Multi-section telescopic rod

A technology of telescopic rods and section rods, which is applied to the connection of rods, slender elements, connecting components, etc., can solve the problems of increasing the shaking range of multi-section telescopic rods, the superimposed increase of slight shaking ranges, and large swinging ranges, etc., to achieve fast Effective positioning direction and in-position operation, improved mechanical properties, and reduced swing amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so as to help understand the content of the present invention. The methods used in the present invention are conventional methods unless otherwise specified; the raw materials and devices used are conventional commercially available products unless otherwise specified.

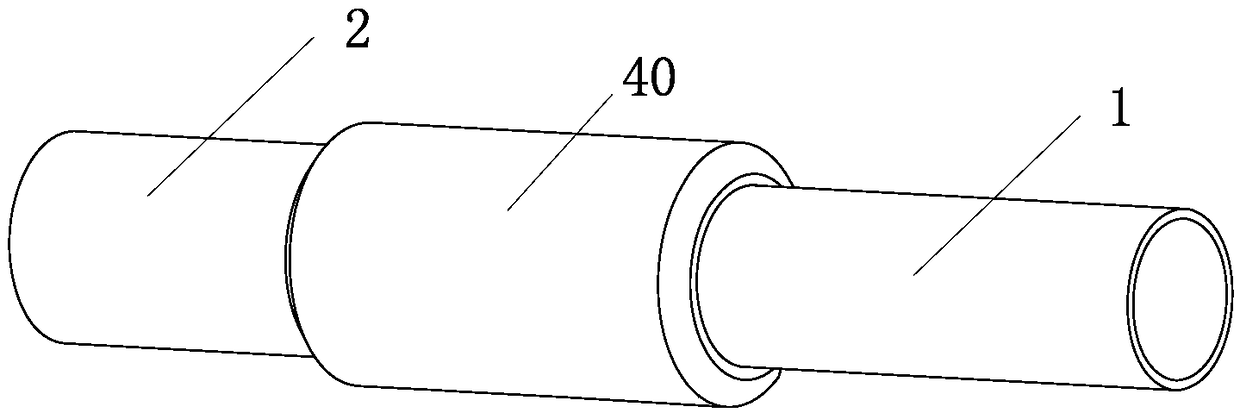

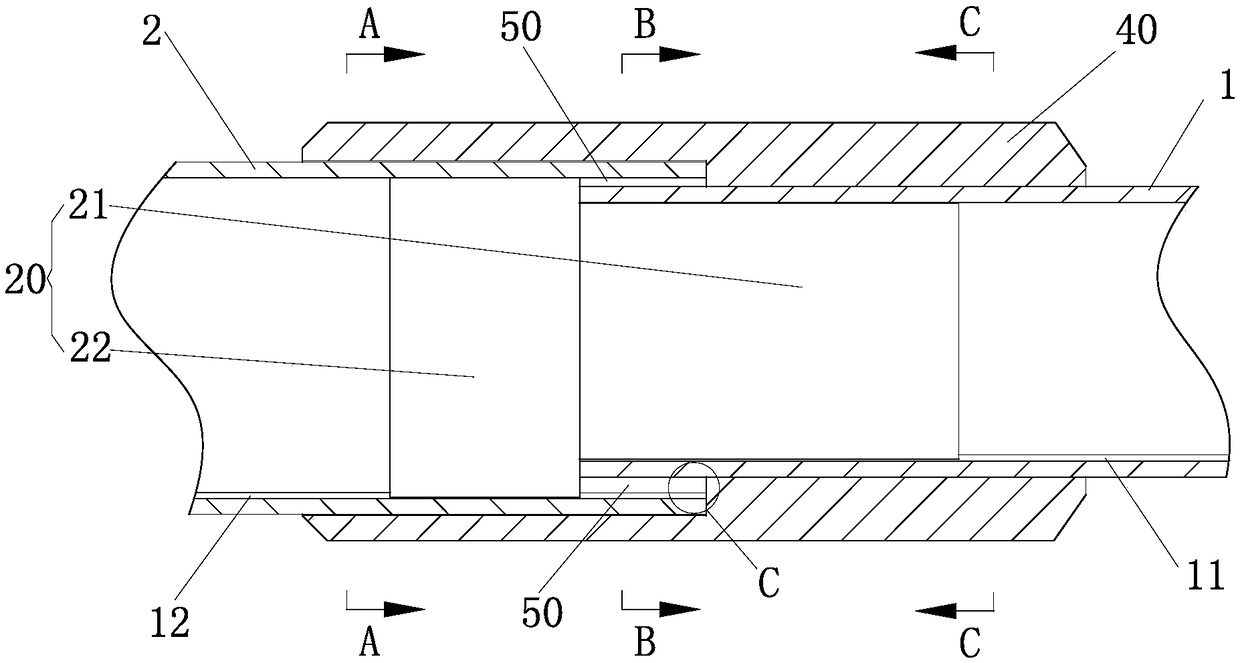

[0040] Depend on Figure 1-Figure 7 As shown, the present invention provides a multi-section telescopic rod. When a multi-section telescopic rod needs to be used for elongation work, the user stretches a plurality of multi-section telescopic rods, and now arbitrarily selects two adjacent ones. Take the joint bar as an example, which is provided with two joint bars, one joint 20 and one connecting lock piece 40 . The joint bar is tubular, which can be a circular tubular structure. The joint bar is provided with a first joint bar 1 and a second joint bar 2. From front to back, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com