Double-station ACF adhesive high-precision shearing and attaching mechanism

A double-station, high-precision technology, applied in the field of automation, can solve problems such as difficult and convenient operation, complex structure, and difficulty in ensuring verticality direction accuracy, so as to improve production efficiency, improve attachment accuracy, improve attachment accuracy and production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1, the concrete structure of the present invention is as follows:

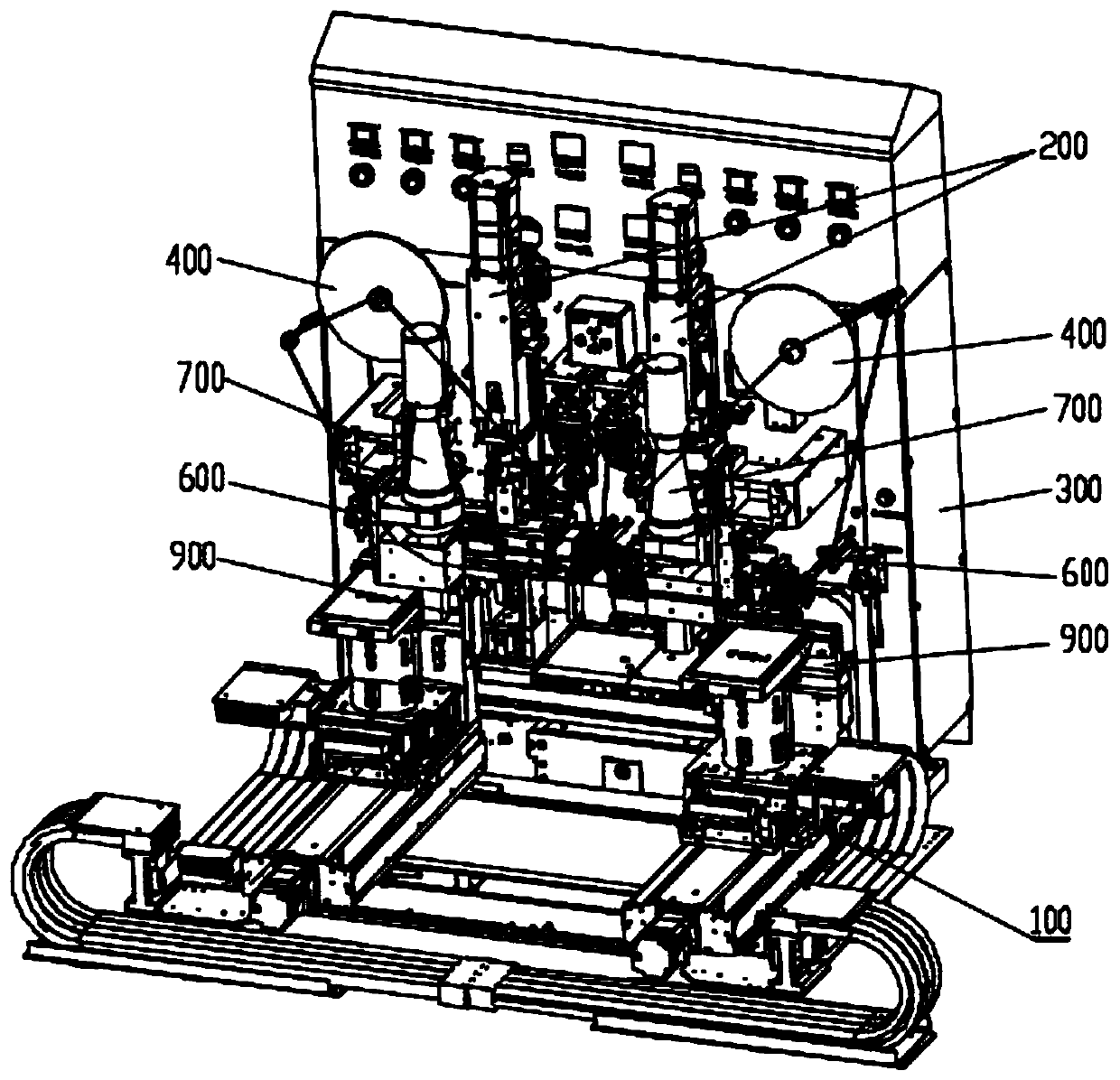

[0049] Please refer to the attached Figure 1-7 , a double-station ACF glue high-precision cutting and attaching mechanism of the present invention includes a vertical machine base 300, and also includes:

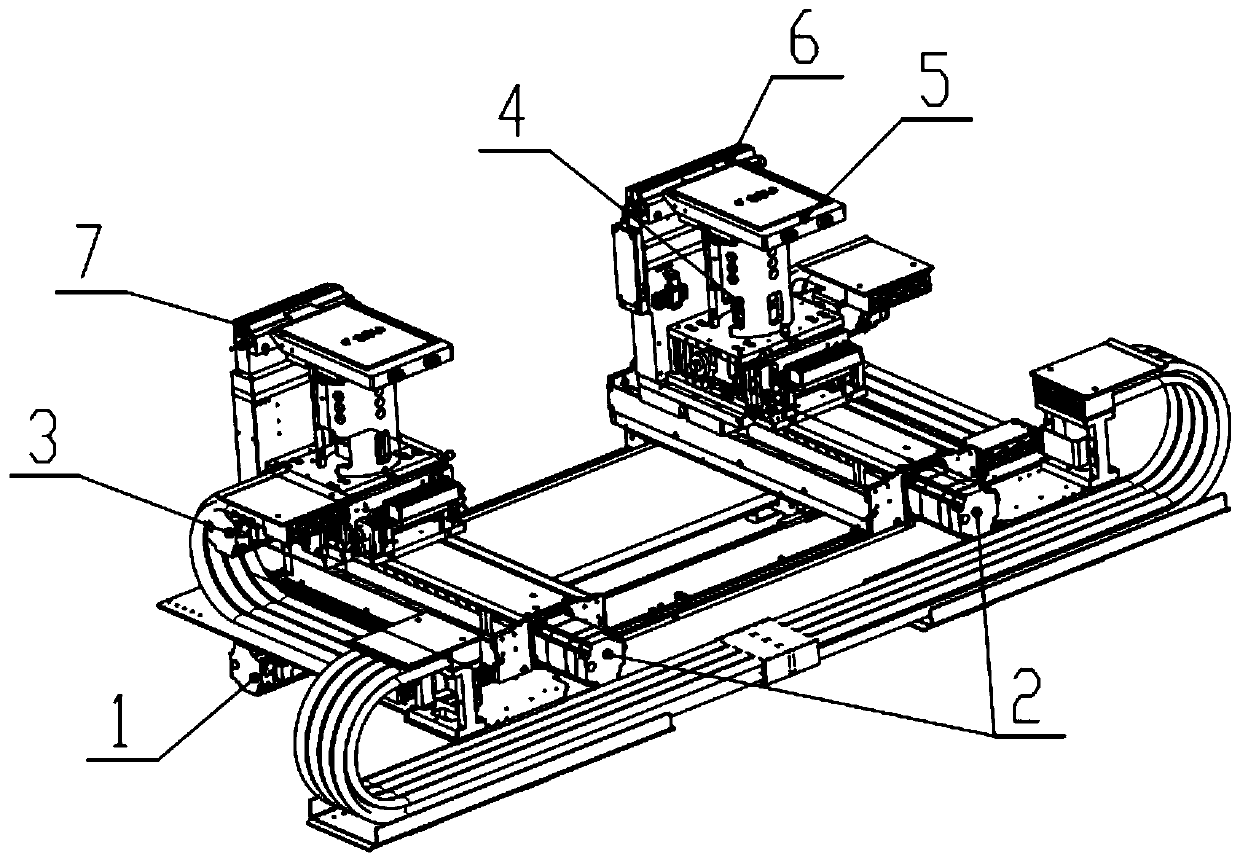

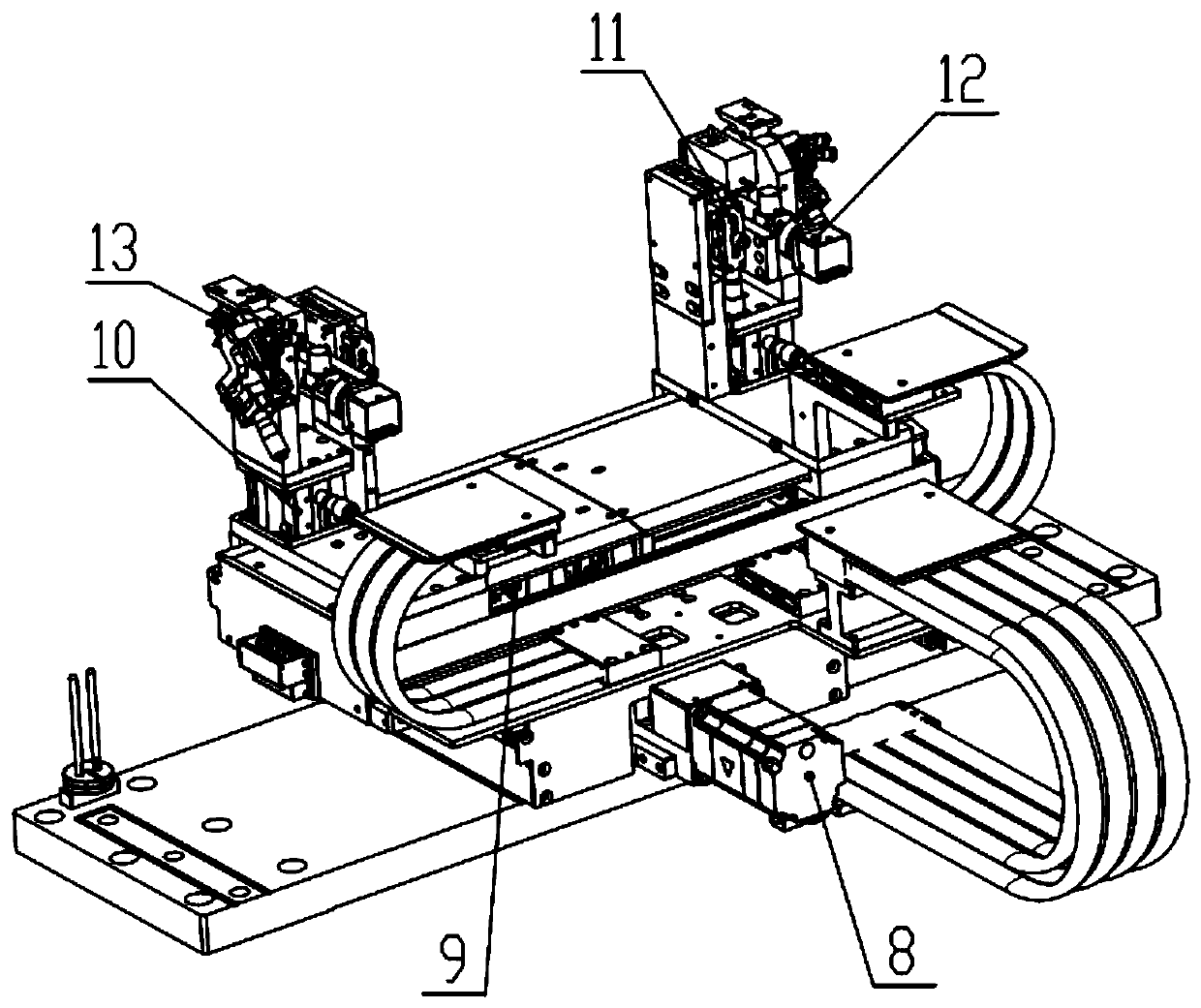

[0050] Attaching platform assembly 100, the attaching platform assembly 100 is arranged on the lower front side of the vertical machine base 300, on which an XYZ θ-axis drive mechanism and a device for absorbing products are installed on the XYZ θ-axis drive mechanism The main platform 5 and the vacuum adsorption attachment platform 6, the main platform 5 can move up and down and rotate and can run to a position at the same height as the vacuum adsorption attachment platform 6;

[0051] The cutting assembly 900 is fixed on the front side of the vertical machine base 300 and placed between the vertical machine base 300 and the attachment platform assembly 100, on which a second Y-axis driv...

Embodiment 2

[0077] like Figure 1-7 As shown, the manipulator will be attached with ACF glue and placed on the main platform 5, the XYZθ axis drive mechanism on the attached platform assembly 100 will automatically adjust the position of the main platform 5, the first CCD camera detection device 12 will take pictures of the position, and the scissors will cut Cut the ACF glue, the sticking pressure head 16 is driven down by the third Z-axis driving mechanism 14 and the fourth Z-axis driving mechanism 15 to perform automatic sticking. The ACF glue is automatically peeled off on the front side of the vertical machine base 300, and the second CCD camera inspection device 700 performs photo inspection of ACF attachment accuracy, and flows into the next station after inspection.

Embodiment 3

[0079] The invention adopts a double-station ACF glue high-precision cutting and attaching mechanism, which can realize the simultaneous attachment of ACF glue on two pieces of products. Before attaching, there is a camera for up and down alignment, and after attaching, a high-precision camera [high-precision camera is The second CCD camera detection device 700] inspects the attachment accuracy of the ACF glue, and sets the vacuum position stepless adjustment function on the structure of the vacuum adsorption attachment platform 6, and only needs to adjust the screw to open and close the required vacuum adsorption hole. Various products can be attached without replacing parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com