Pile foundation reinforcing method

A technology of pile foundation and reinforcing plate, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of destroying the integrity of pile caps, reducing the bearing capacity of pile caps, unfavorable reinforcement of pile foundations, etc., so as to improve the bearing capacity. ability, reducing the amount of bending deformation, and improving the effect of restraint performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

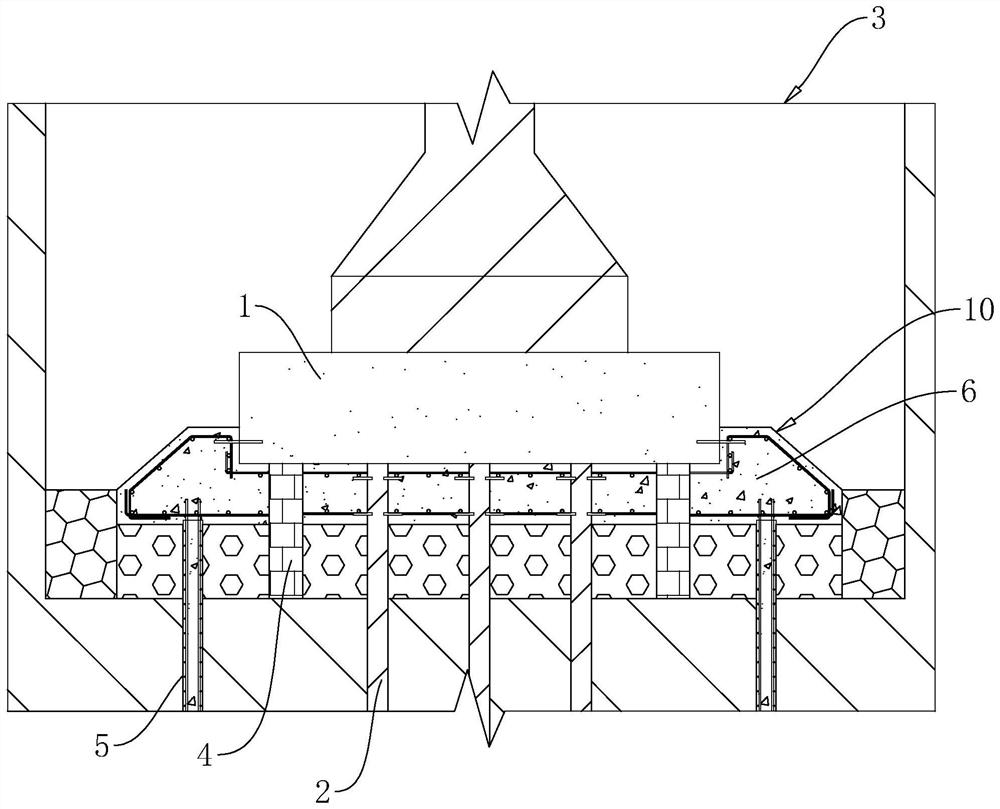

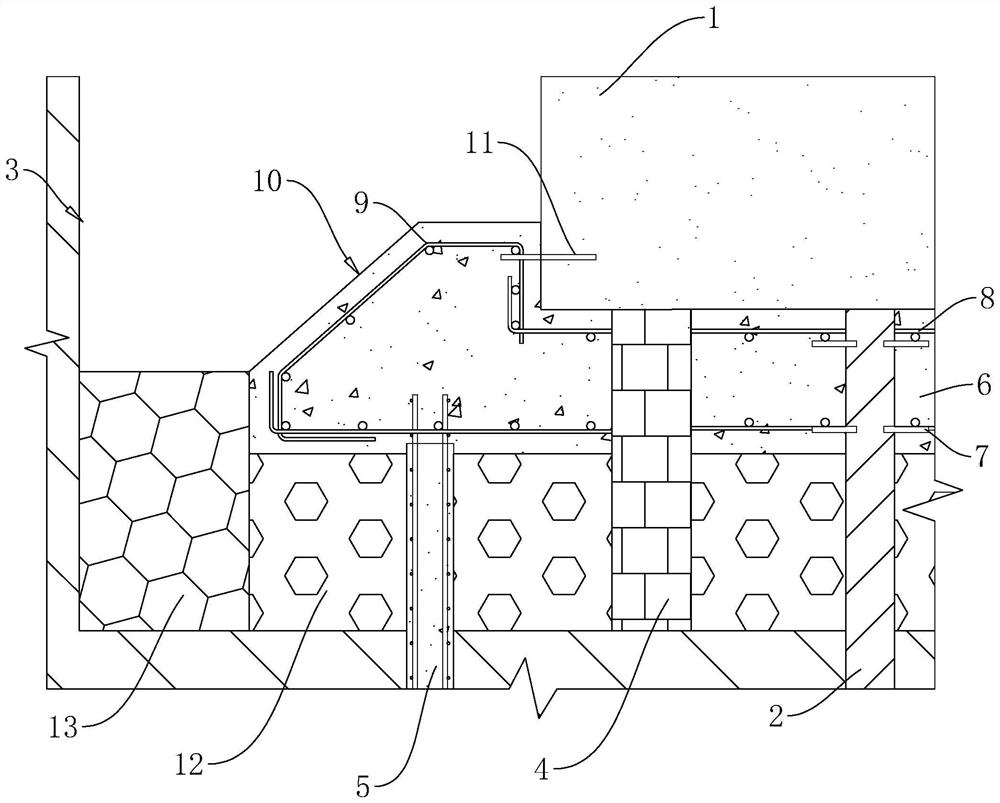

[0042] The following is attached Figure 2-3 The application is described in further detail.

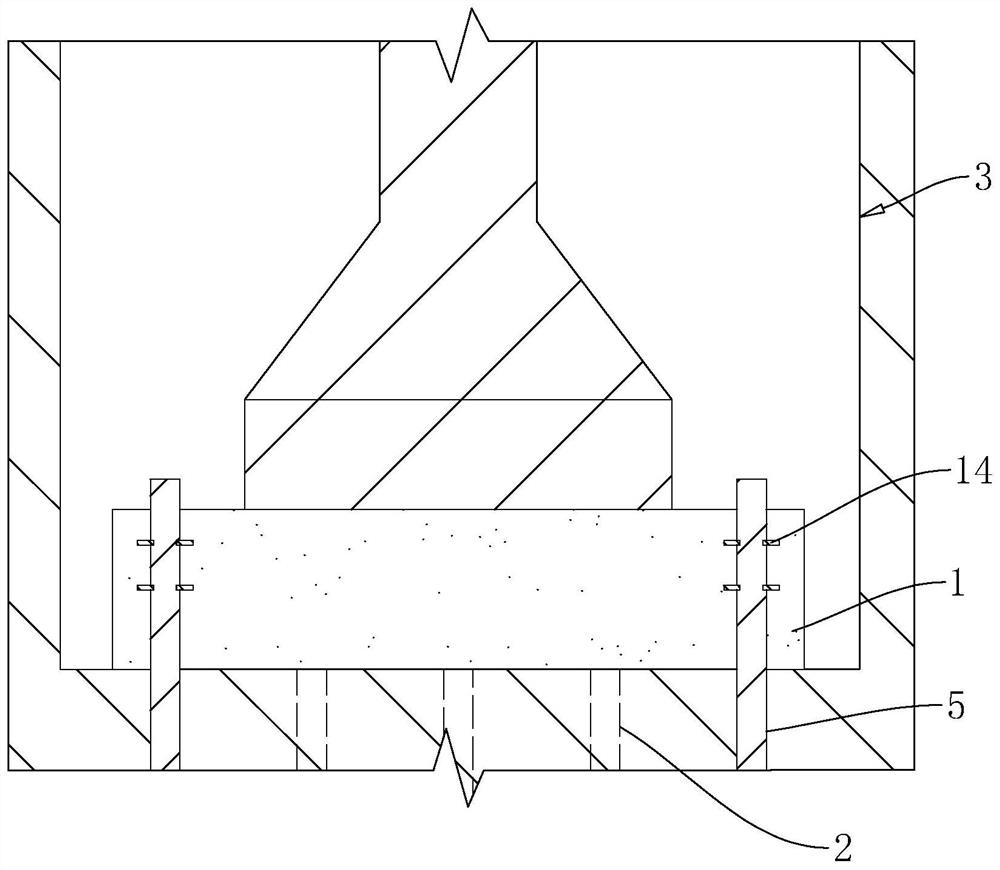

[0043] After dismantling the equipment in the original factory building, and then reinforcing the pile foundation, refer to figure 2 , the pile foundation includes a pile cap 1 and an original pile 2 for supporting the pile cap 1 .

[0044] The embodiment of the application discloses a pile foundation strengthening method. refer to figure 2 , 3 , the foundation pit 3 reinforcement method comprises the following steps: S1, excavating the foundation pit 3, excavating on the ground corresponding to the independent foundation, the bottom of the foundation pit 3 after excavation is lower than the lower surface of the pile cap 1, the foundation pit 3 There is a construction space formed by a gap between the bottom of the pit and the pile cap 1, and the height interval of the construction space is greater than 120cm. The construction space is convenient for on-site personnel to opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com