A kind of insulating sheet made by drawing die

A technology of insulating sheet and drawing die, which is applied to insulators and other directions, can solve the problems of reduced attachment accuracy, troublesome production, inconvenient production and use, etc., and achieves improved processing and attachment speed, high attachment accuracy, Easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

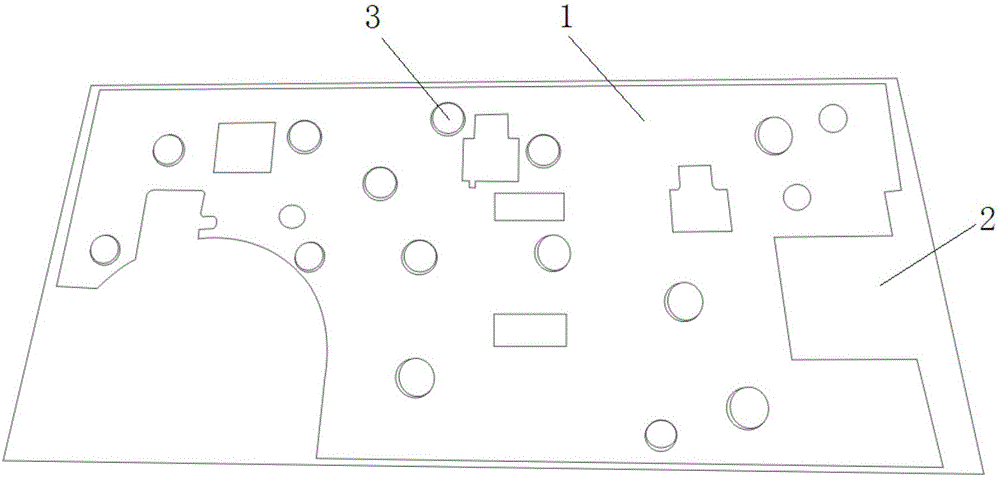

[0013] Such as figure 1 As shown, an insulating sheet made by a stretching die includes an insulating sheet body 1 and a release paper 2, an adhesive layer is arranged on the back of the insulating sheet body 1, and the release paper 2 is attached to the insulating sheet through the adhesive layer Body 1 back. The insulating sheet body 1 is stretched out from the back to the front by stretching a number of arc-shaped dots 3, and the set arc-shaped dots 3 correspond to the protruding positions of the circuit board welding points one by one, and the arc-shaped dots The edge of 3 is connected to the insulating sheet body 1, and the height of the arc-shaped dot 3 is higher than the height of the plane of the insulating sheet body 1. The arc-shaped dots 3 can wrap the solder joint protrusions on the circuit board.

[0014] In summary, the present invention is an insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com