Three-layer cylinder gasket for engine

A technology of cylinder head gasket and engine, which is applied in the direction of engine components, machine/engine, engine sealing device, etc., can solve problems such as affecting reliability, inaccurate compression of cylinder head gasket, and sealing failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

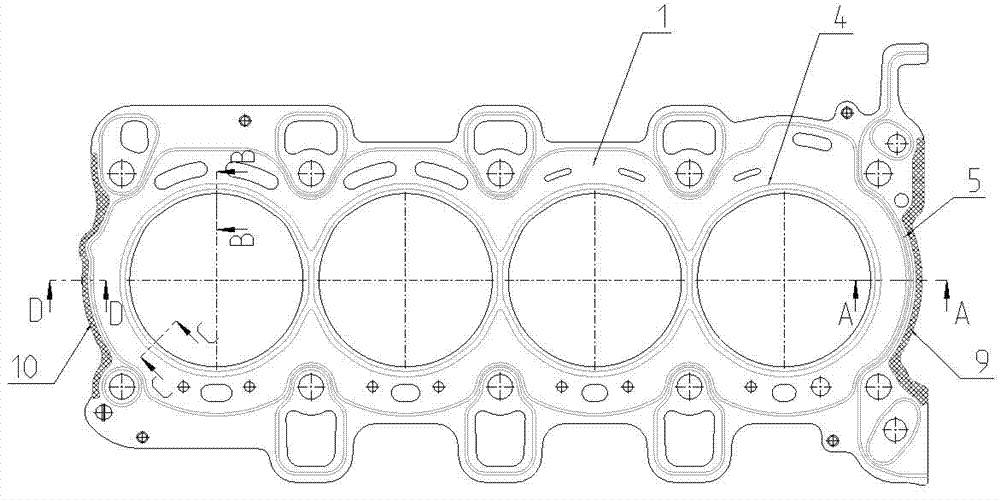

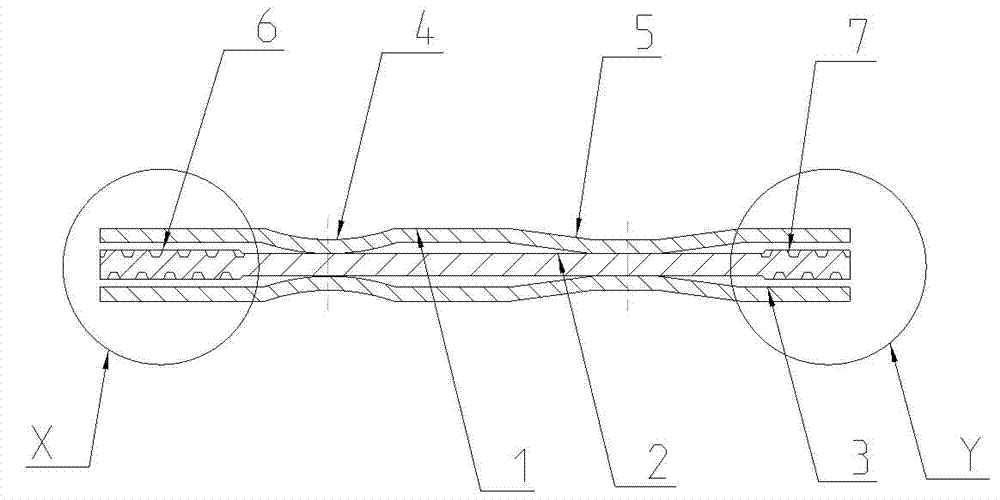

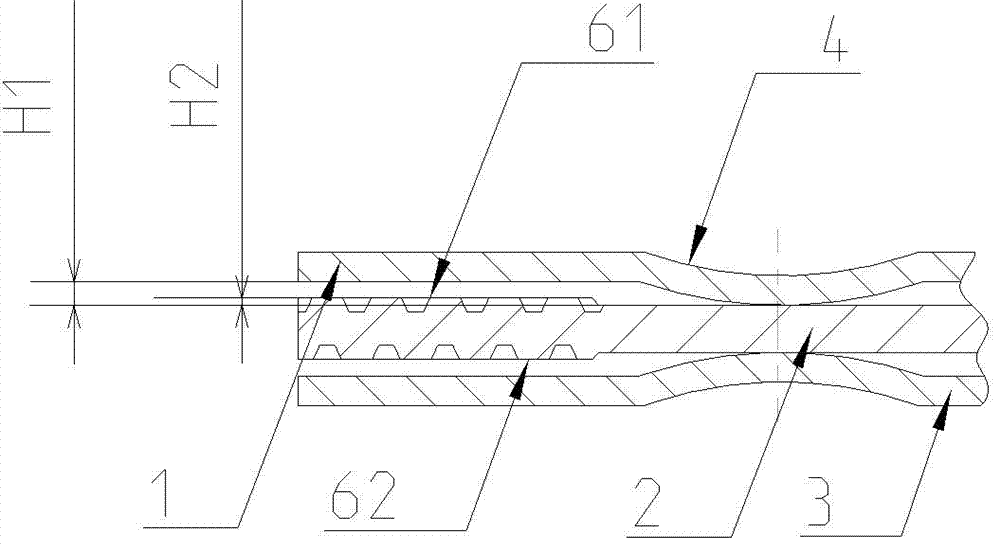

[0024] see figure 1 and figure 2 , The cylinder gasket of the engine is a three-layer cylinder gasket composed of an upper metal plate 1, a supporting layer metal plate 2 and a lower metal plate 3. The upper metal plate 1, the supporting layer metal plate 2 and the lower metal plate 3 are fixed together by riveting. There are more than two cylinder holes, oil holes, water holes, oil and gas through holes and bolt holes on the three-layer cylinder gasket, and the corresponding upper and lower metal plates at the circumference of each cylinder hole are respectively provided with circular arcs. Shaped cylinder hole sealing rib 4, water hole sealing rib 5. The distance between the bottom of the cylinder hole sealing rib arc on the upper metal plate and the lower surface of the upper metal plate or the distance between the top of the cylinder hole sealing rib arc on the lower metal plate and the upper surface of the lower metal plate is the cylinder hole sealing rib Height, both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com