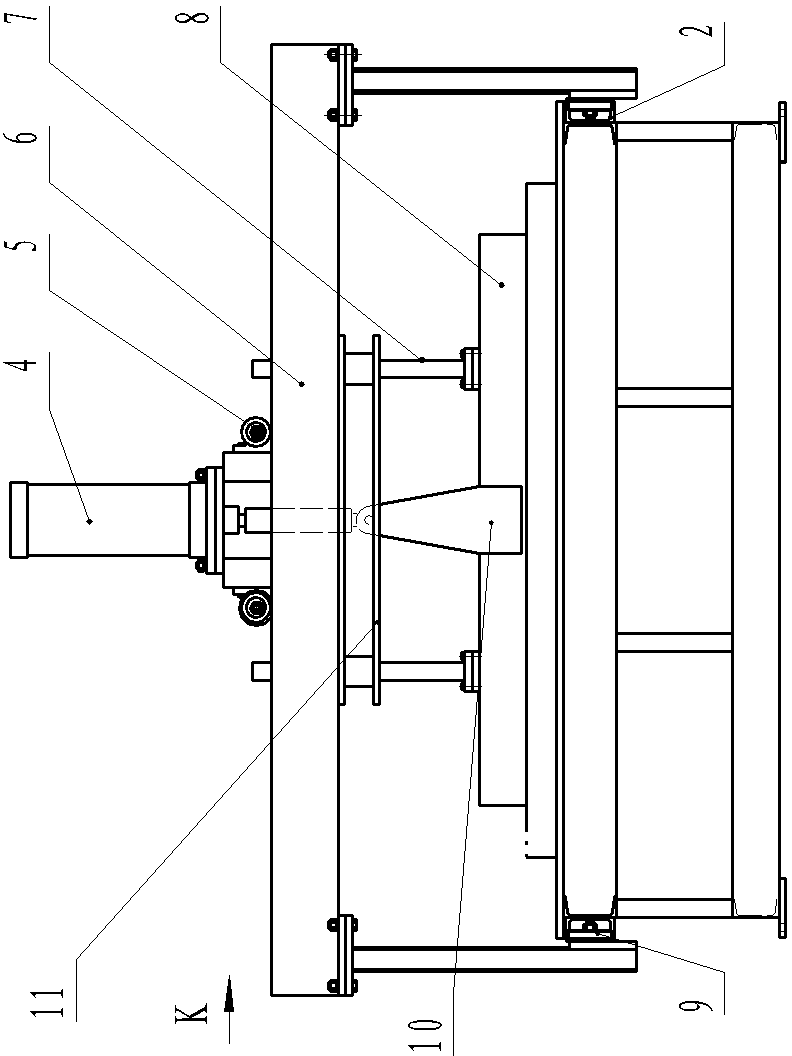

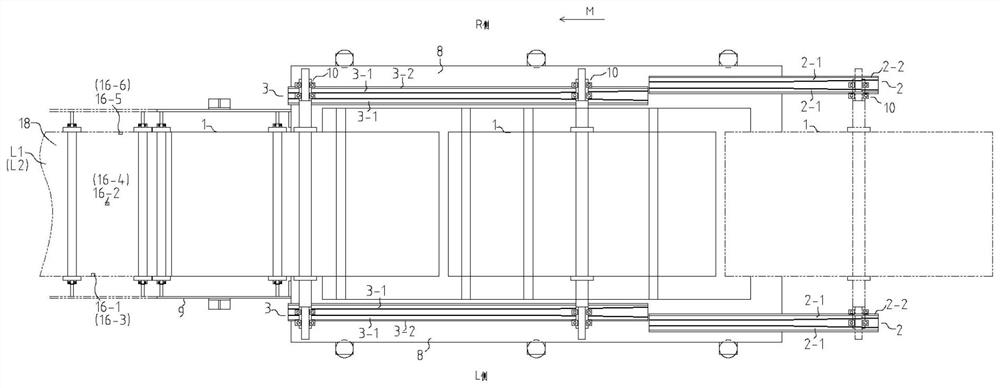

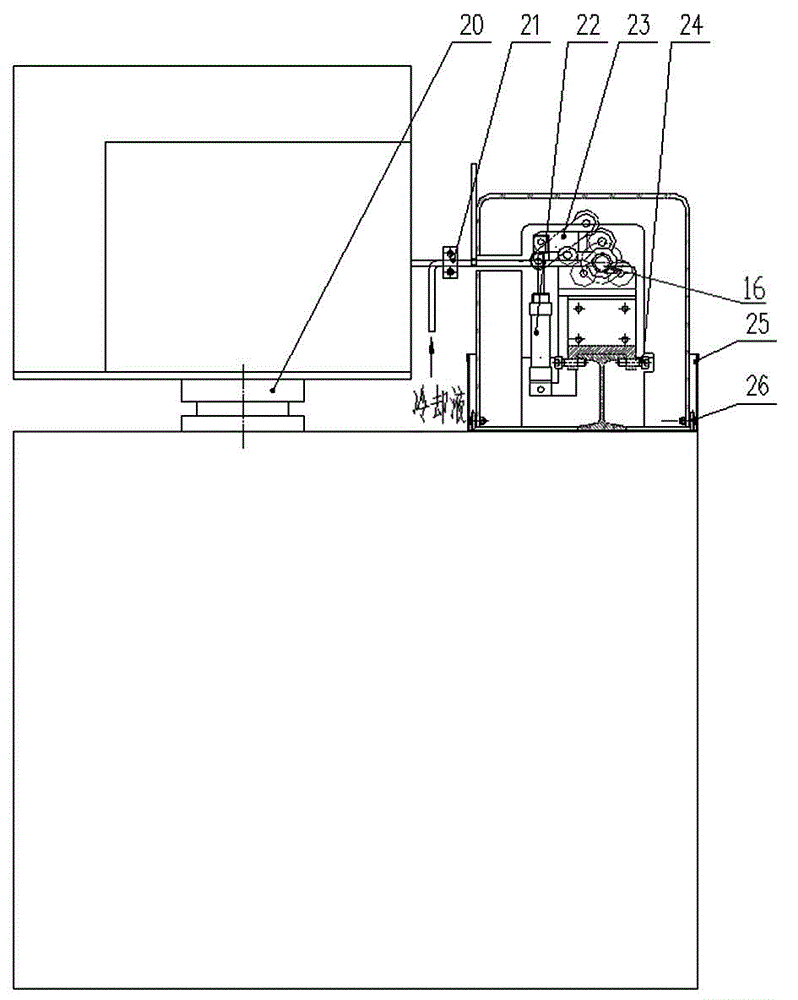

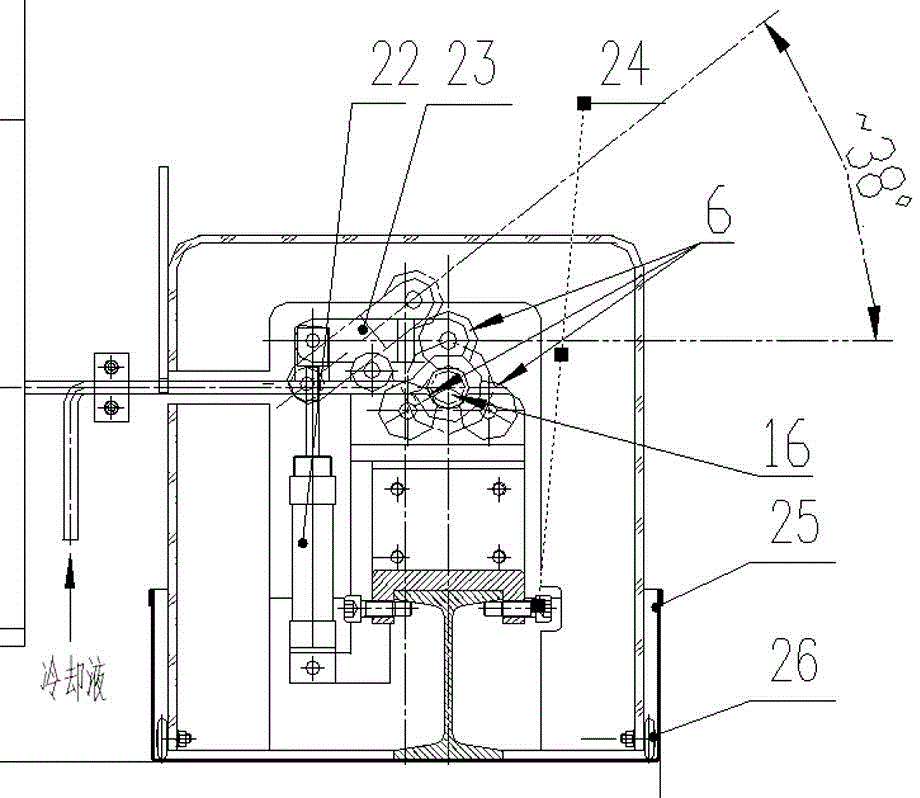

Compressing device for carriage side plate of self-dumper

InactiveCN103008957AReduce the amount of bending deformationReduce welding distortionWelding/cutting auxillary devicesAuxillary welding devicesWeld seamEngineering

The invention discloses a compressing device for a carriage side plate of a self-dumper, which relates to the technical field of welding. The compressing device comprises a frame which is provided with a platform, wherein both sides of the frame are provided with tracks; a plurality of gantries are erected on the tracks through walking wheels; and compressing air cylinders are arranged above the gantries, are arranged on slide rails on the tops of the gantries through rollers at the bottoms of the compressing air cylinders, and are connected with pressure blocks ascending and descending on guide pillars. Compared with the prior art, the compressing device has the advantages that a welding counter-deflection is pre-applied to the carriage side plate, the two ends of the carriage side plate are used for welding a welding seam in a compression state, the welding deflection of the carriage side plate in a welding process counteracts with the pre-applied anti-deflection, and the welding bending deflections of parts are small, so that the welding deflection of the carriage side plate along a thickness direction is reduced.

Owner:SINOTRUK LIUZHOU YUNLI SPECIAL PURPOSE VEHICLES

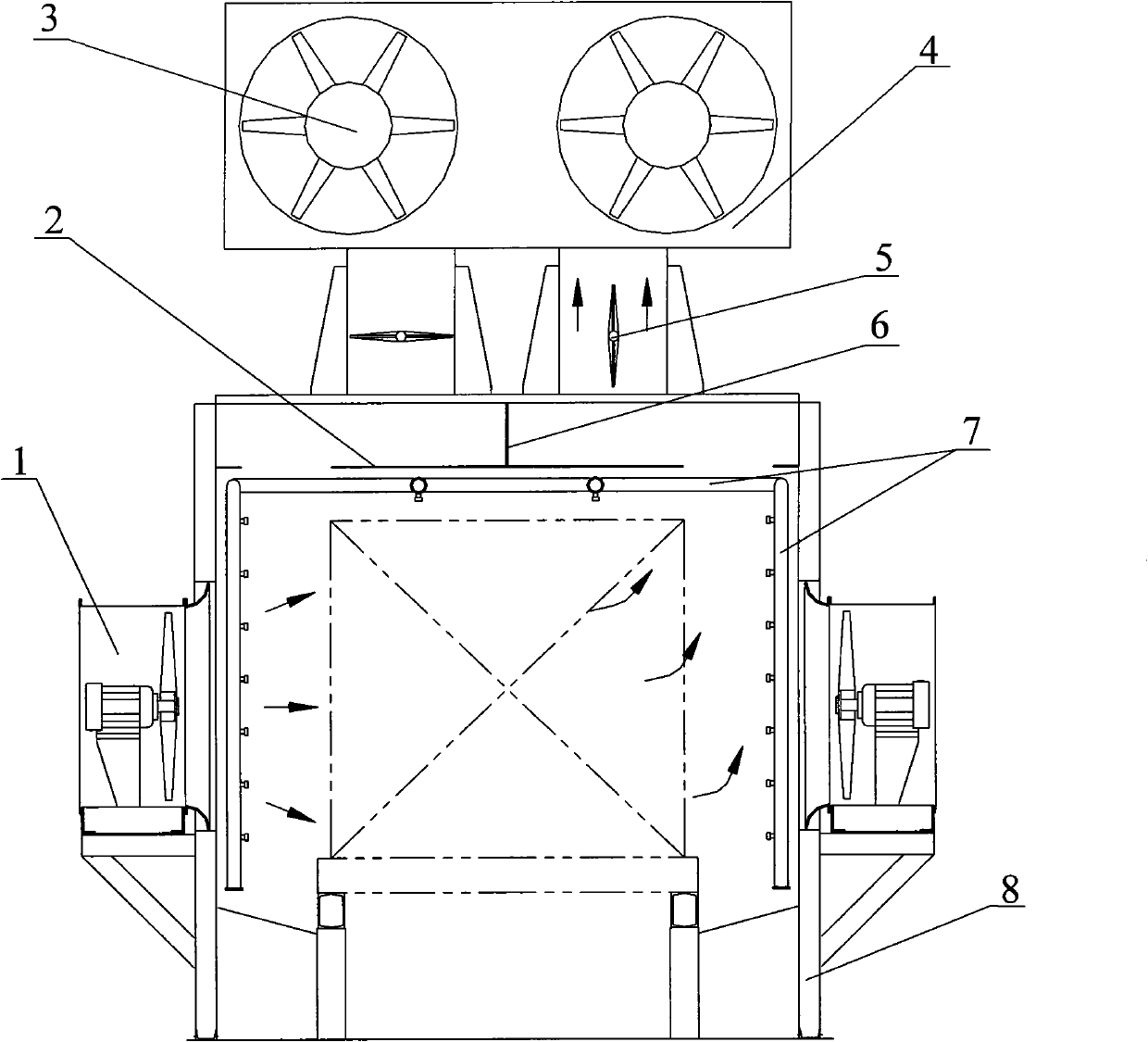

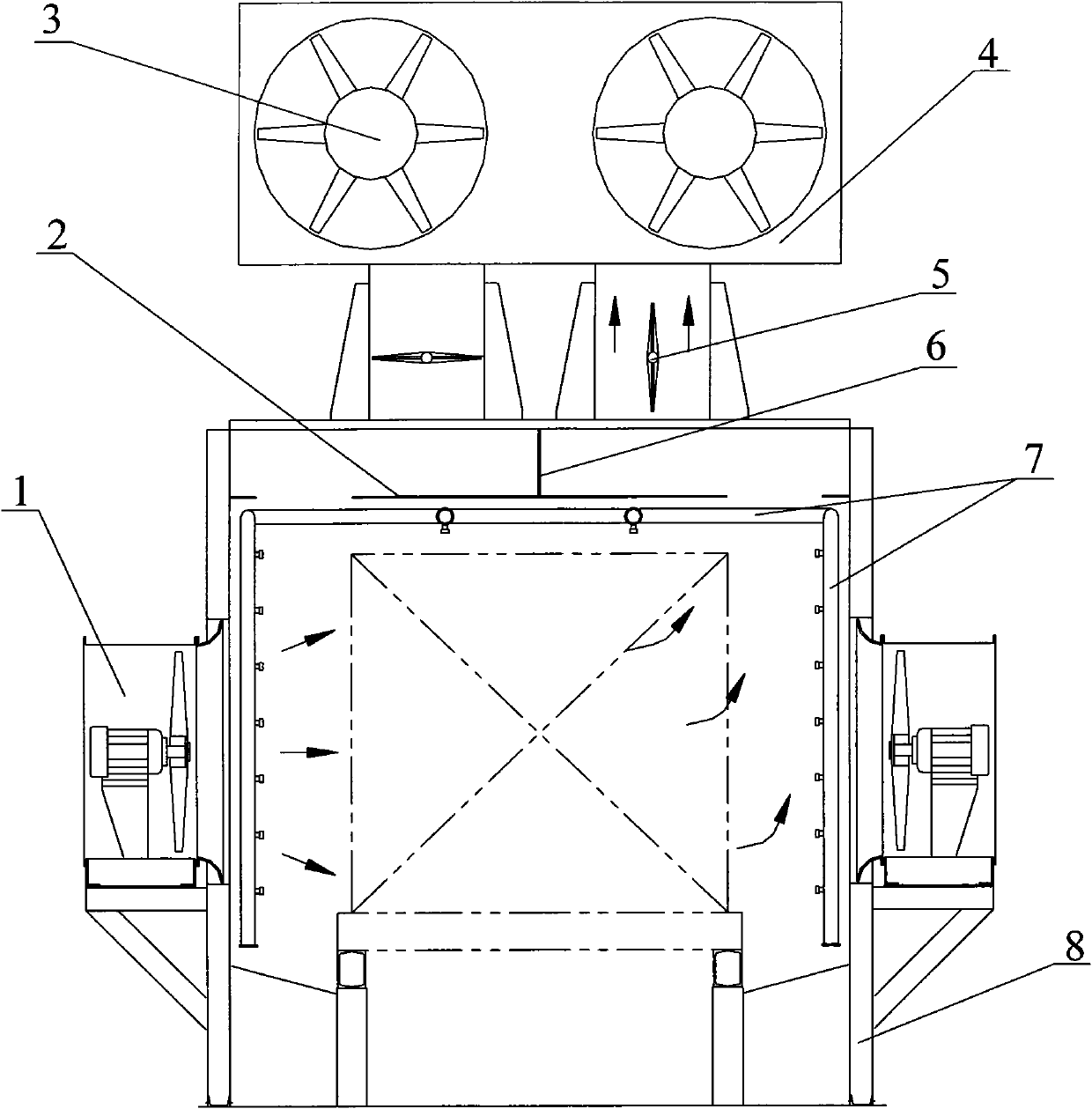

Equipment for quickly cooling aluminum material

The invention relates to equipment for quickly cooling an aluminum material. Cooling fans are arranged on both side walls of a cooling chamber; an air deflector is arranged at the upper part of the cooling chamber; air vents are arranged at two sides of the air deflector; a vertical clapboard is arranged between the air deflector and the top wall of the cooling chamber and placed in the middle; two air outlets are arranged on the top wall of the cooling chamber and each air outlet is connected with a flue which is internally provided with a plate tipping mechanism; a gas collection tank is arranged above the two flues and communicated with the two flues; two smoke tubes are drawn out from the gas collection tank and a tube smoke venting fan is arranged on each smoke tube; and water mist systems are also arranged at two sides of the cooling chamber and below the air deflector. During the use, the fan ensures that the strong wind is blown from left to right along an air flue so as to cool the work pieces; after a certain time, the airflow is blown from right to left along the air flue; and the circulatory frequent reversion ensures that the large-quantity strong wind flows sufficiently and circularly, ensures that the cooled wind are distributed more uniformly in a windrow area of the cooling chamber, and improves the quality of the aluminum material.

Owner:SUZHOU LONGRAY THERMAL TECH

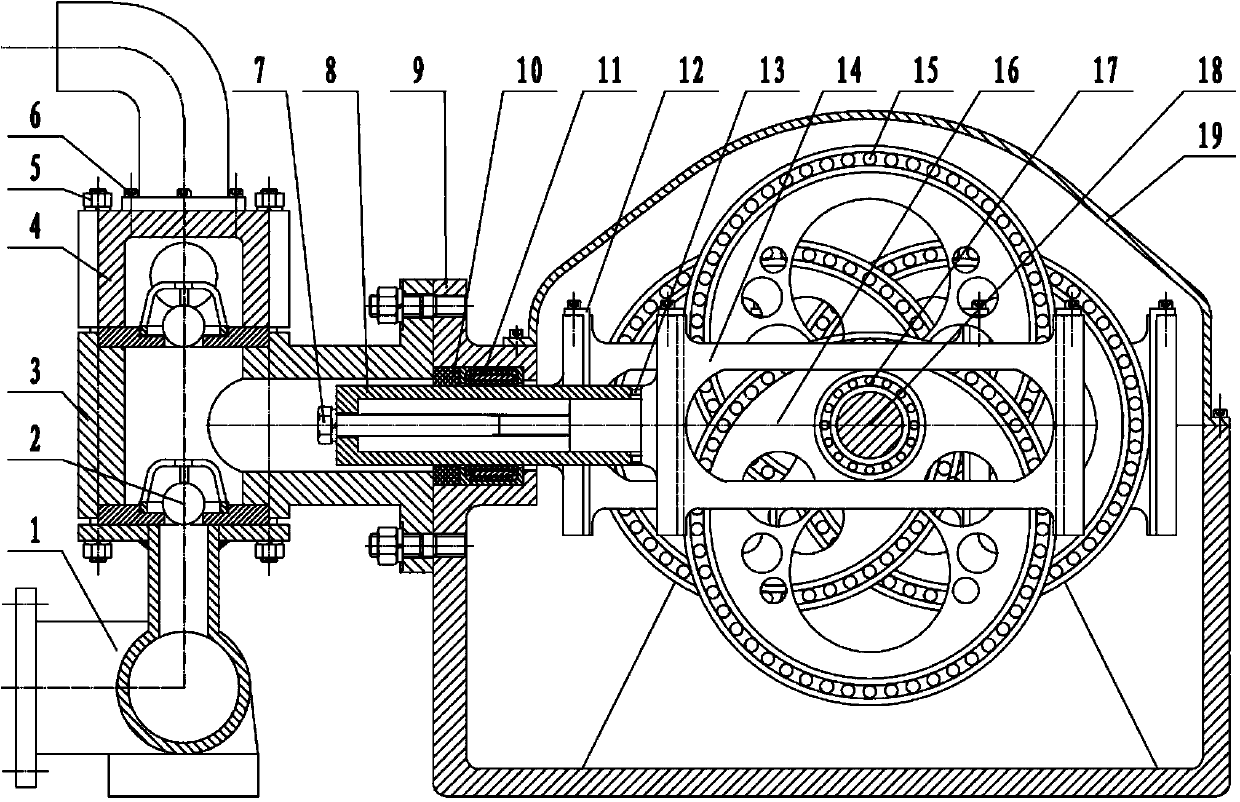

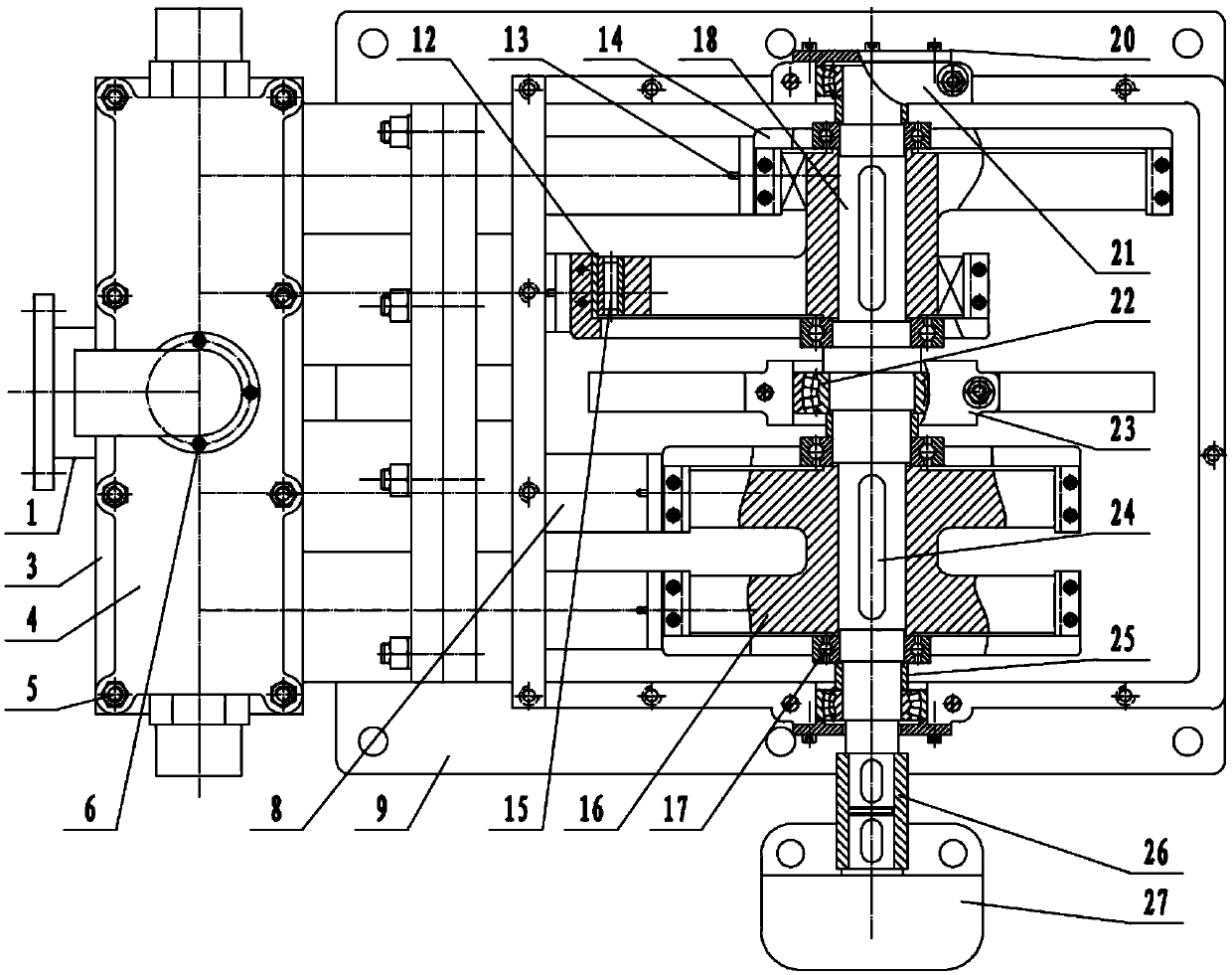

Reciprocating four-cylinder slurry pump

InactiveCN104196693AReduce lateral supportReduce surface frictionPositive displacement pump componentsPumpsReciprocating motionEngineering

The invention provides a reciprocating four-cylinder slurry pump. The reciprocating four-cylinder slurry pump comprises four single-cylinder pump head systems, a flat-bottom driven part eccentric wheel type disk cam plunger driving system and an eccentric wheel type cam supporting and transmission system. Each single-cylinder pump head system is provided with a slurry suction channel, a slurry discharge channel, two steel ball one-way valves and a plunger cavity. Four flat-bottom driven part eccentric wheel type disk cam mechanisms are adopted for the plunger driving system. Plungers are fixedly connected with flat-bottom driven parts. The flat-bottom driven parts directly drive the plungers to conduct reciprocating motion. Four eccentric wheel type cams are evenly mounted on a cam supporting shaft in the eccentric wheel type cam supporting and transmission system at the interval of 90 degrees. The reciprocating four-cylinder slurry pump is compact in structure, light in weight, low in vibration and noise, convenient to maintain, high in mechanical efficiency and reliability and small in flow rate and pressure pulsation, and the cam supporting shaft is small in stress.

Owner:JIANGSU UNIV

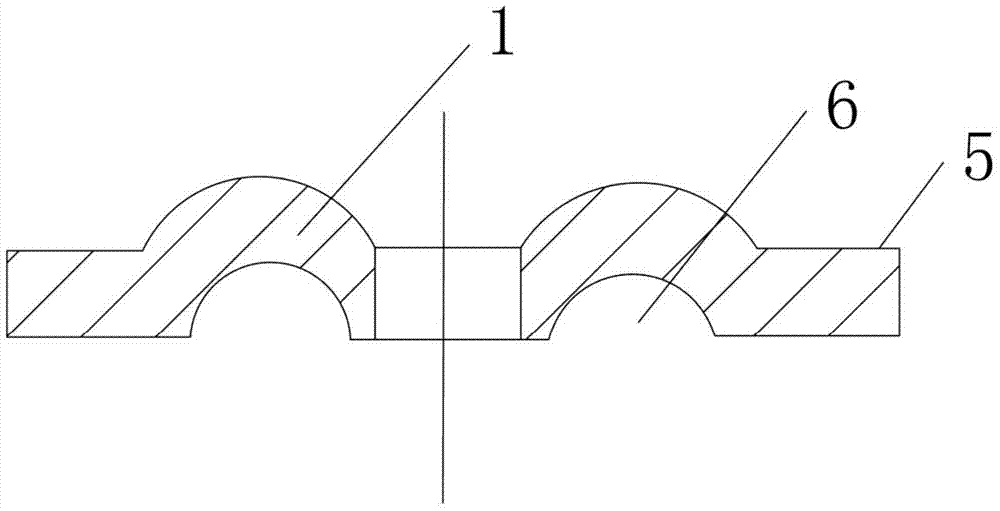

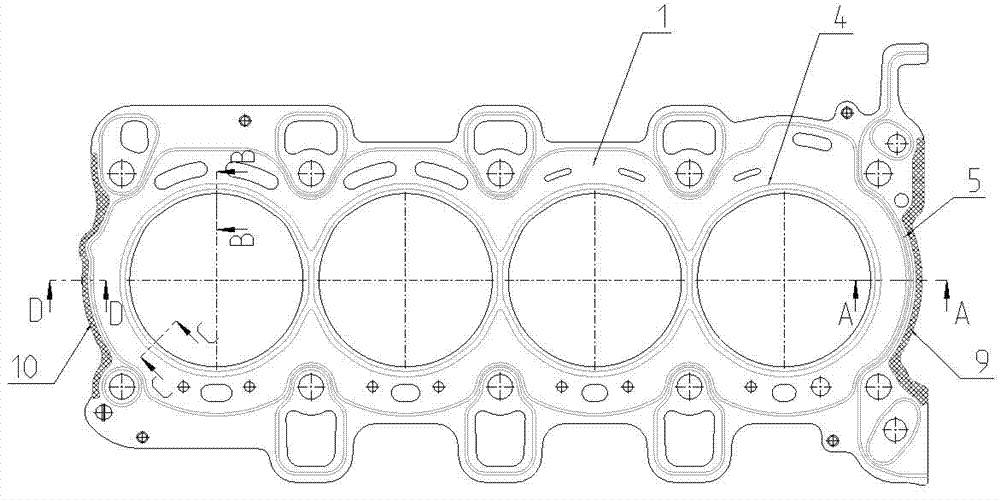

Three-layer cylinder gasket for engine

InactiveCN102817742AUniform and continuous contact pressureReduce the amount of bending deformationSealing arrangements for enginesMachines/enginesContact pressureEngineering

The invention relates to a cylinder gasket of an engine. The three-layer cylinder gasket comprises an upper layer metal plate, a support layer metal plate and a lower layer metal plate; circular cylinder hole sealing ribs are arranged at the circumference of the upper layer metal plate and the lower layer metal plate; the upper surface and lower surface of the support layer metal plate form a cylinder hole retainer at the circumference of a cylinder hole; and the front end area and rear end area of the support layer metal plate form a front end retainer and a rear end retainer respectively. The height of the cylinder hole retainer is changeable, so the contact pressure between the sealing ribs of the cylinder gasket and a cylinder cover as well as a cylinder body is uniform; and the front end retainer and the rear end retainer can counteract a part of the upward bending deformation of the cylinder cover resulted from the explosion of pressure, namely, the longitudinal bending deformation of the cylinder cover can be reduced, thus the sealing reliability of the cylinder gasket and the flexible life of the cylinder cover can be improved conveniently.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

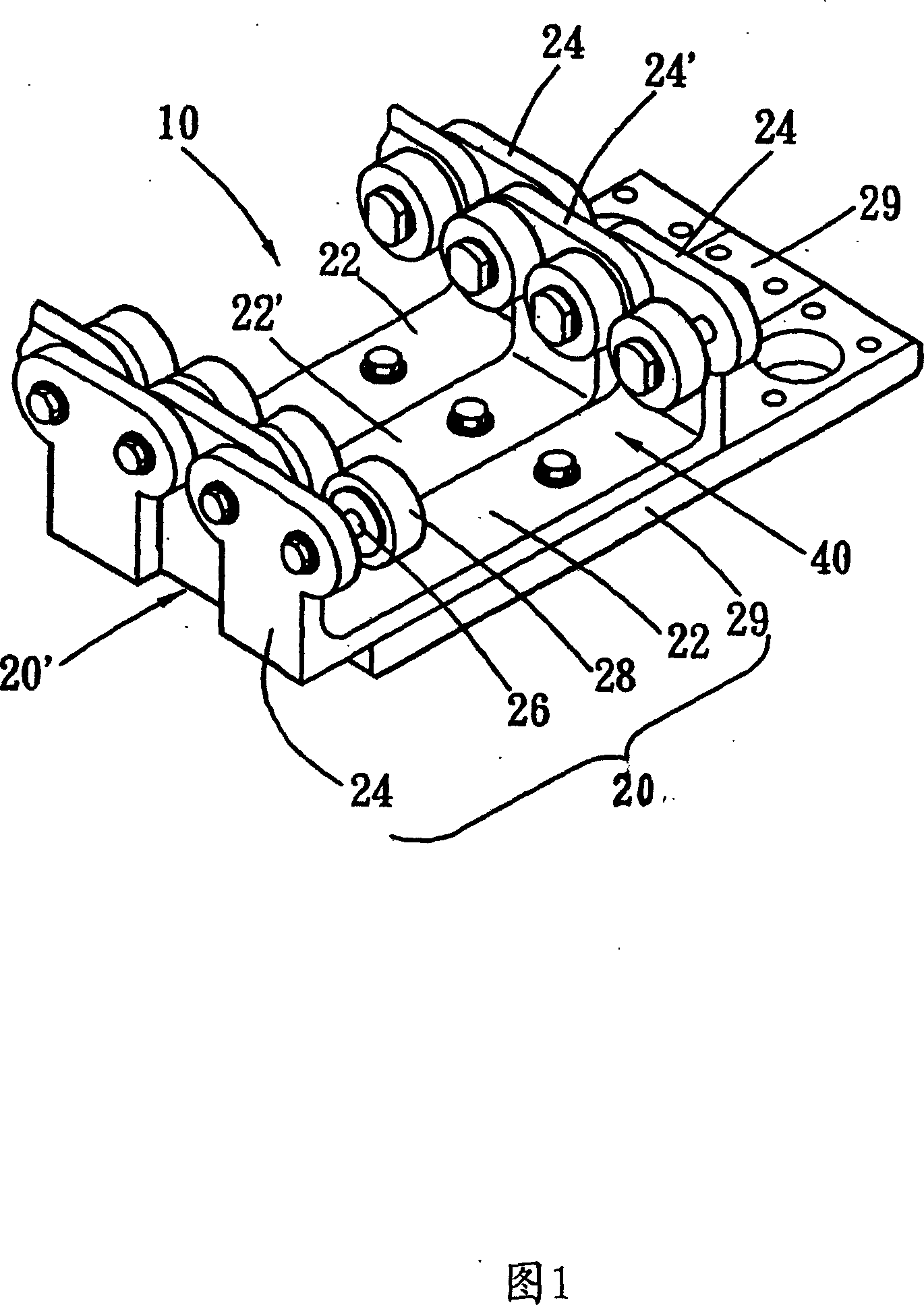

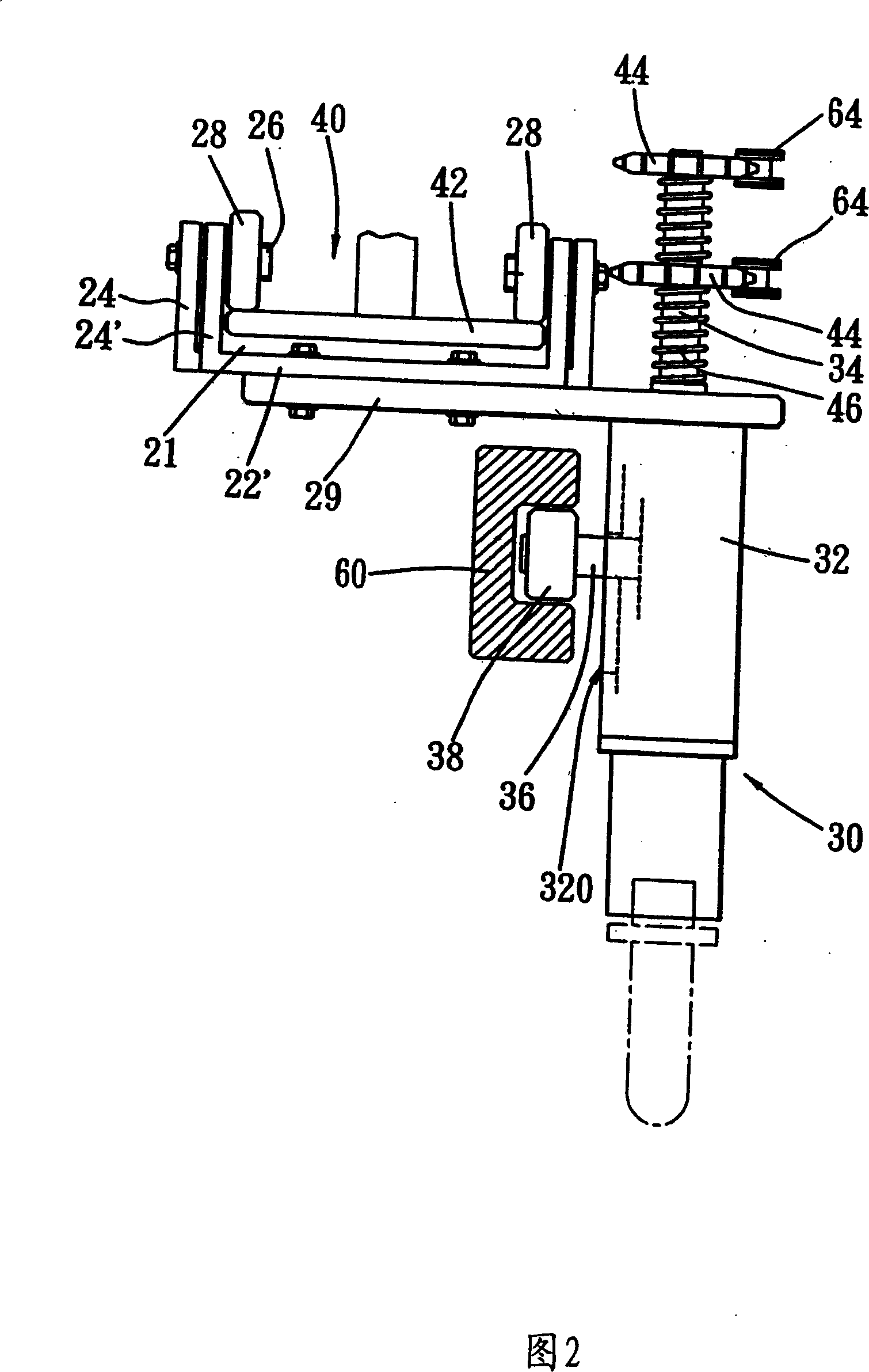

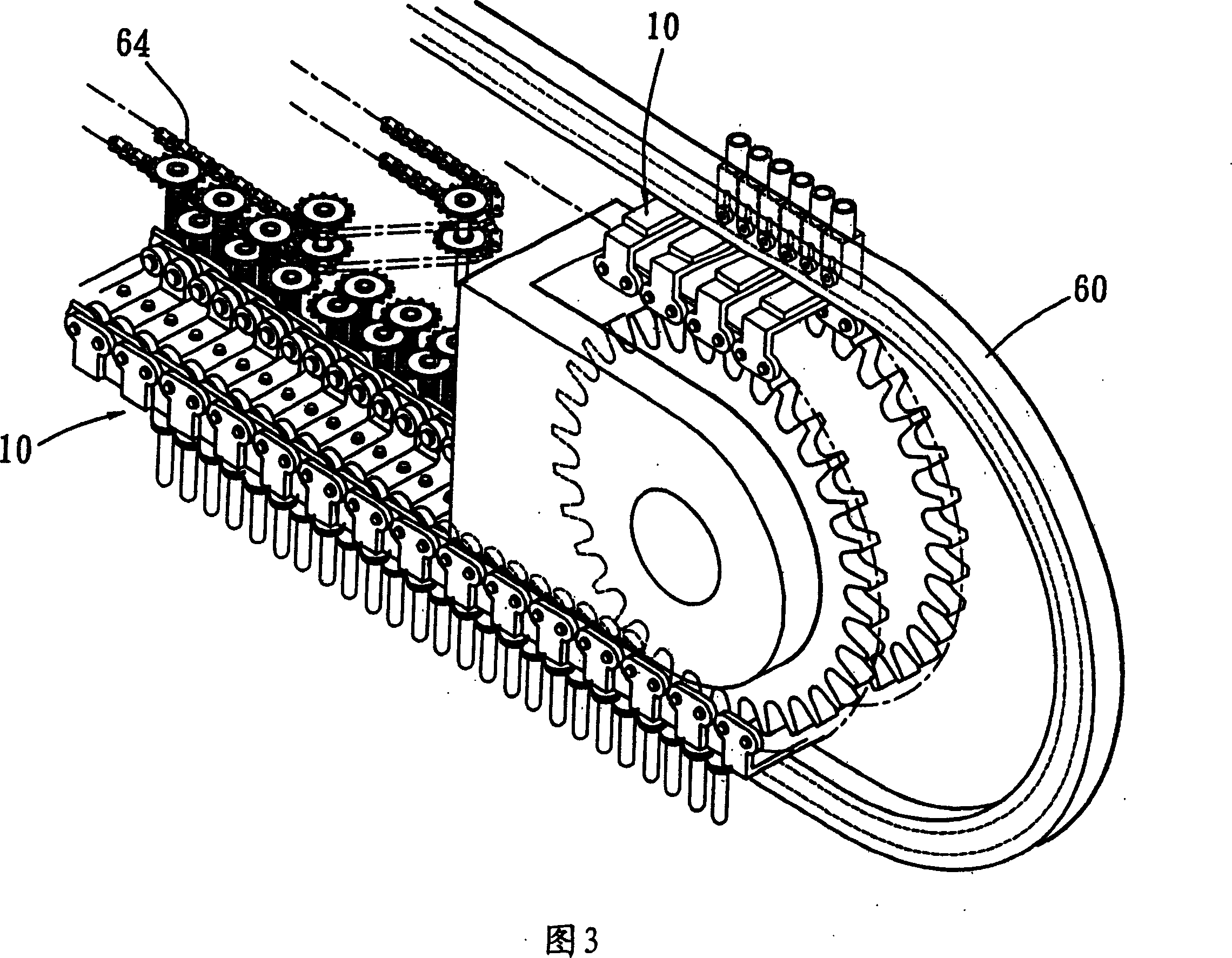

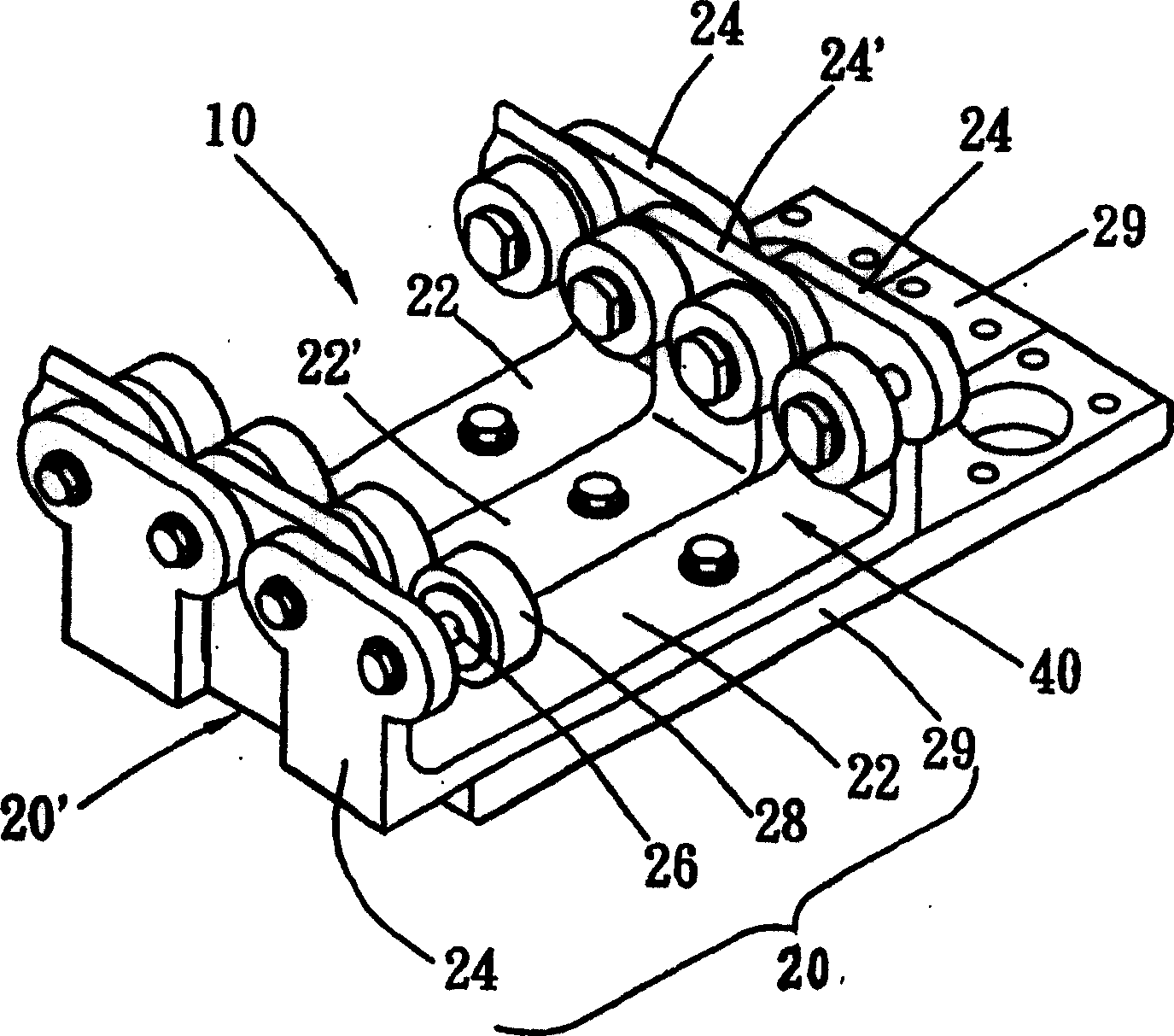

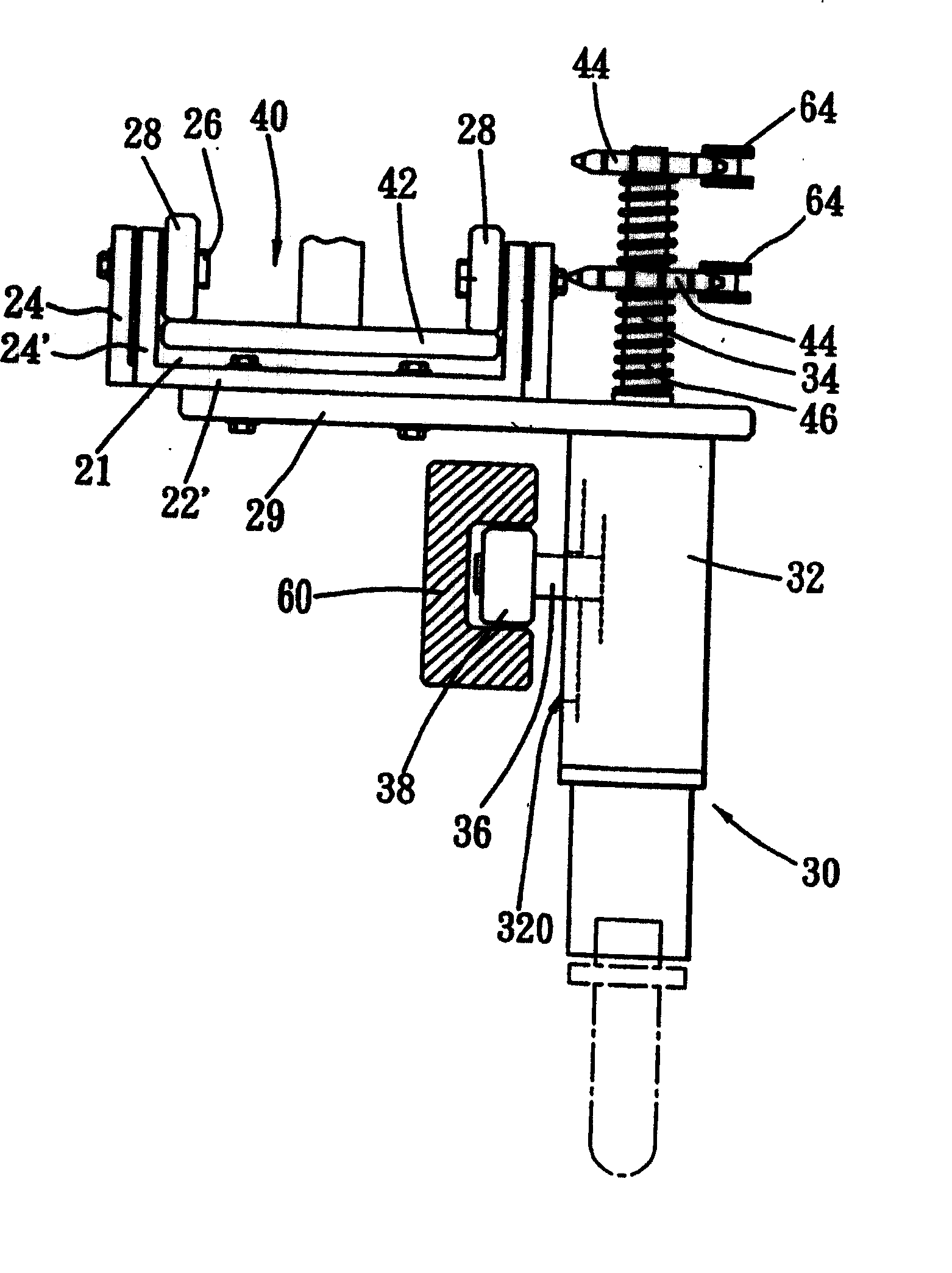

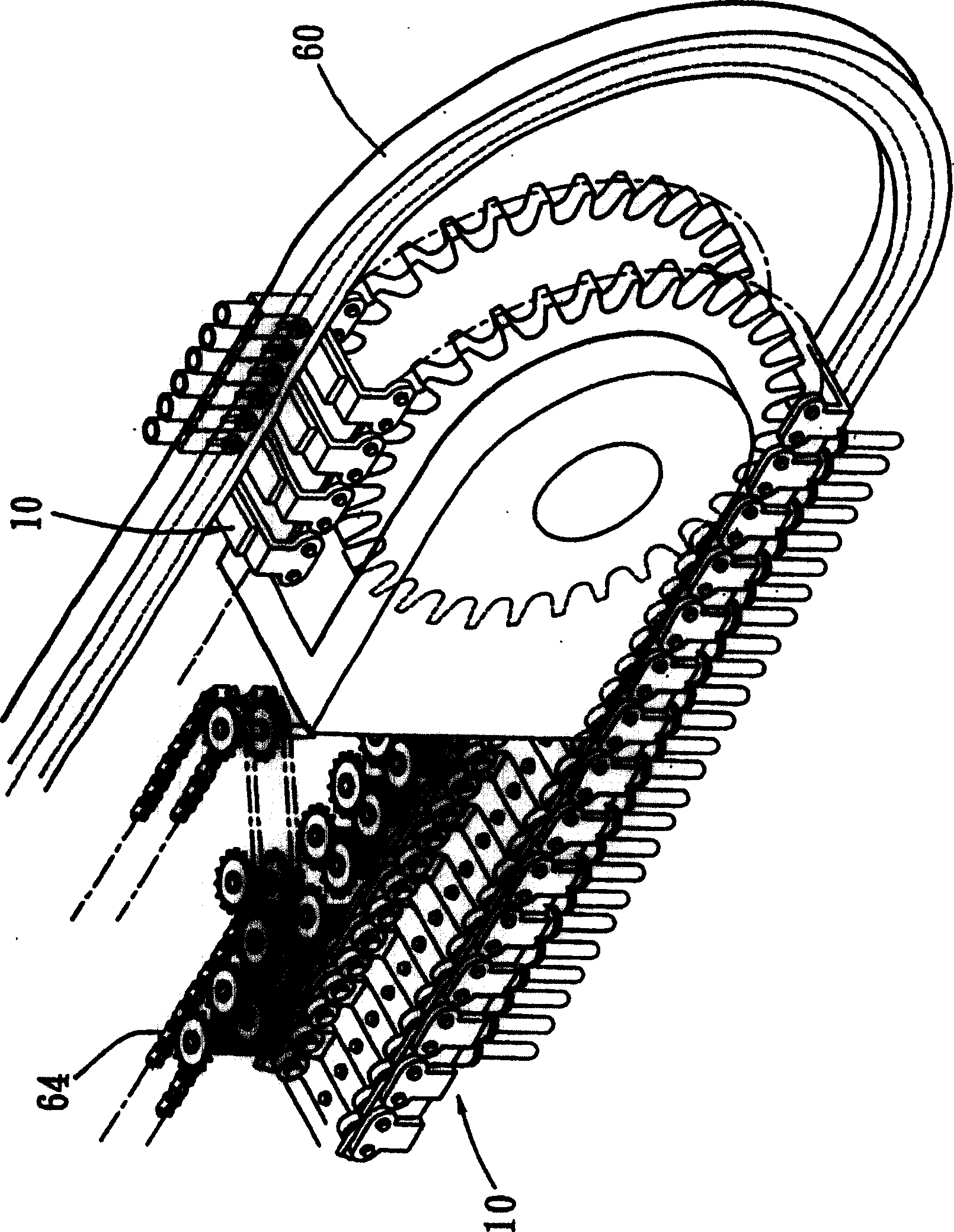

Circulating structure for drawing-blowing forming machine

The invention provides a circulation structure for a stretch-blow molding machine, comprising a conveyer belt which cycles along a preset route. The conveyer belt consists of two or more chain links which are pivoted one by one in order and a chain link comprises a bridging part with preset length, whose prolate axis is perpendicular to the circulation direction, a pair of connecting parts convexly arranged parallel on the preset places of the bridging part respectively with a preset distance; the connecting parts have preset length and the front ends and the rear ends of the connecting parts are respectively pivoted with the rear ends and the front ends of the adjacent chain links through the same bolt; a accommodation room is confined among the bridging part, a pair of connecting parts and a pair of bolts. A bracket is arranged inside the accommodation room to hold the conveyer belt which has certain length and weight.

Owner:CHUM POWER MASCH CORP

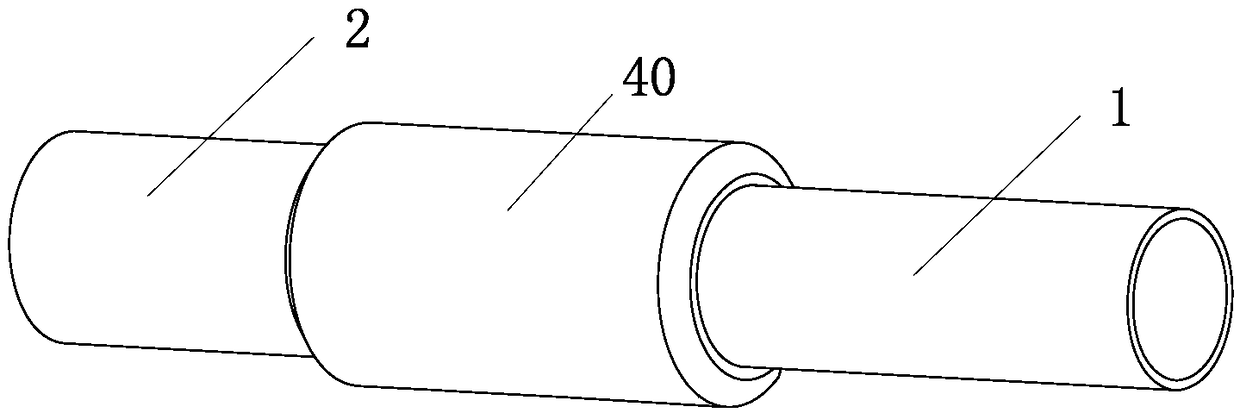

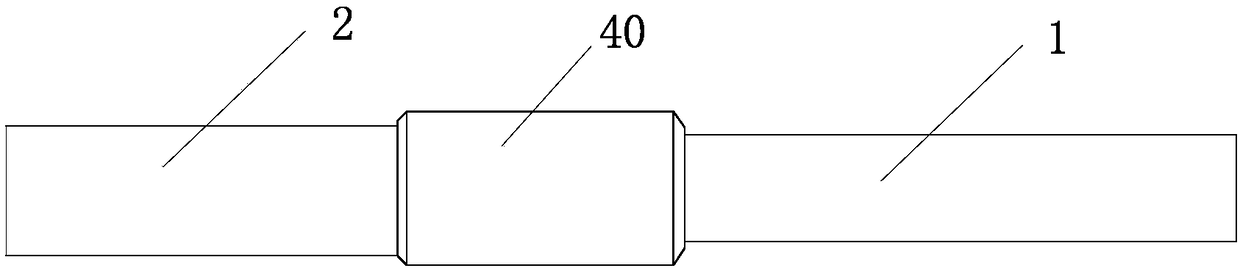

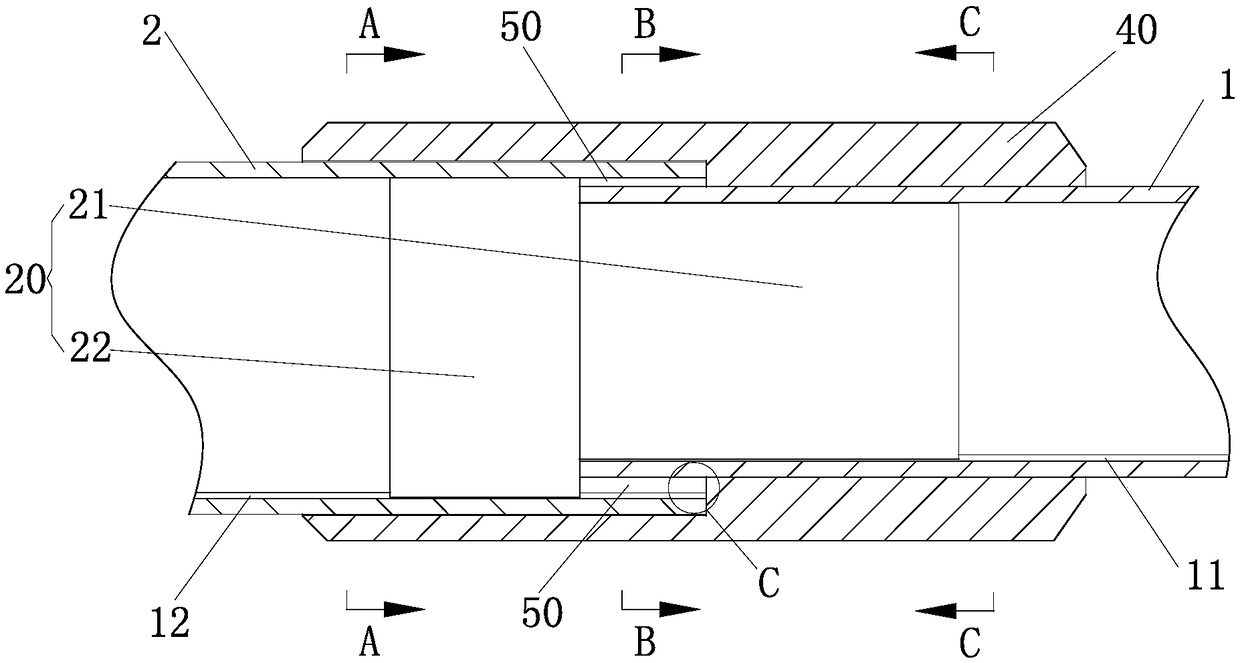

Multi-section telescopic rod

InactiveCN109058251AReduce the amount of bending deformationReduce shakingElongated constructional elementsRod connectionsEngineering

The invention provides a multi-section telescopic rod. The multi-section telescopic rod solves the technical problem that in the case of an existing multi-section telescopic rod, when multiple sections of the telescopic rod need to be used for the extension operation, a rod body of the telescopic rod is relatively large in swinging amplitude under the action of external force and then is not easyto control. The multi-section telescopic rod is provided with n sectional rods, n-1 joints and n-1 connecting lock pieces, wherein n is a positive integer not smaller than 2; and a cylindrical first locking through hole and a cylindrical second locking through hole which communicate with each other are formed in each connecting locking piece, the hole diameter of each first locking through hole isthe same as the outer diameter of the corresponding front sectional rod, moreover, each first locking through hole is connected with the outer wall of the corresponding front sectional rod in a sliding fit mode, the hole diameter of each second locking through hole is the same as the outer diameter of the corresponding rear sectional rod adjacent to the corresponding front sectional rod, and eachsecond locking through hole is connected with the outer wall of one end of the corresponding rear sectional rod adjacent to the corresponding front sectional rod in a fastening mode. The multi-section telescopic rod can be widely applied to the technical field of telescopic pipes.

Owner:赵丽红

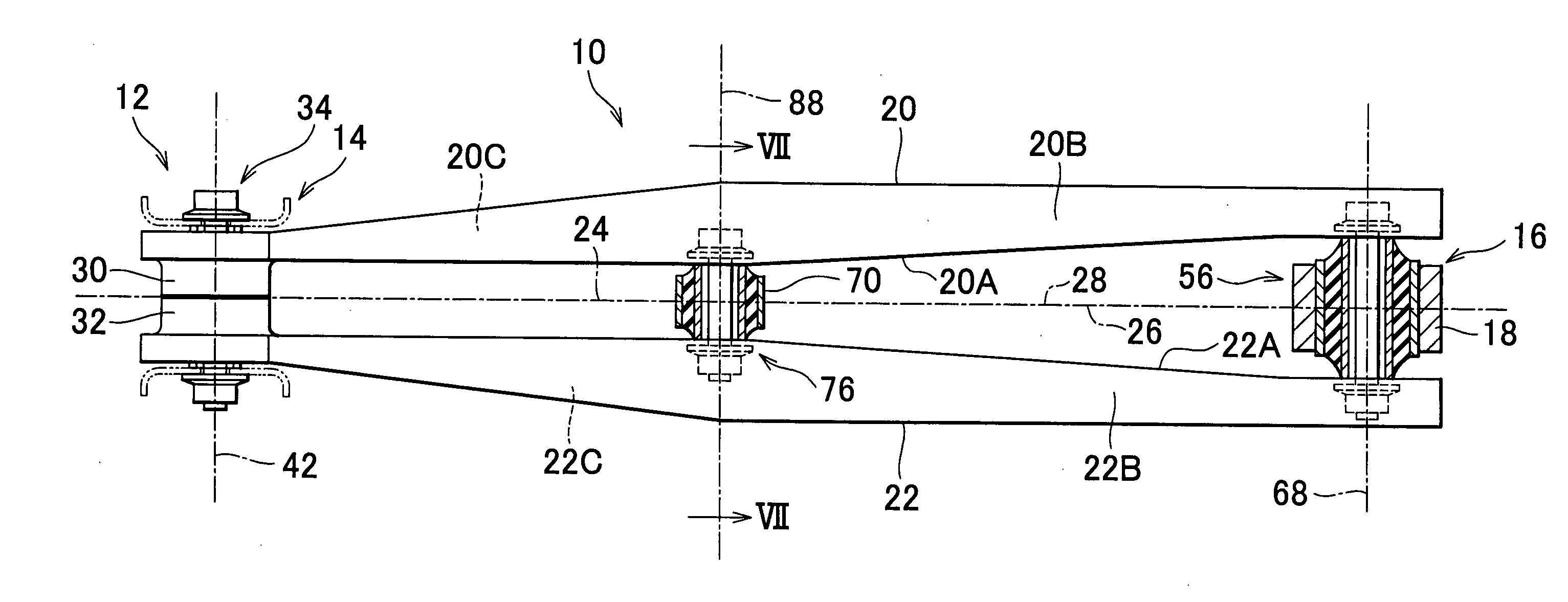

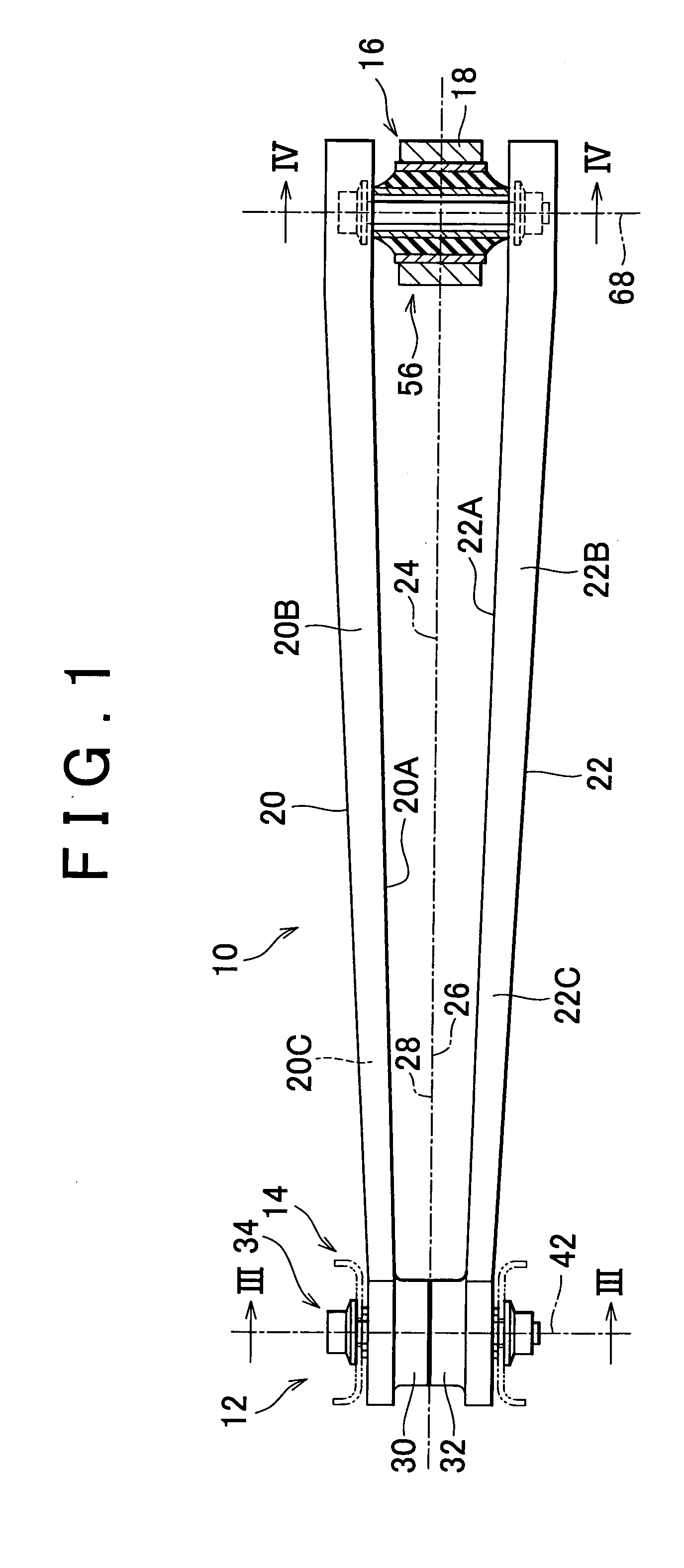

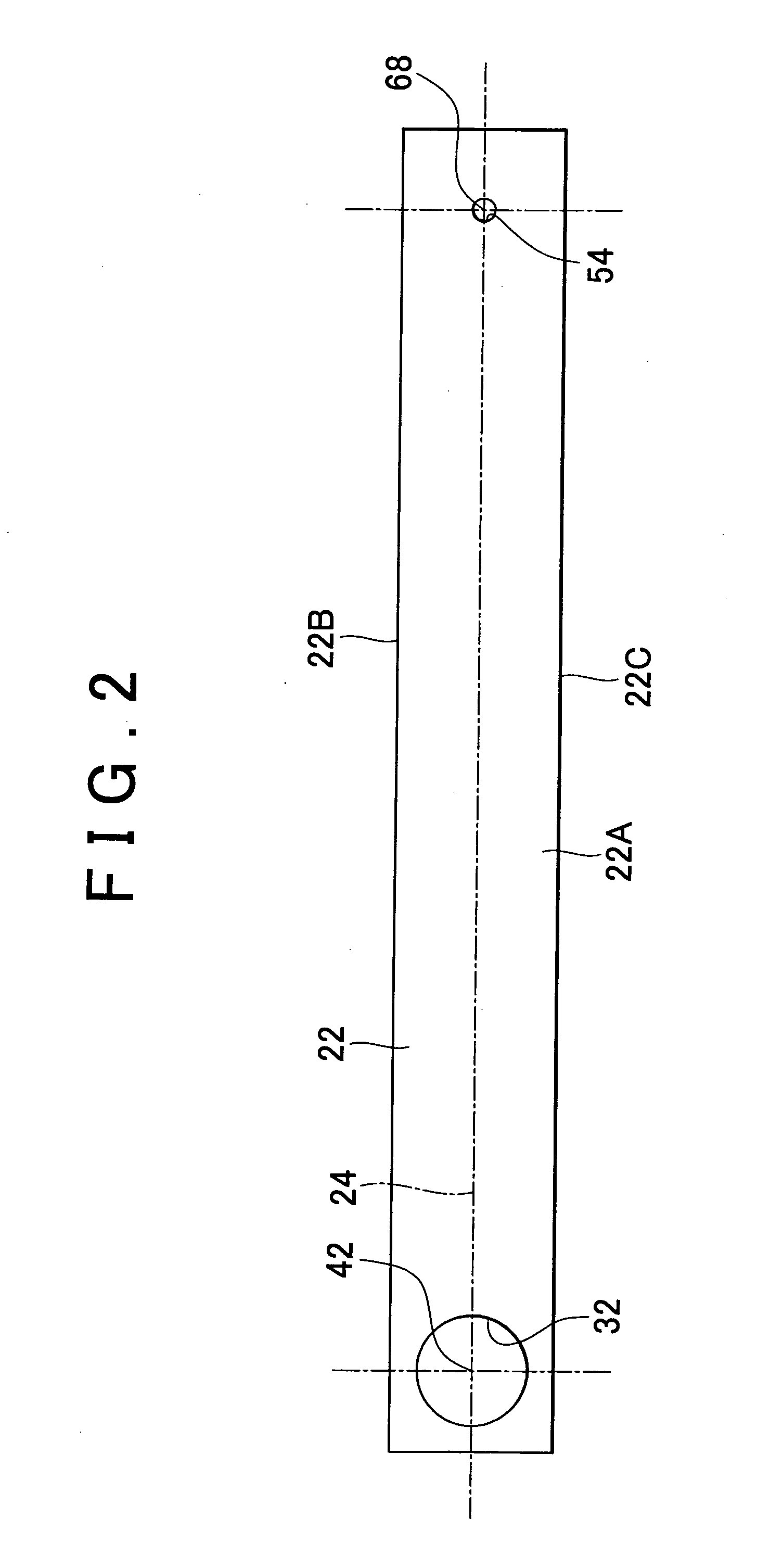

Vehicle suspension arm

InactiveUS20110079979A1Favorable torsional deformationReduce the amount of bending deformationResilient suspensionsPivoted suspension armsEngineeringMechanical engineering

Owner:TOYOTA JIDOSHA KK

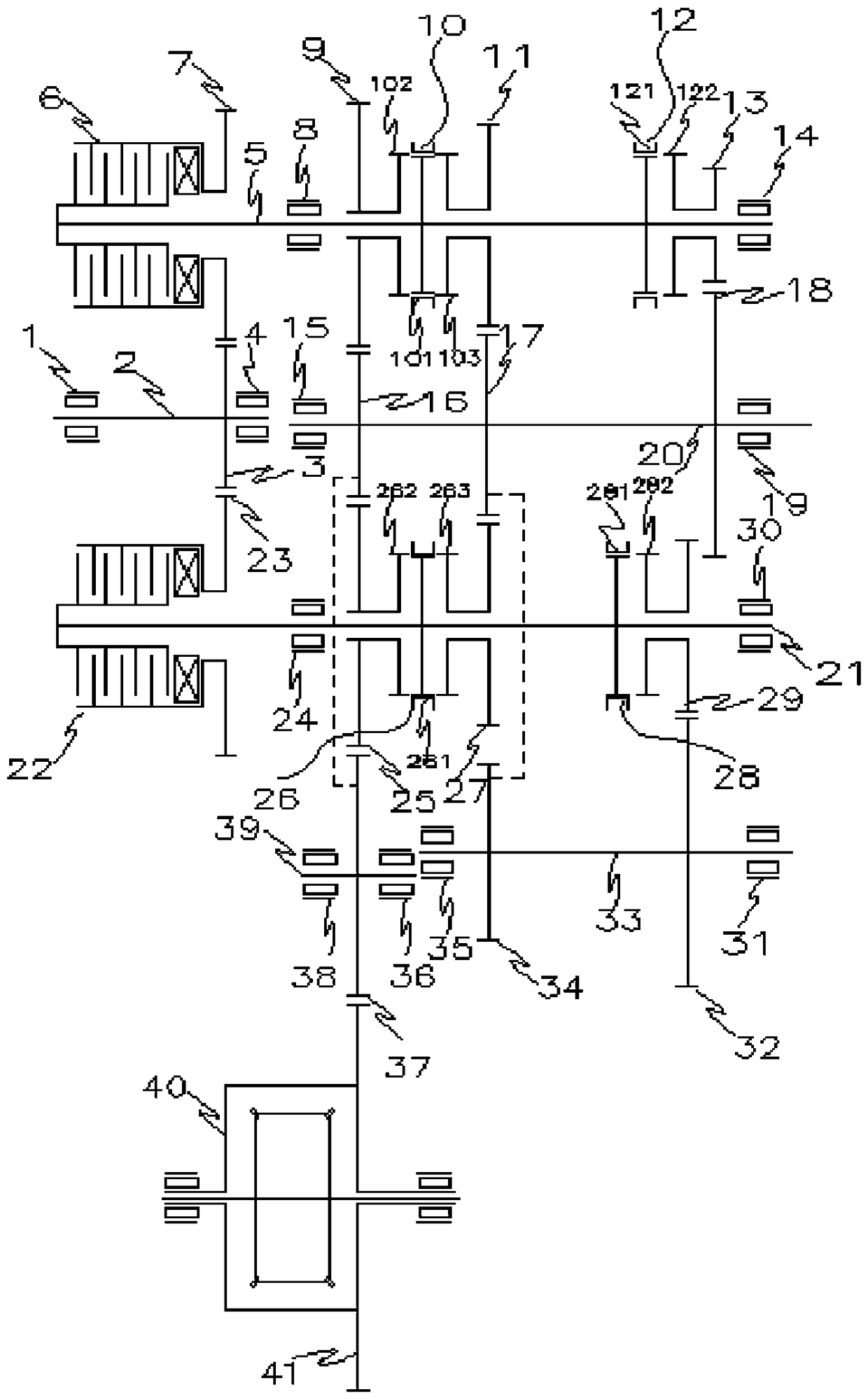

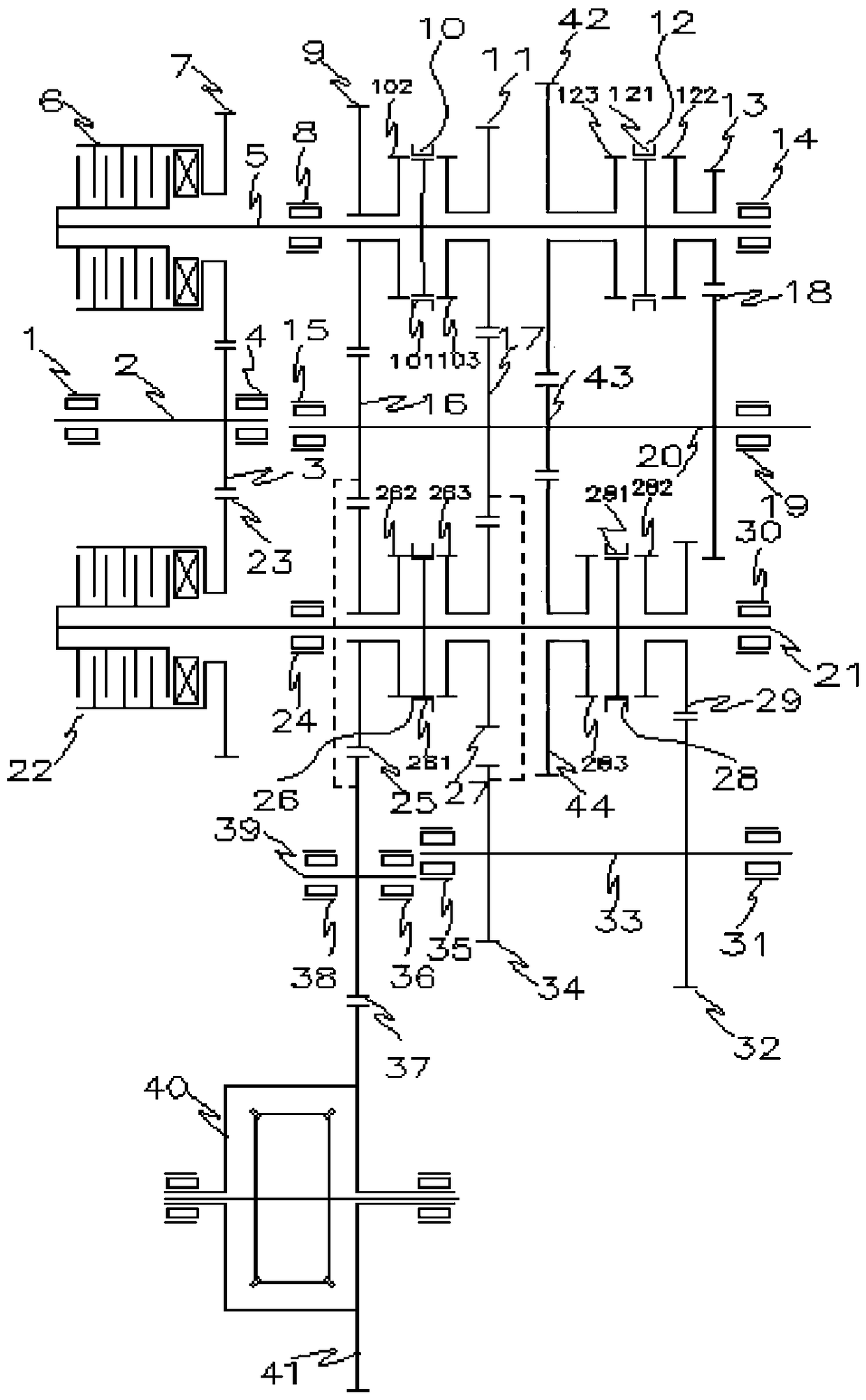

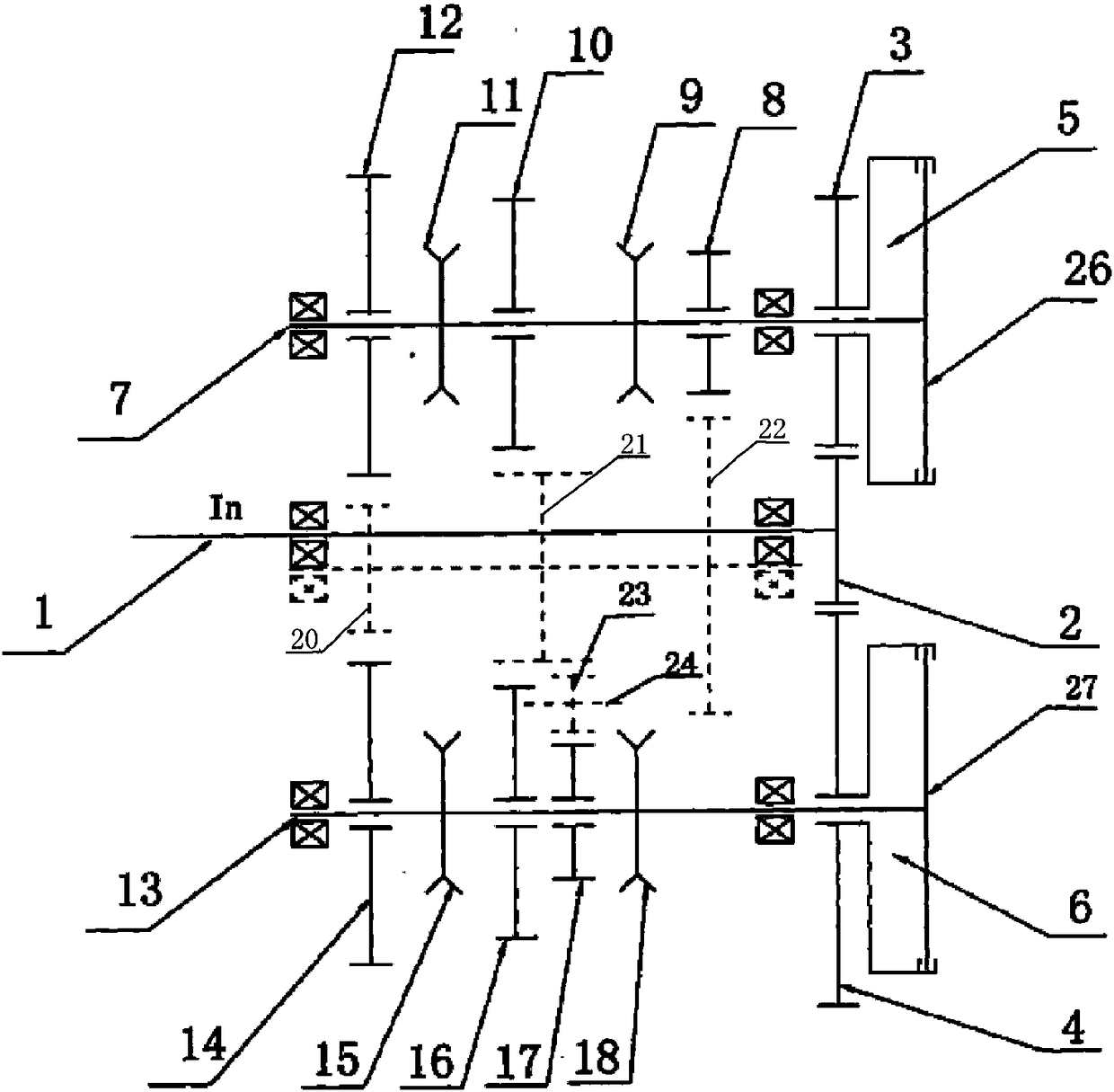

Double-clutch-type automatic gearbox transmission mechanism

PendingCN108317225AImprove NVH performanceOptimize structure layoutToothed gearingsTransmission elementsAutomatic transmissionEngineering

The invention relates to a double-clutch-type automatic gearbox transmission mechanism. The double-clutch-type automatic gearbox transmission mechanism comprises an input shaft, a first auxiliary shaft, a second auxiliary shaft, an intermediate shaft, a reverse-gear shaft and an idle gear shaft which are supported through bearings and arranged in parallel; the first auxiliary shaft is sleeved witha five-gear drive gear, a three-gear drive gear and a one-gear drive gear; the second auxiliary shaft is sleeved with a four-gear drive gear, a two-gear drive gear and a reverse-gear gear; a first driven gear, a second driven gear and a third driven gear are fixedly arranged on the intermediate shaft; a reverse-gear drive gear and a reverse-gear driven gear are fixedly arranged on the reverse-gear shaft; and the first driven gear meshes with the five-gear drive gear, the four-gear drive gear and an output idle gear simultaneously, and the second driven gear meshes with the three-gear drive gear, the two-gear drive gear and the reverse-gear drive gear simultaneously. Power is input from an input shaft gear arranged on the input shaft and transmitted and output through the output idle geararranged on the idle gear shaft. According to the transmission mechanism, few gears mesh with one another simultaneously, the NVH performance of a transmission is good, and structural arrangement is good.

Owner:CHONGQING TSINGSHAN IND

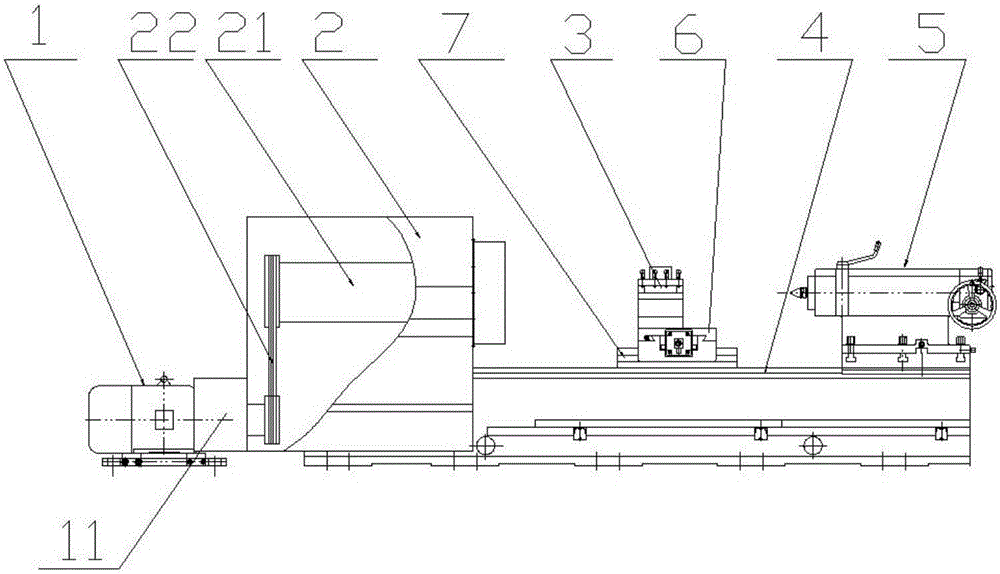

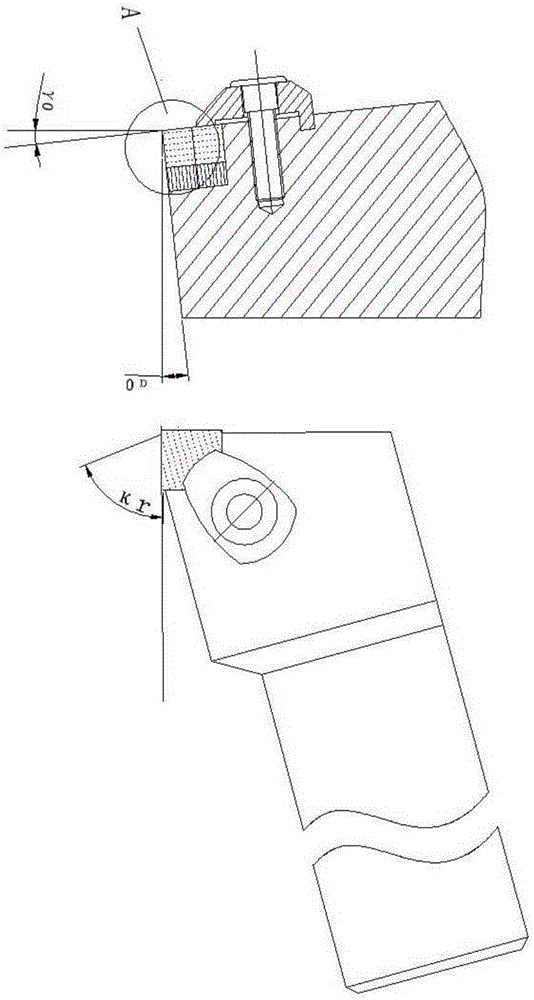

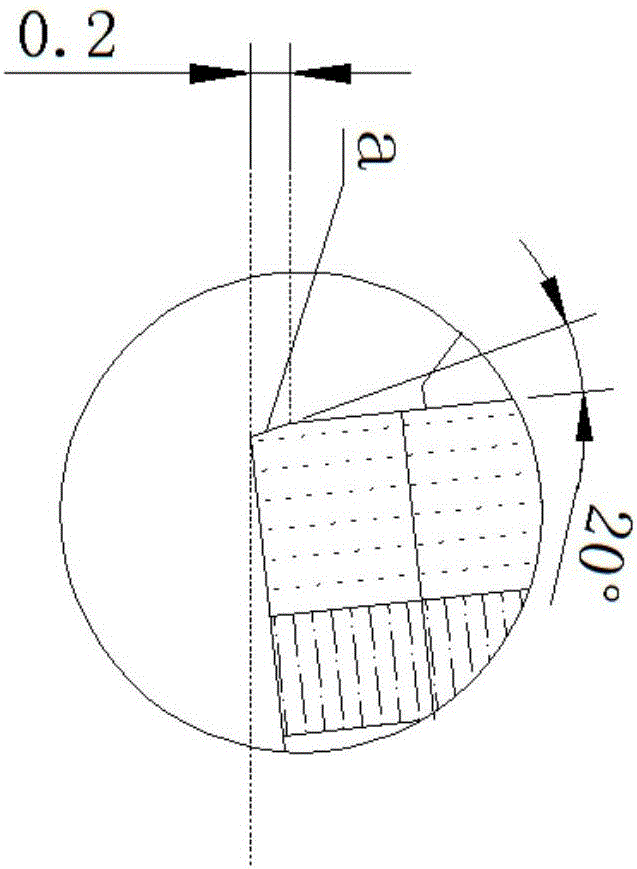

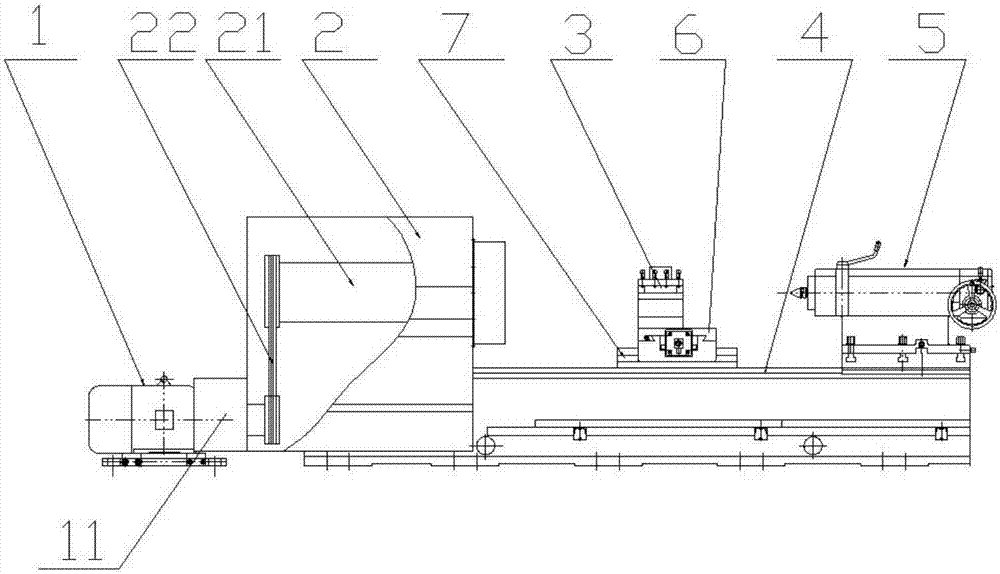

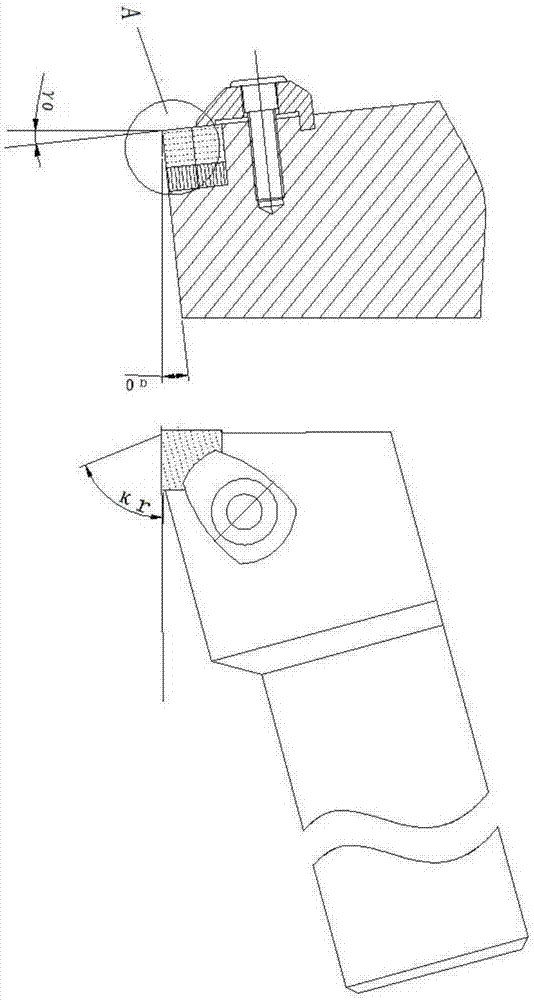

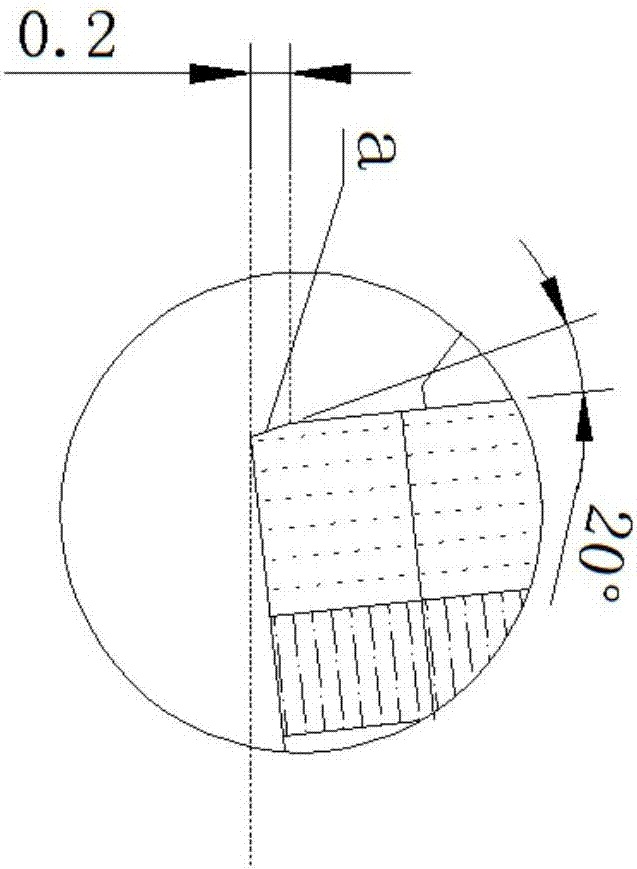

Method for machining complete martensitic alloy steel cold working roll after hardening and copious cooling

ActiveCN106216954AImprove efficiencyHigh precisionRollsMetal rolling arrangementsReducerMachine tool

The invention discloses a method for machining a complete martensitic alloy steel cold working roll after hardening and copious cooling, belongs to the field of cutting work, and solves the problems of complex process, low efficiency and high cost of the conventional hardened martensitic alloy steel cold working roll hard cutting process. The method disclosed by the invention comprises the following steps: S1, controlling the length bending deformation of a working roll to be cut after quenching; S2, correcting a central hole in the second end of the working roll to be cut; S3, mounting the working roll, of which the central hole in the second end is corrected in the step S2, on a dedicated configuration lathe, wherein the dedicated configuration lathe comprises a main motor, a reducer, a spindle box, a large carriage, a medium carriage, an electric tool carrier, a guide rail and a rotary tailstock; S4, mounting an integral CBN tool on the electric tool carrier of the lathe, and optimizing the angle and the parameters of the integral CBN tool; and S5, setting machining parameters of the dedicated configuration lathe, and carrying out powerful cutting to fulfil cutting at a time. The method disclosed by the invention has the advantages that the cutting forbidden area of a martensitic hardened layer of a roll shaft-type part is broken through; powerful cutting is realized; and the effects of high precision and high efficiency are achieved.

Owner:马鞍山市恒久特材有限公司

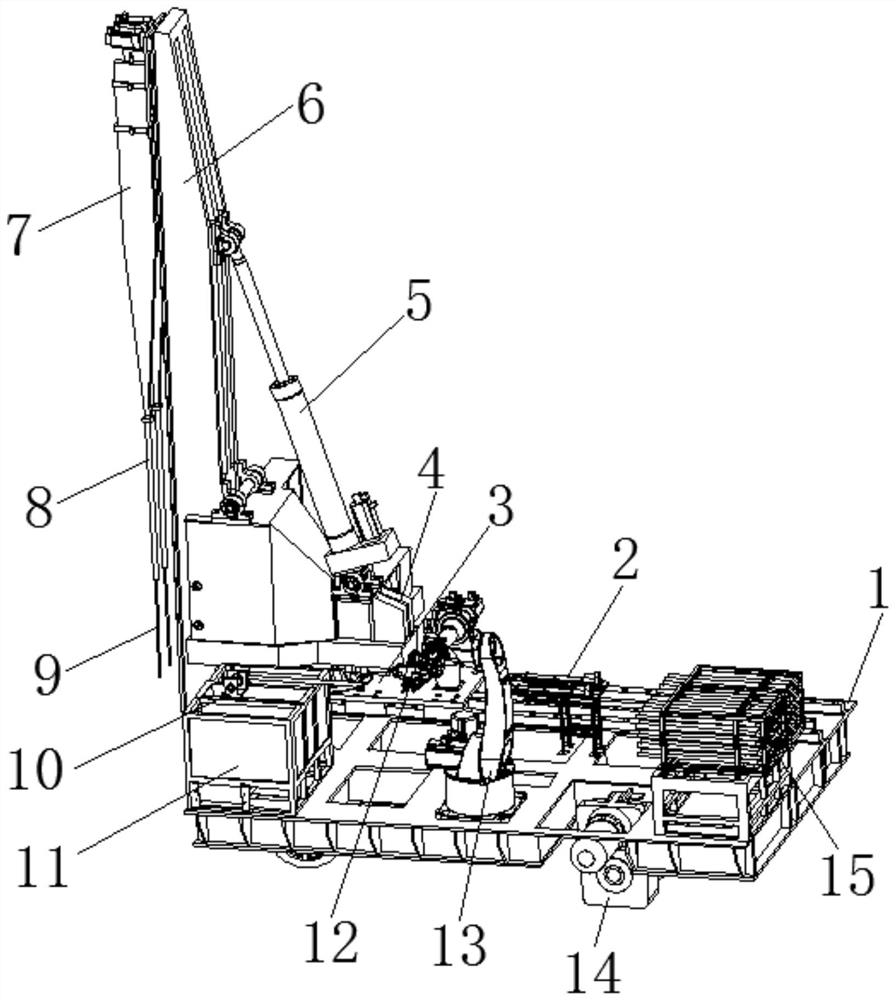

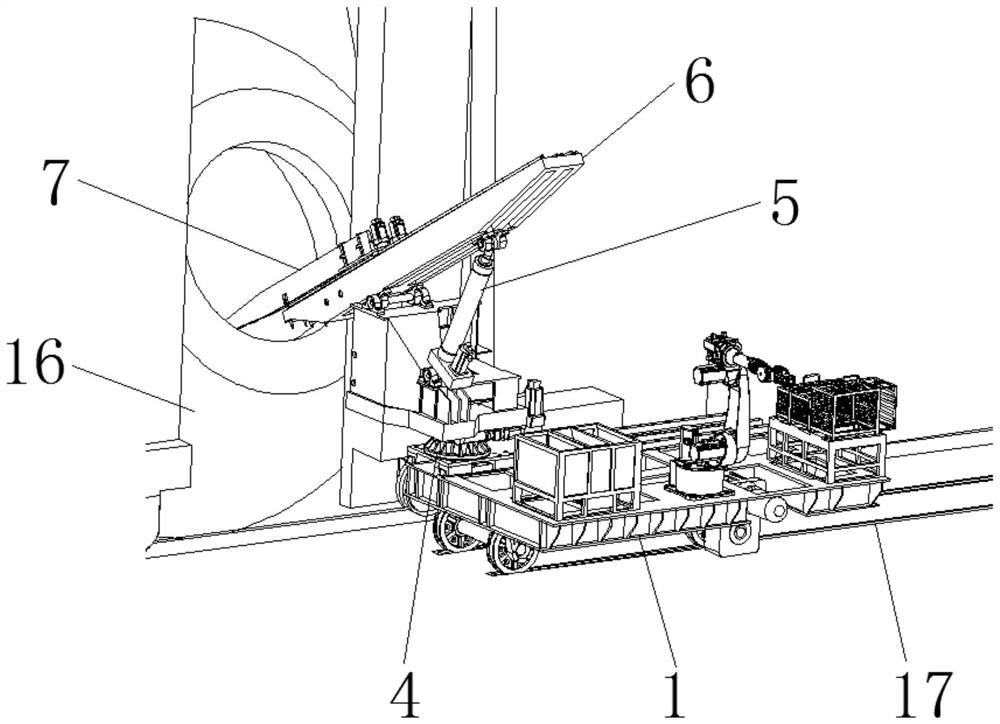

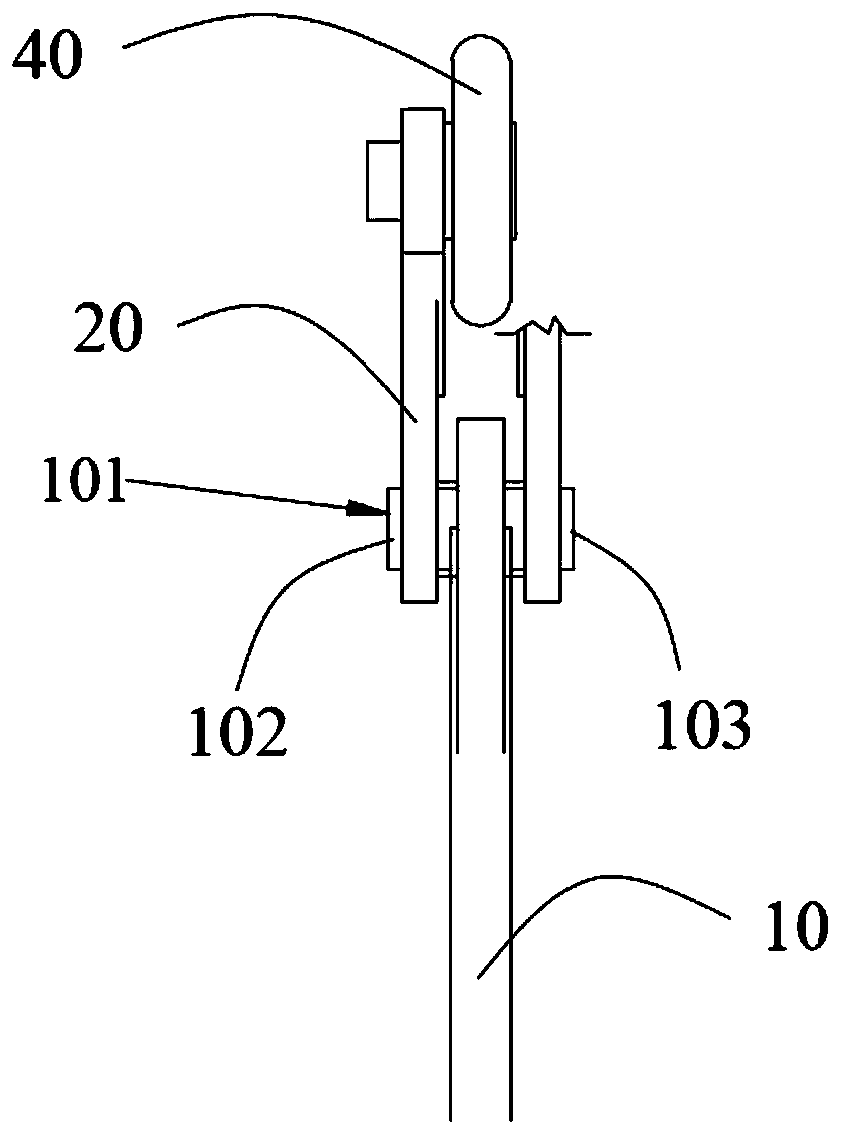

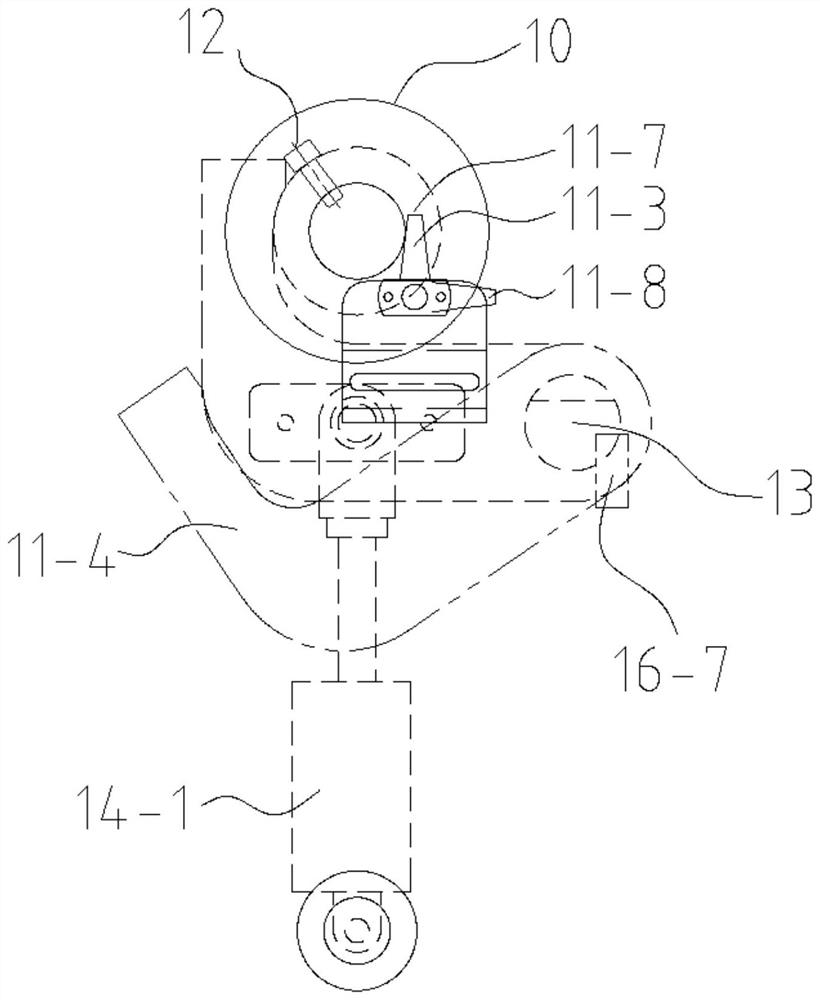

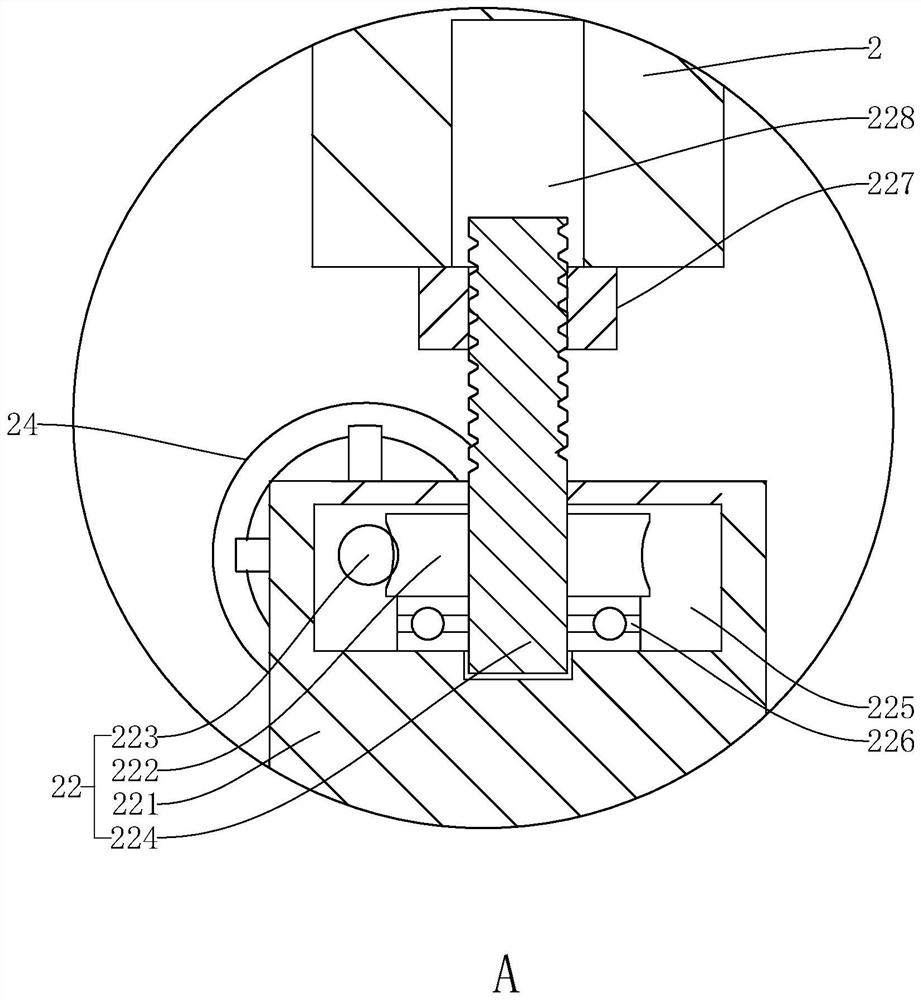

Steelmaking automatic temperature measuring and sampling equipment and temperature measuring and sampling method thereof

ActiveCN111855025ASolve the deformationSolution success rateThermometer applicationsSteelmakingControl theory

The invention discloses steelmaking automatic temperature measuring and sampling equipment and a temperature measuring and sampling method thereof in the technical field of steelmaking. According to the equipment, a walking vehicle linearly moves and is fixed on a heavy rail; a robot gripper is mounted at the arm end of a robot; a pneumatic hammer device is mounted at the top of a collecting bin;a transverse moving vehicle linearly moves and is fixed at the top of the walking vehicle; a rotating device is mounted at the top of the transverse moving vehicle; the rotating axis of the rotating device is perpendicular to the top of the walking vehicle; one end of an overturning plate and one end of a second telescopic device are hinged to the rotating device; the other end of the second telescopic device is hinged with the overturning plate; a temperature measurement and sampling gun connecting plate moves linearly on the overturning plate and is fixed; and a temperature measurement and sampling gun is arranged on the temperature measurement and sampling gun connecting plate. According to the invention, the problems that a temperature measuring and sampling gun deforms and is prone todamage, the installation success rate of a temperature measuring and sampling sleeve is low, the deformation amount of the temperature measuring and sampling gun cannot be accurately judged visuallyand the like are solved, automatic temperature measuring and sampling are achieved, and the success rate of temperature measuring and sampling is high.

Owner:HAIXI (FUJIAN) INST CHINA ACAD OF MASCH SCI&TECH GRP

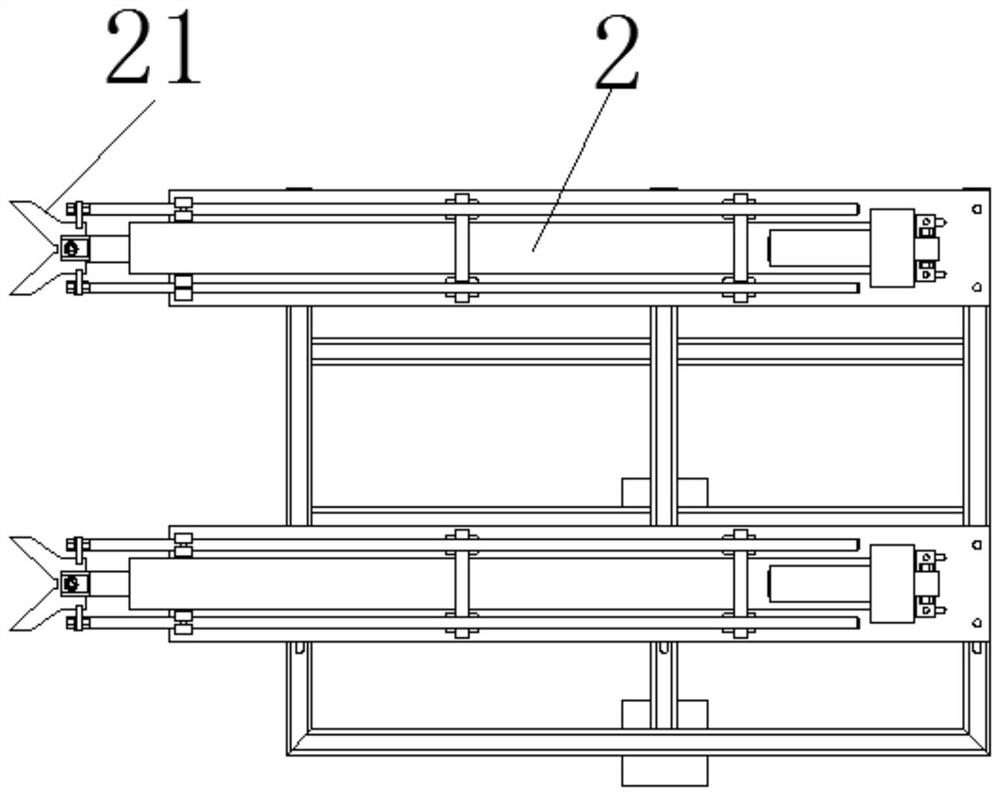

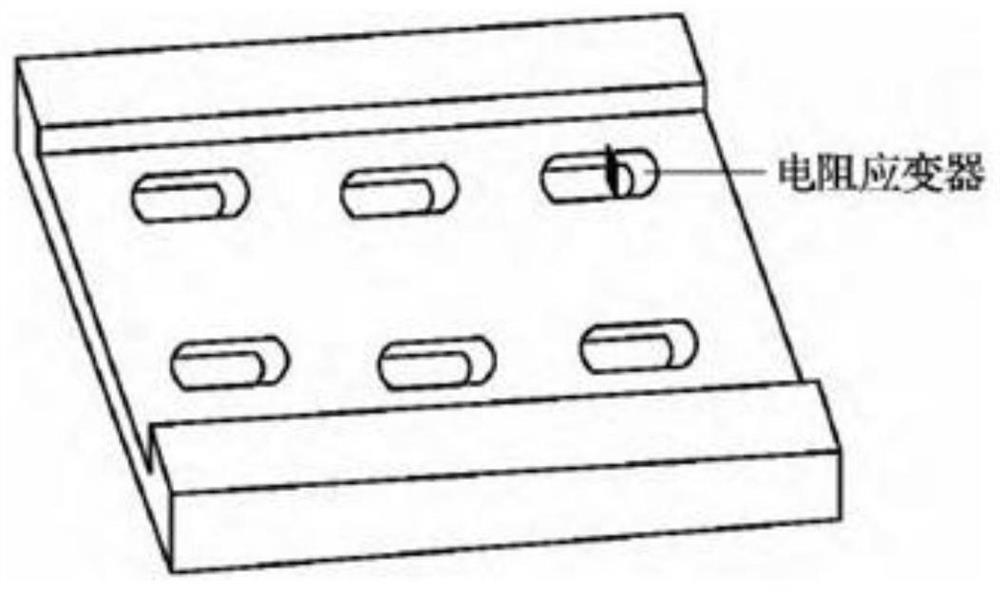

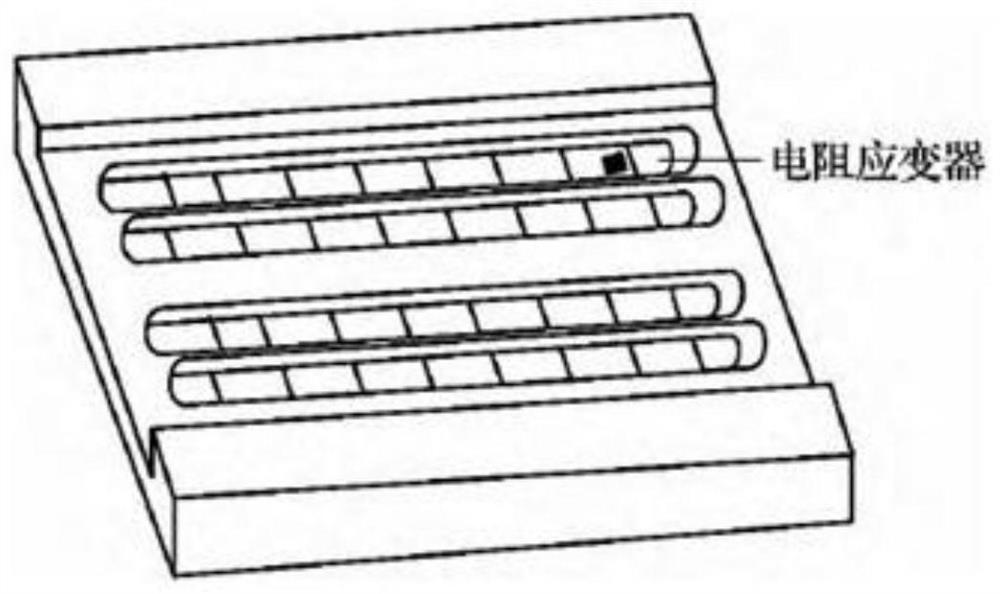

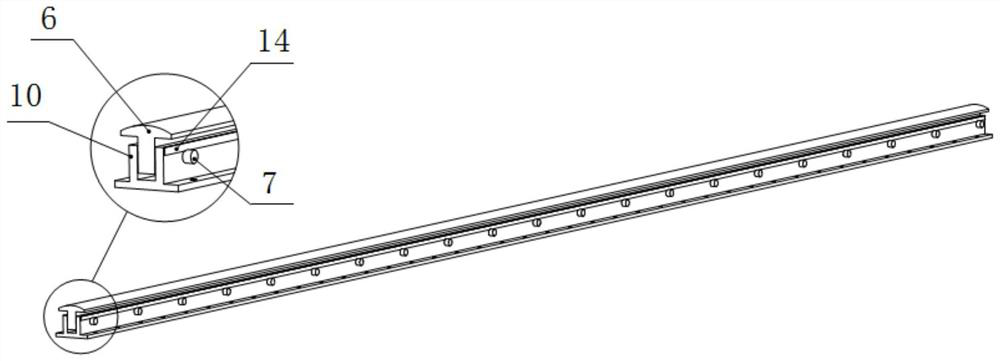

Narrow strip strain weighing sensor, narrow strip array dynamic scale and use method thereof

PendingCN111664925ABending deformation will notMeasurement results will not affectWeighing apparatus detailsSpecial purpose weighing apparatusVehicle dynamicsVertical plane

The invention discloses a narrow strip strain weighing sensor. The sensor comprises a bearing beam, a plurality of pin shaft sensors and a base, wherein the pin shaft sensor is horizontally installedon the base, the bearing beam includes a horizontal plate and a vertical plate which are arranged in a T shape, the vertical plate is connected with the pin shaft sensor, the pin shaft sensor is perpendicular to the bearing beam, a counter bore is formed in the side wall of the pin shaft sensor, a bottom of the counter bore is a vertical plane, and a shear type strain gauge is arranged at the bottom of the counter bore. Measurement accuracy can be improved. The invention also discloses a narrow strip array dynamic scale and a use method thereof. The narrow strip array dynamic scale is integrally installed on the ground, a position error of each installed narrow strip weighing sensor can be reduced, a measurement error is decreased, and measurement accuracy is improved. In effective test time, vehicle wheels completely act on the upper plate, namely the weighing surface, so that a requirement on installation levelness of the vehicle dynamic scale and the road surface is far lower than that of a narrow quartz weighing sensor which is directly installed on the road surface, and installation cost is further reduced.

Owner:李小芳 +1

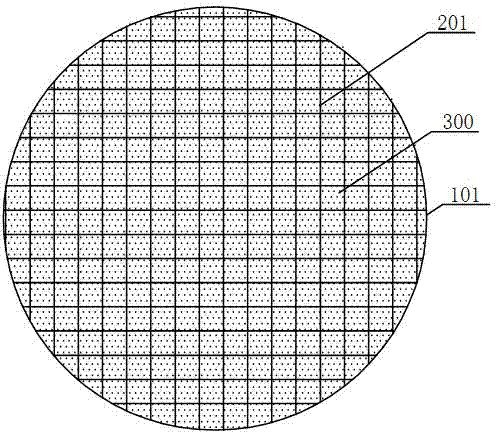

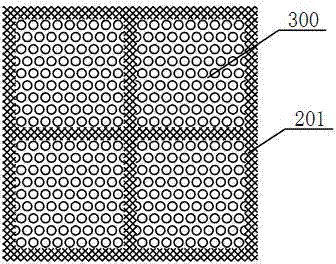

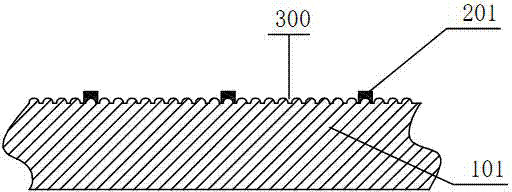

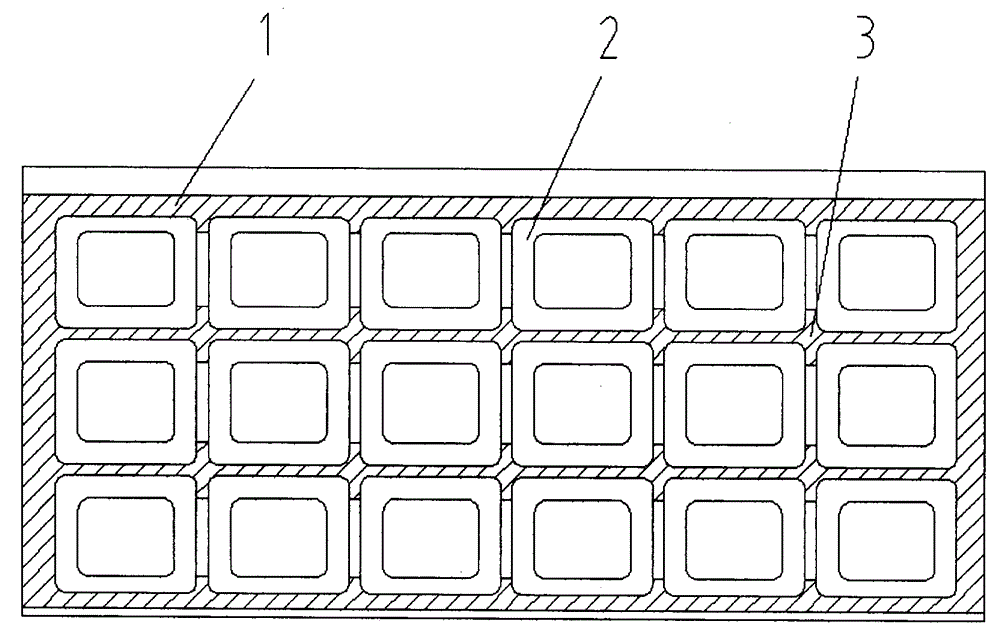

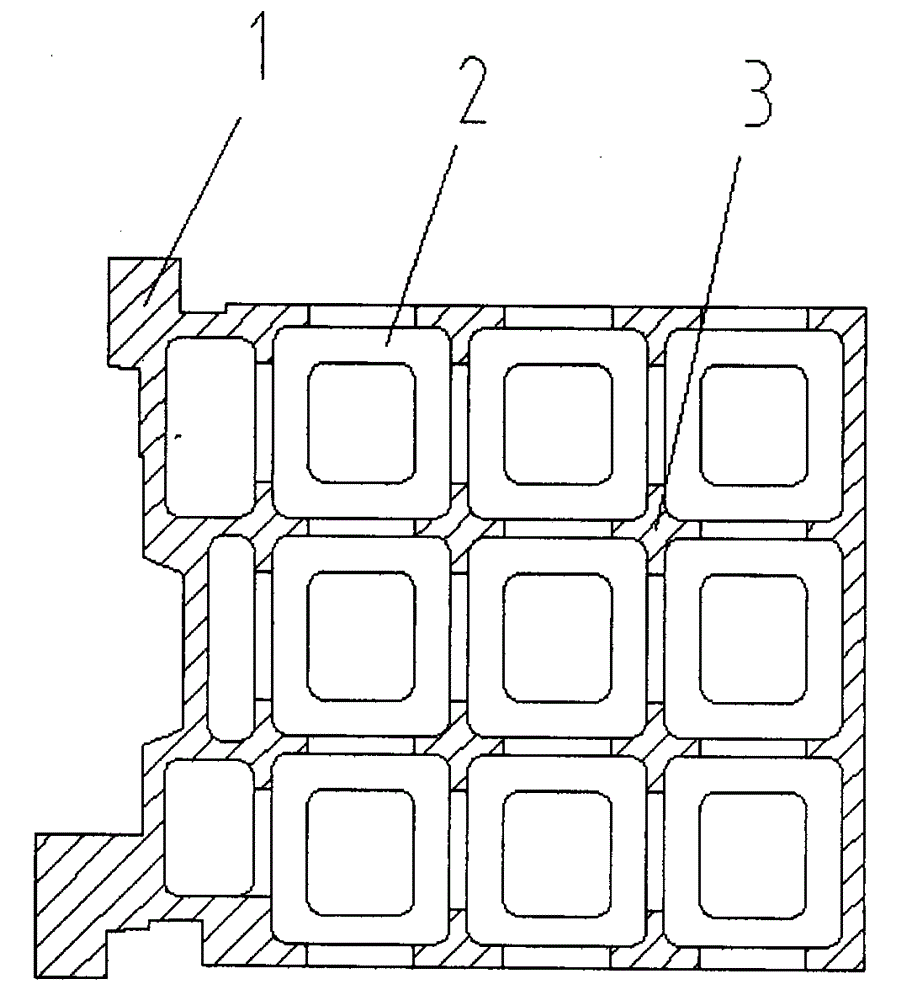

Pattern-segmented sapphire substrate used for AlGaInN material system film growth

InactiveCN103647005AImprove wavelength uniformityReduce the amount of bending deformationSemiconductor/solid-state device manufacturingFine working devicesThin membraneCondensed matter physics

The invention discloses a pattern-segmented sapphire substrate used for AlGaInN material system film growth. The pattern-segmented sapphire substrate comprises a sapphire substrate body; pattern segmentation grooves divide the upper surface of the sapphire substrate body into a plurality of mutually-independent repeated pattern units, wherein the pattern units are growing platforms of AlGaInN materials. The sapphire substrate body is a plane sapphire substrate body or a pattern sapphire substrate body. The pattern segmentation grooves are trench-type pattern segmentation grooves or second medium-type pattern segmentation grooves. The pattern-segmented sapphire substrate is formed by dividing the sapphire substrate into the plurality of mutually-independent and mutually-isolated pattern units through the grooves or second medium. According to the segmented AlGaInN epitaxial thin films, the wave length uniformity of an LED can be greatly improved, the qualified rate of an LED epitaxial wafer is improved, and the giant thermal stress and thermal shock, due to laser lift-off, between the AlGaInN epitaxial thin films and the sapphire substrate are greatly reduced, the pass rate of the laser lift-off can be greatly improved, and the qualified rate of sapphire substrate vertical structure LED chips is improved.

Owner:NANCHANG UNIV +1

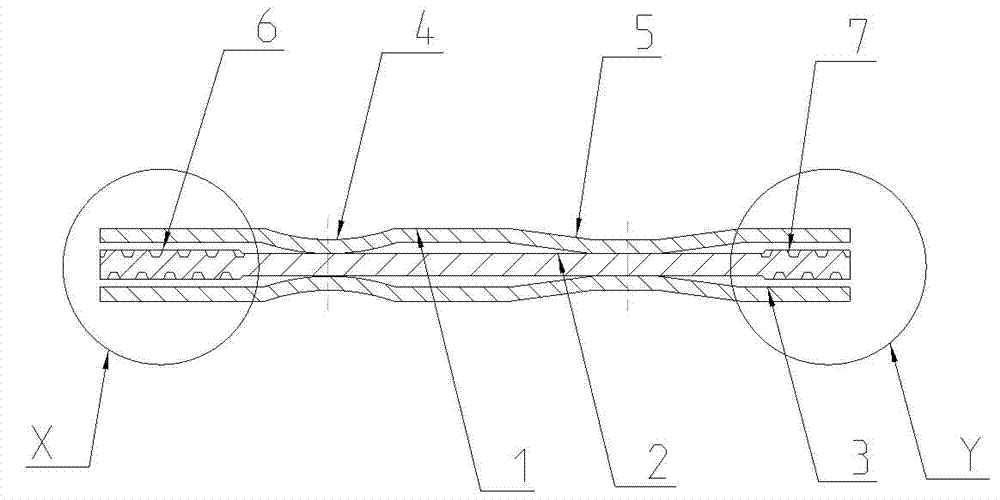

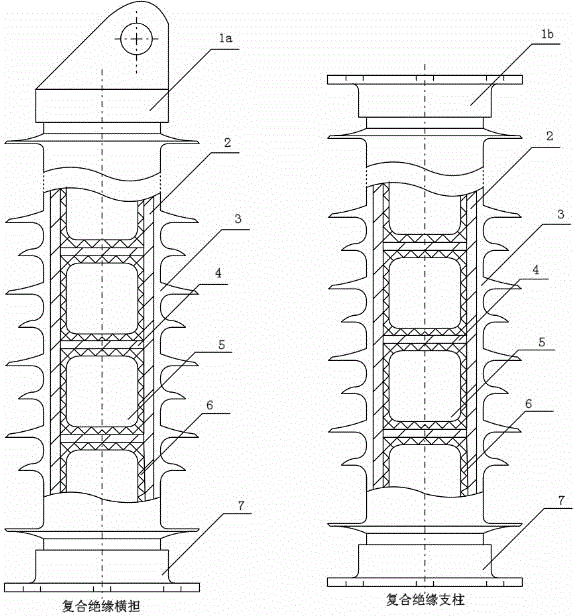

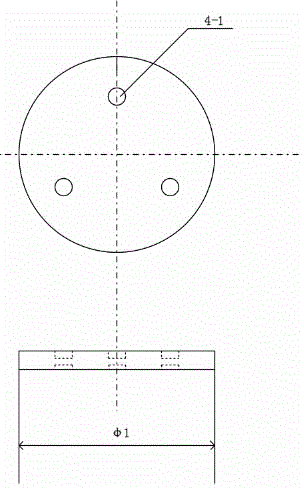

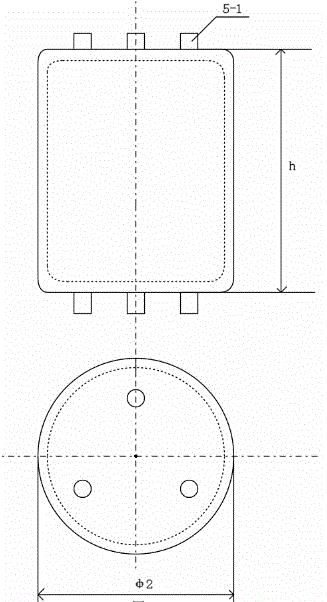

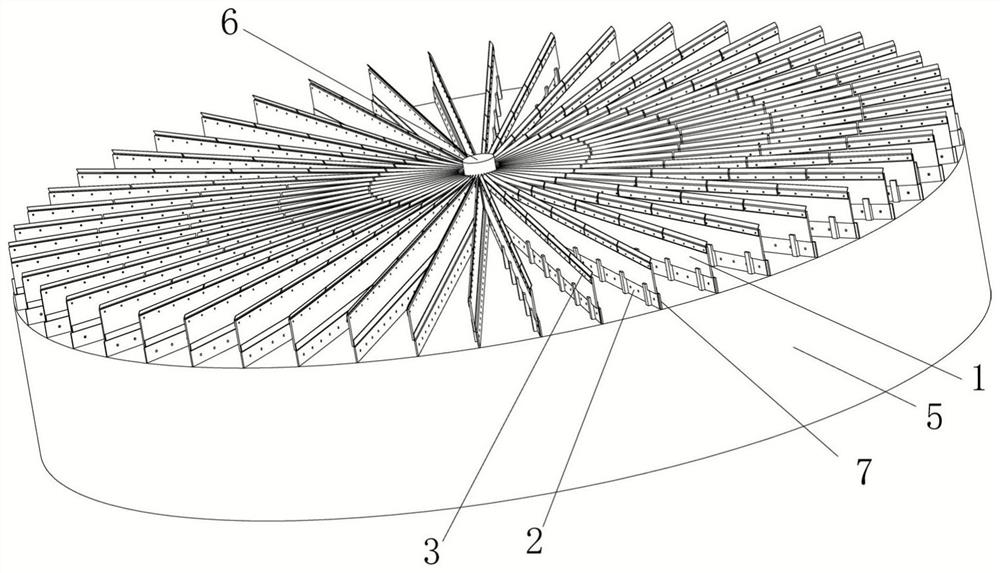

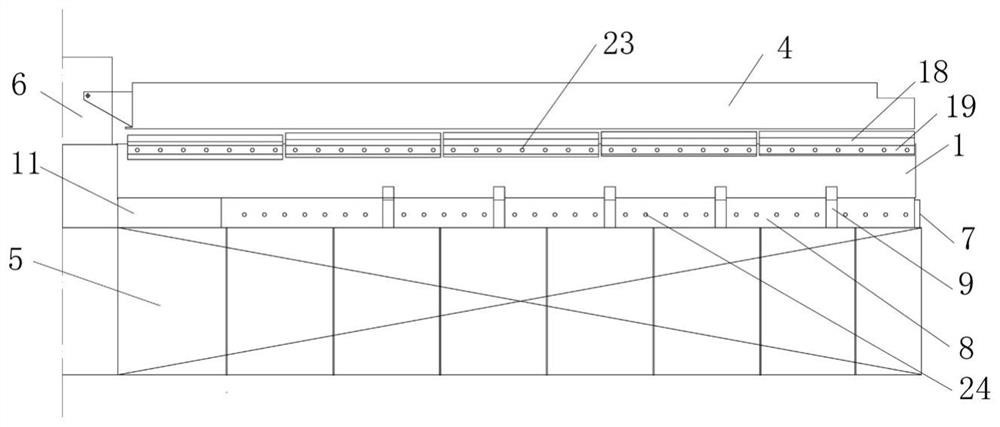

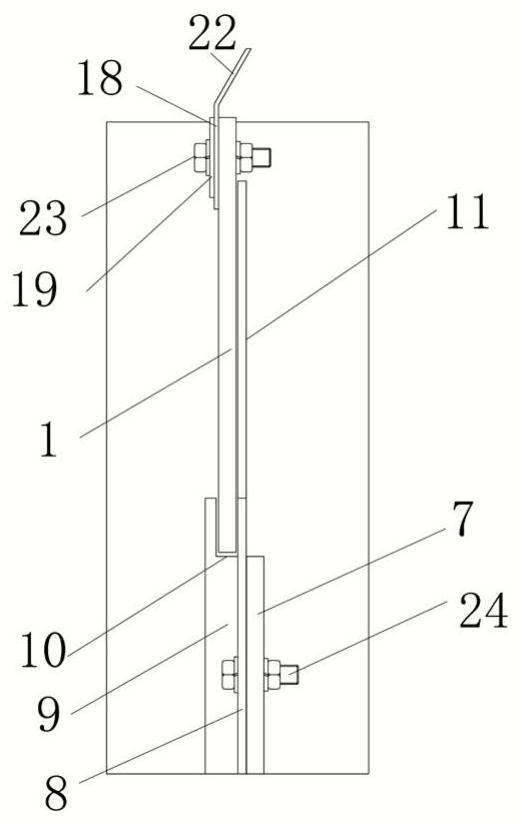

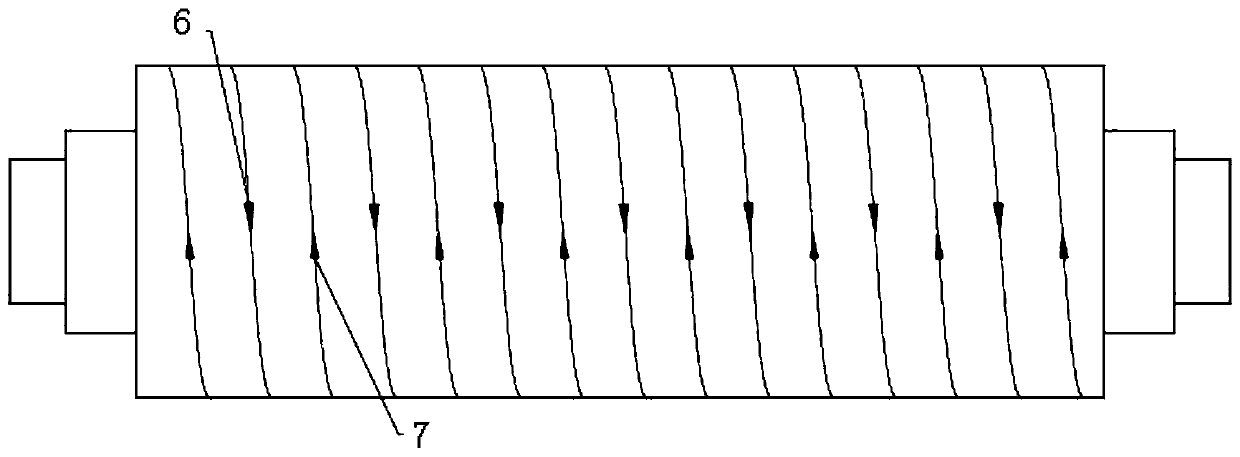

Light composite crossarm and pillar of solid insulators interruptedly filled in epoxy glass fiber tube

InactiveCN106158166AIncrease stiffnessReduce the amount of bending deformationInsulatorsEngineeringRaw material

The invention discloses a light composite crossarm and pillar of solid insulators interruptedly filled in an epoxy glass fiber tube. The product consists of an upper accessory 1, the epoxy glass fiber tube 2, a silicone rubber umbrella skirt 3, an insulated supporting plate 4, an insulated air bag 5, a filling insulator 6 and a lower accessory 7. The light composite crossarm and pillar has the following innovations: a, after the insulated supporting plate 4 is arranged in the epoxy glass fiber tube 2 and the insulator is filled in the epoxy glass fiber tube 2, inner wall leakage current and air breakdown of the epoxy glass fiber tube are blocked, no out-of-round deformation during bending stress of the epoxy glass fiber tube can also be supported, the rigidity of the product is increased, and the bending deformation is reduced; and b, the insulated air bag 5 is arranged in the epoxy glass fiber tube 2, so that the weight of the product is alleviated, the raw materials are saved, the cost is reduced, the out-of-round deformation can be transferred to the space inside the bag during the bending stress of the epoxy glass fiber tube; and meanwhile, due to fewer filler, the influence of the difference of two material dilatation coefficients on the product is reduced, and air gaps formed by poor interface and solid material tearing or deformation recovery are avoided.

Owner:王伟

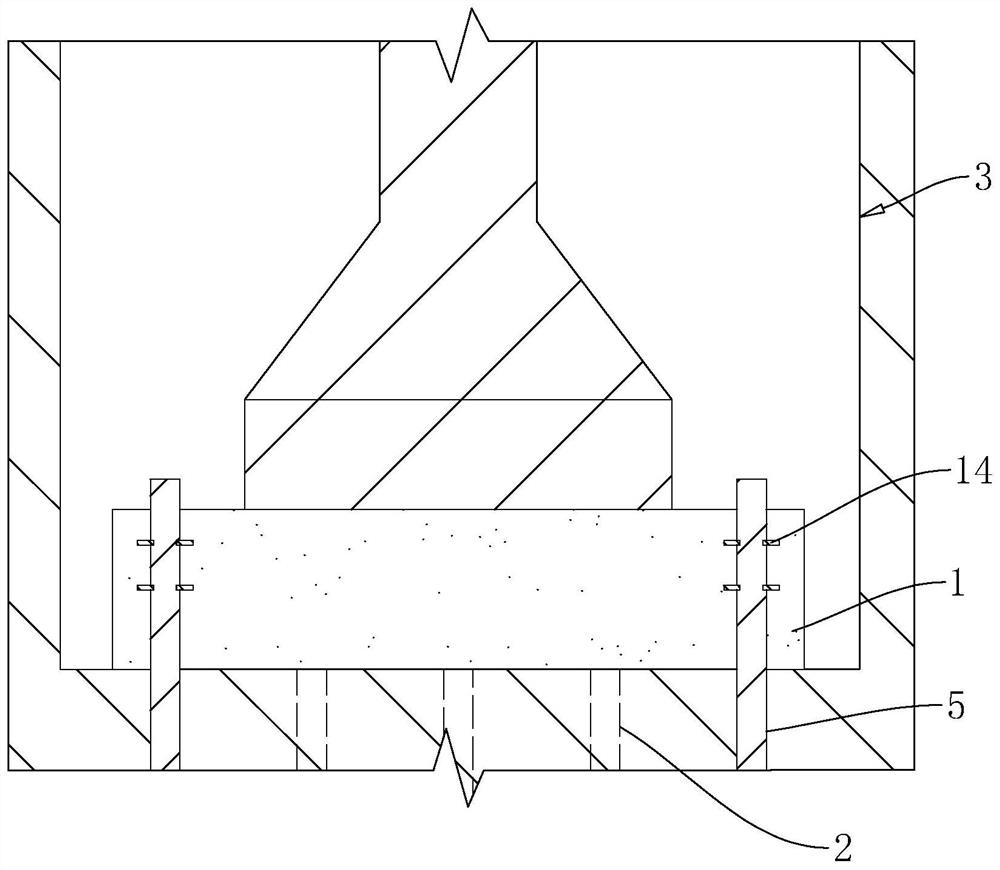

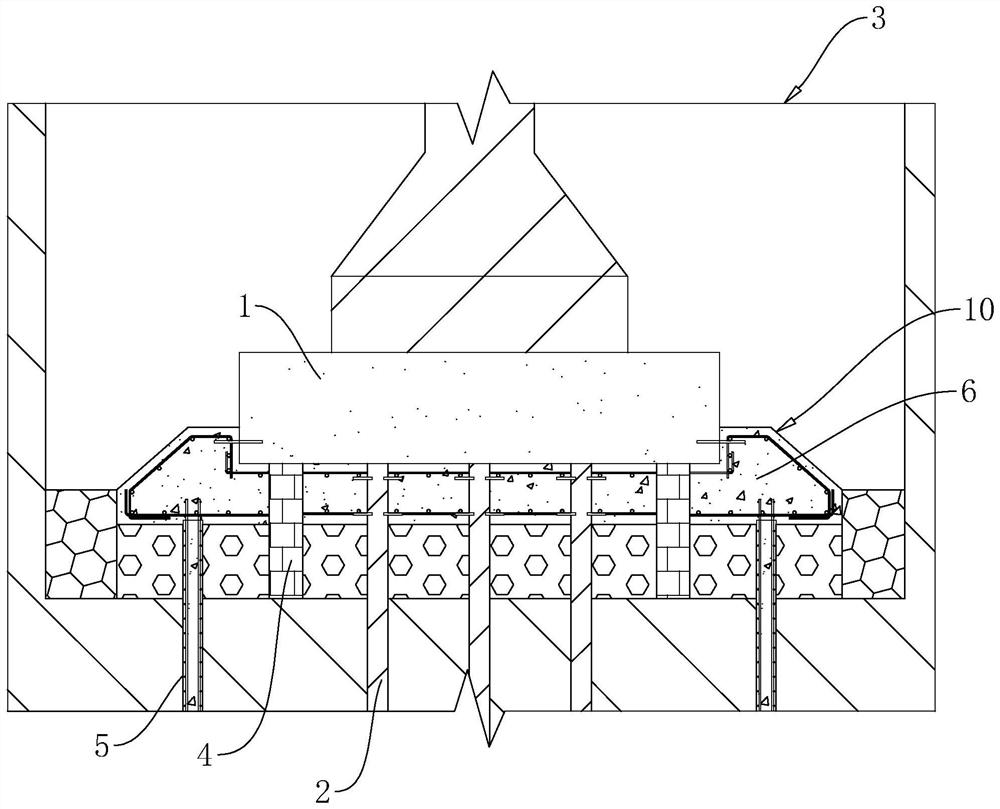

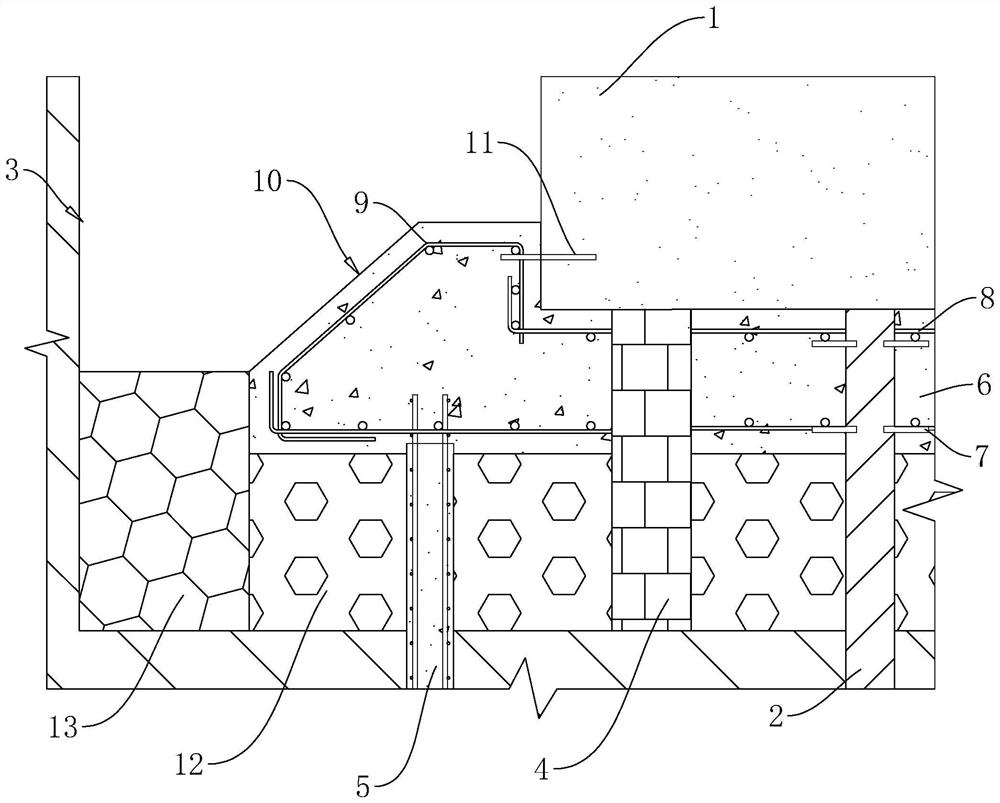

Pile foundation reinforcing method

The invention relates to a pile foundation reinforcing method. The method comprises the following steps that S1, a foundation pit is excavated, the foundation pit is formed through excavation, the bottom of the foundation pit is lower than the lower surface of a pile bearing platform, and a construction space is formed between the bottom of the foundation pit and the lower surface of the pile bearing platform; S2, structure construction is reinforced: S2-1, pile construction is reinforced: constructing at the bottom of the foundation pit and on one side of the vertical projection of the pile cap at the bottom of the foundation pit to form a reinforcing pile; and S2-2, reinforcing plate construction is conducted, specifically, a reinforcing plate is formed on the lower surface of the pile cap through construction, and the reinforcing plate is fixedly connected with the reinforcing pile. S3, the foundation pit is backfilled: S3-1, filling a first filler layer, and filling a first filler between the lower surface of the reinforcing plate and the pit bottom of the foundation pit to form the first filler layer. and S3-2, second filler layer filling is conducted, specifically, the side wall of the first filler layer is filled with the second filler layer, the second filler layer is vibrated and compacted from the upper surface of the second filler layer, and the upper surface of the second filler layer is higher than the lower surface of the reinforcing plate. The method has the effect of reducing damage to the pile cap during pile foundation reinforcement.

Owner:浙江鼎固建筑技术有限公司

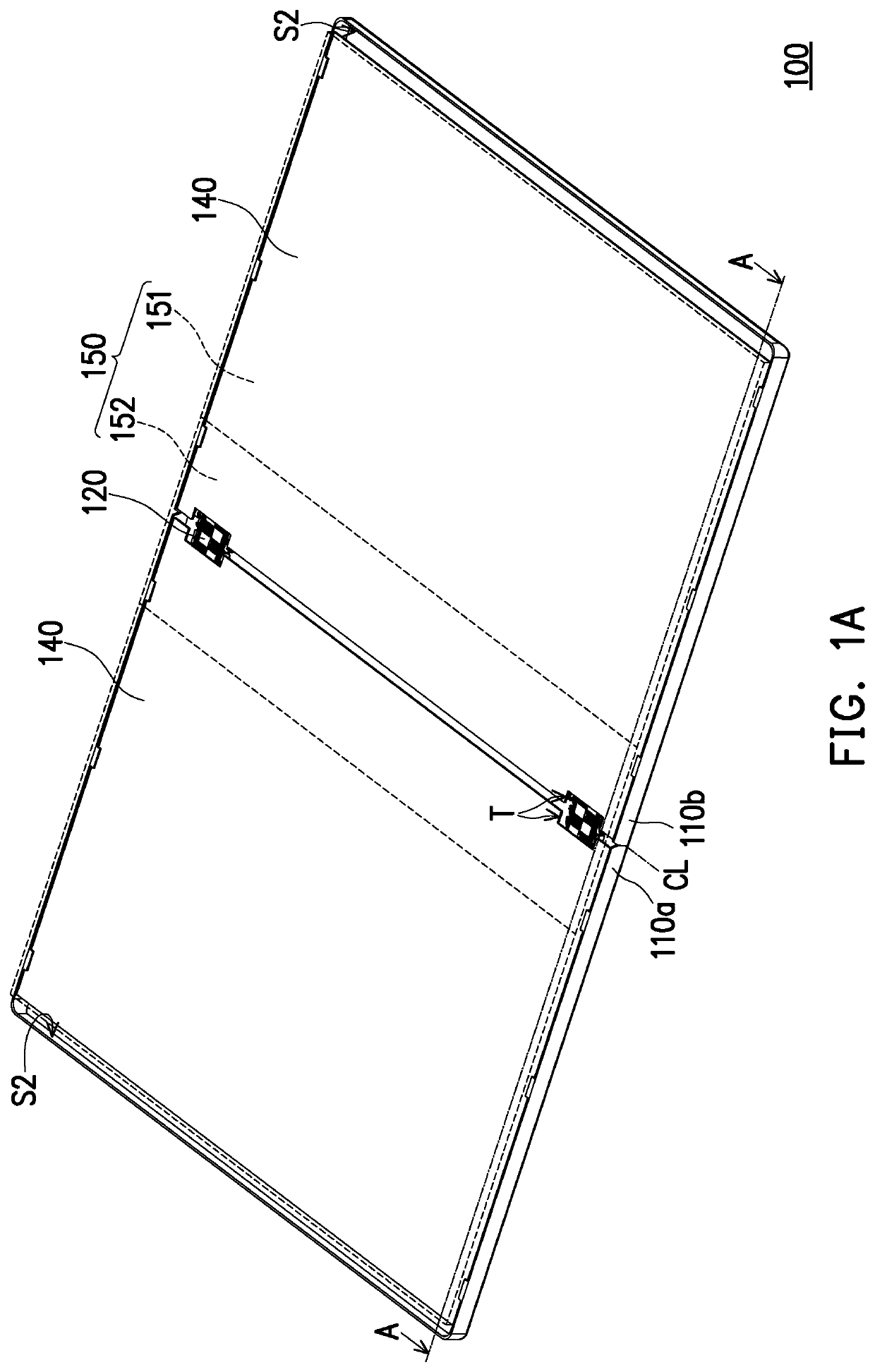

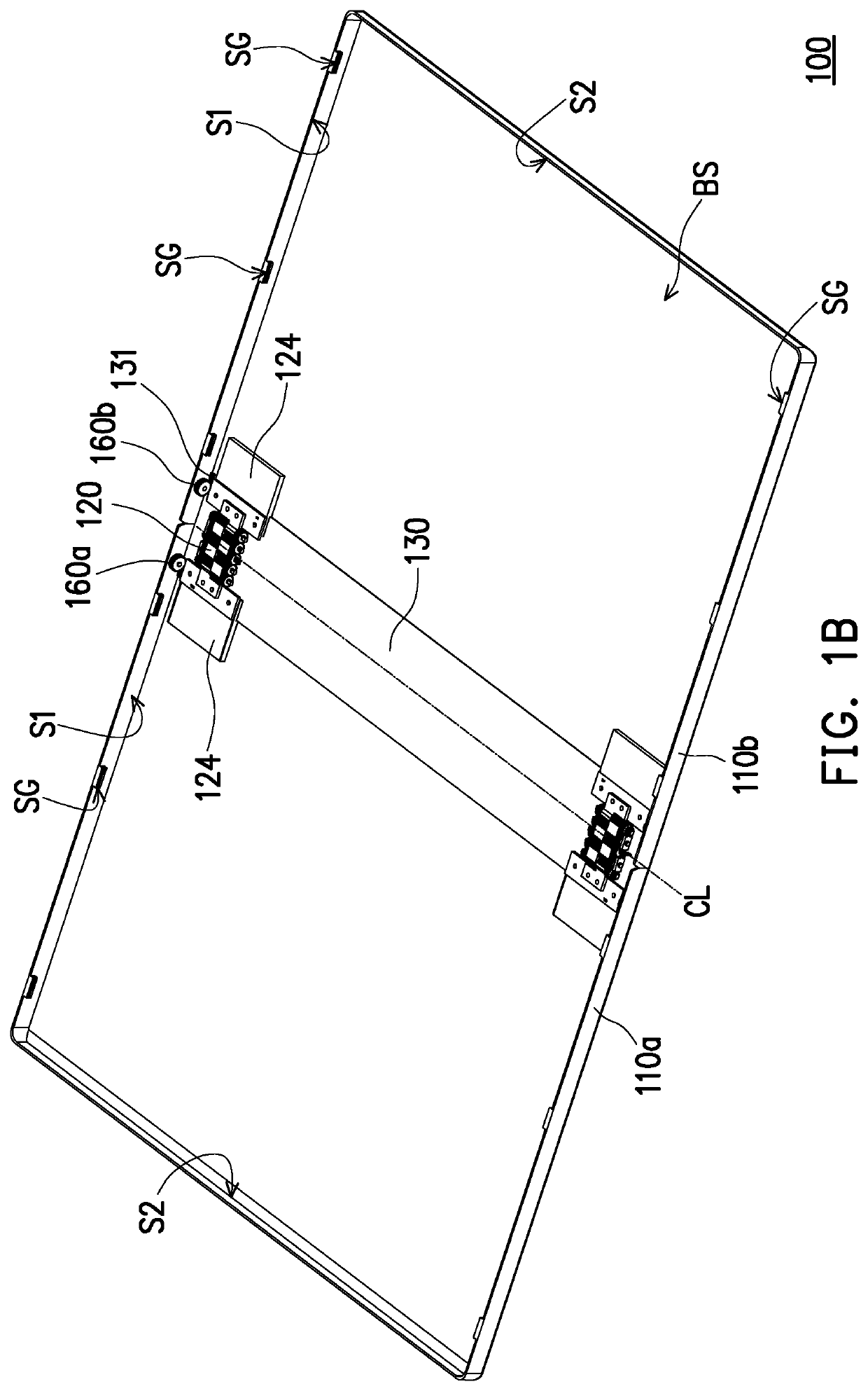

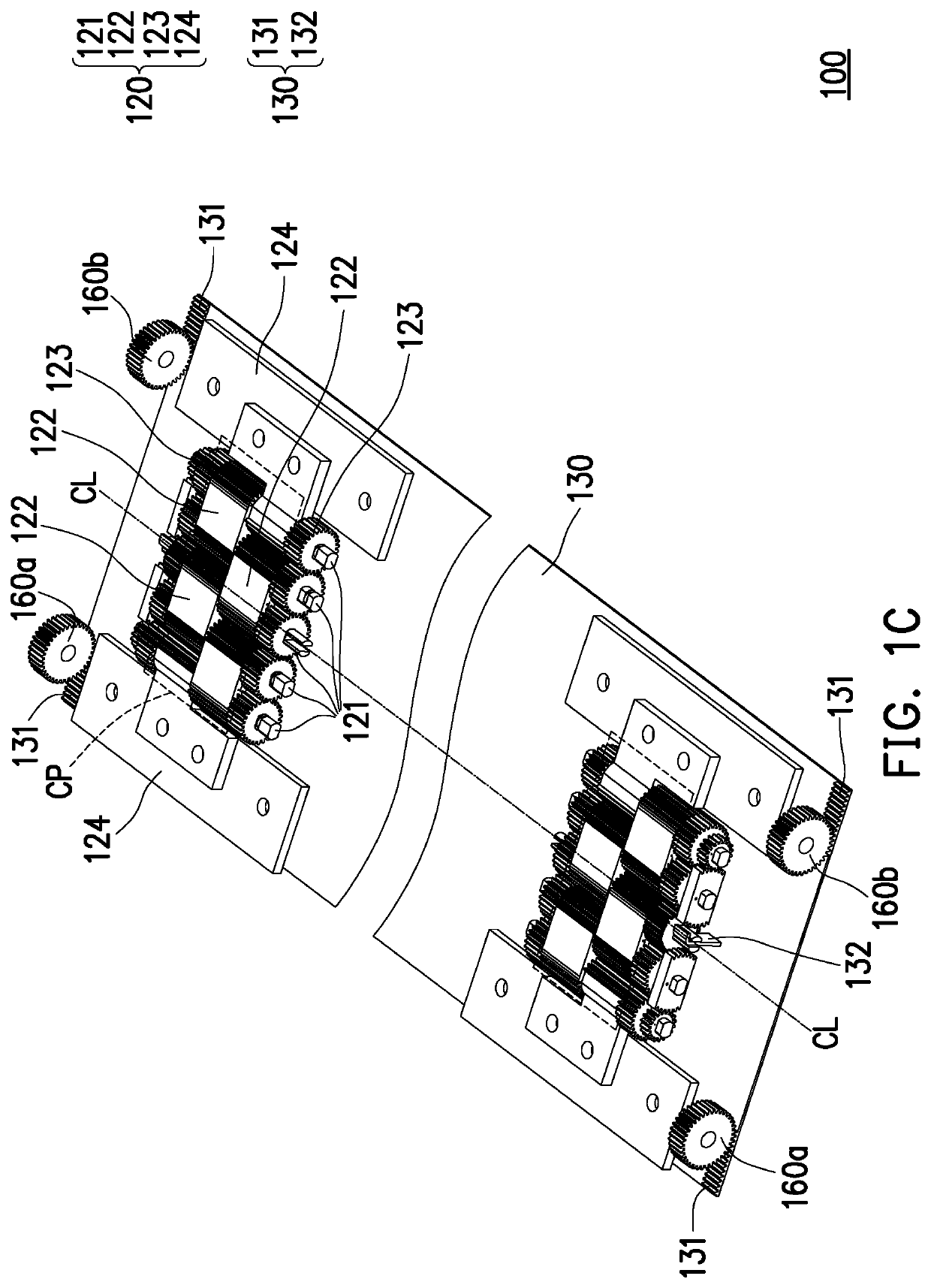

Folding-type electronic device

ActiveUS11262793B2Reduce the amount of bending deformationAvoid stress concentrationDetails for portable computersSubstation equipmentGear wheelElectronic equipment

Owner:COMPAL ELECTRONICS INC

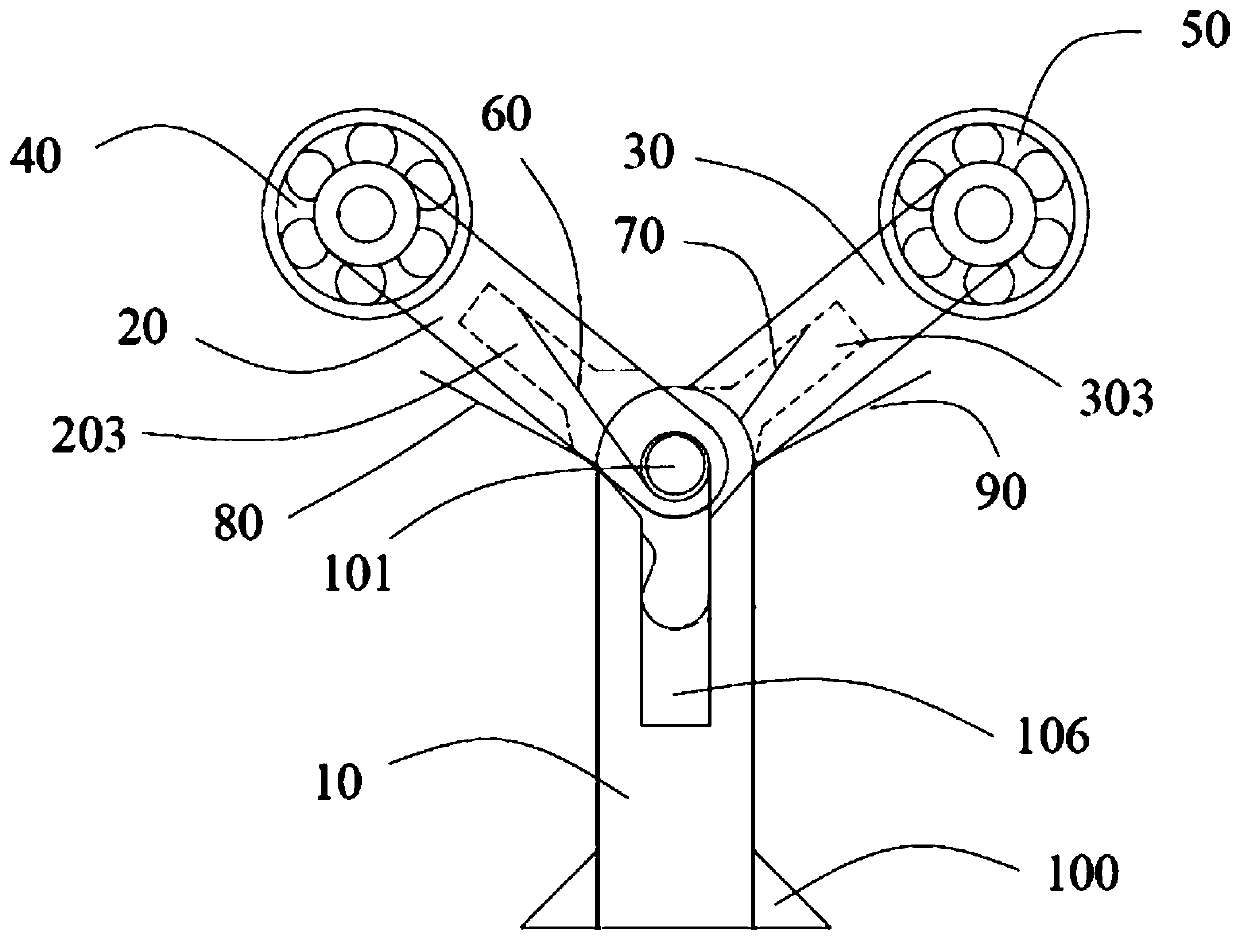

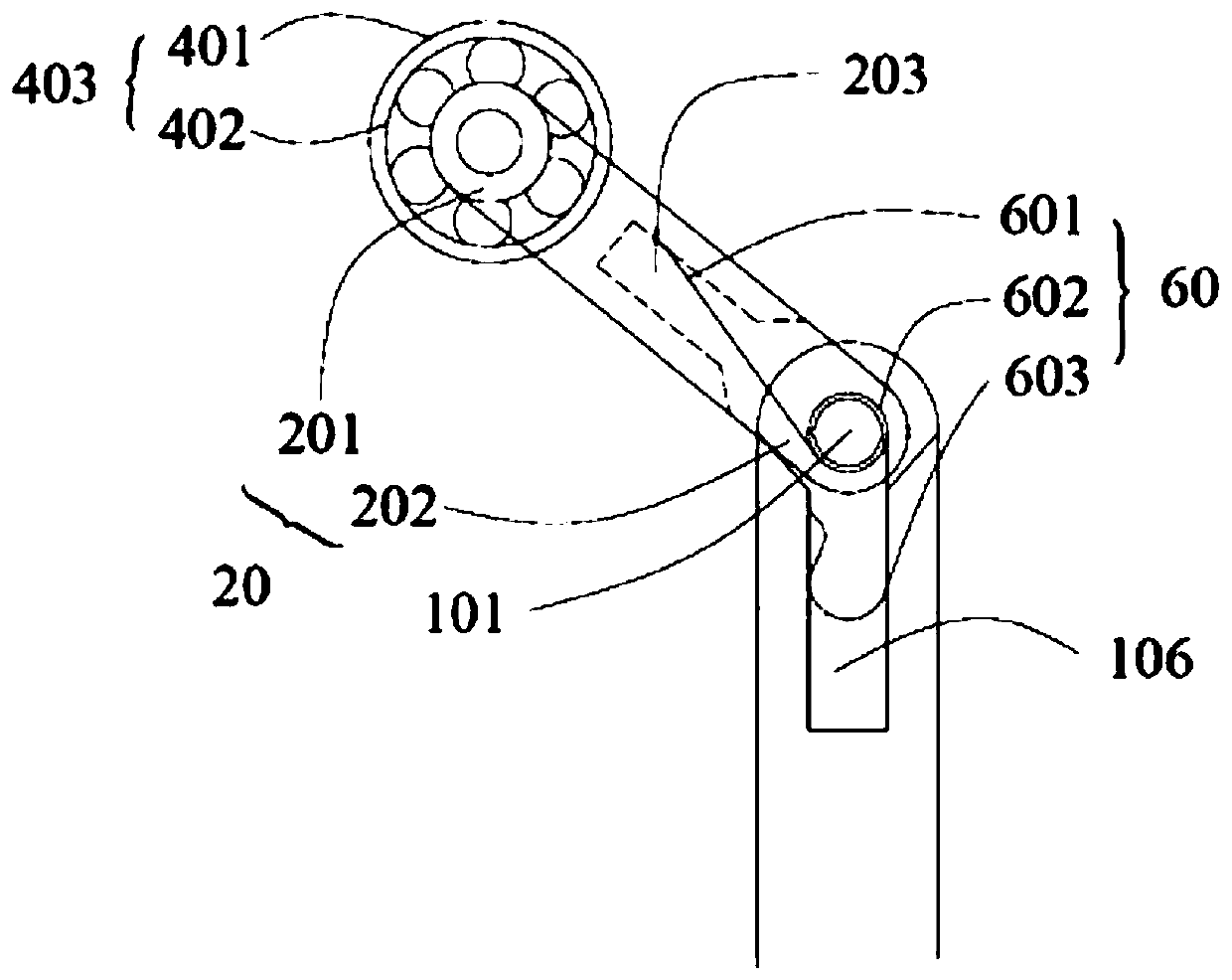

Teleporter

ActiveCN108382856BReduce the amount of bending deformationAvoid impact fragmentsCharge manipulationRollersEngineeringMechanical engineering

The invention provides a conveying device. The conveying device is used for conveying a bade plate, and comprises a main support rod, two branch support rods and two elastic support elements arrangedon the main support rod, wherein the two branch support rods are rotationally connected to the two opposite sides of the main support rod separately, and oppositely arranged in a staggered manner; thetwo branch support rods are capable of stretching relative to the main support rod; the two elastic support elements are used for elastically supporting the two branch support rods when the two branch support rods relatively stretch; a free roll is fixedly connected to one end away from the main support rod, of each branch support rod; and the two branch support rods support the base plate when the two free rolls convey the base plate. According to the conveying device provided by the invention, the technical problem that the local stress of the base plate is non-uniform because unevenness iseasily generated between the independent free rolls due to the installation and production difference or the use process change of the free rolls, and then the damage risk probability of the back surface of the base plate is increased, is solved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Novel non-deformation constant-air-leakage-rate sealing device for air pre-heater

PendingCN114234226AReduce weightSave materialCombustion processIndirect carbon-dioxide mitigationStructural engineeringMechanical engineering

The invention discloses a novel non-deformation constant-air-leakage-rate sealing device of an air pre-heater. The flexible sealing device comprises a floating plate, a limiting mechanism and a flexible sealing mechanism, the flexible sealing mechanism is installed at the upper end of the floating plate through a connecting piece, the limiting mechanism is arranged between the floating plate and a bin grid plate and comprises a limiting plate and a limiting supporting hook, and the limiting supporting hook is arranged on the rear side of the limiting plate in the rotating direction; a limiting groove is formed between the limiting supporting hook and the sealing side of the limiting plate, the floating plate is placed in the limiting groove, and the front end face of the limiting plate is attached to the rear end face of a fixed reinforcing plate fixed to the center cylinder. The non-deformation constant air leakage rate device has the beneficial effects that compared with an existing non-deformation constant air leakage rate device, the structure is simple, installation is firm and reliable, and the problem that the existing non-deformation constant air leakage rate device is complex in assembly and disassembly procedures due to various structural parts is solved; and potential safety hazards caused by the fact that a limiting device is limited in welding position, poor in welding effect and prone to falling off after being collided, abraded and impacted by the sector plate are avoided, and disassembly, assembly and maintenance are convenient.

Owner:华能(广东)能源开发有限公司海门电厂

A method for processing cold-rolled work rolls of complete martensitic alloy steel after hardening and cryogenic cooling

ActiveCN106216954BReduce the amount of bending deformationReduce processing difficultyRollsMetal rolling arrangementsCryogenic hardeningReducer

Owner:马鞍山市恒久特材有限公司

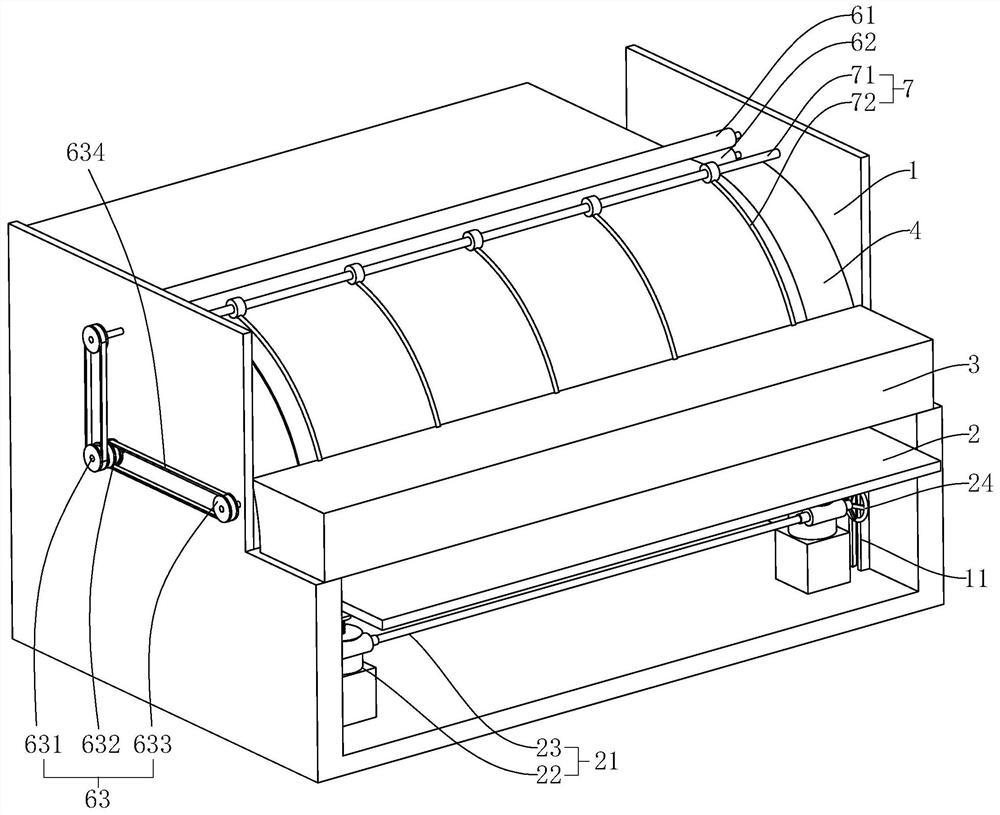

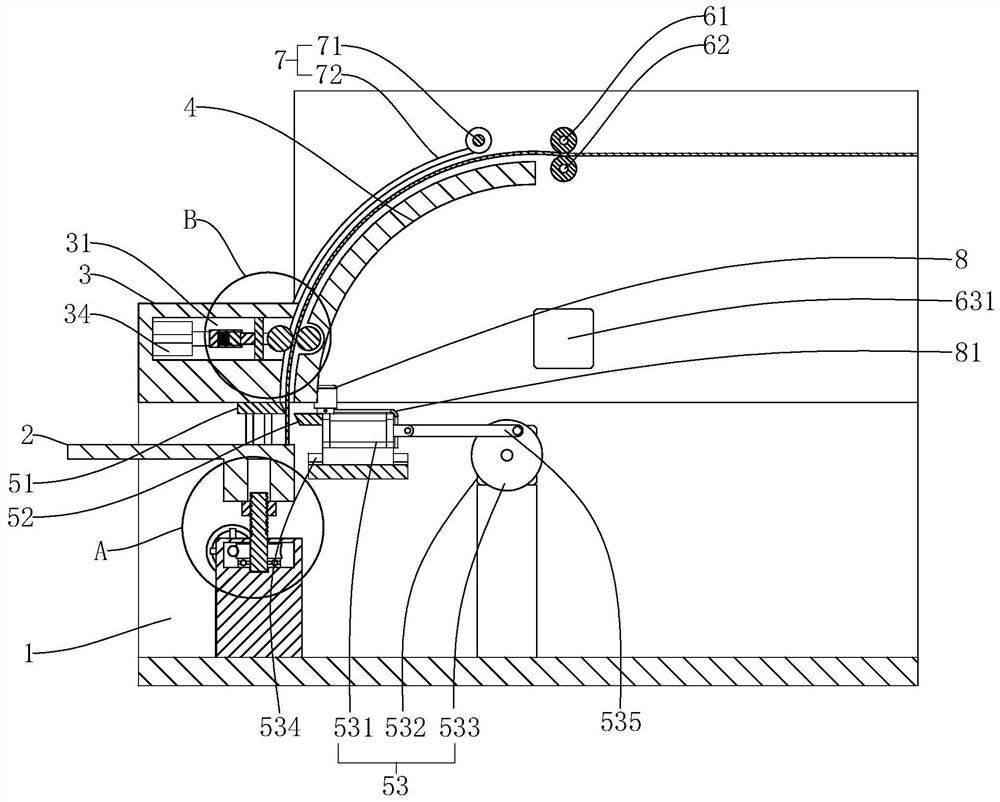

A kind of pulp feeding device and feeding method thereof

ActiveCN110550483BReduce the amount of bending deformationExtended service lifeWebs handlingEngineeringMechanical engineering

The invention discloses a pulp supplying device, which includes a pulp roll, first grooves, second grooves and a frame, wherein the two second grooves are respectively fixed on the two sides of the frame; the tail ends of the two first grooves are rotationally connected with the starting ends of the second grooves through flange plate components respectively; the bottoms of the two first grooves are connected with the bottom of the frame through fourth air cylinders respectively; the fourth air cylinders drive the first grooves to rotate relative to the frame by taking the center lines of theflange plate components as axes; a shaft is arranged on the roll core of the pulp roll; the two ends of the shat move along the first grooves and the second grooves through a first bearing and a second bearing, so that the pulp roll can move among different stations.

Owner:ZUIKO (SHANGHAI) CORP

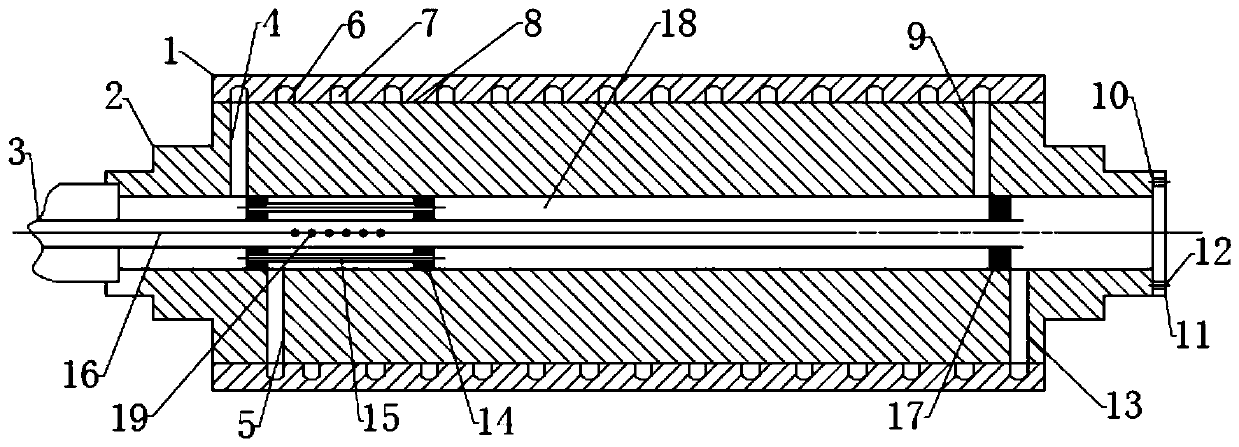

A mill or calender roller and its manufacturing method

The invention discloses a roller of an open mill or a calendaring machine and a manufacturing method of the roller. The roller comprises a roller shaft core and a roller jacket, wherein the roller shaft roller is sleeved with the roller jacket. The roller jacket is made of chilled cast iron or alloy chilled cast iron. The roller shaft core is made of 45 steel or 40Cr or 40MnB. A through hole is formed in the position of the axis of the roller shaft core to serve as a main runner. A liquid inlet pipe and a flow distributing and returning device are arranged in the through hole. Two medium runners located in the roller jacket are formed between the roller jacket and the roller shaft core and communicate with the main runner through the flow distributing and returning device. The roller is good in surface abrasion resistance, good in rigidity, high in strength, remarkable in heat exchange effect and uniform in temperature distribution.

Owner:青岛首科新材料有限公司

Honeycomb crossbeam structure

InactiveCN104400444AReduce the amount of bending deformationReduced cross-sectional areaLarge fixed membersHoneycombElectrical and Electronics engineering

The invention discloses a honeycomb crossbeam structure. The honeycomb crossbeam structure comprises a crossbeam frame; a plurality of reinforcing rib plates are arranged in the crossbeam frame; connecting plates are arranged between adjacent reinforcing rib plates and between the adjacent reinforcing rib plates and the crossbeam frame; the reinforcing rib plates are connected into a whole through the connecting plates. The bending deformation of the crossbeam is greatly reduced under the conditions of the same materials, the same sectional area and the equal stress, so that the cross sectional area is reduced in the same deformation tolerance range, and the manufacturing cost is reduced.

Owner:杨桂珍

A cutting device for honeycomb paper core production line

ActiveCN111844168BLarge amount of bending deformationSize Bending DeformationMetal working apparatusCardboardCarton

This application relates to a shearing device for a honeycomb paper core production line, including a frame, a workbench, a lifting mechanism, a limit block, a paper guide plate, a fixed cutter, a movable cutter and a first drive mechanism, and the middle part of the limit block The side close to the paper guide plate is provided with a first mounting groove, and a mounting block is slidably arranged in the first mounting groove, and a first traction roller is rotatably arranged on the mounting block, and a driving roller for driving the mounting block to slide is arranged in the first mounting groove. For the second driving mechanism, a second installation groove is opened on the paper guide plate, a second traction roller is rotatably arranged in the second installation groove, a first conveying roller is rotatably arranged above the paper guide plate, and a first conveying roller is located below the first conveying roller. The second conveying roller, and the diameter of the second conveying roller is the same as that of the second traction roller, and the frame is provided with a third drive mechanism for driving the conveying roller and the second traction roller to rotate synchronously. The application can guarantee the quality of the product when the width of the cut paper strip is relatively large.

Owner:佛山和盛隆包装制品有限公司

Pulp supplying device and feeding method thereof

ActiveCN110550483AReduce deflectionReduce the amount of bending deformationWebs handlingFlangePulp and paper industry

The invention discloses a pulp supplying device, which includes a pulp roll, first grooves, second grooves and a frame, wherein the two second grooves are respectively fixed on the two sides of the frame; the tail ends of the two first grooves are rotationally connected with the starting ends of the second grooves through flange plate components respectively; the bottoms of the two first grooves are connected with the bottom of the frame through fourth air cylinders respectively; the fourth air cylinders drive the first grooves to rotate relative to the frame by taking the center lines of theflange plate components as axes; a shaft is arranged on the roll core of the pulp roll; the two ends of the shat move along the first grooves and the second grooves through a first bearing and a second bearing, so that the pulp roll can move among different stations.

Owner:ZUIKO (SHANGHAI) CORP

Circulating structure for drawing-blowing forming machine

The invention provides a circulation structure for a stretch-blow molding machine, comprising a conveyer belt which cycles along a preset route. The conveyer belt consists of two or more chain links which are pivoted one by one in order and a chain link comprises a bridging part with preset length, whose prolate axis is perpendicular to the circulation direction, a pair of connecting parts convexly arranged parallel on the preset places of the bridging part respectively with a preset distance; the connecting parts have preset length and the front ends and the rear ends of the connecting parts are respectively pivoted with the rear ends and the front ends of the adjacent chain links through the same bolt; a accommodation room is confined among the bridging part, a pair of connecting parts and a pair of bolts. A bracket is arranged inside the accommodation room to hold the conveyer belt which has certain length and weight.

Owner:CHUM POWER MASCH CORP

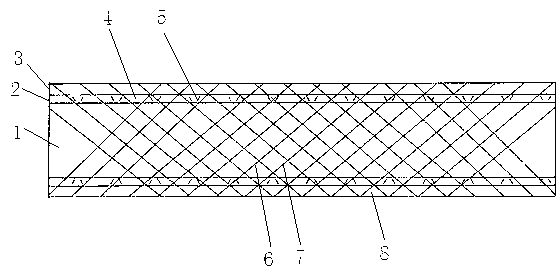

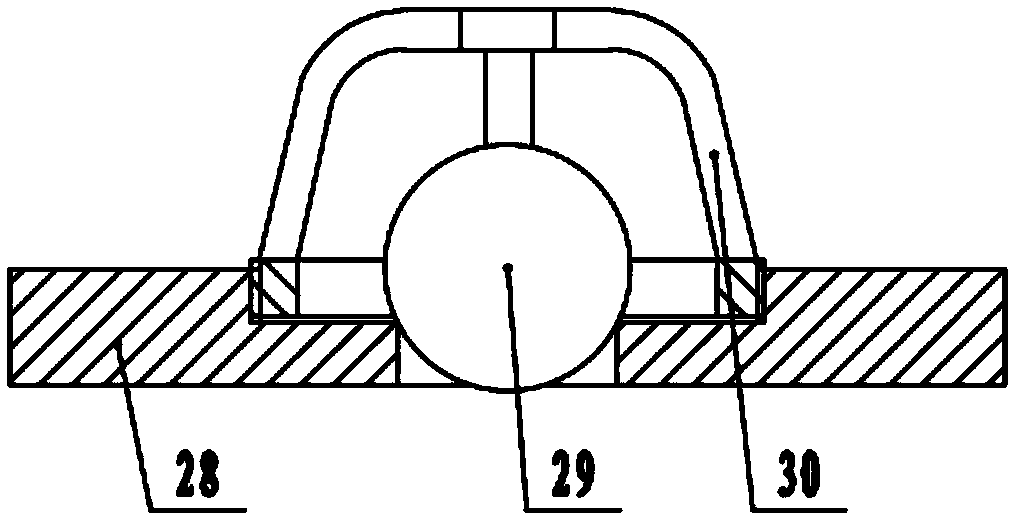

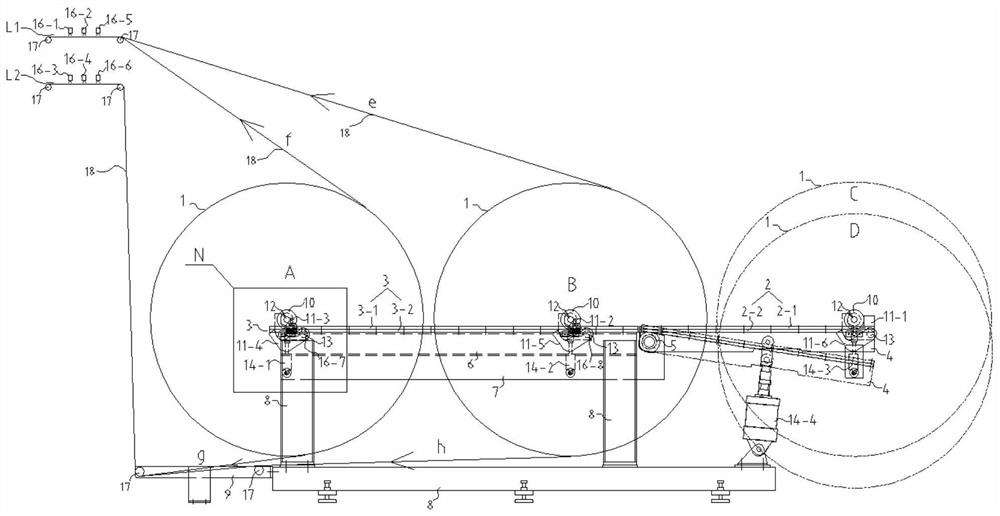

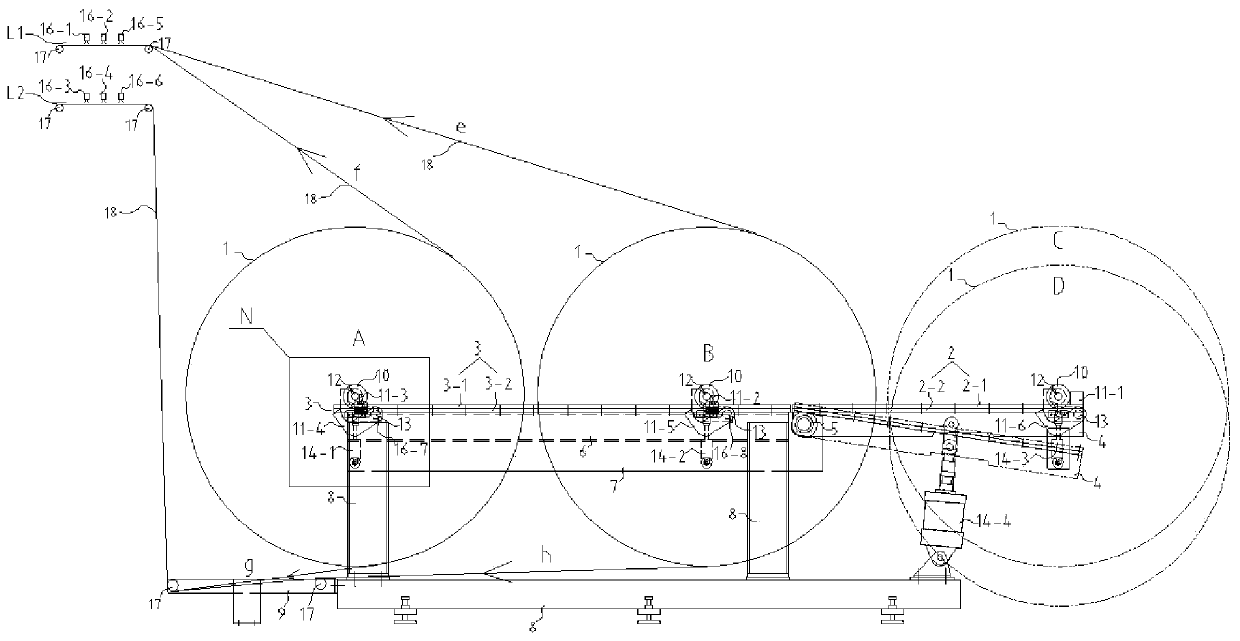

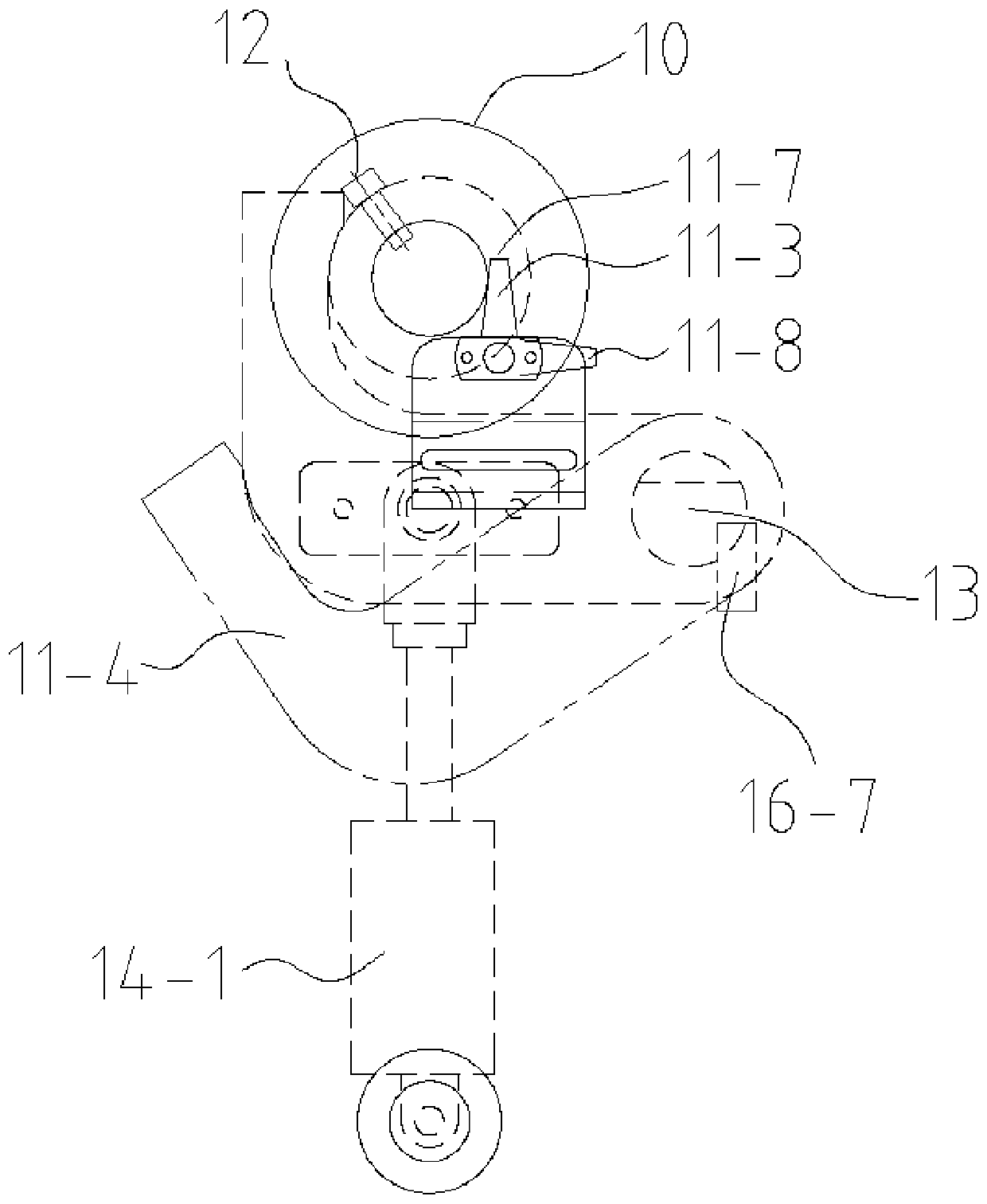

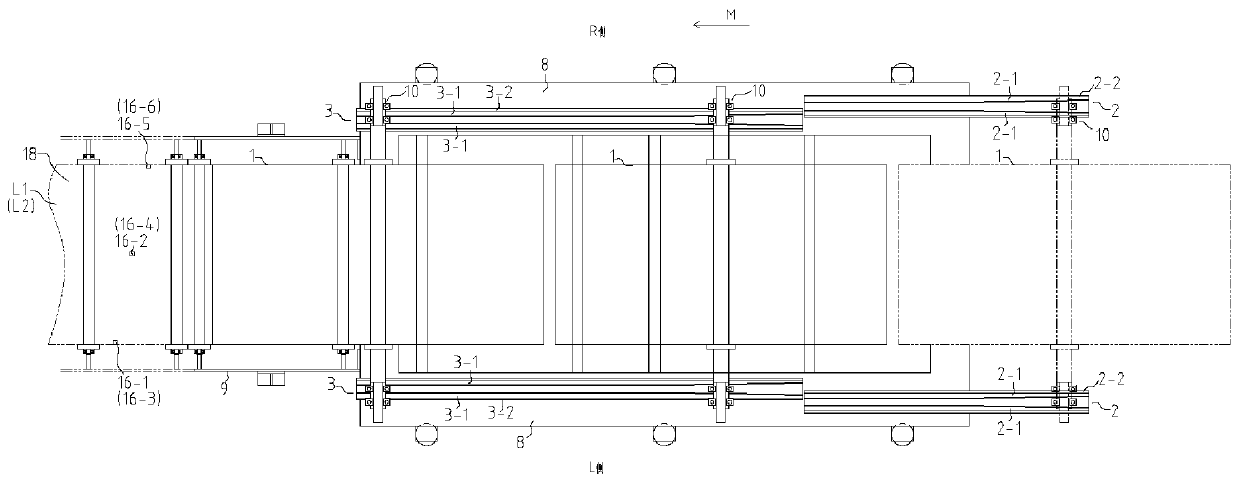

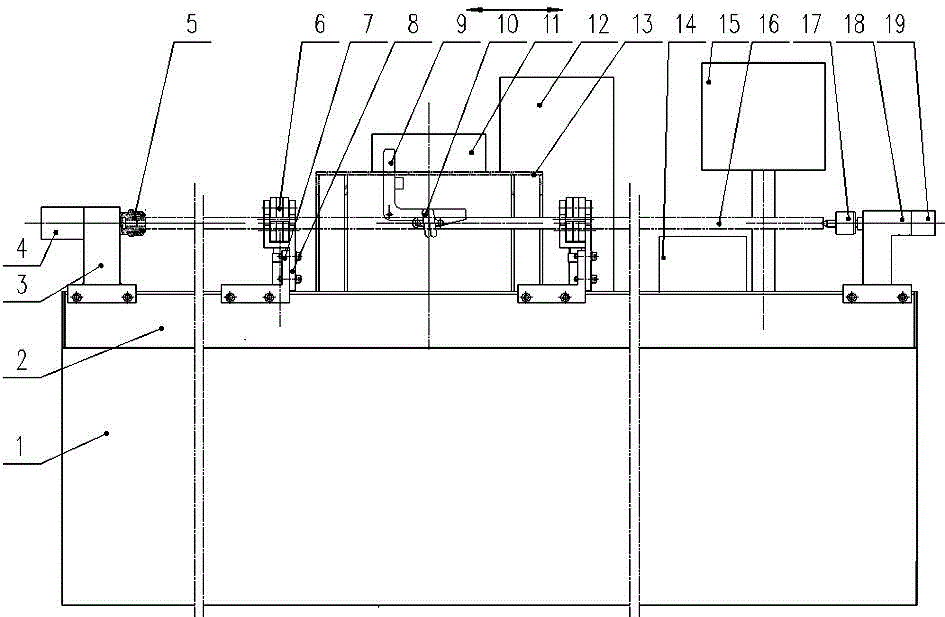

A quenching machine tool capable of preventing bending deformation of slender rods during quenching

ActiveCN103589832BFast spinReduce the amount of bending deformationIncreasing energy efficiencyFurnace typesNumerical controlMotor drive

The invention relates to a quenching machine tool capable of preventing bending deformation of a slender rod piece during quenching. The quenching machine tool comprises a tool body, a track, a bracket mechanism and quenching equipment installed on a numerical control sliding table. The bracket mechanism consists of a headstock and a tailstock disposed on the track, and two sets of middle supporting frames. The headstock is provided with a spring clamp head and a drive motor, and the tailstock is provided with a live center and a drive air cylinder. Each middle supporting frame comprises a base, a center frame and three center frame rollers installed on the center frame. The three center frame rollers are arranged in the shape of an isosceles triangle. After loading, the wheel surfaces press against a rod body. Both ends of the rod piece are fixed through the spring clamp head and the live center. The to-be-quenched part of the rod piece is positioned between the two sets of middle supporting frames. The rod body passes through the voids between the three rollers on the center frame. During quenching, the motor drives rapid rotation of the rod piece through the spring clamping head, so that the rod piece can be evenly heated and cooled. And through the action of the three center frame rollers, bending deformation of the rod piece is further restricted, and the quality of the quenching piece is improved.

Owner:ZHENJIANG TIANXIANG PRECISION ELECTRIC MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com