Patents

Literature

130results about How to "Improve attachment efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

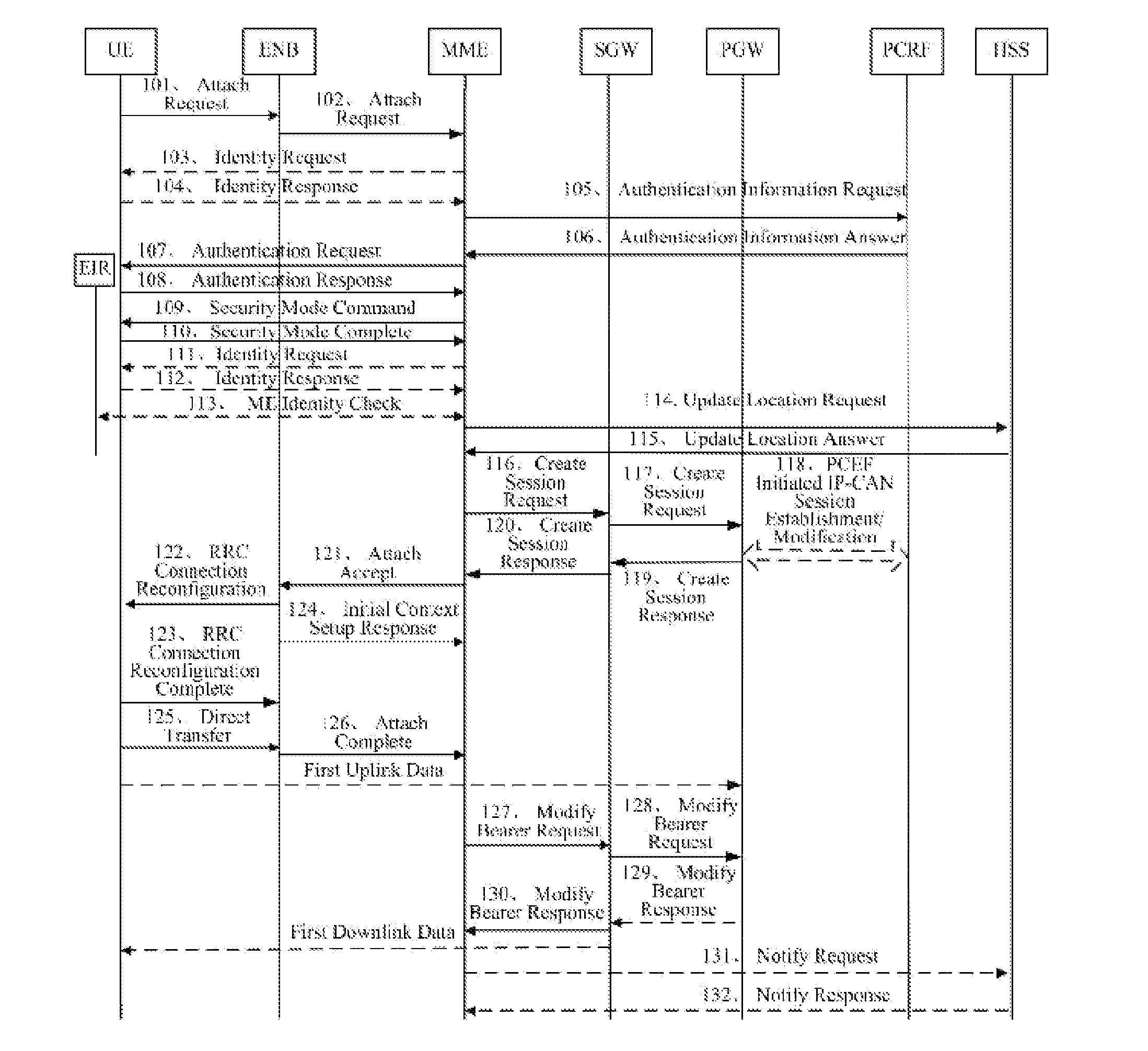

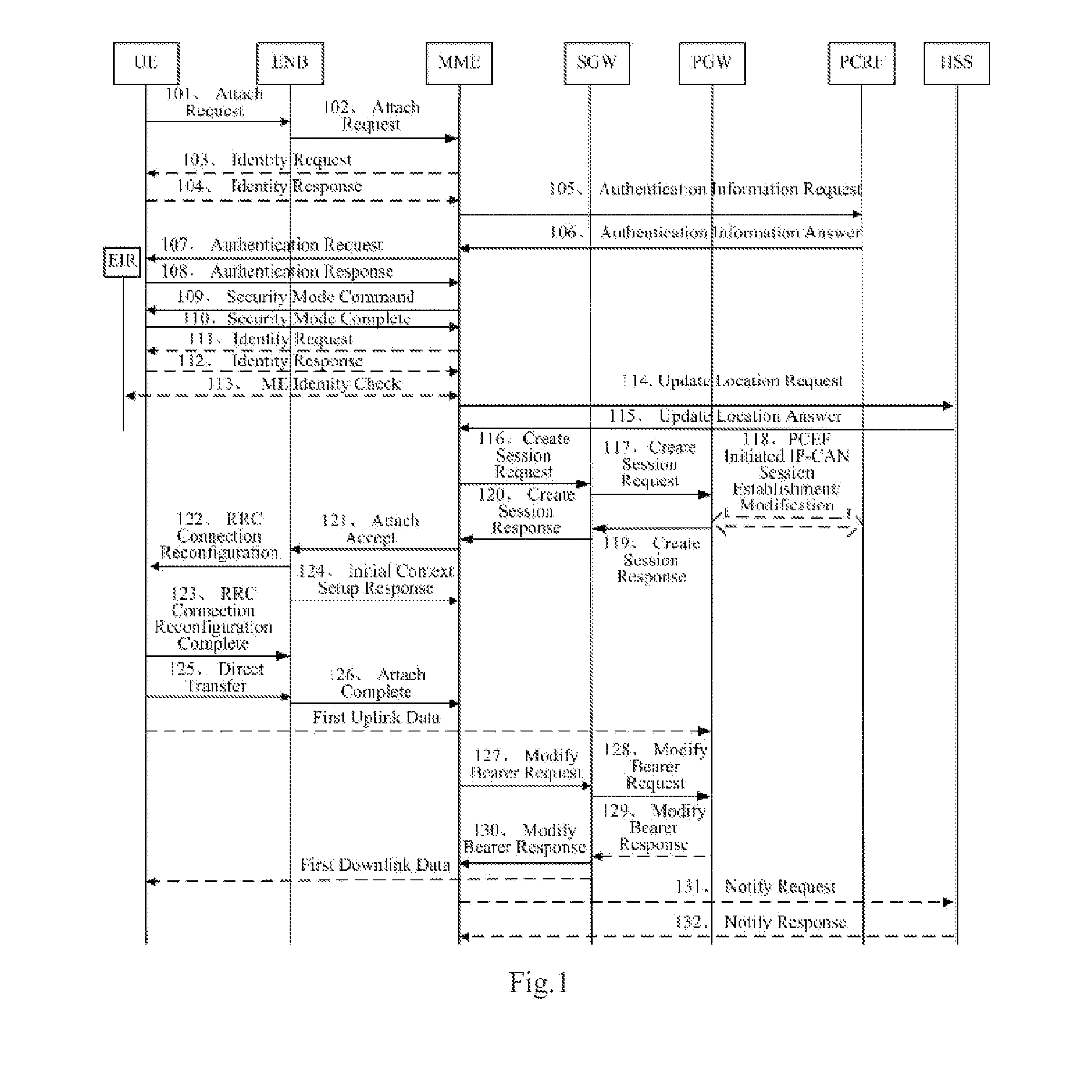

Method for attaching to E-TRAN (Evolved Universal Terrestrial Radio Access Network) and mobility management entity

InactiveCN102438330AReduce latencyImprove attachment efficiencyConnection managementSecurity arrangementInformation transmissionRadio access network

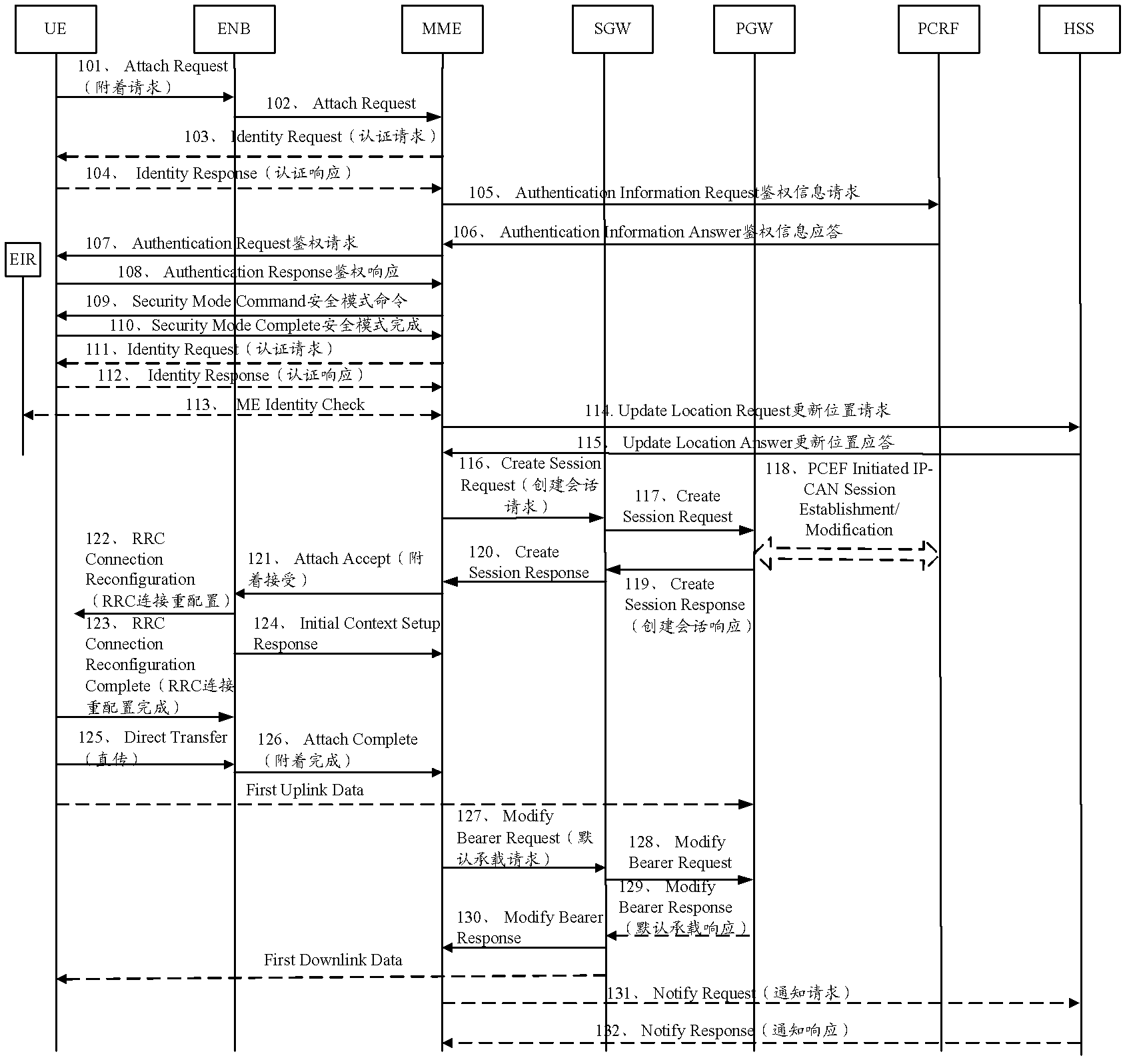

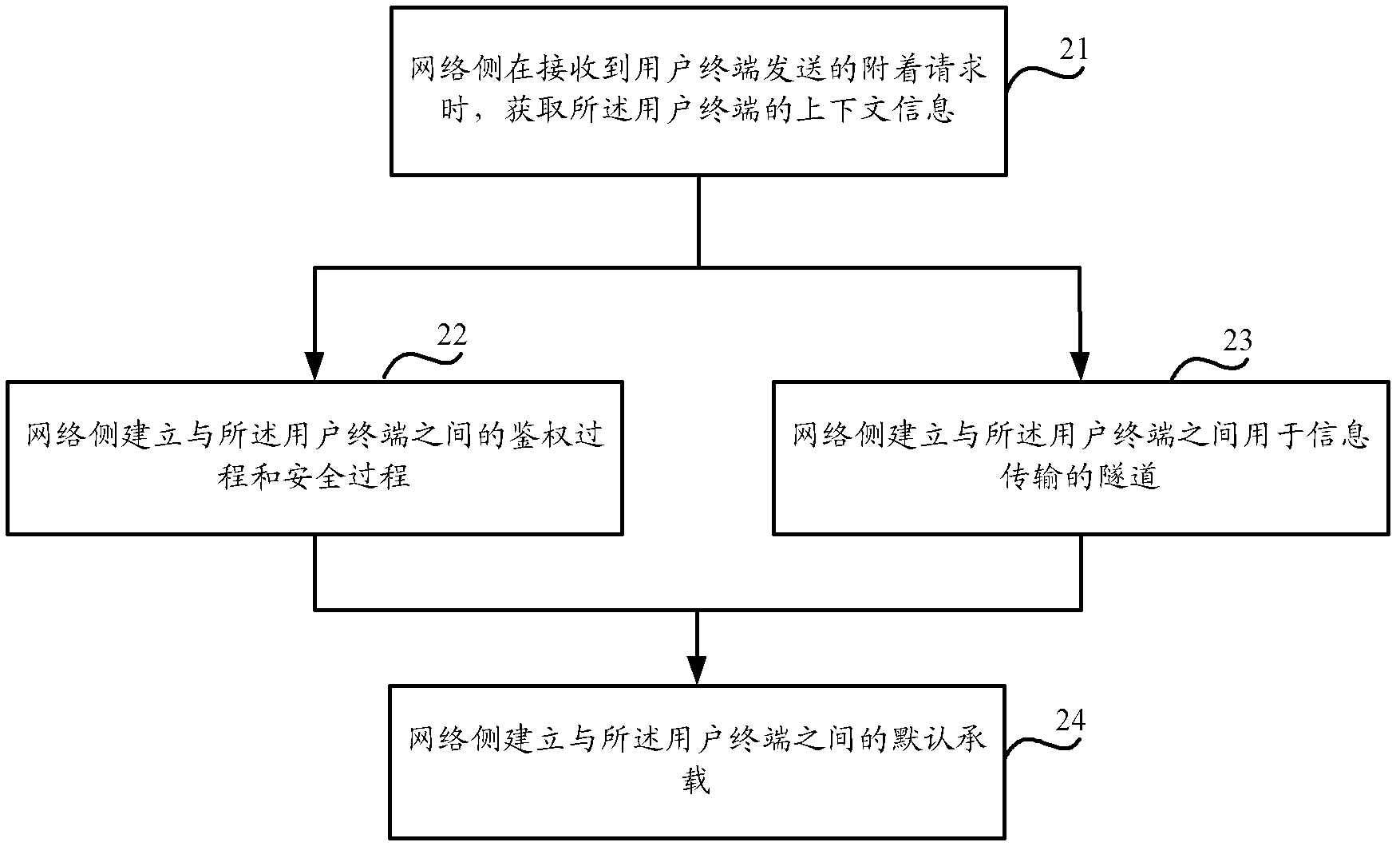

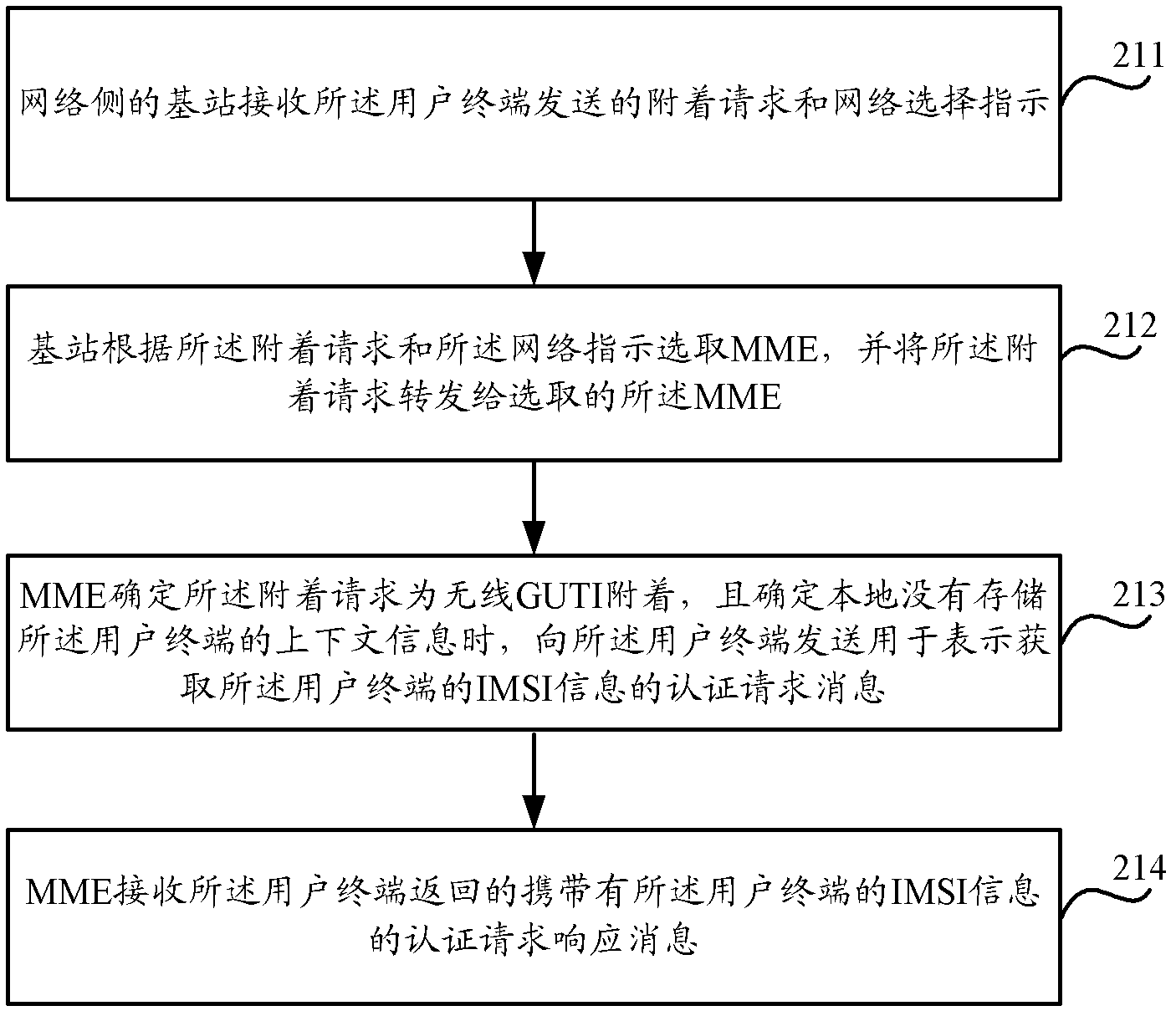

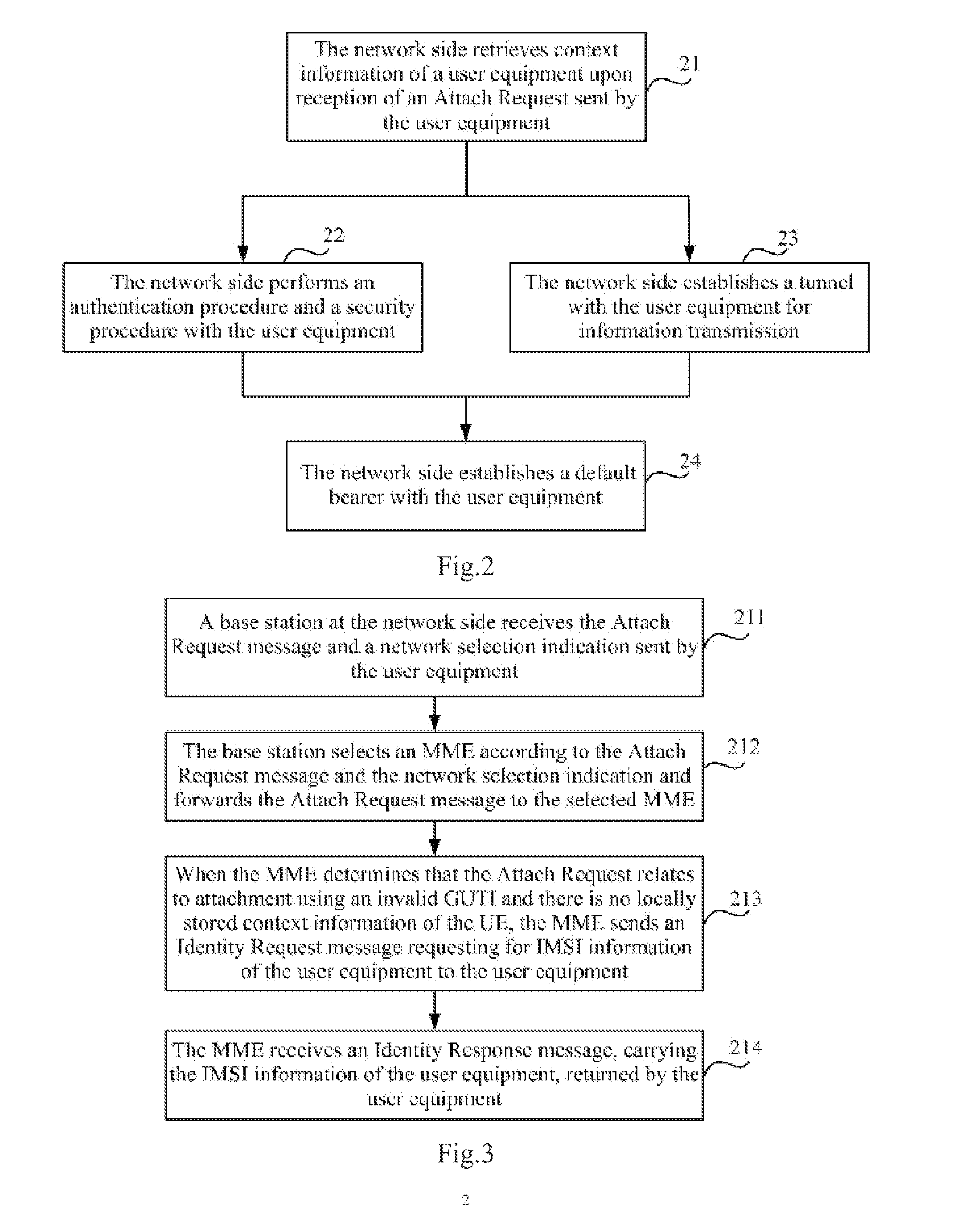

The invention discloses a method for attaching to an E-TRAN (Evolved Universal Terrestrial Radio Access Network) and a mobility management entity, which are used for reducing time delay that a user terminal is attached into a network and improving the attachment efficiency. The attaching method comprises the following steps that: in a step A, a network side acquires context information of the user terminal when receiving an attaching request sent by the user terminal; in a step B, the authentication process and the safety process between the network side and the user terminal are established; in a step C, a channel for information transmission between the network side and the user terminal is established; and in a step D, a default load between the network side and the user terminal is established, wherein the step B and the step C are executed in parallel after the step A is successfully executed and the step D is executed after the success execution of the step B and the step C is confirmed.

Owner:DATANG MOBILE COMM EQUIP CO LTD

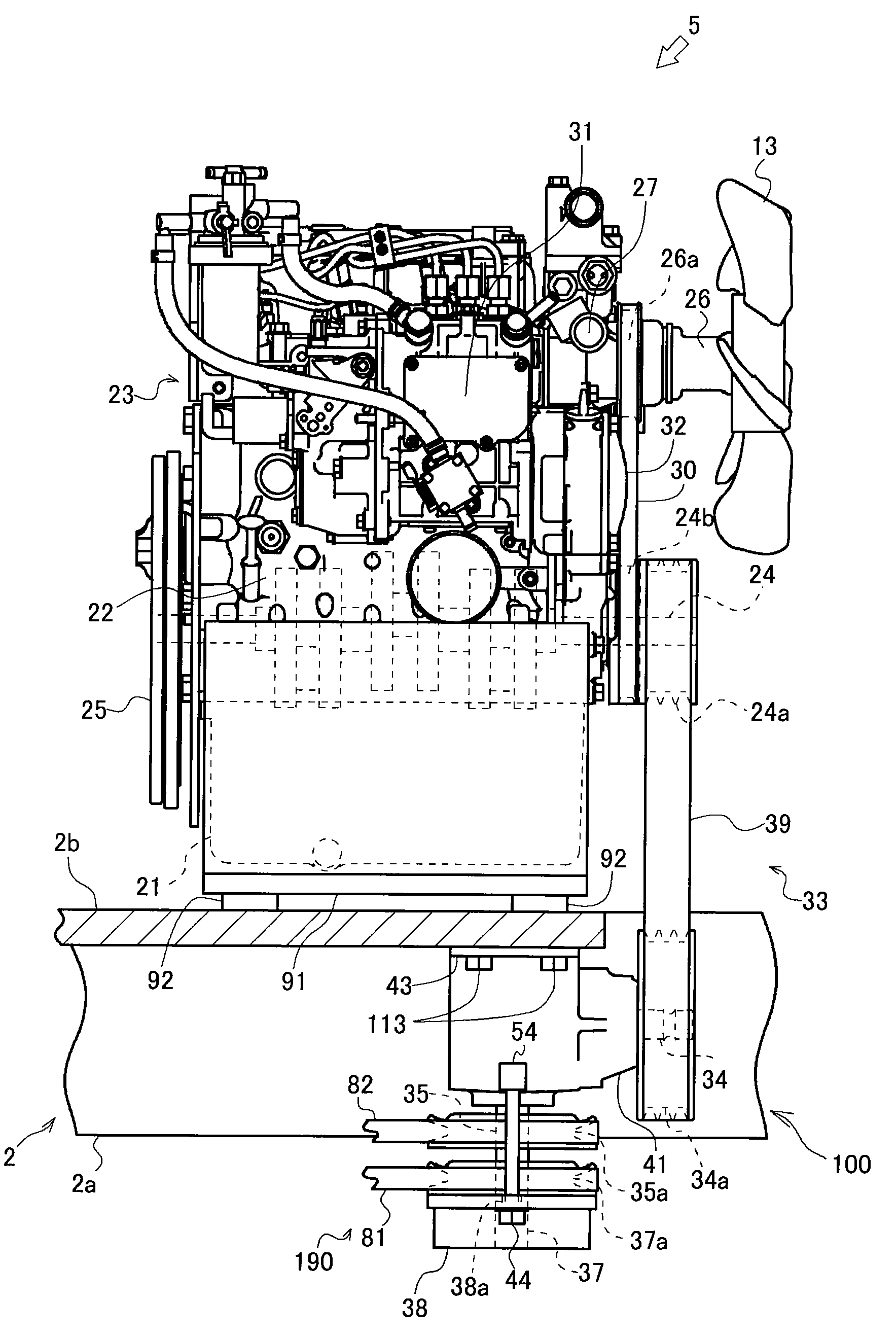

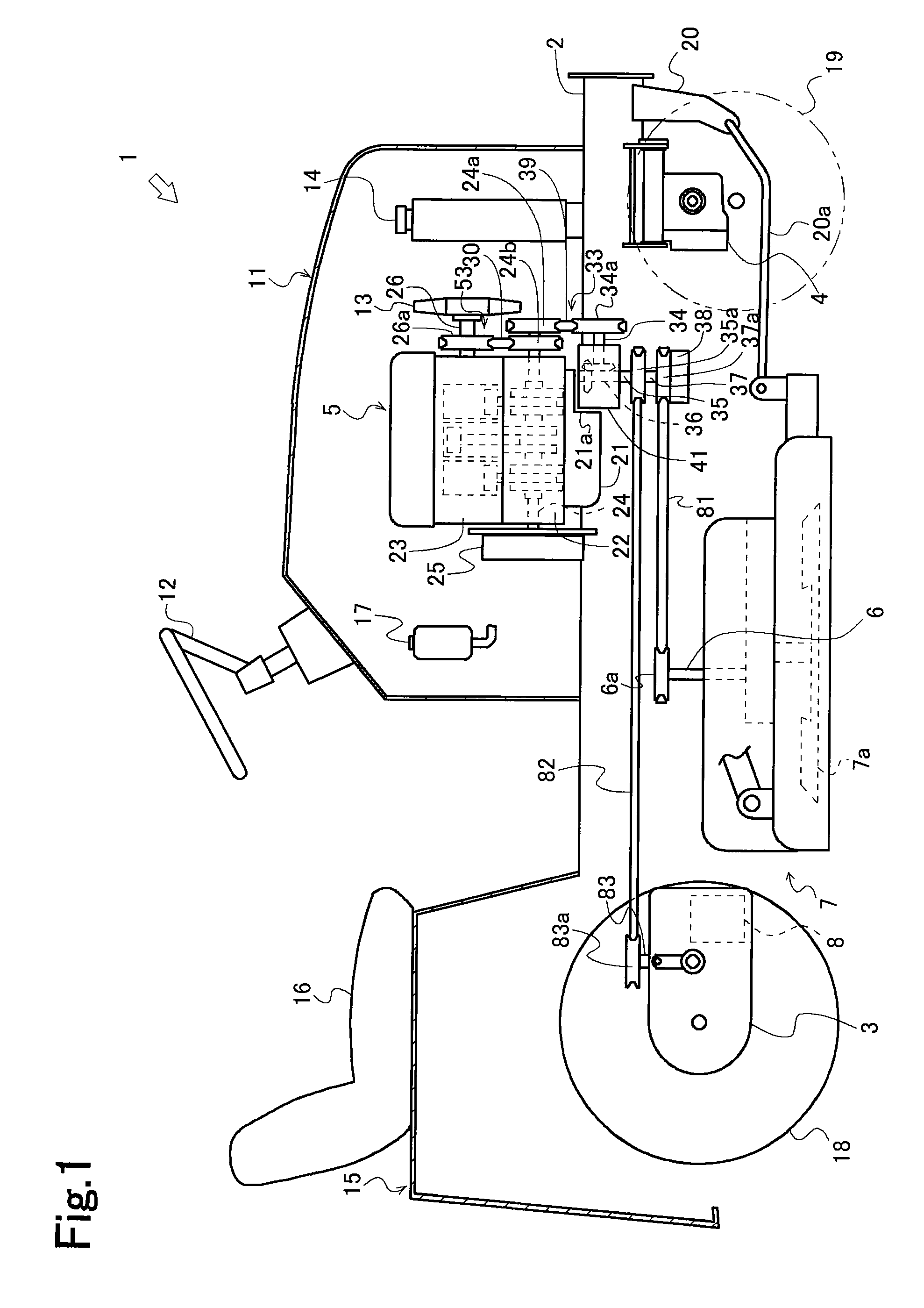

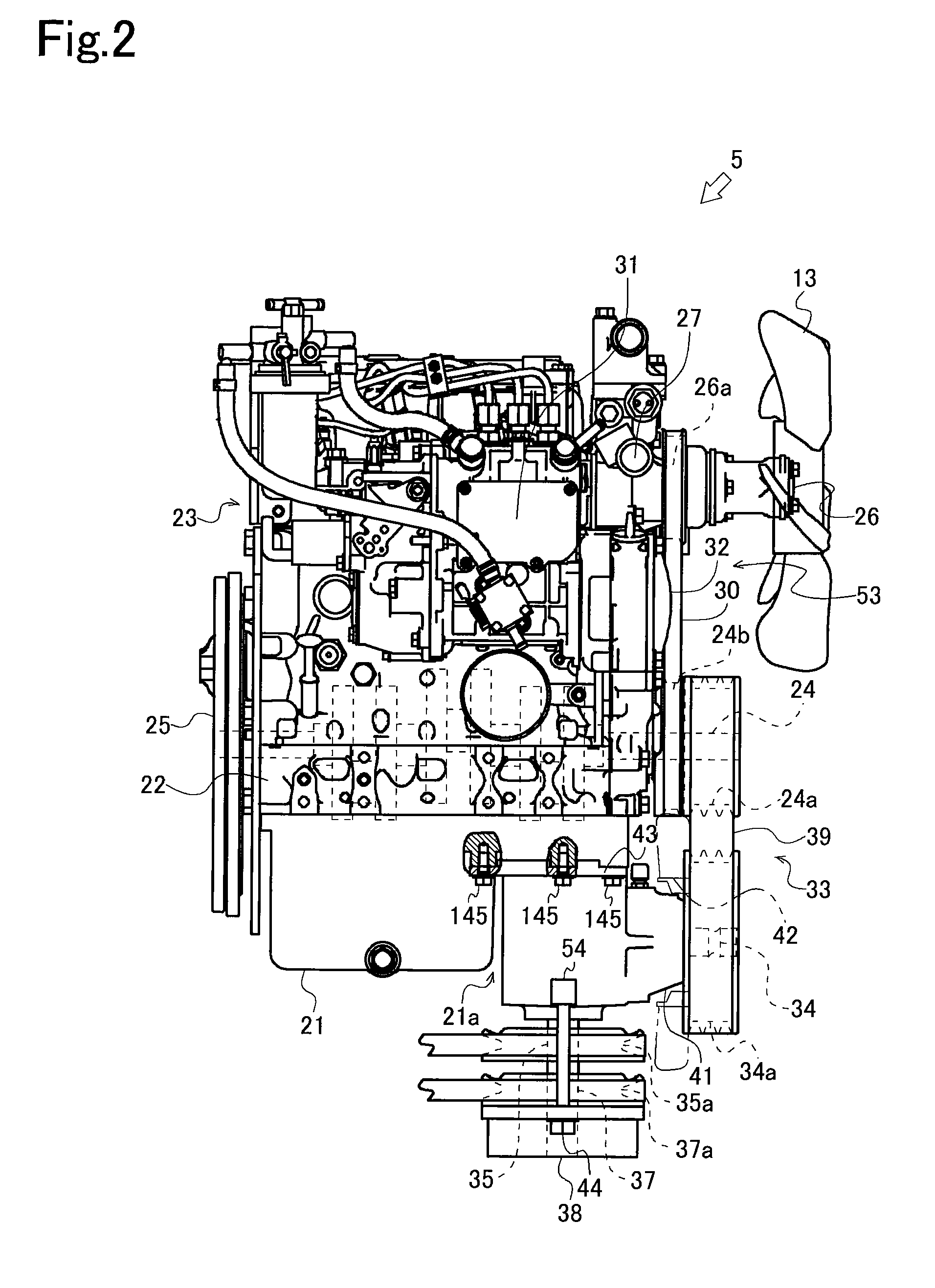

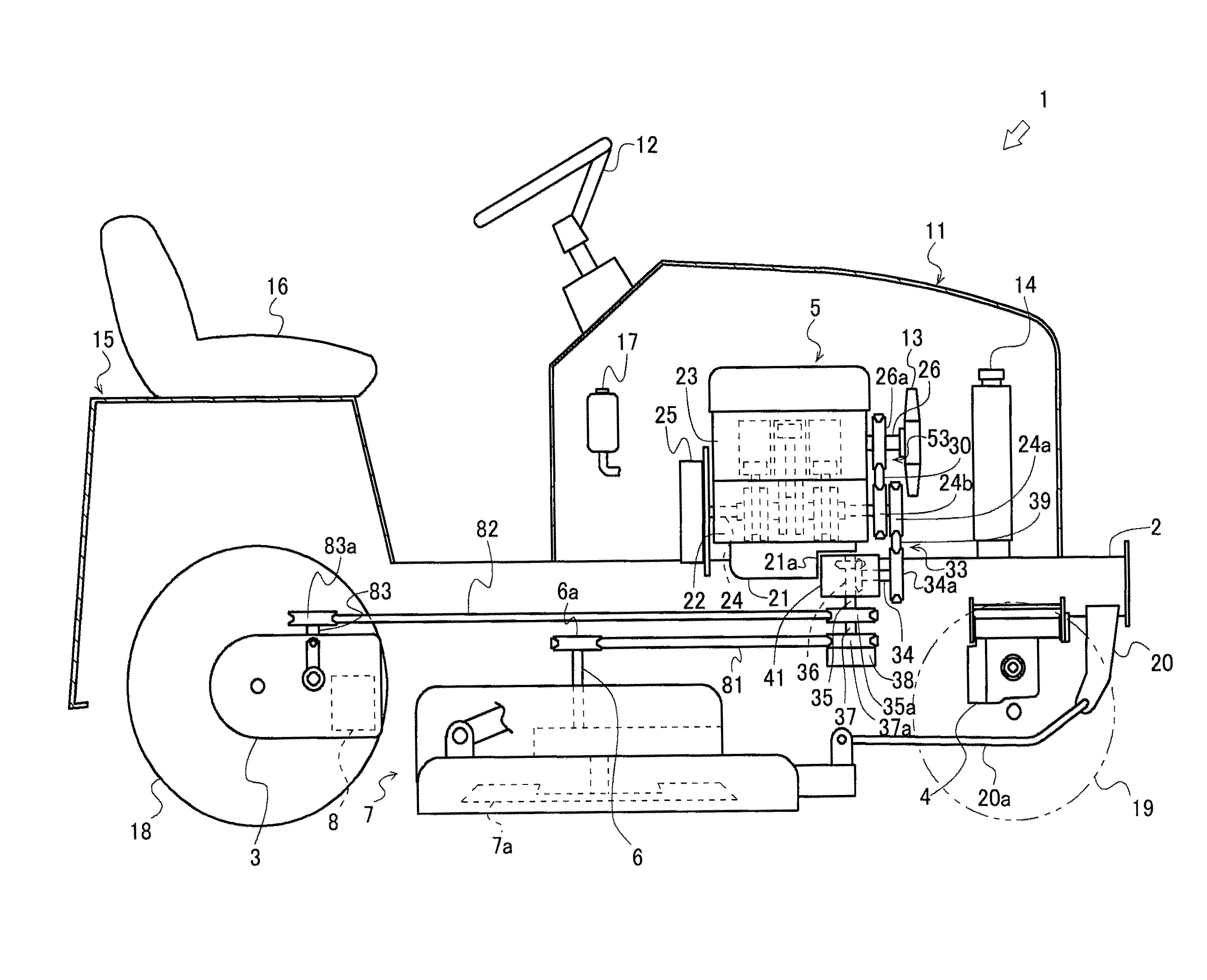

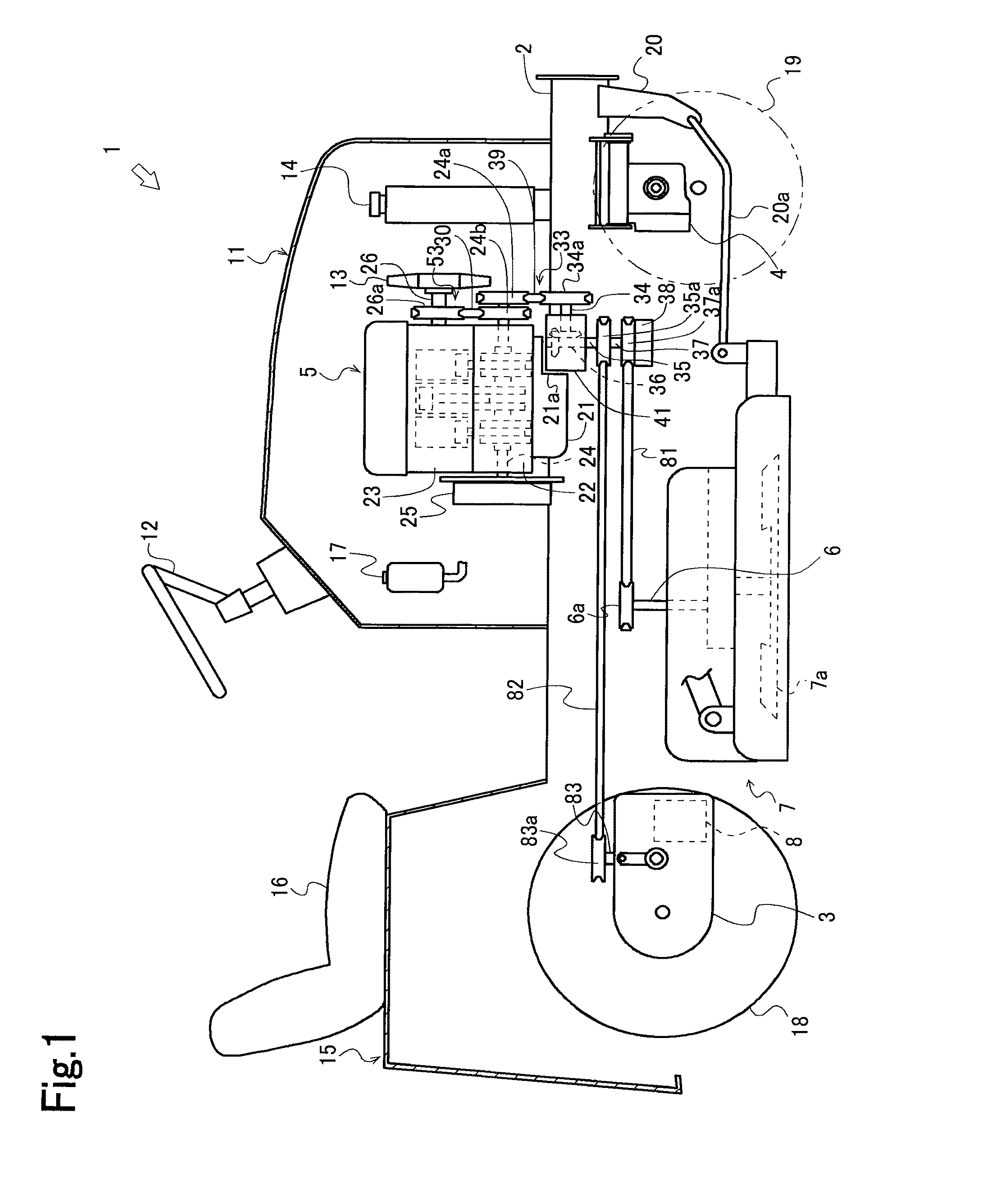

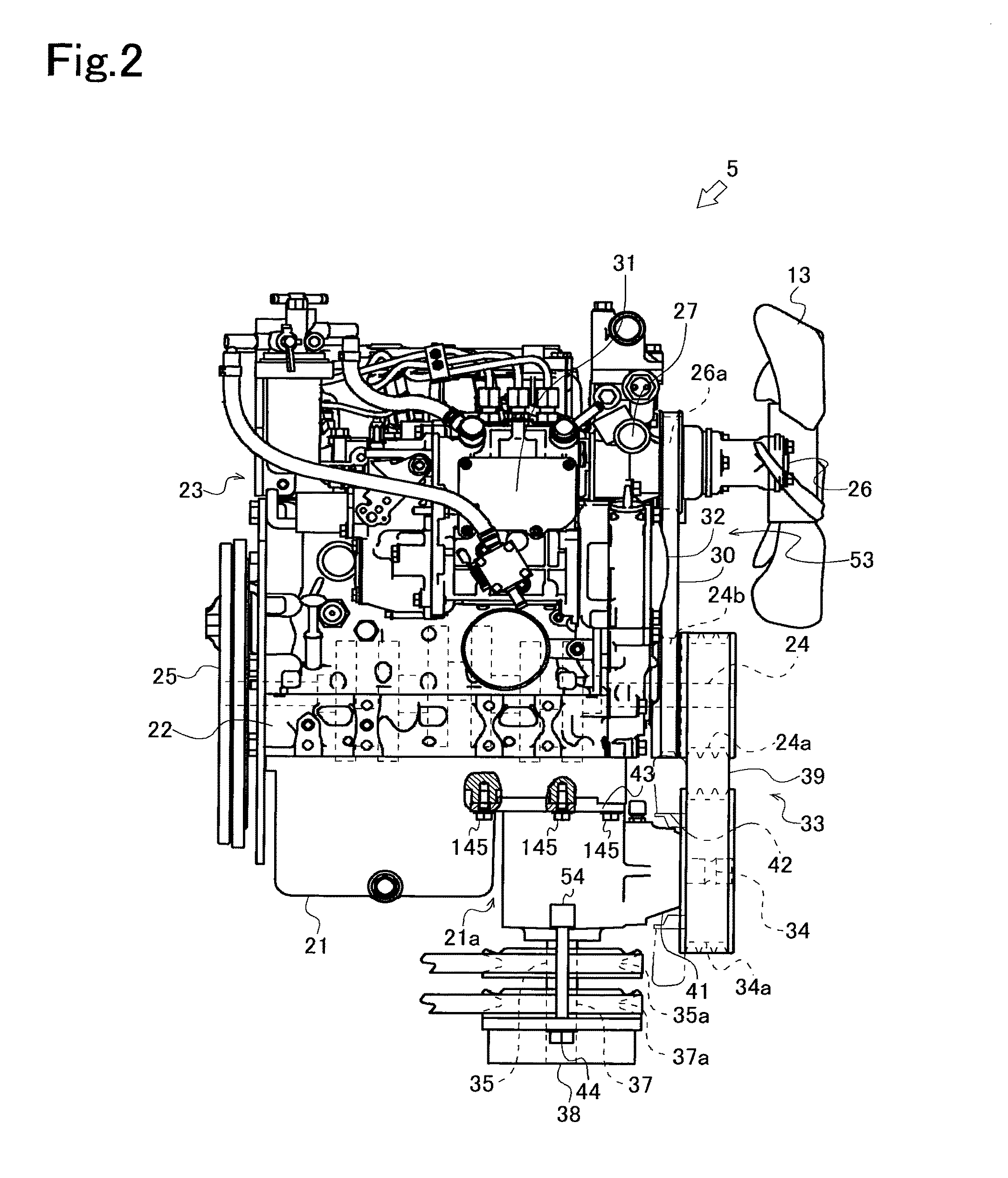

Engine and Power Transmission Device

InactiveUS20090301429A1Easily miniaturizeImprove efficiencyCrankshaftsCoolant flow controlCrankshaftPower transmission

An engine according to an aspect of the present invention includes a crankshaft which is disposed in a substantially horizontal direction, first power transmission means, an input shaft, a first output shaft, second power transmission means, and a power transmission case. The input shaft is disposed below the crankshaft in parallel with the crankshaft, and the input shaft receives a power from the crankshaft through the first power transmission means. The first output shaft supplies the power from the input shaft, and the first output shaft is disposed perpendicular to the crankshaft. The second power transmission means transmits the power of the input shaft to the first output shaft. The power transmission case accommodates the input shaft, the first output shaft, and the second power transmission means therein.

Owner:YANMAR CO LTD

Method for attaching e-utran and mobility management entity

InactiveUS20140335830A1Reduce time delayImprove attachment efficiencyUnauthorised/fraudulent call preventionEavesdropping prevention circuitsInformation transmissionTime delays

This application discloses a method of attaching to E-UTRAN and a mobility management entity so as to lower the time delay in attachment of a user equipment to the network and improve the efficiency of attachment. The method includes: a step A of retrieving at the network side context information of a user equipment upon reception of an Attach Request sent by the user equipment; a step B of performing at the network side an authentication procedure and a security procedure with the user equipment; a step C of establishing at the network side a tunnel with the user equipment for information transmission; and a step D of establishing at the network side a default bearer with the user equipment, wherein the step B and the step C are performed in parallel after the step A is performed successfully; and the step D is performed upon determining that the step B and the step C are performed successfully.

Owner:DATANG MOBILE COMM EQUIP CO LTD

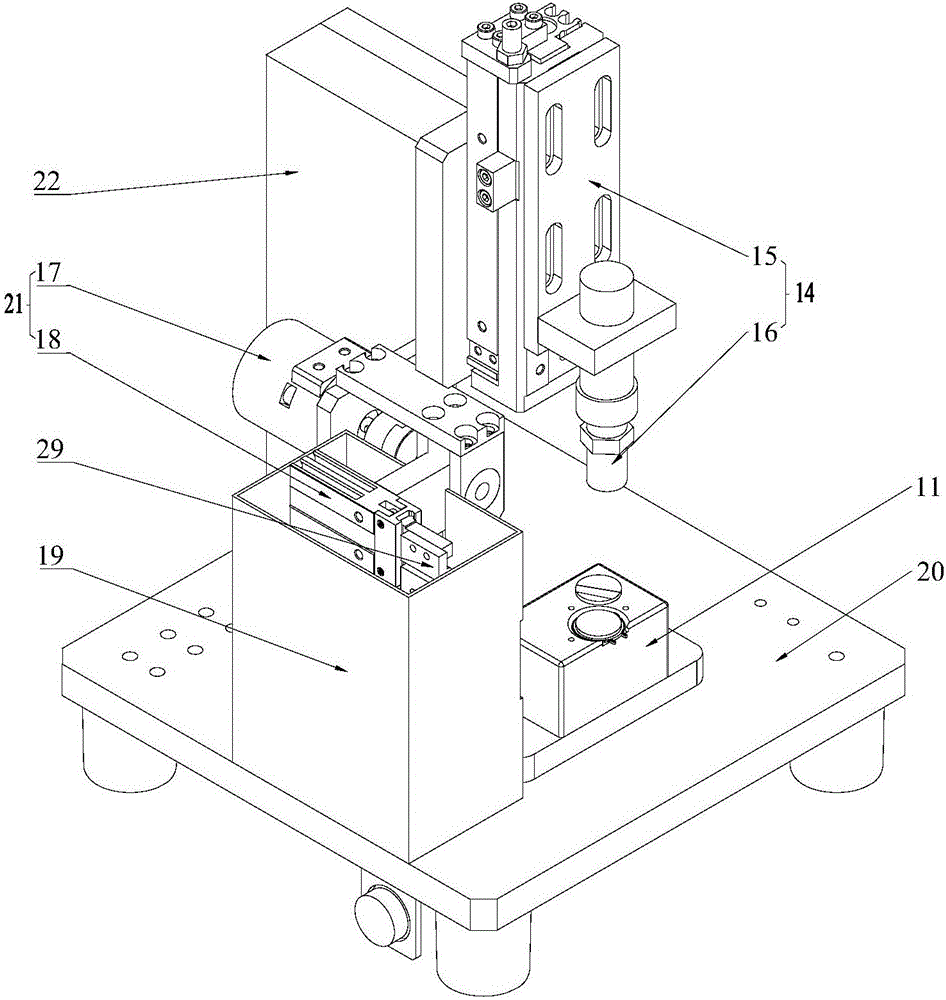

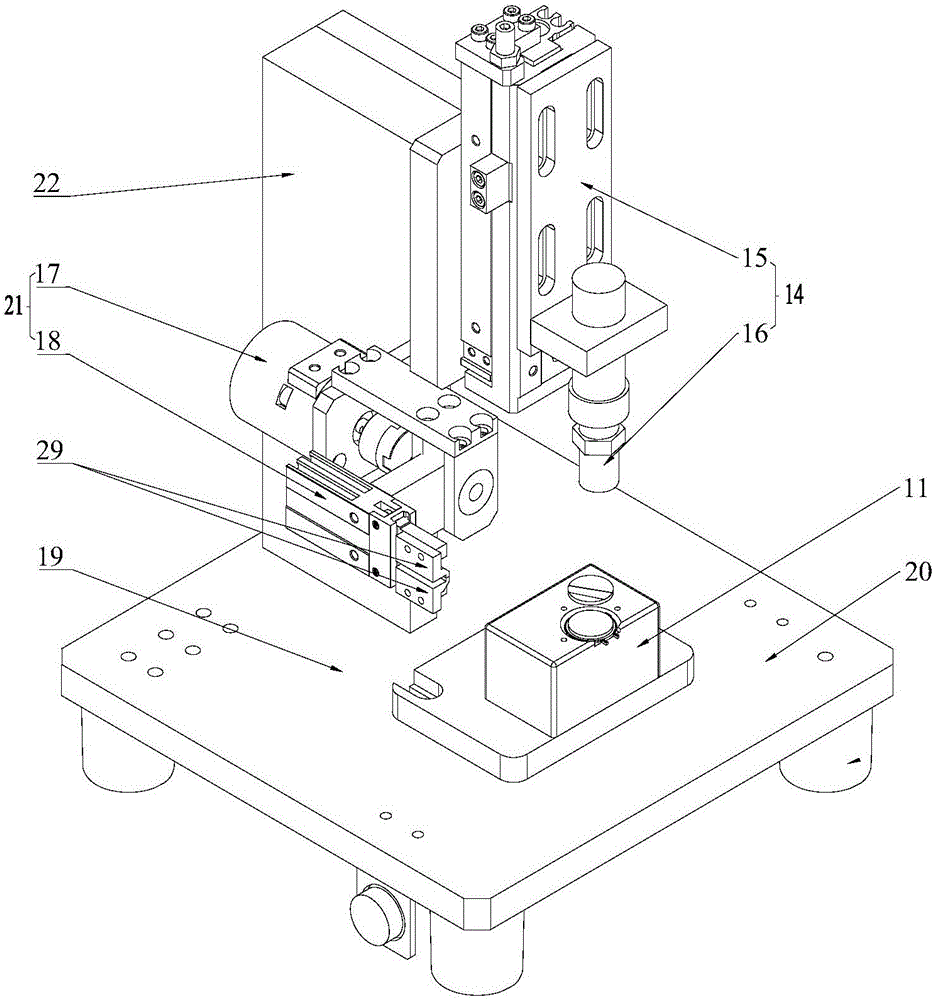

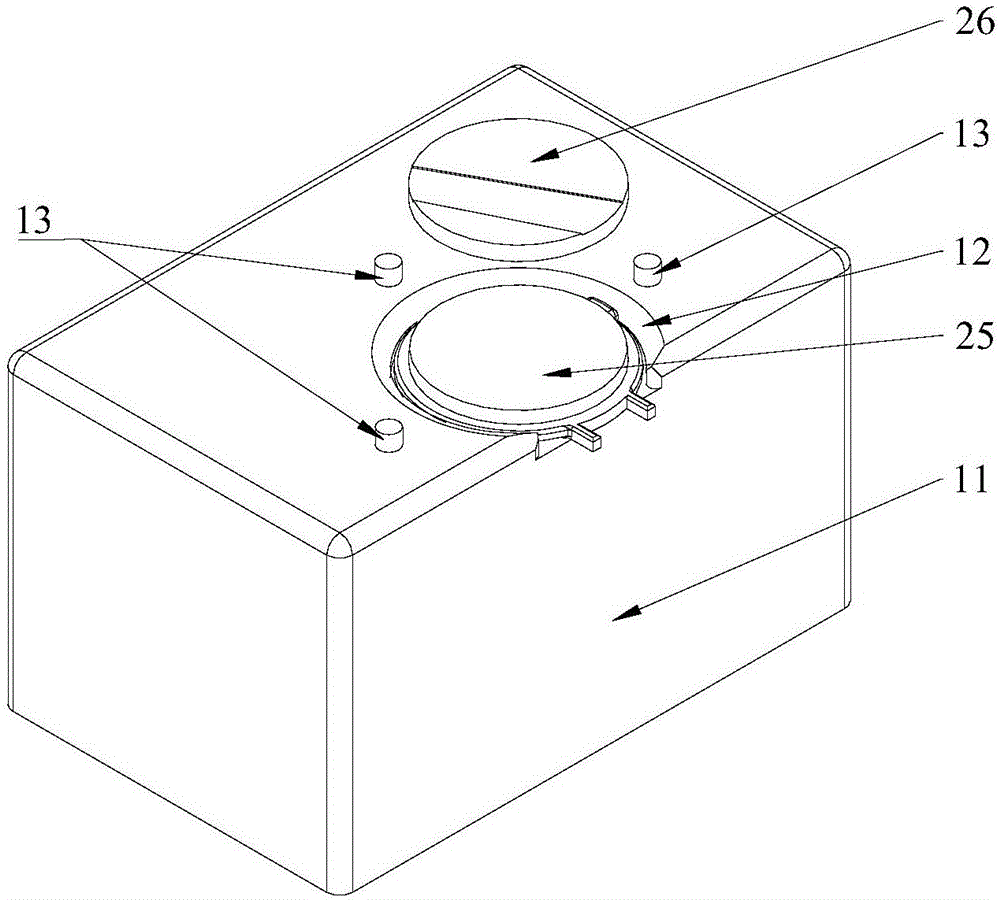

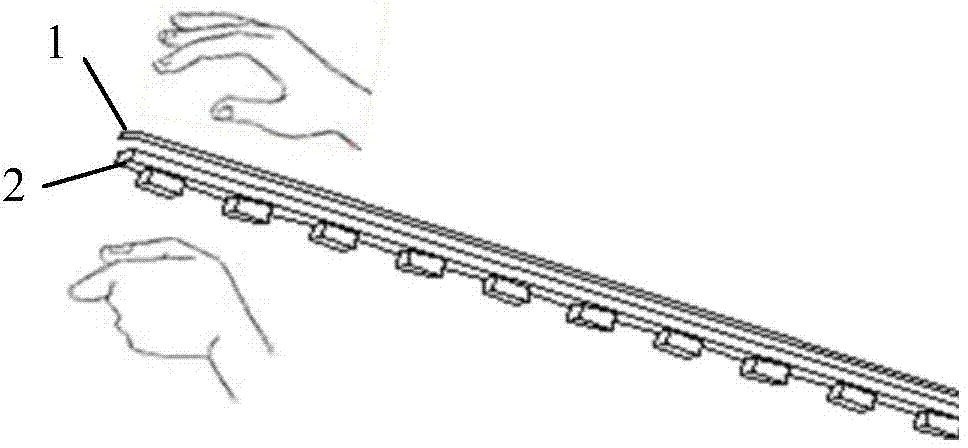

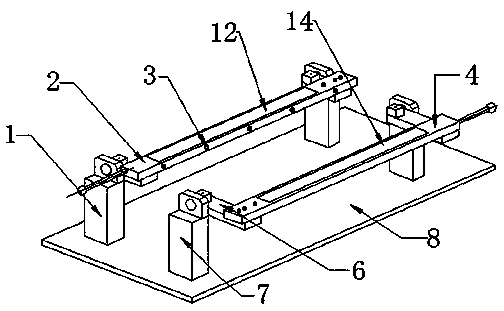

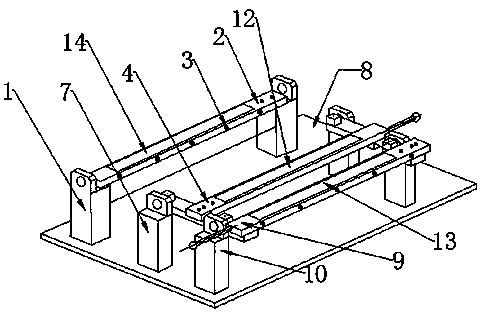

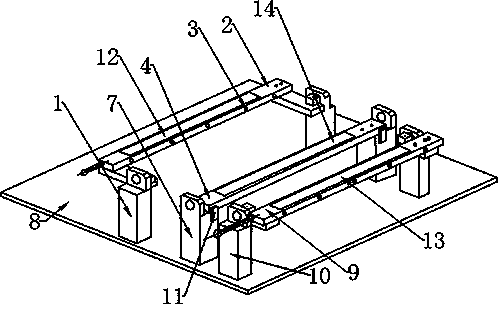

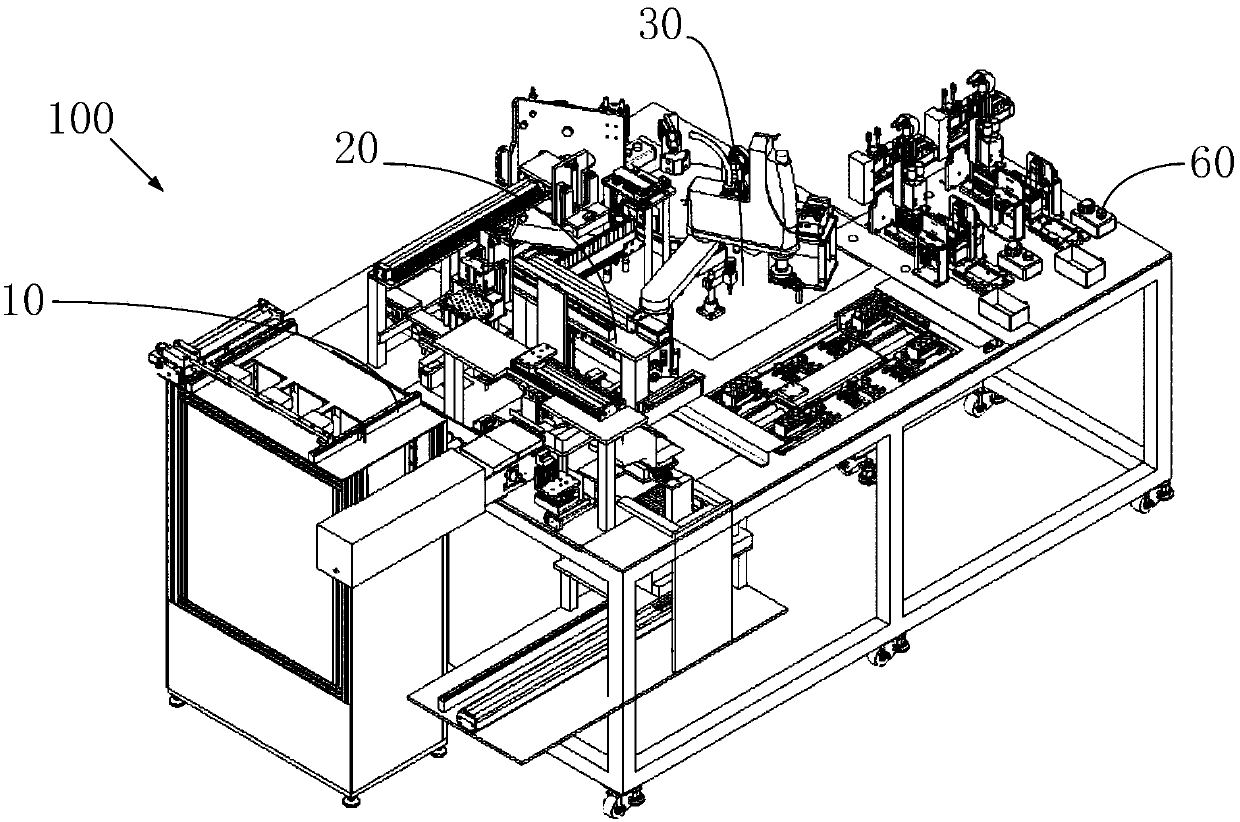

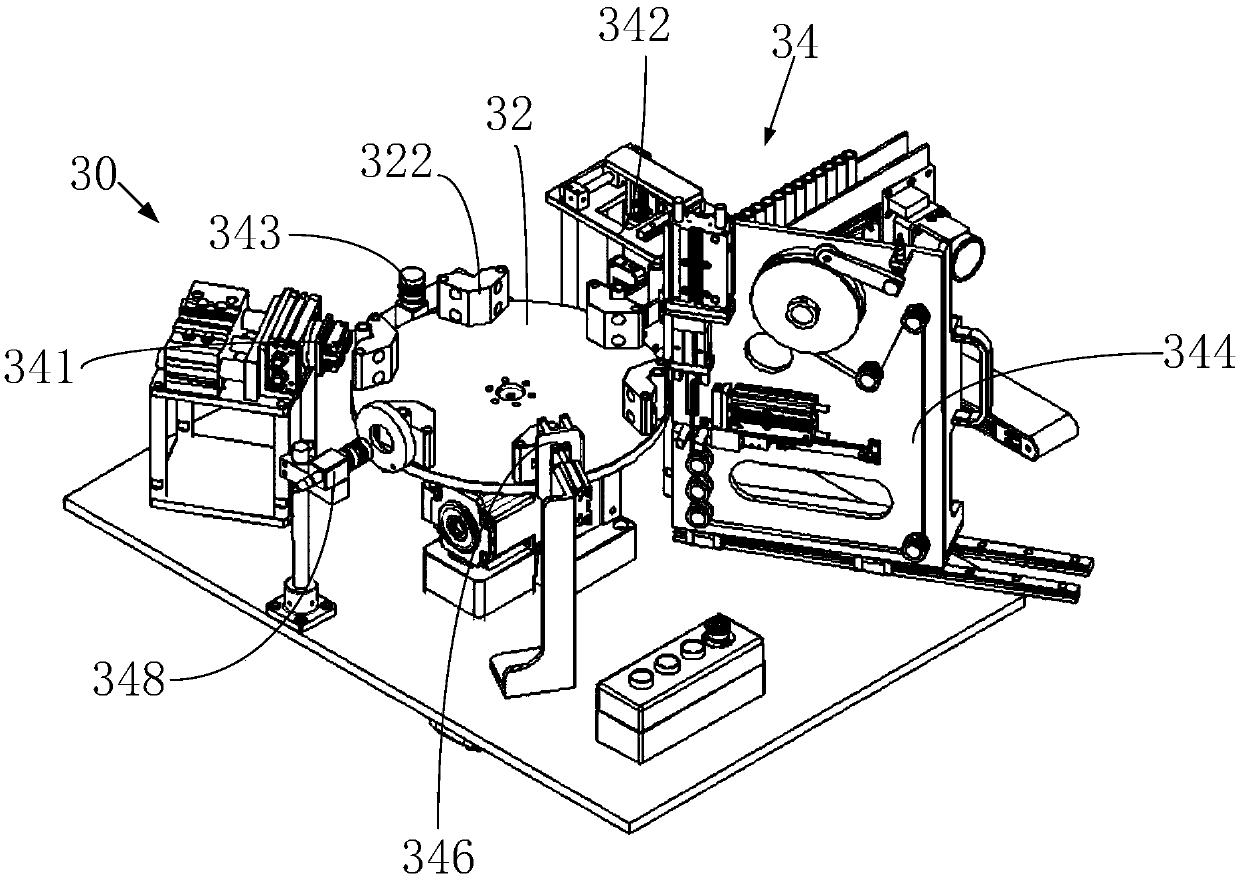

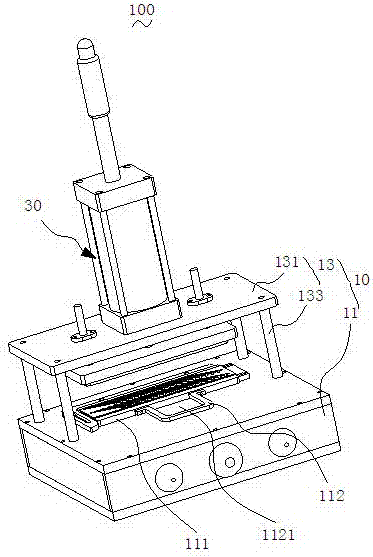

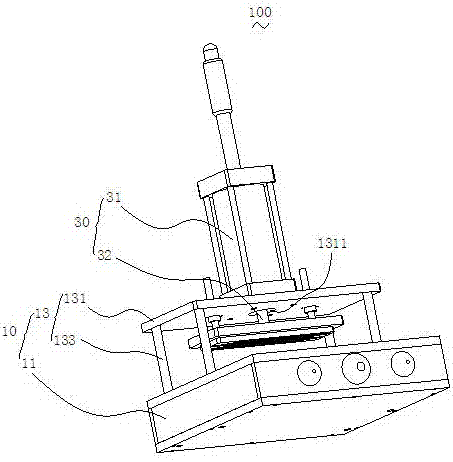

Double-sided adhesive tape attaching device and method

ActiveCN105110061APrevent taking awayImprove alignment accuracyProgramme-controlled manipulatorLamination ancillary operationsEngineeringManipulator

The embodiment of the invention provides a double-sided adhesive tape attaching device and method and relates to the field of preparation of electronic products. The problem that the attachment precision and attachment efficiency are low when double-sided adhesive tape is attached to the back face of a printed circuit board assembly (PCBA) can be solved. The double-sided adhesive tape attaching device comprises a driver, a workbench and manipulators arranged above the workbench. The manipulators are connected with the driver and used for putting the double-sided adhesive tape at the preset station of the workbench under driving of the driver, tearing off a first protective film of the double-sided adhesive tape at the preset station, pressing a printed circuit board on the double-sided adhesive tape with the first protective film torn off at the preset station and taking down the printed circuit board attached with the double-sided adhesive tape from the preset station. A positioning mechanism is arranged at the preset station, and used for fixing an adhesive layer and a second protective film when the manipulators are used for tearing off the first protective film and releasing fixation of the adhesive layer and the second protective film when the double-sided adhesive tape is attached to the printed circuit board.

Owner:BOE TECH GRP CO LTD +1

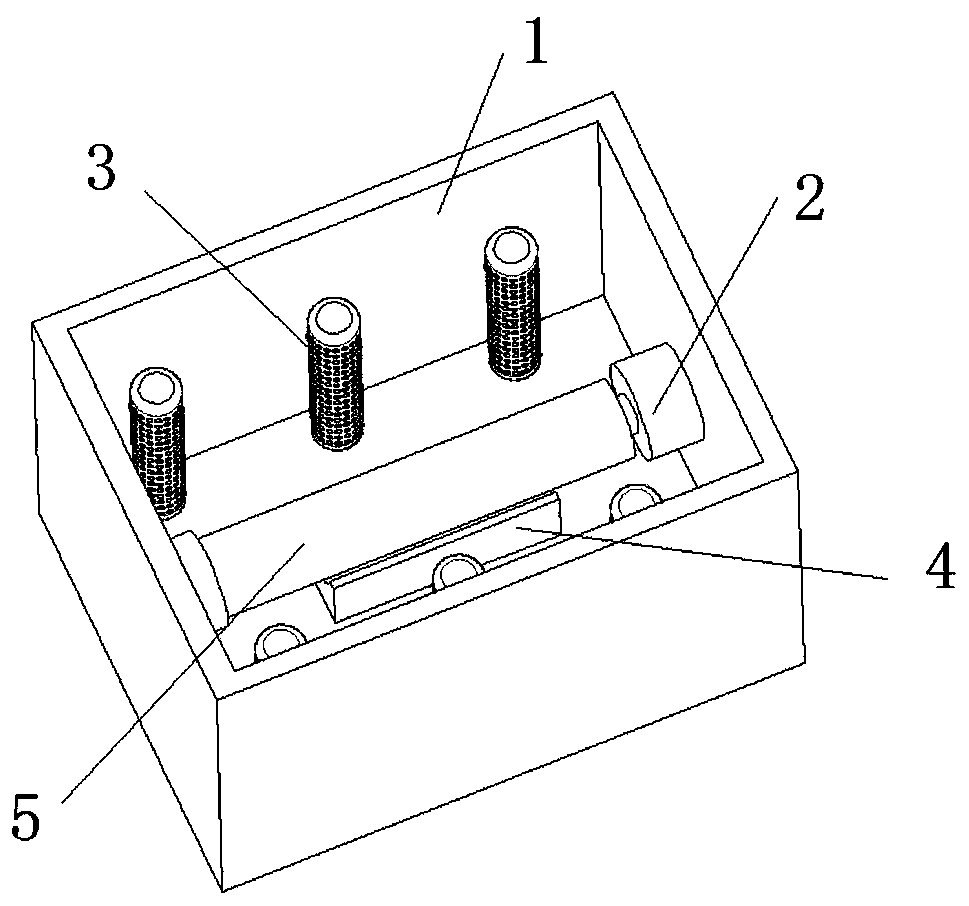

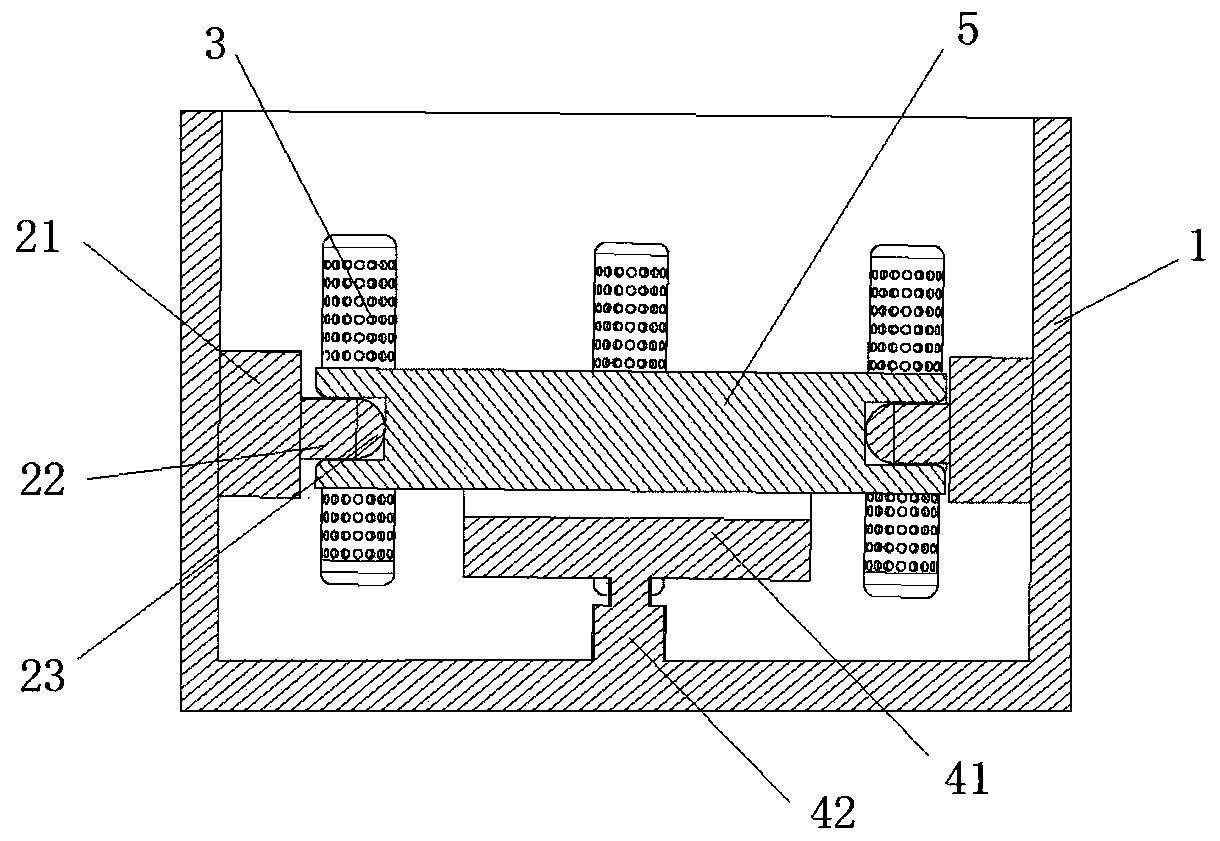

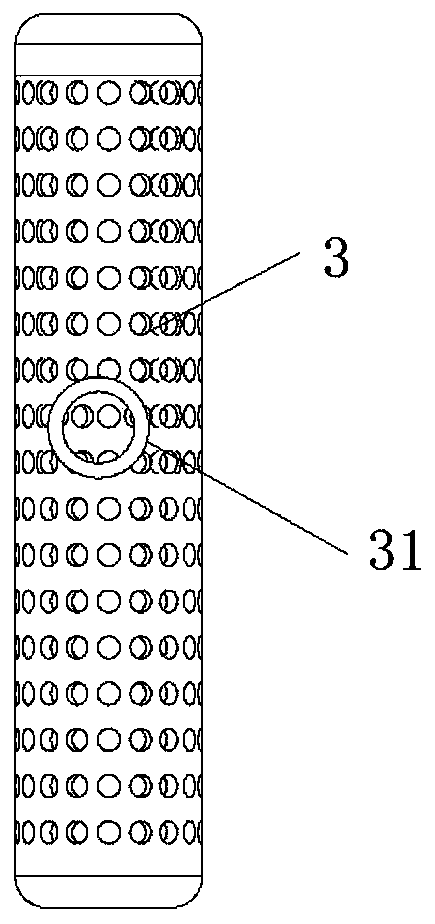

Attaching tool

InactiveCN106275672ARealize automatic attachmentImprove attachment efficiencyLabelling machinesRelease linerElectrical and Electronics engineering

The invention discloses an attaching tool. The tool comprises a fixed base, a bonding device and a tearing device, wherein the fixed base includes a mounting part for placing and positioning an attached part, and a positioning part for placing and positioning a part to be attached; the bonding device includes a transfer device and a sucking device; the transfer device is configured to transfer the sucking device between an attaching station and a tearing station; the tearing device is used for tearing off a release paper on the part to be attached; a moving device is configured to move a clamping device between the tearing station and an unloading station; and the clamping device clamps the release paper on the tearing station. The attaching tool realizes automatic attaching of the attached part and the part to be attached, and has the characteristics of high attaching efficiency and good positioning effect.

Owner:GEER TECH CO LTD

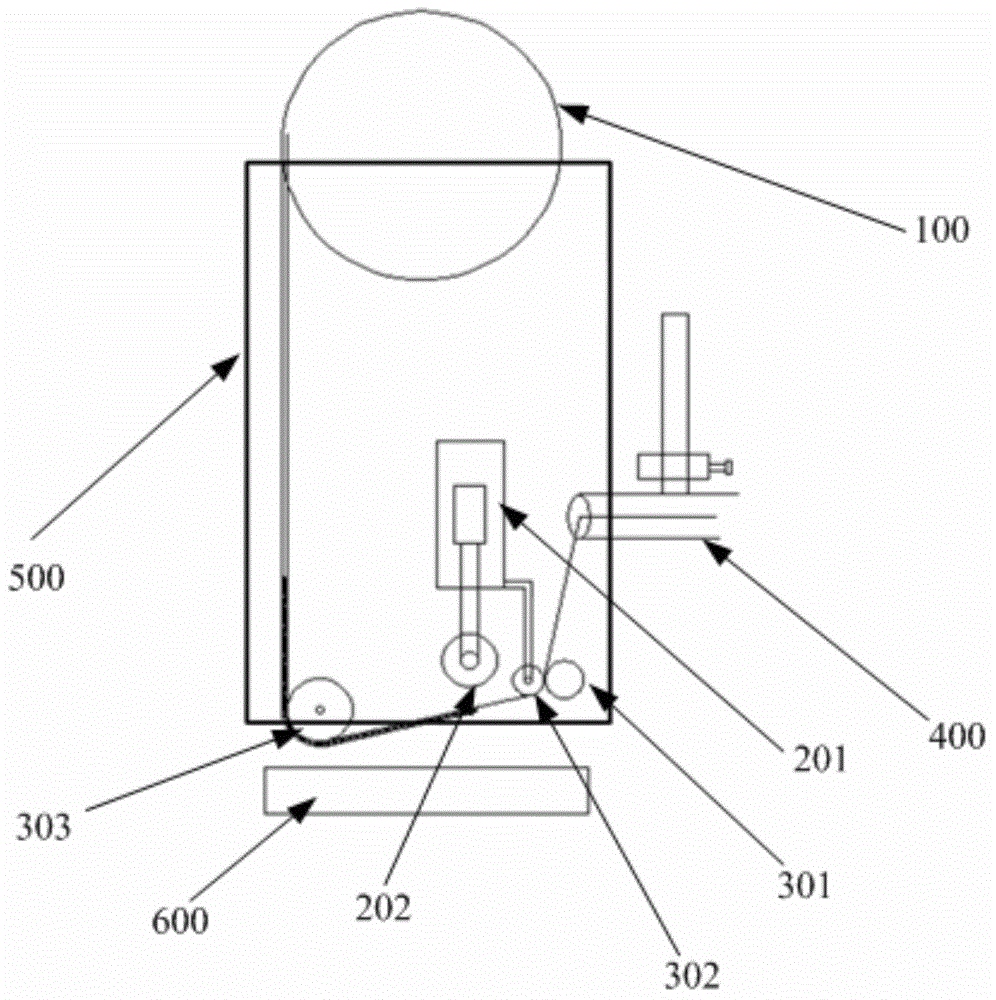

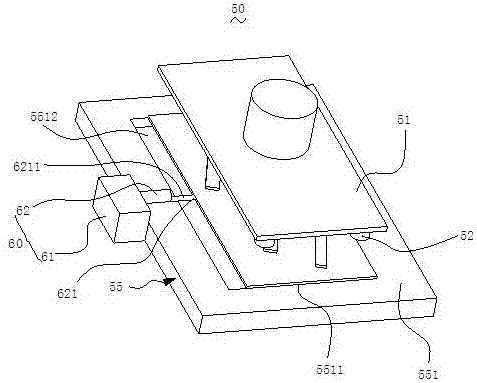

ACF (anisotropic conductive film) attaching device

The invention provides an AFC (anisotropic conductive film) attaching device, belongs to the technical field of attaching devices, and solves the problem that an existing ACF attaching device is low in attaching efficiency. The ACF attaching device comprises a supplying mechanism, a tape conveying mechanism and a tape pressing mechanism, wherein the supplying mechanism is used for supplying ACF adhesive tapes formed by conductive adhesive films and base bands, the tape conveying mechanism is used for conveying the ACF adhesive tapes supplied by the supplying mechanism along a preset conveying path, and the tape pressing mechanism is used for pressing and fixing the conductive adhesive films of the ACF adhesive tapes conveyed by the tape conveying mechanism on object components to be attached; the tape conveying mechanism comprises a first guide wheel and a supplying wheel which are in contact with each other and used for clamping the ACF adhesive tapes to separate the base bands from the conductive adhesive films by means of allowing a first motor to control the supplying wheel to rotate during the time when the conductive adhesive films of the ACF adhesive tapes are pressed and fixed on the object components to be attached through the tape pressing mechanism.

Owner:BOE TECH GRP CO LTD +1

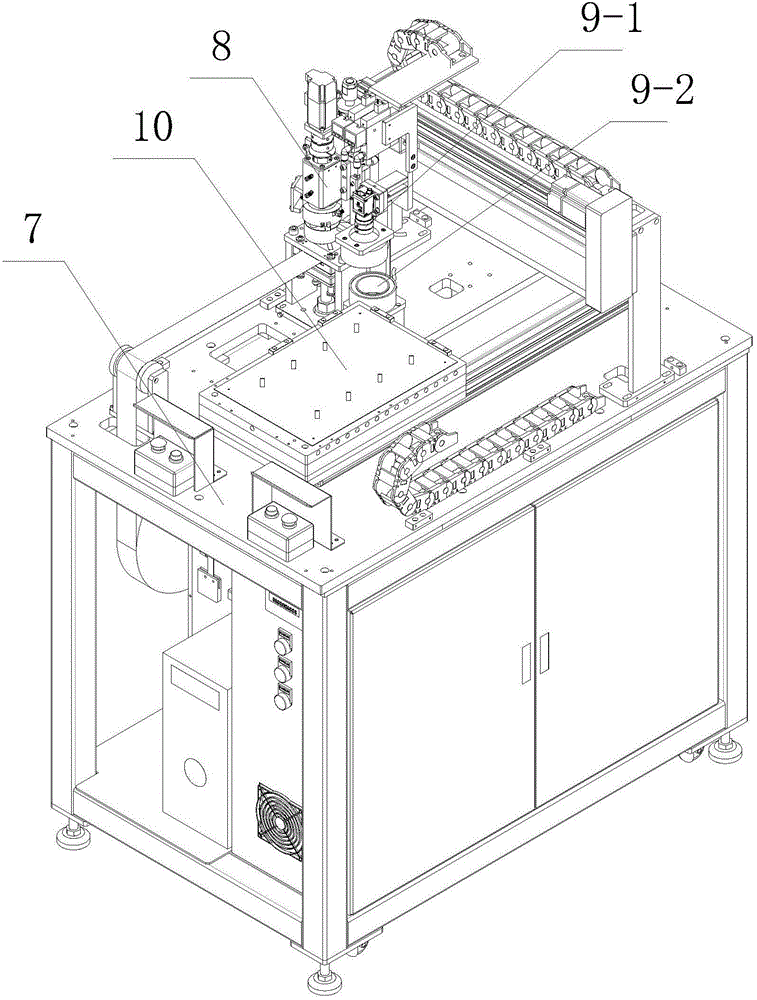

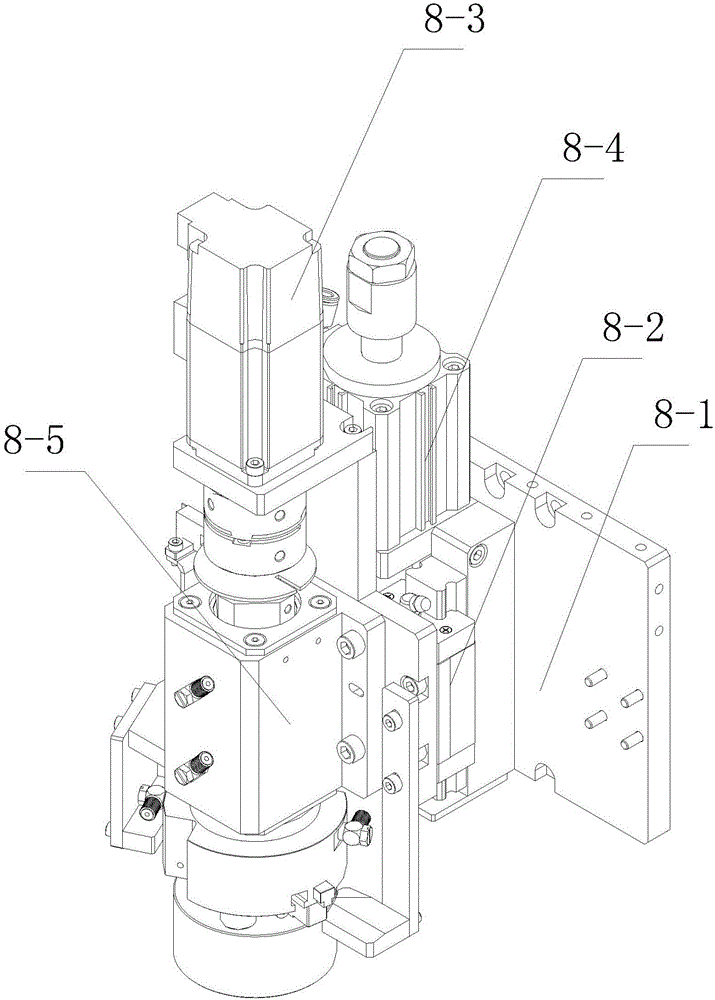

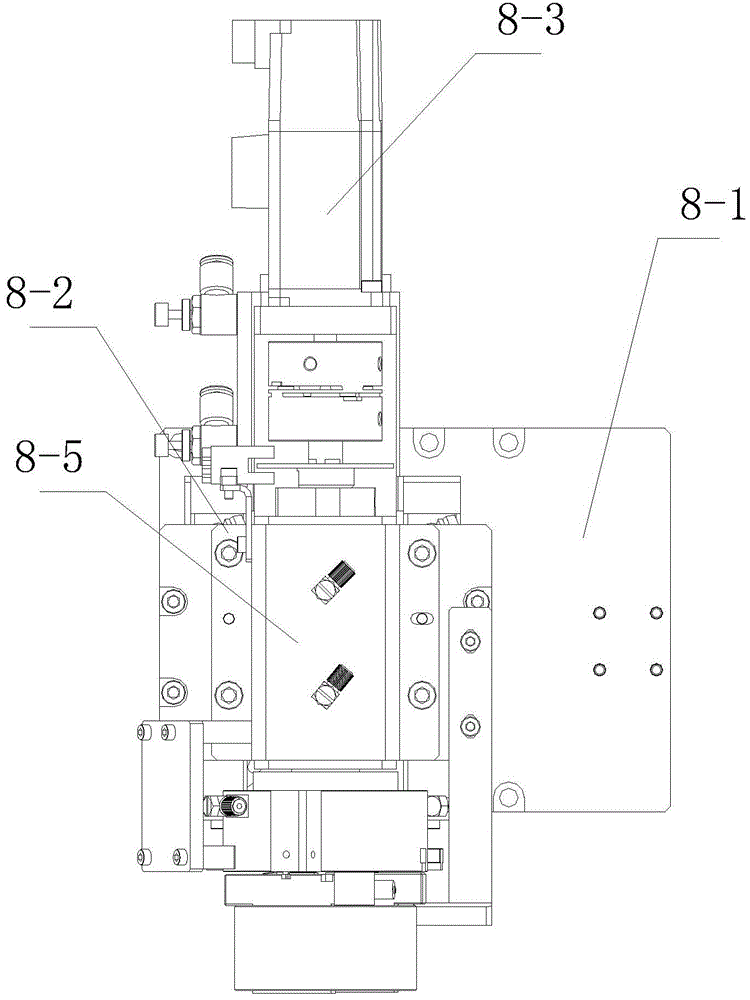

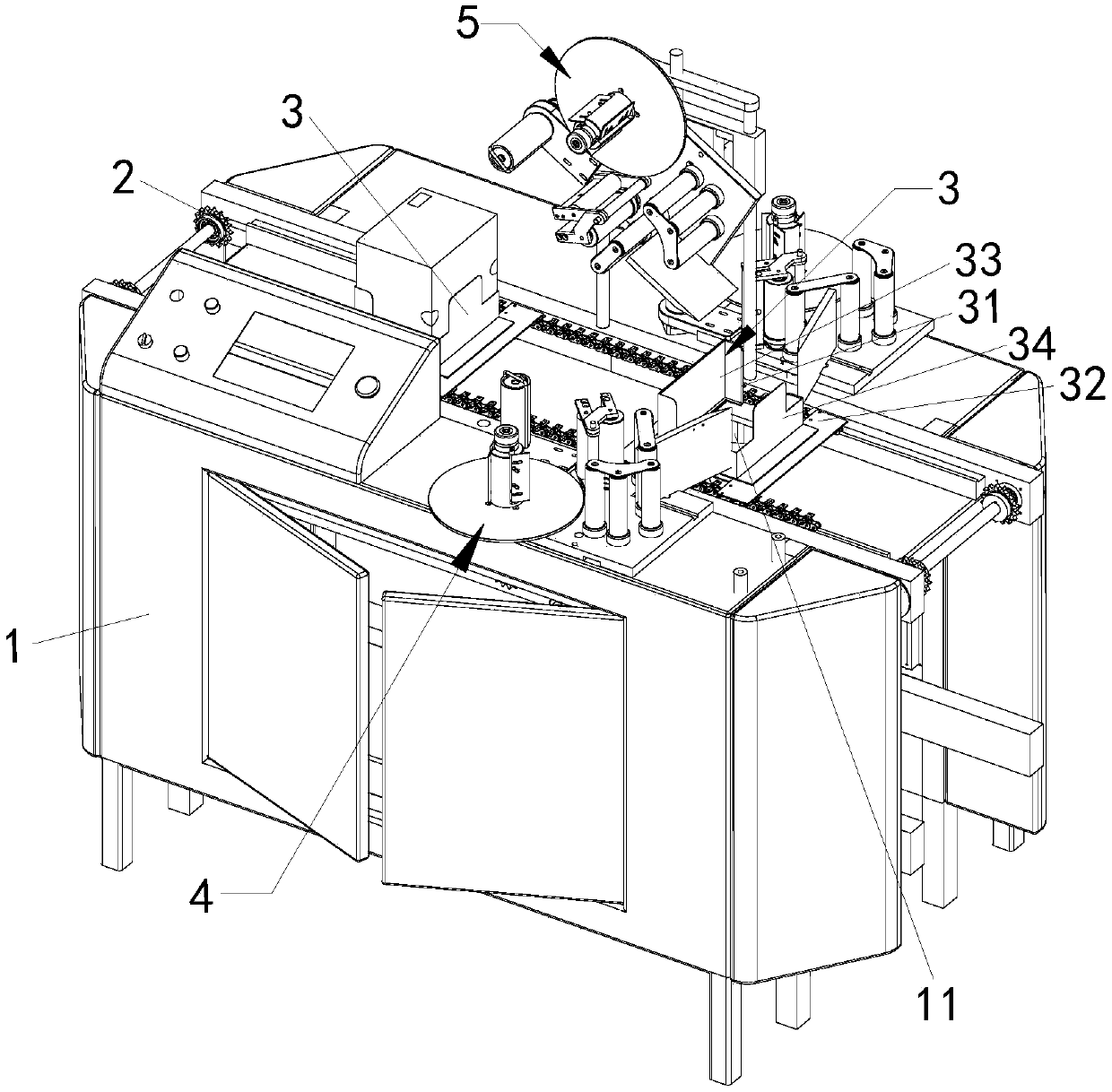

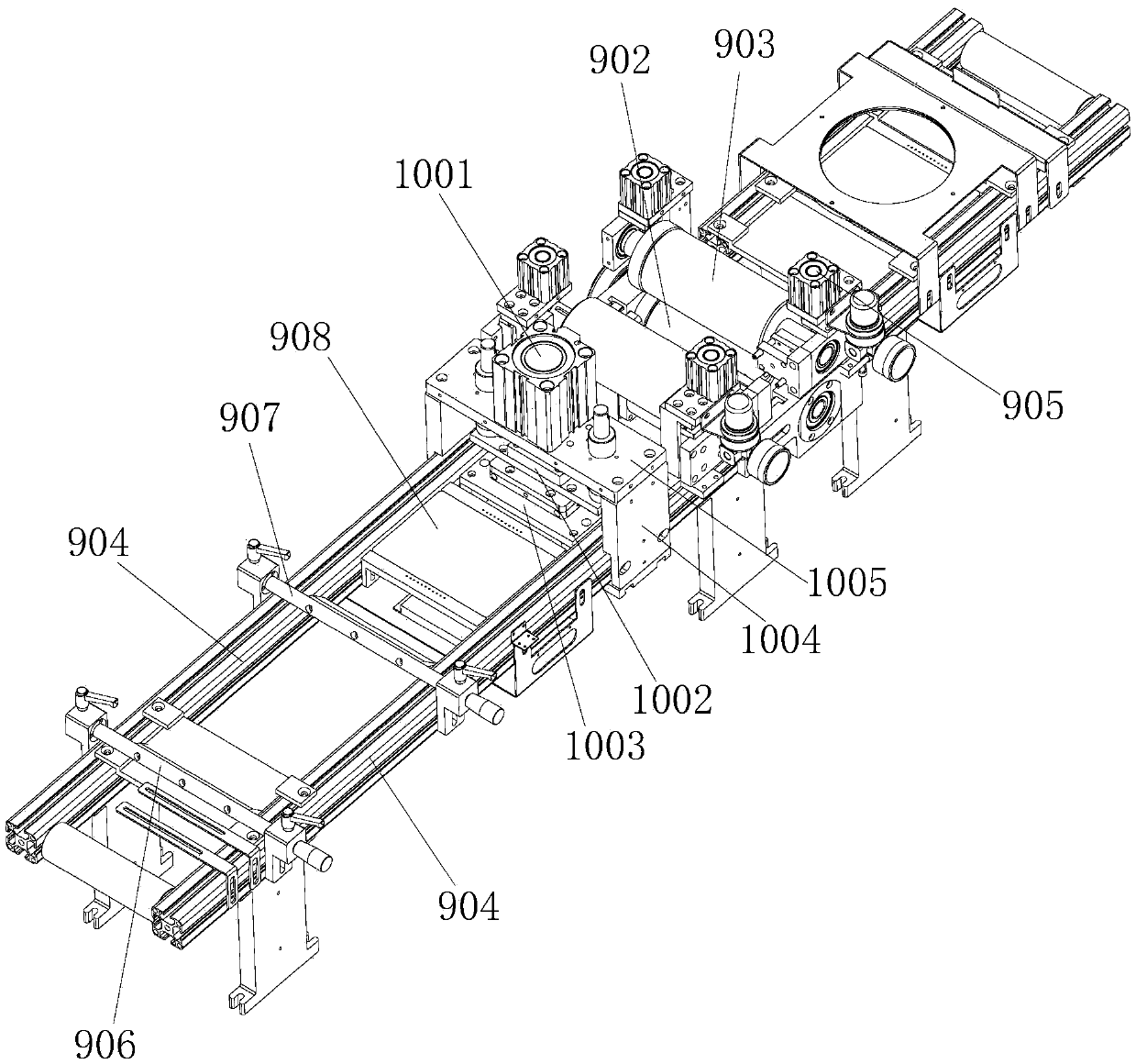

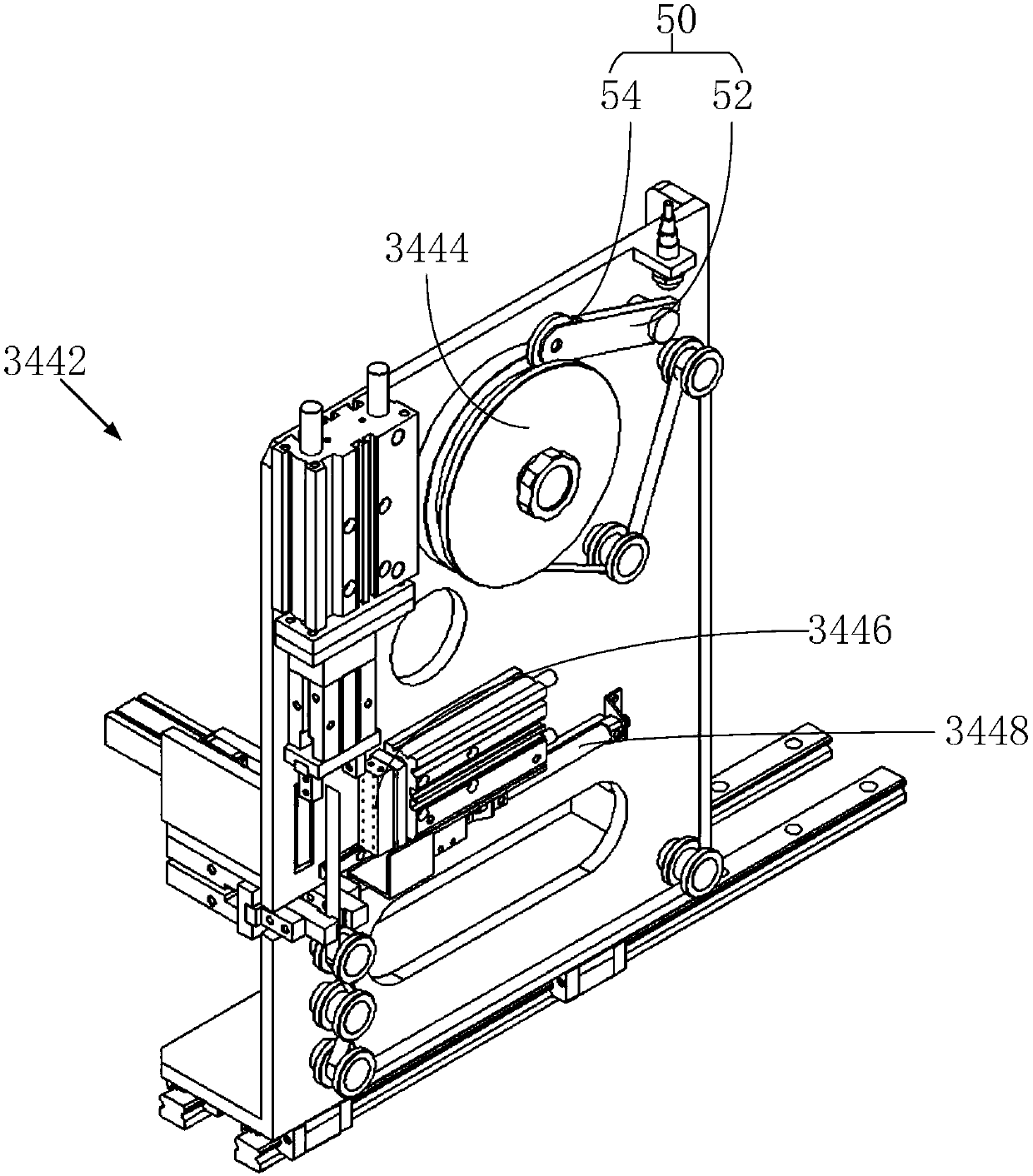

Reinforcing plate high-accuracy intelligent attachment system and attachment method thereof

ActiveCN104576489AAdjustable placement angleAvoid liftingSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingControl systemImage detection

The invention provides a reinforcing plate high-accuracy intelligent attachment system. The system comprises a support platform which is provided with an adsorption assembly platform, a reinforcing plate taking-out device connected with a control system, upper and lower CCD image detection systems and a carrying servo system, wherein the carrying servo system comprises a Y-direction carrying servo system for driving the adsorption assembly platform to move in the Y direction and an X-direction carrying servo system for driving the reinforcing plate taking-out device and the upper CCD image detection system to simultaneously move on the adsorption assembly platform in the X direction, a vertical cylinder capable of driving the reinforcing plate taking-out device to move in the Z direction and a servo motor rotating in the Z direction are arranged on the reinforcing plate taking-out device, and the lower CCD image detection system is fixed to the support platform. Meanwhile, the invention provides an attachment method of the system. Due to the attachment system and the attachment method of the system, reinforcing plates can be automatically punched, automatic feeding is achieved, fast and accurate attachment is achieved, attachment efficiency is high, stability is good, and precision is high.

Owner:DALIAN YUN MING AUTOMATION TECH

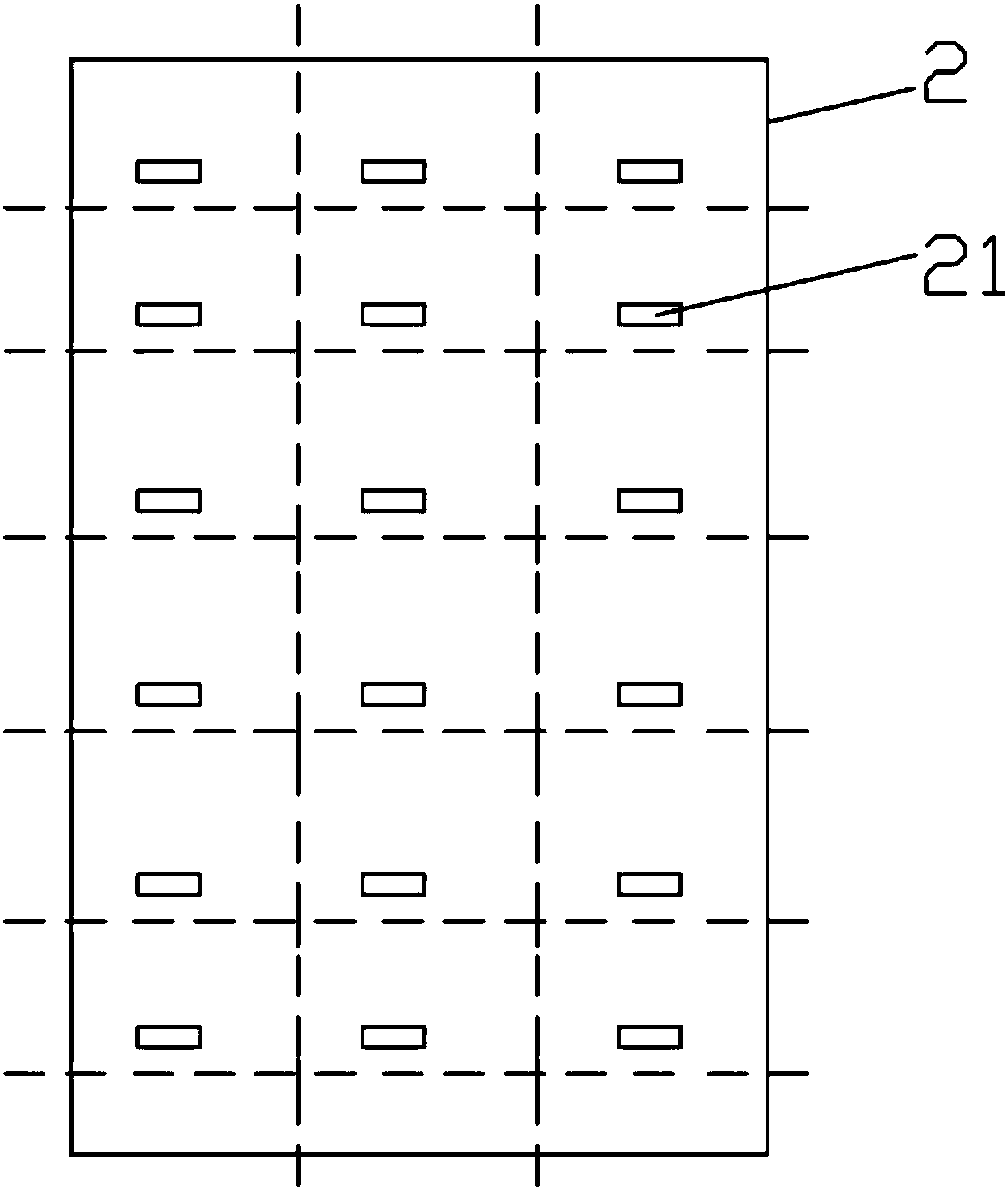

Substrate protective film and preparation method thereof, substrate and preparation method of display panels

InactiveCN108172126AAvoid wrinklesAvoid problemsSynthetic resin layered productsElectrical equipmentTectorial membraneEngineering

Owner:BOE TECH GRP CO LTD +1

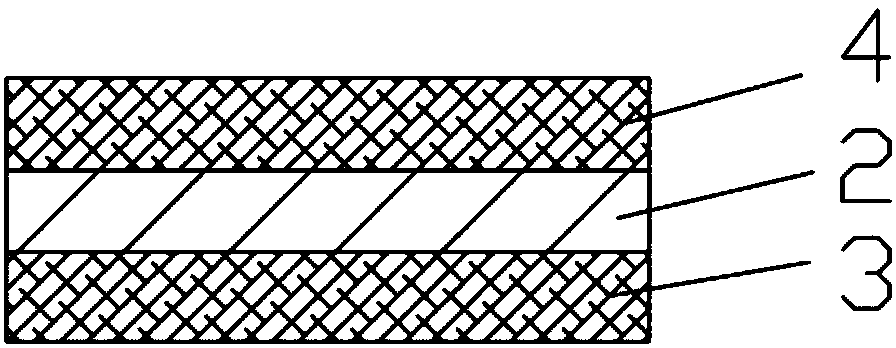

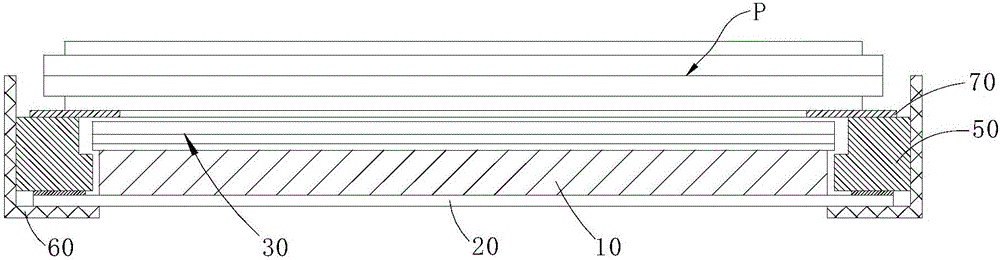

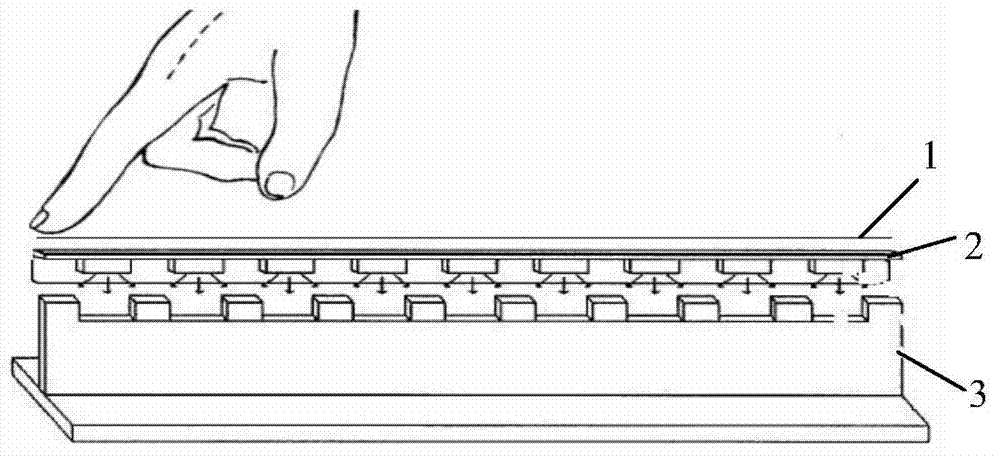

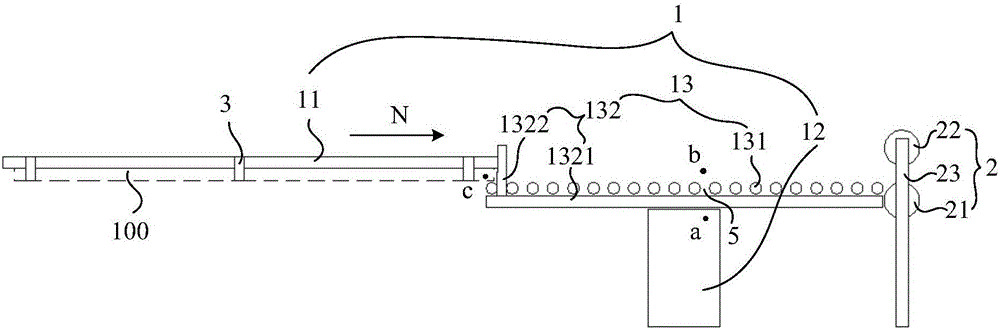

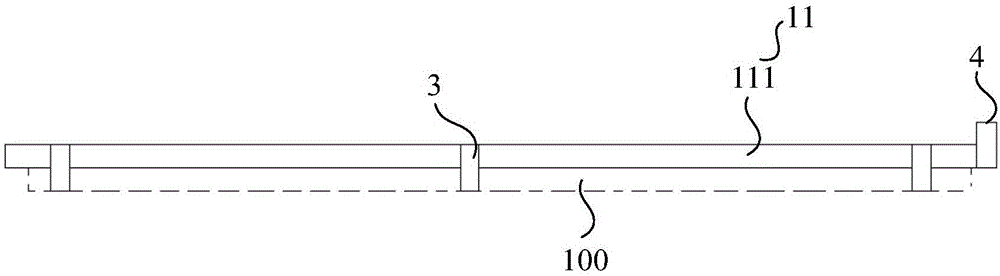

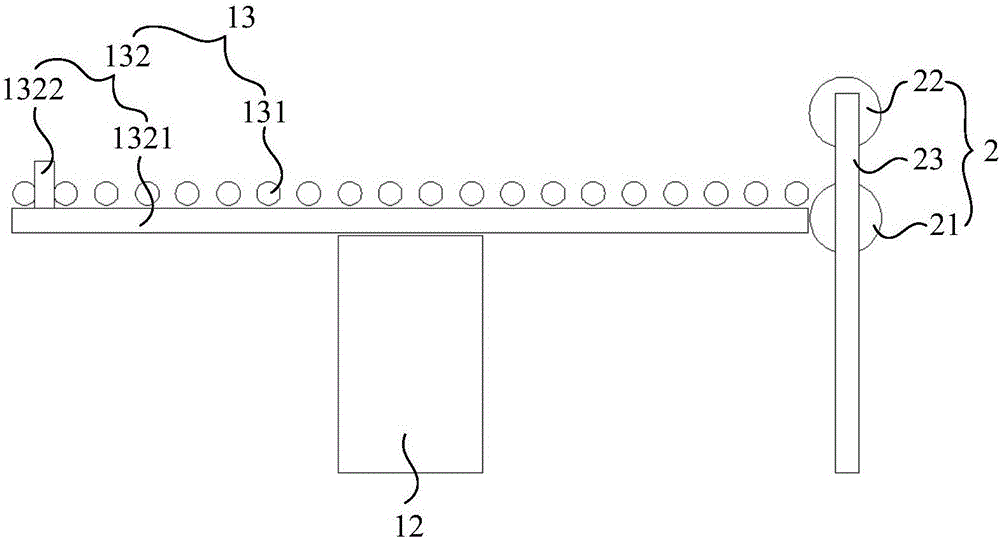

Backlight module and adhesive tape applying apparatus and adhesive tape applying method

ActiveCN106200122AImprove attachment efficiencyImprove Optical TasteNon-linear opticsLight guideMechanical engineering

The invention discloses a backlight module. The module comprises a light guide plate, a reflective sheet and an optical membrane set which are respectively arranged on the lower surface and the upper surface of the light guide plate. The module further comprises a light source assembly arranged on one end of a light-incident side of the light guide plate, a glue frame, and shading glue attached to the outer side wall of the glue frame and the bottom surface of the reflective sheet.The invention further discloses an adhesive tape applying apparatus and an adhesive tape applying method for the backlight module. Due to the fact that the shading glue is attached to the outer side wall of the glue frame and the bottom surface of the reflective sheet, light leakage between the two is avoided so that optical taste of the backlight module is increased. When the shading glue is used for attaching, a boss is clamped on the inner wall of the glue frame and close to a carrying table of the reflective sheet. After the glue frame is extruded on the reflective sheet, the shading glue is attached to the outer side wall of the glue frame through motion of an adhesive tape attaching block. Therefore, attaching efficiency of the shading glue is effectively improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

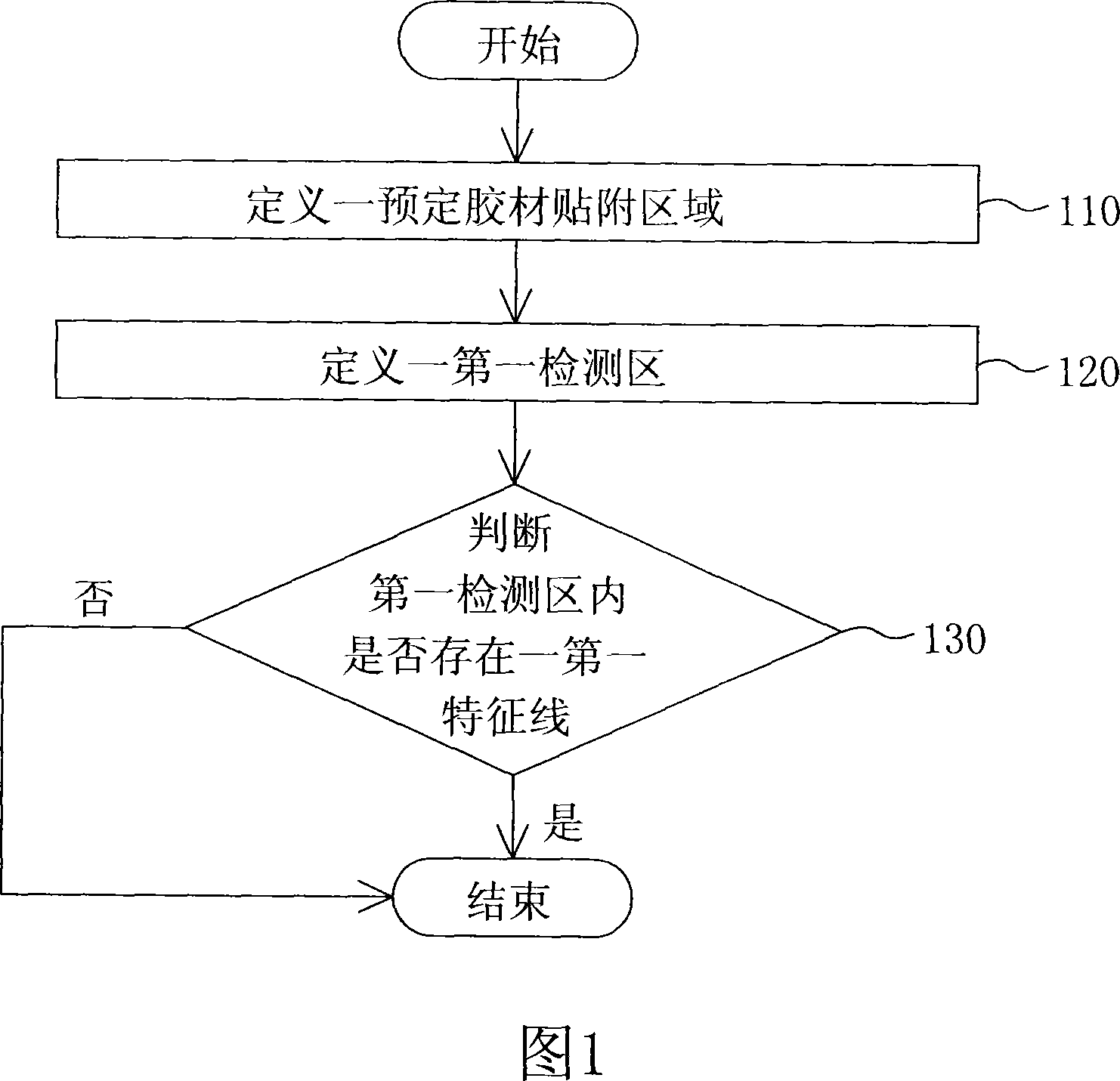

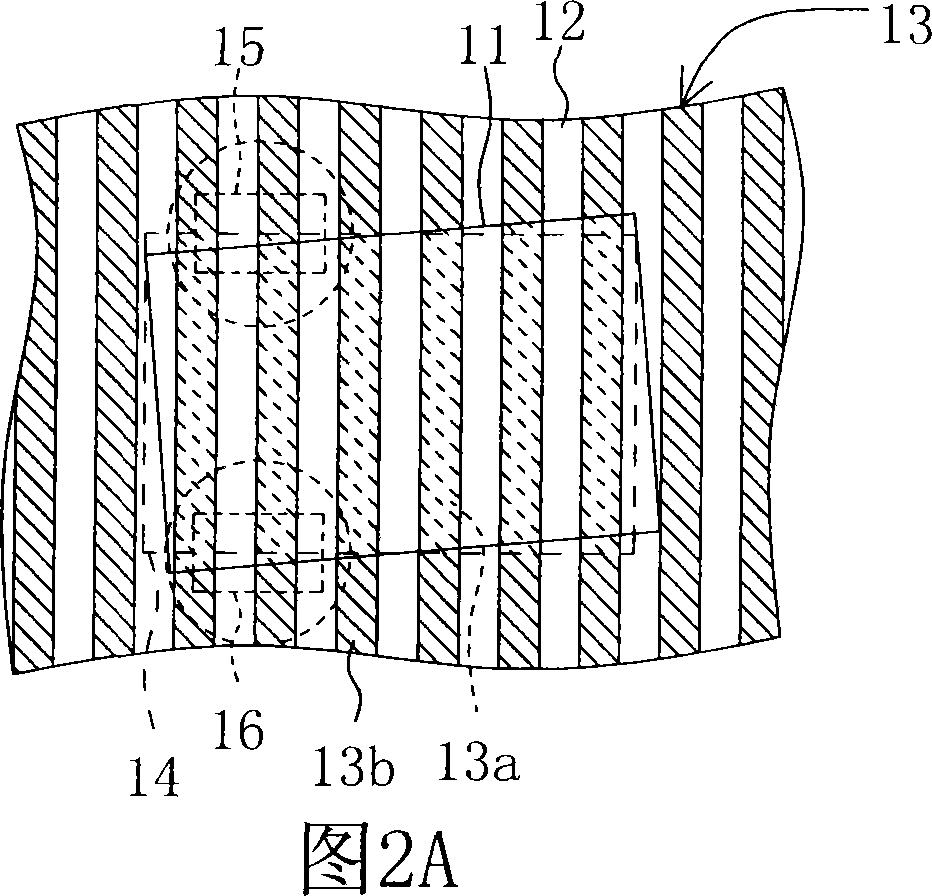

Detecting method of rubber material and detecting device

InactiveCN101034068AImprove accuracyAvoid misjudgmentSemiconductor/solid-state device testing/measurementOptically investigating flaws/contaminationRubber materialEngineering

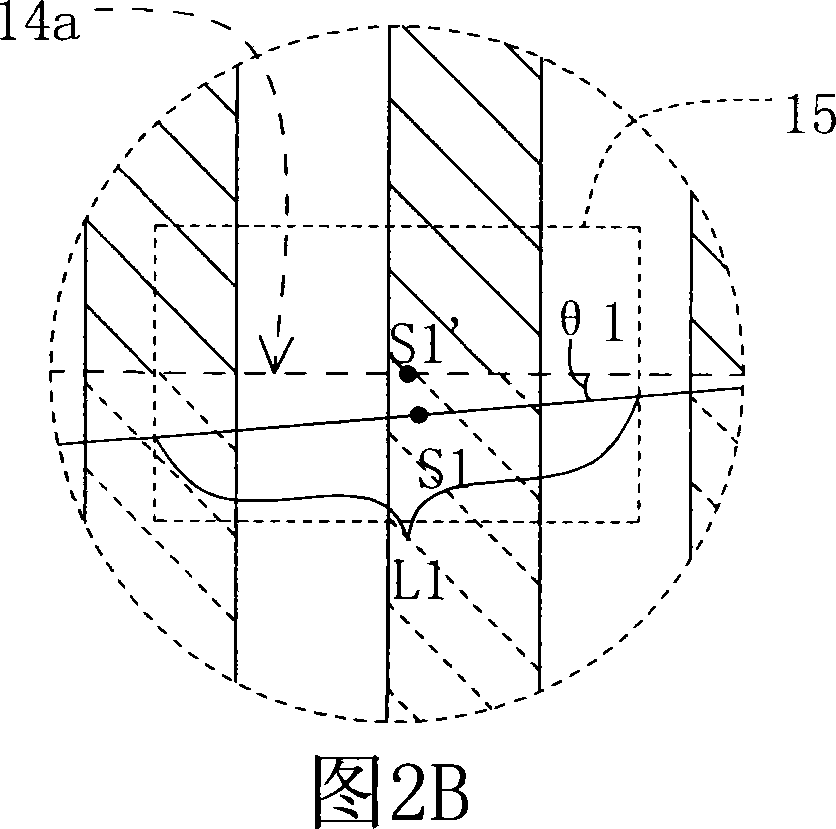

This invention disclose a glue material test method and detection device, used for detecting sticking status of one glue material attaching on one surface; This surface set multiterm electric conduction line. On this electric conduction line, sticking glue material place correspond first grey scale value, whereas not sticking glue material place correspond second grey scale value. Test method includes following steps: first, prearrange a glue material sticking region on this surface, this region possess a fist verge; secondly, define a first detection area on this surface, which cover segmental first verge; then detect multi- first detection point's grey scale value within first detection area, and base on first and second grey scale value to judge whether within first detection area present first typical line that represent glue material has stocked. This invention can by midpoint of first typical line and midpoint of second typical line to judge glue material's sticking width whether abnormity, also can by first offset and second offset to judge glue material's sticking excursion status whether abnormity.

Owner:AU OPTRONICS CORP

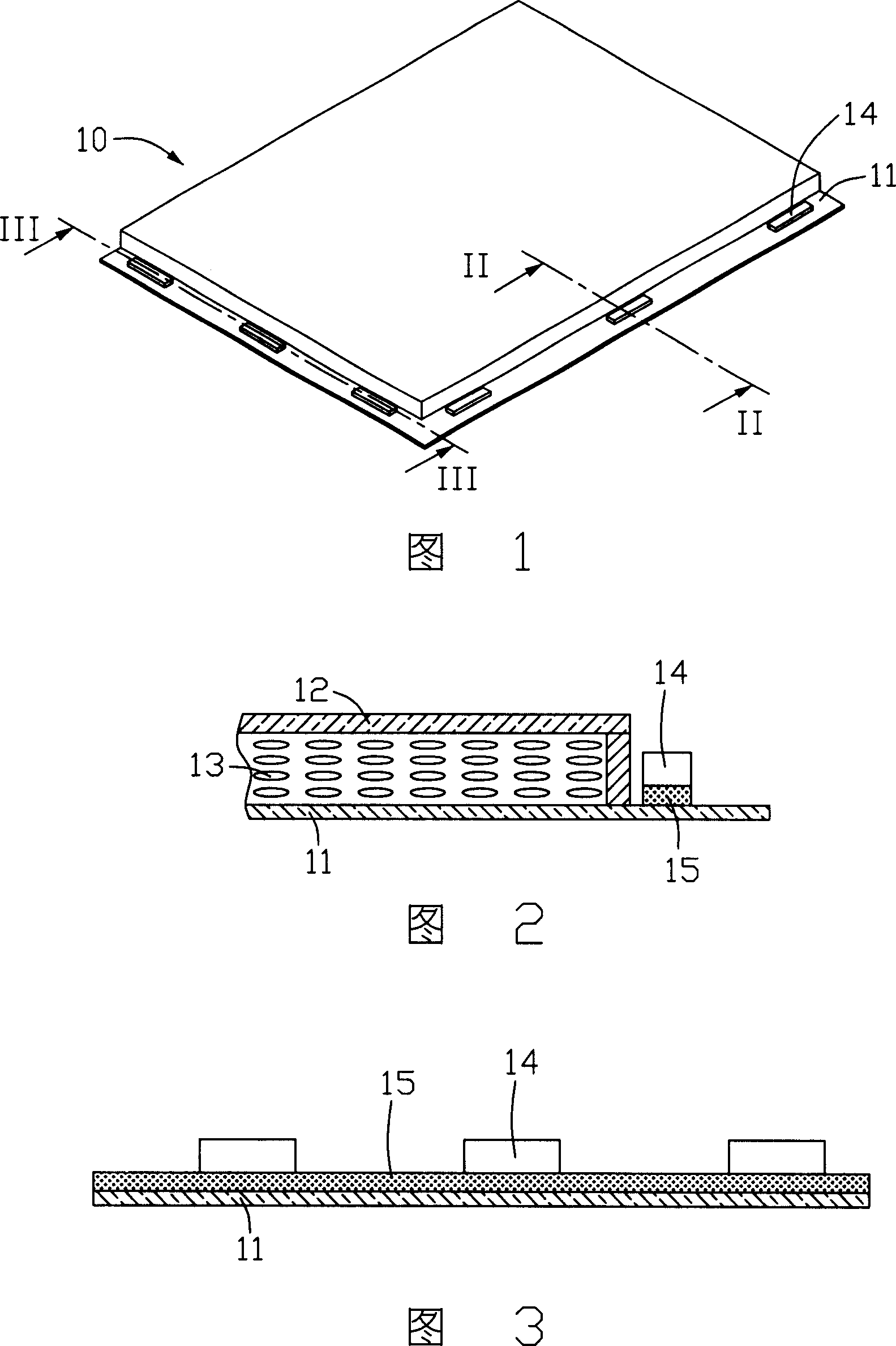

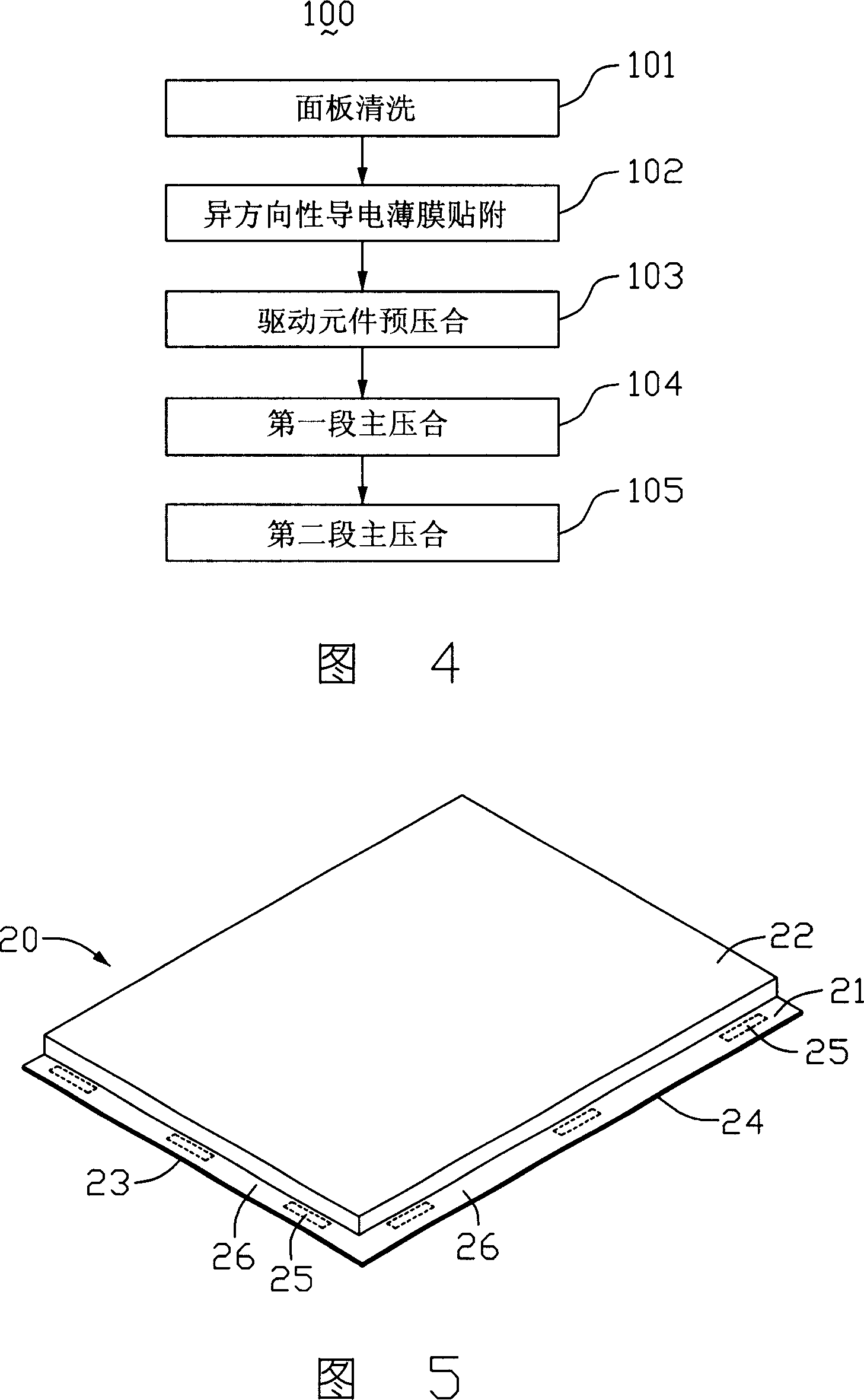

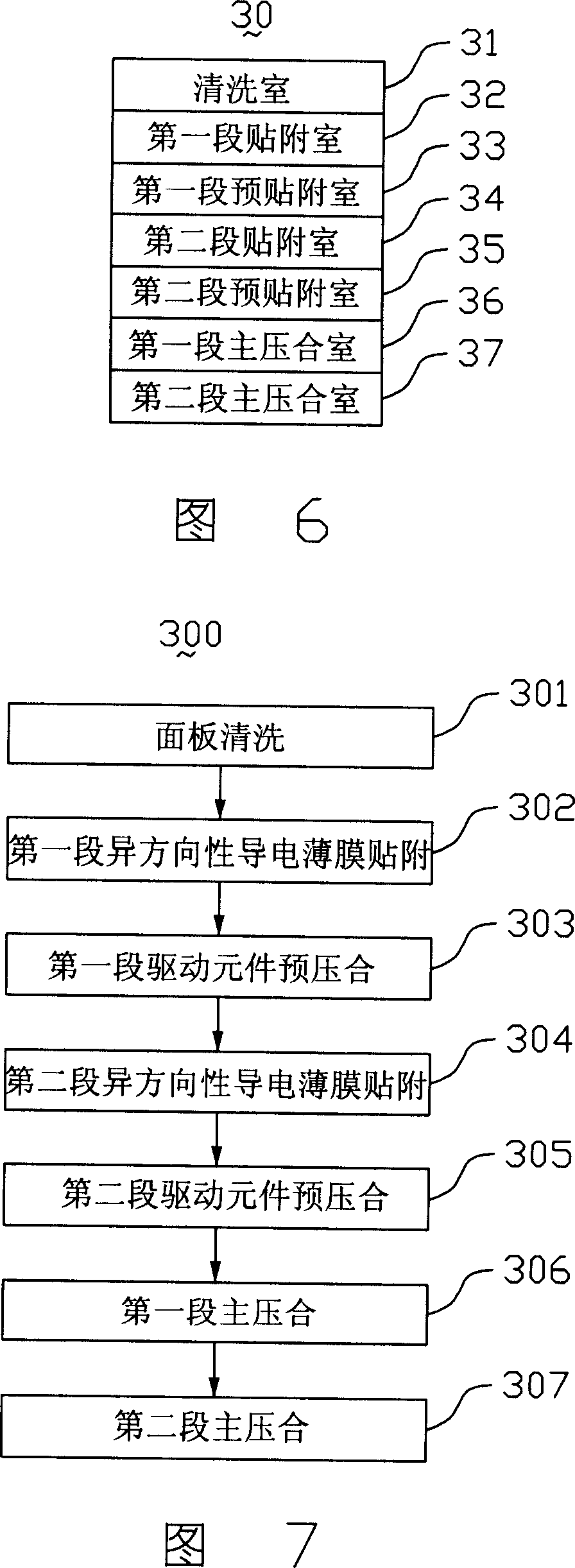

Method and apparatus for adhering driving component

ActiveCN1982996AReduce usageDoes not affect bond strengthStatic indicating devicesNon-linear opticsLiquid-crystal displayDriven element

A method for sticking the driving elements includes providing liquid crystal display face plate with base plate having two ends both being set with sticking region (SR) including connection region, cleaning said SR, sticking heteroscedasticity conduction film at the first end SR and the second end SR of said base plate separately, setting a driving element at the first end connection region and the second end connection region separately then pre-pressing these driving elements, carrying out master pressing on said driving elements at two said ends for making them be connected with said base plate.

Owner:INNOCOM TECH SHENZHEN +1

Engine and power transmission device

InactiveUS8230761B2MiniaturizationImprove attachment efficiencyCoolant flow controlGearingCrankshaftPower transmission

An engine includes a crankshaft which is disposed in a substantially horizontal direction, a first power transmission device, an input shaft, a first output shaft, a second power transmission device, and a power transmission case. The input shaft is disposed below the crankshaft in parallel with the crankshaft, and the input shaft receives a power from the crankshaft through the first power transmission device. The first output shaft supplies the power from the input shaft, and the first output shaft is disposed perpendicular to the crankshaft. The second power transmission device transmits the power of the input shaft to the first output shaft. The power transmission case accommodates the input shaft, the first output shaft, and the second power transmission device therein.

Owner:YANMAR CO LTD

Adhesive tape attaching device

ActiveCN103939861APrevent disengagementExcellent adhesionPoint-like light sourceLight fasteningsEngineeringMechanical engineering

The invention provides an adhesive tape attaching device used for attaching adhesive tape to a workpiece. The adhesive tape attaching device comprises a fixing mechanism and a first pressing-attaching part, wherein the fixing mechanism is used for fixing the workpiece, and the first pressing-attaching part can move in the attaching direction of the adhesive tape relative to the fixing mechanism so as to attach the adhesive tape to the workpiece. The adhesive tape attaching device can improve bonding strength between the adhesive tape and the workpiece and smoothness of the adhesive tape, improves the attaching effect of the adhesive tape and meanwhile improves attaching efficiency of the adhesive tape.

Owner:HEFEI BOE DISPLAY LIGHT +1

Turnover device

A turnover device is used for performing surface mounting on products. The turnover device comprises a frame and at least two turnover portions; the turnover portions are arranged on the frame in turn; every turnover portion comprises at least one composite surface; the composite surfaces of the adjacent turnover portions are attached to each other in a turnover mode. According to the turnover device which is used for performing the surface mounting on the products, one layer or multi-layer attachment can be rapidly achieved through turnover match of the turnover portions and accordingly the attachment quality is improved and the working efficiency is increased.

Owner:YIHE PRECISION IND SUZHOU

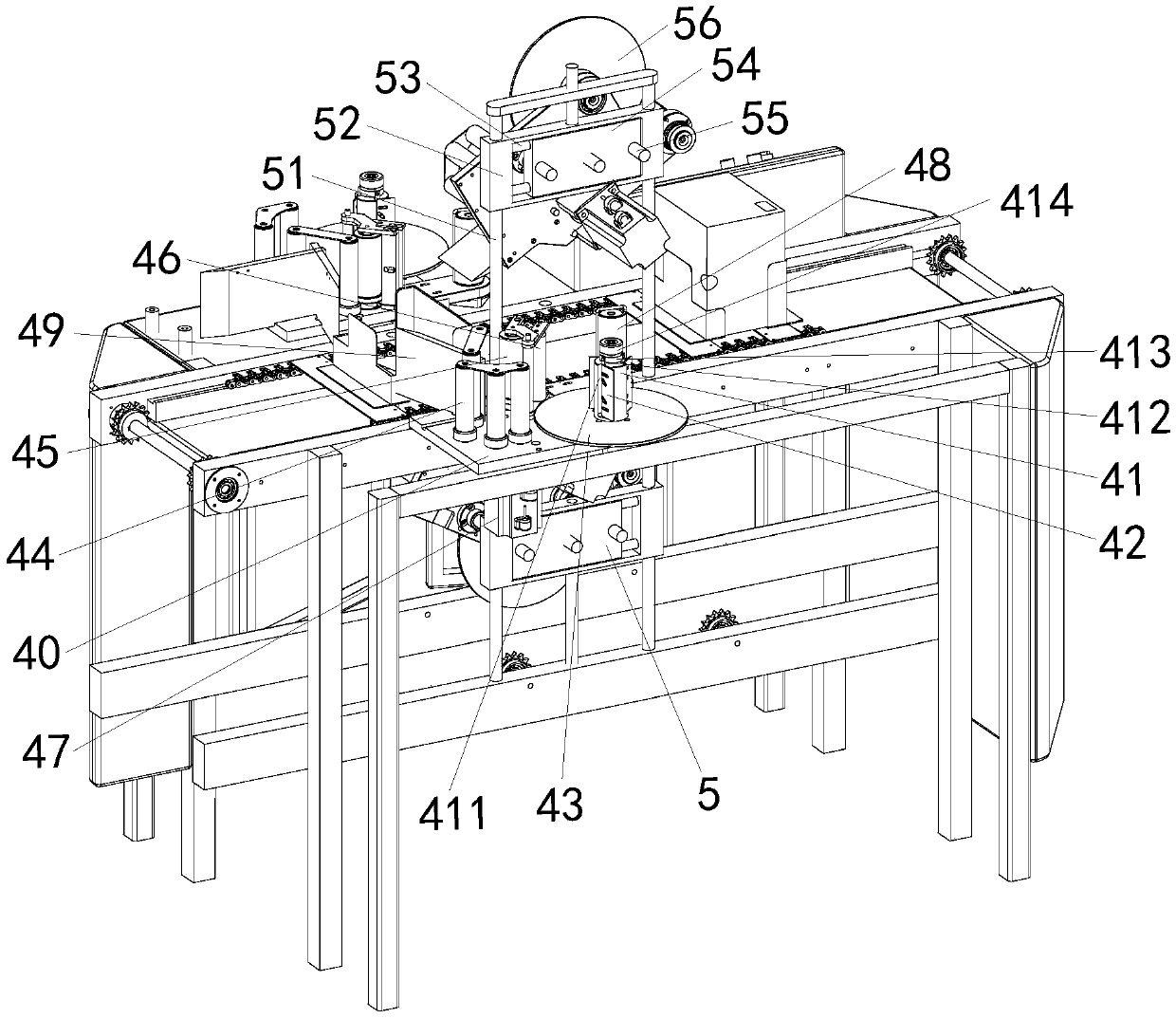

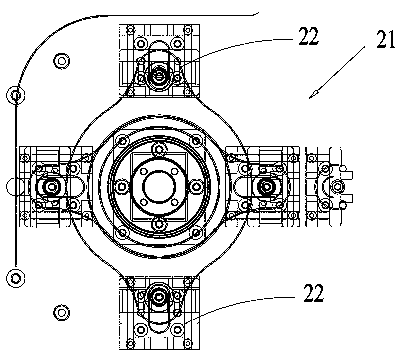

Four-surface automatic labeling equipment

PendingCN109665170ALabeling position is accurateAccurate locationLabelling machinesLabelling short rigid containersEngineeringAutonomation

Owner:SUZHOU UNIV OF SCI & TECH

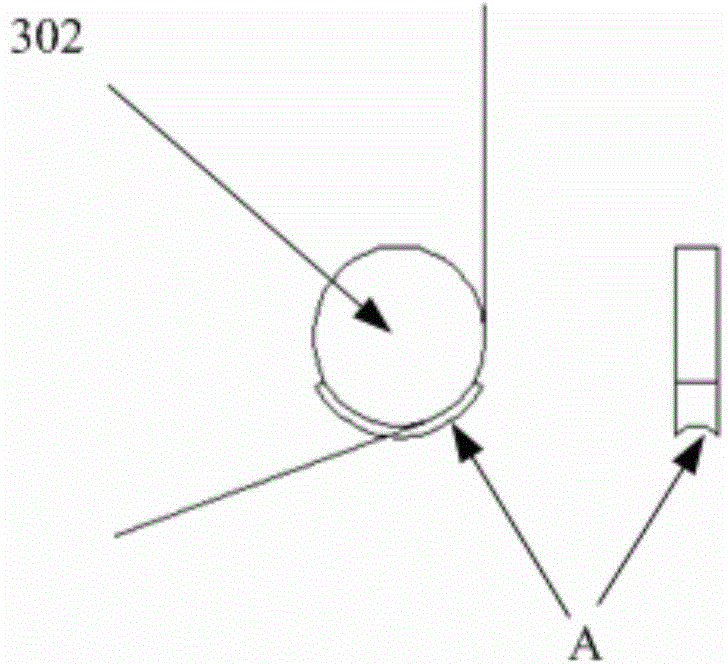

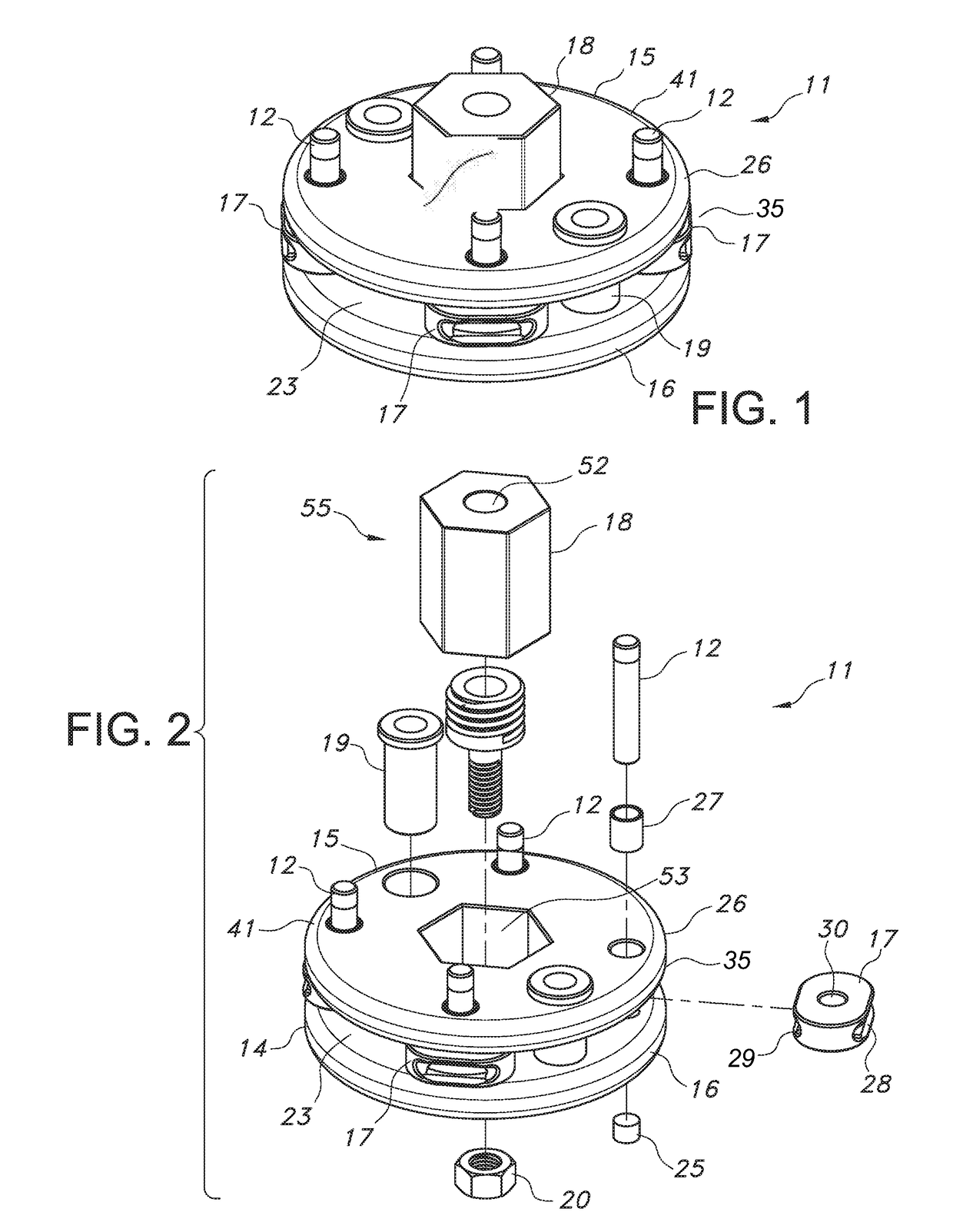

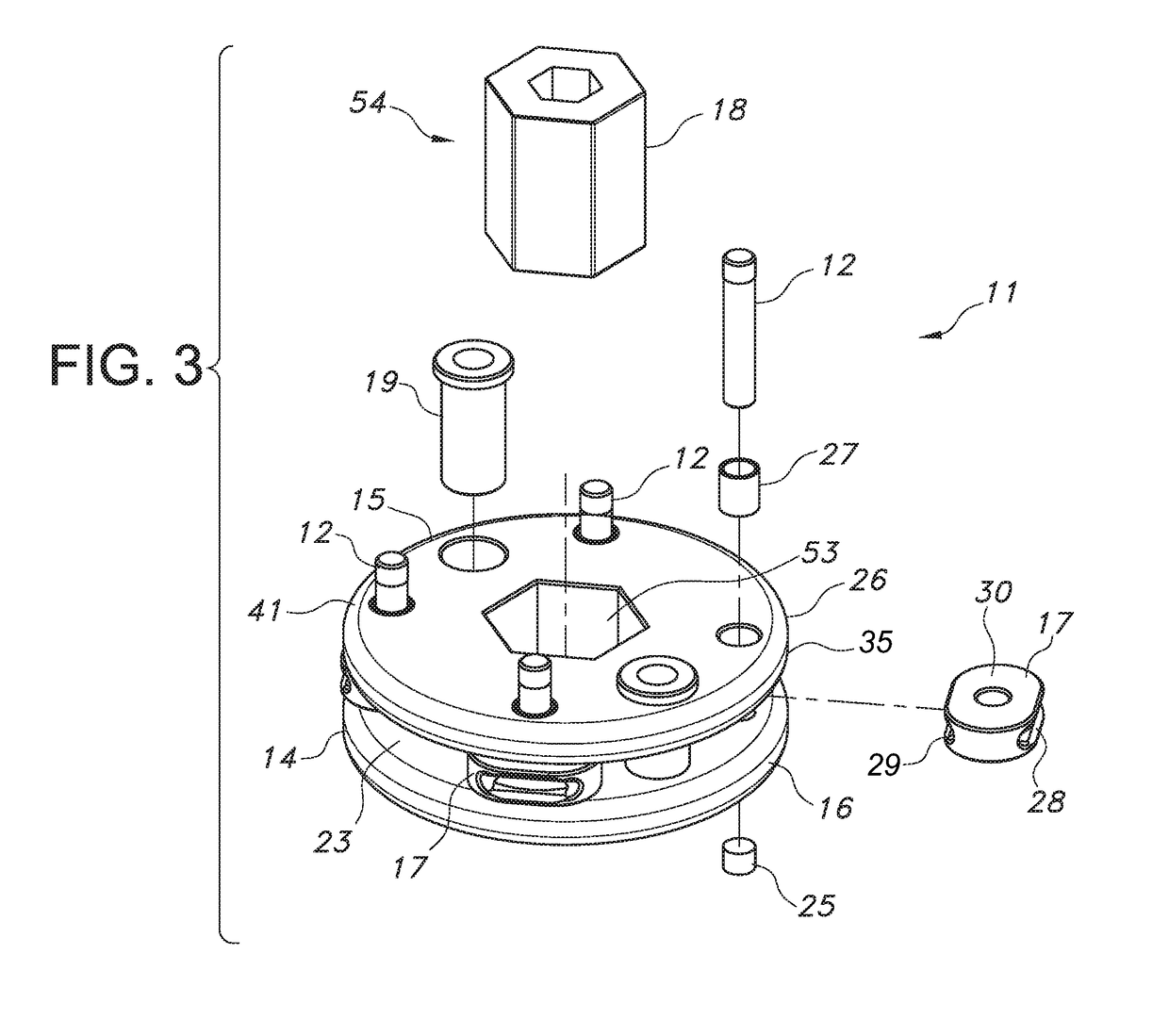

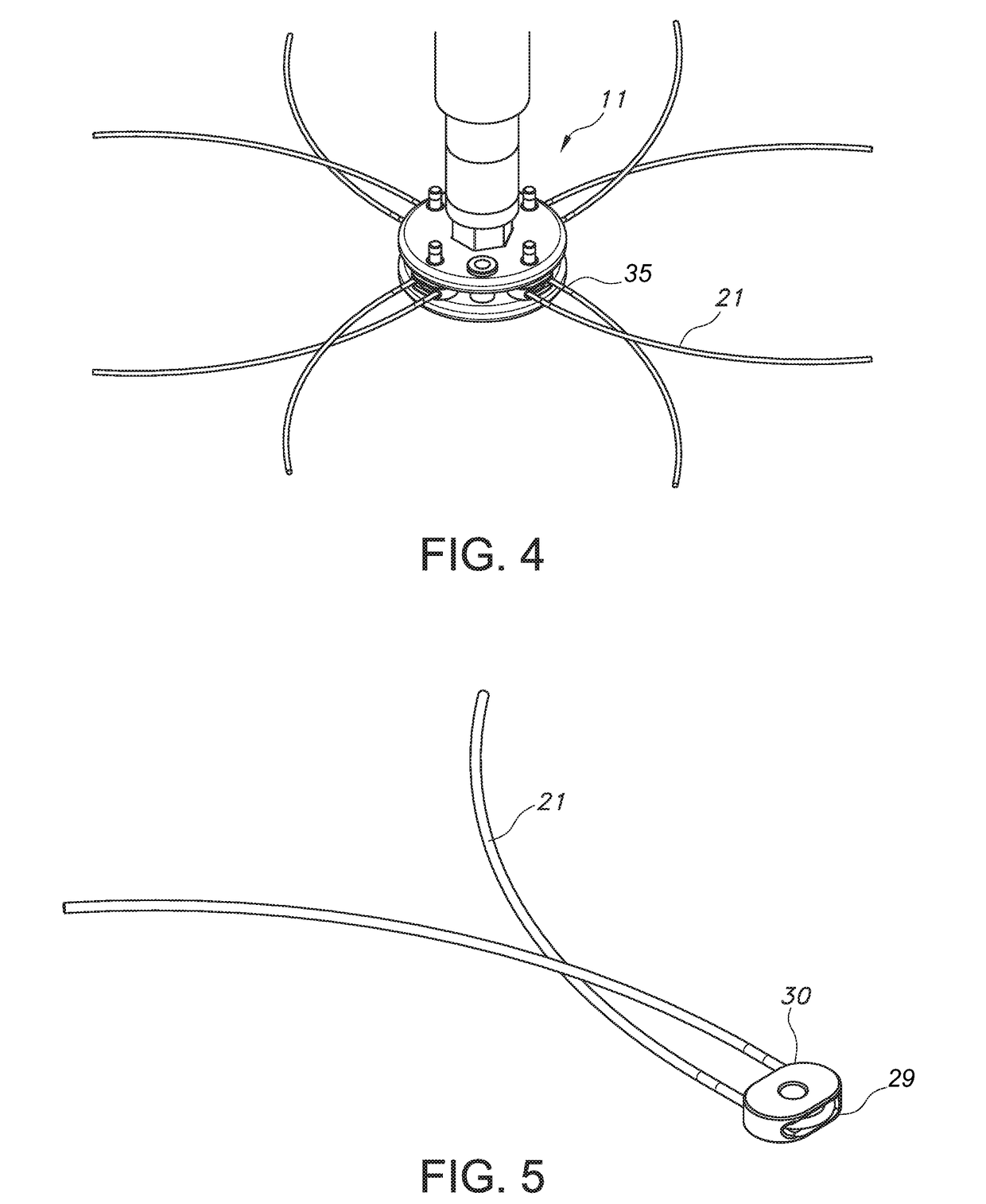

Trimmer head system

InactiveUS20180368315A1Quickly and efficiently interchangedImprove attachment efficiencyManure treatmentMowersOff the shelfEngineering

A method and device for increased efficiency of attachment of traditional accessories at the perimeter of a standard trimmer head via improved attachment means comprising a trimmer head having an upper portion and a lower portion, a cutting medium, and attachment means. The system further comprising an adapter plate for attaching custom accessories and commercially available, off the shelf rotary accessories at the center of the trimmer head, thus increasing the functionality of the trimmer head.

Owner:MULTICRAFT VENTURES LLC

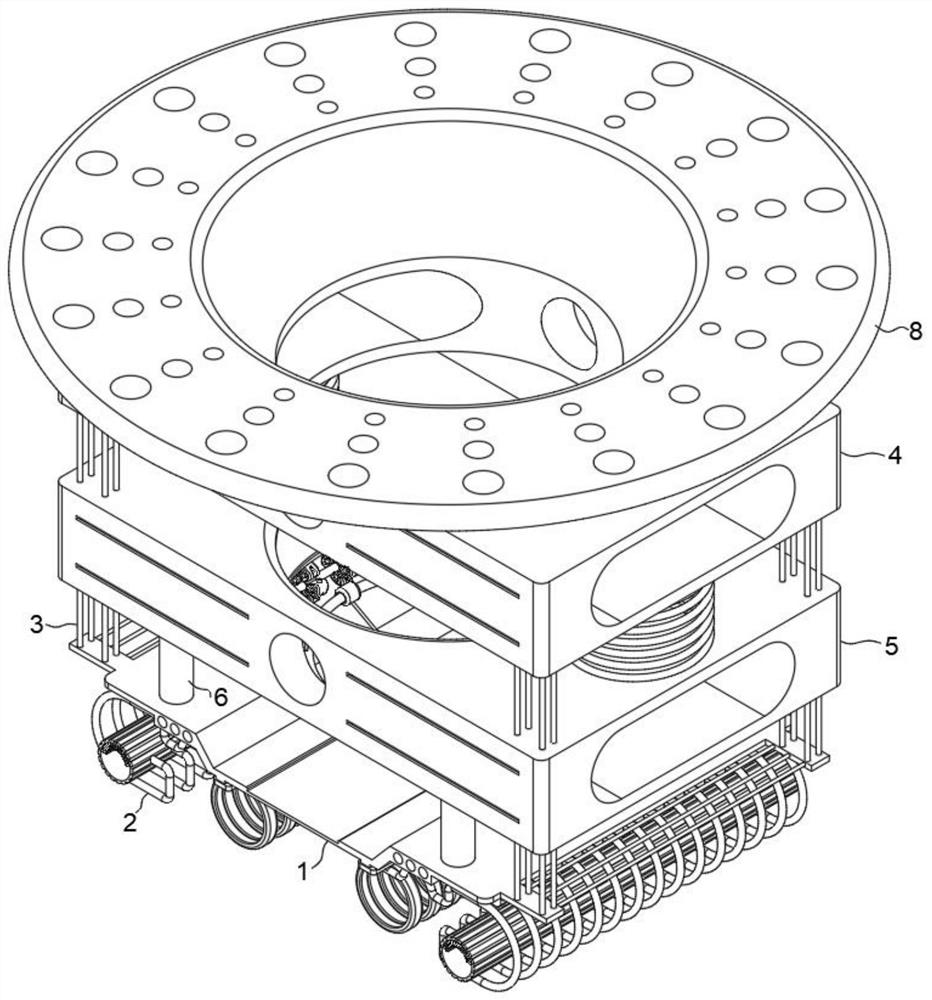

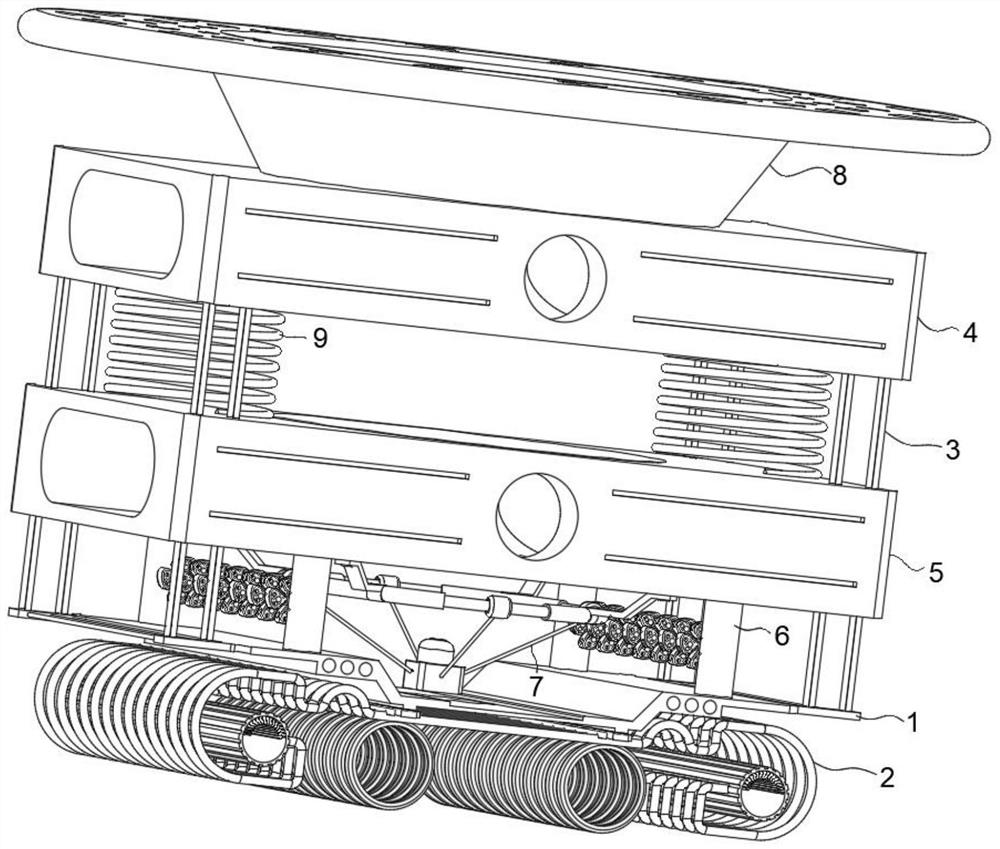

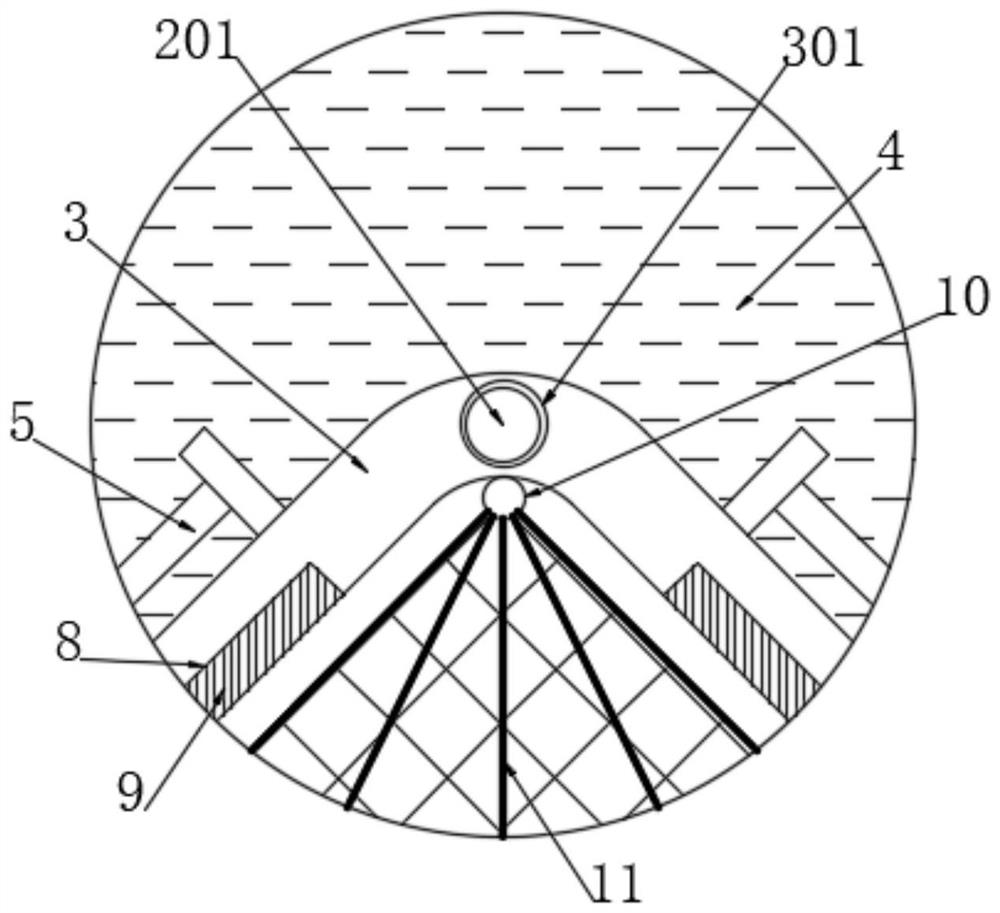

Settlement type artificial fish reef structure

ActiveCN112715447ASpeed up the flowReduce shockClimate change adaptationPisciculture and aquariaJuvenile fishMarine engineering

The invention provides a settlement type artificial fish reef structure. The settlement type artificial fish reef structure comprises a cement fish reef base plate and damping pieces, wherein the cement fish reef base plate is erected on a supporting assembly, vertically-arranged mounting columns are fixedly mounted on the two sides of the cement fish reef base plate correspondingly, and a first fish sheltering piece and a second fish sheltering piece which are distributed up and down are mounted on the mounting columns; and the first fish sheltering piece and the second fish sheltering piece are the same in specification, and the damping pieces used for reducing swing of the gravity center of the cement fish shelter base plate are mounted on the second fish sheltering piece. According to the settlement type artificial fish reef structure, water flow can flow smoothly, the problem of flow choking in a seabed local water area is solved, a cement block in the fish sheltering piece is provided with criss-cross through holes and through cavities, the fluidity of the whole water flow is extremely good, besides, the shielding performance of the fish reef structure is guaranteed, the gathering effect of juvenile fishes is extremely good, and an adult fish habitat field, a fish spawning field and a juvenile fish protection breeding field are created.

Owner:ZHEJIANG OCEAN UNIV

Cermet powder

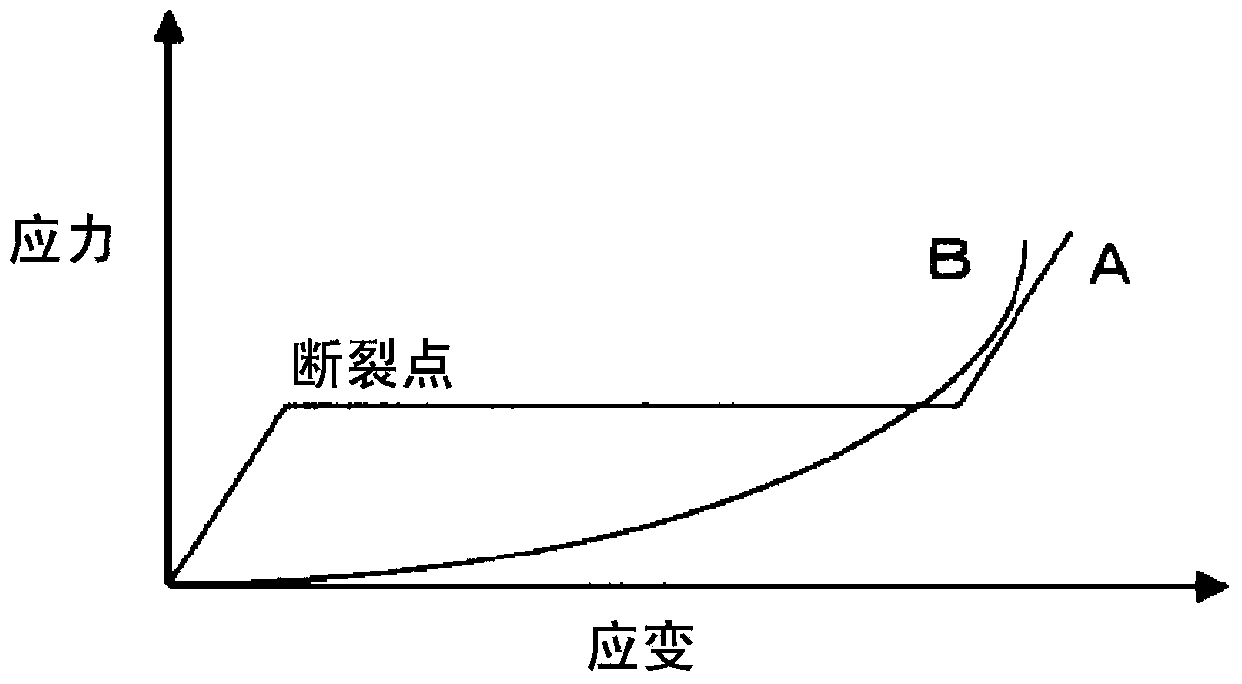

ActiveCN104321458AImprove attachment efficiencyMolten spray coatingThin material handlingComposite pelletCermet

A powder comprising ceramic-metal composite particles, characterized in that at least some of the composite particles do not exhibit any fracture point in a stress-strain diagram obtained by applying a compressive load to the particles up to a maximum value of 10mN or more at a loading rate of 15.0mN / s or less.

Owner:FUJIMI INCORPORATED

Novel graphite electrode manufacturing technology, and manufacturing equipment thereof

InactiveCN110054495AImprove antioxidant capacityReduce oxidative weight lossStable stateMaterials preparation

The invention discloses novel graphite electrode manufacturing technology, and manufacturing equipment thereof. The novel graphite electrode manufacturing technology comprises steps of 1, material preparation; 2, calcining; 3, grinding; 4, stirring; 5, rolling; 6, primary filtering tank immersion; 7, roasting; 8, moulding; 9, secondary filtering tank immersion; and 10, graphitization. The manufacturing equipment comprises a filtering tank main body; the filtering tank main body is of a box type structure with an upper end opening; locking mechanisms are symmetrically arranged on pair of internal side surfaces of the filtering tank main body, and aeration pipes are symmetrically arranged on the other pair of internal side surfaces of the filtering tank main body. According to the novel graphite electrode manufacturing technology, moulded graphite electrode green compacts are subjected to two times of filtering tank immersion, and the manufacturing equipment is adopted, so that anti-oxidation layers are easily formed on graphite electrode green compact surfaces, contact of graphite electrode surfaces with oxygen in the air is prevented, graphite electrode oxidation resistance is improved, graphite electrode oxidation weight loss is reduced, and graphite electrode stable state is improved further.

Owner:HEFEI CARBON CO LTD

Reflector attaching equipment

ActiveCN103465590AImprove attachment efficiencyHigh precisionLaminationLamination apparatusEngineeringAssembly line

The invention provides reflector attaching equipment comprising an attaching component and an assembly line, wherein the attaching component comprises a correcting component and a manipulator connected with the correcting component, the correcting component comprises a plurality of correcting blocks, an attachment processing zone is defined by the correcting blocks, an optical film is accommodated in the attachment processing zone, and the manipulator is used for attaching a reflector to the optical film; the assembly line is disposed at one side of the attaching component and comprises a plurality of accommodating jigs distributed at intervals, and the accommodating jigs are connected with the attachment processing zone through the manipulator for obtaining the optical film; and the correcting blocks are connected with a driving component, and the driving component drives the correcting blocks to rotate, so as to adjust the size of the attachment processing zone to be equal to the size of the accommodating jigs. The reflector attaching equipment provided by the invention is used for attaching the reflector to the optical film and enables the optical film to be directly conveyed to the accommodating jigs through position adjustment, so that the attaching efficiency, accuracy and stability of the reflector are improved, the output efficiency is improved, and the market prospect is good.

Owner:BOE TECH GRP CO LTD +1

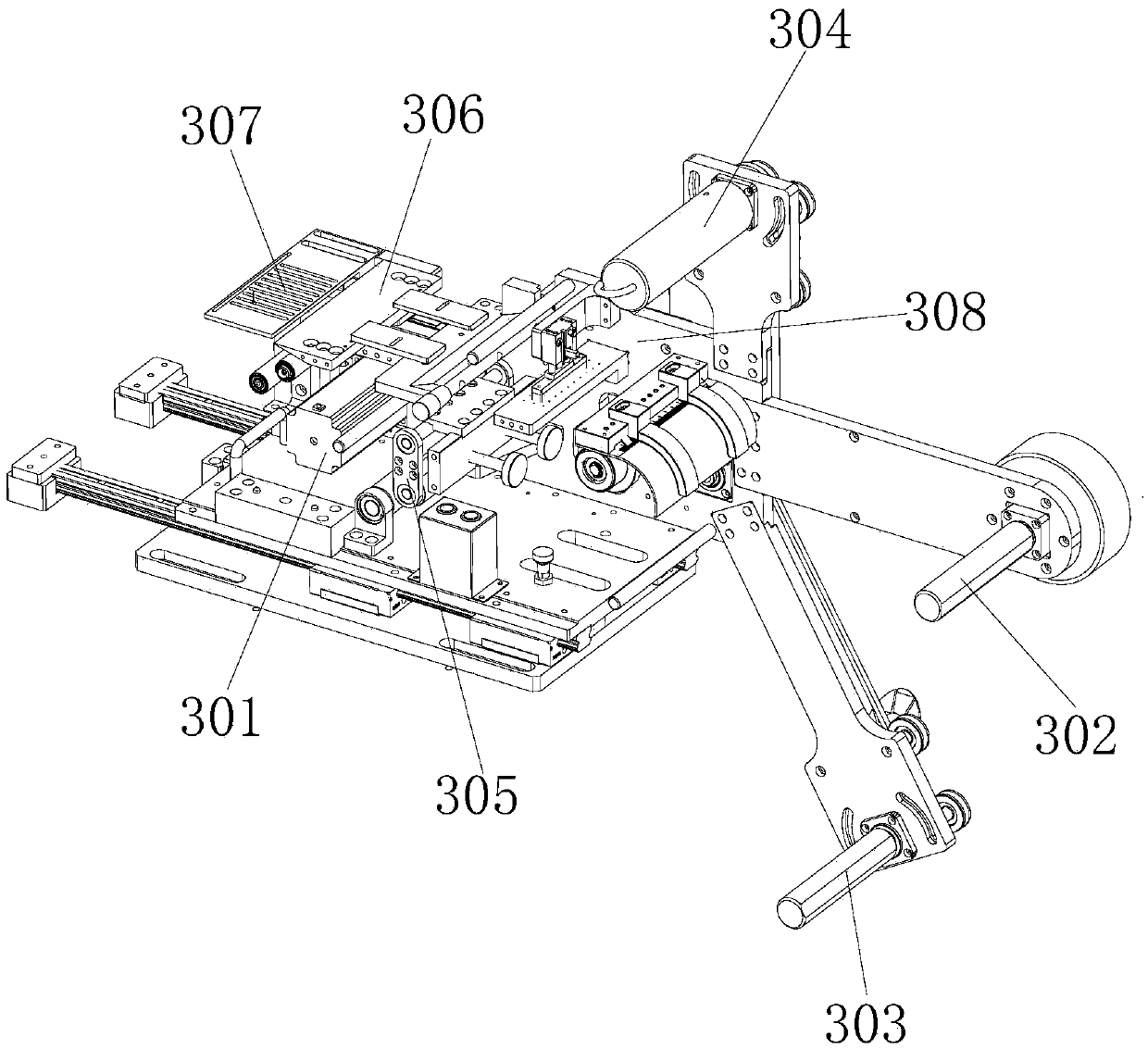

Coiled belt automatic blue film pasting equipment

The invention discloses coiled belt automatic blue film pasting equipment. The coiled belt automatic blue film pasting equipment comprises a working platform, a coiled material feeding module, a double-head linear motor module, a CCD positioning module, a left Z-axis module, a right Z-axis module, a left feeder module, a right feeder module, a material belt conveying module, a pressing module, a CCD detecting module and a coil material receiving module; the coiled material feeding module and the coil material receiving module are located at the two ends of the working platform correspondingly,the material belt conveying module is located on the working platform and arranged between the coiled material feeding module and the coil material receiving module; and the double-head linear motormodule is arranged on the working platform and strides over the front end of the material belt conveying module, the CCD positioning module is fixed to the middle of the double-head linear motor module, and both the left Z-axis module and the right Z-axis module are slidably installed on the double-head linear motor module. The coiled belt automatic blue film pasting equipment has the beneficial effects that automatic pasting, detecting and receiving of blow films are achieved, the working efficiency and the compatibility are high, and the labor intensity of workers is greatly relieved.

Owner:深圳市罗博威视科技有限公司

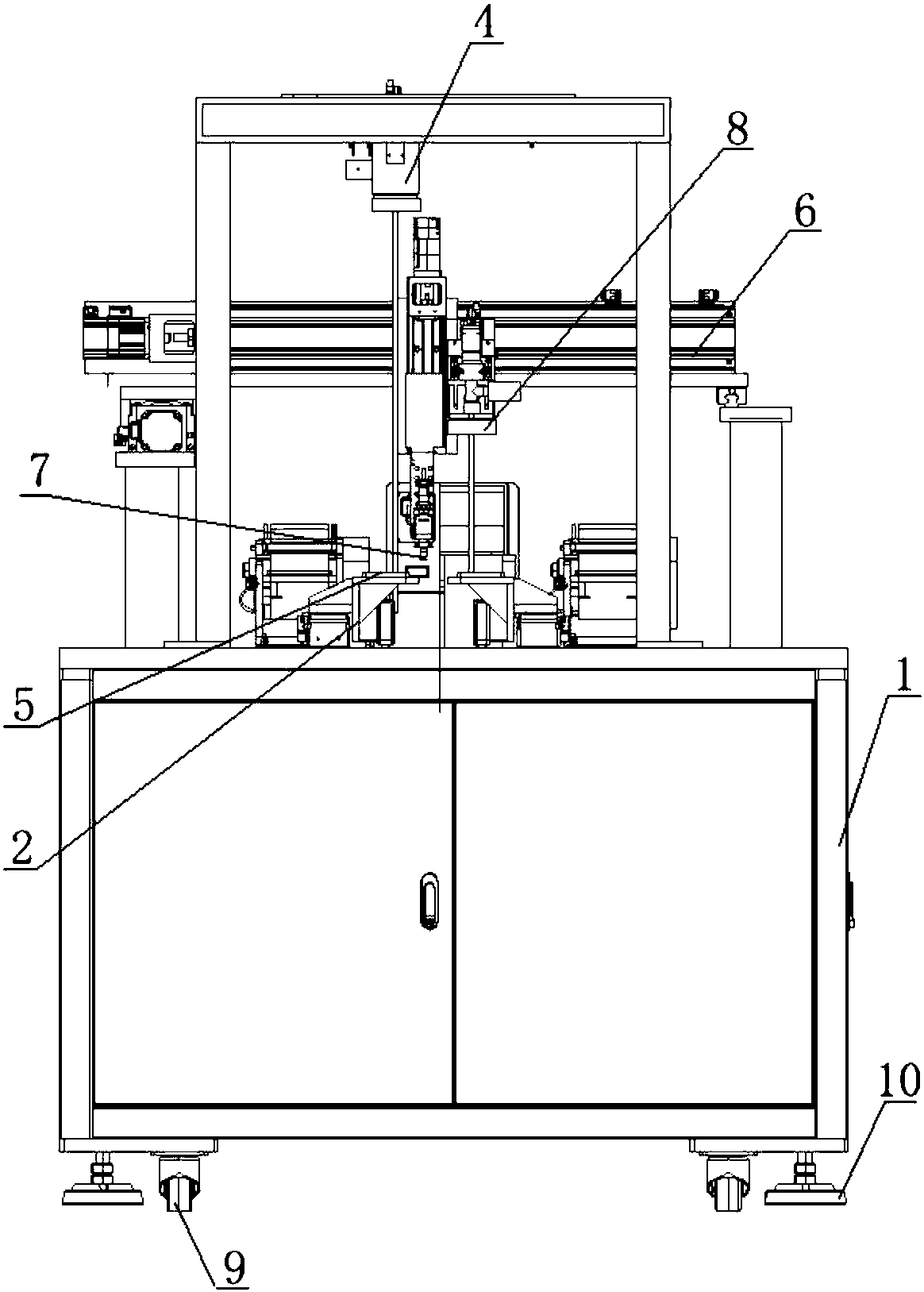

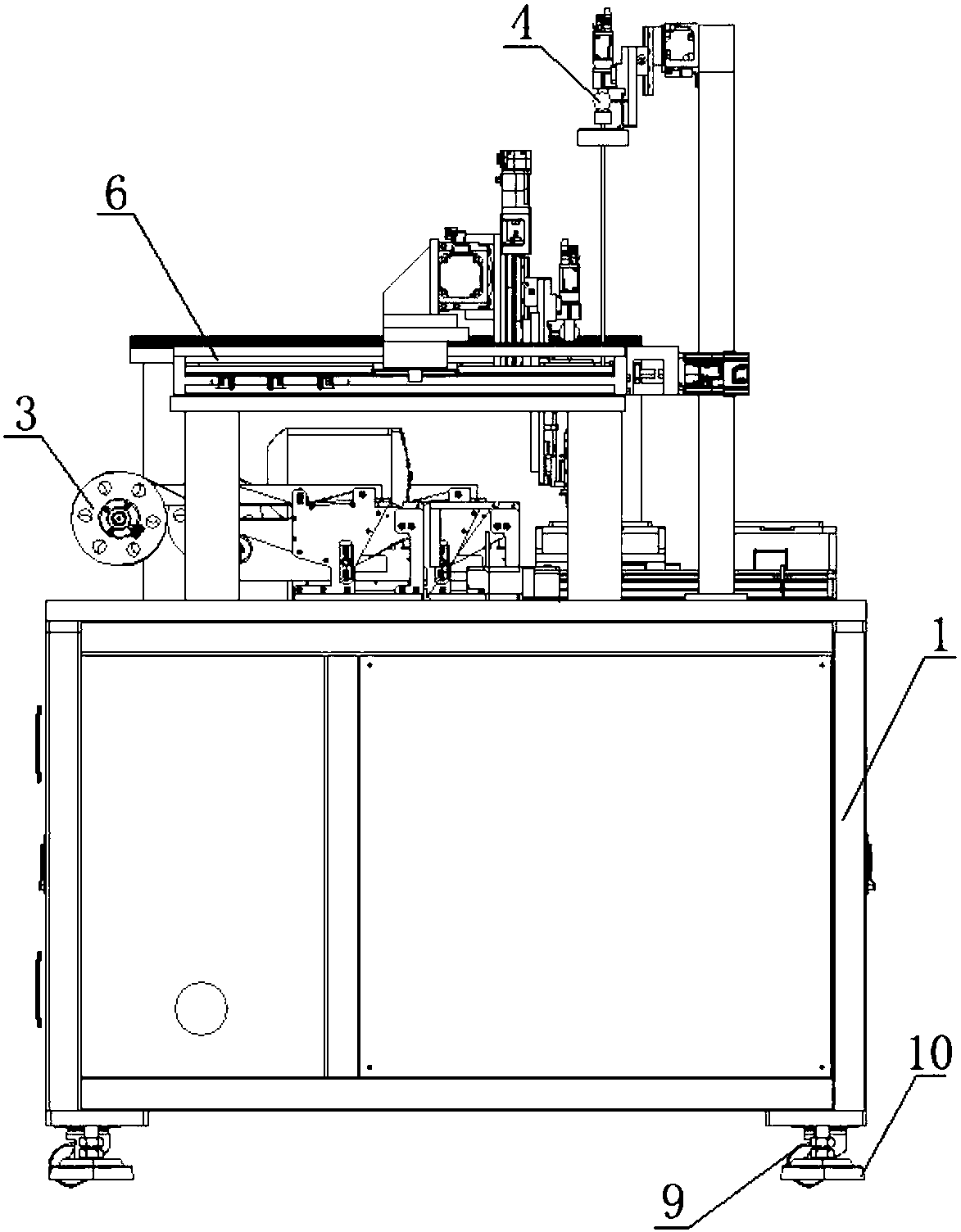

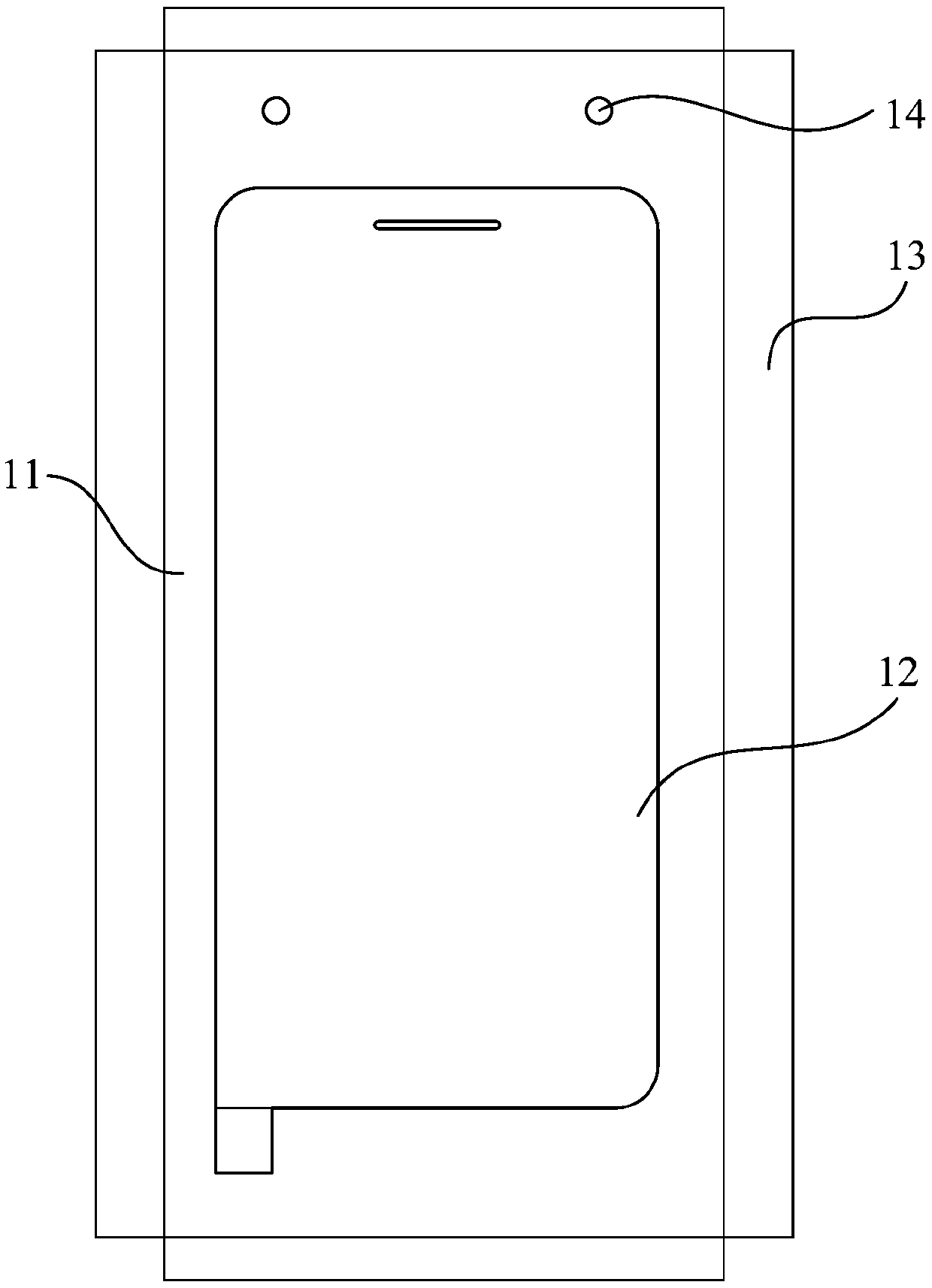

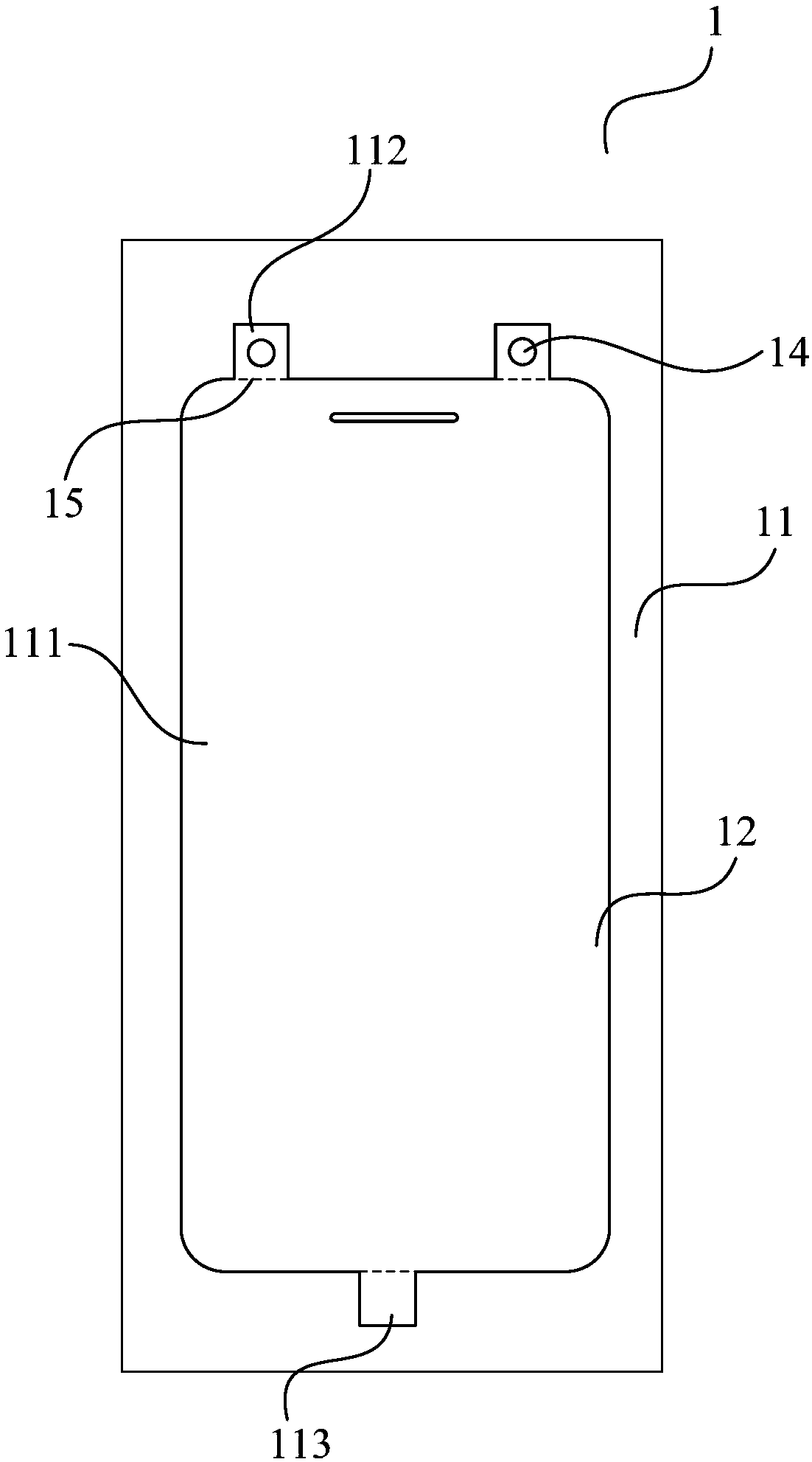

Mobile phone label automatic attaching device

InactiveCN108584056AHigh attachment accuracyImprove attachment efficiencyLabelling machinesDegrees of freedomMechanical engineering

The invention discloses a mobile phone label automatic attaching device, which comprises a working platform, a labeling fixture disposed on the working platform, a labeling module disposed on one sideof the labeling fixture on the working platform, at least one label printing mechanism and a detecting mechanism disposed above the labeling fixture. The labeling fixture is provided with a materialframe for fixing a mobile phone. The labeling module includes a driving mechanism with degree of freedom along the X-axis, the Y-axis and the Z-axis, a label clamping mechanism and a code scanning mechanism arranged at the execution end of the driving mechanism, and an image collecting and positioning mechanism which is disposed at the execution end of the driving mechanism and positioned at one side of the label clamping mechanism and is used for adjusting the labeling position. In the invention, automatic attachment of the label on the back of the mobile phone can be realized. by the use ofthe device, attaching precision and attaching efficiency can be improved, and labor intensity of workers and labor cost of enterprises also can be reduced; and the labeling position can be detected, and product yield can be raised.

Owner:苏州轩明视测控科技有限公司

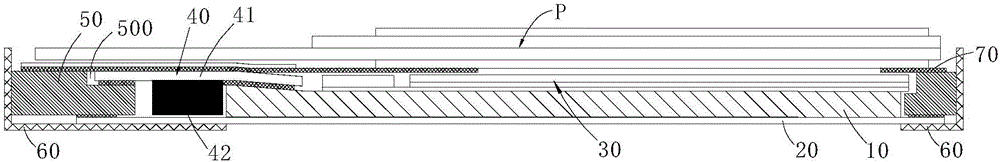

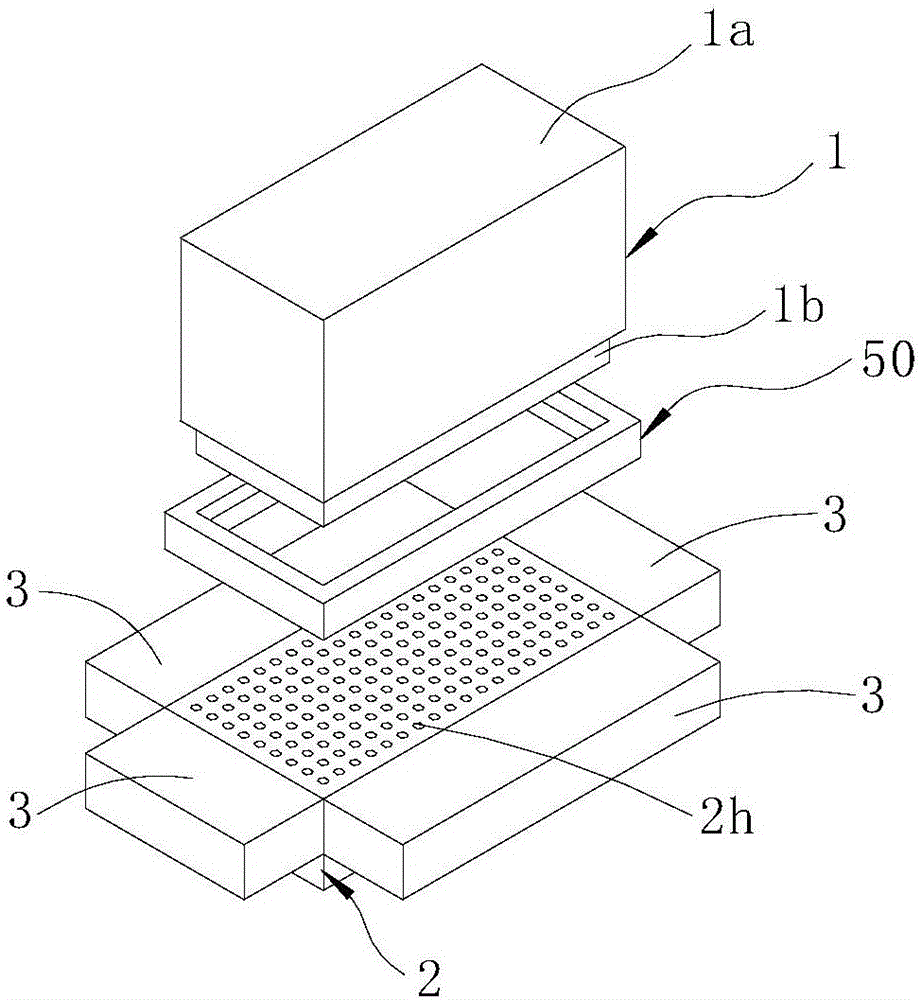

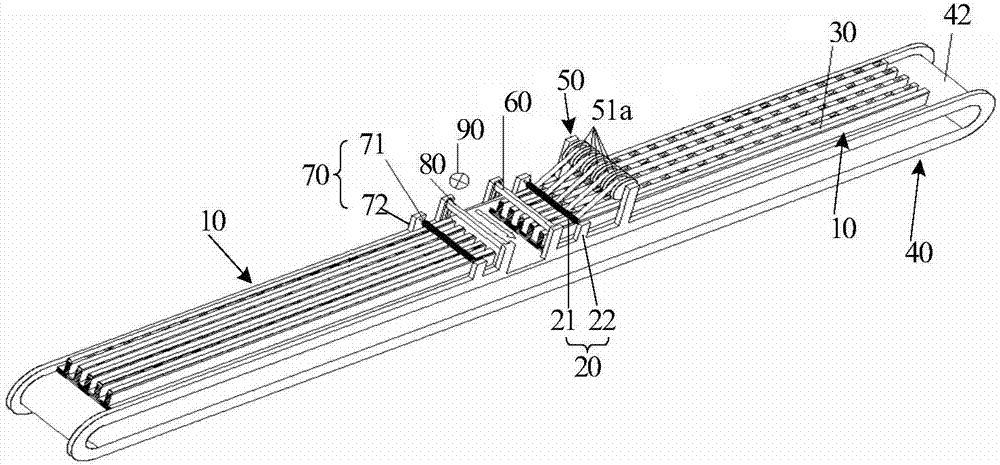

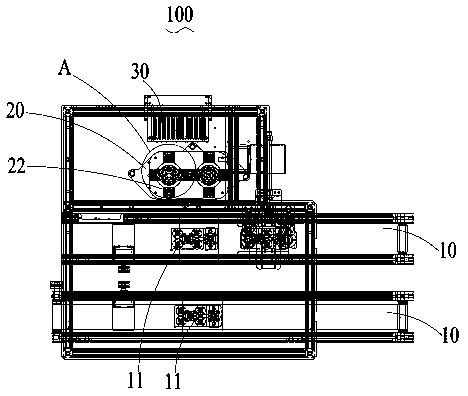

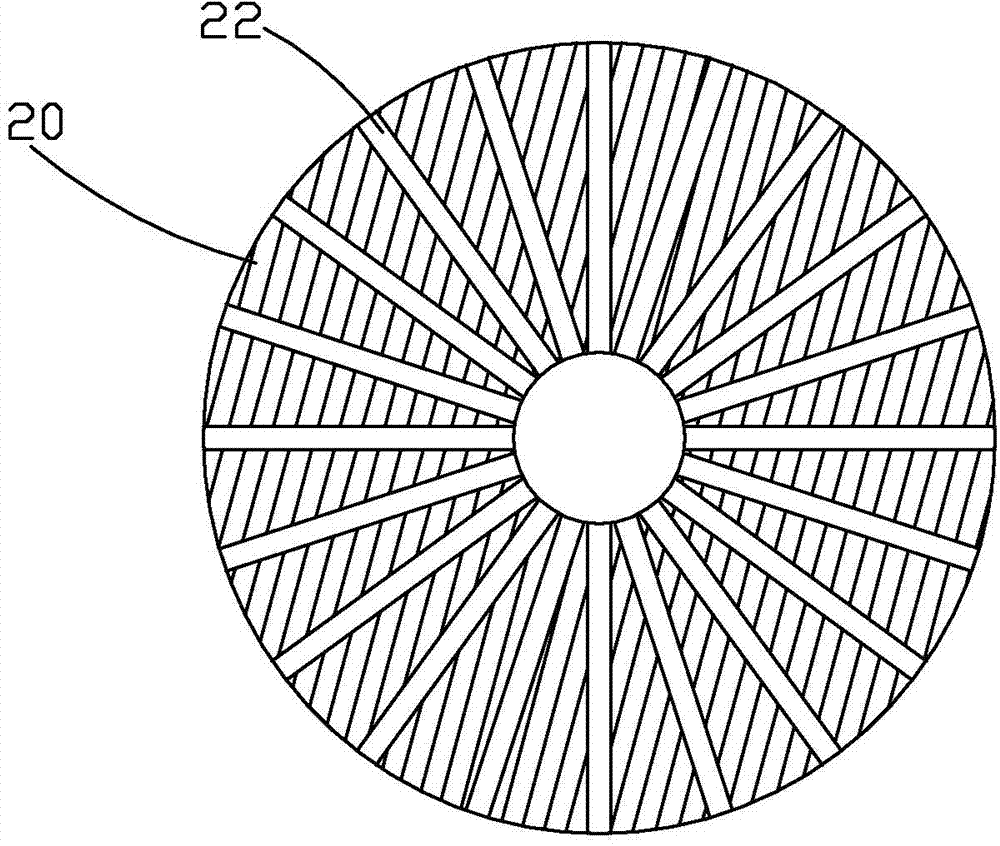

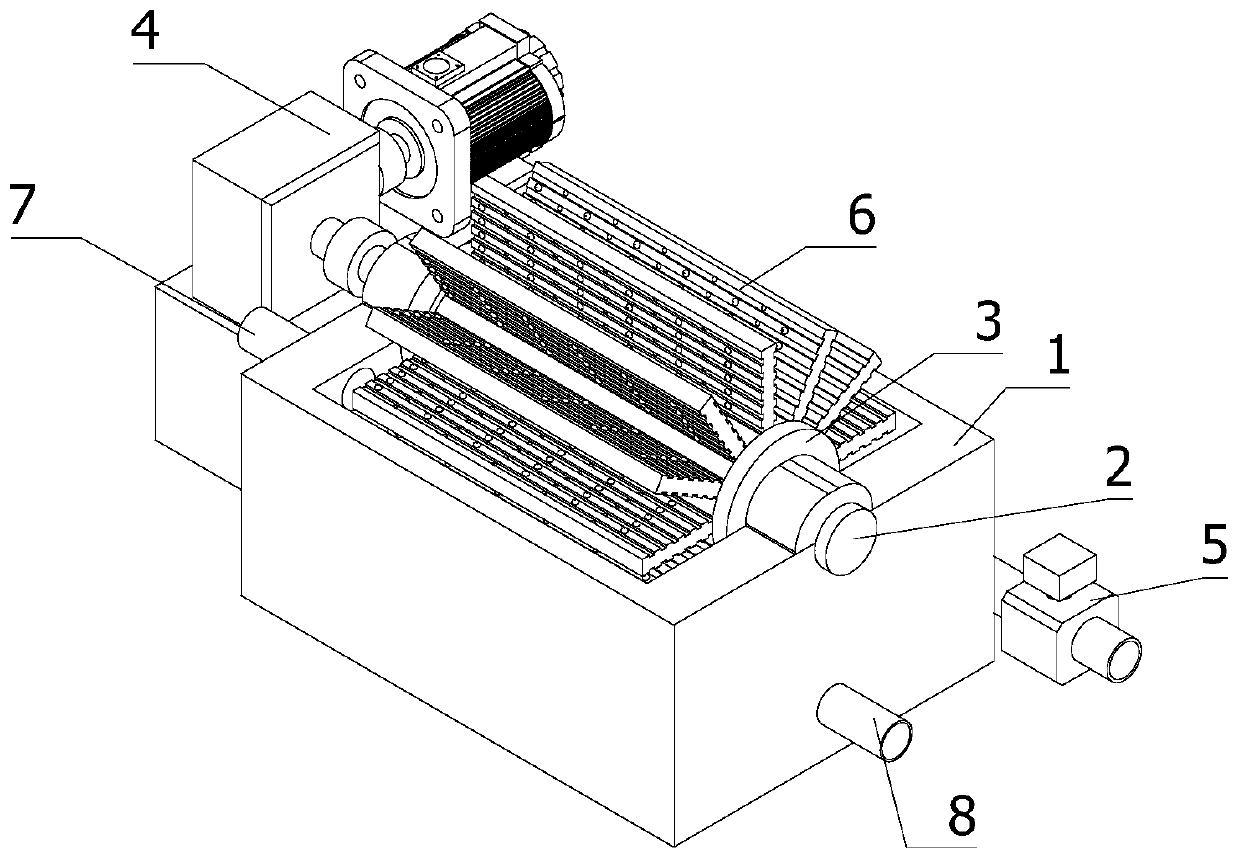

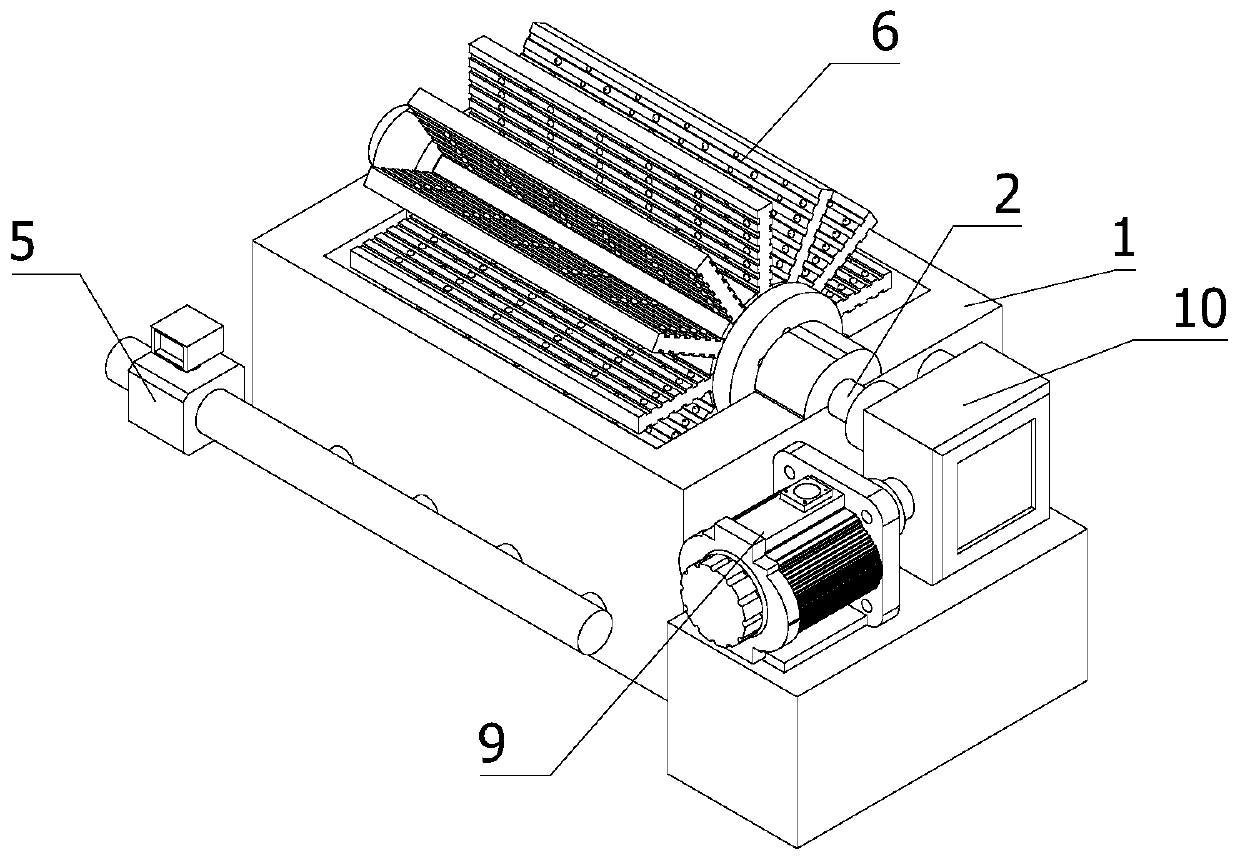

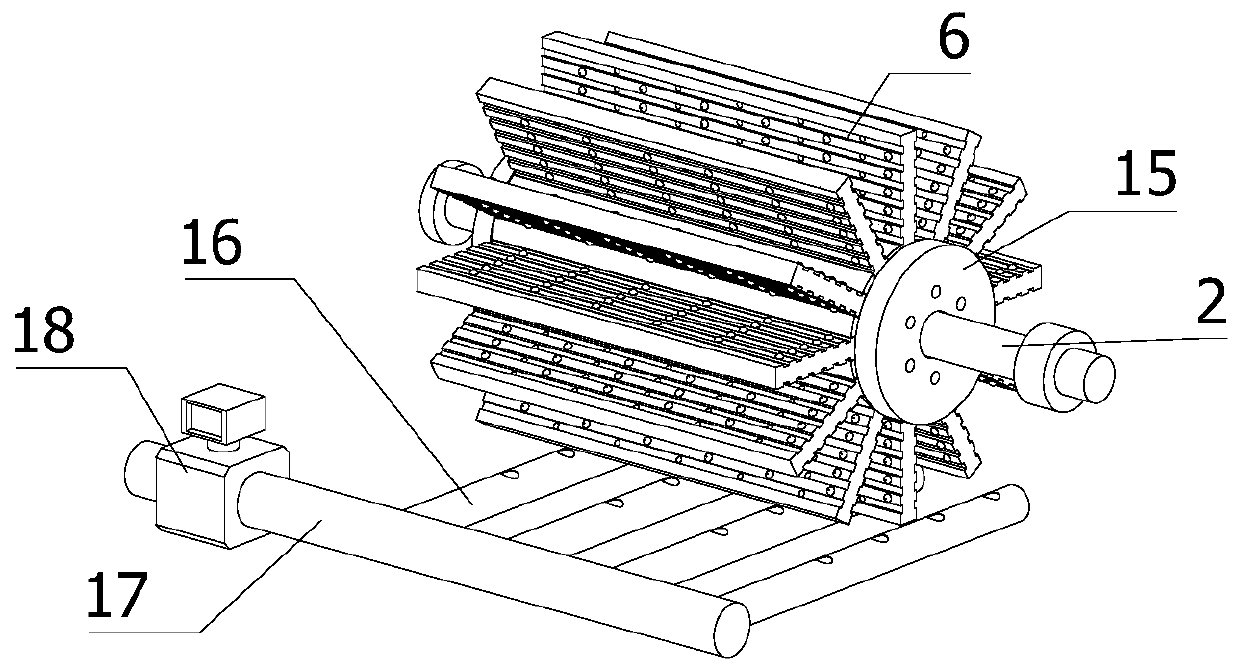

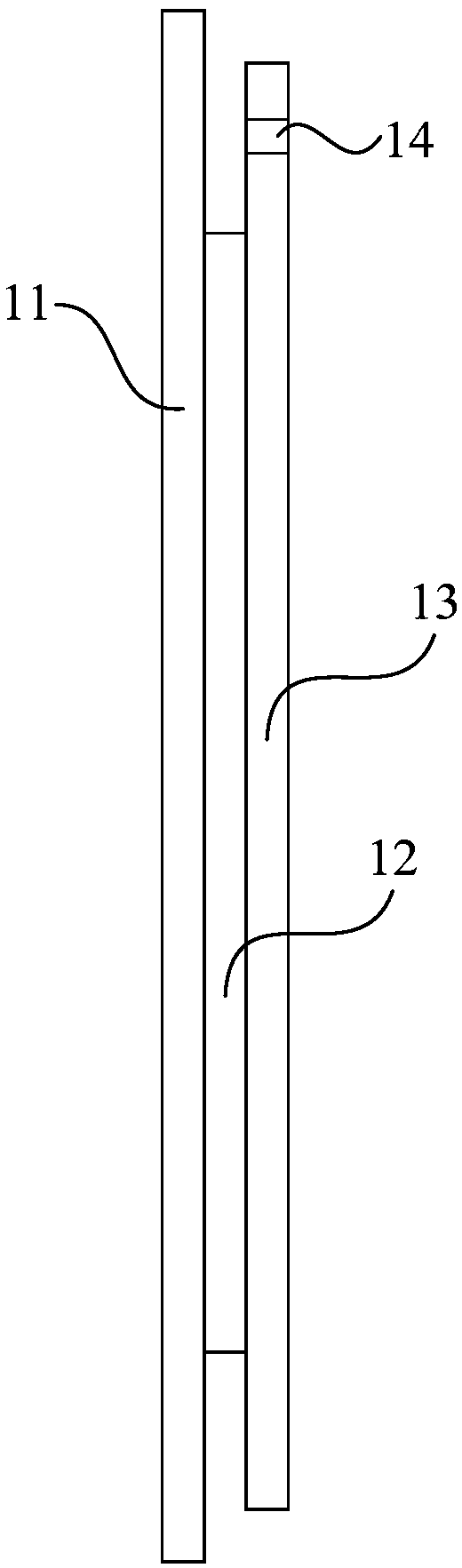

Transfer roller with adjustable vacuum adsorption force and method for attaching thin film by using transfer roller

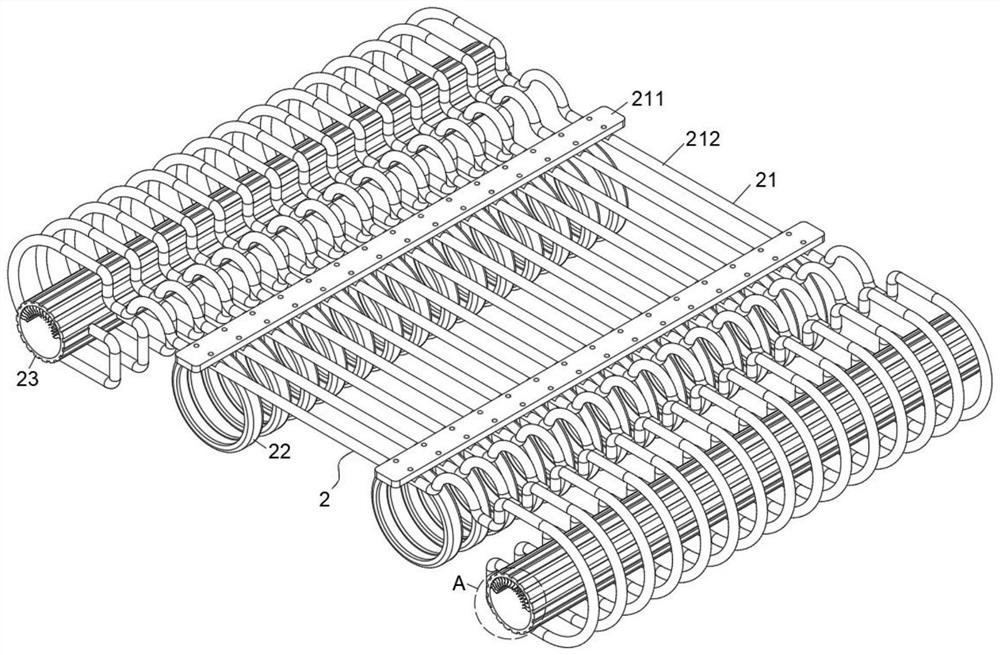

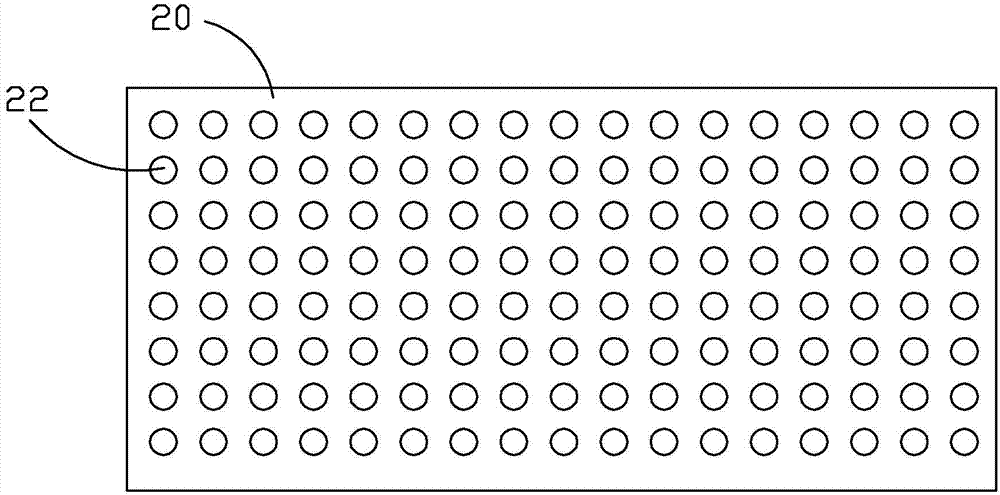

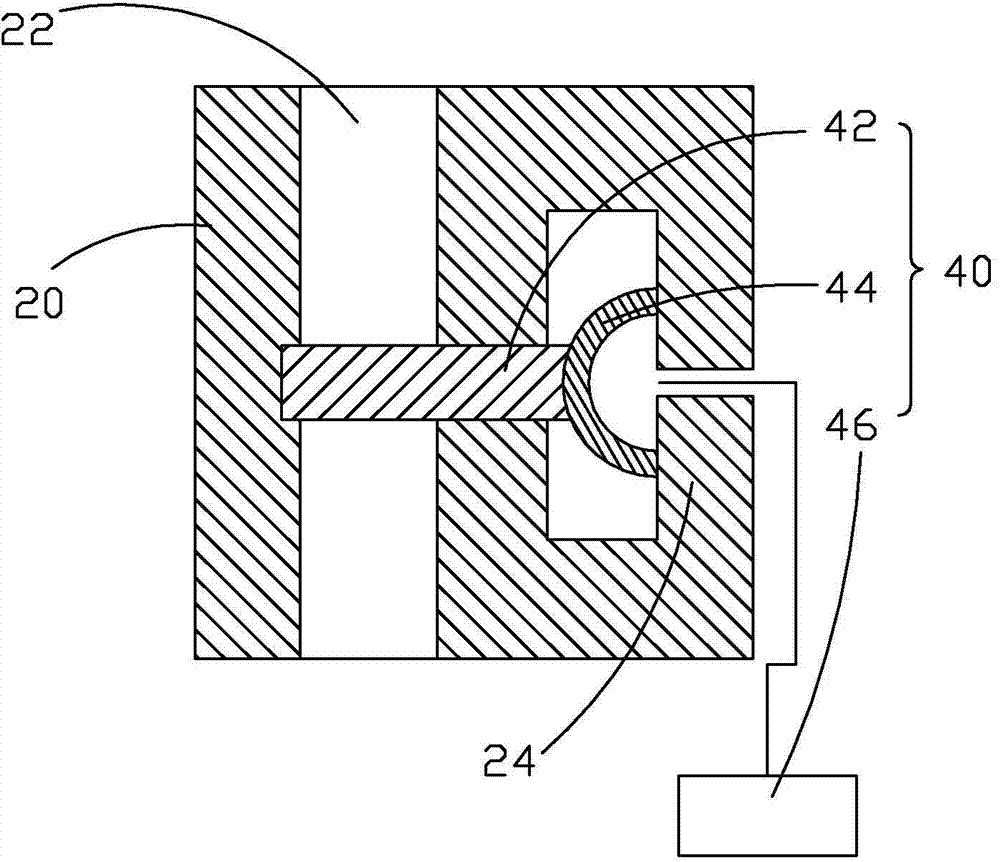

ActiveCN103487959APrecisely control the size of the vacuum adsorption forceAvoid FragmentsOperating means/releasing devices for valvesLamination ancillary operationsEngineeringControl circuit

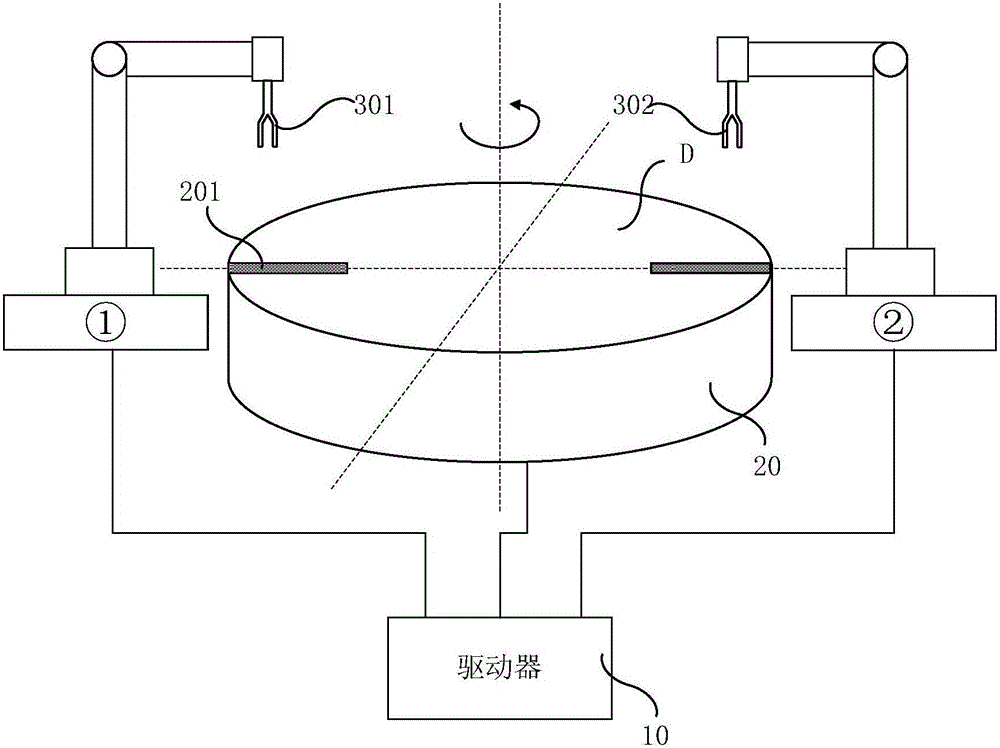

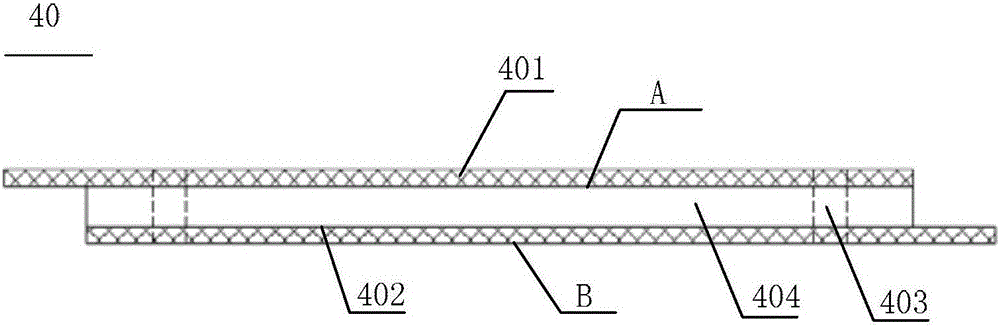

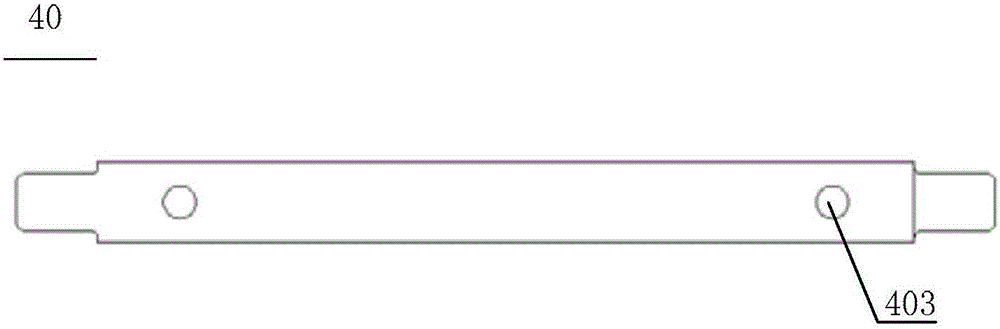

The invention provides a transfer roller with adjustable vacuum adsorption force and a method for attaching a thin film by using the transfer roller. The transfer roller comprises a roller body (20) and a plurality of regulation devices (40) arranged on the roller body (20), wherein a plurality of air suction pipelines (22) are uniformly distributed in the roller body (20), and are used for sucking air through air extractors; each regulation device (40) comprises a valve (42) arranged on the corresponding air suction pipeline (22), piezoelectric ceramics (44) connected to the corresponding valve (42) and a control circuit (46) electrically connected to the corresponding piezoelectric ceramics (44); the control circuits (46) are used for controlling the magnitude of electric fields input into the piezoelectric ceramics (44); the piezoelectric ceramics (44) are deformed under the action of the electric fields; the valves (42) are inserted into or pulled out of the air suction pipelines (22) under the deformation action of the piezoelectric ceramics (44) to control the magnitude of air suction intensity of the air suction pipelines (22) to further control the magnitude of the vacuum adsorption force of the air suction pipelines (22).

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

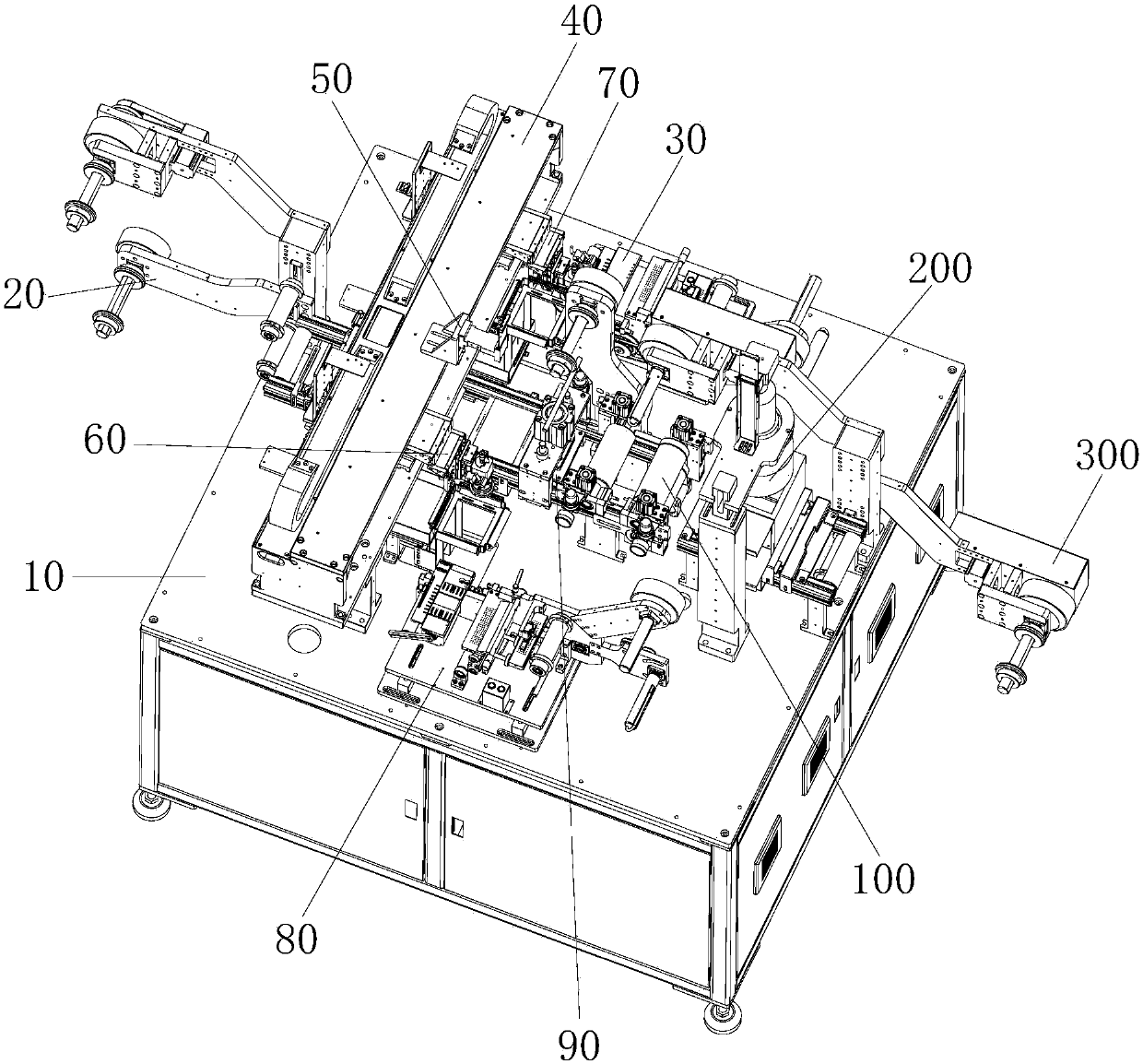

Tape attaching device

PendingCN107731964AEasy to attachImprove attachment efficiencySemiconductor devicesEngineeringElectrical and Electronics engineering

The invention discloses a tape attaching device. The tape attaching device includes a transportation part, a full-automatic box opening part and a comprehensive part; the transportation part is used for transporting battery boxes and batteries in the battery boxes, the full-automatic box opening part is used for opening the battery boxes, the comprehensive part includes a rotary disc and a plurality of processing parts, a plurality of work stations are arranged on the rotary disc, the work stations and the processing parts are arranged in a corresponding mode, and rotation of the rotary disc enables the work stations to pass through the processing parts one by one. According to the tape attaching device, the full-automatic box opening part automatically opens the battery boxes loaded withthe batteries, so that it is convenient for the tape attaching device to conduct attaching treatment on the batteries, and the processing efficiency is greatly improved. Meanwhile, the work stations on the rotary disc and the processing parts are arranged in the corresponding mode so that each work station can execute corresponding different operations, and the efficiency of tape attaching is further improved.

Owner:丰川泽精工机械无锡有限公司

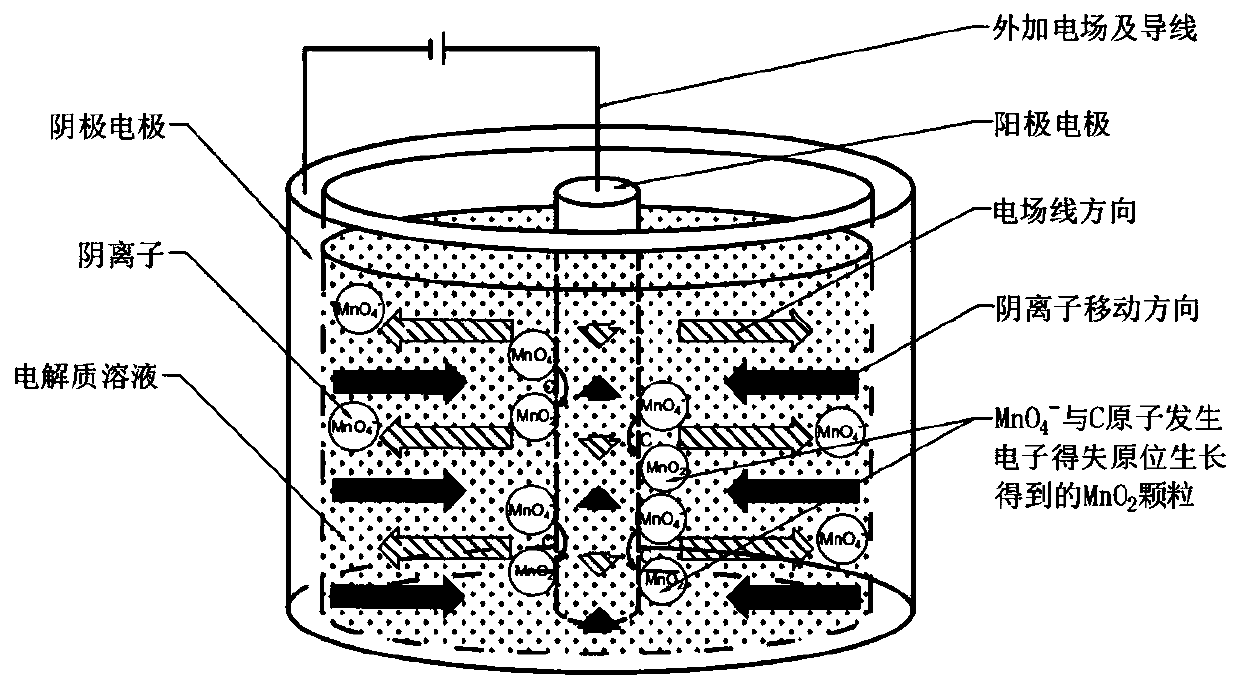

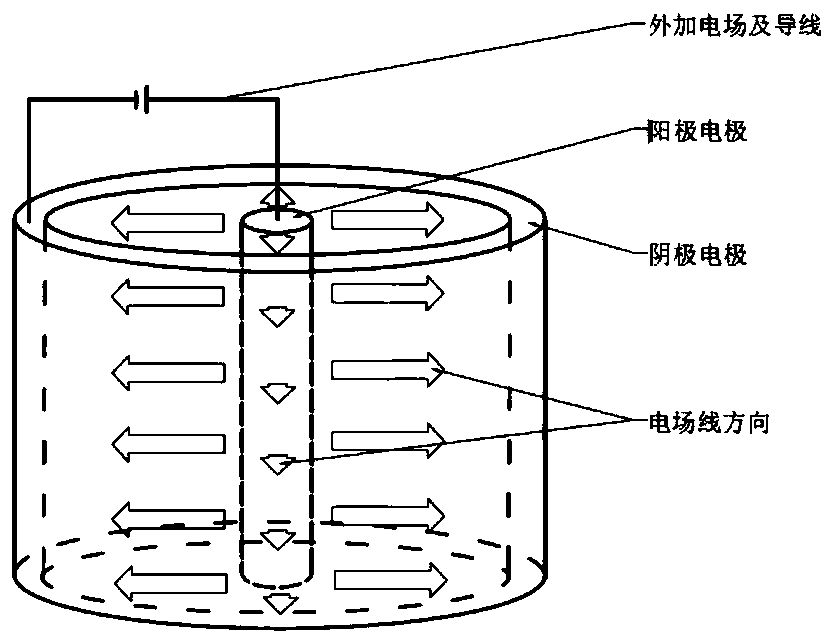

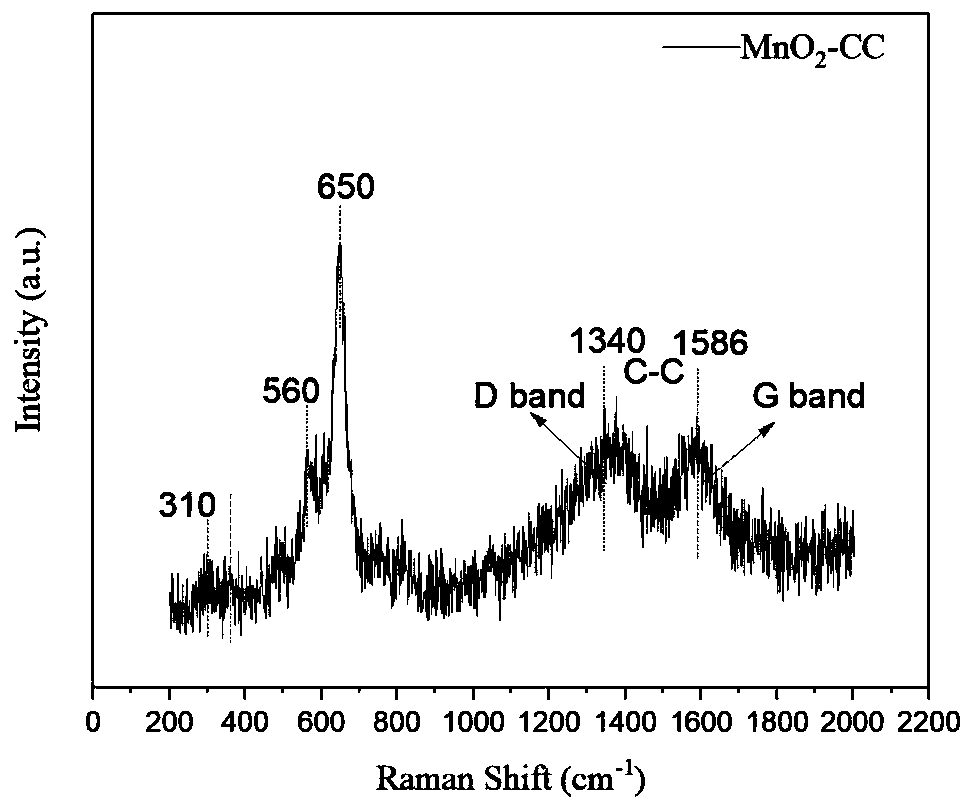

Method for preparation of MnOx hollow nano-tubular porous catalytic material through radial electric field regulation

ActiveCN110624539AShorten production timeImprove attachment efficiencyGas treatmentDispersed particle separationPhysical chemistryRoom temperature

Belonging to the technical field of catalysts, the invention discloses a method for preparation of a MnOx hollow nano-tubular porous catalytic material through radial electric field regulation. An external direct-current radial electric field accelerates the directed migration of negatively charged MnO<4-> in a solution to the vicinity of a loading material, and redox reaction is carried out for in-situ growth of MnOx hollow nanotubes, thus reaching the purposes of short reaction process time, mass loads and change of product morphology. Also after the structure of the electric field is changed, the morphology of MnOx is changed, and the MnOx hollow nano-tubular porous catalytic material capable of rapidly degrading low-concentration HCHO at room temperature can be obtained.

Owner:BEIJING UNIV OF TECH

Efficient sewage microbial sewage treatment device

InactiveCN111498984AEasy to handleImprove attachment efficiencyTreatment using aerobic processesWater aerationMicroorganismSewage

The invention relates to the field of sewage treatment. The invention relates to a sewage treatment device, in particular to an efficient sewage microbial sewage treatment device. The device comprisesa sewage treatment tank, a rotating shaft, a mounting turntable, a turntable driving device, an aeration device and a plurality of rotating sheets, wherein the rotating shaft is horizontally arrangedabove the sewage treatment tank; the rotating shaft is fixedly sleeved with the mounting turntable; the plurality of rotating sheets are annularly and uniformly distributed on the outer side of the mounting turntable; the rotating sheet is detachably connected with the mounting turntable; a water inlet pipe is arranged at the top of one side wall of the sewage treatment tank; a water outlet pipeis arranged at the bottom of one side wall of the sewage treatment tank away from the water inlet pipe; the aeration device is horizontally arranged at the bottom of the sewage treatment tank. According to the invention, the sewage treatment device is simple in structure and good in sewage treatment effect, the aeration device can increase the oxygen content in the sewage treatment tank, accelerate the reproduction speed of microorganisms and increase water circulation in the sewage treatment tank, so that the effects that the rotating pieces are convenient to install and maintain due to detachable installation, and the attaching area of the microorganisms is increased through the rotating pieces are achieved.

Owner:苏州煜水生物科技有限公司

Protective film structure and protective film attaching method

InactiveCN110480998ASimple structureShort operating timeFlexible coversWrappersTectorial membraneEngineering

The embodiment of the invention discloses a protective film structure and a protective film attaching method. The protective film structure comprises a light release film and a protective film, wherein the whole protective film is wholly attached to the light release film, and at least two positioning holes in one-to-one correspondence with positioning piles on an assembly jig are formed in the protective film. The technical scheme provided by the protective film structure and the protective film attaching method can solve the problems that an existing protective film structure is high in manufacturing cost and difficult to attach.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

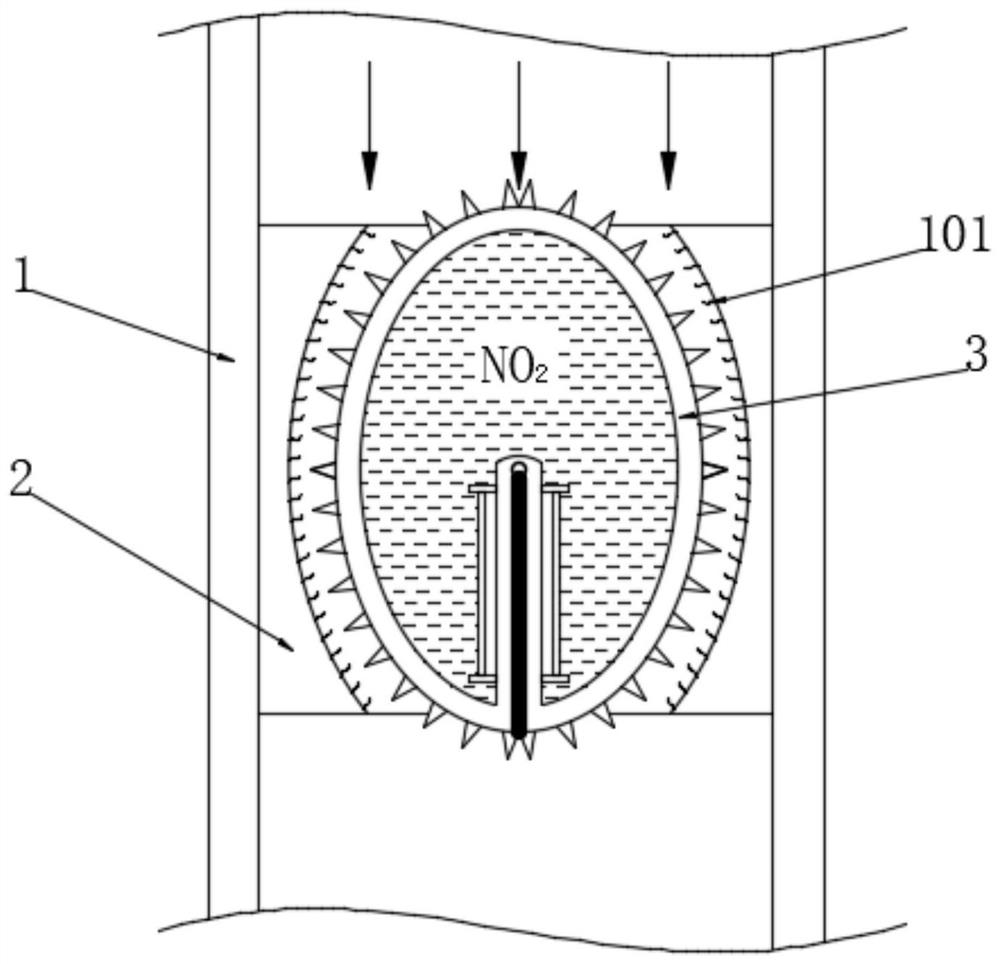

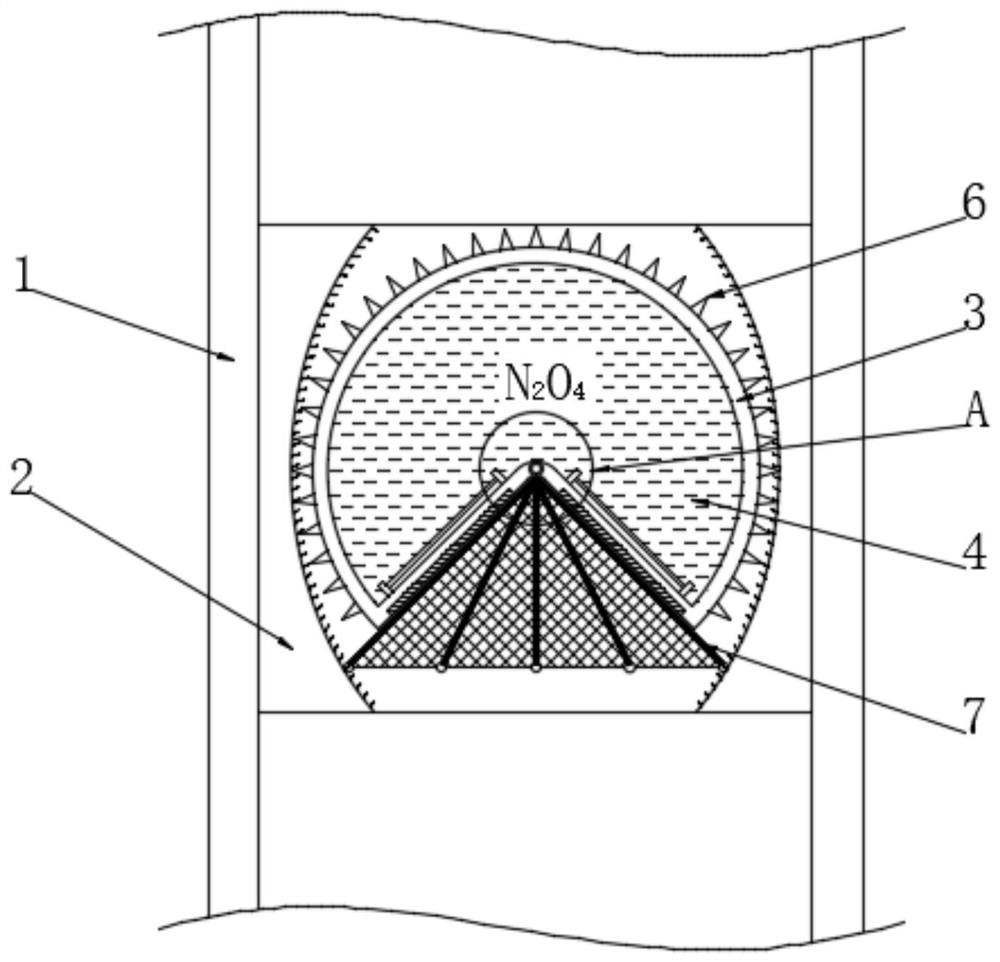

Hedgehog-like curling type high-temperature waste gas treatment device

The invention discloses a hedgehog-like curling type high-temperature waste gas treatment device, and belongs to the technical field of textiles. According to the scheme, when high-temperature textilewaste gas is conveyed through a waste gas conveying pipeline, by using heat contained in the waste gas, nitrogen tetroxide gas in a spherical filter core is promoted to be completely converted into nitrogen dioxide so as to make strip-shaped magnet blocks be forced to be in a non-magnetic shielding environment, so that the spherical filter core is in a closed ellipsoid shape under the mutual attraction between the two strip-shaped magnet blocks; along with continuous expanding of the spherical filter core, filtering conical thorns at the outer end of the spherical filter core can be forced tofully bloom, the spherical filter core and the filter conical thorns are respectively simulated into hedgehog and external protective thorns, and when textile waste gas passes through, the fiber fluff in the waste gas is filtered by the aid of the filter conical thorns unfolded after the spherical filter core is shrunk by simulating the state that the hedgehog shrinks and the protective thorns onthe outer side are unfolded when the hedgehog is in danger.

Owner:周代远

FPC (flexible printed circuit board) lamp strip press-fit device

ActiveCN107390399APressing operation is simpleImprove attachment efficiencyNon-linear opticsPrinted circuit boardSupport plane

The invention relates to an FPC (flexible printed circuit board) lamp strip press-fit device which comprises a base, a power assembly and a press-fit assembly. The base comprises a tank and a support frame, and the support frame is arranged on the tank; the power assembly comprises a driving air cylinder and a driving rod, the driving air cylinder is mounted on the support frame, and the driving rod is connected onto the driving air cylinder and is penetratingly arranged in the support frame; the press-fit assembly comprises a compression plate, a plurality of elastic columns and a press-fit jig, the compression plate is connected onto the driving rod and is opposite to the tank, and the elastic columns are arranged at the peripheral edge of the compression plate and are arranged at intervals. The FPC lamp strip press-fit device has the advantages of high attaching efficiency and simplicity in operation.

Owner:深圳市山本光电股份有限公司

Metal packaging film processing equipment and metal packaging film processing method

ActiveCN106476400AImprove attachment efficiencyAvoid wrinklesLaminationLamination apparatusElectrical and Electronics engineeringHot pressing

The invention discloses metal packaging film processing equipment and a metal packaging film processing method and relates to the technical field of metal packaging film processing. The metal packaging film processing equipment and the metal packaging film processing method are designed for solving the problems of low mounting efficiency and process debugging process complicacy during mounting of a metal film and a packaging film in the prior art. The metal packaging film processing equipment comprises a surface mounting component and a laminating component. The surface mounting component comprises a magnetic carrier plate, a retainer and a first conveying device, the lower surface of the magnetic carrier plate is used for fixing a first film layer, the retainer is used for retaining a second film layer at a first position, a magnetic material is added into the second film layer, and the first conveying device is used for driving the magnetic carrier plate with the fixed first film layer to move closely to the first position, so that the second film layer at the first position can be absorbed on the lower surface of the first film layer. The laminating component is used for laminating the first film layer and the second film layer absorbed on the lower surface of the first film layer into a whole by means of hot pressing. The metal packaging film processing equipment can be used for laminating the metal film and the packaging film into one film.

Owner:BOE TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com