System for attaching film

A technology of film sticking and film sticking, which is applied in the direction of lamination auxiliary operations, instruments, chemical instruments and methods, etc., and can solve problems such as difficult management of polarizing films, backflush errors, errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

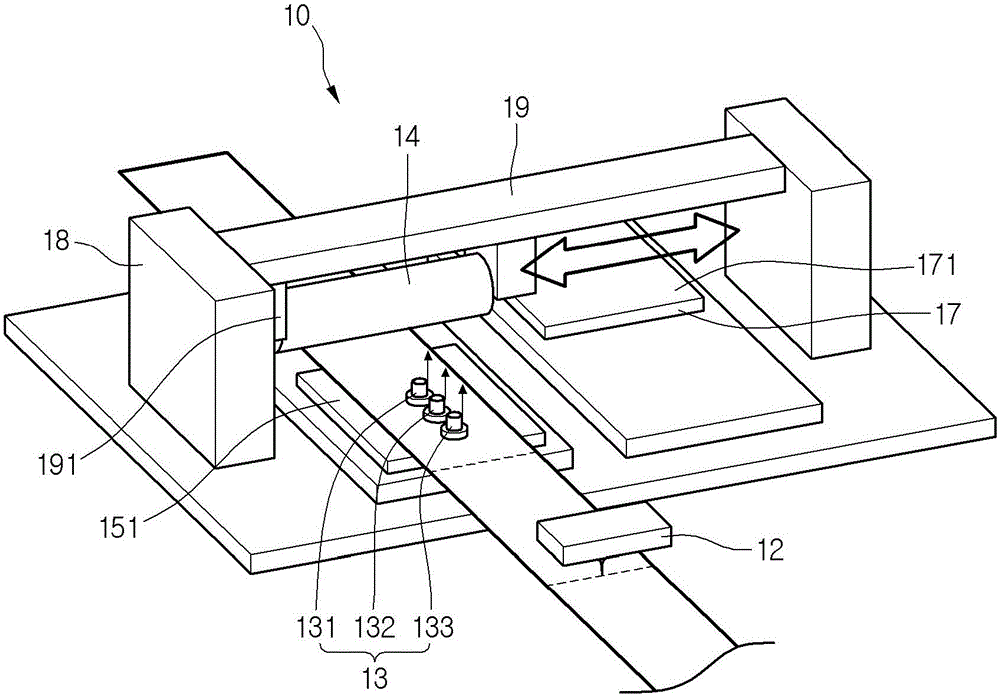

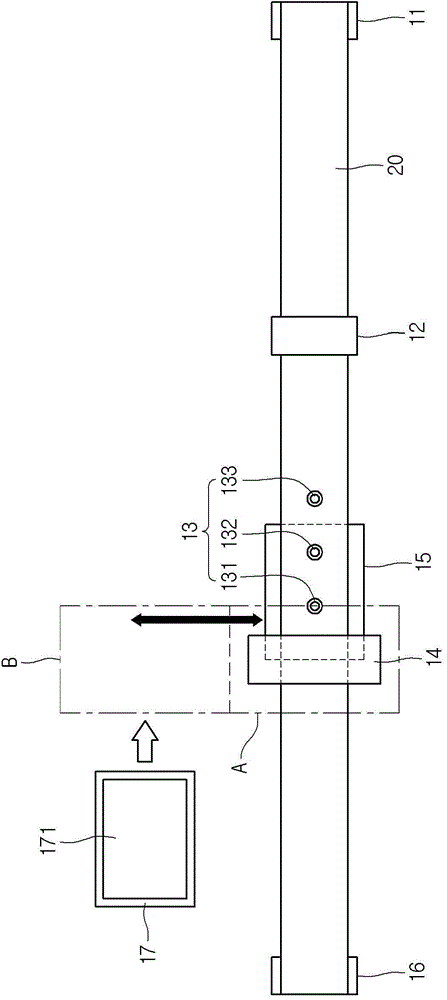

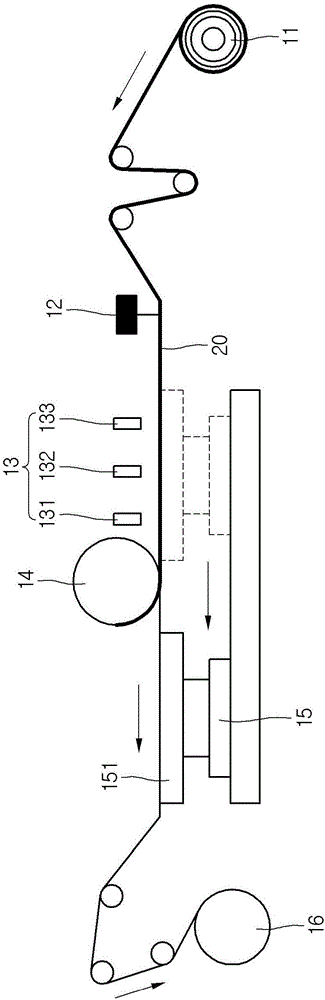

[0031] figure 1 is a perspective view of a system for sticking films according to one embodiment of the present invention, figure 2 is a top view of the system for film application, image 3 is a side view of the system for film application.

[0032] refer to Figure 1 to Figure 3 , the system 10 for sticking film according to the embodiment of the present invention comprises: supply roller 11, and this supply roller 11 is wound with polarizing film 20, and this polarizing film 20 is provided with polarizer or pattern retarder; Part cutter 12, part cutter 12 Cut the polarizing film 20 unwound from the supply roller 11 in a direction perpendicular to the traveling direction of the film based on the size of the panel, and completely cut off the part except the release film placed on the bottom plate; camera module 13, the camera module 13 recog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com