A quenching machine tool capable of preventing bending deformation of slender rods during quenching

A technology for bending deformation and quenching machine tools, applied in the field of quenching machine tools, can solve problems such as low production efficiency, bending deformation, complicated procedures, etc., and achieve the effects of improving production efficiency, reducing bending deformation, and improving quenching quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to clarify the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

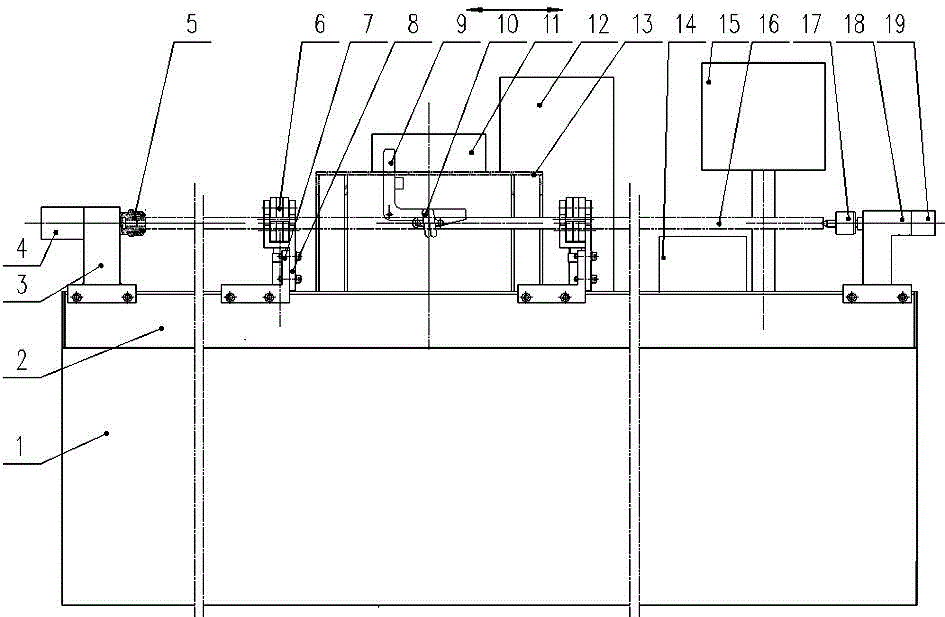

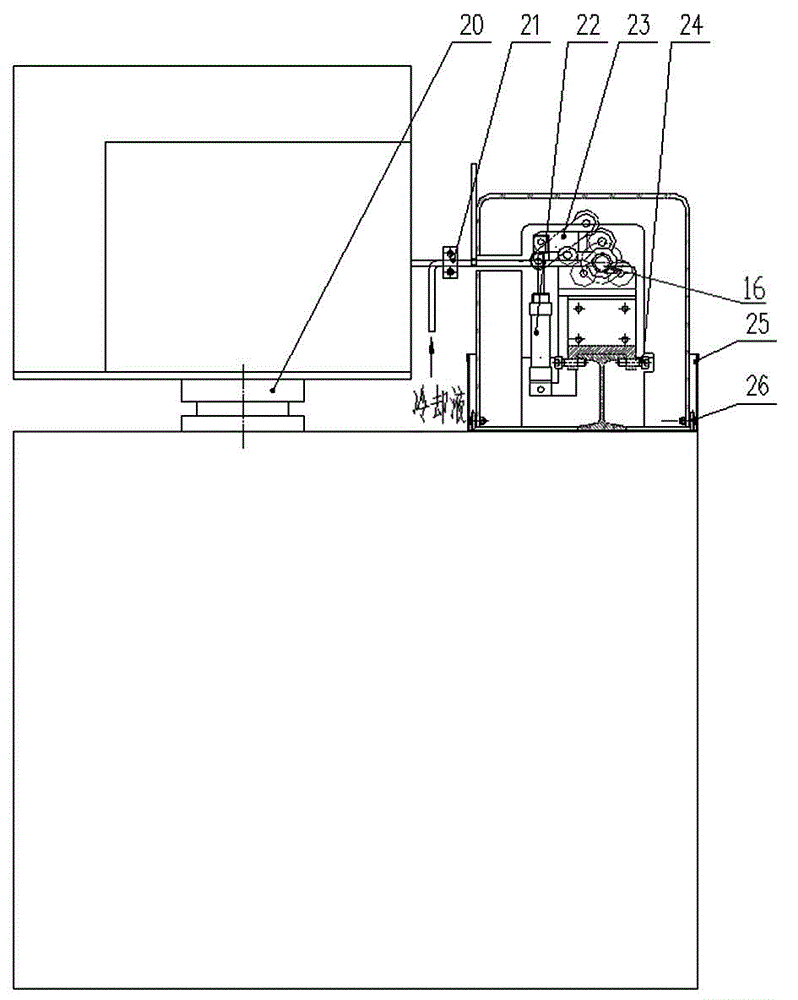

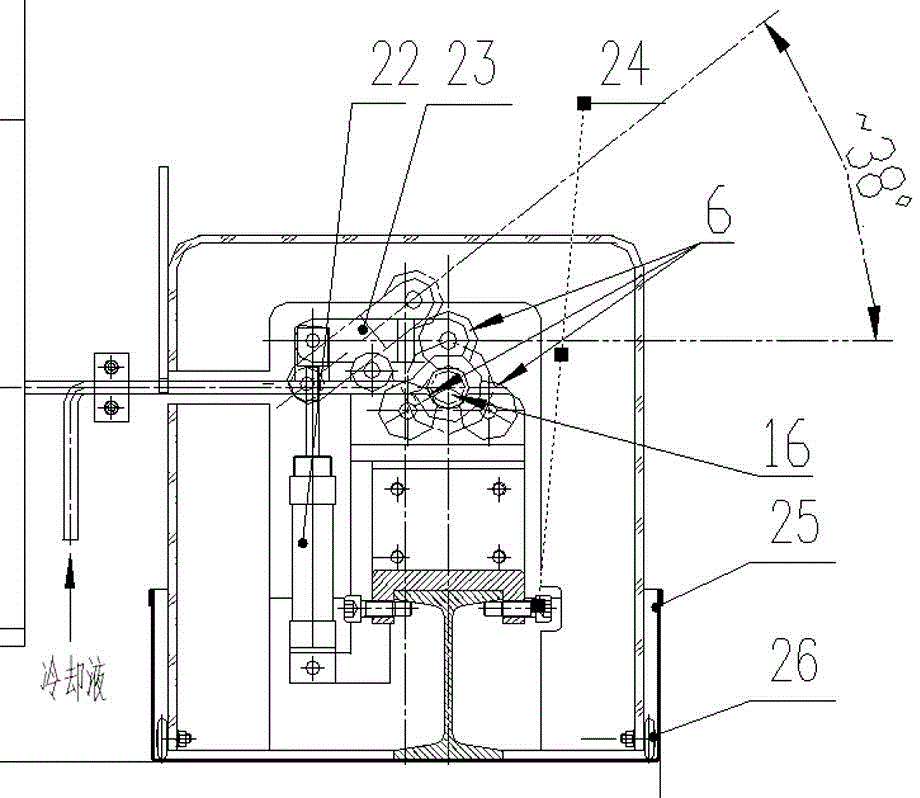

[0024] Such as figure 1 , figure 2 , image 3 The high-frequency quenching machine tool shown is used for high-frequency quenching processing of slender rods, and specifically includes the following components:

[0025] (1) Bed;

[0026] The bed 1 is welded into a box by steel plates, and the detachable panel supporting it is used as a worktable. The bed 1 can double as a coolant tank, and the inside of the bed 1 is provided with a heat exchanger for cooling the coolant.

[0027] A straight I-shaped steel rail 2 is laid on the bed panel, and the coolant pump 14, the console 15 and the sump 25 are all arranged on the bed panel, and the sump 25 is drilled with a hole communicating with the inside of the bed 1. It is convenient for the coolant to flow b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com