Method for preparation of MnOx hollow nano-tubular porous catalytic material through radial electric field regulation

A technology of hollow nanometer and electric field control, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., and can solve the problems of less research on catalytic oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

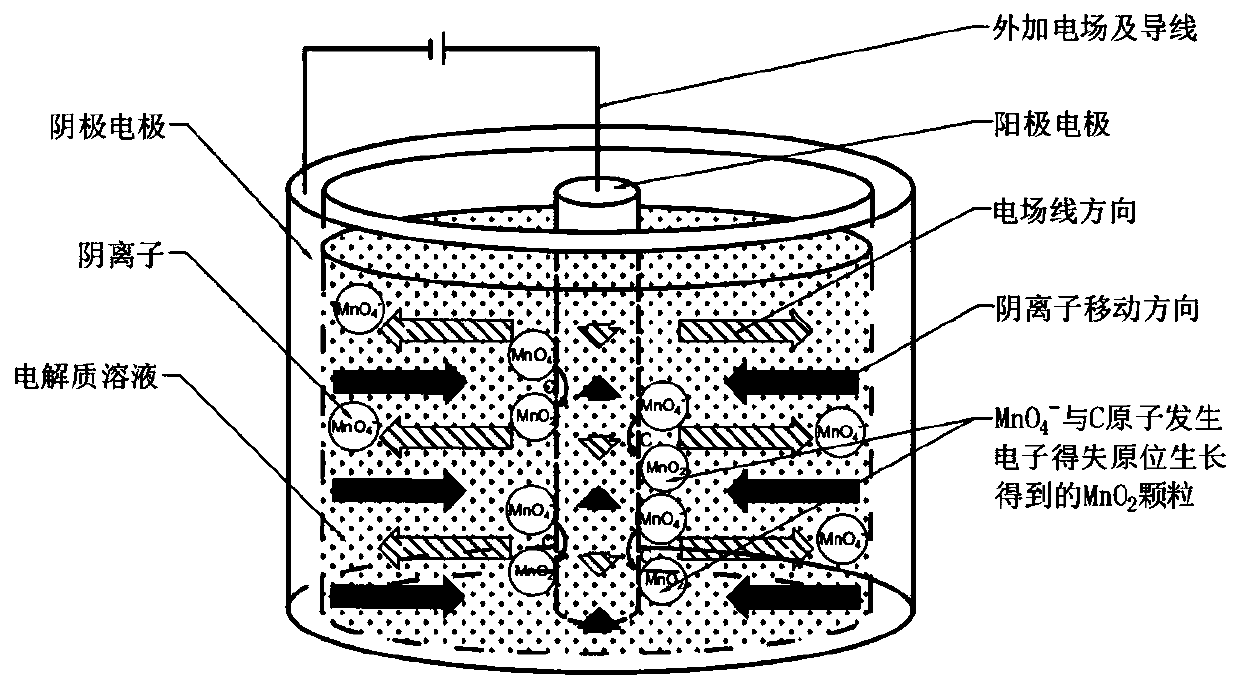

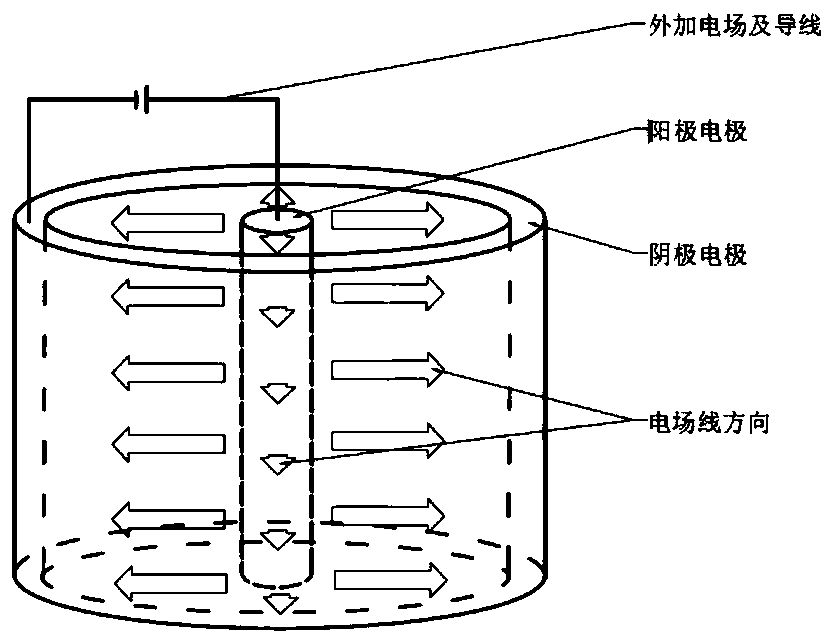

[0021] First configure 0.1M KMnO 4 Solution, bend the cleaned Pt electrode sheet into a cylindrical structure with a diameter of 120mm, connect it to the negative electrode of the power supply through a wire, wrap the top of the carbon fiber cloth tightly on the copper wire, and then connect the copper wire to the positive electrode of the power supply through the wire. Finally, the carbon fiber cloth wrapped with copper wire is bent into a cylinder with a diameter of 30 mm, so that the Pt electrode cylinder and the carbon fiber cylinder or cylinder are coaxially nested (such as Figure 4 shown), the carbon fiber is located inside the center; after completing the above operations, the two are fixed in the KMnO 4 In the reaction bottle of the solution, the copper wire does not touch the KMnO 4 Solution, sealed, connected to an adjustable DC power supply with a voltage of 5V, then placed the entire device in an oil bath at 60°C for 80 minutes, and finally cleaned the removed car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com