A mill or calender roller and its manufacturing method

A calender and open mill technology, applied in the field of open mill or calender roll, open mill or calender roll manufacturing field, can solve the problem of limited water channel feasibility, high processing cost, roll elastic modulus Small problems such as improving heat transfer effect and uniformity of temperature distribution, reducing processing difficulty and cost, and uniform heating or cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

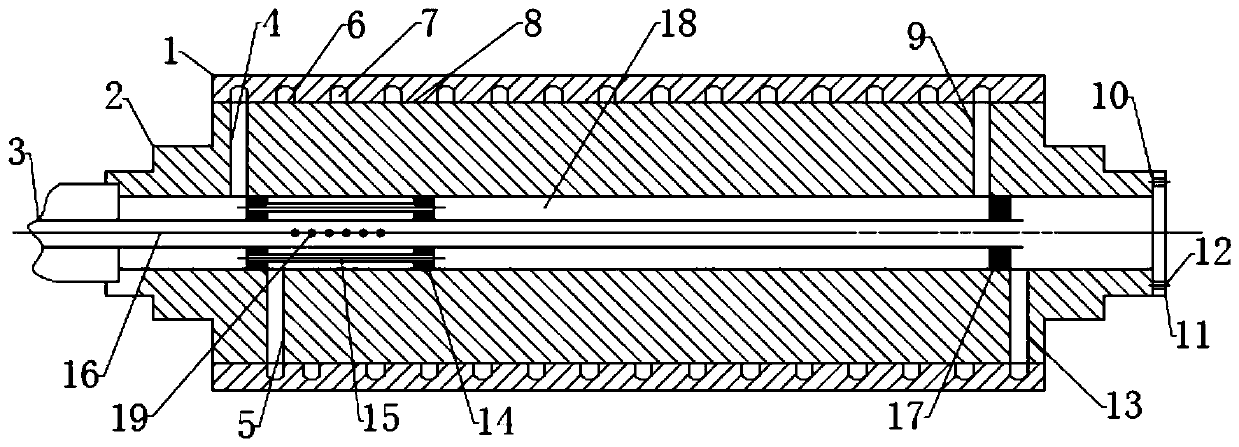

[0025] Attached below Figure 1~2 The specific embodiment of the present invention will be further described in detail.

[0026] Such as figure 1 As shown, a mill or calender roller includes a roller shaft core 2 and a roller jacket 1 sheathed together. The roller jacket 1 is made of chilled cast iron or alloy chilled cast iron, and the surface layer is white Mouth layer. The roller shaft core 2 is made of 45 steel or 40Cr or 40MnB. The roller jacket 1 and the roller shaft core 2 are connected by an interference fit through a shrink-fit method. The outer surface of the roller shaft core 2 is provided with a sealant, such as the sealant layer 8 shown in the figure, to prevent medium leakage.

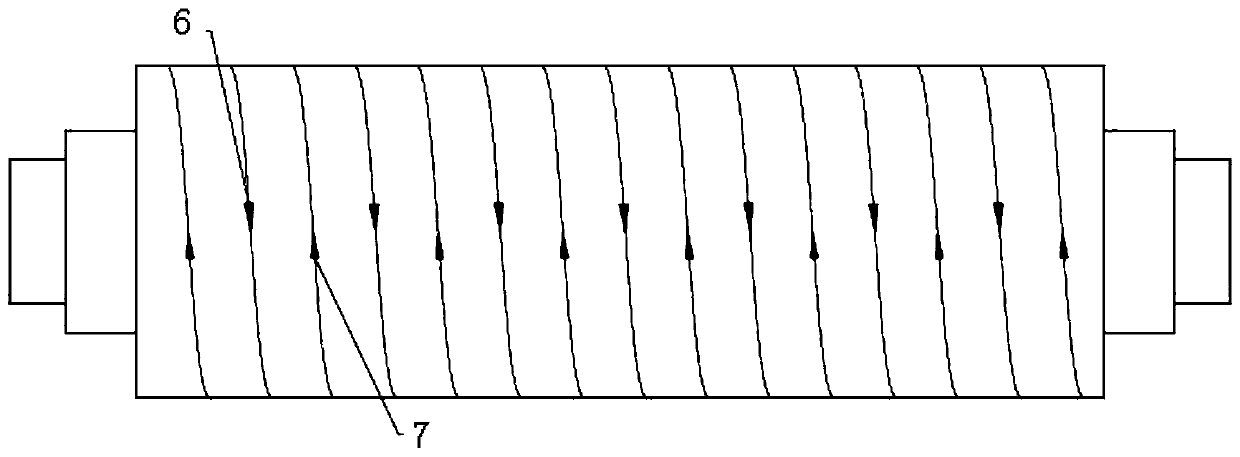

[0027] The shaft center of the roller shaft core 2 is provided with a through hole 18 as the main channel, and the through hole 18 is provided with a liquid inlet pipe 16 and a diversion and return device. The inner surface of the roller jacket 1 is provided with two One end of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com