Dot-sequential color display system

a color display system and dot-sequential technology, applied in the direction of color television details, picture reproducers using projection devices, instruments, etc., can solve the problem of further reducing to around 30% light utilization efficiency, and achieve the effect of high-resolution and economic method of displacing images in tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention relates to pixelated electronic (e.g., liquid crystal display, digital micromirror device, etc.) projection displays, sometimes referred to as electronic display projectors. The invention includes a dot sequential color display system that may be used in such an electronic display projector. It will be appreciated, however, that the dot sequential color display system of the present invention could alternatively be used in other display applications.

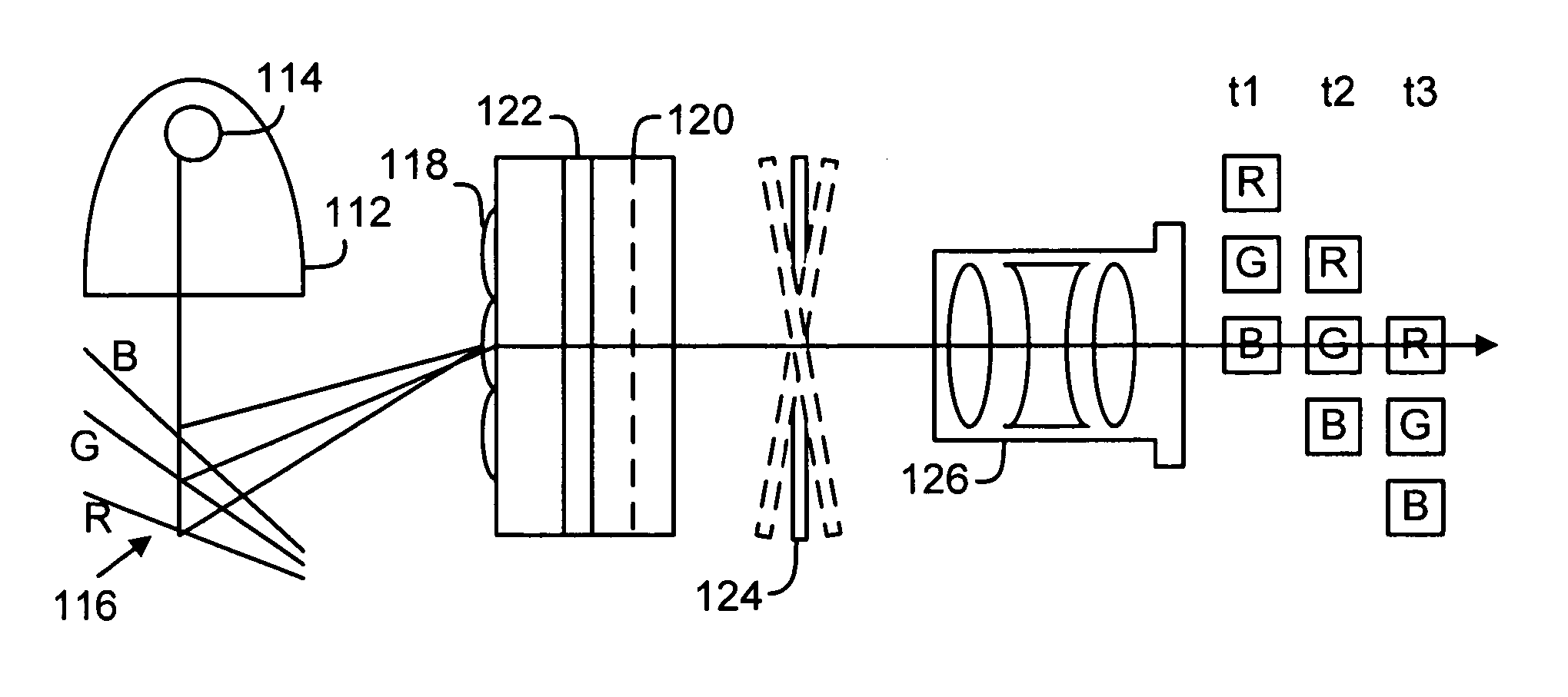

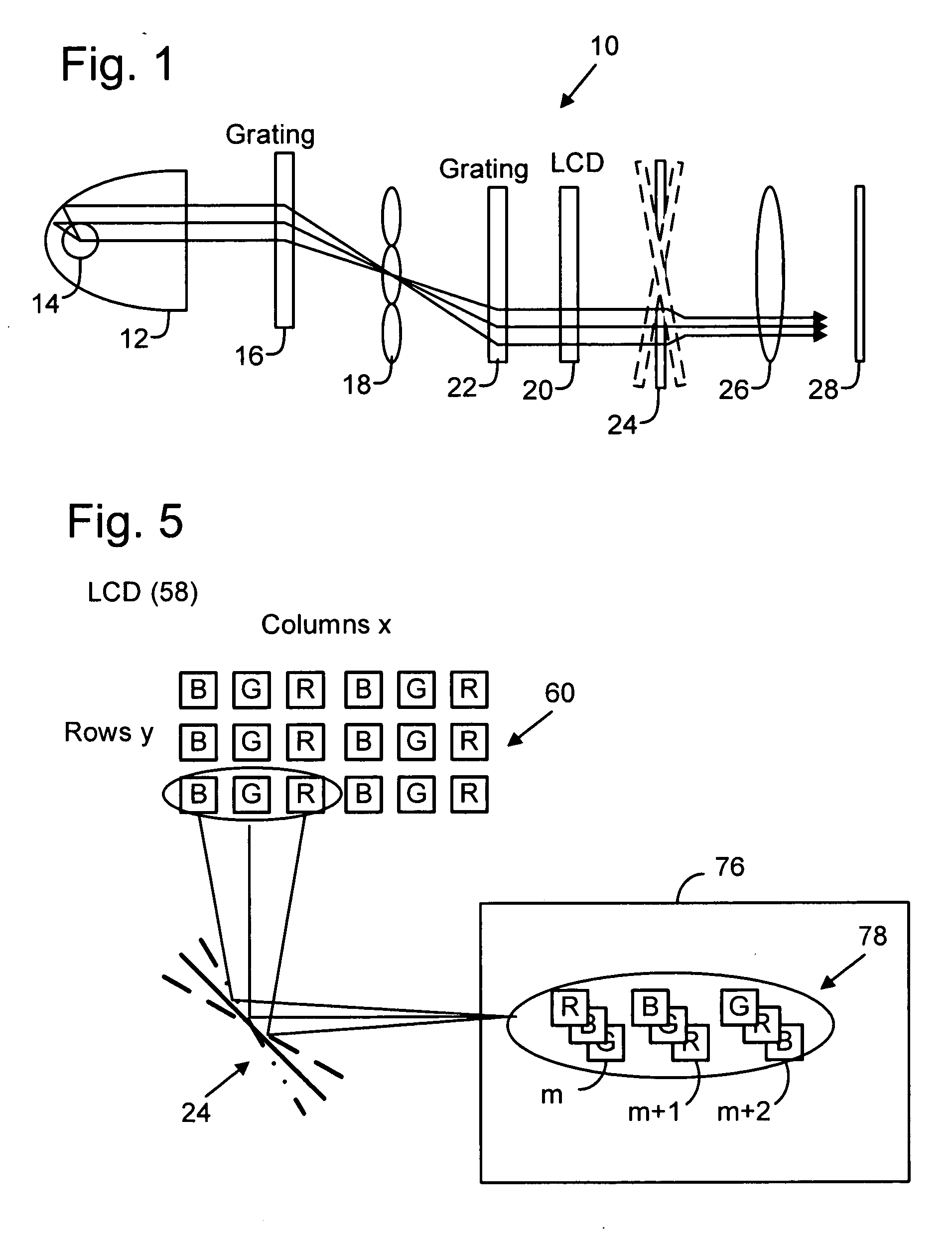

[0048]FIG. 1 is an optical schematic illustration of a dot sequential color display system 10 according to the present invention. A parabolic reflector 12 collects generally white light from a lamp 14 (e.g., an arc lamp) and directs the light in generally parallel rays to a first grating 16. Grating 16 disperses or separates color components of the light (e.g., red, green and blue—“RGB”) and directs them to a microlens array 18 that focuses the dispersed light onto or toward a pixelated electronic display (e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com