ACF (anisotropic conductive film) attaching device

A sticking and vacuum adsorption technology, applied in the directions of transportation and packaging, sending objects, thin material processing, etc., can solve the problems of reducing production efficiency, not being able to carry out at the same time, and long attaching time of ACF conductive adhesive film, so as to improve the sticking performance. The effect of additional efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

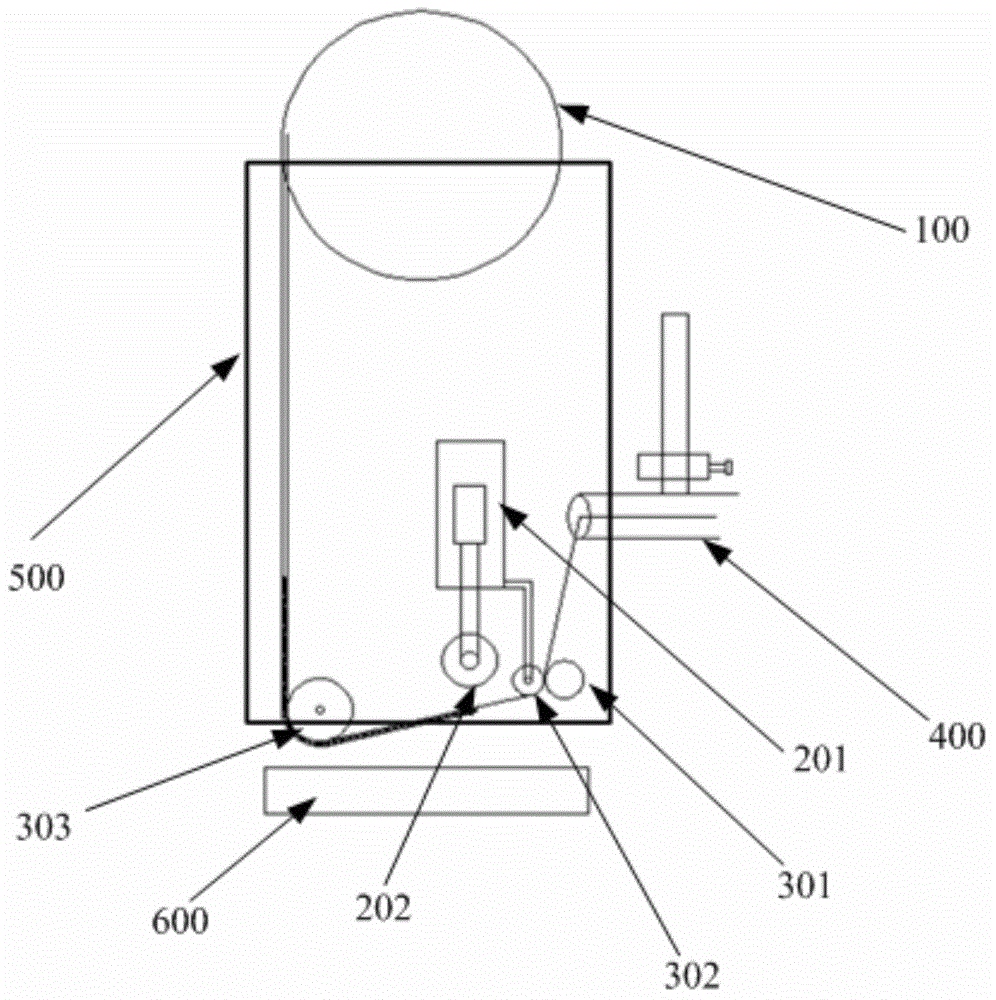

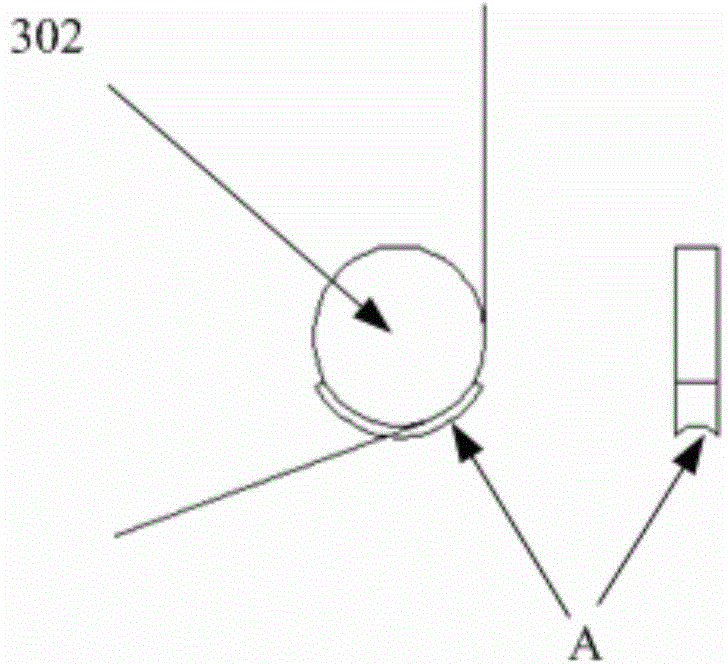

[0026] combine figure 1 As shown, the present embodiment provides an ACF attaching device, which includes: a supply mechanism 100 for supplying the ACF tape composed of a conductive adhesive film and a base tape; a belt transport mechanism for transporting the supply mechanism along a predetermined transport path The ACF adhesive tape supplied by 100; the belt pressing mechanism is used to press and fix the conductive adhesive film of the ACF adhesive tape carried by the belt delivery mechanism on the sticking object part 600; wherein, the belt delivery mechanism includes: The first guide wheel 302 and the supply wheel 301 are used to clamp the ACF tape, and when the tape pressing mechanism presses and fixes the conductive adhesive film of the ACF tape on the attachment object part 600, it is controlled by the first motor The supply wheel 301 rotates to separate the base tape from the conductive adhesive film.

[0027] The ACF attaching device provided in this embodiment can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com