Honeycomb crossbeam structure

A technology of honeycomb type and beam, applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems of increasing the cross-sectional area and the height and thickness of the rib plate, so as to reduce the amount of bending deformation and reduce the manufacturing cost. Effect of cost, cross-sectional area reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

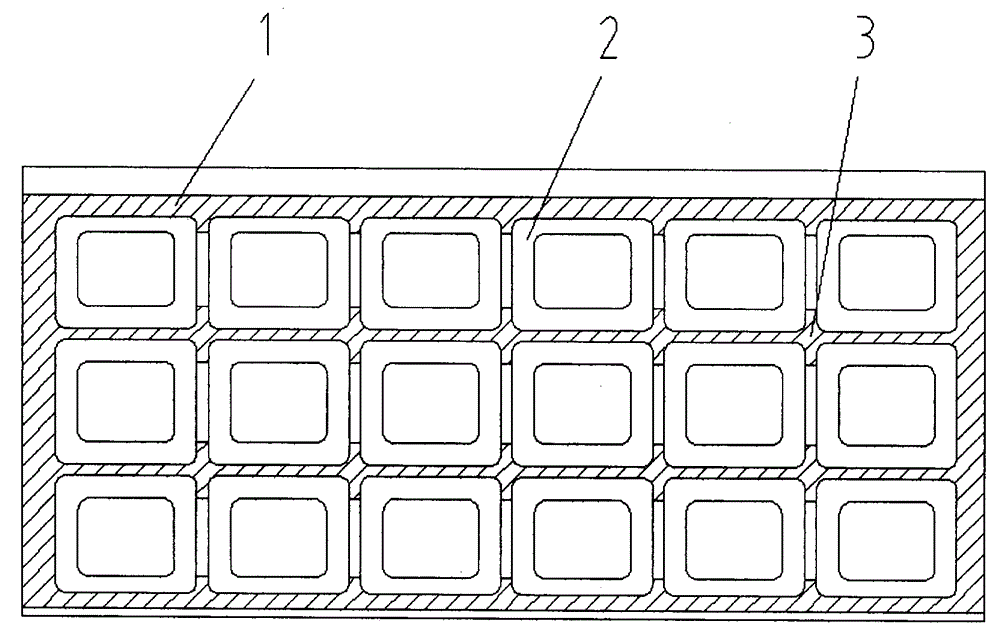

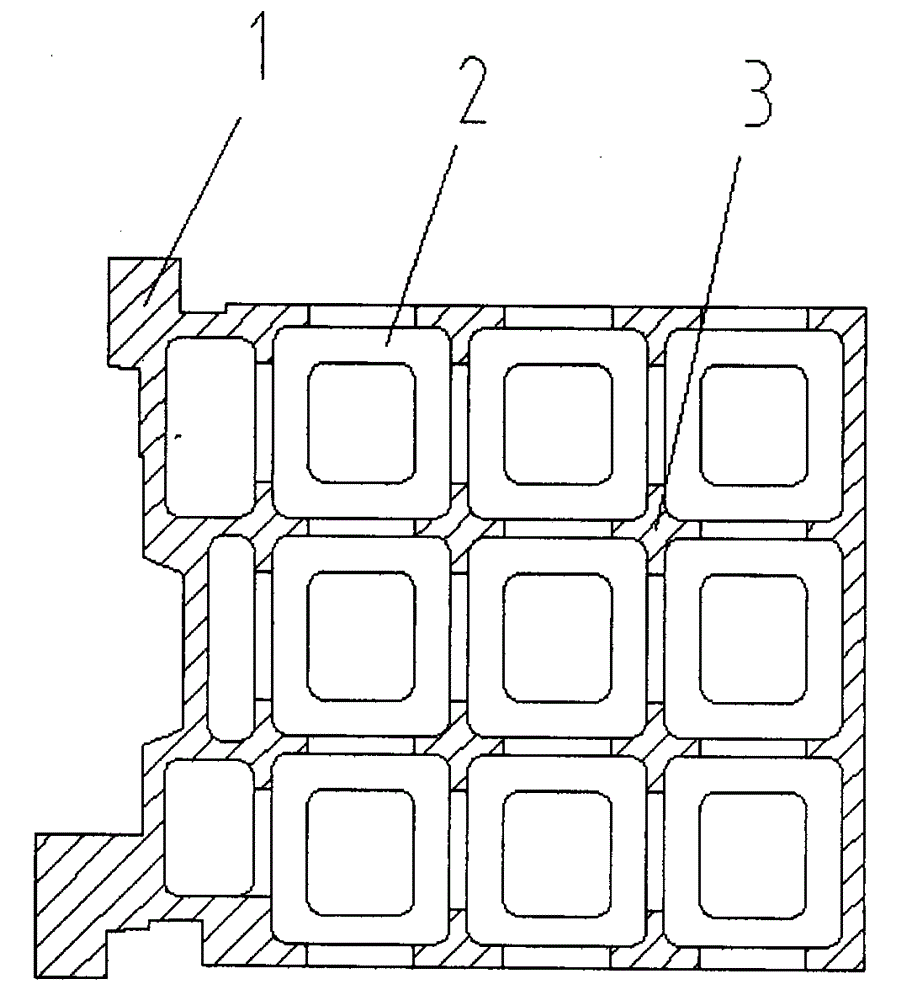

[0012] Such as figure 1 , figure 2 As shown, the present invention provides a honeycomb crossbeam structure, including a crossbeam frame 1, a plurality of stiffeners 2 are arranged in the crossbeam frame, between adjacent stiffeners, and between adjacent stiffeners and A connecting plate 3 is arranged between the crossbeam frames, and all the stiffener plates are connected as a whole through the connecting plate.

[0013] The stiffeners are evenly arranged in the beam in a honeycomb pattern.

[0014] The present invention connects all the ribs inside the beam, when a certain section of the guide rail is subject to overturning moment and gravity bending resistance, because all the ribs are connected to each other, all the ribs in the whole beam are subjected to force , so that the force within a certain range is distributed to all the ribs. In the case of the same material, the same cross-sectional area and the same force, the bending deformation of the beam will be greatly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com