Mobile phone label automatic attaching device

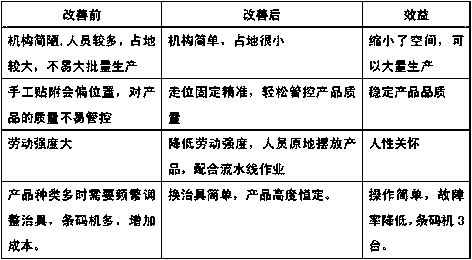

A labeling and automatic technology, applied in the directions of labels, packaging, labeling machines, etc., can solve the problems of high labor intensity of manual sticking, increase labor costs of enterprises, poor sticking accuracy, etc., and improve the sticking precision and sticking efficiency. , The effect of reducing labor intensity and improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

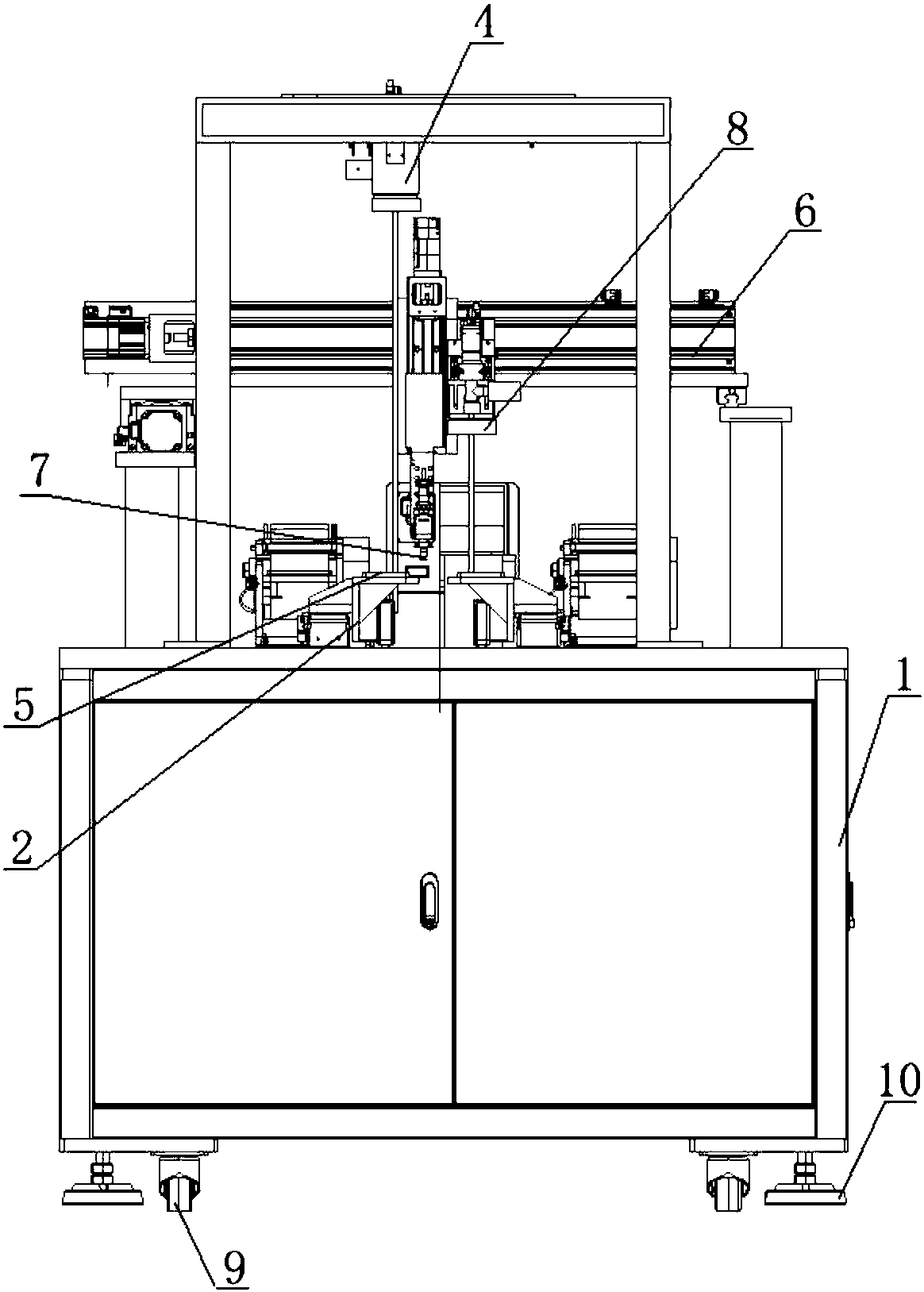

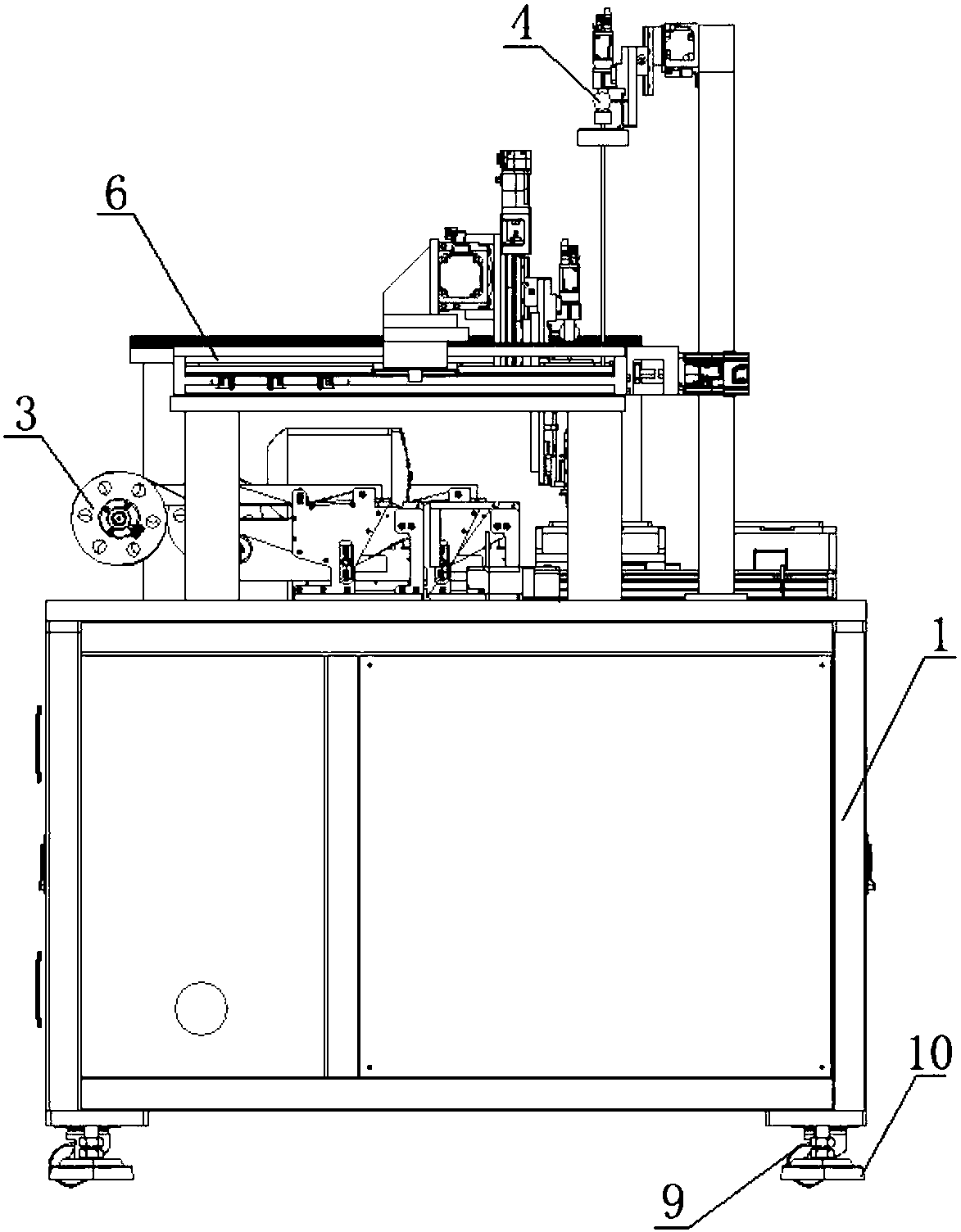

[0024] see figure 1 and 2 Shown, a kind of mobile phone label automatic attaching device, it comprises working platform 1, is located at the labeling jig 2 on the working platform, is located at the labeling module of one side of the labeling jig on the working platform, at least one The label printing mechanism 3 and the detection mechanism 4 arranged above the labeling fixture,

[0025] The labeling jig is provided with a material frame 5 for fixing the mobile phone,

[0026] The labeling module includes a drive mechanism 6 with degrees of freedom along the X-axis, Y-axis and Z-axis directions, a label clamping mechanism 7 and a code scanning mechanism arranged at the execution end of the drive mechanism, and a positioning mechanism located at the execution end of the drive mechanism. The image acquisition and positioning mechanism 8 on the side of the label clamping mechanism is used to adjust the labeling position.

[0027] In this embodiment, the driving mechanism is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com