Film pasting jig

A jig and film technology, which is applied to household appliances, other household appliances, laminating devices, etc., can solve the problems of low operation speed and precision of manual filming, high cost of filming, affecting production capacity, etc., and improve the operation speed. And the effect of attaching precision, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0046] Aiming at the technical problems in the prior art that the production capacity will be occupied when using automatic equipment to stick the film in the process of sticking the protective film on the panel, and the operating speed and the sticking accuracy cannot be guaranteed when the film is sticked manually, the present invention provides a film sticking fixture, which can solve the problem of In the prior art, the cost of using fully automatic equipment for film application is high, which affects production capacity, and the technical problems of manual film application are low speed and attachment accuracy.

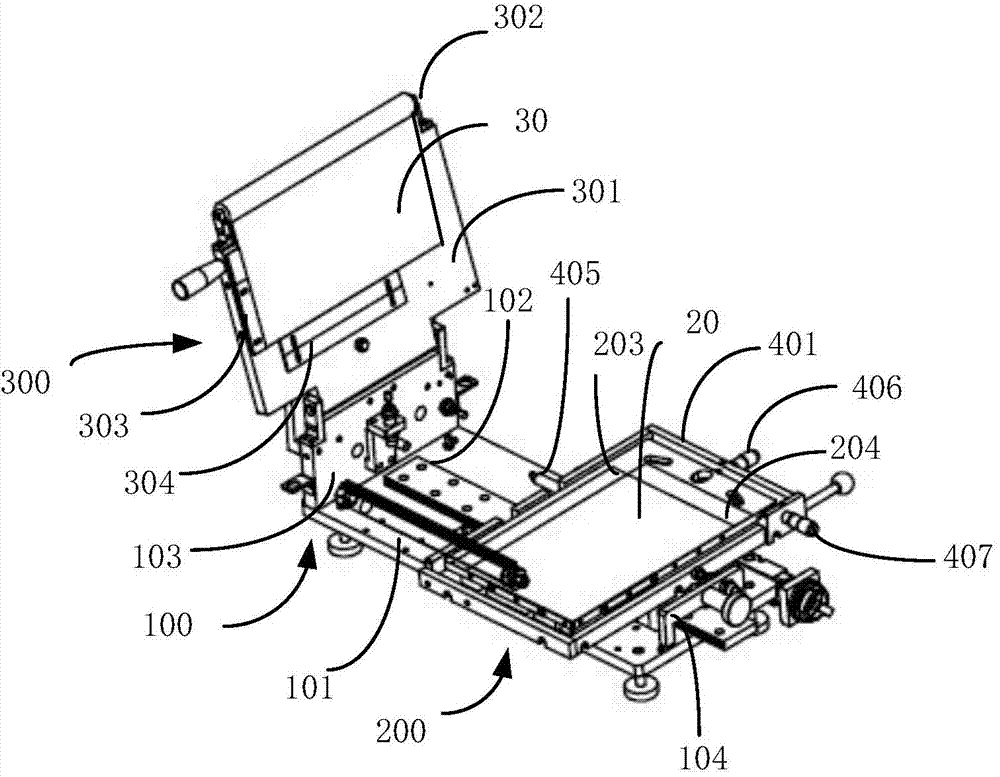

[0047] figure 1 Shown is a schematic structural view of a film sticking fixture provided by the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com