Compressing device for carriage side plate of self-dumper

A pressing device and dump truck technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of large bending deformation of the side plate of the carriage, achieve small bending deformation and reduce welding deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

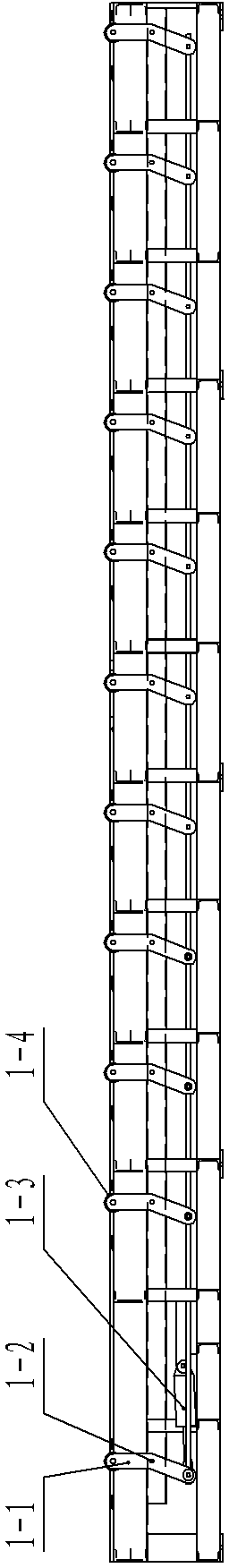

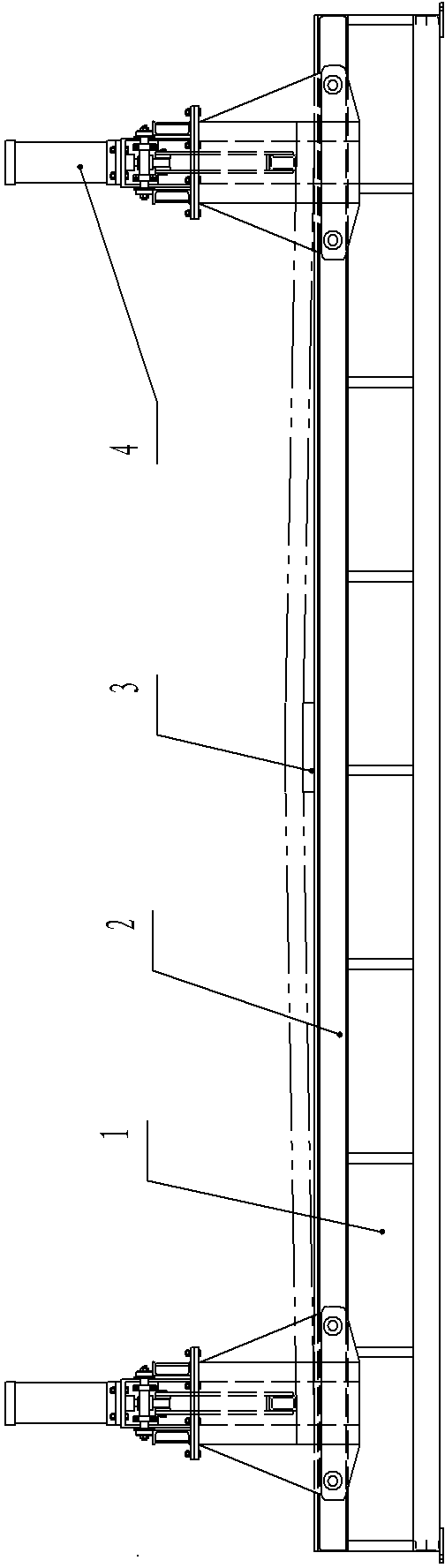

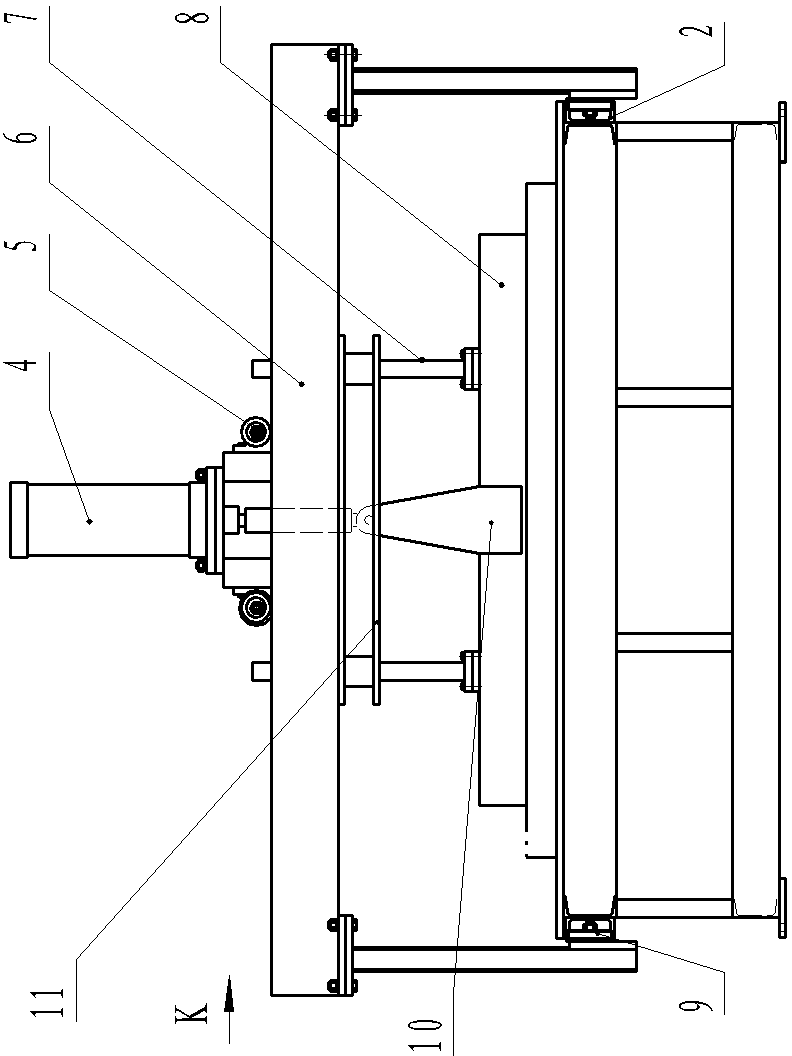

[0013] Such as figure 1 , figure 2 The shown dump car side plate pressing device includes a platform, and the frame 1 of the platform is hinged with a plurality of lifting frames 1-1 through hinge shafts 1-2, and each lifting frame 1-1 extends to one end of the platform table. Drum 1-4 is housed, and the other end of each lifting frame 1-1 is connected and is hinged with the lift oil cylinder 1-3 that drives drum 1-4 to rotate angle around hinge shaft 1-2 through intermediate parts. The two sides of frame 1 are equipped with rails 2, which are made of channel steel and fixed on the upper part of both sides of frame 1 by welding; The bottom of the bottom is connected with two walking wheels 9 by the wheel shaft, and the gantry is supported on the track 2 by the walking wheels 9 mounted on the moving plates on both sides; the track 2 upper frame of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com