A device for attaching double-sided adhesive tape to boards

A technology of double-sided tape and double-sided tape, applied in packaging, labeling machines, transportation and packaging, etc., can solve the problems of time-consuming and labor-intensive, visual fatigue of operators, large attachment deviation, etc., to improve production efficiency and improve production efficiency. The effect of attaching accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

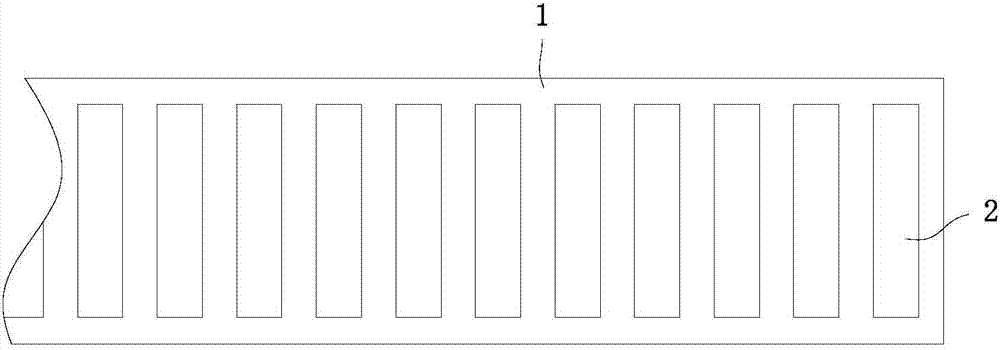

[0021] A kind of panel double-sided adhesive tape sticking device designed by the present invention is to figure 1 The double-sided adhesive tape 2 shown on the double-sided adhesive tape 1 is accurately attached to the board, wherein each double-sided adhesive tape 2 in the double-sided adhesive tape 1 is arranged in a small gap. The traditional manual attachment operation method is to peel off each double-sided adhesive tape 2 one by one and attach it to the board, which is time-consuming and labor-intensive, and the attachment accuracy is low.

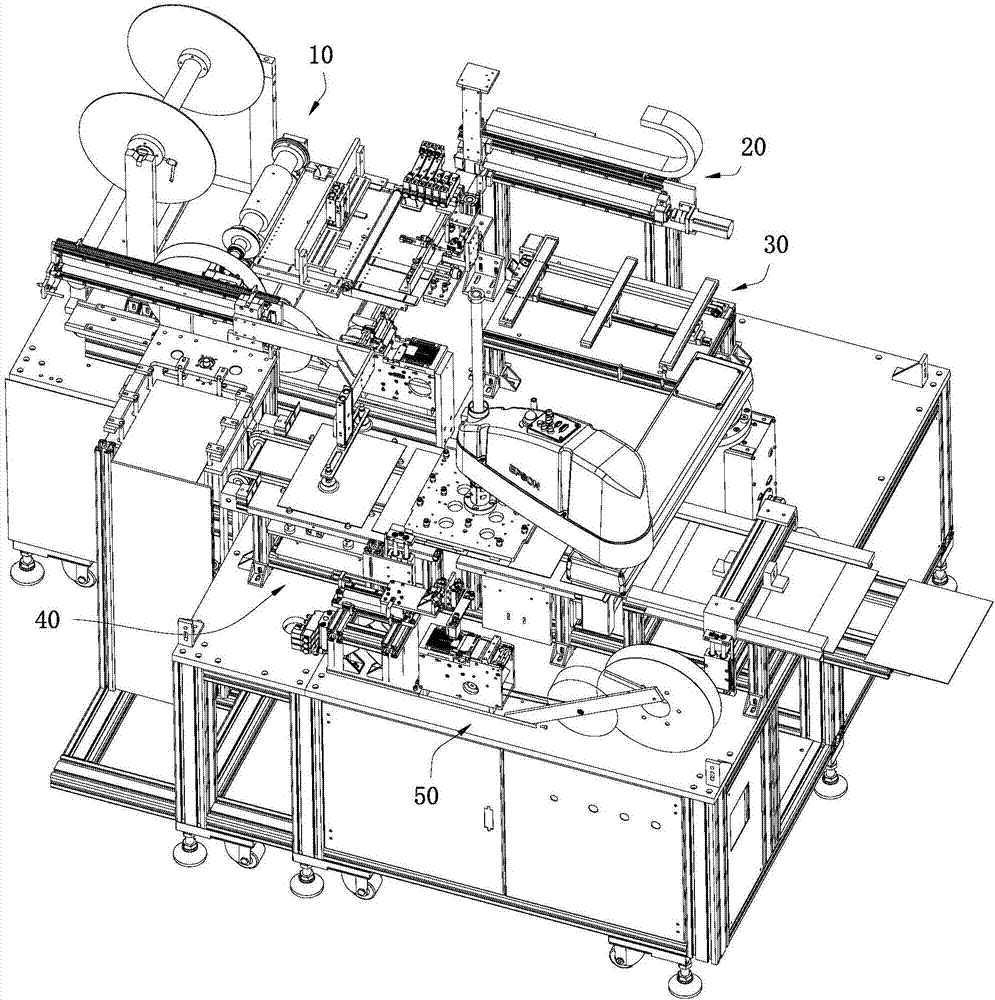

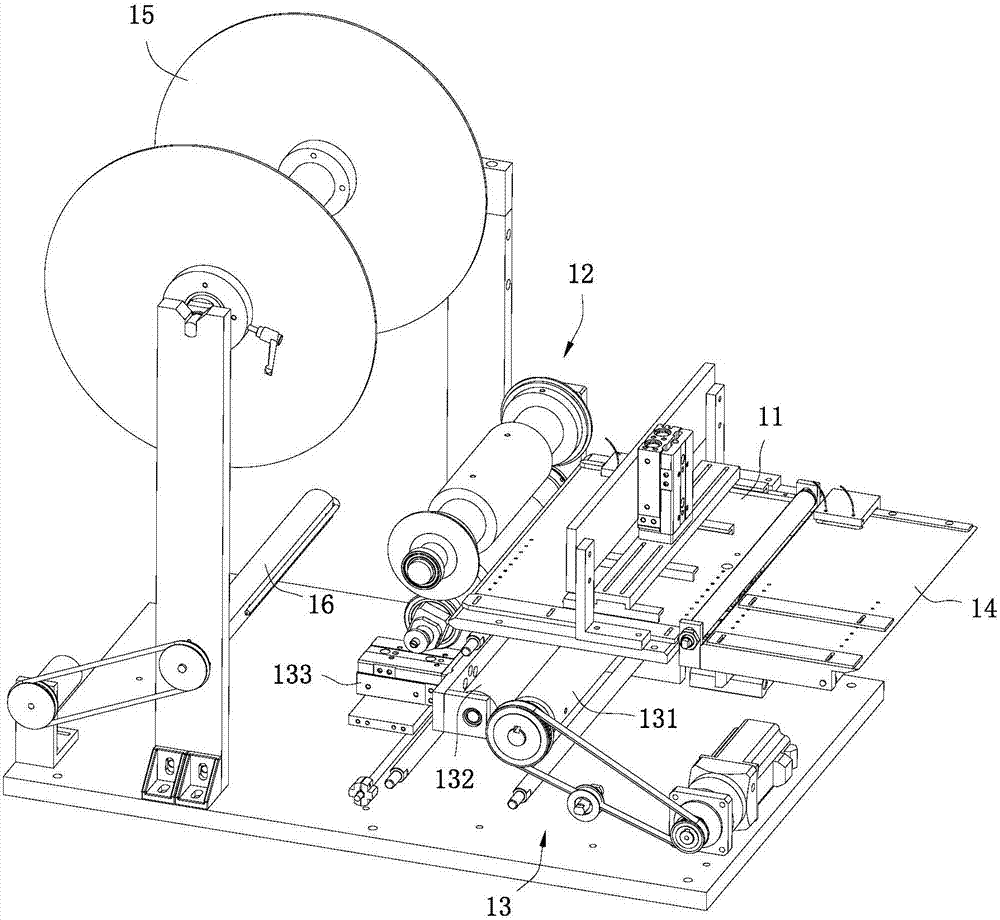

[0022] see Figure 2 to Figure 8 , a device for attaching double-sided adhesive tape to a panel of the present invention includes a double-sided adhesive tape supply device 10 for continuously expanding the double-sided adhesive tape wound on a reel; a double-sided adhesive tape suction device 20 for Absorb and transfer the double-sided adhesive tapes on the unfolded double-sided adhesive tape at one time; the double-sided adhesive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com