Patents

Literature

47results about How to "High attachment accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

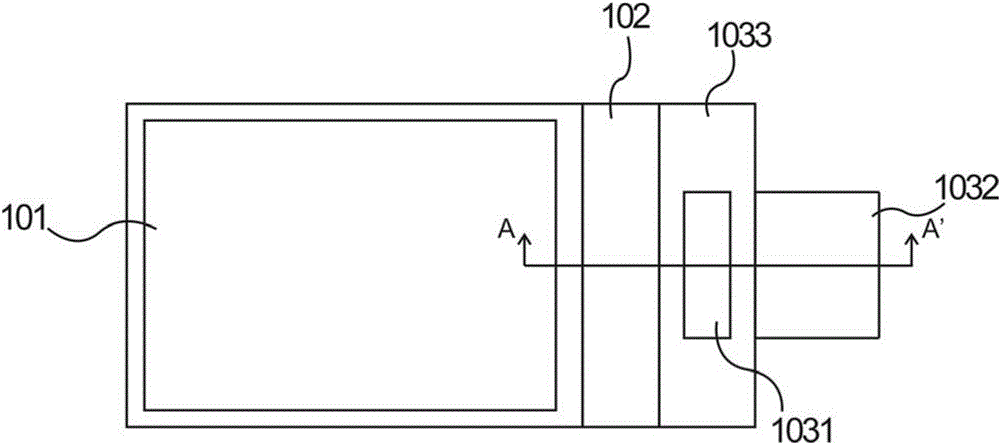

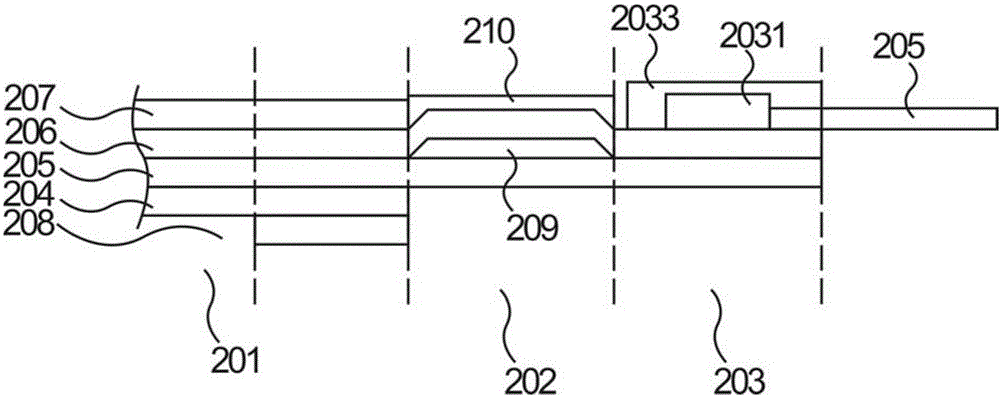

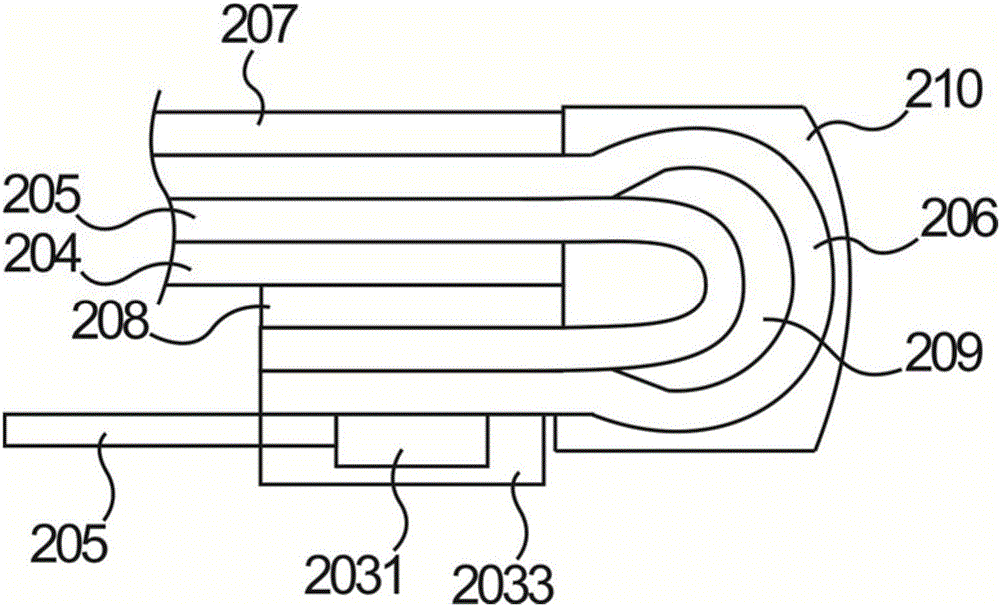

OLED display panel and display device thereof

ActiveCN106847871APlay a protective effectImprove toughnessSolid-state devicesSemiconductor/solid-state device manufacturingFlexible circuitsDisplay device

The invention provides an OLED display panel and a display device thereof. The display panel is defined as a display area, a bending area and a driving binding area, wherein the driving binding area is provided with a driving chip, a flexible circuit board for realizing the connection between the driving chip and a mainboard, and a reinforcing plate adhered on a surface of a substrate wiring layer located in the driving binding area and covering the surface of the substrate wiring layer of the driving binding layer; a cavity is formed in the bottom of the reinforcing plate, and the driving chip is arranged in the cavity. The OLED display panel provided by the invention has the advantages that the reinforcing plate is arranged at the driving area of the OLED display panel so as to increase the tenacity of part of a flexible substrate, the bending is convenient, the bending deformation of the flexible substrate is reduced, the attachment precision is improved, and the protection effect is provided for the driving chip.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

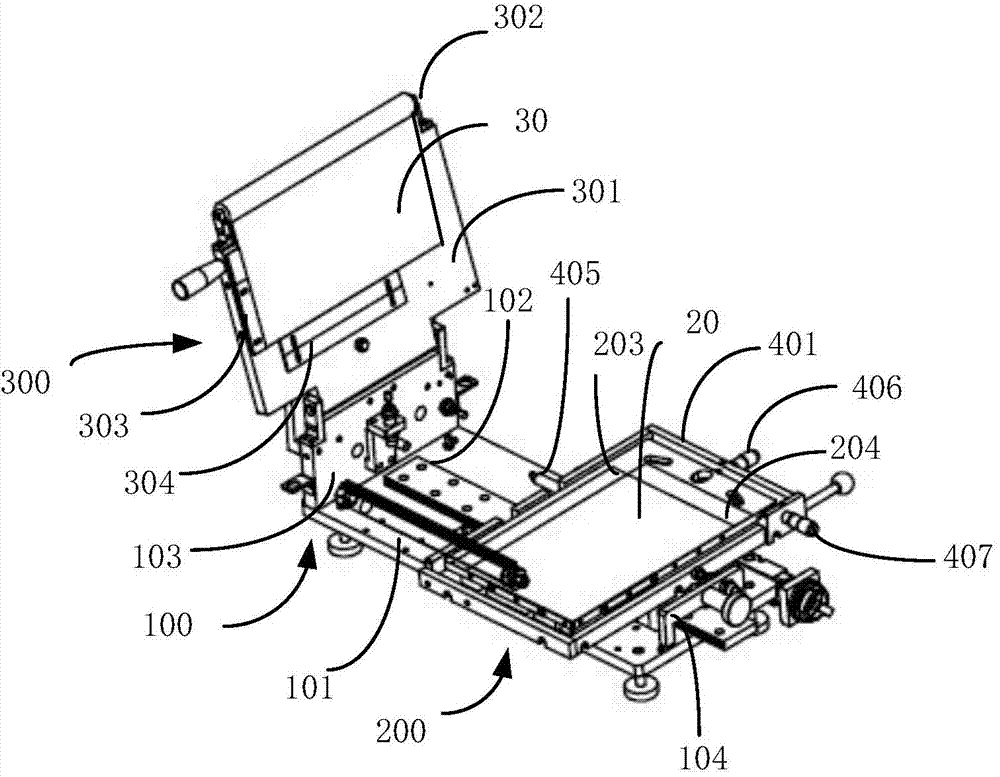

Film pasting jig

ActiveCN104516131ASimple structureEasy to operateLamination ancillary operationsLaminationEngineeringBearing surface

The invention provides a film pasting jig. The film pasting jig comprises a base platform, a base plate bearing part for bearing a base plate, and a film bearing pat for bearing a film; the film bearing part is hinged to the base platform and can be rotated relative to the base platform to reach a closing station and an opening station; when the film bearing part is at the closing station, the bearing surface of the film bearing part is opposite to the bearing surface of the base plate bearing part, so that the first part of the film can be in contact with the first part of the base plate; the base plate bearing part is movably arranged on the base platform and can horizontally move in the direction of the bearing surface of the base plate bearing part after the film bearing part is at the closing station, and then the bearing surface of the base plate bearing part can move relative to the bearing surface of the bearing part to enable the second part of the film to be attached to the second part of the base plate. The film pasting jig is simple in structure and convenient to operate; compared with the method of pasting the film by a full-automatic device, the film pasting jig has the advantages that the cost is saved, and the production capacity is remained; the working speed and the pasting precision are superior to those of manual film pasting.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

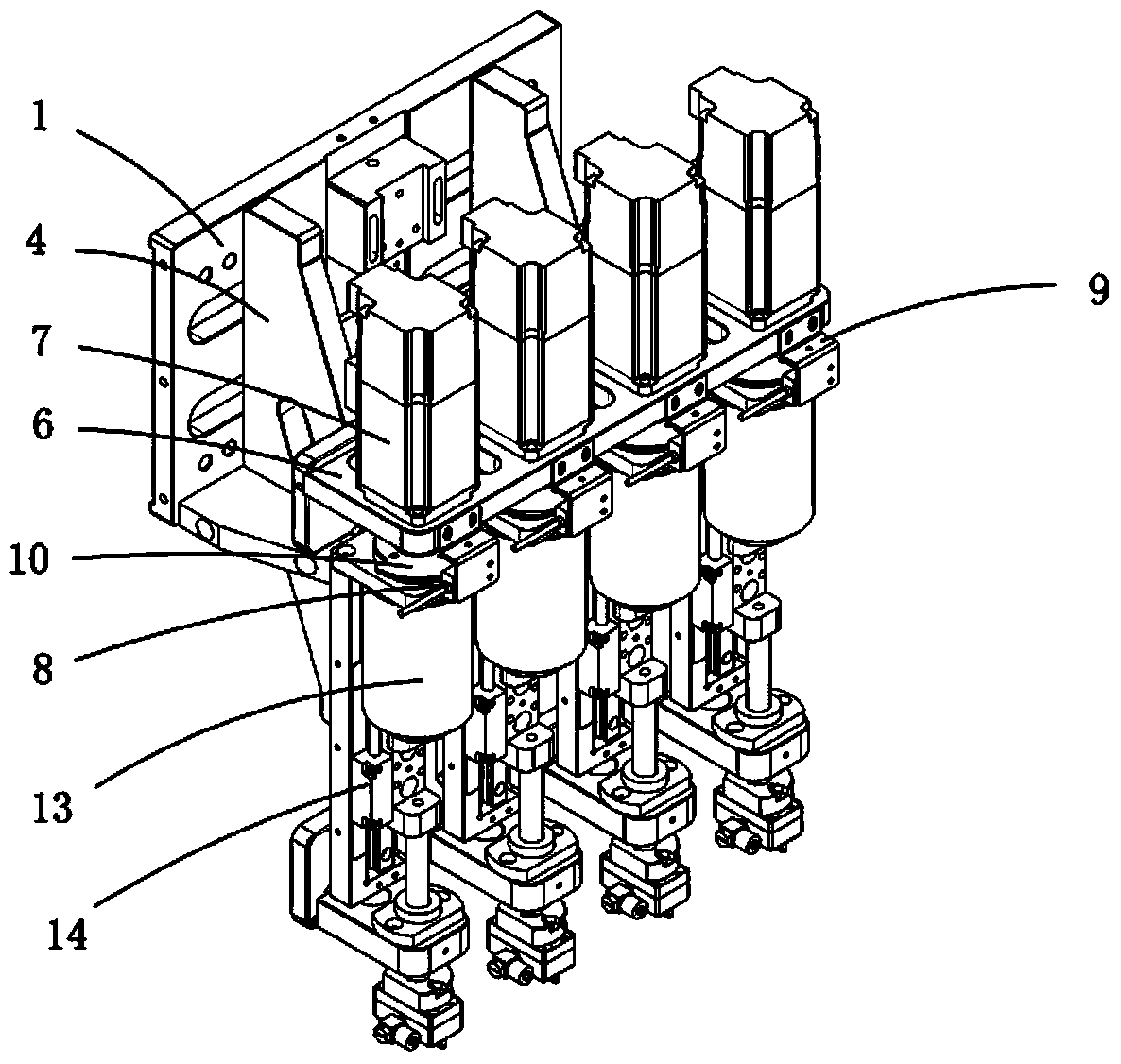

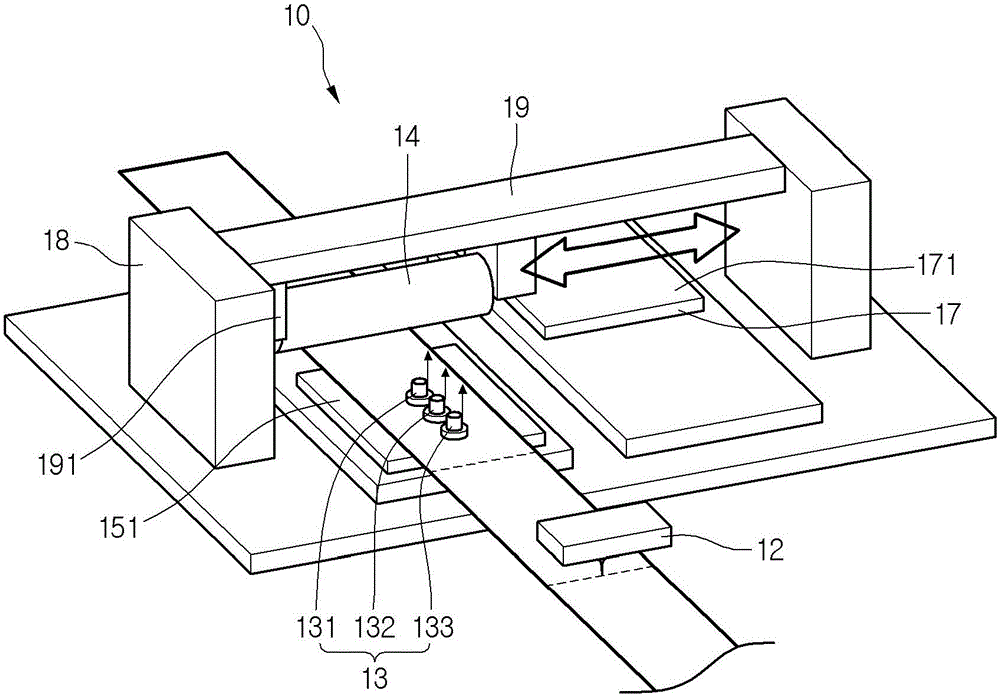

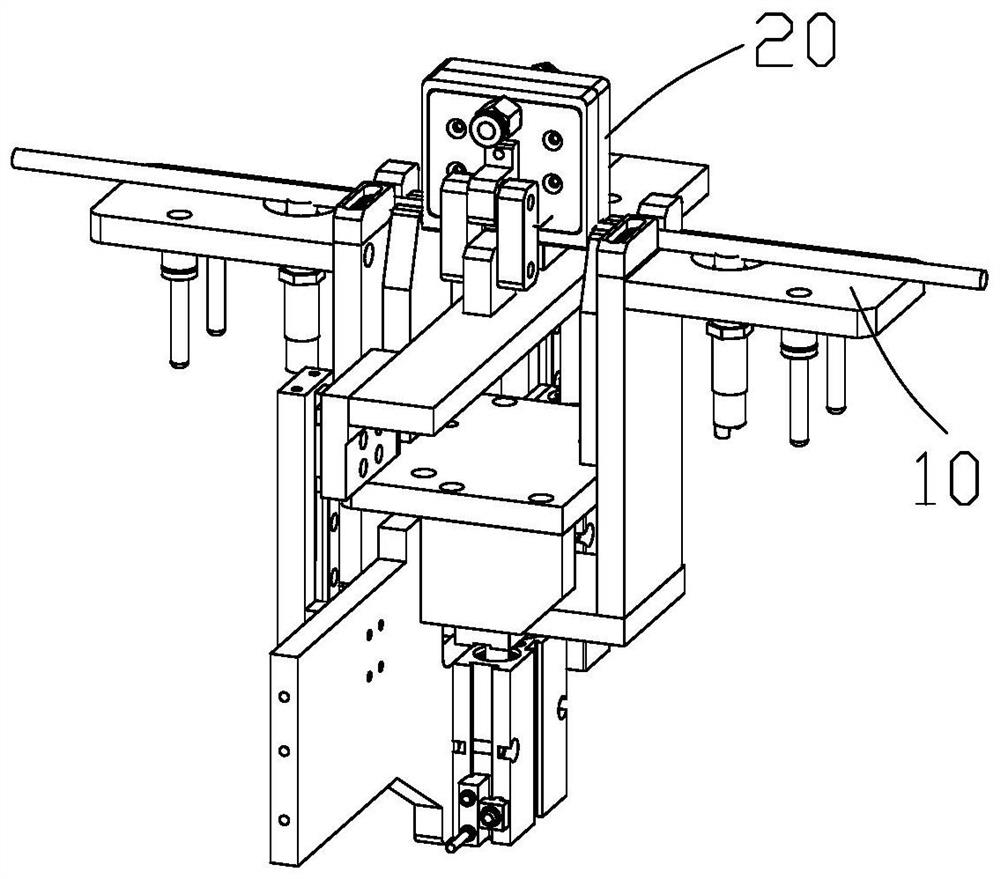

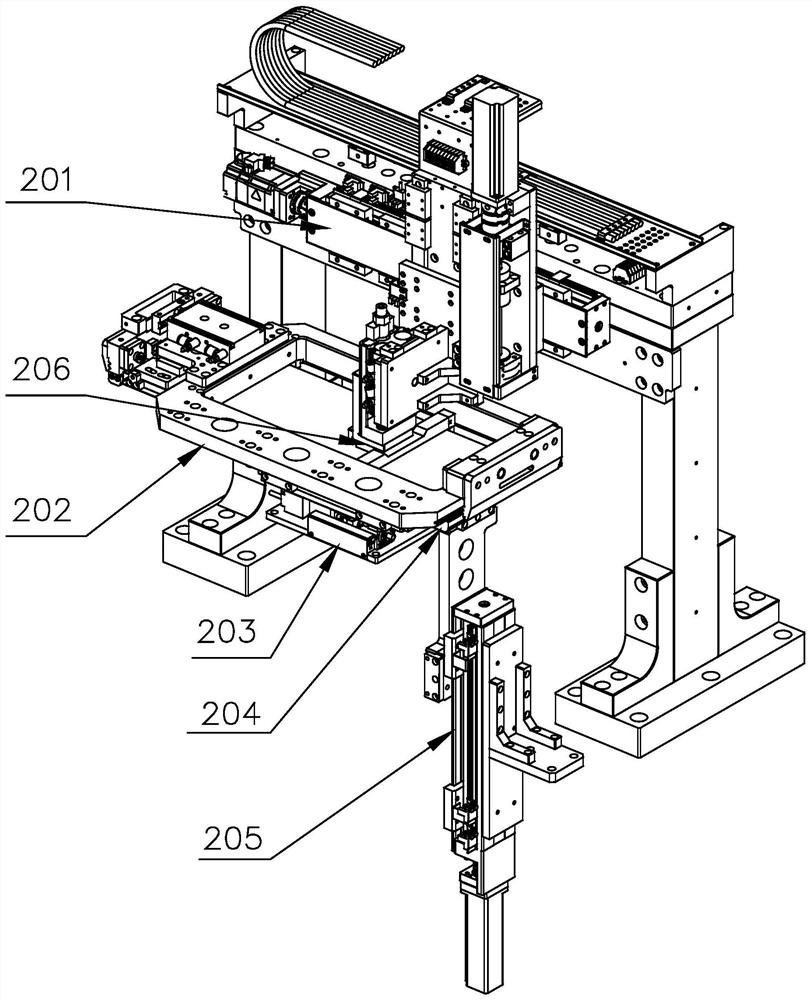

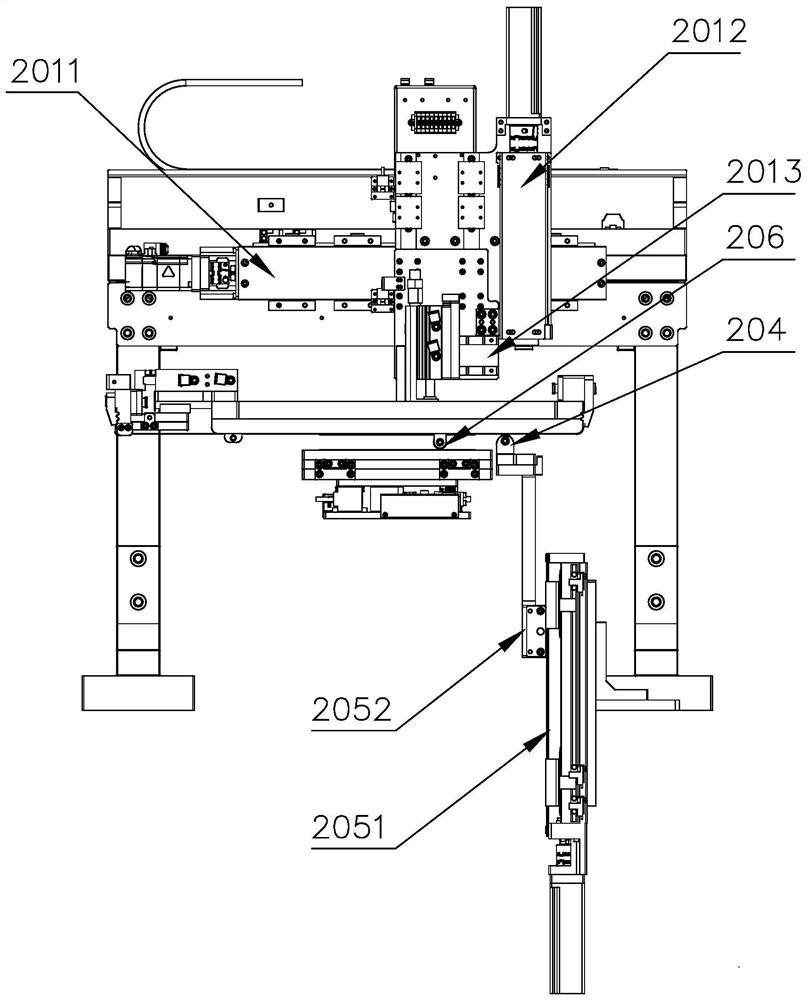

Suction head component

ActiveCN103662830AAdjustable angleAdhesive adjustableSuction cupsConveyor partsTransverse planeEngineering

The invention relates to a suction head component. A connecting plate a is mounted on the right side of a mounting plate, and a connecting plate b is mounted on the right side of the connecting plate a. A motor mounting plate is fixedly connected to the upper end of the connecting plate b, suction head fixing blocks are fixedly connected to the lower end of the connecting plate b, a longitudinal plate is fixedly connected to the right side of the connecting plate b, and a transverse plate is fixed at the upper end of the longitudinal plate. Rectifying servo motors are mounted on the motor mounting plate, a spindle of each rectifying servo motor penetrates the transverse plate, and the lower end of each spindle is connected with a voice coil motor. Grating scales and sliding rails are mounted on the longitudinal plate, and suction head connecting blocks are mounted on the sliding rails in a matched manner. The lower end of each suction head connecting block is connected with a guide rail which penetrates out from the corresponding suction head fixing bock, and the lower end of each guide rail is connected with a suction head. More than three groups of suction modules are provided, each group of suction modules can rotate by 360 degrees, and each suction module can rotate relatively by different angles. The rectifying servo motors are used for rotating angles of the suction heads and angle compensation, and the voice coil motors are used for controlling up-down bonding actions of the suction heads, and have a thrust control function.

Owner:BOZHON PRECISION IND TECH CO LTD

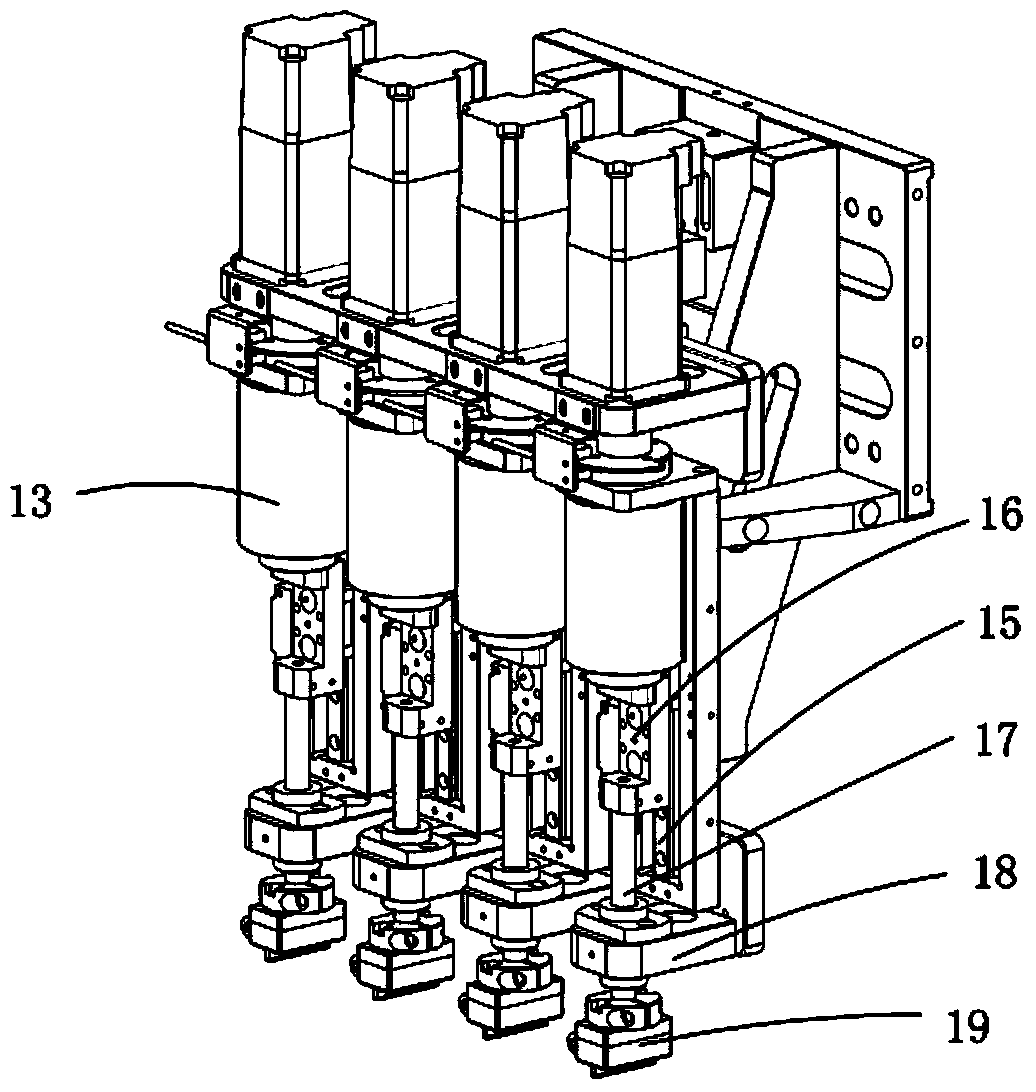

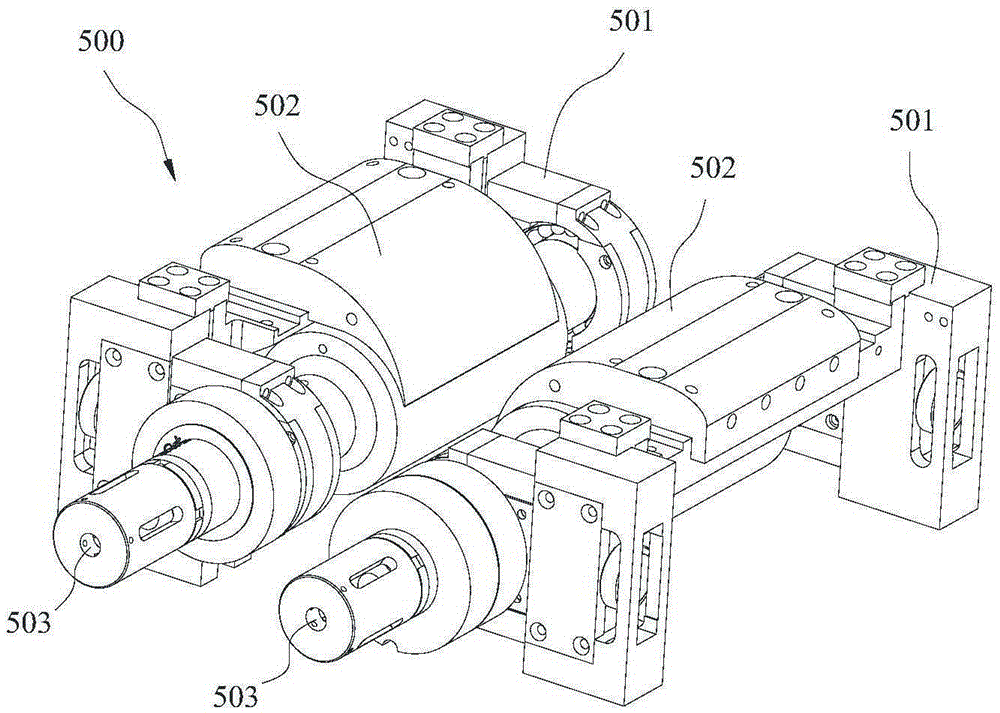

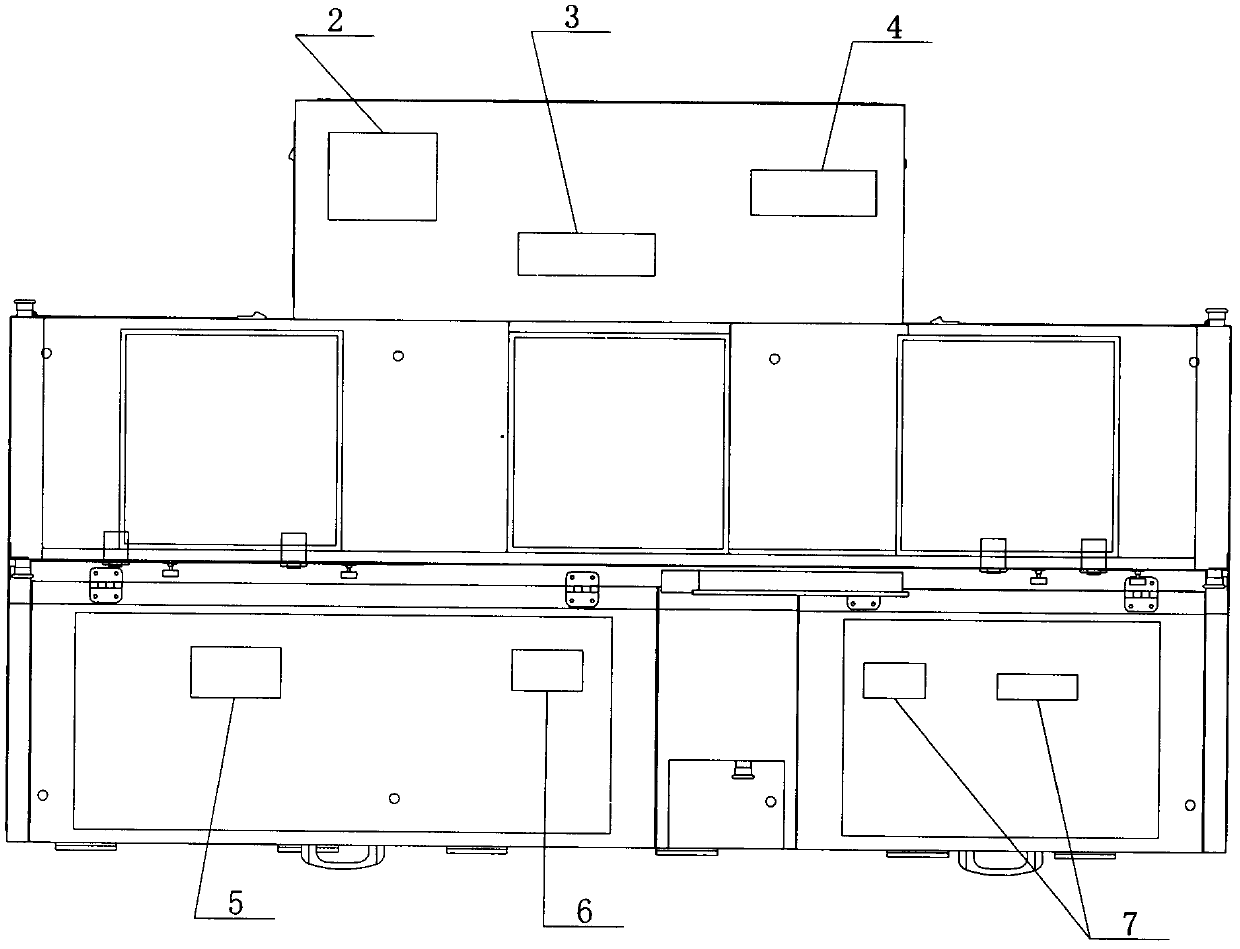

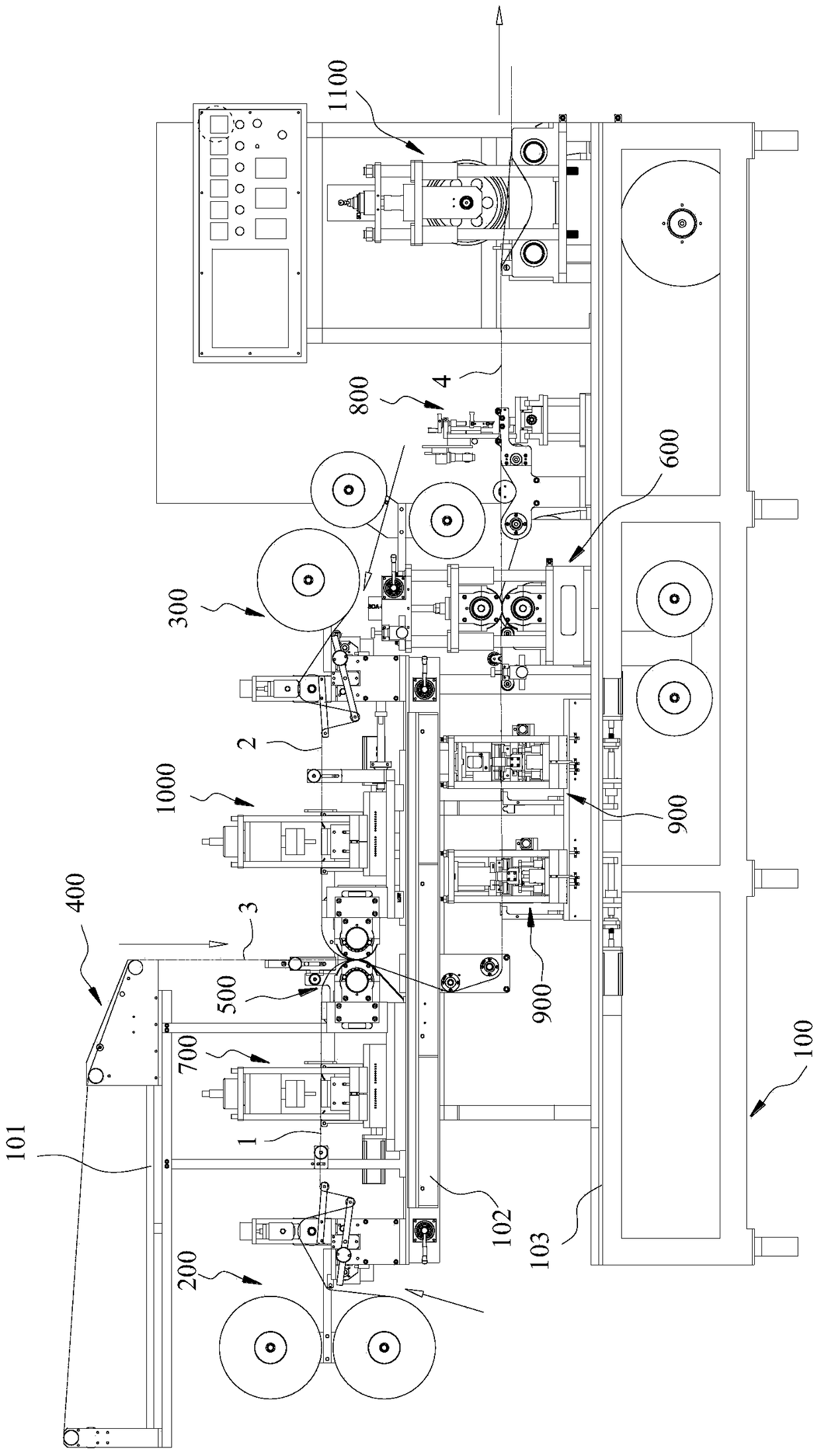

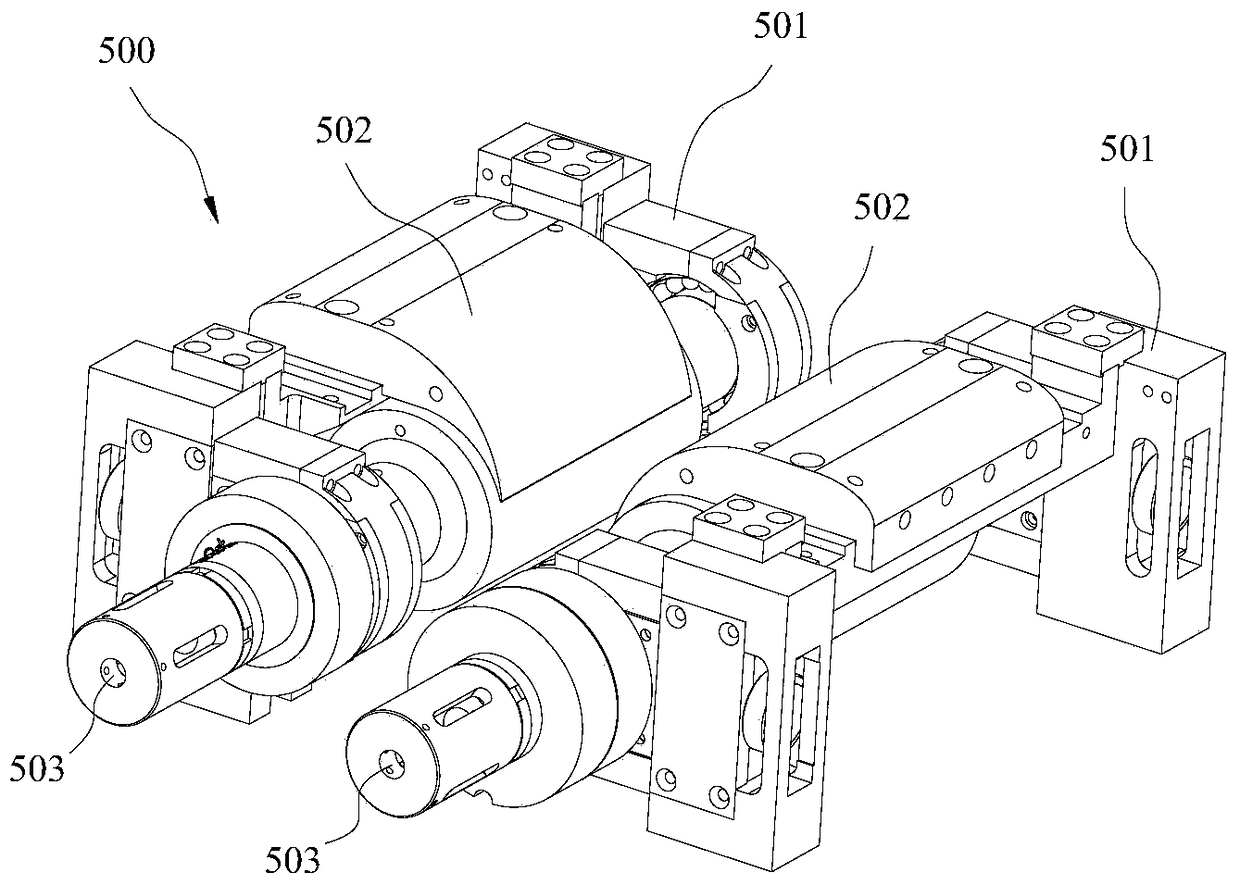

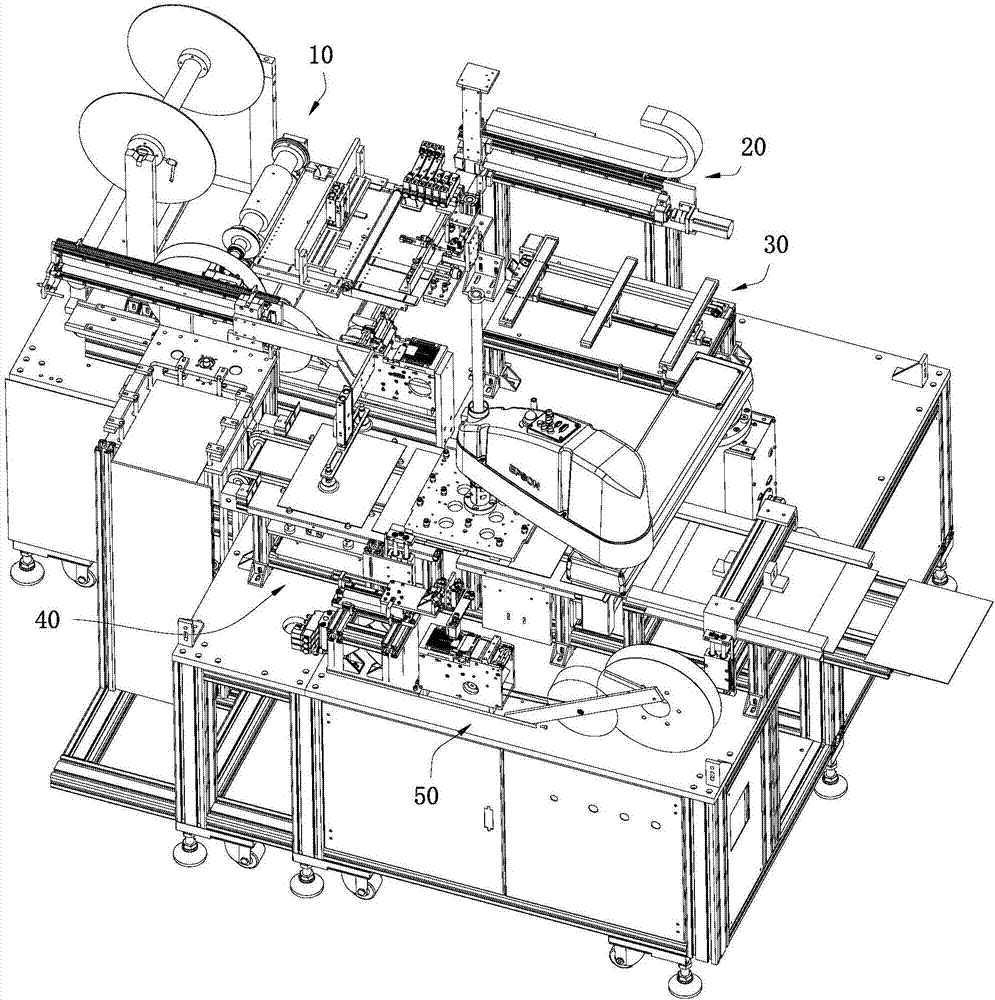

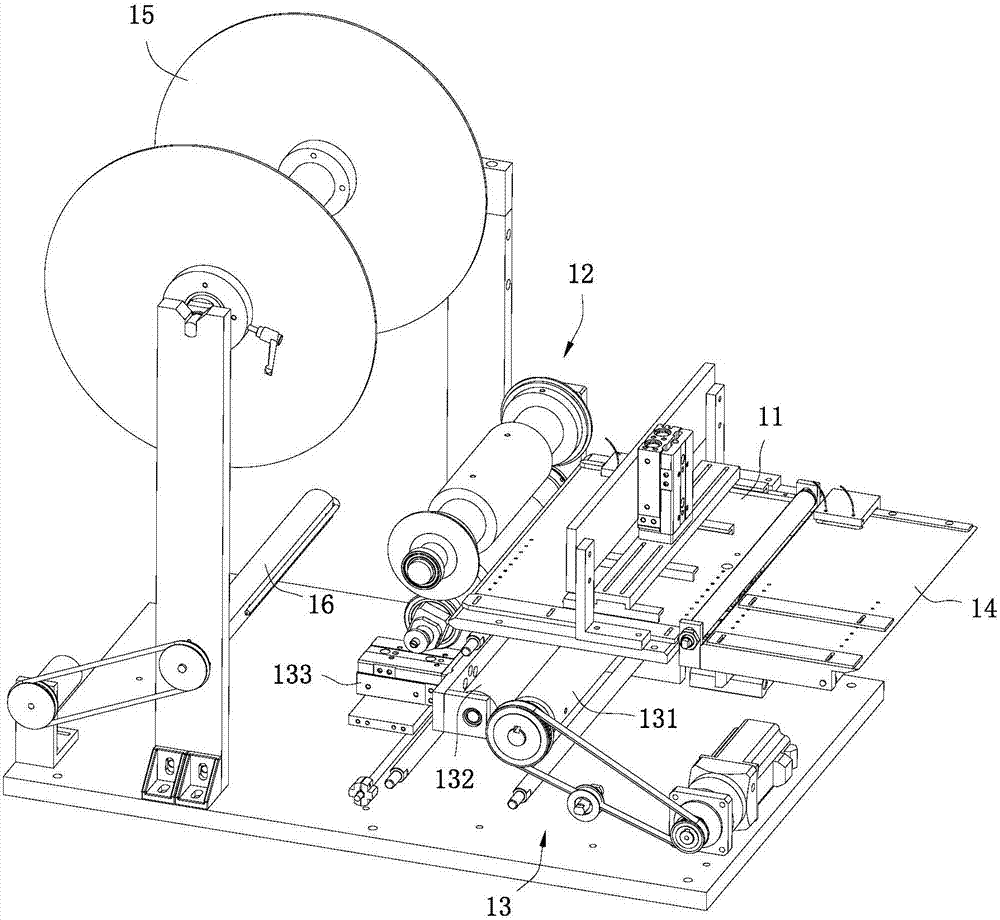

Automatic FFC pressure connecting forming machine

The invention discloses an automatic FFC pressure connecting forming machine. The automatic FFC pressure connecting forming machine comprises a machine frame, a first film feeding mechanism, a second film feeding mechanism, a conductor feeding mechanism, a first hot press device, a second hot press device, a first punching device, a second punching device, a reinforcing plate attaching device and a striping device. The machine frame comprises a top layer frame, a middle layer frame and a bottom layer frame. The conductor feeding mechanism is installed on the top layer frame. The first film feeding mechanism and the second film feeding mechanism are arranged at the two ends of the middle layer frame respectively. The first hot press device is installed on the middle layer frame and located between the first film feeding mechanism and the second film feeding mechanism. The reinforcing plate attaching device, the second hot press device and the striping device are sequentially installed on the bottom layer frame in the conveying direction of semi-finished FFC products. An outlet of the first film feeding mechanism and an outlet of the second film feeding mechanism are right opposite to the first hot press device horizontally. An outlet of the conductor feeding mechanism is right opposite to the first hot press device vertically. By means of the automatic FFC pressure connecting forming machine, the semi-finished FFC products can be attached firmly, reinforcing plates are attached precisely and firmly, the product quality is improved, and the rate of finished products is increased.

Owner:佛山市顺德区禾惠电子有限公司

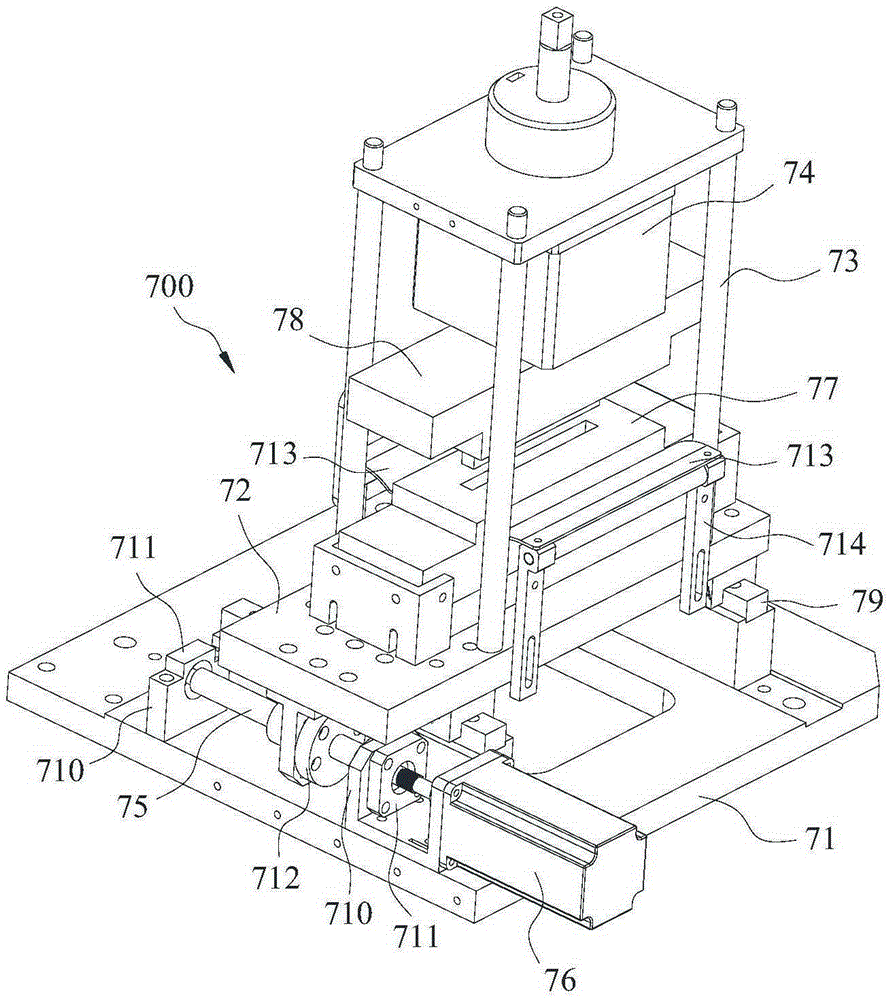

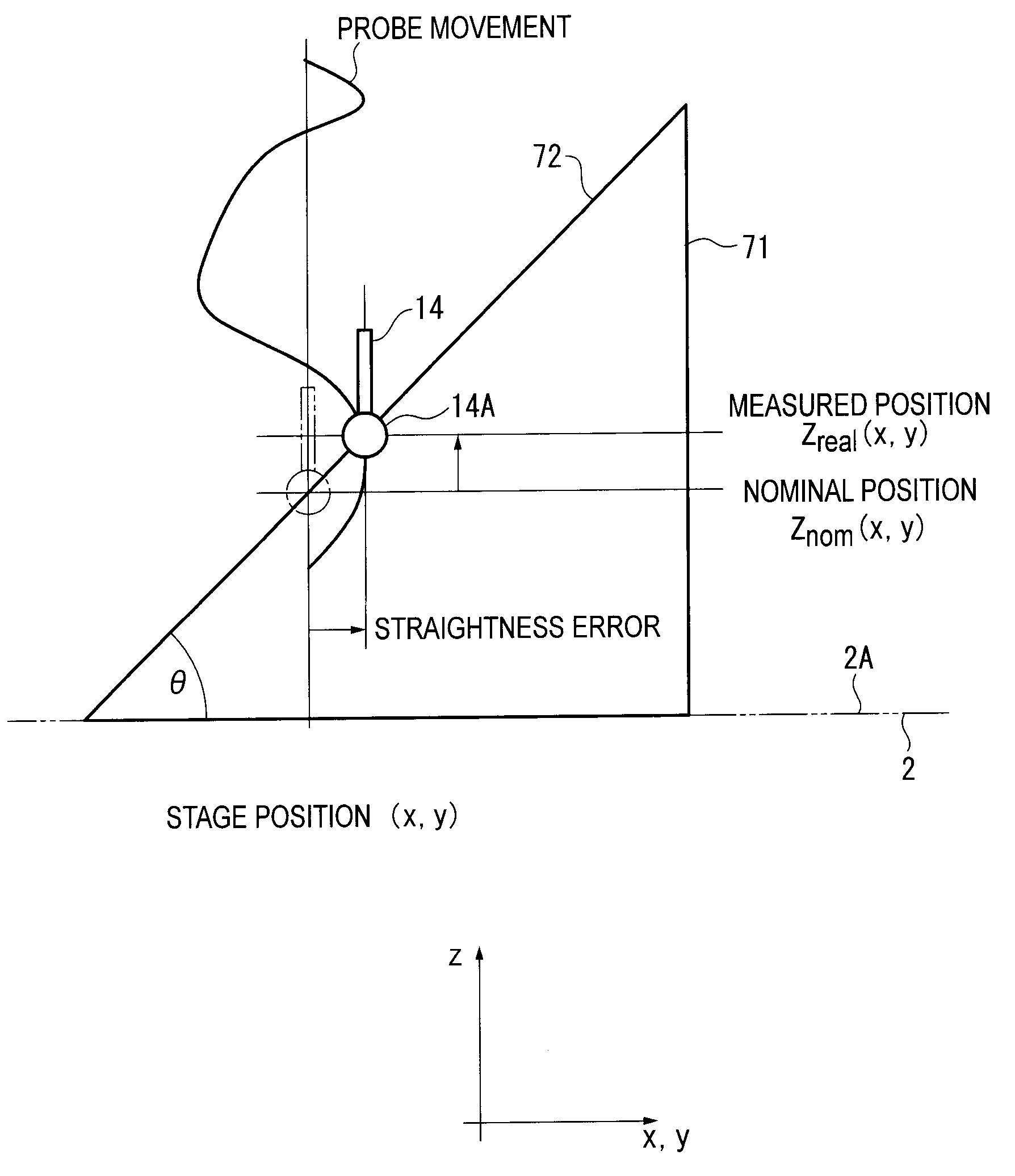

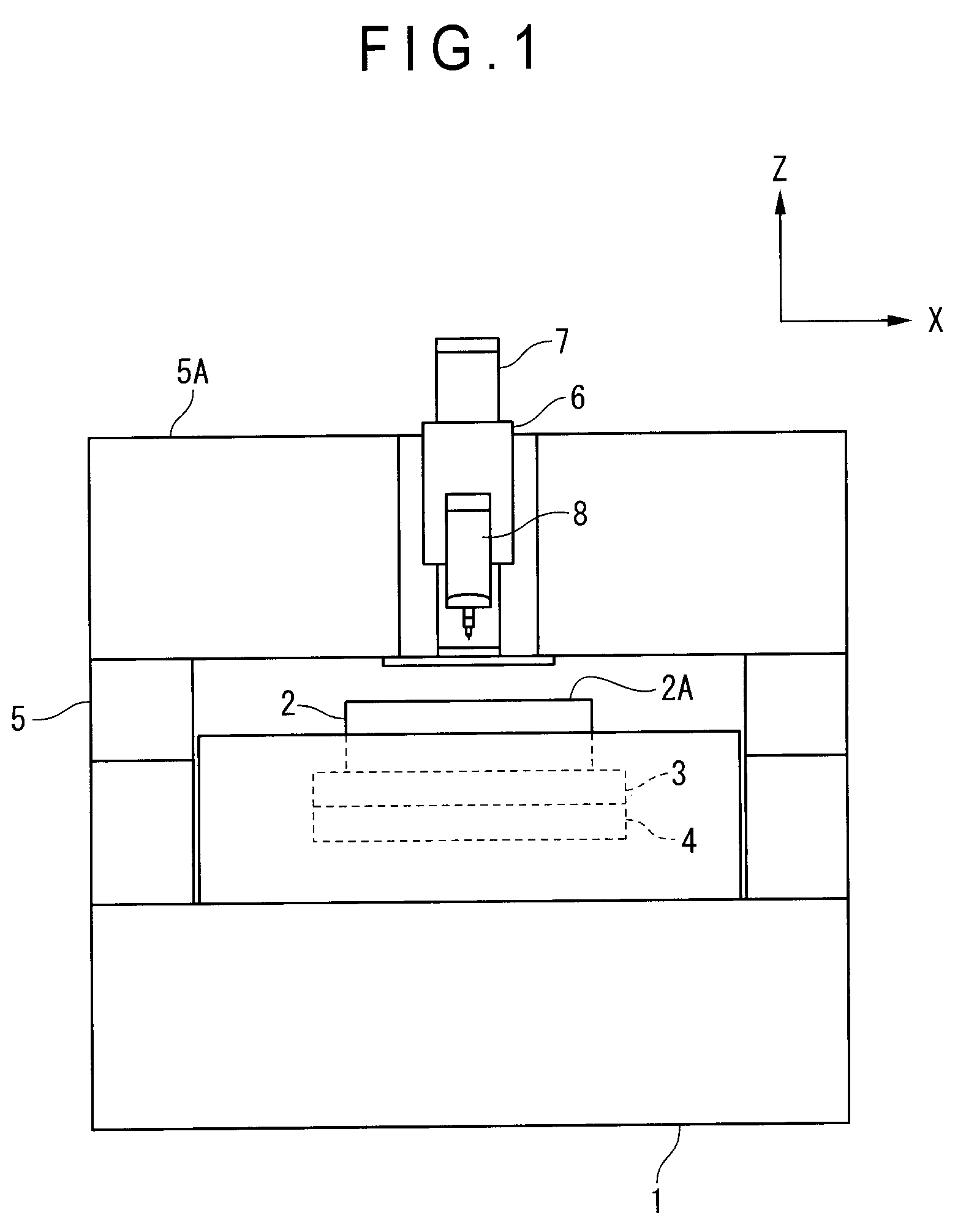

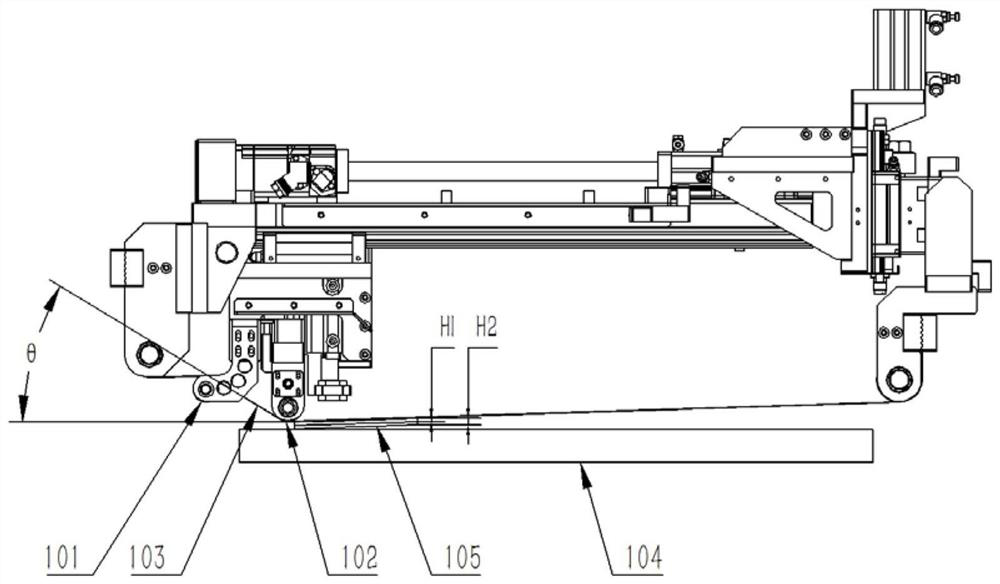

Probe straightness measuring method

ActiveUS20090198472A1Reduced measurement accuracyHigh attachment accuracyDigital computer detailsSpeed measurement using gyroscopic effectsSlant angleContour error

A probe straightness measuring method includes: placing a measurement jig having a measurement reference surface with a known profile error on a stage surface of an XY stage so that the measurement reference surface is slanted in a moving direction of the XY stage; measuring a displaced position of the measurement piece by a displacement detector of the probe each time the XY stage is moved for a predetermined distance while controlling a driving actuator so that the measurement piece of a probe touches the measurement reference surface at a constant pressure; and calculating a straightness error of a measurement-piece moving mechanism on a basis of a measured position of the measurement piece obtained in the measuring, a nominal position of the measurement piece obtained by a calculation and a slant angle of the measurement reference surface.

Owner:MITUTOYO CORP

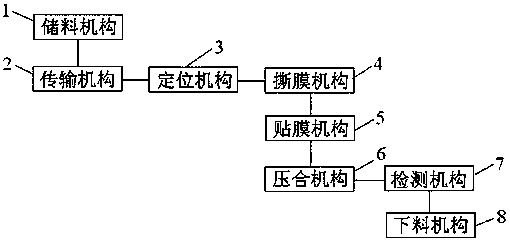

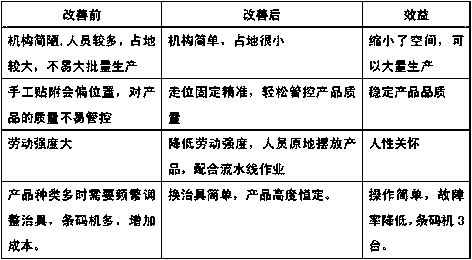

Automatic laminating device of surface protective film of electronic product

The invention discloses an automatic laminating device of a surface protective film of an electronic product. The automatic laminating device comprises a material storage mechanism, a transmission mechanism, a positioning mechanism, a film tearing mechanism, a film pasting mechanism, a lamination mechanism, a detection mechanism and a discharging mechanism which are connected sequentially, whereinthe material storage mechanism, the transmission mechanism, the positioning mechanism, the film tearing mechanism, the film pasting mechanism, the lamination mechanism, the detection mechanism and the discharging mechanism are all electrically connected with a control panel; the transmission mechanism comprises an upper circular conveyor line and a lower circular conveyor line; and the positioning mechanism comprises a plurality of sensors. Through the manner, the automatic laminating device of the surface protective film of the electronic product has a reasonable and compact structure; complete equipment is small and an occupied space is small; mass film-pasting operations can be realized; and moreover, the lamination precision is high, the efficiency is high, and the product yield is high.

Owner:SUZHOU HUACHONG PRECISION MACHINERY

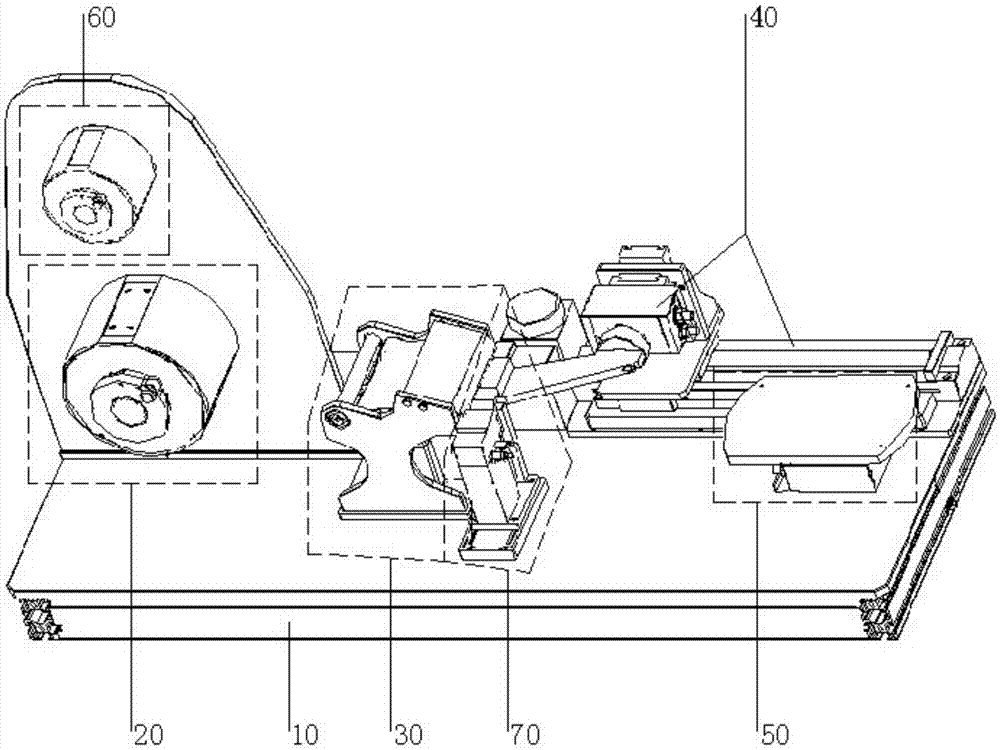

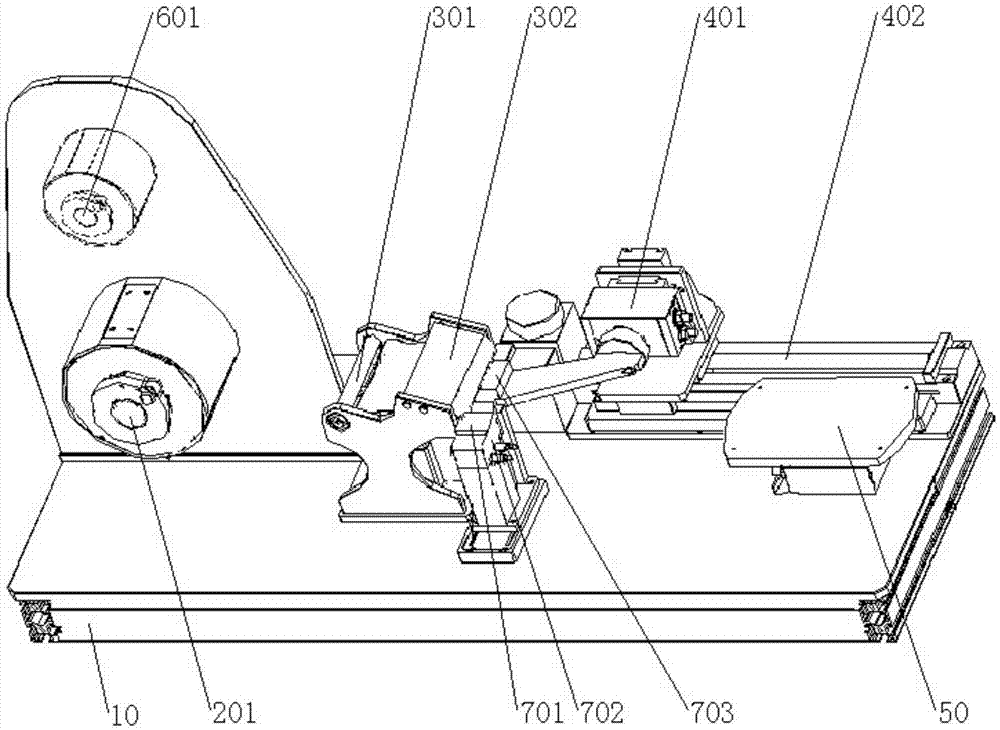

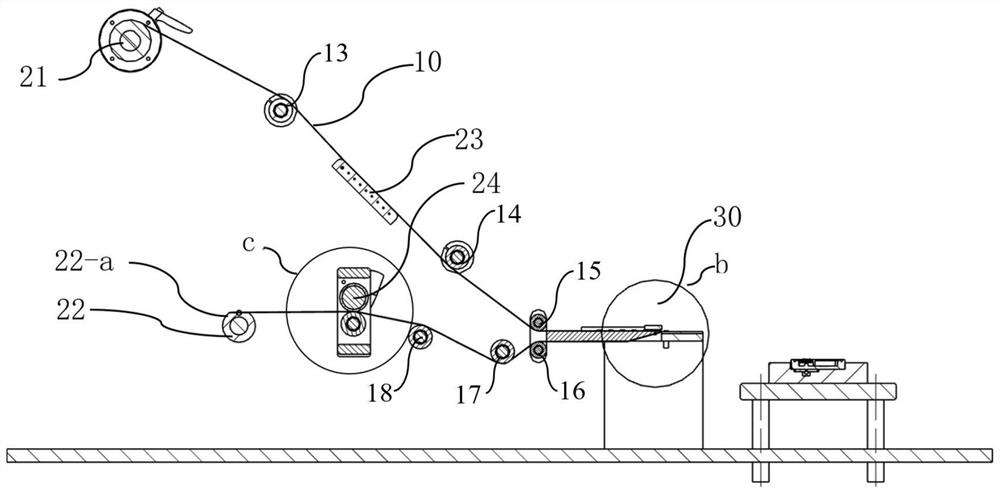

Tape discharging mechanism and tape attaching device

InactiveCN105437725AFix damageAvoid serious wasteLamination ancillary operationsLaminationTectorial membraneAdhesive belt

The invention provides a tape discharging mechanism and a tape attaching device, which belong to the technical field of displays, and can solve the problem that the efficiency is low and the cost is high due to the fact that the tape is manually cut and attached to assemble backlight products in the prior art. The tape discharging mechanism comprises a coil stock tape discharging unit and a protective film stripping unit, wherein the coil stock tape discharging unit comprises a discharge air swelling shaft used for rotationally transporting the coil stock tape; the protective film stripping unit is arranged at the rear opposite to the coil stock tape discharging unit, is used for stripping the protective film from the tape, and transporting the tape. The tape discharging mechanism realizes an automatic discharging and stripping process of the coil stock tape, and the problems of low operation efficiency and high cost due to manual operation are solved. The tape attaching device comprises a manipulator and the tape discharging mechanism, can further complete a process of automatic tape attaching, the efficiency and precision of attaching are further improved, and the cost is reduced.

Owner:BOE OPTICAL SCI & TECH +1

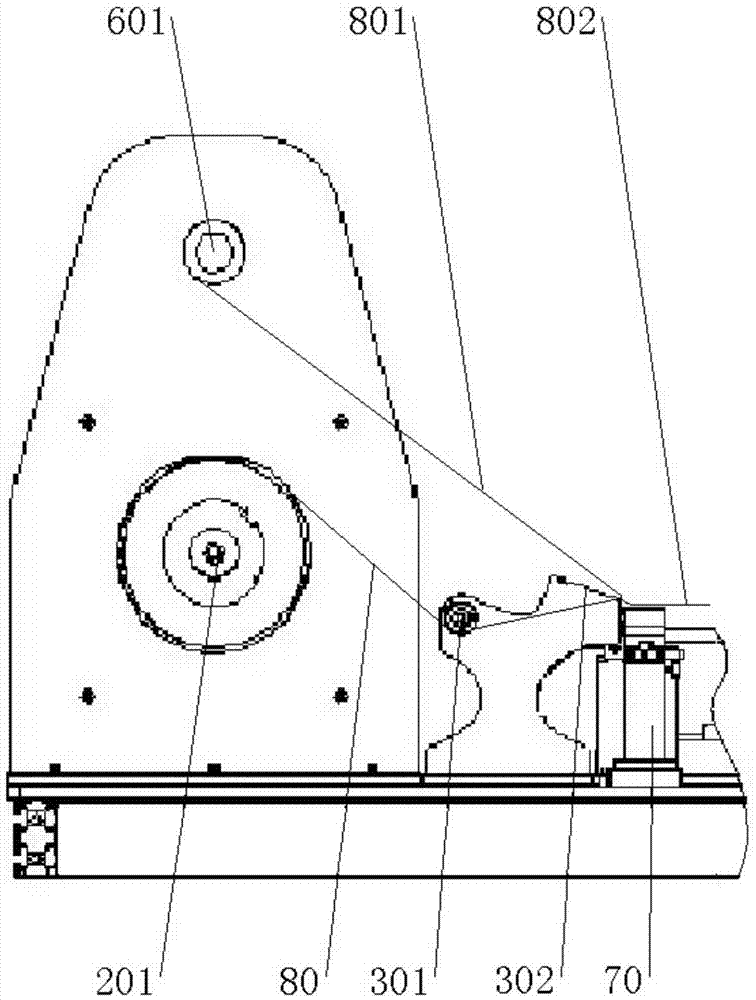

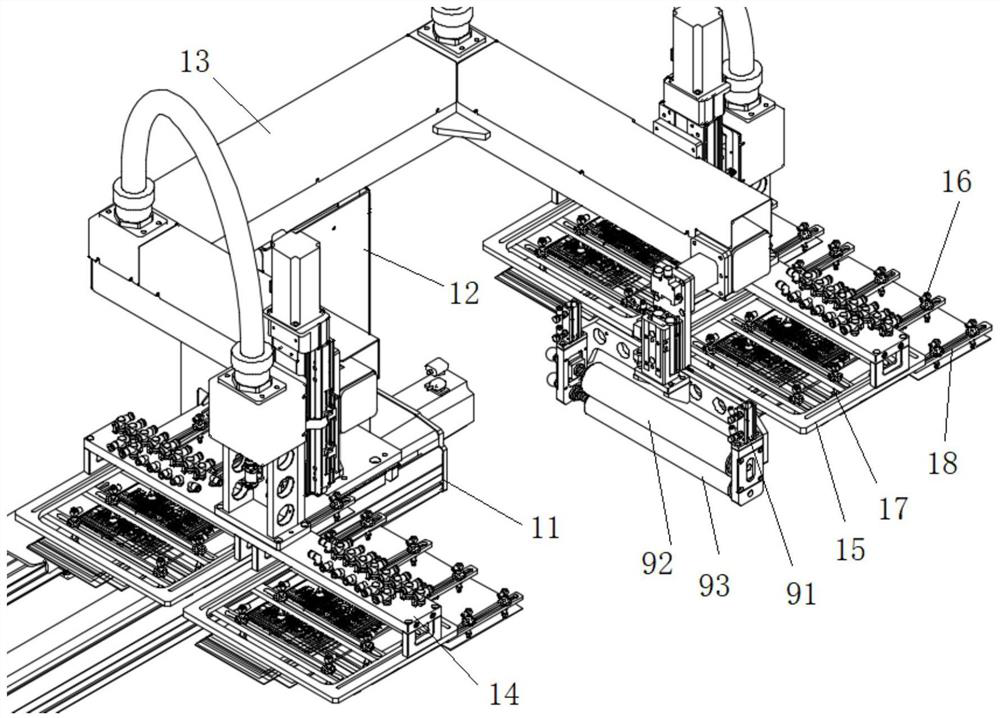

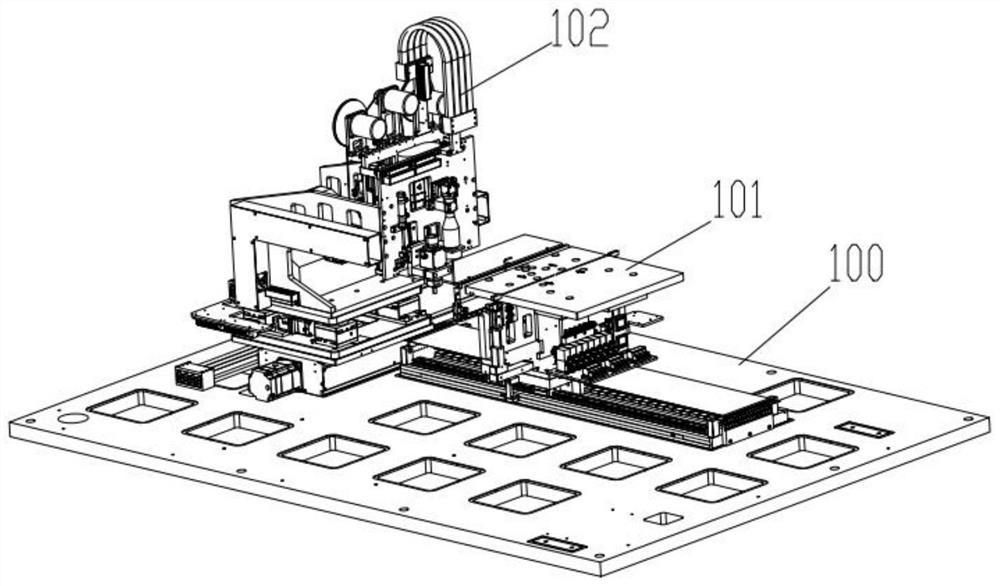

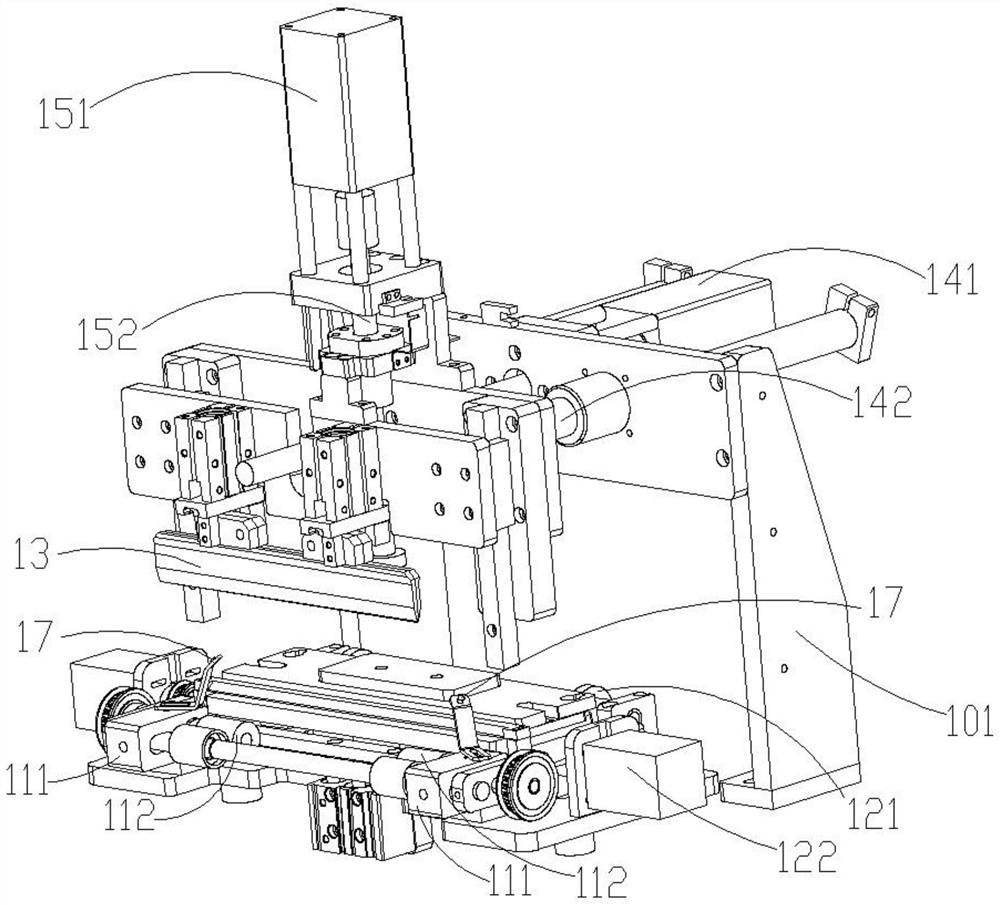

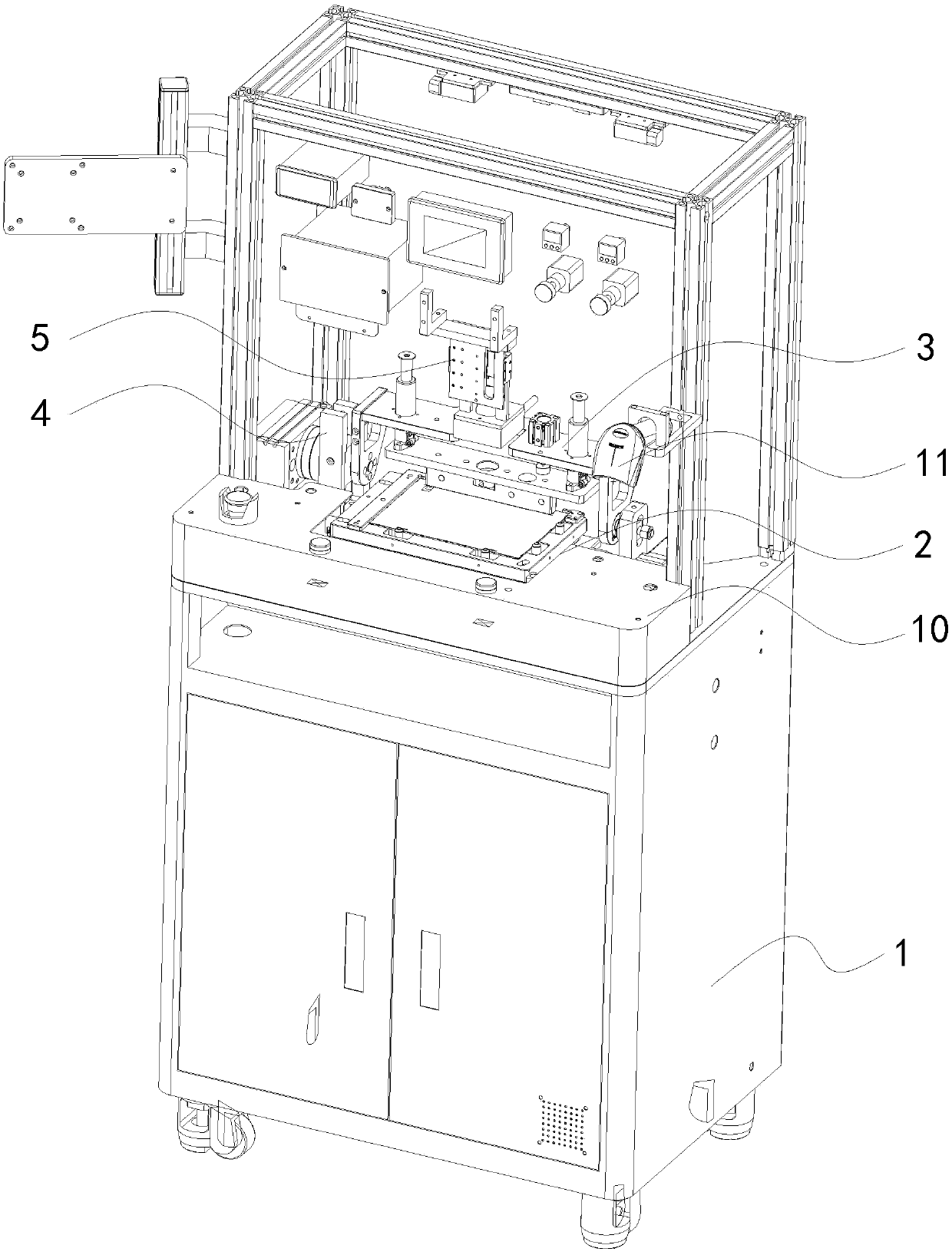

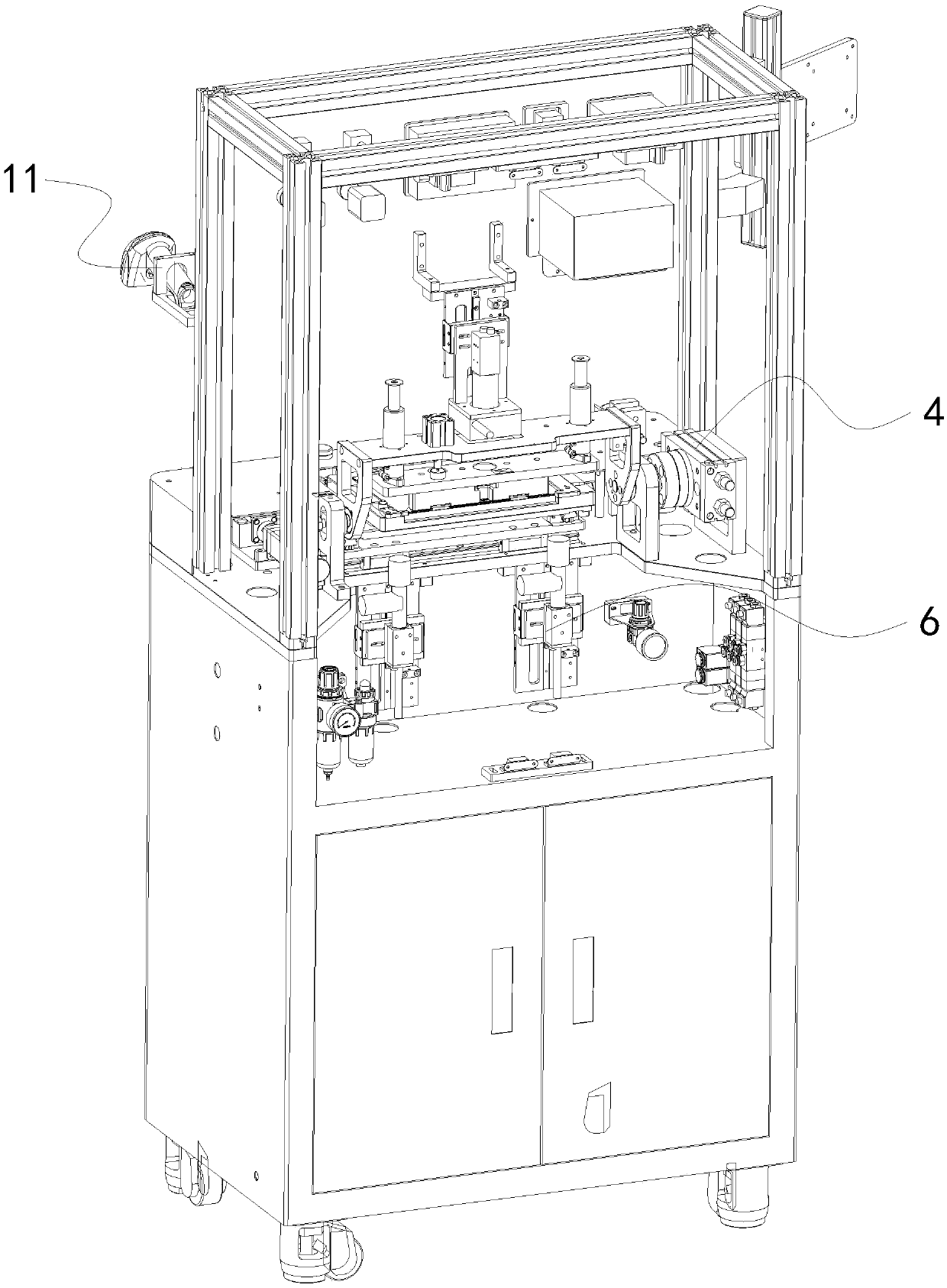

Double-station ACF adhesive high-precision shearing and attaching mechanism

PendingCN111189777AEasy to adjustAdjust flatnessOptically investigating flaws/contaminationMetal working apparatusAdhesiveEngineering

The invention discloses a double-station ACF adhesive high-precision shearing and attaching mechanism. The mechanism comprises a vertical base, an attaching platform assembly, a shearing assembly, anattaching pressure head assembly, an ACF adhesive conveying mechanism, an ACF lower alignment camera, a product attaching ACF position Mark point upper alignment camera and an attaching precision detection camera after the ACF is attached to the product. The attaching platform assembly is provided with an XYZ theta-axis driving mechanism, a main platform and a vacuum adsorption attaching platform,and the main platform and the vacuum adsorption attaching platform are arranged on the XYZ theta-axis driving mechanism and used for adsorbing products. The shearing assembly is used for shearing ACFadhesive, the attaching pressure head assembly is used for pressing and attaching the ACF adhesive, and the ACF adhesive conveying mechanism conveys the ACF adhesive to an attaching station closest to the ACF adhesive conveying mechanism. A second camera CCD detection device is used for detecting whether the attached product is qualified or not. According to the invention, the attaching precisionand the production efficiency of the ACF adhesive to the product are improved, and the attaching precision is improved. Double-station attachment is achieved, and the production efficiency is greatlyimproved.

Owner:SHENZHEN XINSANLI AUTOMATION EQUIP

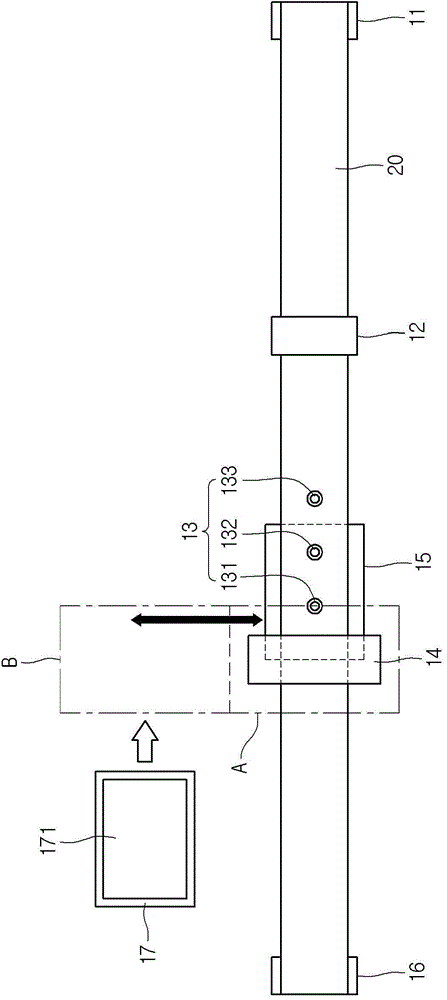

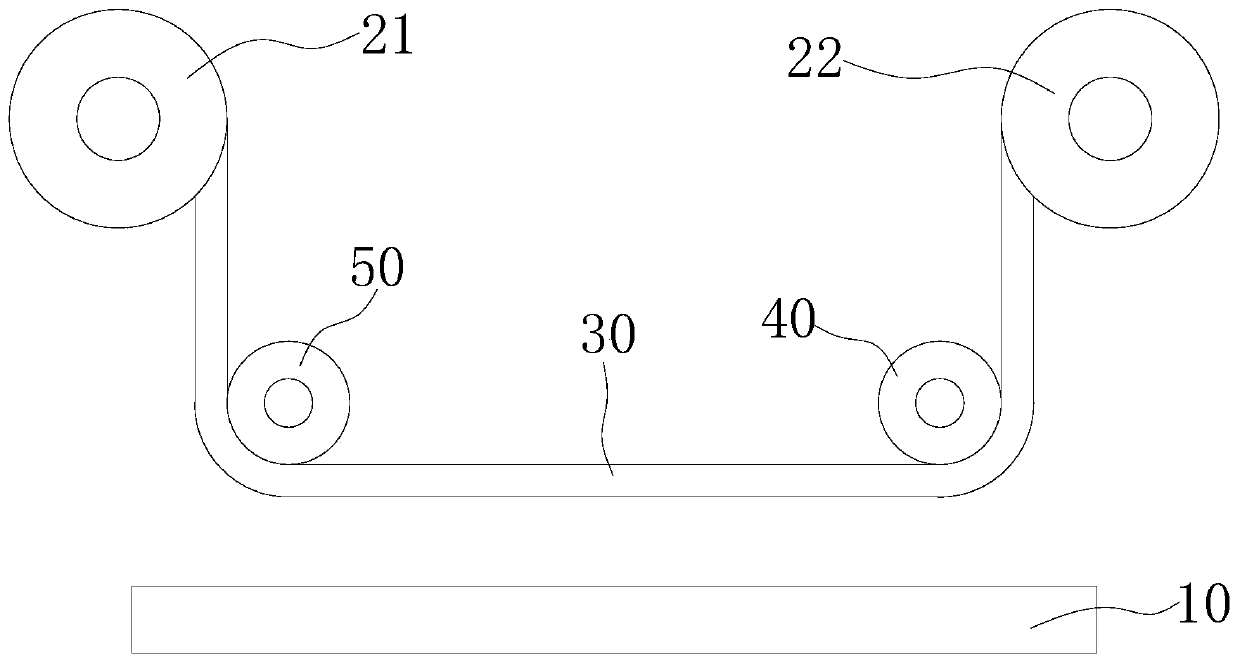

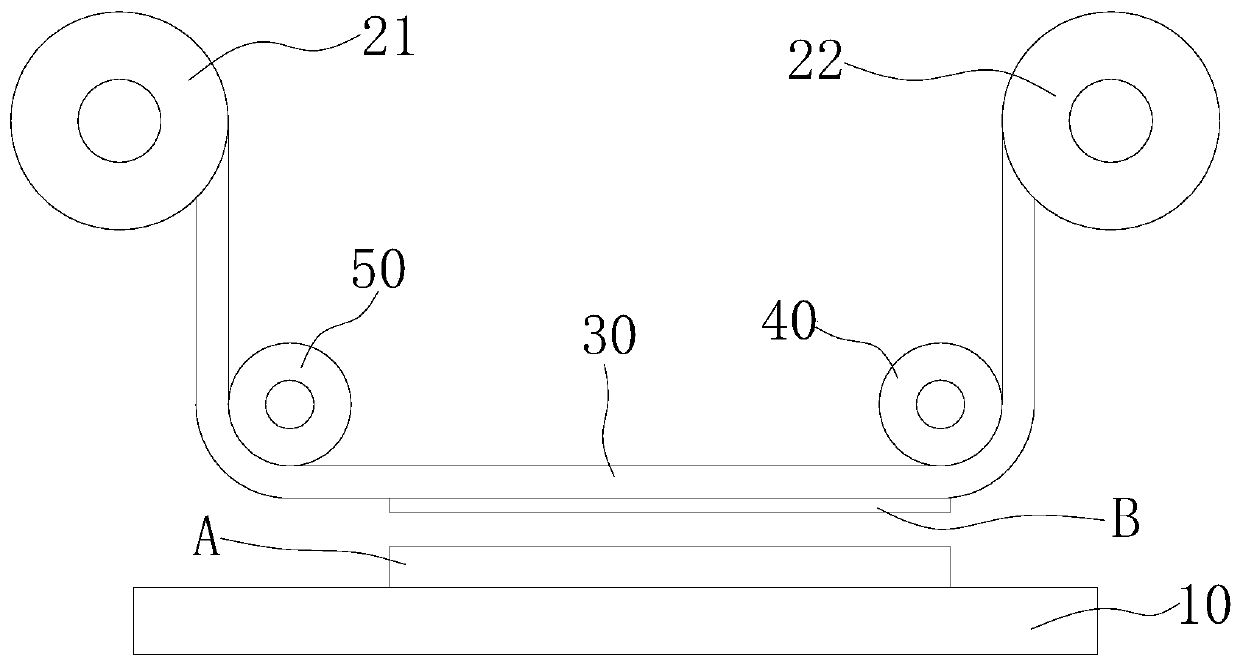

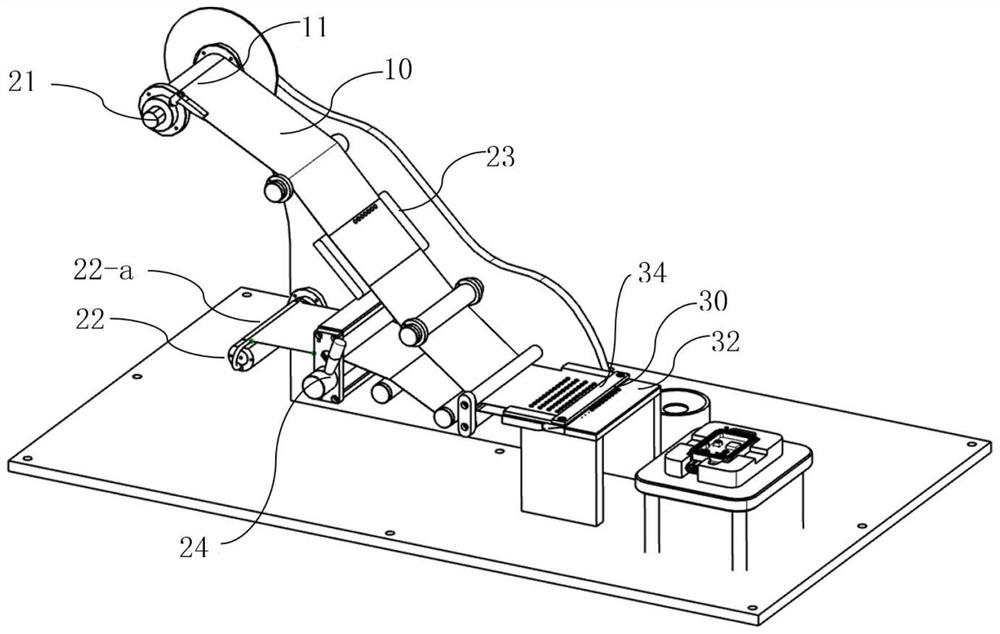

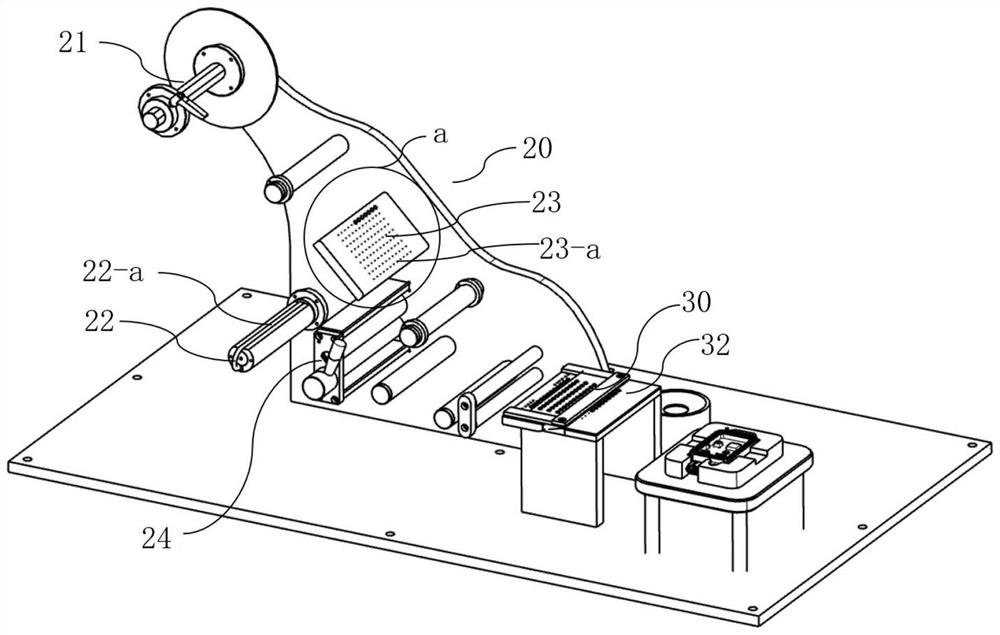

System for attaching film

ActiveCN104339809AHigh attachment accuracyAvoid disadvantagesLamination ancillary operationsControlling laminationElectrical and Electronics engineeringEngineering

A system for attaching film comprises a feeding roller, a cutter, a film carrier, an attaching roller, a recycling roller, a panel carrier and a panel. The feeding roller is wound by a film component which is formed in way that a polarizing film or 3D polarizing film, an adhesive film and a stripping film are stacked in order. The cutter cuts off the polarizing film or 3D polarizing film and the adhesive film of the film component, except the stripping film, being supplied by the feeding roller completely. The film carrier guides the film component which is partly cut off to a film separation region. The attaching roller is placed on the film separation region, and adsorbs the film part which is cut off by the cutter and comprises the polarizing film or 3D polarizing film and the adhesive film. The recycling roller is wound on the stripping film which goes over the attaching roller. The panel carrier is moved to a film attaching area which is spaced from the film separation region. Under the condition of being arranged on the panel carrier, the panel is moved to the film attaching area, after the attaching roller adsorbs the film part in the film separation region, the attaching roller is moved to the film attaching area, when the panel passes through the film attaching area, the film part adsorbed on the attaching roller is attached to the top surface of the panel.

Owner:LG ELECTRONICS INC

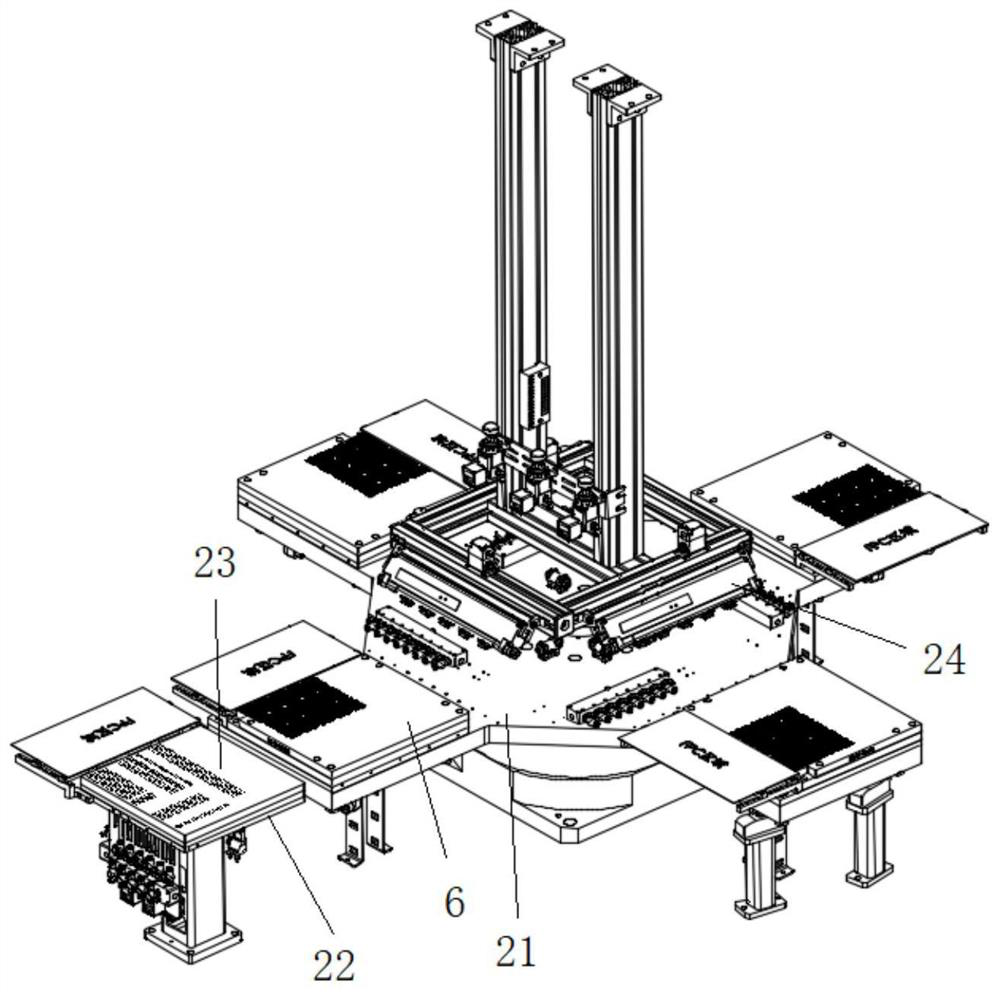

Flexible OLED cover plate laminating and assembling equipment

PendingCN112172297ACooperate accuratelyTransit connection is orderlyLamination ancillary operationsLaminationEngineeringMechanical engineering

The invention discloses flexible OLED cover plate laminating and assembling equipment which comprises a carrying platform used for carrying an OLED plate after the OLED plate is attached, a turntableplatform arranged on the side edge of the carrying platform and used for bearing the OLED plate, a stock bin device used for storing cover plate glass, a transfer platform matched with the stock bin device, a transferring, attaching and shifting device moving along the position between the transfer platform and the turntable platform, a film tearing manipulator device used for tearing off the OLEDplate surface film and the cover plate glass surface film and a visual detection device arranged on the turntable platform; and the transfering assembly is positioned to the surface of the OLED platesubjected to film tearing on the turntable platform, and cover plate glass subjected to film tearing is transferred and pasted. According to the equipment, the functions of automatic feeding and discharging are achieved, multi-station efficient and rapid connection is achieved, full-automatic laminating of flexible OLEDs and cover plate glass and transfer and film tearing procedures involved in the front-back direction are completed, and the cover plate glass is transferred, shifted, aligned and attached to the flexible OLEDs accurately.

Owner:SUZHOU LANGKUN AUTOMATION EQUIP CO LTD

Device for automatic light proof paper attaching and easy tearing and attaching processing

InactiveCN109765703AHigh degree of automationLabor savingNon-linear opticsConveyor partsEngineeringMaterial supply

The invention relates to an auxiliary material attaching device, and in particular to a device for automatic light proof paper attaching and easy tearing and attaching processing. The device comprisesa feeding device, a conveying device, a feeding turnover device, a discharging turnover device, a discharging device, at least one auxiliary material attaching device and an auxiliary material supplying device which is used for providing an auxiliary material and has the quantity corresponding to the quantity of the auxiliary material attaching device, wherein the conveying device is arranged between the feeding device and the discharging device; the auxiliary material attaching device comprises an auxiliary material attaching mechanical arm and an attaching moving platform; the auxiliary material attaching mechanical arm is slidably arranged on the attaching moving platform; the feeding turnover device is arranged between the feeding device and the attaching moving platform; and the discharging turnover device is arranged between the discharging device and the attaching moving platform. The device disclosed by the invention has the technical effects that the automatic light proof paper attaching and the easy tearing and attaching processing of a workpiece is realized; the labor is saved; the processing efficiency is improved; the automation degree of the auxiliary material attaching is increased; and the auxiliary material attaching efficiency of the workpiece and the attaching precision of a product are increased.

Owner:GUANGZHOU LINKCORE AUTOMATIC EQUIP CO LTD

Material identification equipment and control method of material identification equipment

InactiveCN105416738AImprove storage efficiencyReduce labor intensityLabelling machinesEngineeringSupport plane

Owner:CELESTICA DONGGUAN SSL TECH LTD

Mobile phone label automatic attaching device

InactiveCN108584056AHigh attachment accuracyImprove attachment efficiencyLabelling machinesDegrees of freedomMechanical engineering

The invention discloses a mobile phone label automatic attaching device, which comprises a working platform, a labeling fixture disposed on the working platform, a labeling module disposed on one sideof the labeling fixture on the working platform, at least one label printing mechanism and a detecting mechanism disposed above the labeling fixture. The labeling fixture is provided with a materialframe for fixing a mobile phone. The labeling module includes a driving mechanism with degree of freedom along the X-axis, the Y-axis and the Z-axis, a label clamping mechanism and a code scanning mechanism arranged at the execution end of the driving mechanism, and an image collecting and positioning mechanism which is disposed at the execution end of the driving mechanism and positioned at one side of the label clamping mechanism and is used for adjusting the labeling position. In the invention, automatic attachment of the label on the back of the mobile phone can be realized. by the use ofthe device, attaching precision and attaching efficiency can be improved, and labor intensity of workers and labor cost of enterprises also can be reduced; and the labeling position can be detected, and product yield can be raised.

Owner:苏州轩明视测控科技有限公司

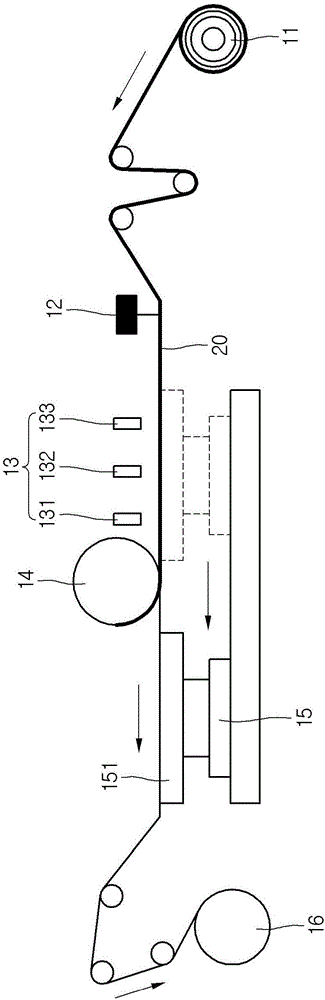

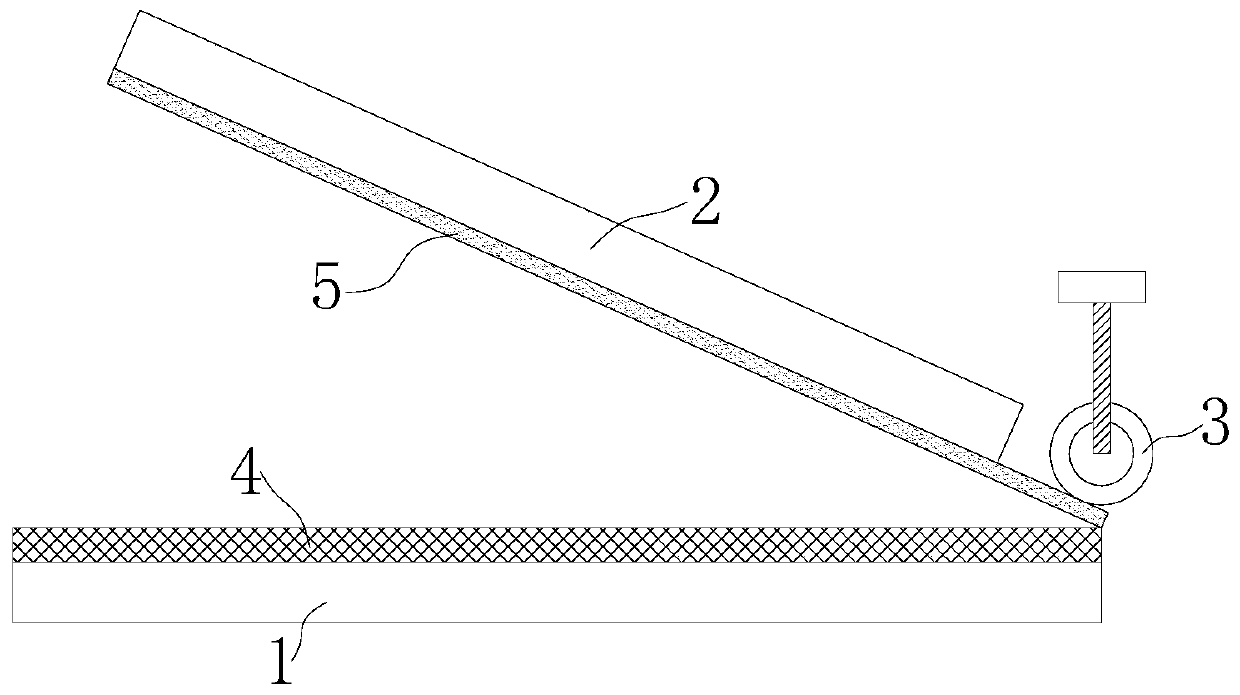

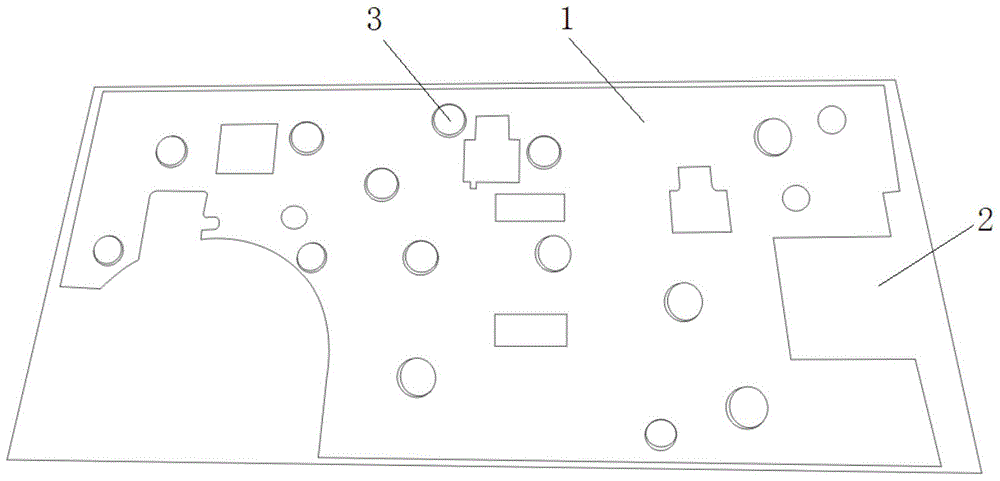

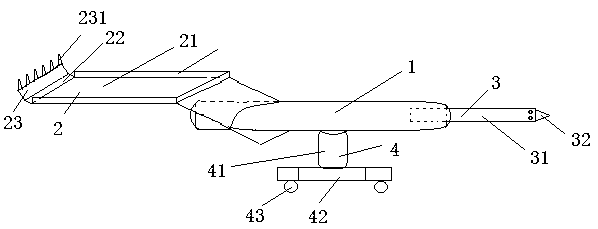

Back membrane attachment device for flexible substrates and method thereof

The invention discloses a back membrane attachment device for flexible substrates. The device comprises a workbench, above which a band-shaped membrane is arranged. The upper surface of the band-shaped membrane is provided with a pressure roller. When the pressure roller moves downward, the band-shaped membrane slopes down to drive one end of a membrane to be attached, close to the pressure roller, to fit a corresponding end of the substrate. When the pressure roller rolls on the upper surface of the band-shaped membrane in the horizontal direction, the lower surface of the membrane to be attached fits the upper surface of the substrate. A back membrane attachment method for flexible substrates comprises the following steps: respectively fixing the substrate and the membrane to be attachedon the workbench and the band-shaped membrane; moving the workbench to make the whole body of the substrate to be located below the membrane to be attached; driving the pressure roller to move downward until the membrane to be attached fit the end portion of the substrate; driving the pressure roller to roll until the lower surface of the membrane to be attached fits the upper surface of the substrate. According to the above scheme, the membrane to be attached fits the substrate through roll-in movement of the pressure roller, displacement of the membrane to be attached and the substrate willnot take place in the horizontal direction, no bubble will be generated during the attachment process, and the attachment precision is high.

Owner:SUZHOU LANGKUN AUTOMATION EQUIP CO LTD

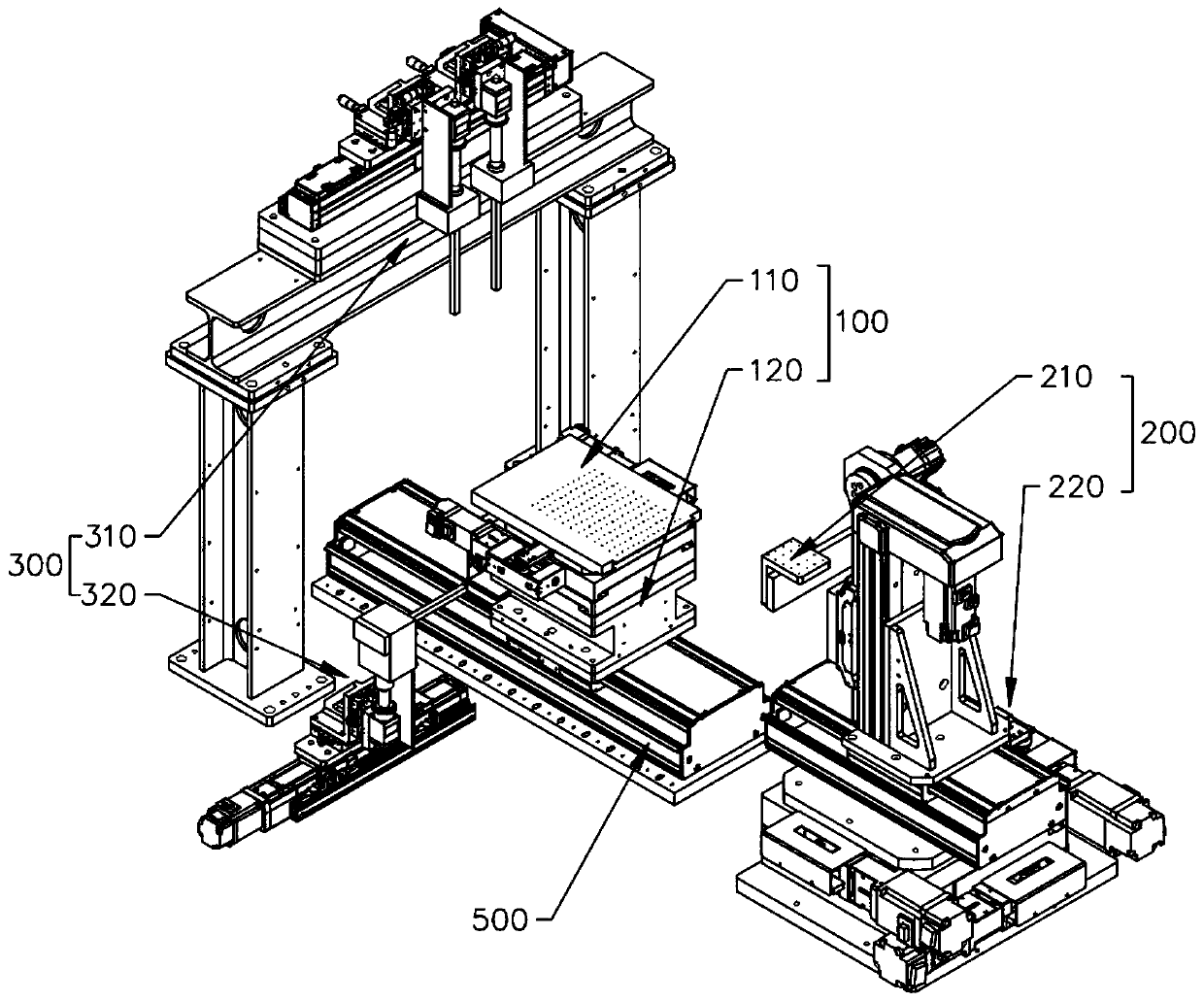

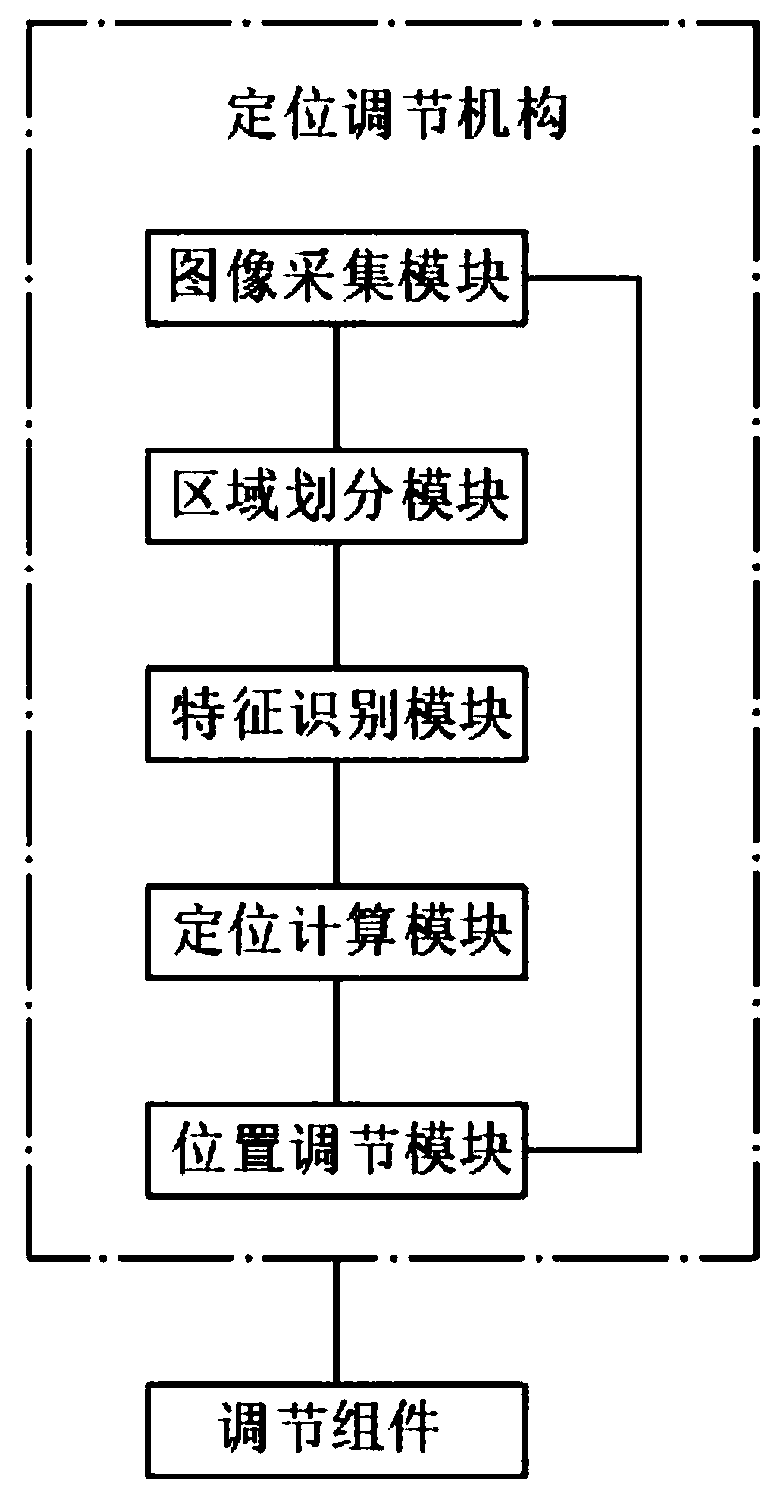

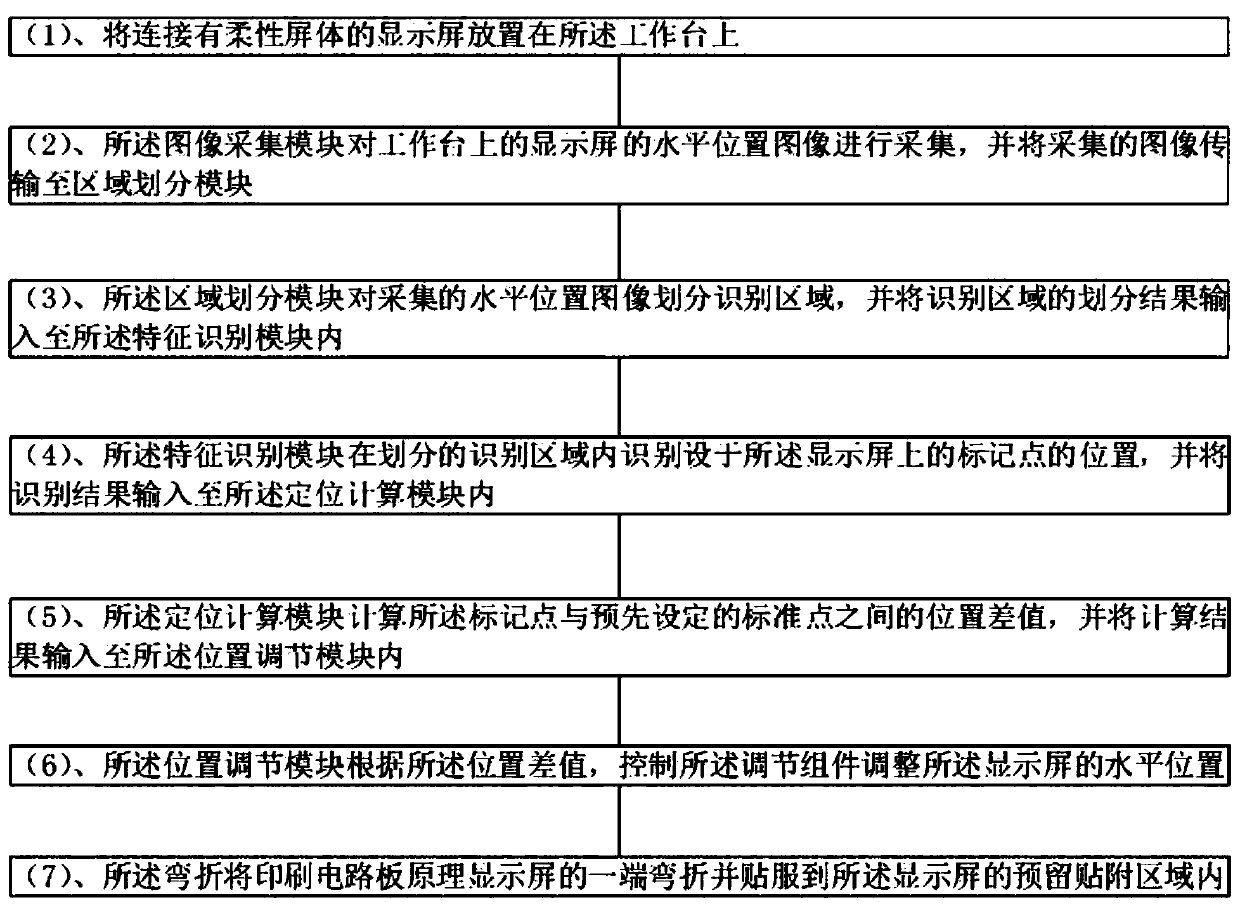

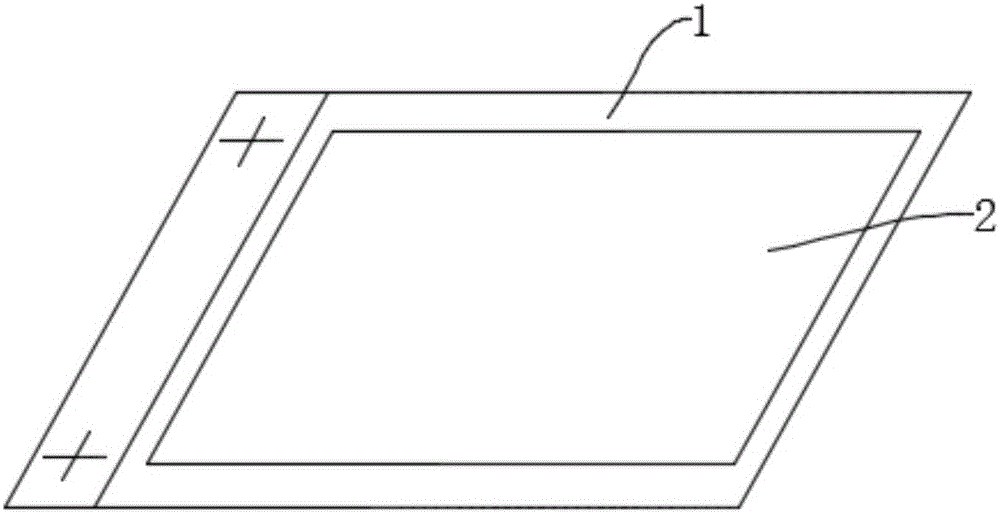

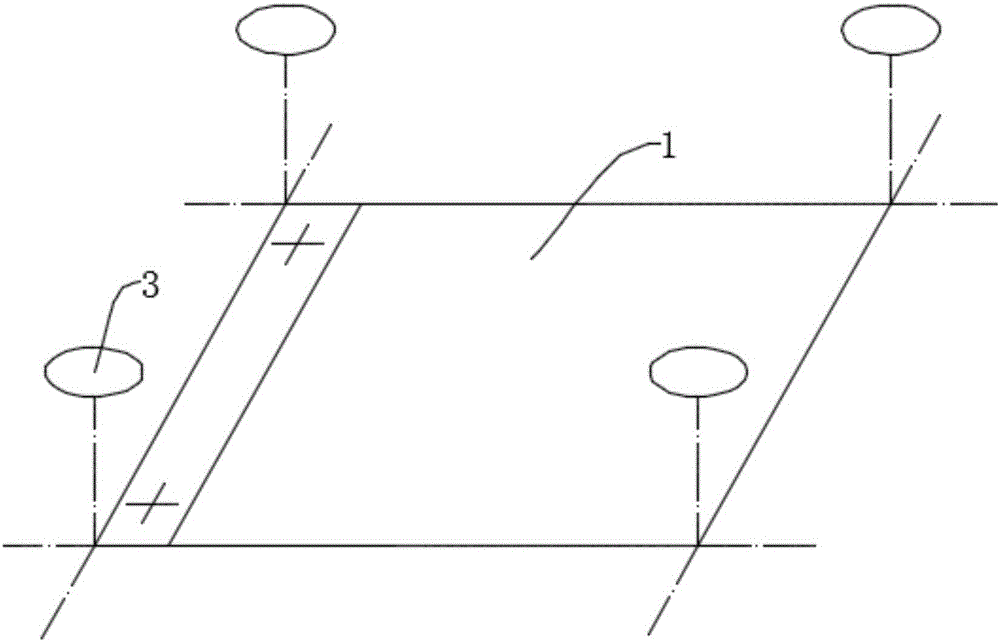

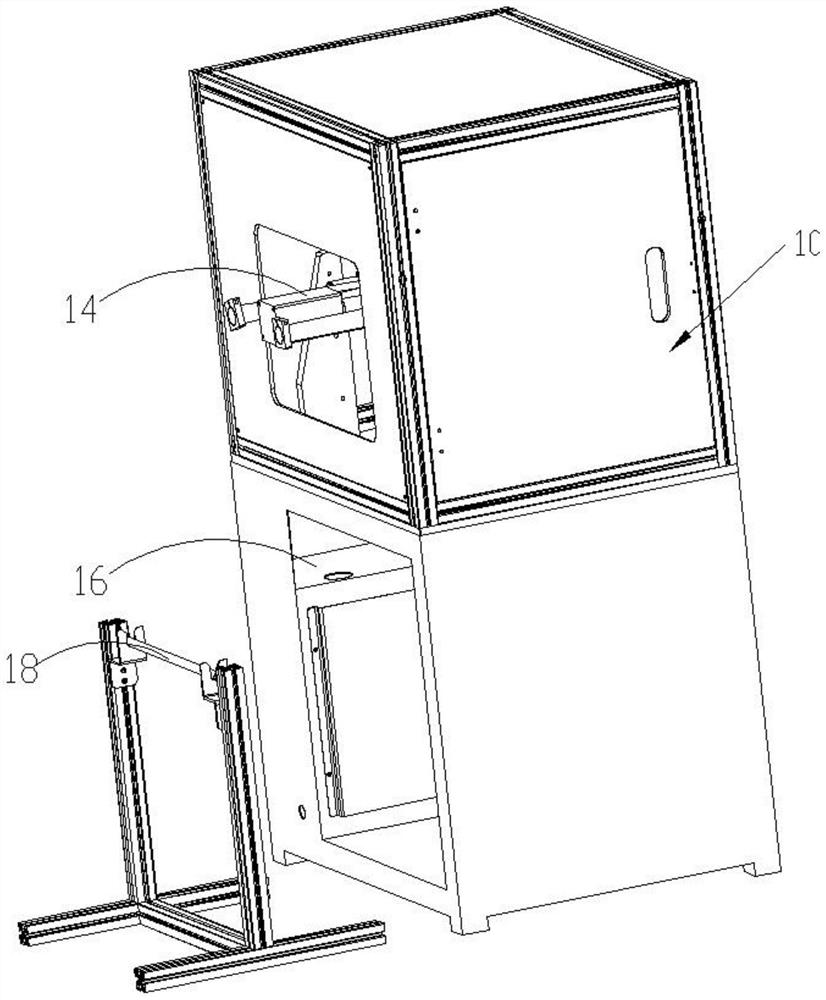

Flexible screen body bending and attaching machine

ActiveCN111415585AHigh attachment accuracyIncrease the level of automationFastening meansIdentification meansPrinted circuit boardMechanical engineering

The invention discloses a flexible screen body bending and attaching machine, which belongs to the technical field of display screens, and comprises a workbench, a bending mechanism and a positioningand adjusting mechanism, and the workbench is used for bearing a display screen and comprises an object carrying clamp used for fixing the display screen and an adjusting assembly used for adjusting the position of the object carrying clamp. The positioning and adjusting mechanism is used for detecting whether the horizontal positions of the display screens on the workbench is within a preset range or not, and if not, an adjusting instruction is sent to the adjusting assembly so as to drive the adjusting assembly to adjust the horizontal positions of the display screens, and if yes, a drivinginstruction is sent to the bending mechanism; the bending mechanism is used for bending the end, away from the display screens, of the printed circuit board and attaching the end to the reserved attaching areas of the display screens according to the received driving instruction. The attaching precision of the printed circuit board can be improved, and the automation level is high.

Owner:SHENZHEN TENSUN IND EQUIP

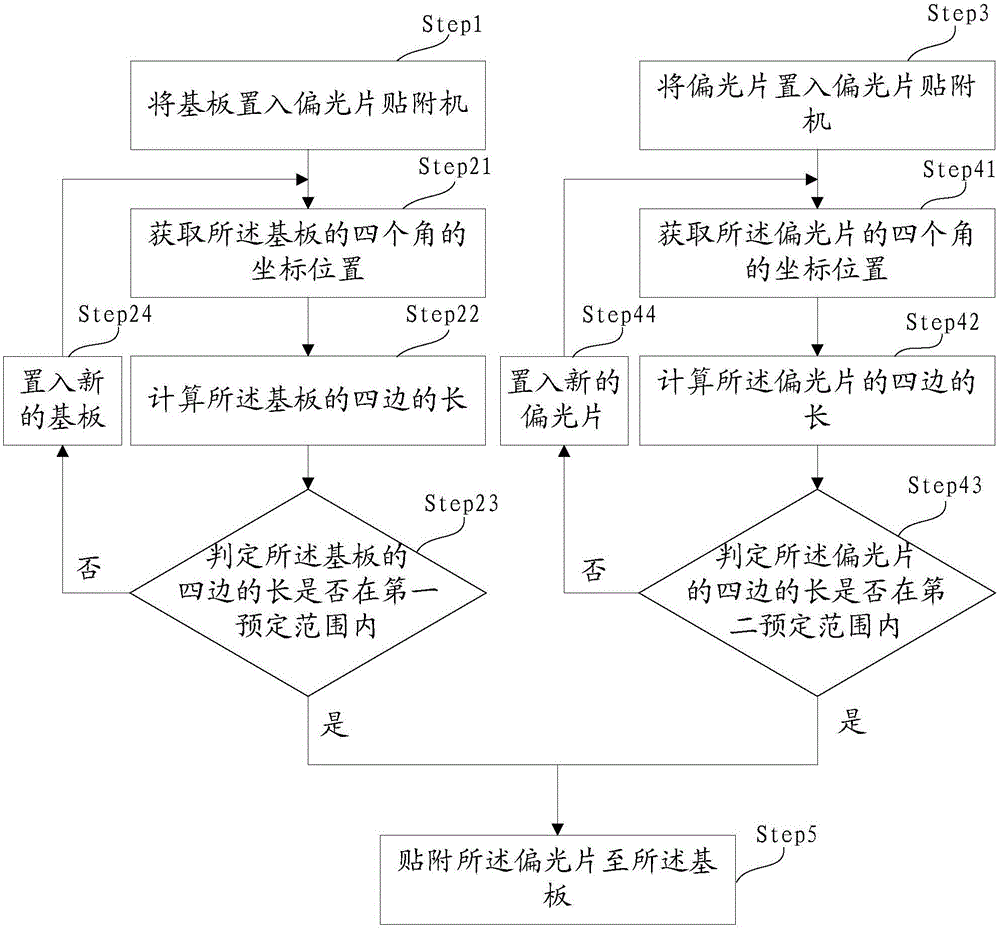

Attaching method of polaroid and attaching machine for polaroid

The invention discloses an attaching method of a polaroid. The method comprises following steps: putting a substrate into an attaching machine for the polaroid; determining whether the substrate is up to the standard through the attaching machine for the polaroid or not; putting the polaroid into the attaching machine for the polaroid; determining whether the polaroid is up to the standard or not through the attaching machine for the polaroid; and attaching the polaroid to the substrate if the substrate and the polaroid are up to the standard. The attaching method of the polaroid is high in attaching precision. The invention further discloses the attaching method of the polaroid.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

T-FOF plasma cleaning and ACF attaching combined mechanism for

PendingCN111712124AEasy to adjustSave time adjusting positionCleaning processes and apparatusElectrical componentsPhysicsEngineering

The invention discloses a T-FOF plasma cleaning and ACF attaching combined mechanism, which comprises a bottom plate, a platform assembly and a cleaning and attaching assembly, wherein the platform assembly is provided with a plasma film placing platform and a Y-axis driving mechanism mounted on the bottom plate, the Y-axis driving mechanism is provided with a first sliding block assembly moving in the Y-axis direction, the top face of the first sliding block assembly is provided with a Z-axis mechanism used for adjusting the height of the plasma film placing platform in the Z-axis direction,two sets of stripping rod mechanisms arranged on the two sides of the Z-axis mechanism and an adjustable ejector pin separating mechanism, and the cleaning and attaching assembly is provided with a cleaning mechanism and an attaching mechanism. According to the invention, the same working platform is adopted for product cleaning and ACF adhesive attaching, and an automatic stripping rod mechanismis arranged according to the complexity of the product, so that cleaning of M-FPC and T-FPC and attaching of the ACF adhesive are facilitated, and improvement of the subsequent binding precision is well facilitated.

Owner:SHENZHEN XINSANLI AUTOMATION EQUIP

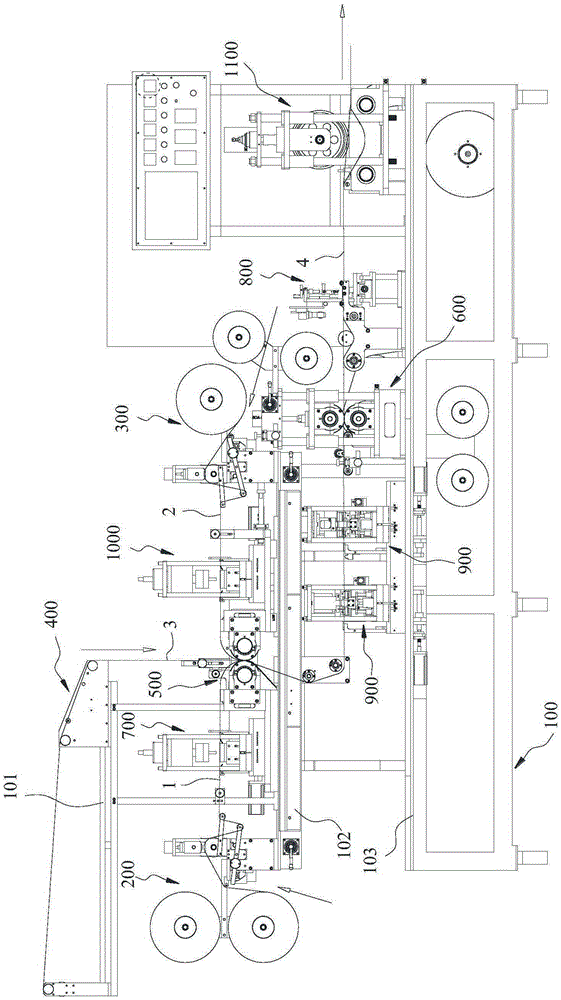

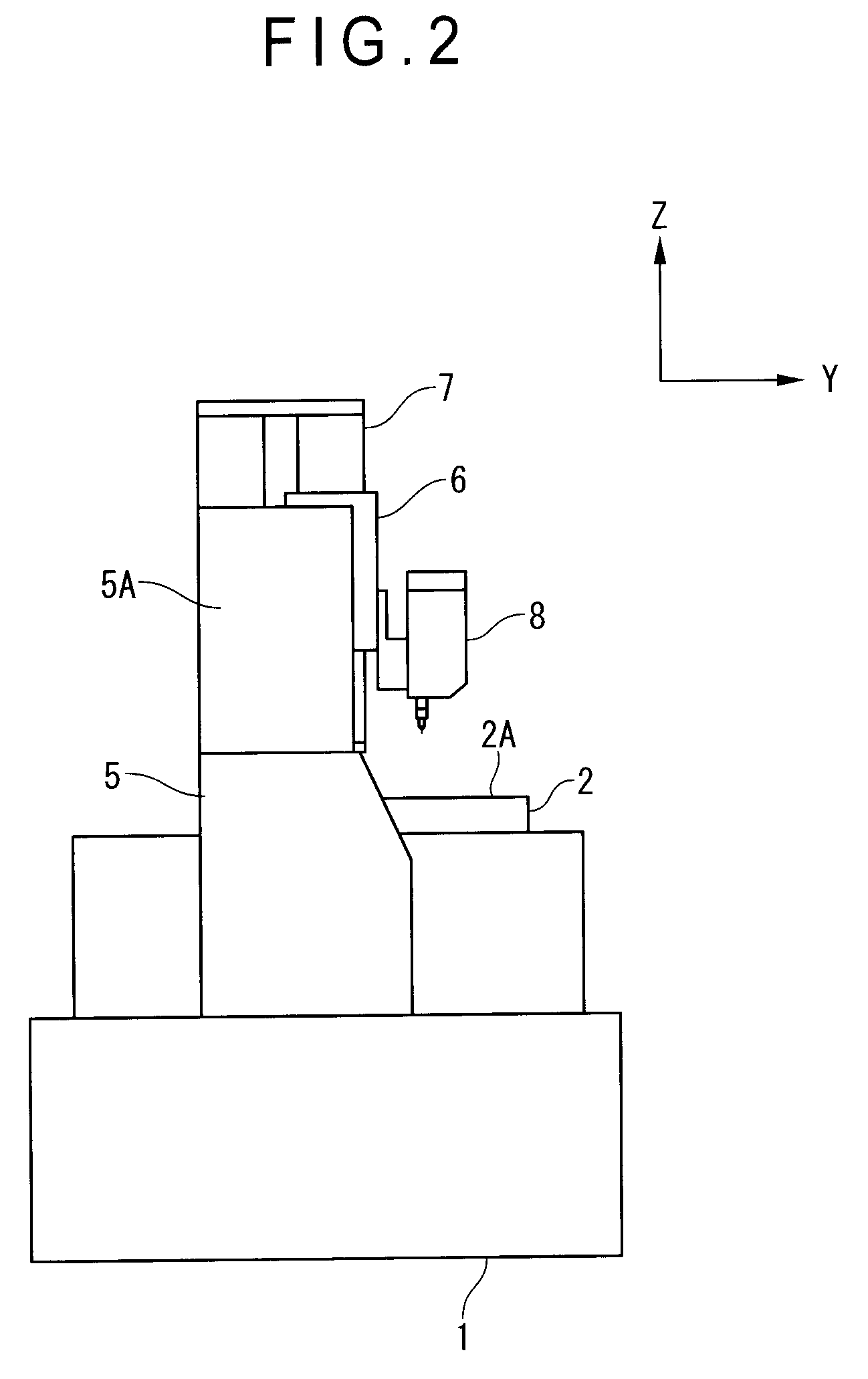

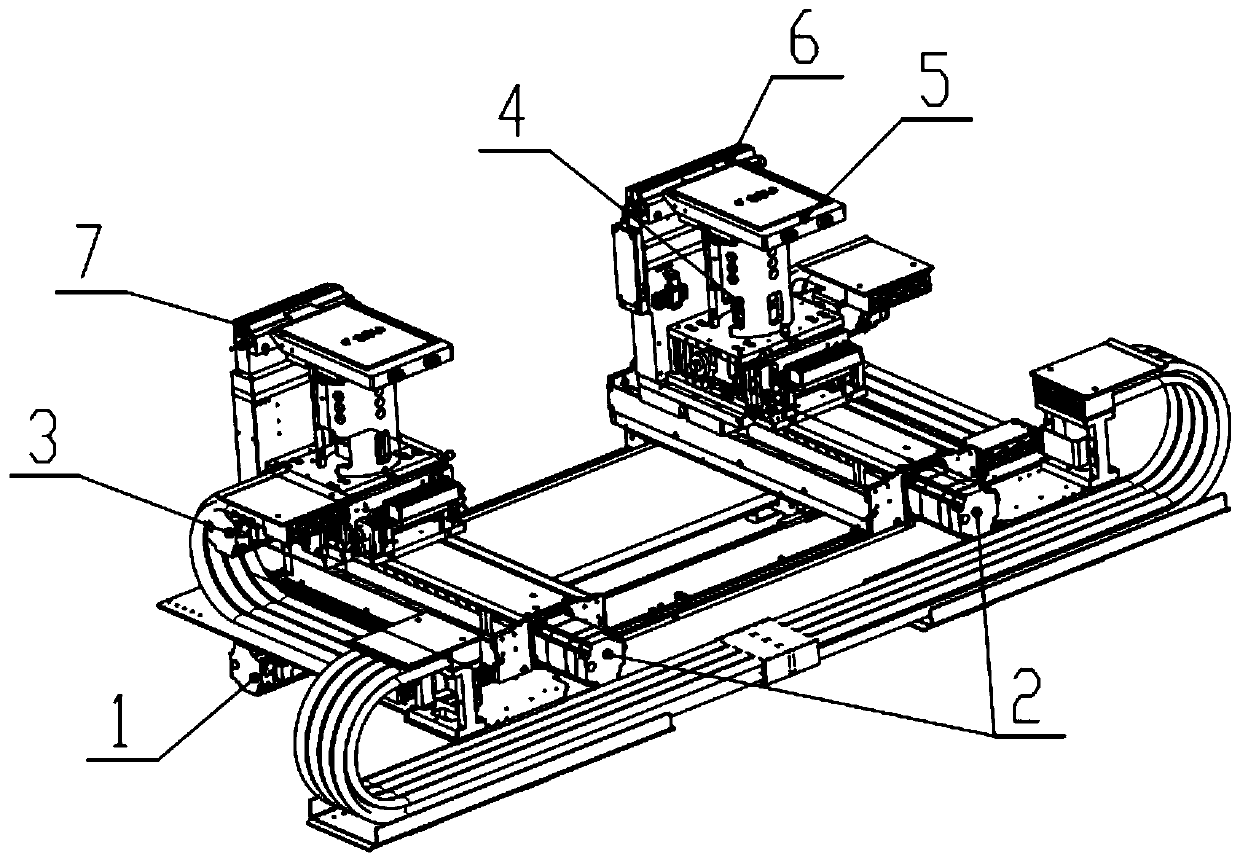

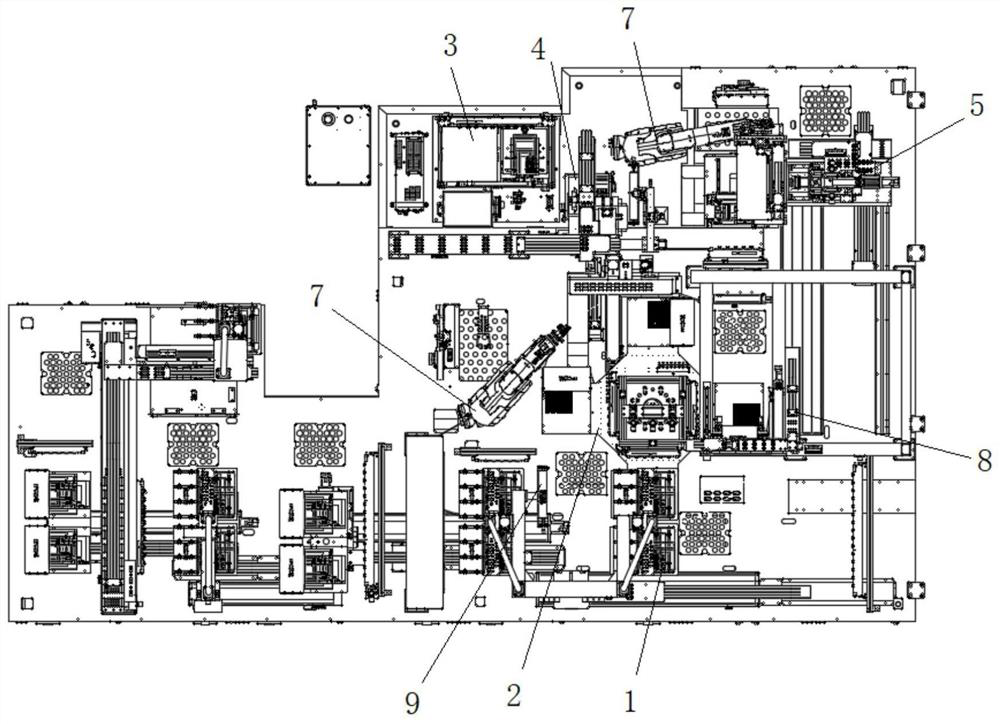

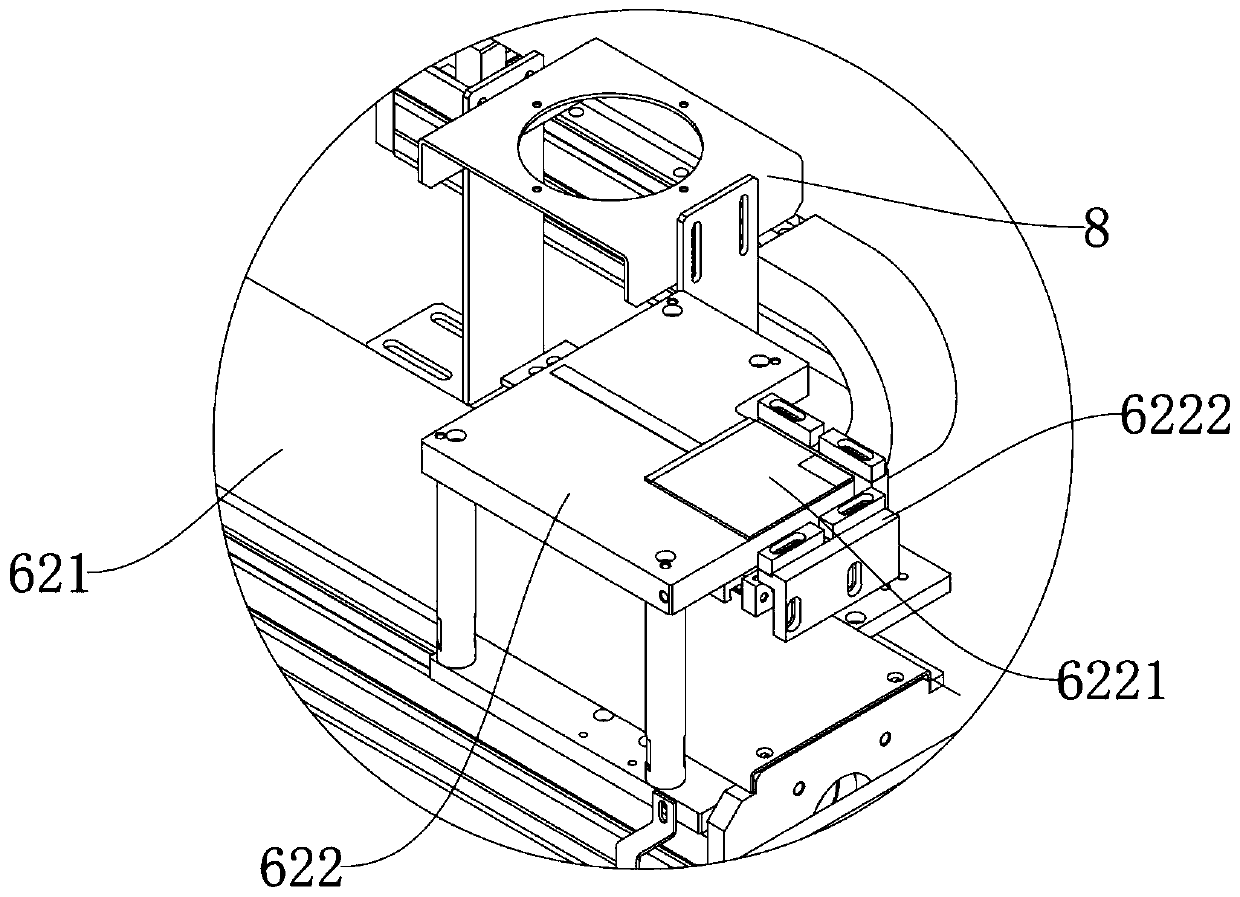

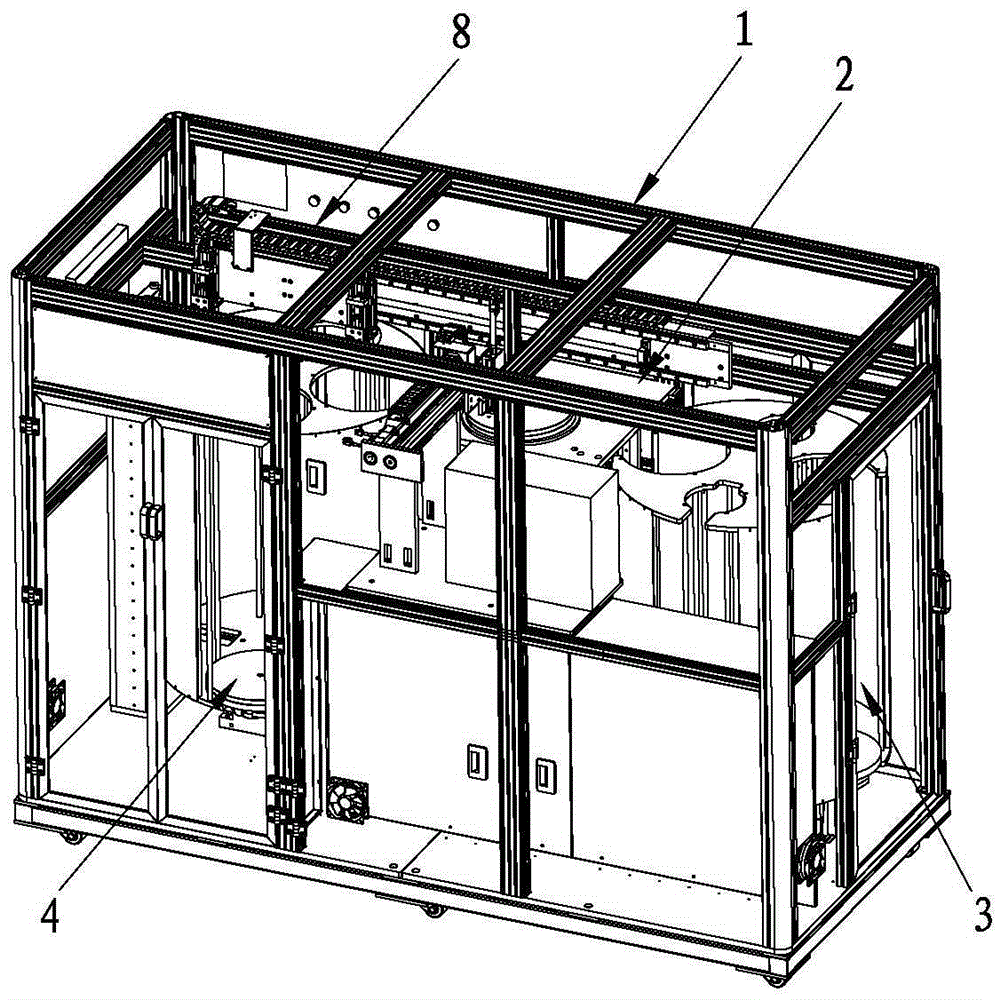

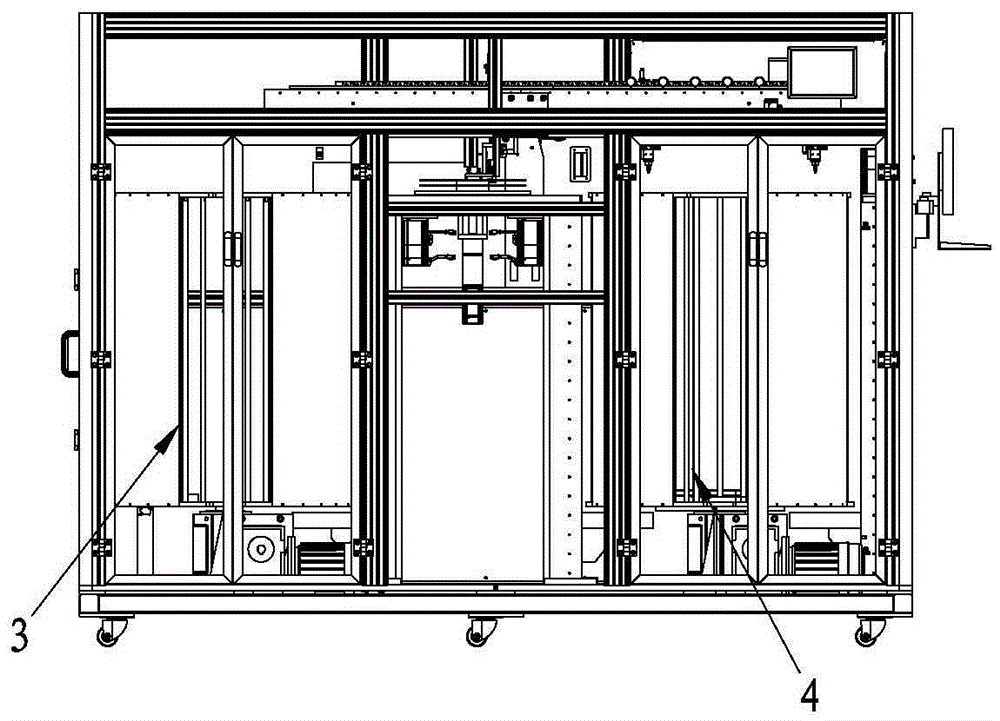

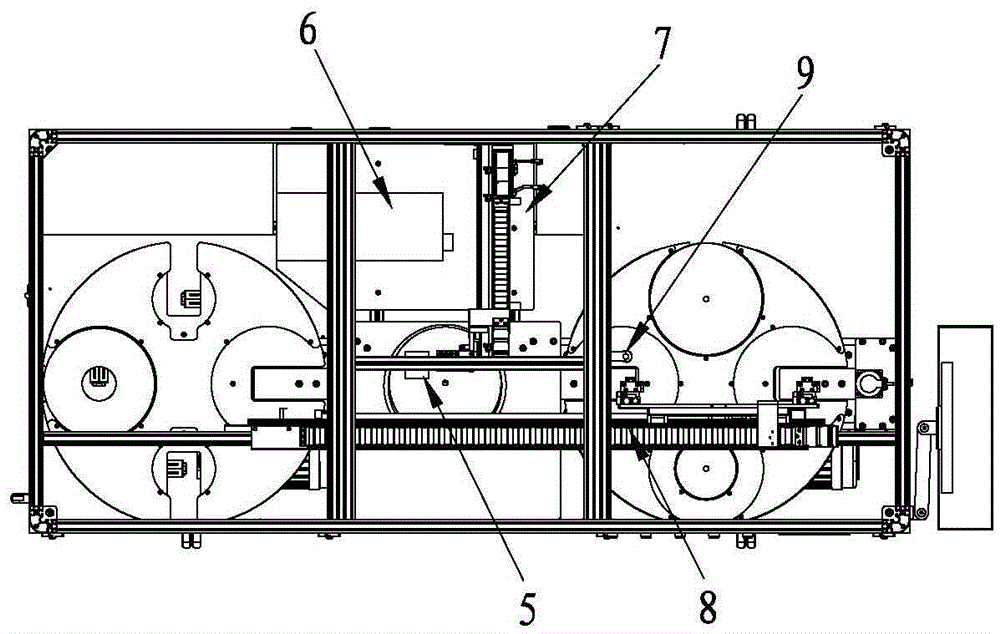

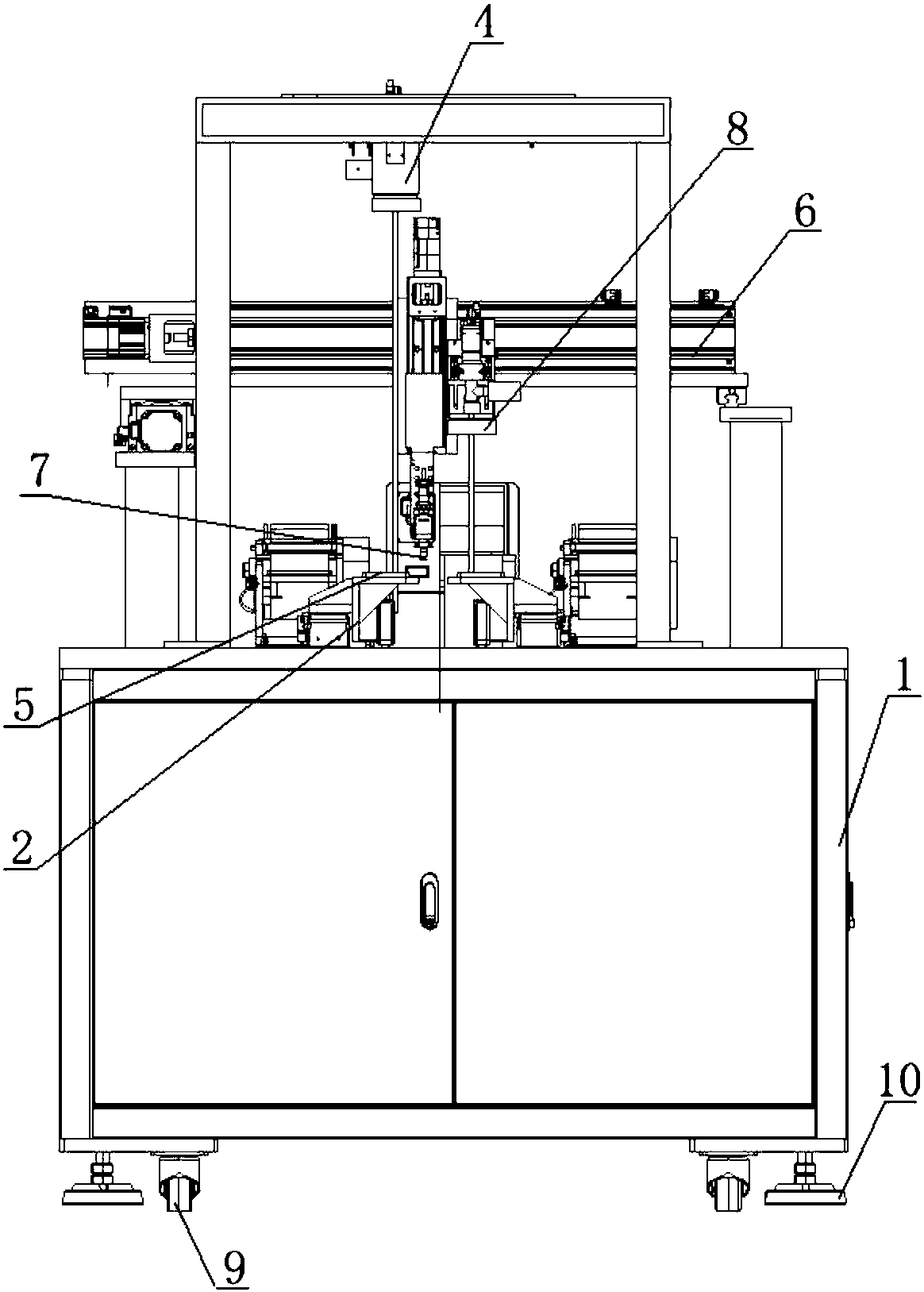

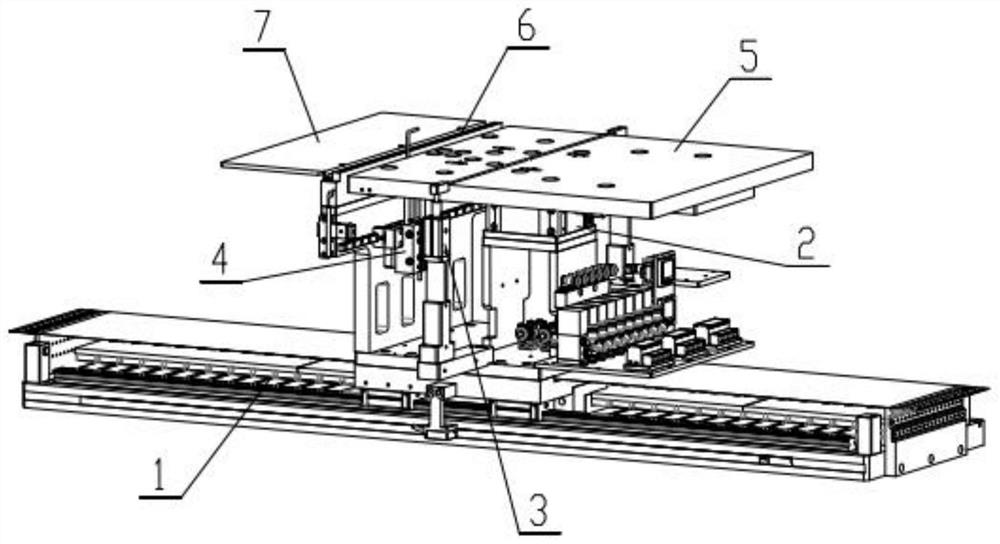

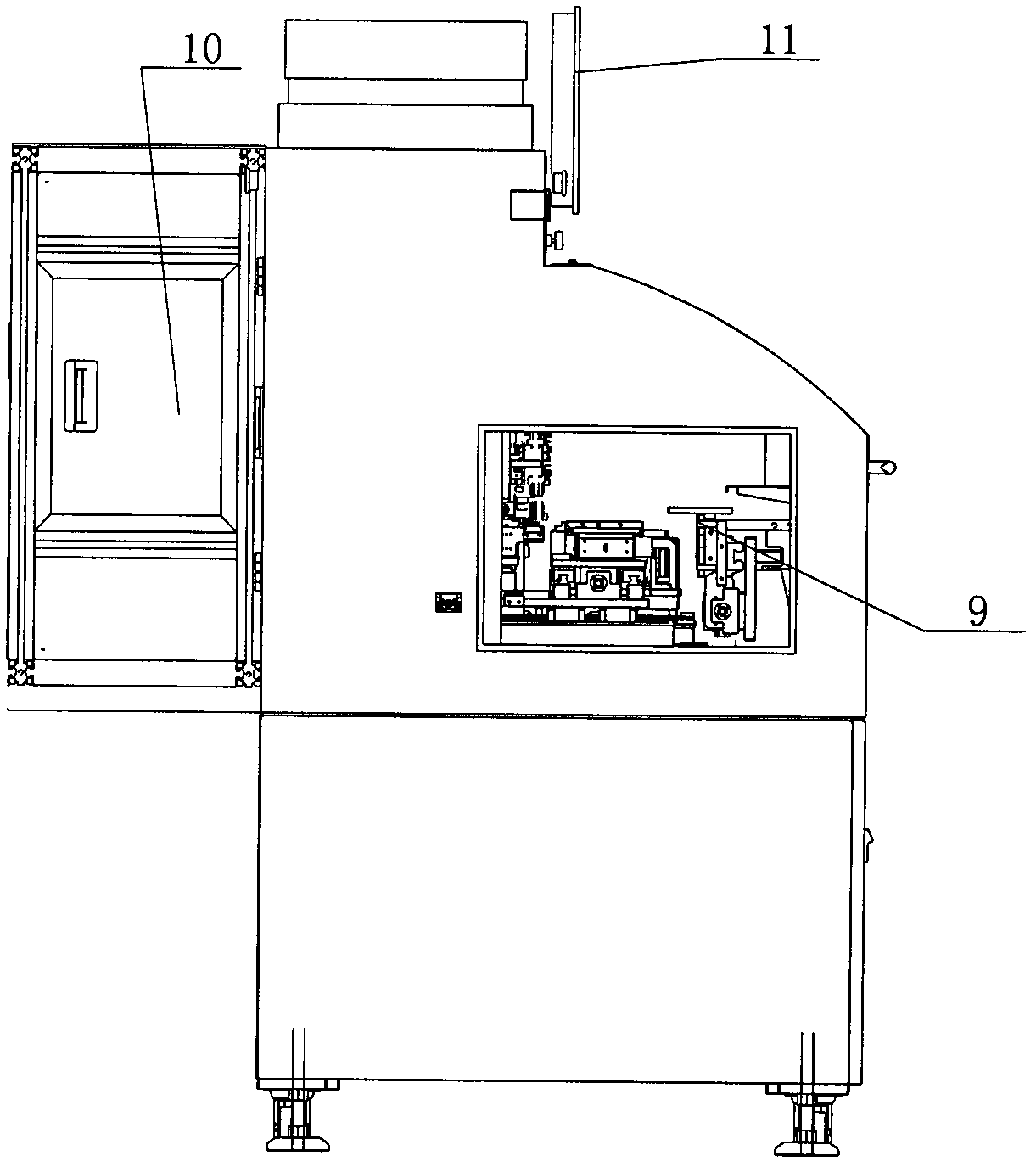

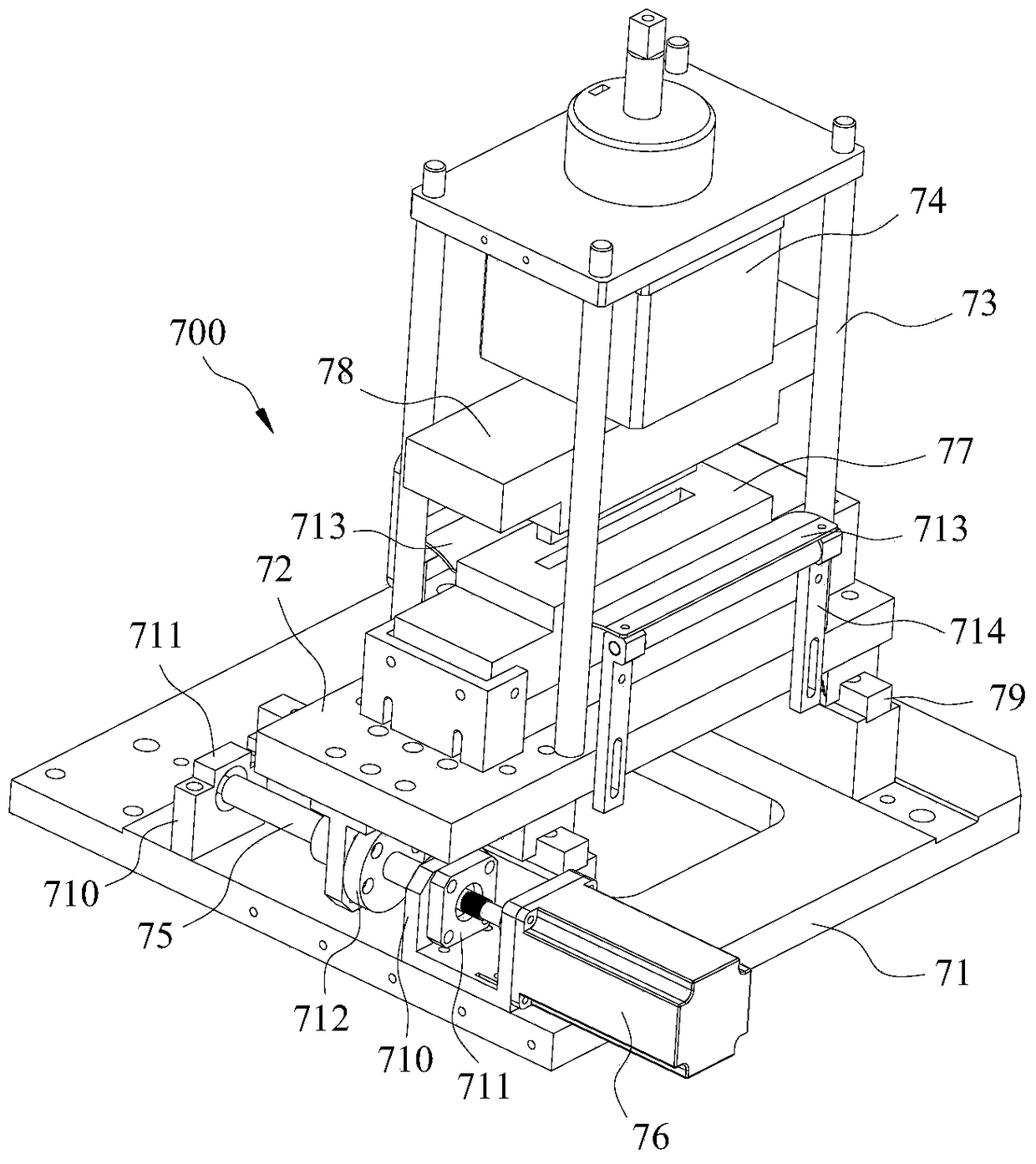

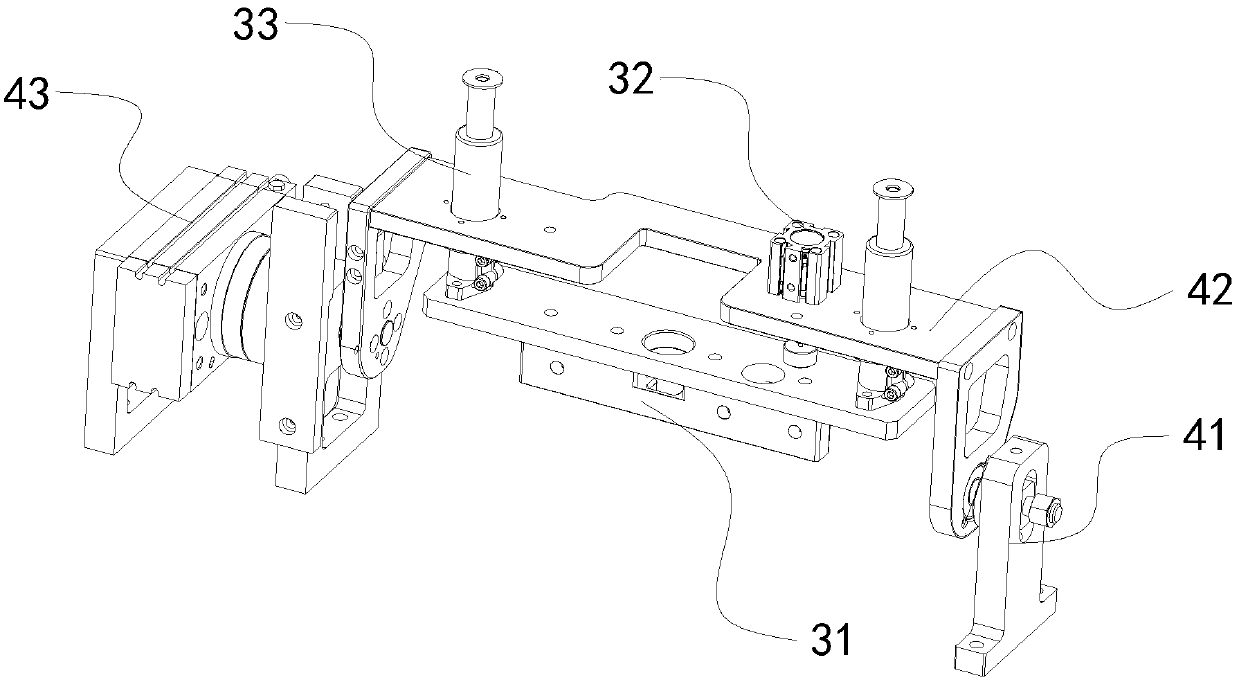

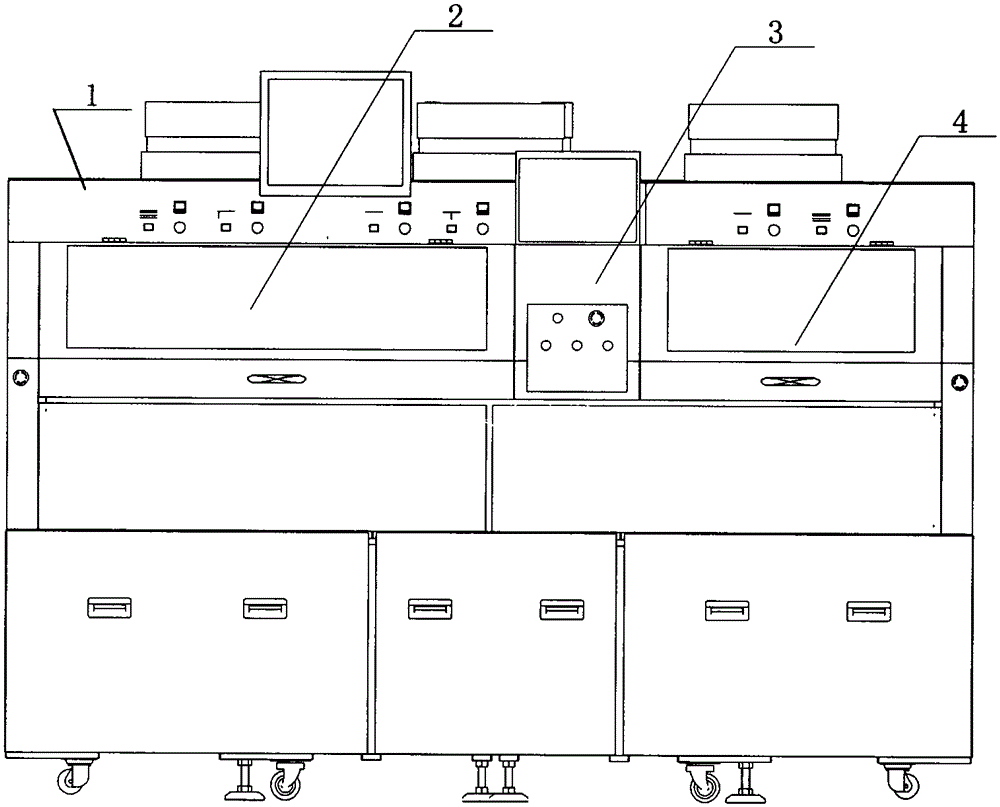

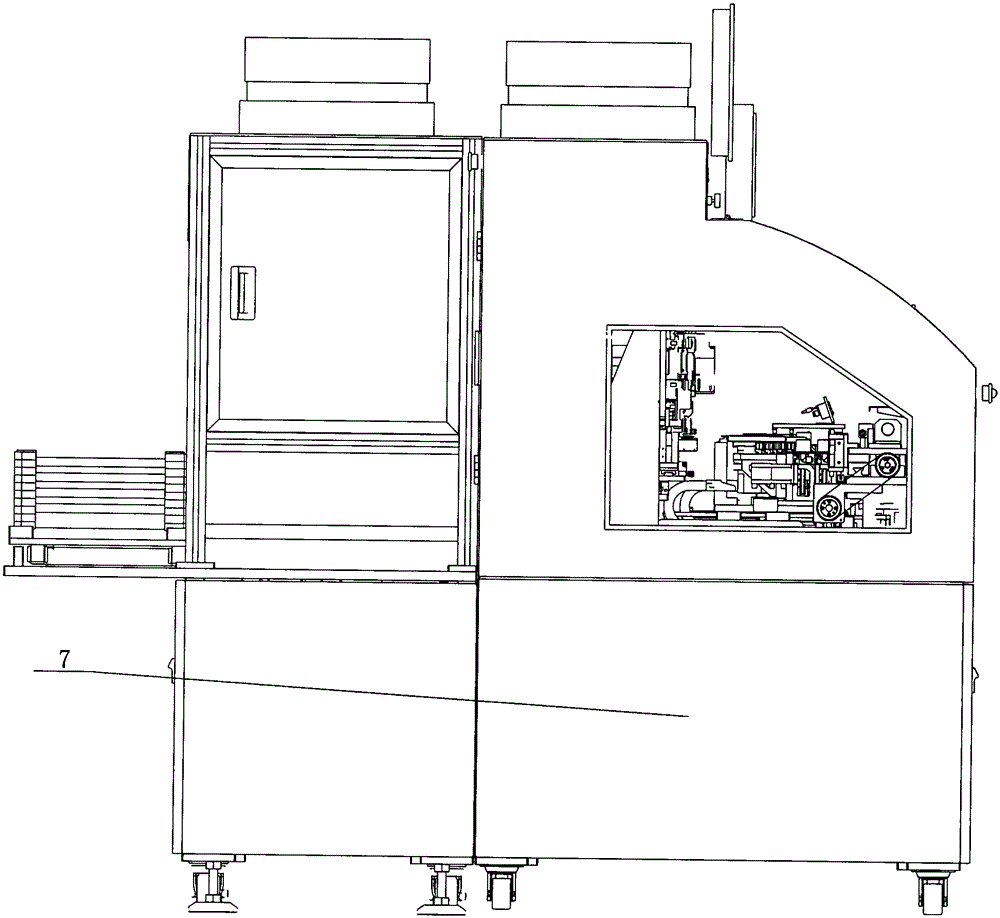

Automatic bonding machine for connection between chip and glass circuit

ActiveCN103379741AHigh attachment accuracyImprove efficiencyPrinted circuit assemblingManipulatorElectrical and Electronics engineering

The invention provides an automatic bonding machine for connection between a chip and a glass circuit, and relates to the technical field of automatic bonding machines. An IC feeding portion (2) is arranged on the rear portion of an automatic bonding machine body (1), an IC disc working area (3) is arranged on the right side of the IC feeding portion (2), an IC empty disc recovery area (4) is arranged on the right side of the IC disc working area (3), an ACF portion (5) is arranged on the left side of the front portion of the automatic bonding machine body (1), a pre-pressing portion (6) is arranged on the right side of the ACF portion (5), a currently pressing portion (7) is arranged on the right side of the pre-pressing portion (6), a mechanical arm portion (9) is arranged on the left side face of the automatic bonding machine body (1), and an IC carrying mechanism (10) is arranged on the rear portion of the automatic bonding machine (1). The automatic bonding machine for connection between the chip and the glass circuit is high in efficiency, little in required manpower and high in ACF attaching accuracy due to the fact that a detection mechanism is arranged.

Owner:SHENZHEN LIANDE AUTOMATION EQUIP

automatic ffc crimp forming machine

The invention discloses an automatic FFC pressure connecting forming machine. The automatic FFC pressure connecting forming machine comprises a machine frame, a first film feeding mechanism, a second film feeding mechanism, a conductor feeding mechanism, a first hot press device, a second hot press device, a first punching device, a second punching device, a reinforcing plate attaching device and a striping device. The machine frame comprises a top layer frame, a middle layer frame and a bottom layer frame. The conductor feeding mechanism is installed on the top layer frame. The first film feeding mechanism and the second film feeding mechanism are arranged at the two ends of the middle layer frame respectively. The first hot press device is installed on the middle layer frame and located between the first film feeding mechanism and the second film feeding mechanism. The reinforcing plate attaching device, the second hot press device and the striping device are sequentially installed on the bottom layer frame in the conveying direction of semi-finished FFC products. An outlet of the first film feeding mechanism and an outlet of the second film feeding mechanism are right opposite to the first hot press device horizontally. An outlet of the conductor feeding mechanism is right opposite to the first hot press device vertically. By means of the automatic FFC pressure connecting forming machine, the semi-finished FFC products can be attached firmly, reinforcing plates are attached precisely and firmly, the product quality is improved, and the rate of finished products is increased.

Owner:佛山市顺德区禾惠电子有限公司

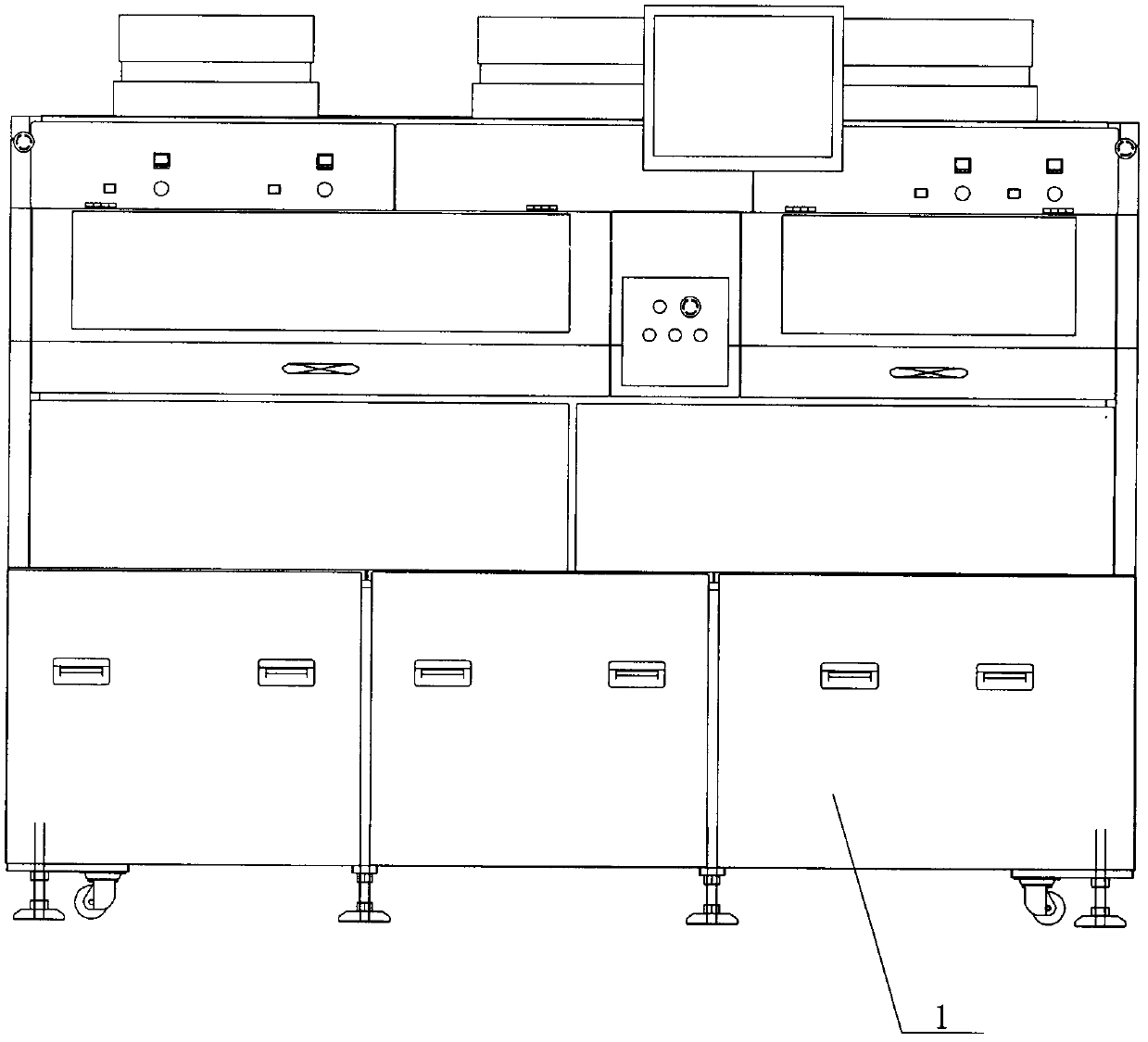

Full-automatic low-viscosity double-sided tape attaching and hot-pressing equipment

PendingCN114824416AHigh speedIncrease production capacityAssembling battery machinesArticle deliveryAdhesive beltBattery cell

According to the technical scheme, the full-automatic low-viscosity double-sided tape attaching and hot-pressing equipment comprises a supporting plate, and a hot-pressing mechanism is arranged on the supporting plate; the hot pressing mechanism comprises a feeding conveyor, the feeding conveyor is arranged on the supporting plate and extends out of one side of the supporting plate, a feeding turnover assembly is arranged on the portion, located on one side of the feeding conveyor, of the supporting plate, and a feeding robot is arranged on the portion, located on the other side of the feeding conveyor, of the supporting plate. According to the invention, the equipment has the characteristics of high productivity, high attaching precision, high cost performance and full automation, solves the investment of a large amount of personnel cost, improves the overall qualified rate of products, further improves the adhesive tape attaching precision, solves a series of problems of wrinkled attaching effect, many bubbles, low yield and the like, is stable in battery adsorption, and is suitable for large-scale production. Therefore, the stability of the battery can be ensured without clamping a workpiece, the battery is not easy to damage, and the use is convenient.

Owner:WUI GELIN SITONG AUTOMATION EQUIP CO LTD

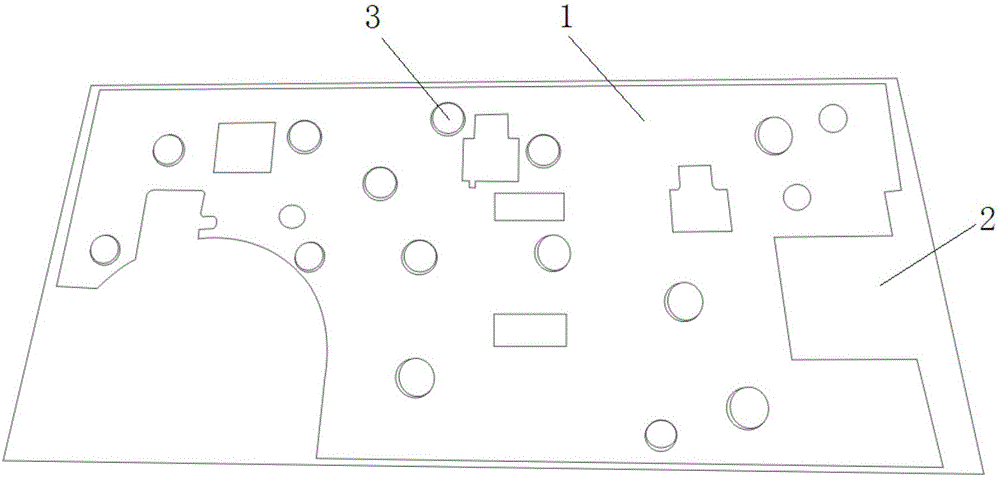

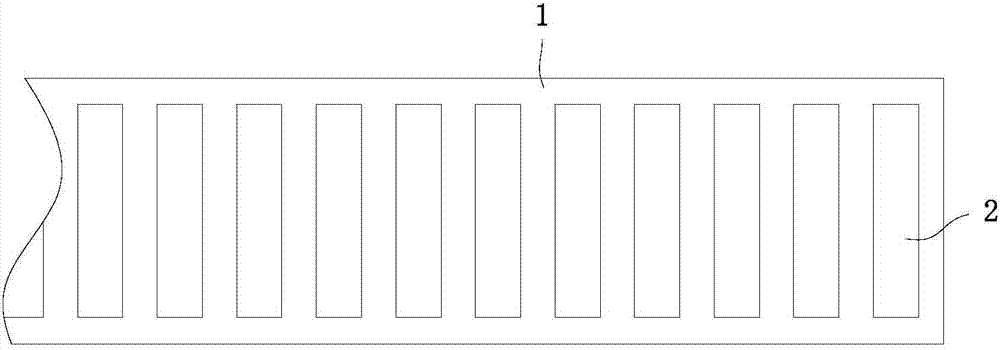

A kind of insulating sheet made by drawing die

The invention discloses an insulating strip manufactured through a drawing die. The insulating strip manufactured through the drawing die comprises an insulating strip body and release paper. The insulating strip manufactured through the drawing die is characterized in that a glue layer is arranged on the back face of the insulating strip body, and the release paper is attached to the back face of the insulating strip body through the glue layer. Arc round points corresponding to welding point protrusions of a circuit board in position are formed in the front face of the insulating strip body, the edges of the arc round points are connected with the insulating strip body, and the height of the arc round points is larger that that of the plane of the insulating strip body. According to the insulating strip manufactured through the drawing die, the drawing die is adopted to draw a convex-concave structure which are at the round point positions and are matched with the welding point protrusions on the circuit board at a time, one-time forming and one-time attaching are adopted, the machining efficiency and the machining speed are greatly improved, and attaching accuracy is ensured.

Owner:武汉光大同创新材料有限公司

Automatic long cotton sticking machine

PendingCN112722380AAutomate attachmentImprove attachment efficiencyWrapping material feeding apparatusWrappingEngineeringStructural engineering

The invention relates to an automatic long sponge sticking machine which comprises a rack main body, a powder box fixing frame, a long sponge conveying mechanism, a clamping mechanism, a horizontal driving mechanism, a vertical driving mechanism and a control device, wherein the powder box fixing frame is arranged in the middle of the rack main body and is used for fixing a powder box to be treated; the long sponge conveying mechanism is arranged in the middle of the rack main body, is spaced from the powder box fixing frame and is used for conveying long sponge; the clamping mechanism is arranged above the powder box fixing frame and used for clamping the long sponge; the horizontal driving mechanism is connected to the upper end of the clamping mechanism and used for driving the clamping mechanism to move horizontally; the vertical driving mechanism is connected to the upper end of the clamping mechanism and used for driving the clamping mechanism to move vertically; and the control device is connected with the long sponge conveying mechanism, the horizontal driving mechanism and the vertical driving mechanism. According to the automatic long sponge sticking machine, sticking automation of the long sponge is achieved, manual sticking is replaced, the sticking efficiency of the long sponge is improved, and meanwhile, the sticking precision is improved.

Owner:珠海市颂洋科技有限公司

Wire rod labeling device

PendingCN114426129AAvoid hurting handsSimple structureLabelling machinesLabelling elongated objectsWire rodStructural engineering

The invention provides a wire rod labeling device which comprises a wire rod discharging module and a label folding and attaching module, the wire rod discharging module comprises a support used for supporting a to-be-labeled wire rod, and the label folding and attaching module is used for adsorbing a label and folding the label to wrap the to-be-labeled wire rod supported on the support. A label adsorbed by the label folding and attaching module can be divided into a first part and a second part by a to-be-labeled wire rod, the label folding and attaching module comprises two overturning pieces, and during labeling, the two overturning pieces drive the first part and the second part to rotate from a first position located below the to-be-labeled wire rod to a second position located above the to-be-labeled wire rod, so that the to-be-labeled wire rod is attached to the label. And the first part and the second part are oppositely combined to wrap the to-be-labeled wire rod. The device is simple in structure, high in attaching precision and good in stability; and moreover, the two overturning pieces move from bottom to top, so that hands can be prevented from being injured under the condition that a worker places the wire rod to attach, and potential safety hazards are avoided.

Owner:LCFC HEFEI ELECTRONICS TECH

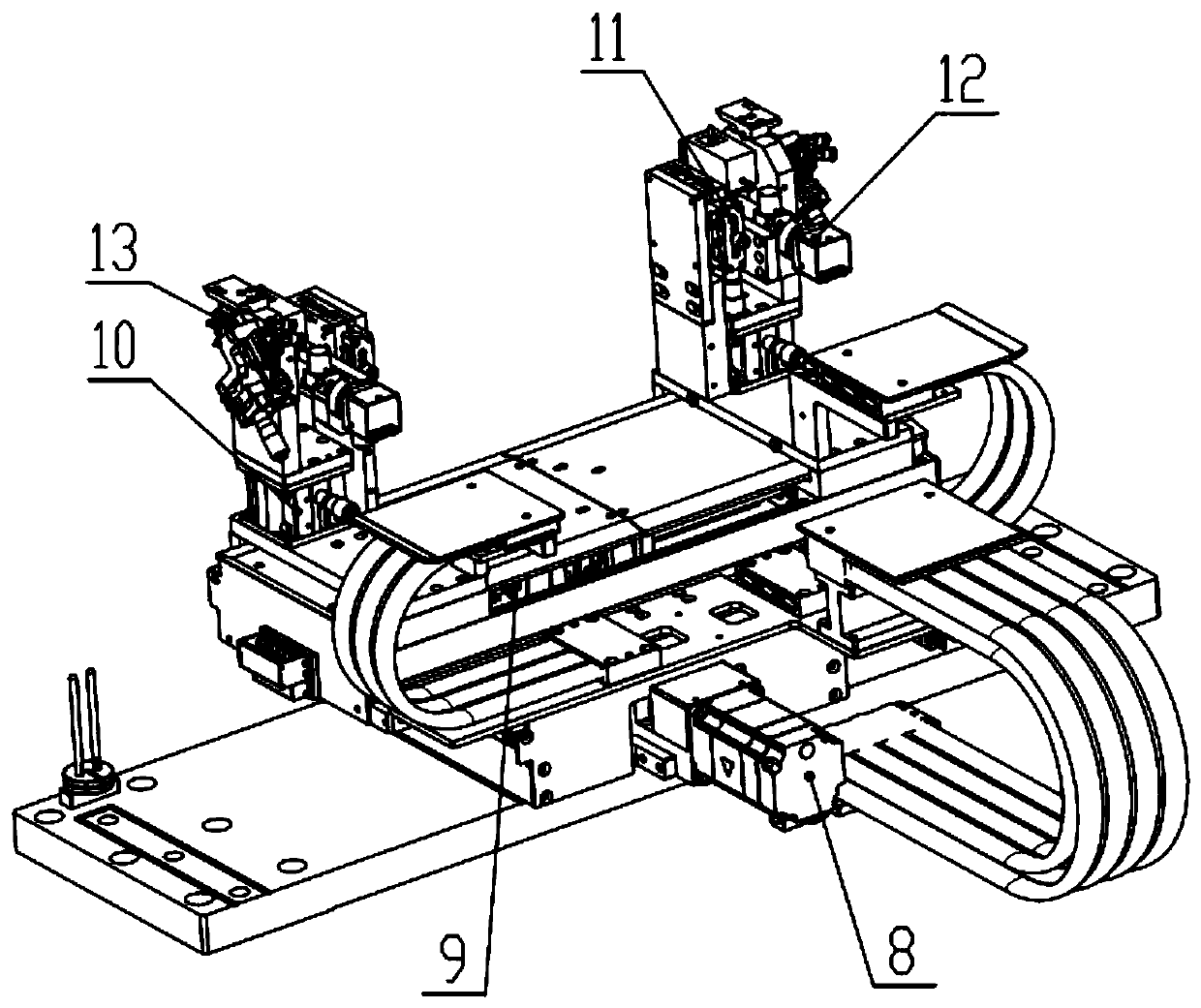

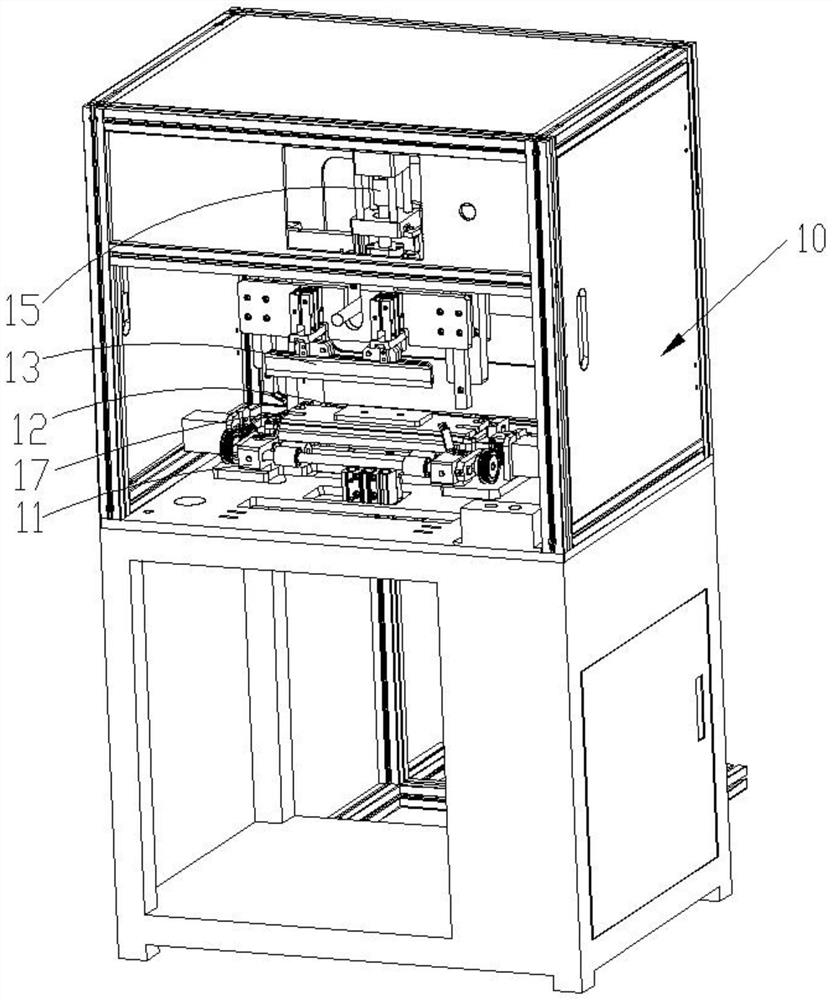

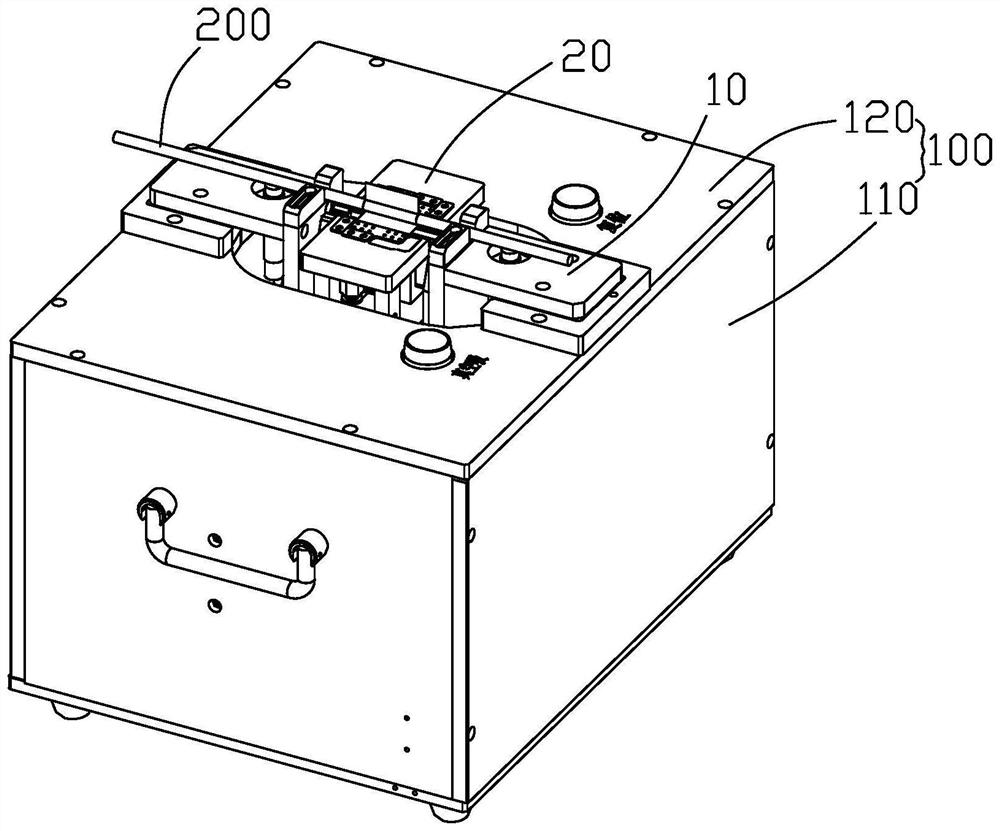

Automatic attachment device

ActiveCN105584185BRealize automatic attachmentAccurate and firm attachmentLamination ancillary operationsControlling laminationEngineeringCcd camera

The invention discloses an automatic attaching device which comprises a frame, wherein a worktable is arranged on the frame, a lower mold assembly for holding a backlight module is arranged on the worktable, and an upper mold assembly and an overturning mechanism for driving the upper mold assembly to overturn is arranged above the worktable; a detection mechanism for detecting the position of the lower mold assembly and an adjusting mechanism for adjusting the position of the lower mold assembly are also arranged on the frame; the detection mechanism comprises a CCD camera assembly for detecting and calculating the distance from the mark point of the backlight module to the center point of a soft plate; the backlight module to be attached with the soft plate is arranged in the lower mold assembly, the overturning mechanism is used for overturning the upper mold assembly and overturning the upper mold assembly for resetting after the soft plate is arranged on the upper mold assembly, and the upper mold assembly is used for attaching the soft plate to the backlight module; and after the detection mechanism detects the position of the lower mold assembly, the adjusting mechanism adjusts the position of the lower mold assembly, so that the product precision is improved while automatic attaching of the soft plate is realized.

Owner:SUZHOU WUJIANG YINGFEIDA AUTOMATIC EQUIP CO LTD

Attaching device and attaching method

ActiveCN109677090BHigh attachment accuracyExcellent adhesionLaminationLamination apparatusThin membraneEngineering

The invention discloses an attaching device which is applied to attaching of a thin film product to the surface of a substrate, and comprises a bearing platform, a steel strip component, an attachingrubber roll and a separating rubber roll, wherein the bearing platform is provided with a bearing surface for bearing the substrate; the steel strip component is movably arranged above the bearing platform and can be fixed on an attaching station and a material taking station; the steel strip component comprises a steel strip for attaching the thin film product; the attaching rubber roll is movably arranged above the steel strip at the attaching station; the separating rubber roll is arranged below the steel strip at the attaching station and can move along the direction vertical to the bearing surface. The invention also provides an attaching method. The attaching device disclosed by the invention adopts the design of the separately-driven attaching rubber roll and the separating rubber roll, so that the attaching rubber roll and the separating rubber roll are mutually matched to move, so that the thin film product is attached to the substrate, and a separating angle between the attaching rubber roll and the separating rubber roll is kept unchanged in the attaching process.

Owner:深圳市九天中创自动化设备有限公司

Insulating strip manufactured through drawing die

The invention discloses an insulating strip manufactured through a drawing die. The insulating strip manufactured through the drawing die comprises an insulating strip body and release paper. The insulating strip manufactured through the drawing die is characterized in that a glue layer is arranged on the back face of the insulating strip body, and the release paper is attached to the back face of the insulating strip body through the glue layer. Arc round points corresponding to welding point protrusions of a circuit board in position are formed in the front face of the insulating strip body, the edges of the arc round points are connected with the insulating strip body, and the height of the arc round points is larger that that of the plane of the insulating strip body. According to the insulating strip manufactured through the drawing die, the drawing die is adopted to draw a convex-concave structure which are at the round point positions and are matched with the welding point protrusions on the circuit board at a time, one-time forming and one-time attaching are adopted, the machining efficiency and the machining speed are greatly improved, and attaching accuracy is ensured.

Owner:武汉光大同创新材料有限公司

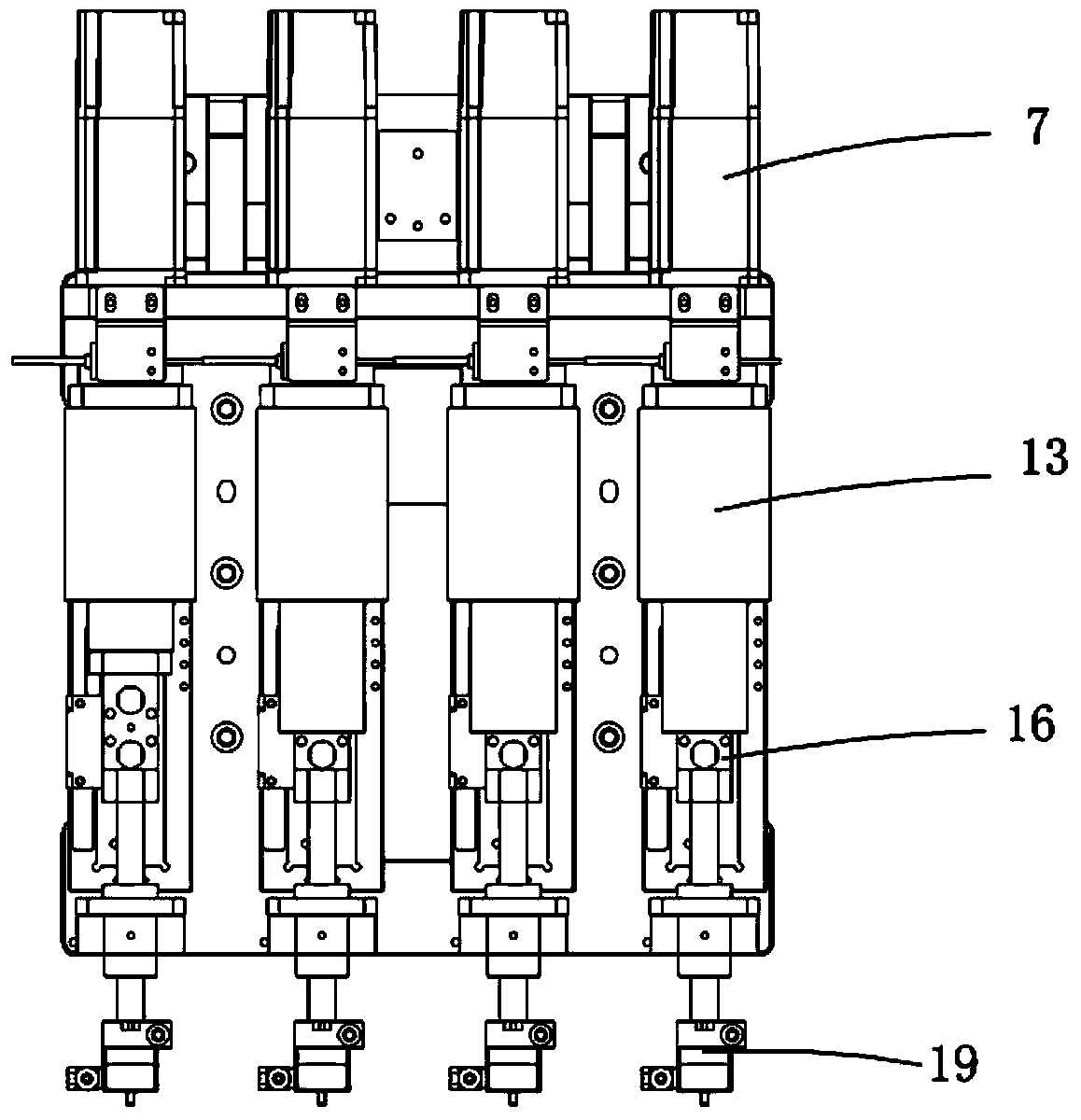

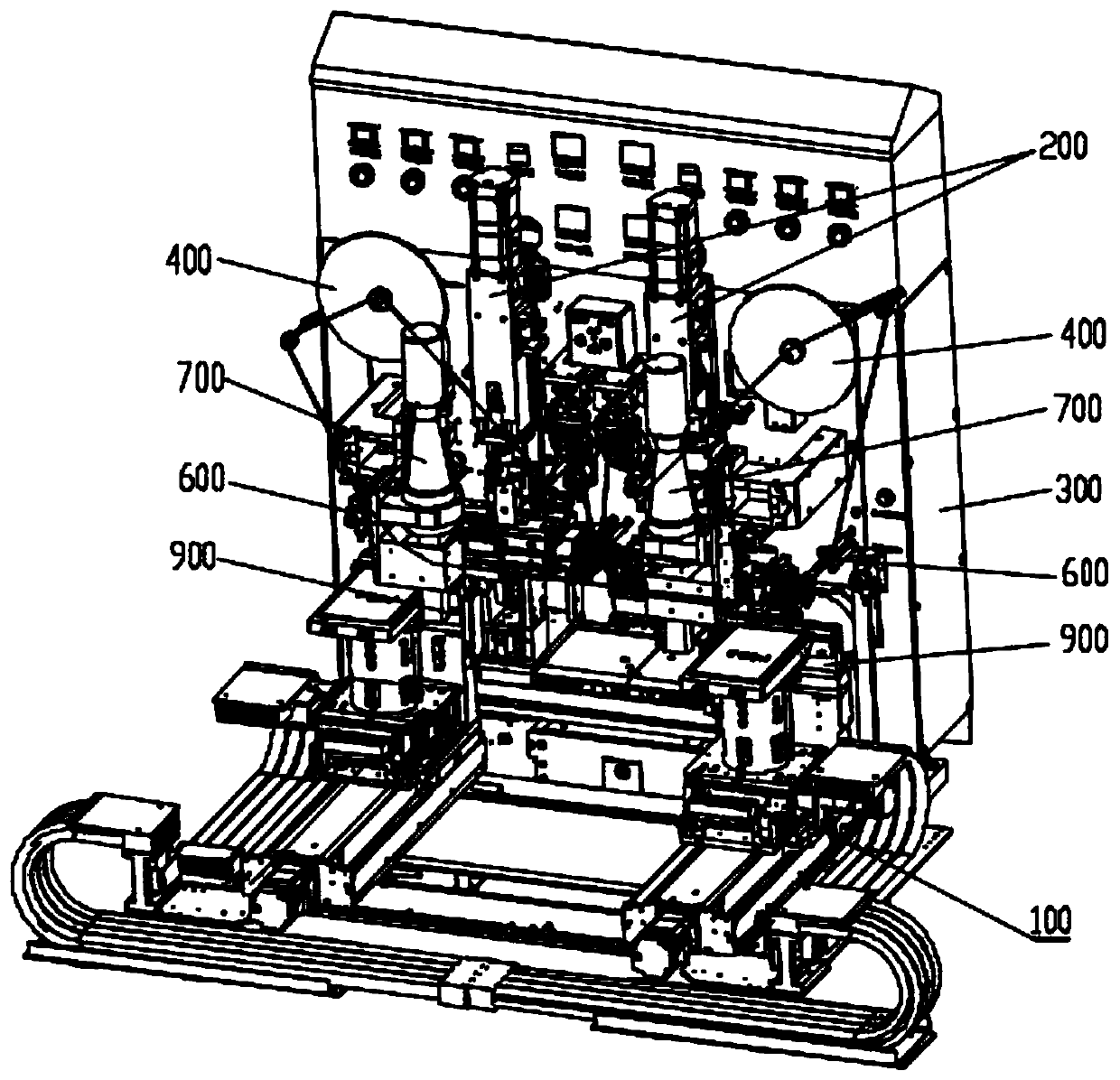

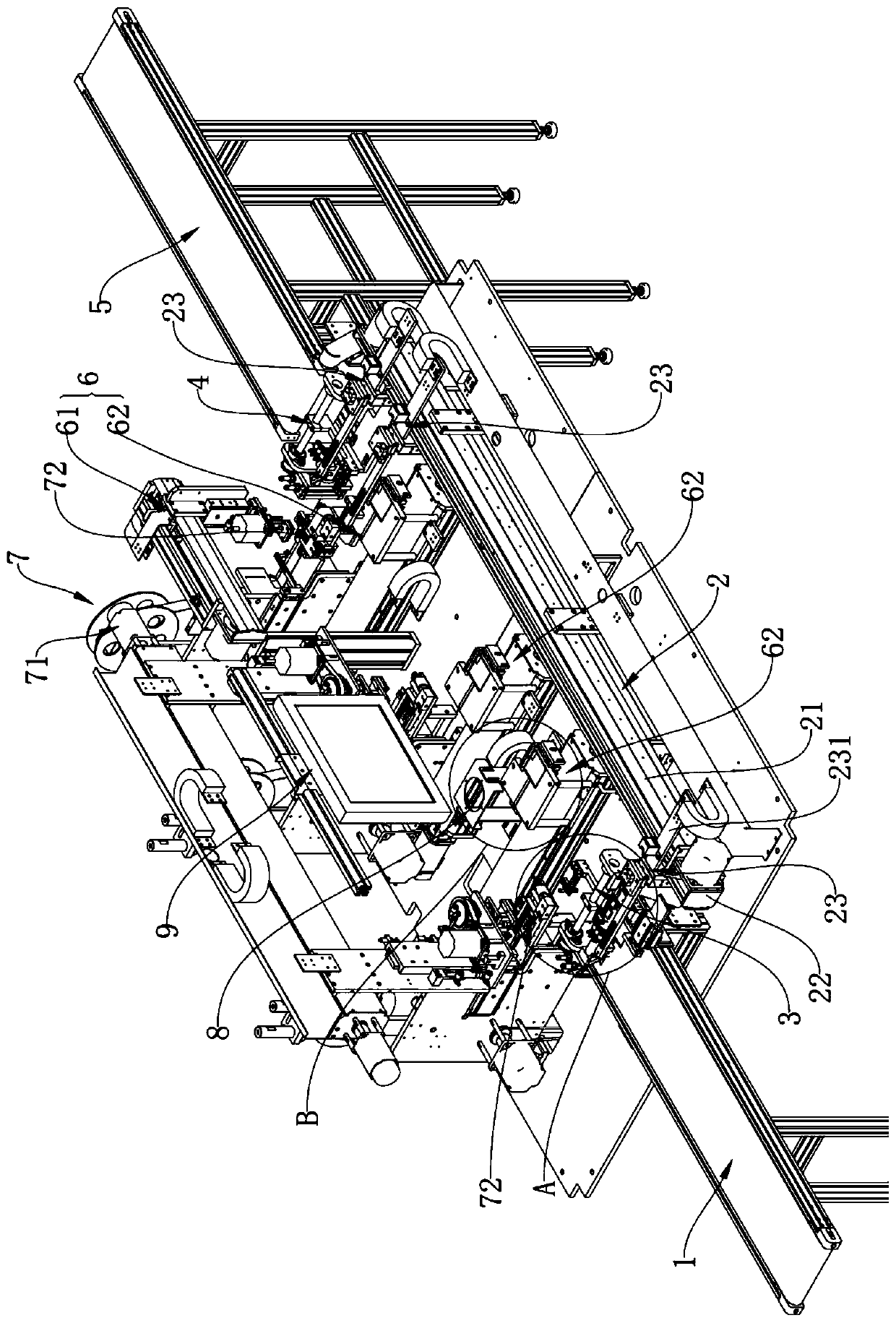

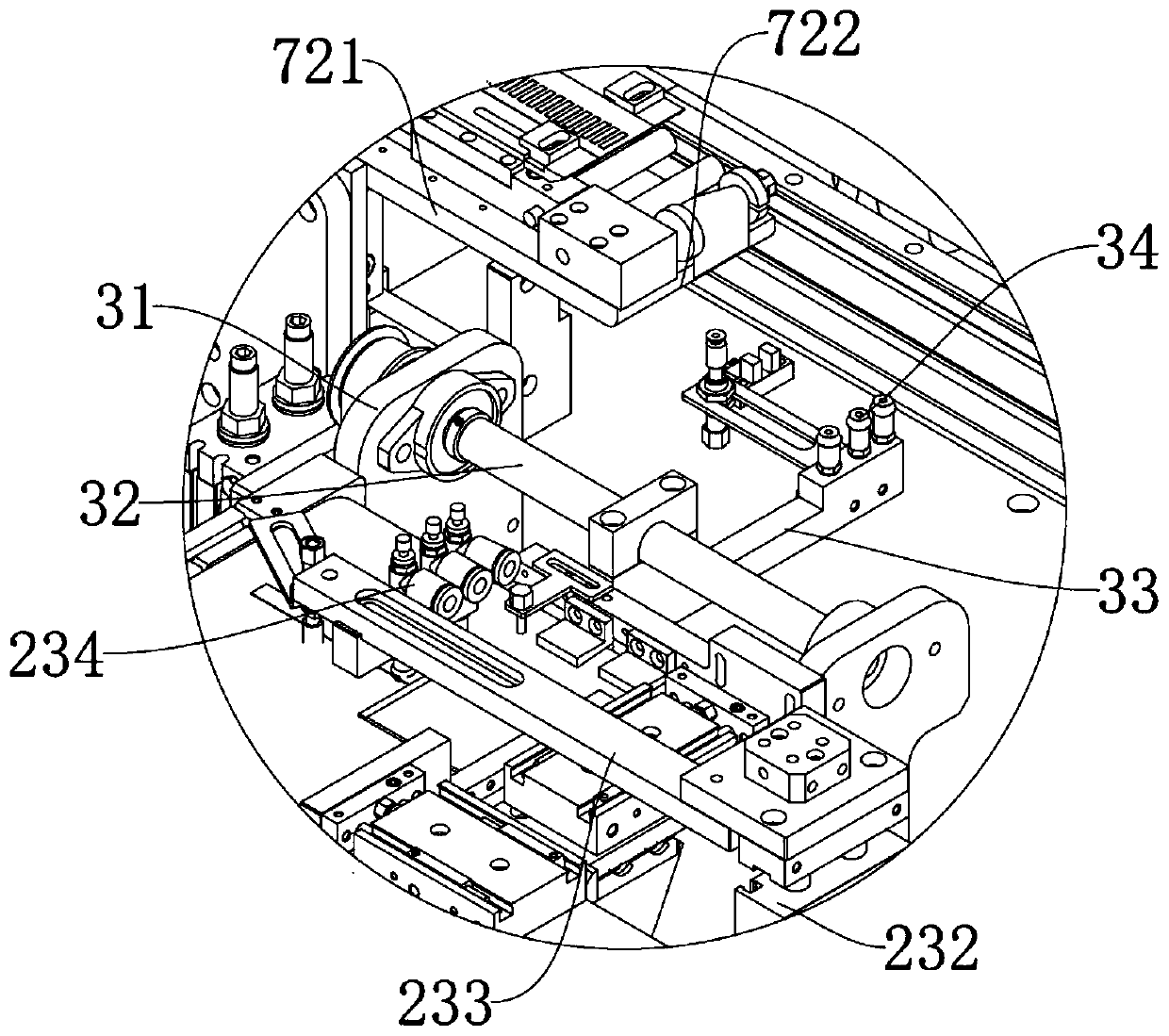

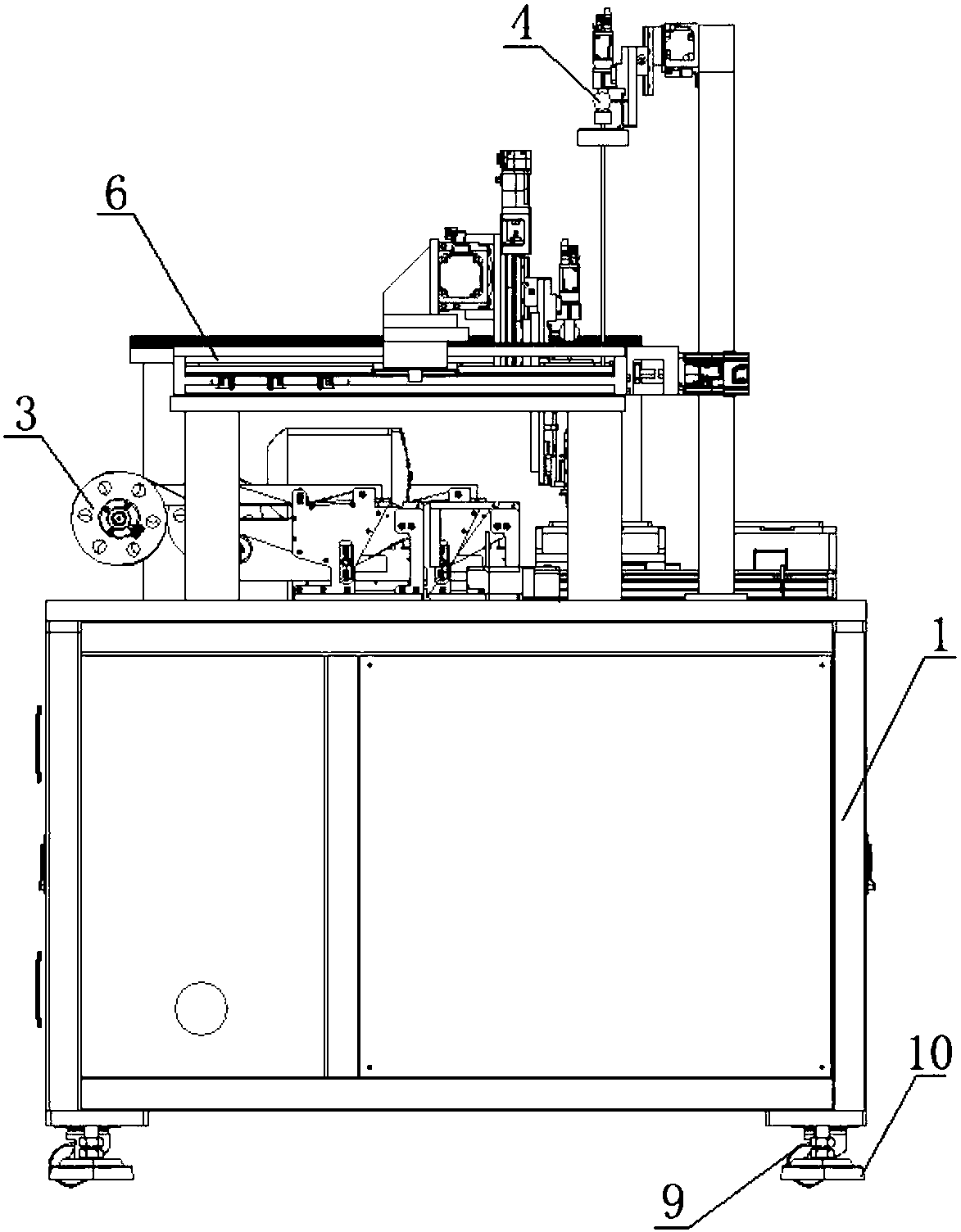

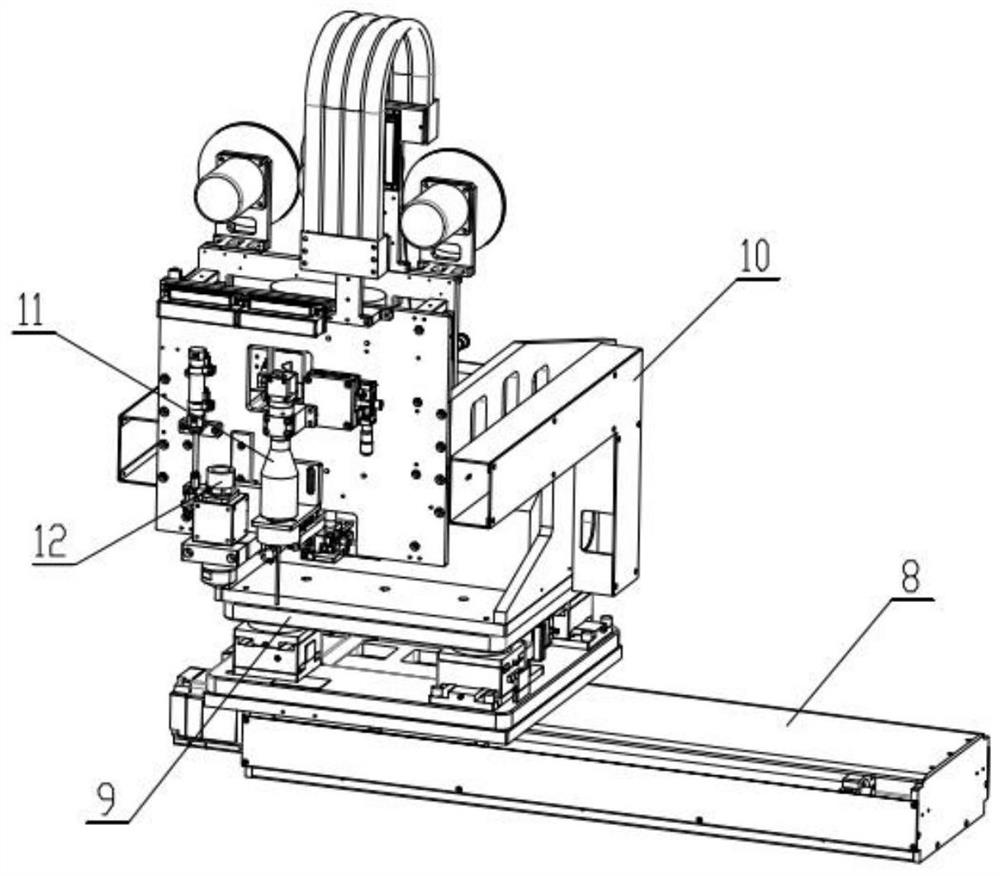

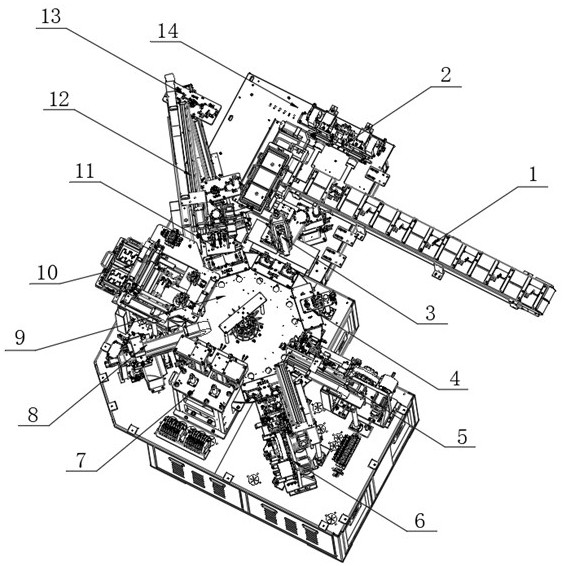

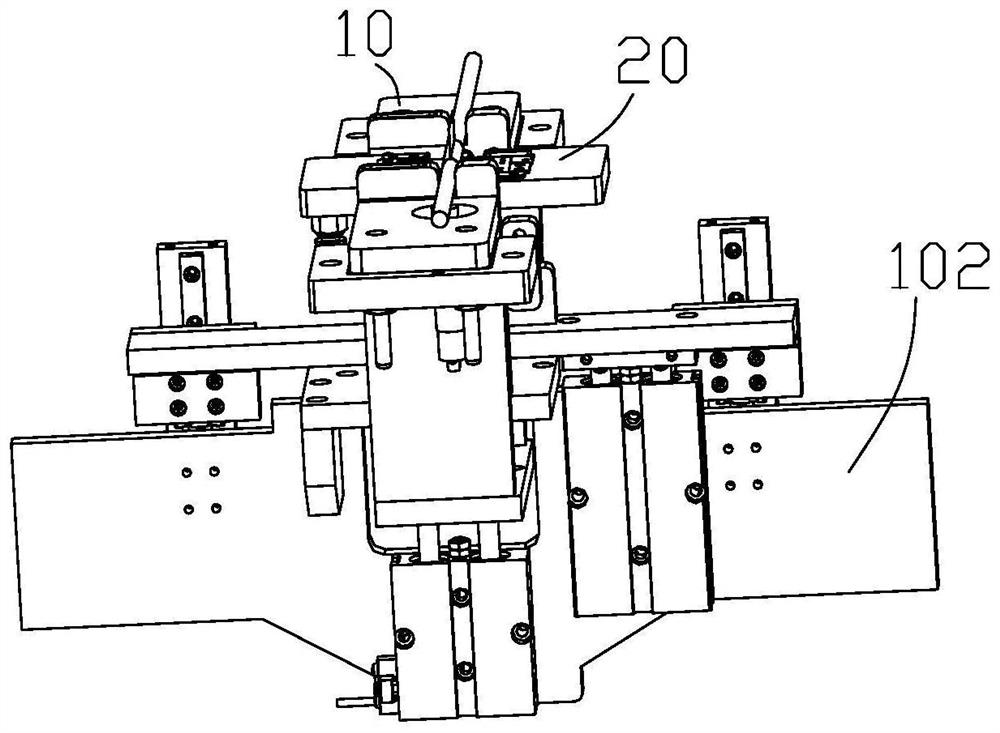

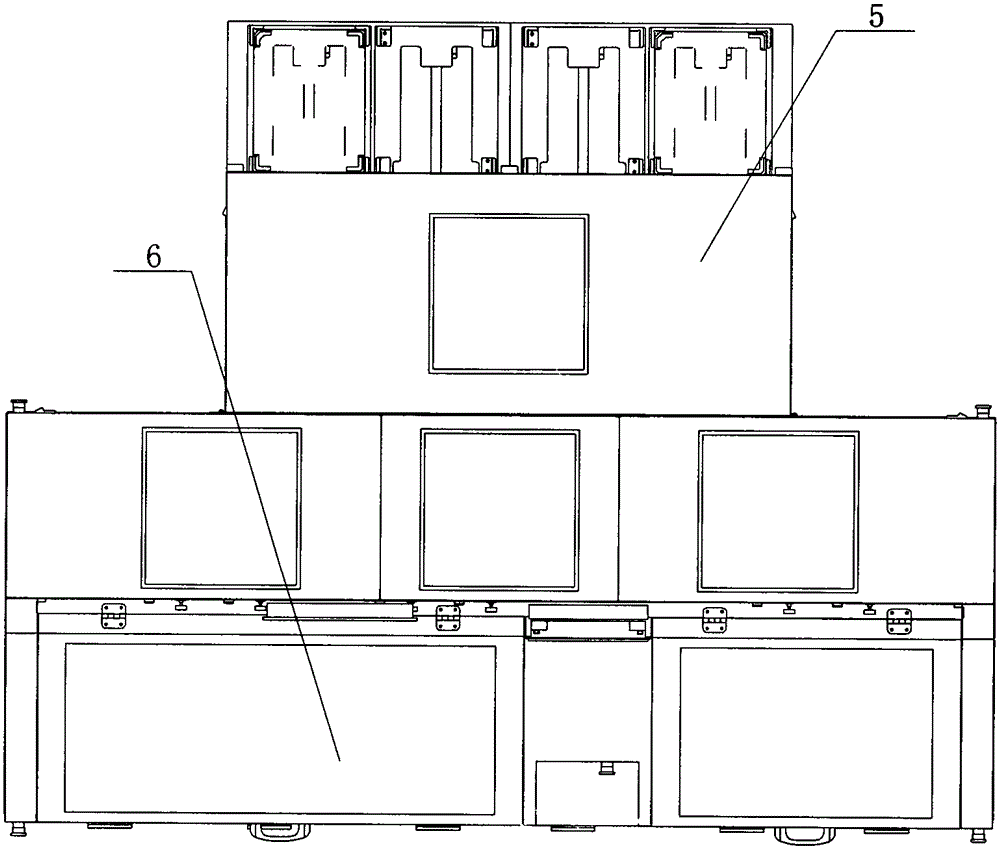

Automatic bonding machine for connecting flexible printed circuit boards to glass lines

ActiveCN103379746BHigh attachment accuracyIncrease productionPrinted circuit assemblingFlexible circuitsEngineering

The invention discloses an automatic wire bonder with a flexible circuit board in line connection with glass and relates to the technical field of automatic wire bonders. According to the automatic wire bonder with the flexible circuit board in line connection with the glass, an ACF component (2) is arranged on the left side of an automatic wire bonder body (1), a pre-pressing component (3) is arranged on the right side of the ACF component (2), a main pressing component (4) is arranged on the right side of the pre-pressing component (3), an FPC feeding machine (5) is arranged in the middle of the top of the automatic wire bonder body (1), an internal mechanical arm (6) is arranged at the front end of the top of the automatic wire bonder body (1), and a lower machine frame (7) is arranged on the lower portion of the automatic wire bonder body (1). According to the automatic wire bonder with the flexible circuit board in line connection with the glass, the yield is high, ACF attaching accuracy is high, and main pressing accuracy is high and practicality is strong due to the arrangement of a corresponding detecting device.

Owner:SHENZHEN LIANDE AUTOMATION EQUIP

A device for attaching double-sided adhesive tape to boards

ActiveCN106005643BRealize automatic attachmentIncrease productivityLabelling machinesMechanical engineering

The invention discloses a device for attaching double-faced adhesive tape pieces to a plate. The device comprises a double-faced adhesive tape piece supplying device, a double-faced adhesive tape piece sucking device, a double-faced adhesive tape piece positioning device and a positioning and attaching device. The positioning and attaching device comprises a conveying belt, a plate supplying mechanism and an adhesive tape piece attaching mechanism, wherein the plate supplying mechanism is arranged at the upstream end of the conveying belt, and the adhesive tape piece attaching mechanism is arranged at the downstream end of the conveying belt. Double-faced adhesive tape in the coiled state is unfolded through the double-faced adhesive tape piece supplying device. All double-faced adhesive tape pieces on the double-faced adhesive tape are sucked one time and transferred to the double-faced adhesive tape piece positioning device through the double-faced adhesive tape piece sucking device. The multiple double-faced adhesive tape pieces are positioned at predetermined intervals through the double-faced adhesive tape piece positioning device. Then the multiple positioned double-faced adhesive tape pieces are attached to the plate through the positioning and attaching device. In this way, automated attaching of the double-faced adhesive tape pieces is achieved; the traditional mod of manual attaching operation is abandoned; and production efficiency and attaching precision are effectively improved.

Owner:GUANGDONG JINHONGDA AUTOMATION TECH CO LTD

Patch device and automatic patch method

The invention discloses a chip mounting device and an automatic chip mounting method, and the chip mounting device comprises a feeding mechanism which comprises a material taking shaft and a material receiving shaft, and the axial directions of the material taking shaft, the material receiving shaft and a reel are consistent; the discharging mechanism comprises a discharging plate and an anti-sticking plate, the surface of the discharging plate is provided with a first sliding face and a second sliding face of the material belt, the included angle between the first sliding face and the second sliding face is an acute angle, and a material belt corner is formed through arc transition; the working surface of the anti-sticking plate is lapped at the corner, and the first gap is larger than the thickness of the material belt and smaller than the length of the patch in the conveying direction; and the material taking mechanism comprises an adsorption column for stripping the patch from the working surface, and a moving assembly for moving the adsorption column to the surface of the to-be-pasted piece for pasting. Through the specific structure of the feeding mechanism, the discharging mechanism and the material taking mechanism, the purpose that the device can conveniently strip the patch from the material belt is achieved.

Owner:SHANGHAI VEI SHENG AUTO PARTS MFG CO LTD

Cleaning tool for reflow welding furnace

PendingCN107790410AHigh attachment accuracyReduce assembly tolerancesCleaning using toolsEngineeringFront and back ends

The invention discloses a cleaning tool for a reflow welding furnace. The cleaning tool for the reflow welding furnace comprises a scraper knife bracket, a first scraper knife, a second scraper knifeand a slide base; the first scraper knife and the second scraper knife are respectively mounted at the front and back ends of the scraper knife bracket; the first scraper knife comprises a first knifebody part, a connecting part and a first knife bit part; an included angle is preset between two planes corresponding to the connecting part and the first knife bit part; one end of the connecting part is connected with the first knife bit part, and the other end is connected with the first knife body part; the second scraper knife comprises a second knife body part and a second knife bit part; and the second knife body part and the second knife bit part are connected through screws and screw holes. Through the mode, the cleaning tool for the reflow welding furnace can easily, quickly and thoroughly remove residues on the inner cavity of a machine cavity and in narrow gaps, reduces the maintenance time, reduces the product pollution probability, reduces the defective percent and the scraprisk, is longer in use time, and can be disassembled to clean for recycling.

Owner:FLEXTRONICS ELECTRONICS TECH SUZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com