Full-automatic low-viscosity double-sided tape attaching and hot-pressing equipment

A technology of double-sided adhesive tape and hot pressing equipment, which is applied in thin material processing, secondary battery manufacturing, and delivery of objects, etc. It can solve the problems of low adhesive tape attachment accuracy, wrinkled attachment effect, and low yield rate, and achieve the goal of solving personnel problems. Cost input, improved pass rate, low dependence effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the preferred embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

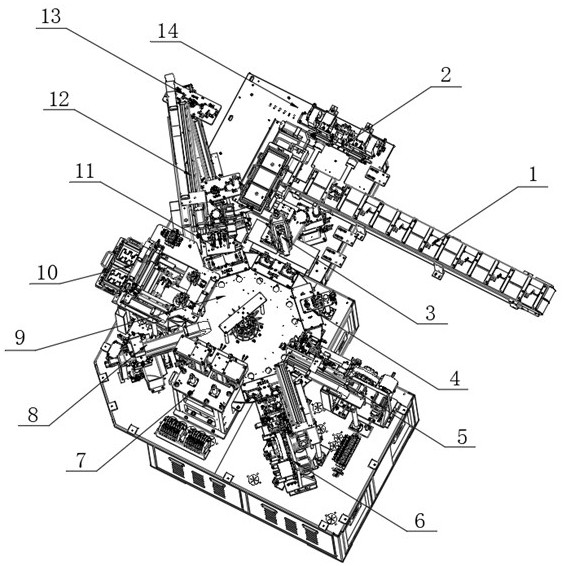

[0023] Refer to the attached figure 1 , the present invention provides a fully automatic low-viscosity double-sided tape attaching hot pressing equipment, including a support plate 14, and a hot pressing mechanism is arranged on the support plate 14;

[0024] The hot-pressing mechanism includes a feeding conveyor 1. The feeding conveyor 1 is arranged on the support plate 14 and extends out of one side of the supporting plate 14. The supporting plate 14 is provided with a feeding turning assembly 2 on one side of the feeding conveyor 1. The support plate 14 is provided with a feeding robot 3 on the other side of the feeding conveyor 1, and a turntable assembly 9 is provided on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com